Which Strategy Saves the Most Energy for Stratified Water Heaters?

Abstract

:1. Introduction

1.1. Factors That Influence Energy Consumption

1.2. Comparison of Savings from the Literature

1.3. Contributions

2. Savings from Literature for Individual Aspects

3. Experimental Setup

3.1. Hot Water Usage Profiles

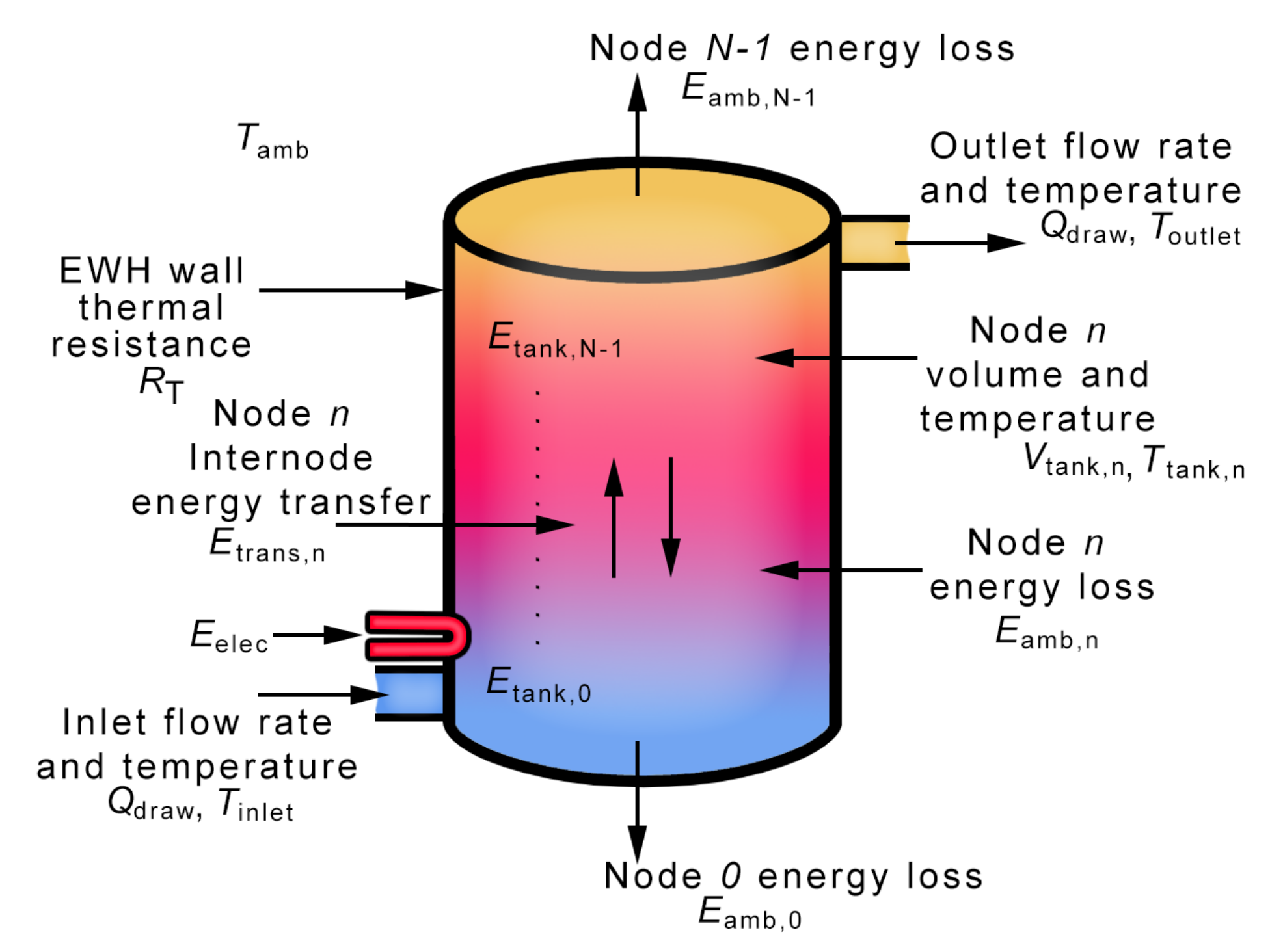

3.2. EWH Simulation Model

3.3. Heating Control Strategies

3.4. Simulation Setup

