Machine Learning-Based Fault Detection and Diagnosis of Faulty Power Connections of Induction Machines

Abstract

:1. Introduction

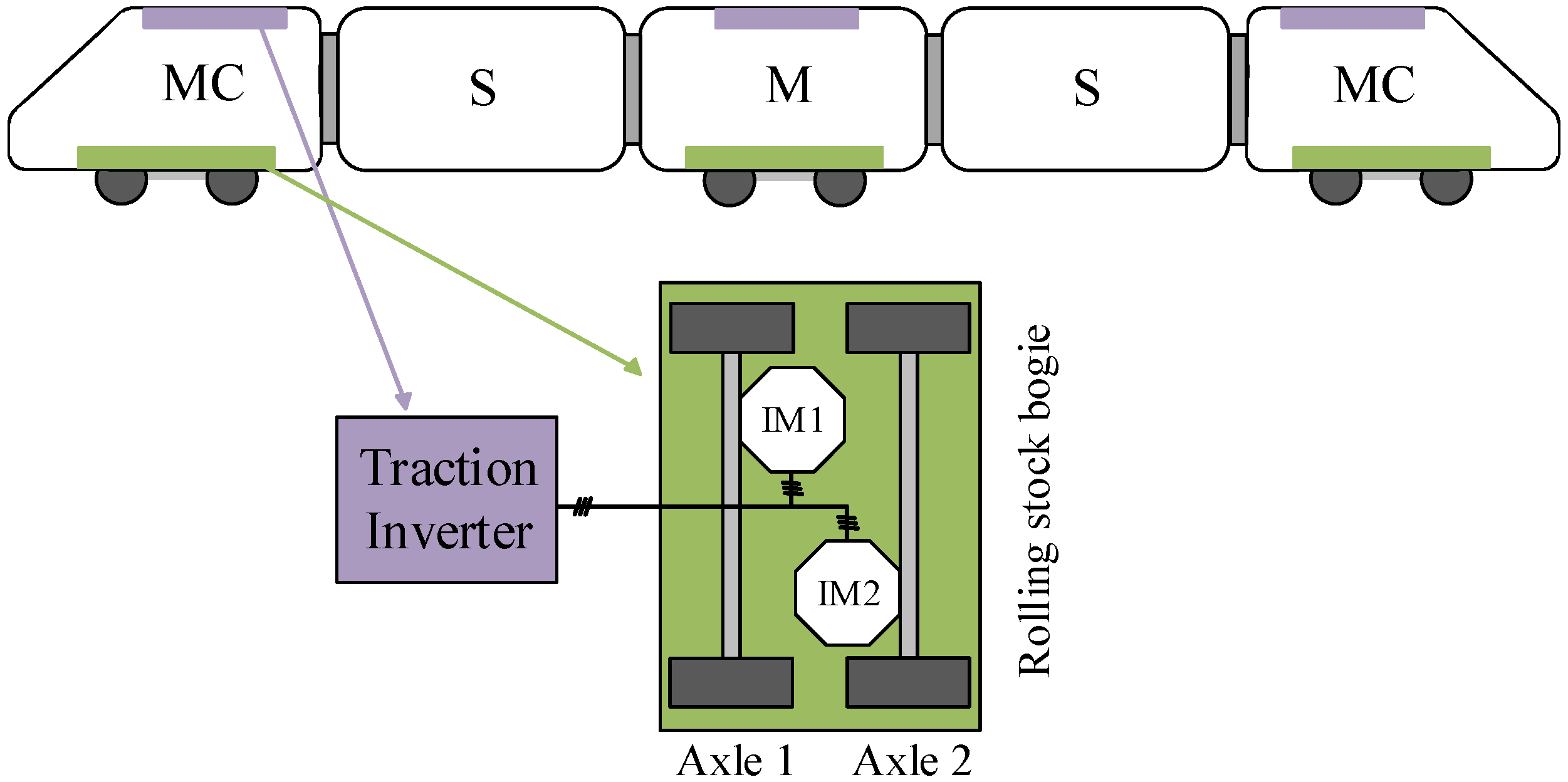

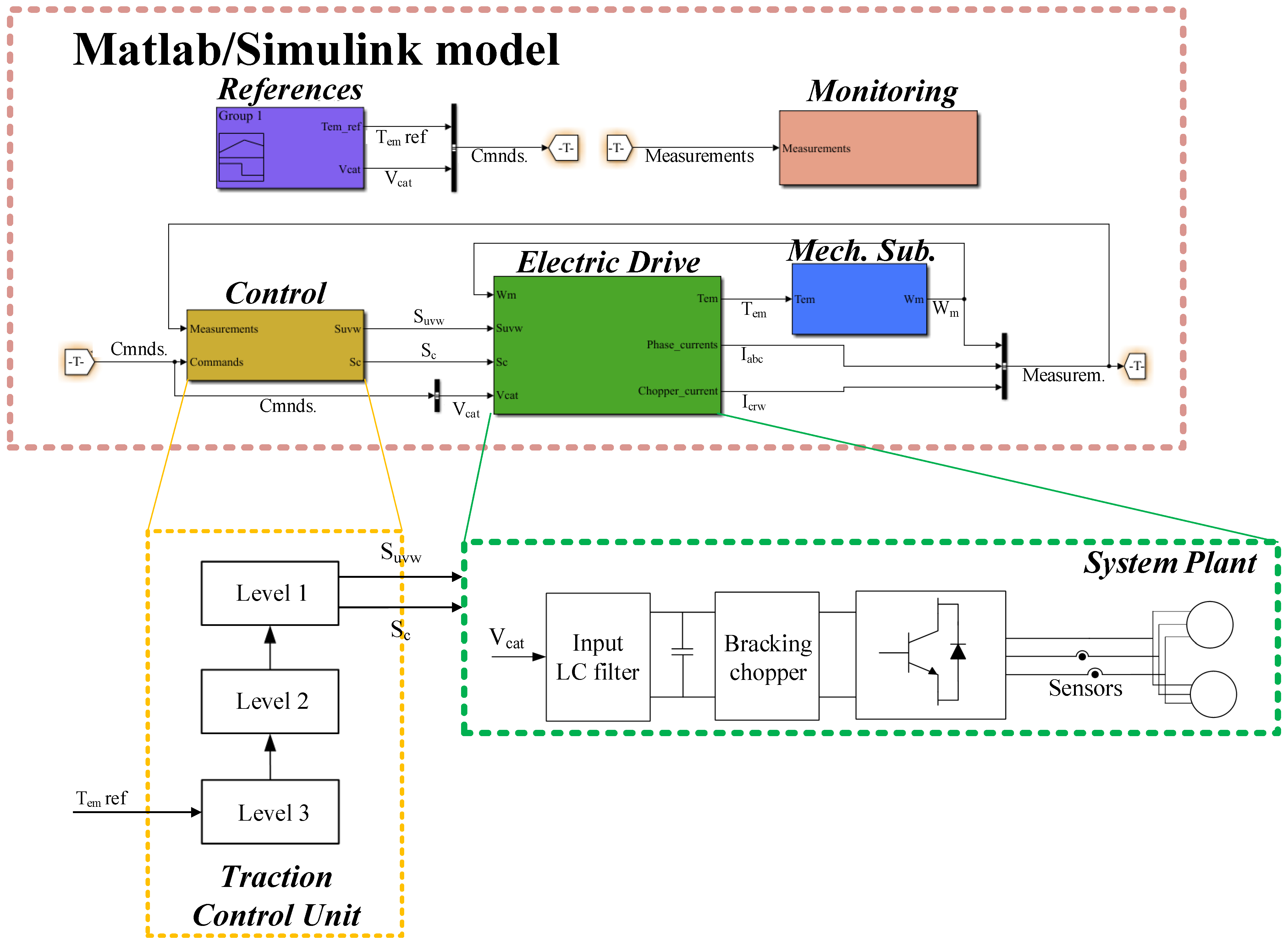

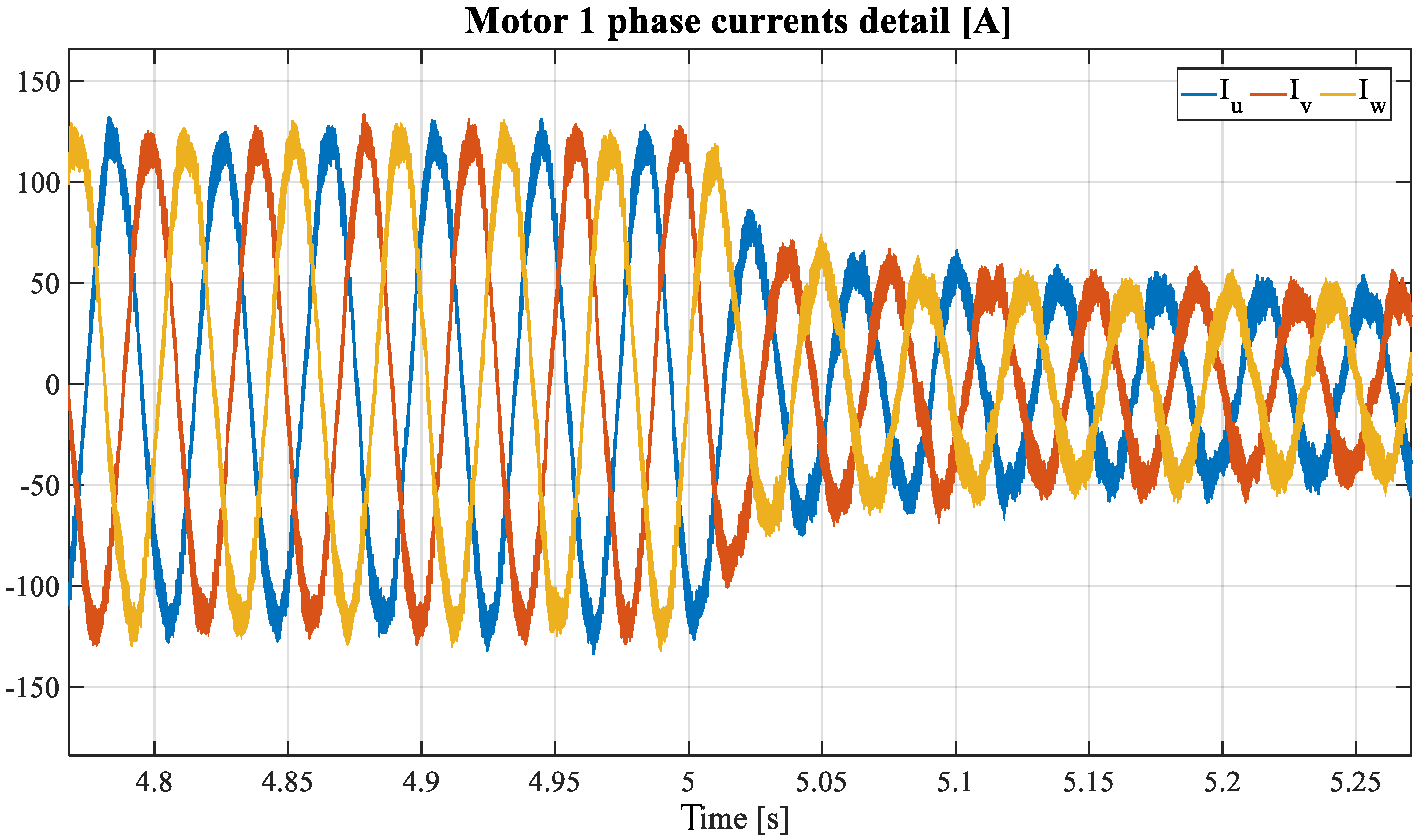

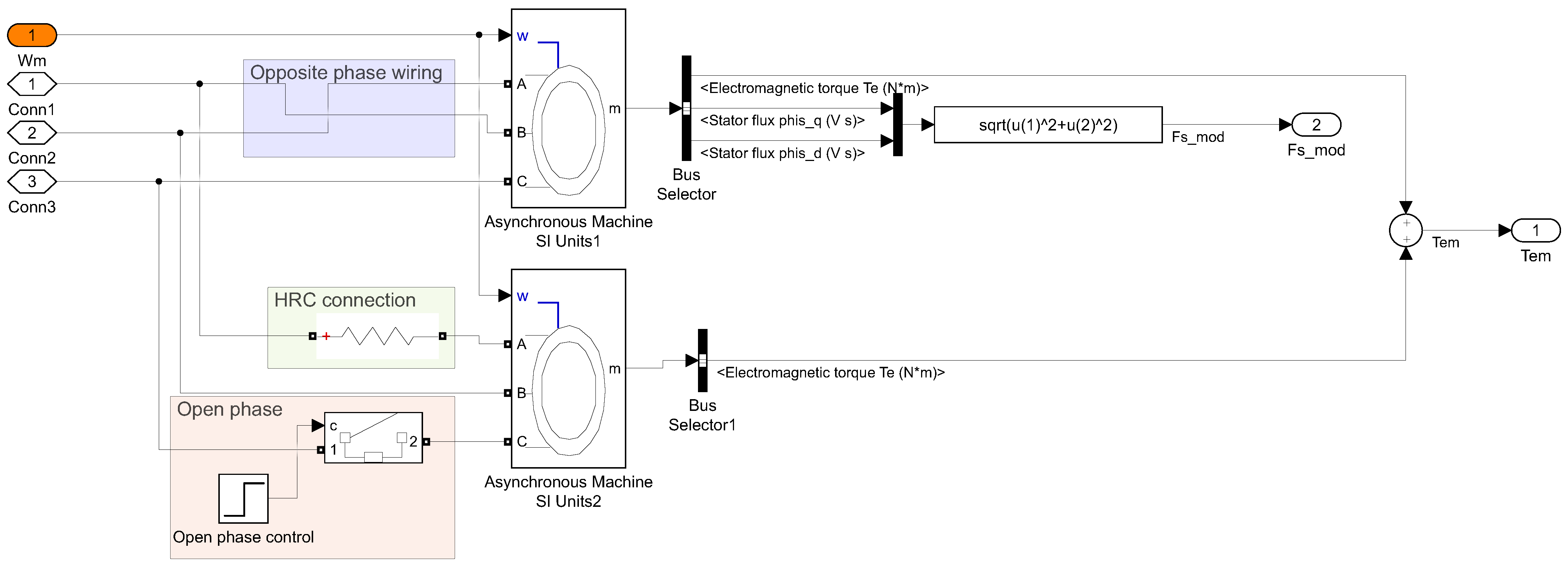

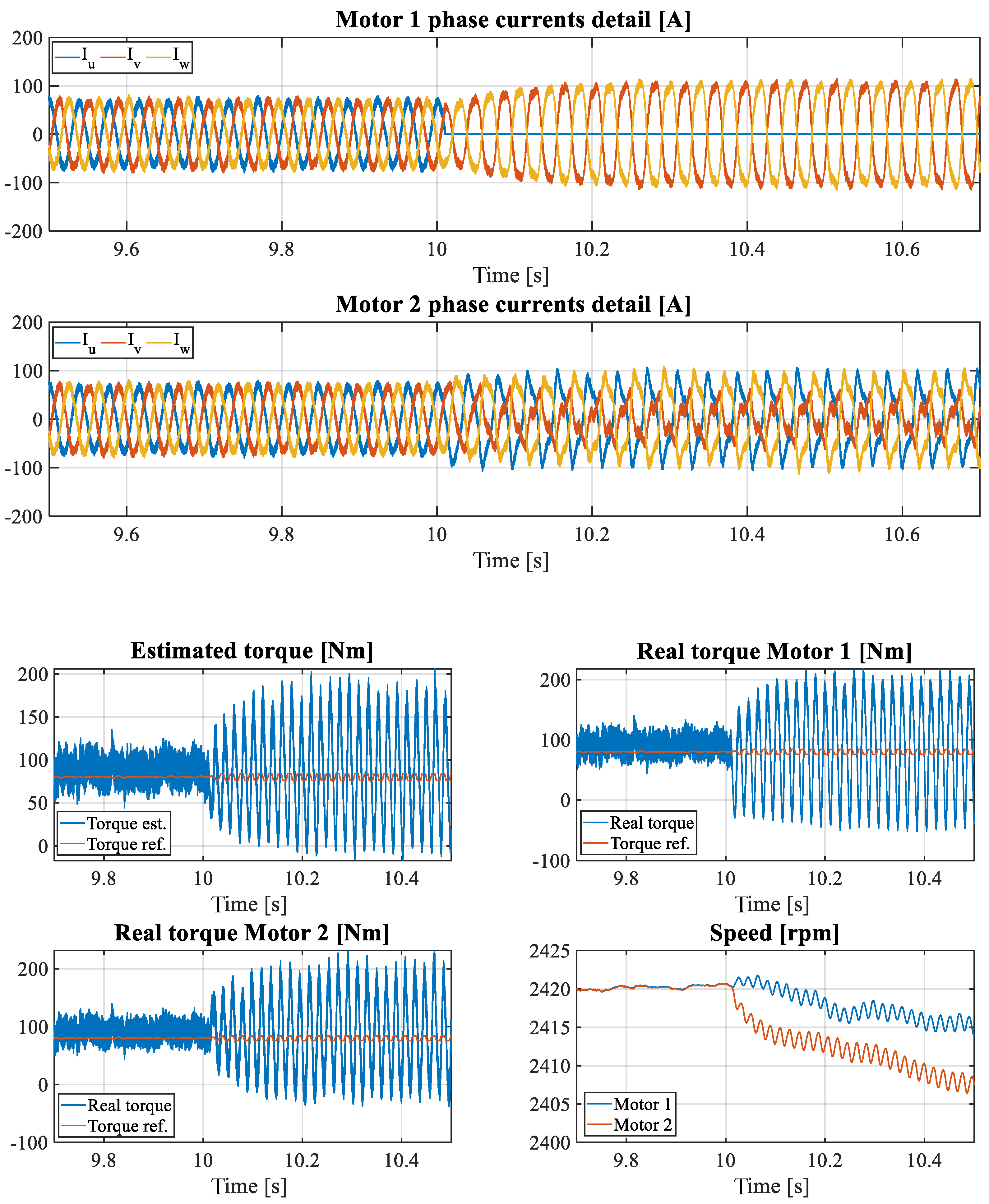

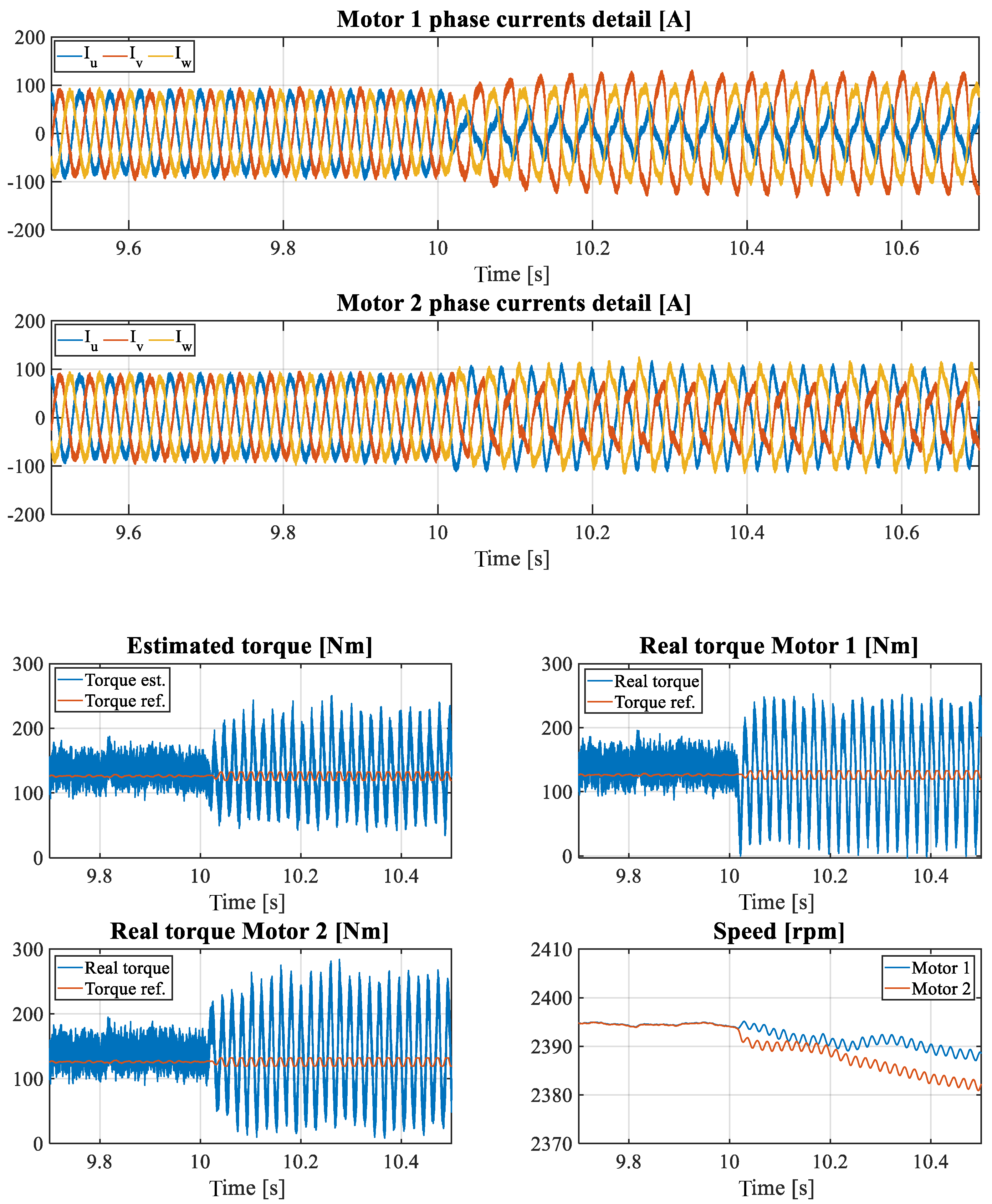

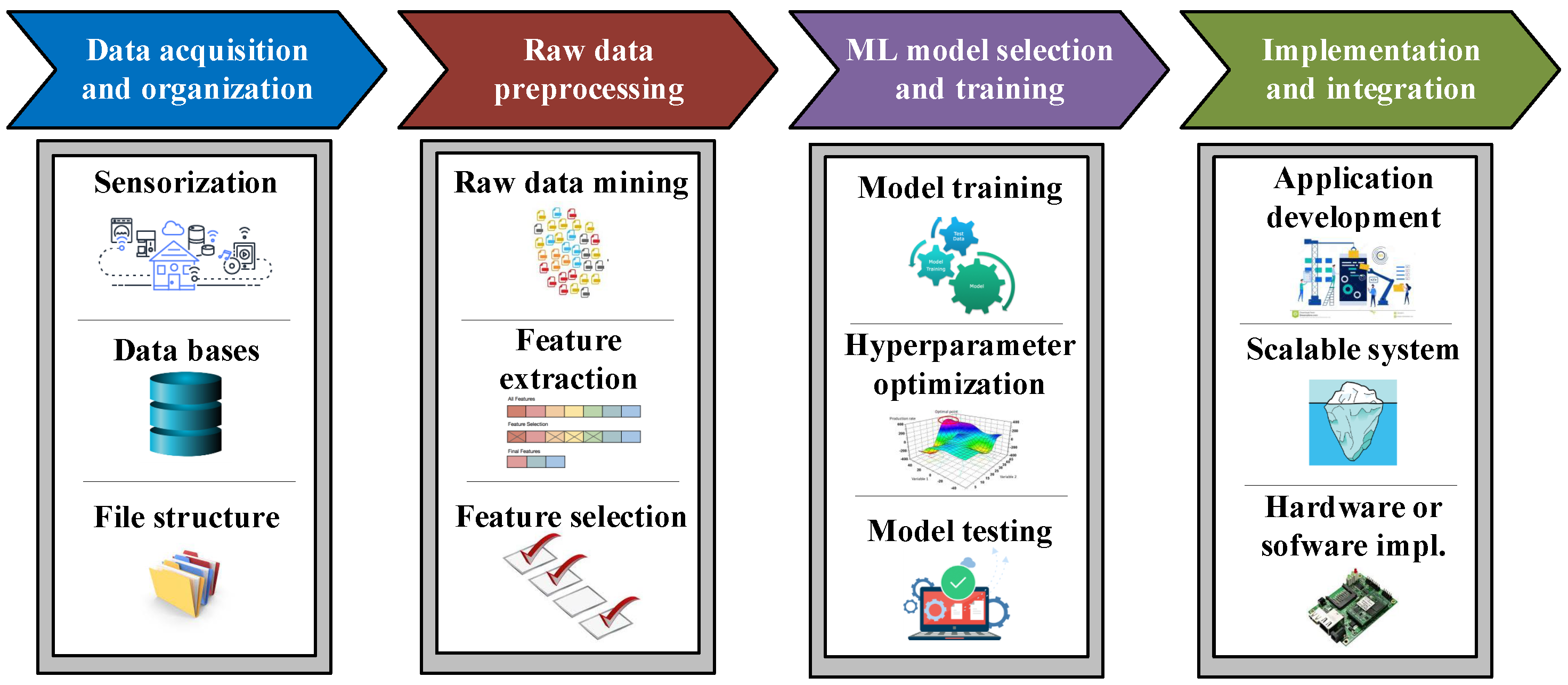

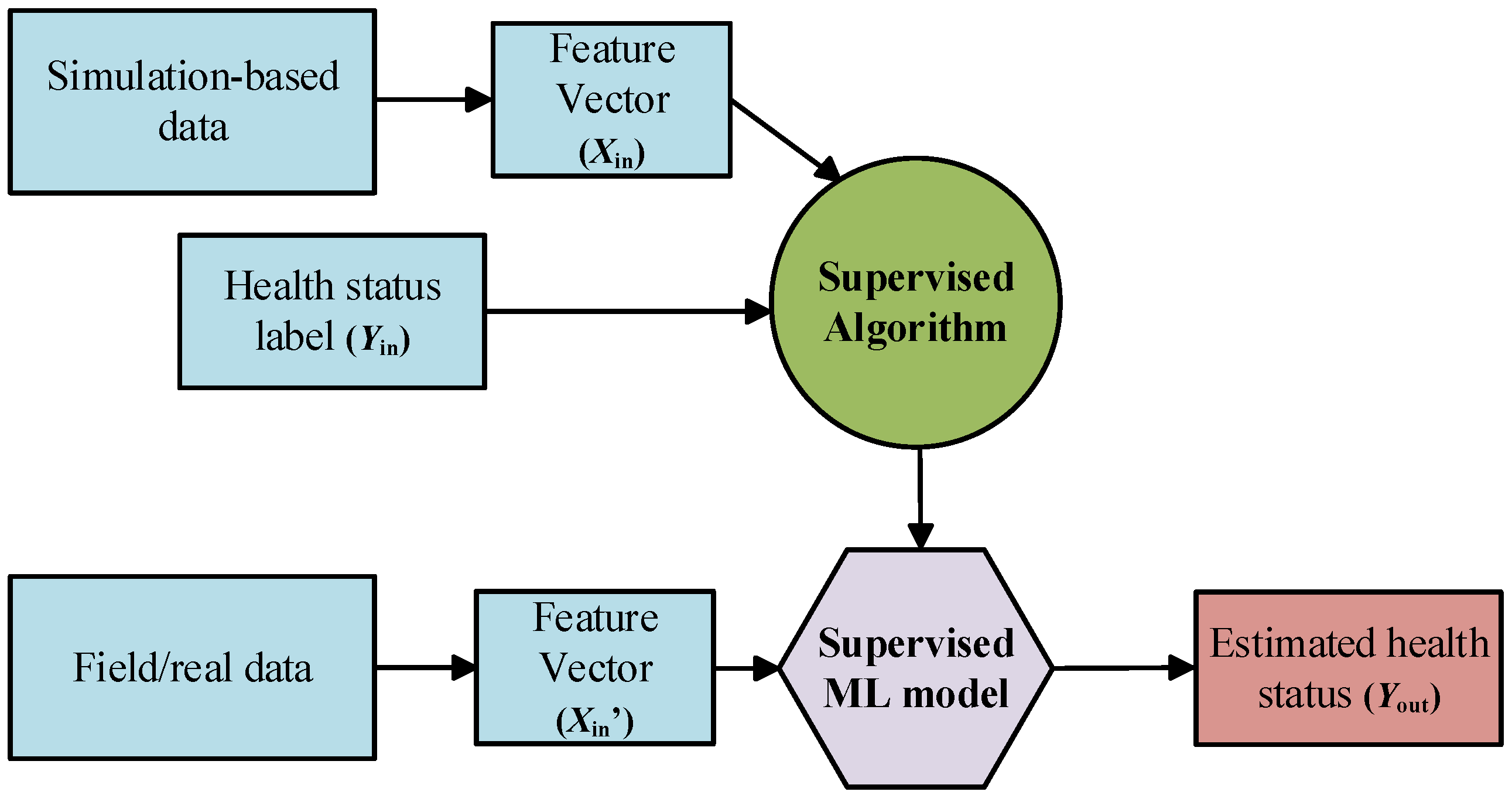

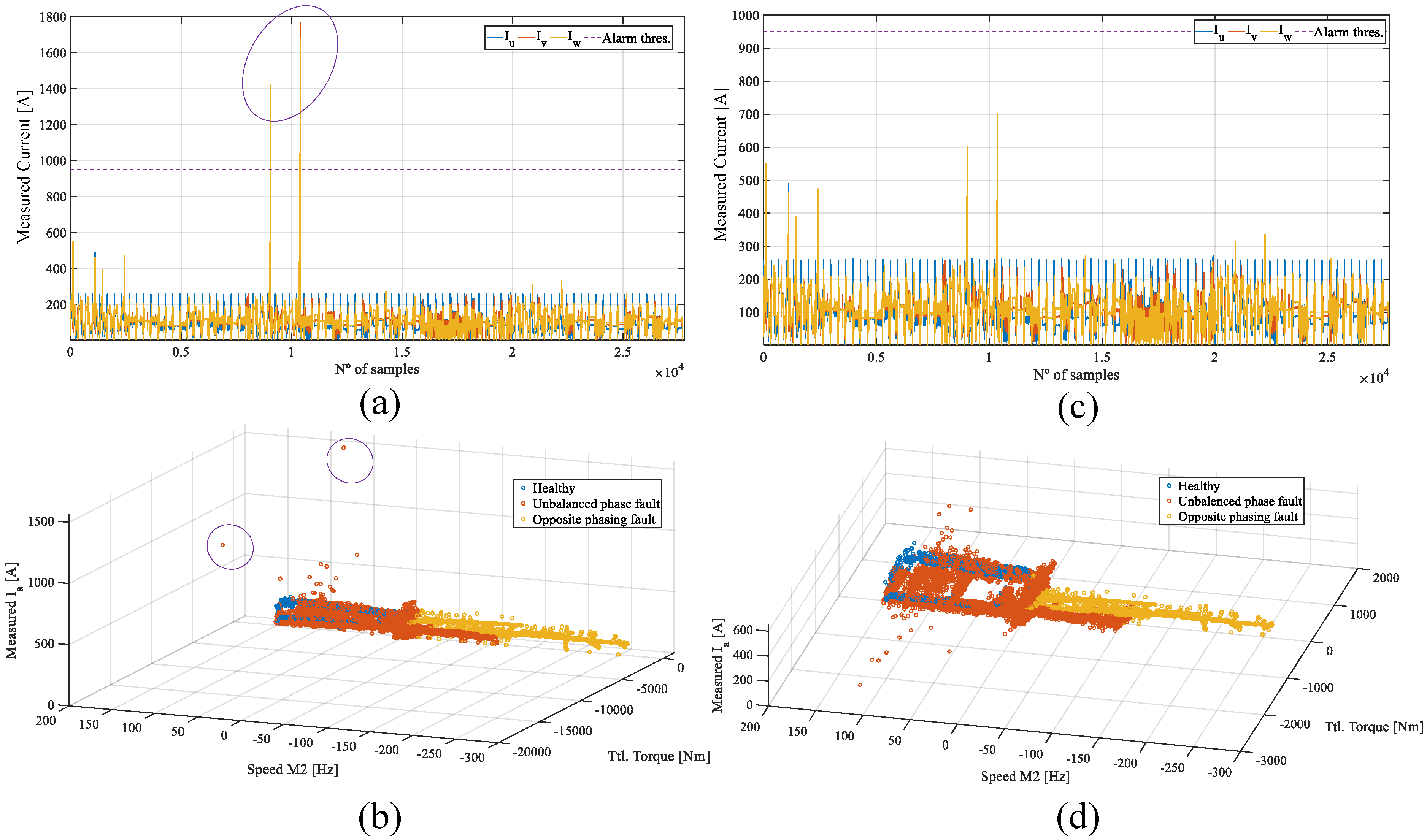

2. SiL Simulation-Based Data Generation

3. ML-Based Fault Diagnosis Strategy

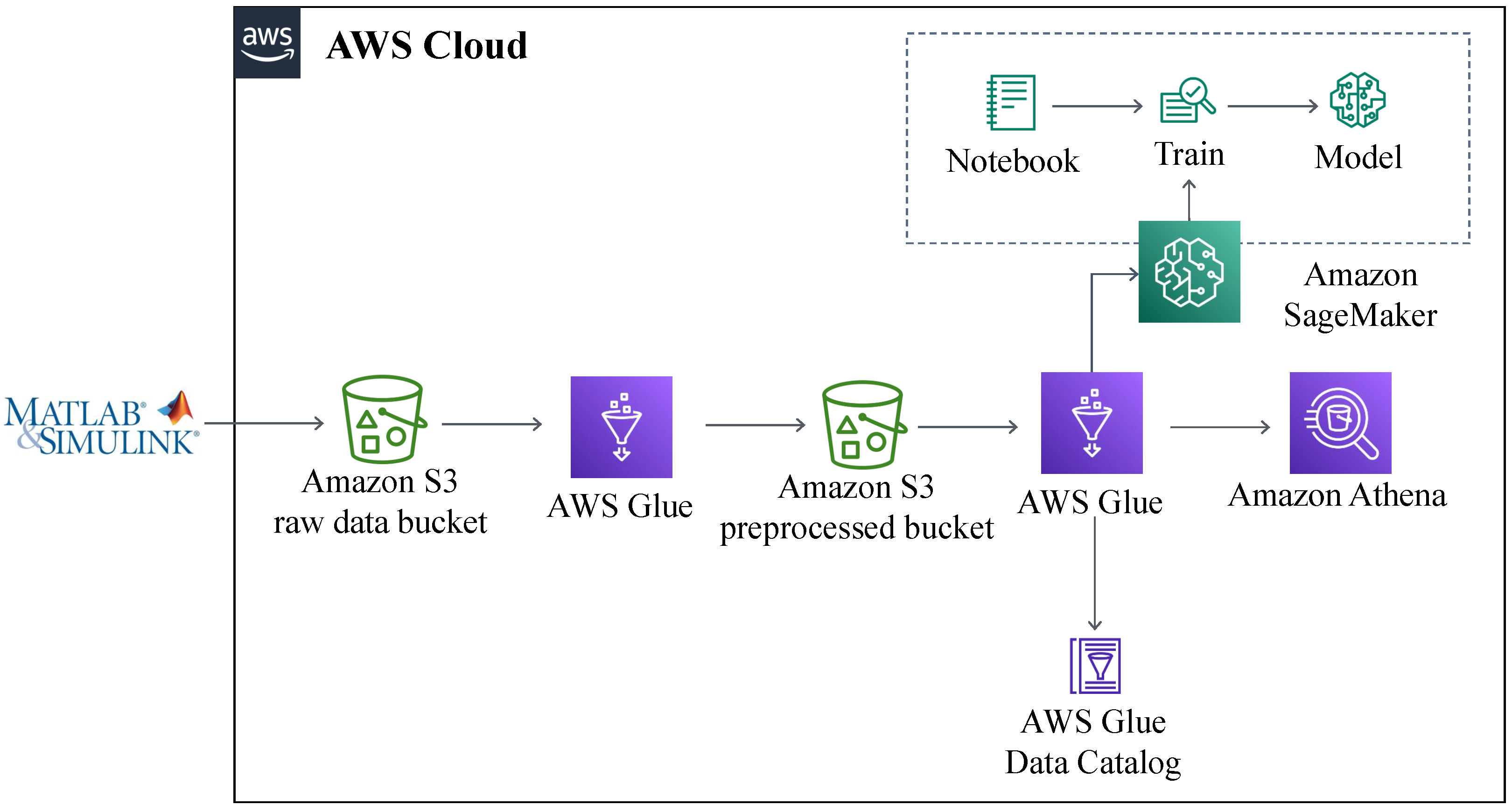

3.1. Data Acquisition and Organization

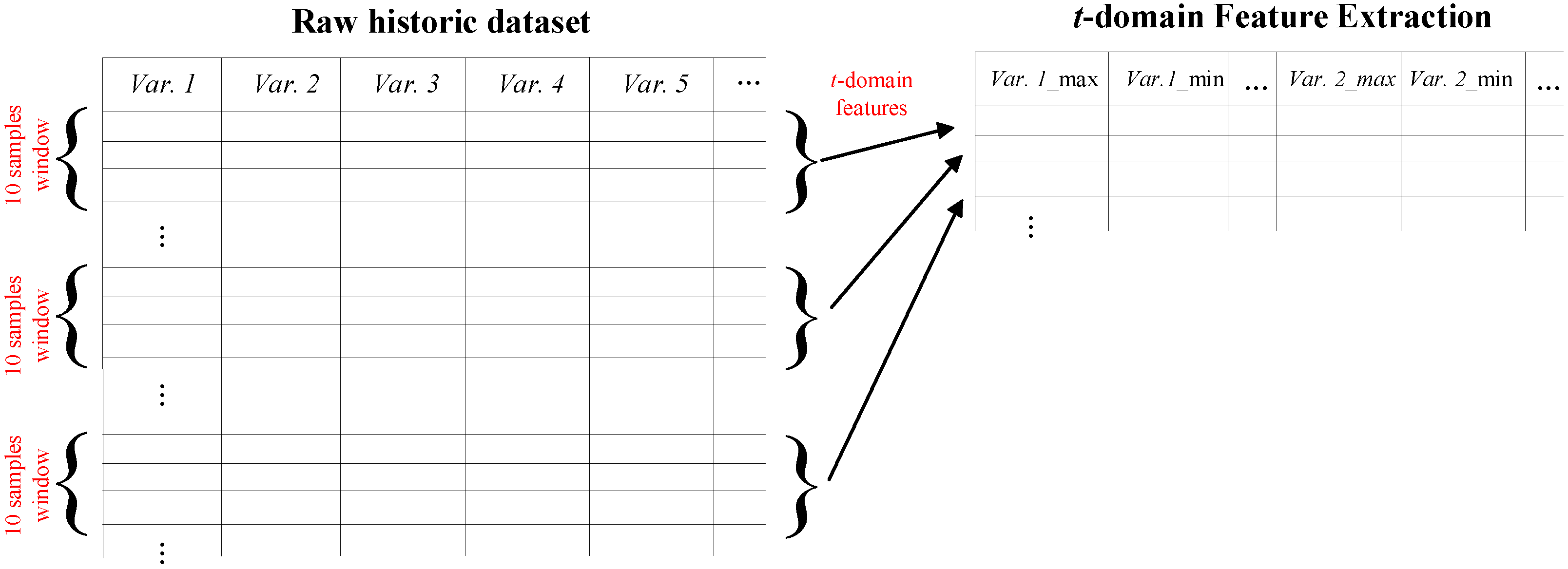

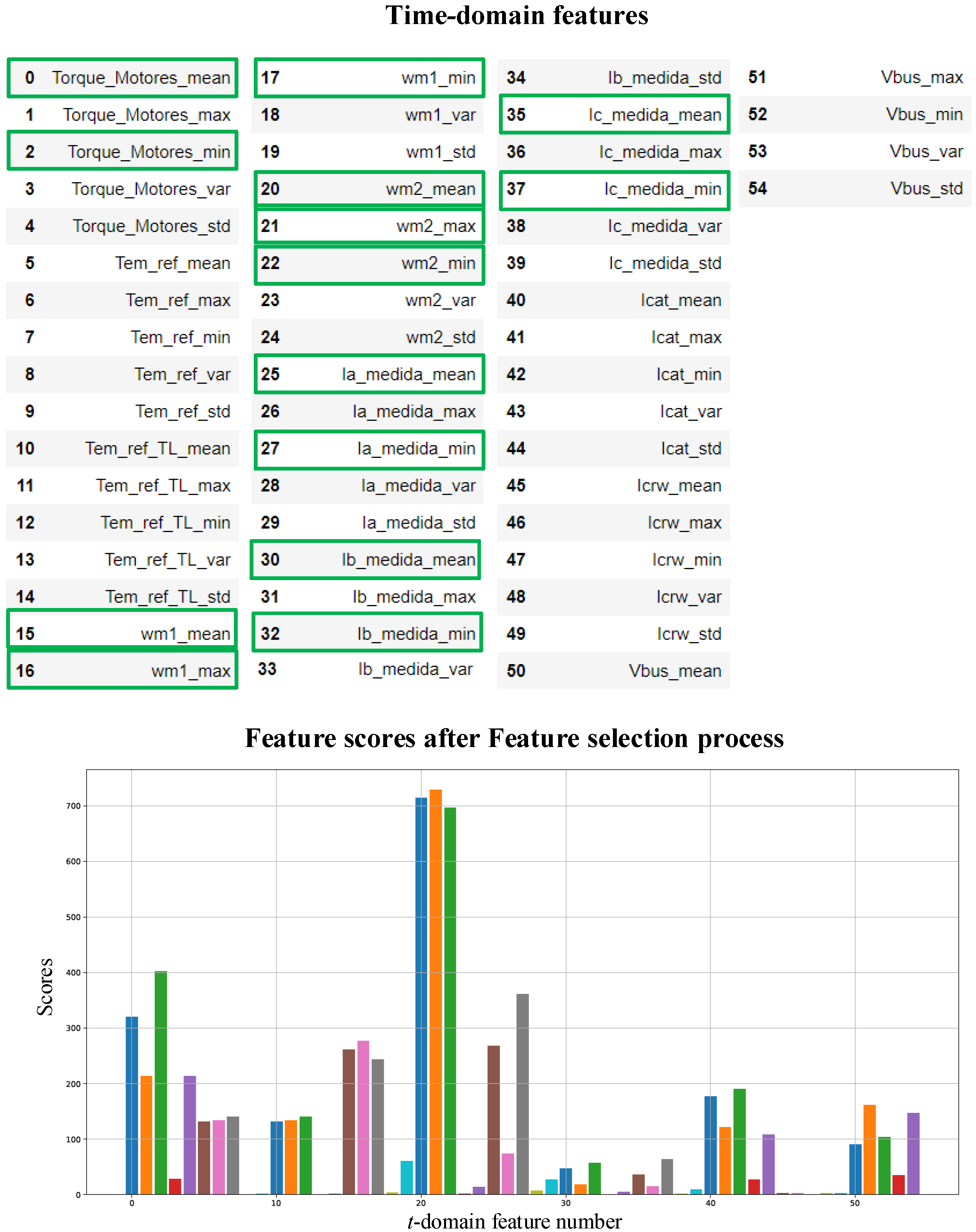

3.2. Raw Data Preprocessing

3.3. ML Model Selection and Training

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| IM | Induction Machine |

| FDD | Fault Detection and Diagnosis |

| ML | Machine Learning |

| DL | Deep Learning |

| HRC | High Resistive Connection |