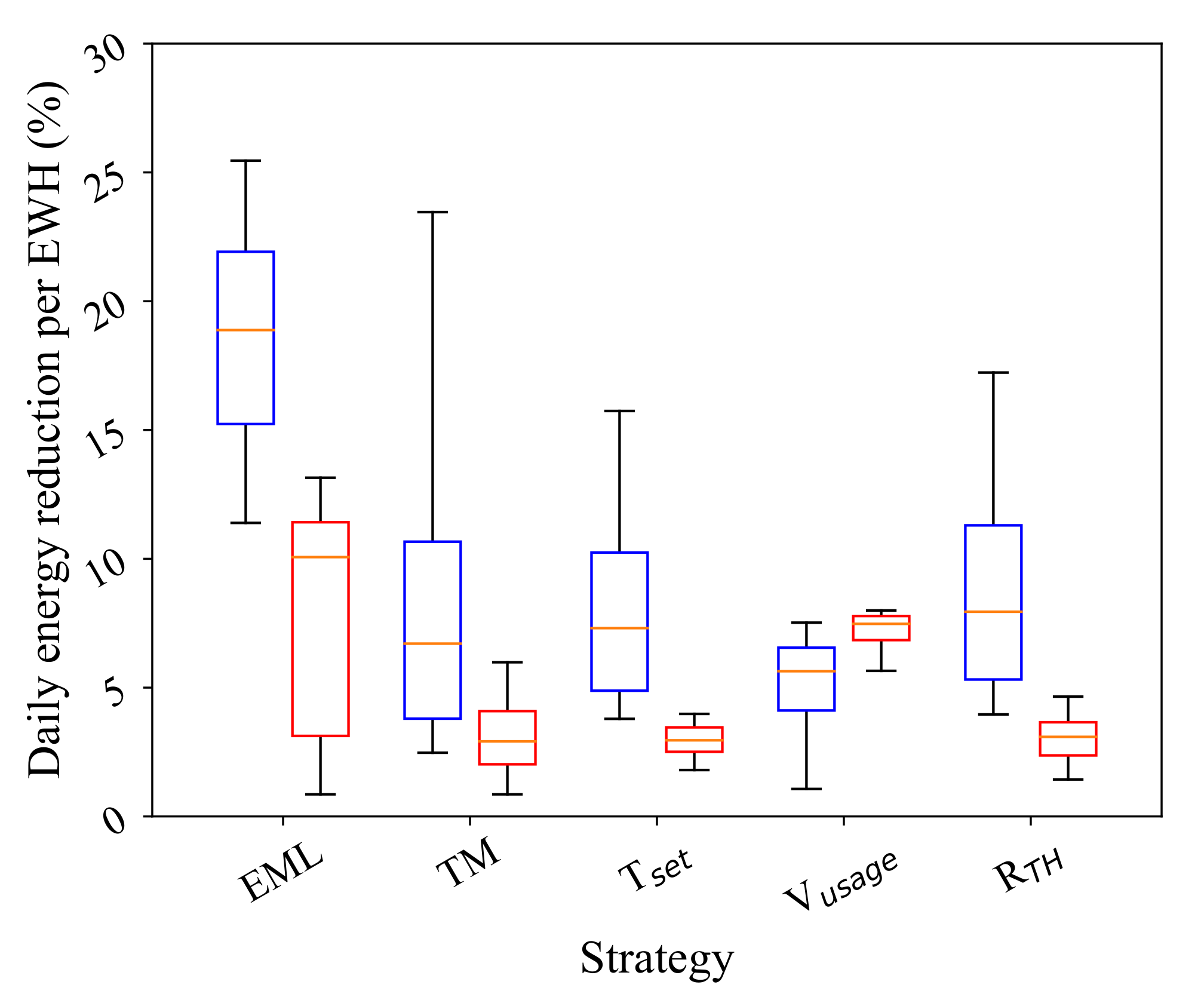

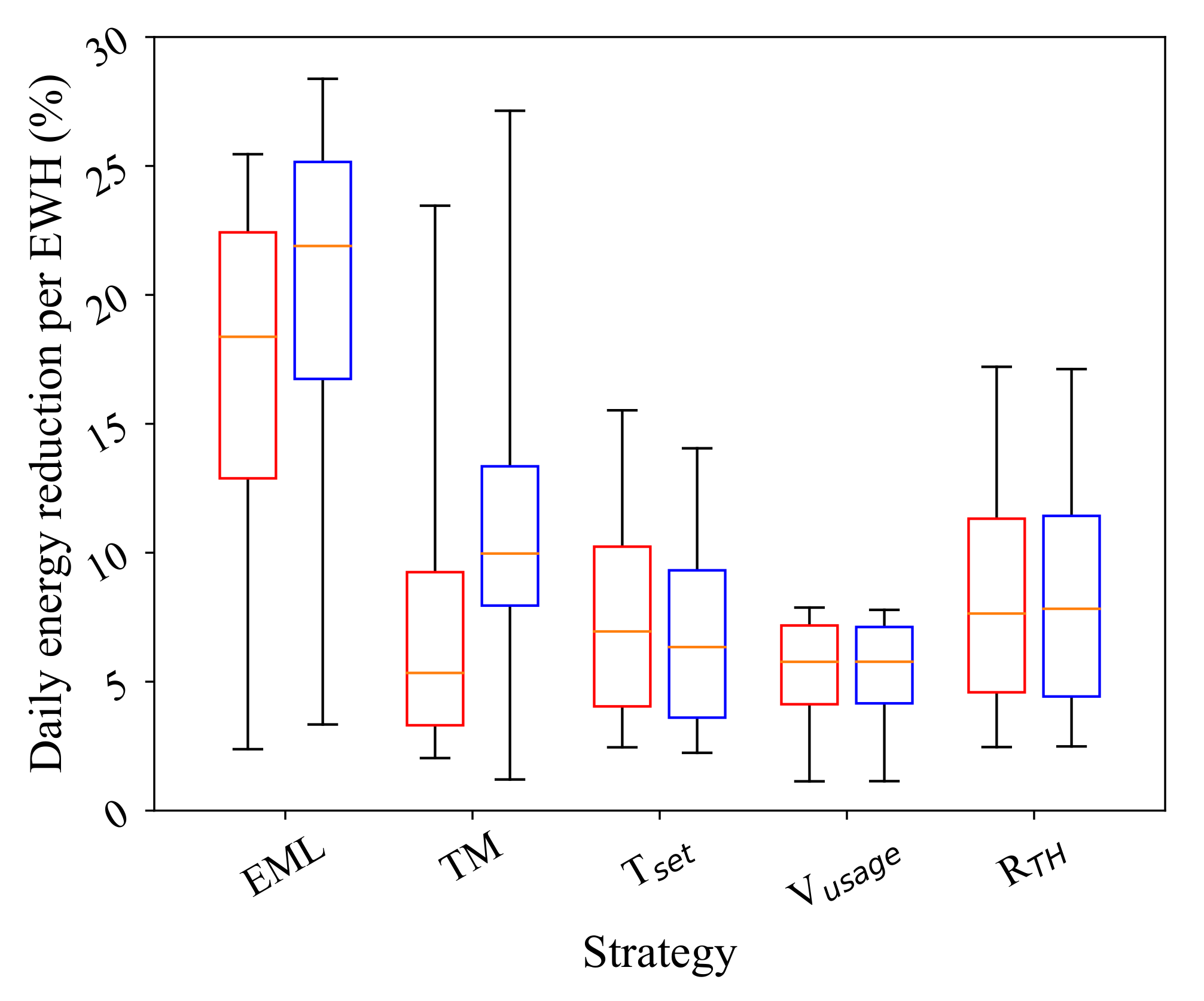

4. Results

- For , the set-point must be set to 45.5 .

- For , the volume of water used must be reduced by 25.4%.

- For , the thermal resistance of the EWH must increase by 96%.

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Tejero-Gómez, J.A.; Bayod-Rújula, A.A. Energy management system design oriented for energy cost optimization in electric water heaters. Energy Build. 2021, 243, 111012. [Google Scholar] [CrossRef]

- Mathu, K. Cleaning South Africa’s Coal Supply Chain. J. Bus. Divers. 2017, 17. [Google Scholar] [CrossRef]

- Jamie, M. Ramaphosa Announces Plan to Save Eskom and Stop Load-Shedding; MyBroadband 2021. Available online: https://mybroadband.co.za/news/energy/386264-ramaphosa-announces-plan-to-save-eskom-and-stop-load-shedding.html (accessed on 6 August 2021).