| SiL | Software-in-the-Loop |

| TCU | Traction Control Unit |

| AWS | Amazon Web Services |

| RMS | Root Mean Square |

| LR | Logistic Regression |

| SVM | Support Vector Machine |

| kNN | k-Nearest Neighbours |

| RF | Random Forest |

References

- Riera-Guasp, M.; Antonino-Daviu, J.A.; Capolino, G.A. Advances in electrical machine, power electronic, and drive condition monitoring and fault detection: State of the art. IEEE Trans. Ind. Electron. 2015, 62, 1746–1759. [Google Scholar] [CrossRef]

- Li, Z.; Gao, Y.; Zhang, X.; Wang, B.; Ma, H. A Model-Data-Hybrid-Driven Diagnosis Method for Open-Switch Faults in Power Converters. IEEE Trans. Power Electron. 2020, 36, 4965–4970. [Google Scholar] [CrossRef]

- Gou, B.; Xu, Y.; Xia, Y.; Deng, Q.; Ge, X. An Online Data-driven Method for Simultaneous Diagnosis of IGBT and Current Sensor Fault of 3-Phase PWM Inverter in Induction Motor Drives. IEEE Trans. Power Electron. 2020, 35, 13281–13294. [Google Scholar] [CrossRef]

- Oh, H.; Han, B.; Mccluskey, P.; Han, C.; Youn, B.D. Physics-of-Failure, Condition Monitoring, and Prognostics of IGBT Modules: A Review. IEEE Trans. Power Electron. 2015, 30, 2413–2426. [Google Scholar] [CrossRef]

- Wang, H.; Blaabjerg, F. Reliability of capacitors for DC-link applications in power electronic converters—An overview. IEEE Trans. Ind. Appl. 2014, 50, 3569–3578. [Google Scholar] [CrossRef] [Green Version]

- Liao, L.; Gao, H.; He, Y.; Xu, X.; Lin, Z.; Chen, Y.; You, F. Fault Diagnosis of Capacitance Aging in DC Link Capacitors of Voltage Source Inverters Using Evidence Reasoning Rule. Math. Probl. Eng. 2020. [Google Scholar] [CrossRef]

- Khelif, M.A.; Bendiabdellah, A.; Cherif, B.D.E. Short-circuit fault diagnosis of the DC-Link capacitor and its impact on an electrical drive system. Int. J. Electr. Comput. Eng. 2020, 10, 2807–2814. [Google Scholar] [CrossRef]

- Imam, A.M.; Divan, D.M.; Harley, R.G.; Habetler, T.G. Real-time condition monitoring of the electrolytic capacitors for power electronics applications. In Proceedings of the IEEE Applied Power Electronics Conference and Exposition—APEC, Anaheim, CA, USA, 25 February–1 March 2007. [Google Scholar] [CrossRef]