- Rothausen, S.G.; Conway, D. Greenhouse-gas emissions from energy use in the water sector. Nat. Clim. Chang. 2011, 1, 210–219. [Google Scholar] [CrossRef]

- Osório, G.J.; Shafie-khah, M.; Carvalho, G.C.; Catalão, J.P. Analysis Application of Controllable Load Appliances Management in a Smart Home. Energies 2019, 12, 3710. [Google Scholar] [CrossRef] [Green Version]

- Salameh, W.; Faraj, J.; Harika, E.; Murr, R.; Khaled, M. On the Optimization of Electrical Water Heaters: Modelling Simulations and Experimentation. Energies 2021, 14, 3912. [Google Scholar] [CrossRef]

- Ritchie, M.J.; Engelbrecht, J.A.; Booysen, M.J. Practically-achievable energy savings with the optimal control of stratified water heaters with predicted usage. Energies 2021, 14, 1963. [Google Scholar] [CrossRef]

- Haase, P.; Thomas, B. Test and optimization of a control algorithm for demand-oriented operation of CHP units using hardware-in-the-loop. Appl. Energy 2021, 294, 116974. [Google Scholar] [CrossRef]

- Hohne, P.; Kusakana, K.; Numbi, B. A review of water heating technologies: An application to the South African context. Energy Rep. 2019, 5, 1–19. [Google Scholar] [CrossRef]

- Dutkiewicz, R.K. Energy for Hot Water in the Domestic Sector. In Proceedings of Domestic Use of Electrical Energy Conference; Energy Research Institute: Cape Town, South Africa, 1990; pp. 6–11. [Google Scholar]

- Harris, A.; Kilfoil, M.; Uken, E. Domestic Energy Savings with Geyser Blankets; Cape Peninsula University of Technology, Cape Town, South Africa. 2007. Available online: http://digitalknowledge.cput.ac.za/bitstream/11189/3457/1/Harris%2C_Domestic_2007.pdf (accessed on 6 August 2021).

- Diao, R.; Lu, S.; Elizondo, M.; Mayhorn, E.; Zhang, Y.; Samaan, N. Electric water heater modeling and control strategies for demand response. In Proceedings of the 2012 IEEE Power and Energy Society General Meeting, San Diego, CA, USA, 22–26 July 2012; pp. 1–8. [Google Scholar] [CrossRef]

- Kepplinger, P.; Huber, G.; Petrasch, J. Autonomous optimal control for demand side management with resistive domestic hot water heaters using linear optimization. Energy Build. 2015, 100, 50–55. [Google Scholar] [CrossRef]

- Nel, P.; Booysen, M.J.; Van der Merwe, B. Saving on household electric water heating: What works best and by how much? In Proceedings of the 2017 IEEE Innovative Smart Grid Technologies-Asia (ISGT-Asia), Auckland, New Zealand, 4–7 December 2017; pp. 1–6. [Google Scholar] [CrossRef] [Green Version]

- Fuentes, E.; Arce, L.; Salom, J. A review of domestic hot water consumption profiles for application in systems and buildings energy performance analysis. Renew. Sustain. Energy Rev. 2018, 81, 1530–1547. [Google Scholar] [CrossRef]

- Matos, C.; Bentes, I.; Pereira, S.; Faria, D.; Briga-Sa, A. Energy consumption, CO2 emissions and costs related to baths water consumption depending on the temperature and the use of flow reducing valves. Sci. Total Environ. 2019, 646, 280–289. [Google Scholar] [CrossRef] [PubMed]

- Pereira, T.C.; Lopes, R.A.; Martins, J. Exploring the energy flexibility of electric water heaters. Energies 2019, 13, 46. [Google Scholar] [CrossRef] [Green Version]

- Gato, S.; Jayasuriya, N.; Roberts, P. Forecasting residential water demand: Case study. J. Water Resour. Plan. Manag. 2007, 133, 309–319. [Google Scholar] [CrossRef]

- Heidari, A.; Olsen, N.; Mermod, P.; Alahi, A.; Khovalyg, D. Adaptive hot water production based on Supervised Learning. Sustain. Cities Soc. 2021, 66, 102625. [Google Scholar] [CrossRef]

- Yildiz, B.; Bilbao, J.I.; Roberts, M.; Heslop, S.; Dore, J.; Bruce, A.; MacGill, I.; Egan, R.J.; Sproul, A.B. Analysis of electricity consumption and thermal storage of domestic electric water heating systems to utilize excess PV generation. Energy 2021, 235, 121325. [Google Scholar] [CrossRef]