- Dybkowski, M.; Klimkowski, K. Artificial neural network application for current sensors fault detection in the vector controlled induction motor drive. Sensors 2019, 19, 571. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Gou, B.; Xu, Y.; Xia, Y.; Wilson, G.; Liu, S. An Intelligent Time-adaptive Data-driven Method for Sensor Fault Diagnosis in Induction Motor Drive System. IEEE Trans. Ind. Electron. 2018, 66, 9817–9827. [Google Scholar] [CrossRef]

- Chen, H.; Jiang, B.; Lu, N. Data-Driven Incipient Sensor Fault Estimation with Application in Inverter of High-Speed Railway. Math. Probl. Eng. 2017. [Google Scholar] [CrossRef] [Green Version]

- Mohammadhassani, A.; Teymouri, A.; Mehrizi-Sani, A.; Tehrani, K. Performance Evaluation of an Inverter-Based Microgrid under Cyberattacks. In Proceedings of the SOSE 2020—IEEE 15th International Conference of System of Systems Engineering, Budapest, Hungary, 2–4 June 2020. [Google Scholar] [CrossRef]

- Singh, G.K.; Al Kazzaz, S.A.S. Induction machine drive condition monitoring and diagnostic research—A survey. Electr. Power Syst. Res. 2003, 64, 145–158. [Google Scholar] [CrossRef]

- Henao, H.; Capolino, G.A.; Fernandez-Cabanas, M.; Filippetti, F.; Bruzzese, C.; Strangas, E.; Pusca, R.; Estima, J.; Riera-Guasp, M.; Hedayati-Kia, S. Trends in fault diagnosis for electrical machines: A review of diagnostic techniques. IEEE Ind. Electron. Mag. 2014, 8, 31–42. [Google Scholar] [CrossRef]

- Liang, X. Condition monitoring techniques for induction motors. In Proceedings of the 2017 IEEE Industry Applications Society Annual Meeting, IAS 2017, Cincinnati, OH, USA, 1–5 October 2017. [Google Scholar] [CrossRef]

- Basak, D.; Tiwari, A.; Das, S.P. Fault diagnosis and condition monitoring of electrical machines—A review. In Proceedings of the IEEE International Conference on Industrial Technology, Mumbai, India, 15–17 December 2006. [Google Scholar] [CrossRef]

- Garramiola, F.; Poza, J.; Madina, P.; del Olmo, J.; Almandoz, G. A Review in fault diagnosis and Health Assessment for Railway traction drives. Appl. Sci. 2018, 8, 2475. [Google Scholar] [CrossRef] [Green Version]

- Isermann, R. Model-based fault detection and diagnosis: Status and applications. IFAC Proc. Vol. 2004, 37, 49–60. [Google Scholar] [CrossRef]

- Duvvuri, S.S. Model-Based Bearing Fault Detection in Induction Motors under Speed Varying Conditions. In Proceedings of the India International Conference on Power Electronics, IICPE, Jaipur, India, 13–15 December 2018. [Google Scholar] [CrossRef]

- Duvvuri, S.S.; Detroja, K. Model-based stator interturn short-circuit fault detection and diagnosis in induction motors. In Proceedings of the 2015 7th International Conference on Information Technology and Electrical Engineering: Envisioning the Trend of Computer, Information and Engineering, ICITEE 2015, Chiang Mai, Thailand, 29–30 October 2015. [Google Scholar] [CrossRef]