- Jacobs, H.; Botha, B.; Blokker, M. Household Hot Water Temperature—An Analysis at End-Use Level. In Proceedings of the WDSA/CCWI Joint Conference Proceedings, Kingston, ON, Canada, 23–25 July 2018; Volume 1. [Google Scholar]

- Agudelo-Vera, C.; Avvedimento, S.; Boxall, J.; Creaco, E.; de Kater, H.; Di Nardo, A.; Djukic, A.; Douterelo, I.; Fish, K.E.; Iglesias Rey, P.L.; et al. Drinking water temperature around the globe: Understanding, policies, challenges and opportunities. Water 2020, 12, 1049. [Google Scholar] [CrossRef] [Green Version]

- Iglesias, F.; Palensky, P. Profile-based control for central domestic hot water distribution. IEEE Trans. Ind. Inform. 2013, 10, 697–705. [Google Scholar] [CrossRef]

- Zhou, S.; McMahon, T.; Walton, A.; Lewis, J. Forecasting operational demand for an urban water supply zone. J. Hydrol. 2002, 259, 189–202. [Google Scholar] [CrossRef]

- Gerin, O.; Bleys, B.; De Cuyper, K. Seasonal variation of hot and cold water consumption in apartment buildings. In Proceedings of the CIB W062, 40th International Symposium on Water Supply and Drainage for Building, Sao Paulo, Brazil, 8–10 September 2014; pp. 1–9. [Google Scholar]

- Roux, M.; Booysen, M.J. Use of smart grid technology to compare regions and days of the week in household water heating. In Proceedings of the 2017 International Conference on the Domestic Use of Energy (DUE), Cape Town, South Africa, 4–5 April 2017; pp. 276–283. [Google Scholar] [CrossRef] [Green Version]

- Booysen, M.J.; Visser, M.; Burger, R. Temporal case study of household behavioural response to Cape Town’s “Day Zero” using smart meter data. Water Res. 2019, 149, 414–420. [Google Scholar] [CrossRef] [Green Version]

- Armstrong, P.M.; Uapipatanakul, M.; Thompson, I.; Ager, D.; McCulloch, M. Thermal and sanitary performance of domestic hot water cylinders: Conflicting requirements. Appl. Energy 2014, 171–179. [Google Scholar] [CrossRef]

- Stone, W.; Louw, T.M.; Gakingo, G.K.; Nieuwoudt, M.J.; Booysen, M.J. A potential source of undiagnosed Legionellosis: Legionella growth in domestic water heating systems in South Africa. Energy Sustain. Dev. 2019, 130–138. [Google Scholar] [CrossRef] [Green Version]

- Stout, J.E.; Best, M.G.; Yu, V.L. Susceptibility of members of the family Legionellaceae to thermal stress: Implications for heat eradication methods in water distribution systems. Appl. Environ. Microbiol. 1986, 52, 396–399. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ritchie, M.J.; Engelbrecht, J.; Booysen, M.J. Impact of node count on energy-optimal control of stratified vertical water heaters in smart grid applications. Prepr. Curr. Under Rev. 2021. [Google Scholar] [CrossRef]

- Fikru, M.G.; Gautier, L. The impact of weather variation on energy consumption in residential houses. Appl. Energy 2015, 144, 19–30. [Google Scholar] [CrossRef]

- Booysen, M.J.; Engelbrecht, J.; Ritchie, M.J.; Apperley, M.; Cloete, A.H. How much energy can optimal control of domestic water heating save? Energy Sustain. Dev. 2019, 51, 73–85. [Google Scholar] [CrossRef] [Green Version]

- Geasy-A Smart Geasy Controller by BridgIoT. Available online: https://www.bridgiot.co.za/solutions/geasy-2/ (accessed on 17 September 2019).

- Bosman, I.; Grobler, L.; Dalgleish, A. Determination of the impact on the standing losses of installing blankets to electric hot water heaters in South Africa. J. Energy South. Afr. 2006, 17, 57–64. [Google Scholar]

- Climate-data.org-Cape Town Climate. Available online: https://en.climate-data.org/africa/south-africa/western-cape/cape-town-788/ (accessed on 6 August 2021).