- Karami, F.; Poshtan, J.; Poshtan, M. Model-based fault detection in induction Motors. In Proceedings of the IEEE International Conference on Control Applications, Yokohama, Japan, 8–10 September 2010. [Google Scholar] [CrossRef]

- Cruz, S.; Cardoso, A. Stator winding fault diagnosis in three-phase synchronous and asynchronous motors, by the extended Park’s vector approach. IEEE Trans. Ind. Appl. 2001, 37, 1227–1233. [Google Scholar] [CrossRef]

- Marques Cardoso, A.; Cruz, S.; Fonseca, D. Inter-turn stator winding fault diagnosis in three-phase induction motors, by Park’s vector approach. IEEE Trans. Energy Convers. 1999, 14, 595–598. [Google Scholar] [CrossRef]

- Nejjari, H.; Benbouzid, M. Monitoring and diagnosis of induction motors electrical faults using a current Park’s vector pattern learning approach. IEEE Trans. Ind. Appl. 2000, 36, 730–735. [Google Scholar] [CrossRef]

- Acosta, G.; Verucchi, C.; Gelso, E. A current monitoring system for diagnosing electrical failures in induction motors. Mech. Syst. Signal Process. 2006, 20, 953–965. [Google Scholar] [CrossRef]

- Bruzzese, C.; Honorati, O.; Santini, E. Rotor bars breakage in railway traction squirrel cage induction motors and diagnosis by MCSA technique Part I: Accurate fault simulations and spectral analyses. In Proceedings of the 2005 5th IEEE International Symposium on Diagnostics for Electric Machines, Power Electronics and Drives, Vienna, Austria, 7–9 September 2005; pp. 1–6. [Google Scholar] [CrossRef]

- Boccaletti, C.; Bruzzese, C.; Honorati, O.; Santini, E. Rotor bars breakage in railway traction squirrel cage induction motors and diagnosis by MCSA technique Part II: Theoretical arrangements for fault-related current sidebands. In Proceedings of the 2005 5th IEEE International Symposium on Diagnostics for Electric Machines, Power Electronics and Drives, Vienna, Austria, 7–9 September 2005; pp. 1–6. [Google Scholar] [CrossRef]

- Thomson, W.; Rankin, D.; Dorrell, D. On-line current monitoring to diagnose airgap eccentricity in large three-phase induction motors-industrial case histories verify the predictions. IEEE Trans. Energy Convers. 1999, 14, 1372–1378. [Google Scholar] [CrossRef]

- Zhang, P.; Du, Y.; Habetler, T.G.; Lu, B. A Survey of Condition Monitoring and Protection Methods for Medium-Voltage Induction Motors. IEEE Trans. Ind. Appl. 2011, 47, 34–46. [Google Scholar] [CrossRef]

- Gou, X.; Bian, C.; Zeng, F.; Xu, Q.; Wang, W.; Yang, S. A Data-Driven Smart Fault Diagnosis Method for Electric Motor. In Proceedings of the 2018 IEEE International Conference on Software Quality, Reliability and Security Companion (QRS-C), Lisbon, Portugal, 16–20 July 2018; pp. 250–257. [Google Scholar] [CrossRef]

- Shao, S.Y.; Sun, W.J.; Yan, R.Q.; Wang, P.; Gao, R.X. A Deep Learning Approach for Fault Diagnosis of Induction Motors in Manufacturing. Chin. J. Mech. Eng. 2017, 30, 1347–1356. [Google Scholar] [CrossRef] [Green Version]

- Saucedo-Dorantes, J.J.; Delgado-Prieto, M.; Osornio-Rios, R.A.; De Jesus Romero-Troncoso, R. Multifault Diagnosis Method Applied to an Electric Machine Based on High-Dimensional Feature Reduction. IEEE Trans. Ind. Appl. 2017, 53, 3086–3097. [Google Scholar] [CrossRef] [Green Version]

- Langarica, S.; Ruffelmacher, C.; Nunez, F. An Industrial Internet Application for Real-Time Fault Diagnosis in Industrial Motors. IEEE Trans. Autom. Sci. Eng. 2019, 17, 284–295. [Google Scholar] [CrossRef]

- Zhang, W.; Li, C.; Peng, G.; Chen, Y.; Zhang, Z. A deep convolutional neural network with new training methods for bearing fault diagnosis under noisy environment and different working load. Mech. Syst. Signal Process. 2018, 100, 439–453. [Google Scholar] [CrossRef]

- Alwan, H.O.; Farhan, N.M.; Sabbagh, Q.S.A. Detection of Static Air-Gap Eccentricity in Three Phase induction Motor by Using Artificial Neural Network (ANN). Int. J. Eng. Res. Appl. 2017, 7, 15–23. [Google Scholar] [CrossRef]

- Gonzalez-Jimenez, D.; del-Olmo, J.; Poza, J.; Garramiola, F.; Madina, P. Data-Driven Fault Diagnosis for Electric Drives: A Review. Sensors 2021, 21, 4024. [Google Scholar] [CrossRef] [PubMed]

- Barański, M.; Polak, M. Thermal diagnostic in electrical machines. Prz. Elektrotech. 2011, 33, 305–308. [Google Scholar]

- de la Barrera, P.M.; Bossio, G.R.; Solsona, J.A. High-Resistance Connection Detection in Induction Motor Drives Using Signal Injection. IEEE Trans. Ind. Electron. 2014, 61, 3563–3573. [Google Scholar] [CrossRef]

- Stojčić, G.; Wolbank, T.M. Detecting high-resistance connection asymmetries in inverter fed AC drive systems. In Proceedings of the 2013 9th IEEE International Symposium on Diagnostics for Electric Machines, Power Electronics and Drives (SDEMPED), Valencia, Spain, 27–30 August 2013; pp. 227–232. [Google Scholar] [CrossRef]

- Lee, S.B.; Yang, J.; Hong, J.; Yoo, J.Y.; Kim, B.; Lee, K.; Yun, J.; Kim, M.; Lee, K.W.; Wiedenbrug, E.J.; et al. A New Strategy for Condition Monitoring of Adjustable Speed Induction Machine Drive Systems. IEEE Trans. Power Electron. 2011, 26, 389–398. [Google Scholar] [CrossRef]

- Yun, J.; Cho, J.; Lee, S.B.; Yoo, J.Y. Online Detection of High-Resistance Connections in the Incoming Electrical Circuit for Induction Motors. IEEE Trans. Ind. Appl. 2009, 45, 694–702. [Google Scholar] [CrossRef]

- Yun, J.; Lee, K.; Lee, K.W.; Lee, S.B.; Yoo, J.Y. Detection and Classification of Stator Turn Faults and High-Resistance Electrical Connections for Induction Machines. IEEE Trans. Ind. Appl. 2009, 45, 666–675. [Google Scholar] [CrossRef]

- Mengoni, M.; Zarri, L.; Tani, A.; Gritli, Y.; Serra, G.; Filippetti, F.; Casadei, D. Online Detection of High-Resistance Connections in Multiphase Induction Machines. IEEE Trans. Power Electron. 2015, 30, 4505–4513. [Google Scholar] [CrossRef]

- Leandro, E.; de Lacerda de Oliveira, L.E.; da Silva, J.G.B.; Lambert-Torresm, G.; da Silv, L.E.B. Predictive Maintenance by Electrical Signature Analysis to Induction Motors. Induction Mot. Model. Control 2012. [Google Scholar] [CrossRef] [Green Version]

- Rothenhagen, K.; Fuchs, F. Performance of diagnosis methods for IGBT open circuit faults in three phase voltage source inverters for AC variable speed drives. In Proceedings of the 2005 European Conference on Power Electronics and Applications, Dresden, Germany, 11–14 September 2005. [Google Scholar] [CrossRef]

- Guan, Y.; Sun, D.; He, Y. Mean Current Vector Based Online Real-Time Fault Diagnosis for Voltage Source Inverter fed Induction Motor Drives. In Proceedings of the 2007 IEEE International Electric Machines Drives Conference, Antalya, Turkey, 3–5 May 2007; Volume 2, pp. 1114–1118. [Google Scholar] [CrossRef]

- Trabelsi, M.; Boussak, M.; Gossa, M. Multiple IGBTs open circuit faults diagnosis in voltage source inverter fed induction motor using modified slope method. In Proceedings of the XIX International Conference on Electrical Machines—ICEM 2010, Rome, Italy, 6–8 September 2010; pp. 1–6. [Google Scholar] [CrossRef]

- Estima, J.O.; Marques Cardoso, A.J. A New Algorithm for Real-Time Multiple Open-Circuit Fault Diagnosis in Voltage-Fed PWM Motor Drives by the Reference Current Errors. IEEE Trans. Ind. Electron. 2013, 60, 3496–3505. [Google Scholar] [CrossRef]

- Thomsen, J.; Kallesoe, C. Stator fault modeling in induction motors. In Proceedings of the International Symposium on Power Electronics, Electrical Drives, Automation and Motion, 2006. SPEEDAM 2006, Taormina, Italy, 23–26 May 2006; pp. 1275–1280. [Google Scholar] [CrossRef]

- Martin-Diaz, I.; Morinigo-Sotelo, D.; Duque-Perez, O.; Romero-Troncoso, R.J. An Experimental Comparative Evaluation of Machine Learning Techniques for Motor Fault Diagnosis Under Various Operating Conditions. IEEE Trans. Ind. Appl. 2018, 54, 2215–2224. [Google Scholar] [CrossRef]

- Godoy, W.; Silva, I.; Goedtel, A.; Palácios, R.H.C.; Lopes, T.D. Application of intelligent tools to detect and classify broken rotor bars in three-phase induction motors fed by an inverter. IET Electr. Power Appl. 2016, 10, 430–439. [Google Scholar] [CrossRef]

- Martins, J.F.; Ferno Pires, V.; Pires, A.J. Unsupervised Neural-Network-Based Algorithm for an On-Line Diagnosis of Three-Phase Induction Motor Stator Fault. IEEE Trans. Ind. Electron. 2007, 54, 259–264. [Google Scholar] [CrossRef]

- Colby, R. Detection of high-resistance motor connections using symmetrical component analysis and neural network models. In Proceedings of the 4th IEEE International Symposium on Diagnostics for Electric Machines, Power Electronics and Drives, SDEMPED 2003, Atlanta, GA, USA, 24–26 August 2003; pp. 2–6. [Google Scholar] [CrossRef]

- Lee, J.; Singh, J.; Azamfar, M.; Pandhare, V. Chapter 8—Industrial AI and predictive analytics for smart manufacturing systems. In Smart Manufacturing; Soroush, M., Baldea, M., Edgar, T.F., Eds.; Elsevier: Amsterdam, The Netherlands, 2020; pp. 213–244. [Google Scholar] [CrossRef]

- Garramiola, F.; del-Olmo, J.; Poza, J.; Madina, P.; Almandoz, G. Integral sensor fault detection and isolation for railway traction drive. Sensors 2018, 18, 1543. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Garramiola, F.; Poza, J.; Madina, P.; del-Olmo, J.; Ugalde, G. A Hybrid Sensor Fault Diagnosis for Maintenance in Railway Traction Drives. Sensors 2020, 20, 962. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- del Olmo, J.; Garramiola, F.; Poza, J.; Almandoz, G. Model-Based Fault Analysis for Railway Traction Systems. Mod. Railw. Eng. 2018. [Google Scholar] [CrossRef] [Green Version]

- MathWorks. Mastering Machine Learning A Step-by-Step Guide with MATLAB; Technical Report; MathWorks: Natick, MA, USA, 2018. [Google Scholar]

- Zhong, K.; Han, M.; Han, B. Data-driven based fault prognosis for industrial systems: A concise overview. IEEE/CAA J. Autom. Sin. 2019, 7, 330–345. [Google Scholar] [CrossRef]

- Bikov, E.; Boyko, P.; Sokolov, E.; Yarotsky, D. Railway incident ranking with machine learning. In Proceedings of the 16th IEEE International Conference on Machine Learning and Applications, ICMLA 2017, Cancun, Mexico, 18–21 December 2017; pp. 601–606. [Google Scholar] [CrossRef]

- Melendez, I.; Doelling, R.; Bringmann, O. Self-supervised Multi-stage Estimation of Remaining Useful Life for Electric Drive Units. In Proceedings of the 2019 IEEE International Conference on Big Data (Big Data), Los Angeles, CA, USA, 9–12 December 2019; pp. 4402–4411. [Google Scholar] [CrossRef]

- Xue, Z.Y.; Li, M.S.; Xiahou, K.S.; Ji, T.Y.; Wu, Q.H. A Data-Driven Diagnosis Method of Open-Circuit Switch Faults for PMSG-Based Wind Generation System. In Proceedings of the 2019 IEEE 12th International Symposium on Diagnostics for Electrical Machines, Power Electronics and Drives, SDEMPED 2019, Toulouse, France, 27–30 August 2019. [Google Scholar] [CrossRef]

- Xu, Z.; Hu, J.; Hu, C.; Nadarajan, S.; Goh, C.K.; Gupta, A. Data-Driven Fault Detection of Electrical Machine. In Proceedings of the 2018 15th International Conference on Control, Automation, Robotics and Vision, ICARCV 2018, Singapore, 18–21 November 2018; pp. 515–520. [Google Scholar] [CrossRef]

- Shi, W.; Lu, N.; Jiang, B.; Zhi, Y.; Xu, Z. An Unsupervised Anomaly Detection Method Based on Density Peak Clustering for Rail Vehicle Door System. In Proceedings of the 2019 Chinese Control And Decision Conference (CCDC), Nanchang, China, 3–5 June 2019; pp. 1954–1959. [Google Scholar]

| Speed Ref. [rpm] | Load Torque [Nm] |

|---|---|

| 900 | 50 |

| 100 | |

| 2400 | 50 |

| 100 | |

| 4500 | 50 |

| 100 |

| Variable Name | Acq. Freq [ms] | Acq. Mode | Explanation |

|---|---|---|---|

| Torque_Motores | 64 | Inst. | Sum of the two parallel IM torques [Nm] |

| Tem_ref | 64 | Inst. | Torque reference for each of the IMs [Nm] |

| Tem_ref_TL | 64 | Inst. | Torque reference after control limitations [Nm] |

| wm1 | 64 | Inst. | Speed of IM1 [Hz] |

| wm2 | 64 | Inst. | Speed of IM2 [Hz] |

| Ia_medida | 64 | RMS | Total output current of the inverter in phase A [A] |

| Ib_medida | 64 | RMS | Total output current of the inverter in phase B [A] |

| Ic_medida | 64 | RMS | Total output current of the inverter in phase C [A] |

| Icat | 64 | Inst. | Input measured current to the system [A] |

| Icrw | 64 | Inst. | Crowbar current [A] |

| Vbus | 64 | Inst. | BUS voltage [V] |

| Steps | Accuracy [(TP + TN)/(Total Samples)] | Precision [TP/(TP + FP)] | ||||||

|---|---|---|---|---|---|---|---|---|

| LR | SVM | RF | k-NN | LR | SVM | RF | k-NN | |

| Training with raw dataset | 0.719 | 0.806 | 0.967 | 0.938 | 0.753 | 0.831 | 0.978 | 0.932 |

| Training with t-domain features | 0.848 | 0.921 | 0.975 | 0.933 | 0.872 | 0.923 | 0.982 | 0.933 |

| Optimized algorithms testing | 0.923 | 0.967 | 0.985 | 0.942 | 0.911 | 0.953 | 0.976 | 0.934 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gonzalez-Jimenez, D.; del-Olmo, J.; Poza, J.; Garramiola, F.; Sarasola, I. Machine Learning-Based Fault Detection and Diagnosis of Faulty Power Connections of Induction Machines. Energies 2021, 14, 4886. https://doi.org/10.3390/en14164886

Gonzalez-Jimenez D, del-Olmo J, Poza J, Garramiola F, Sarasola I. Machine Learning-Based Fault Detection and Diagnosis of Faulty Power Connections of Induction Machines. Energies. 2021; 14(16):4886. https://doi.org/10.3390/en14164886

Chicago/Turabian StyleGonzalez-Jimenez, David, Jon del-Olmo, Javier Poza, Fernando Garramiola, and Izaskun Sarasola. 2021. "Machine Learning-Based Fault Detection and Diagnosis of Faulty Power Connections of Induction Machines" Energies 14, no. 16: 4886. https://doi.org/10.3390/en14164886

APA StyleGonzalez-Jimenez, D., del-Olmo, J., Poza, J., Garramiola, F., & Sarasola, I. (2021). Machine Learning-Based Fault Detection and Diagnosis of Faulty Power Connections of Induction Machines. Energies, 14(16), 4886. https://doi.org/10.3390/en14164886