- Ritchie, M.; Engelbrecht, J.; Booysen, M. A probabilistic hot water usage model and simulator for use in residential energy management. Energy Build. 2021, 235, 110727. [Google Scholar] [CrossRef]

| Parameter | Description | Value |

|---|---|---|

| Power rating of heating element | 3 kW | |

| Set-point temperature | 68.5 | |

| Hysteresis | ||

| Ambient temperature | 20 | |

| Inlet water temperature | 20 | |

| Thermal resistance of EWH | 0.4807 | |

| Tank volume | 150 L |

| Strategy | Value | Energy Losses (kWh/day) | Energy Used (kWh/day) | Total EWH Energy (kWh/day) | - Energy Efficiency (%) | Energy Losses (kWh/day) | Energy Used (kWh/day) | Total EWH Energy (kWh/day) | (Percentage Points) |

|---|---|---|---|---|---|---|---|---|---|

| Baseline | - | 2.40 | 4.77 | 7.16 | 66.3 | - | - | - | - |

| Optimal control (TM) | - | 2.02 | 4.77 | 6.75 | 75.2 | 0.367 | 0.000 | 0.385 | 8.9 |

| Optimal control (EML) | - | 1.34 | 4.77 | 6.06 | 85.5 | 1.06 | 0.000 | 1.09 | 19.2 |

| 55 C | 1.73 | 4.74 | 6.48 | 73.1 | 0.666 | 0.000 | 0.666 | 6.83 | |

| 60 C | 1.98 | 4.77 | 6.75 | 70.4 | 0.420 | 0.000 | 0.419 | 4.1 | |

| 70 C | 2.47 | 4.76 | 7.24 | 65.6 | −0.074 | 0.001 | −0.073 | −0.710 | |

| 10 C | 2.89 | 4.78 | 7.68 | 62.0 | −0.495 | 0.003 | −0.491 | −4.25 | |

| 15 C | 2.65 | 4.77 | 7.41 | 64.3 | −0.248 | 0.003 | −0.244 | −1.96 | |

| 10 C | 2.39 | 5.74 | 8.14 | 70.3 | 0.007 | −0.952 | −0.945 | 4.01 | |

| 15 C | 2.40 | 5.26 | 7.66 | 68.5 | 0.003 | −0.484 | −0.480 | 2.19 | |

| −5% | 2.40 | 4.53 | 6.93 | 65.2 | −0.001 | 0.230 | 0.229 | −1.10 | |

| −10% | 2.40 | 4.30 | 6.70 | 64.0 | −0.003 | 0.459 | 0.457 | −2.26 | |

| −15% | 2.40 | 4.06 | 6.46 | 62.5 | −0.003 | 0.693 | 0.689 | −3.78 | |

| −20% | 2.40 | 3.82 | 6.22 | 61.4 | −0.004 | 0.927 | 0.923 | −4.93 | |

| Thermal blanket | 18% | 2.04 | 4.77 | 6.81 | 69.9 | 0.363 | −0.007 | 0.356 | 3.59 |

| Pipe insulation | 6% | 2.26 | 4.77 | 7.03 | 67.8 | 0.135 | −0.004 | 0.131 | 1.46 |

| Thermal blanket + pipe insulation | 24% | 1.94 | 4.78 | 6.72 | 70.9 | 0.461 | −0.008 | 0.452 | 4.63 |

| Tank size | 200 L | 2.77 | 4.78 | 7.55 | 59.8 | −0.371 | 0.004 | −0.367 | −6.47 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ritchie, M.J.; Engelbrecht, J.A.A.; Booysen, M.J. Which Strategy Saves the Most Energy for Stratified Water Heaters? Energies 2021, 14, 4859. https://doi.org/10.3390/en14164859

Ritchie MJ, Engelbrecht JAA, Booysen MJ. Which Strategy Saves the Most Energy for Stratified Water Heaters? Energies. 2021; 14(16):4859. https://doi.org/10.3390/en14164859

Chicago/Turabian StyleRitchie, Michael J., Jacobus A. A. Engelbrecht, and M. J. (Thinus) Booysen. 2021. "Which Strategy Saves the Most Energy for Stratified Water Heaters?" Energies 14, no. 16: 4859. https://doi.org/10.3390/en14164859

APA StyleRitchie, M. J., Engelbrecht, J. A. A., & Booysen, M. J. (2021). Which Strategy Saves the Most Energy for Stratified Water Heaters? Energies, 14(16), 4859. https://doi.org/10.3390/en14164859