A Novel Optimization Algorithm for Solar Panels Selection towards a Self-Powered EV Parking Lot and Its Impact on the Distribution System

Abstract

:1. Introduction

1.1. Motivation and Background

1.2. Literature Review

1.3. Contribution

- A rank-weigh-rank (RWR) optimization algorithm is proposed to rank and select the best solar panels from a list of alternatives. In addition, it optimally places and distributes the solar panels on the rooftops of the EVPL considering many criteria and constraints,

- Some equations and definitions are proposed as presented in Algorithm 1, including but not limited to: energy and power self-sufficiency ratios, excess and lack of energy production ratio, surface filling ratio, etc.

- ○

- Case 1: EVPL without roof-mounted PV system;

- ○

- Case 2: EVPL with roof-mounted PV System with the best selected SP using RWR method;

- ○

- Case 3: EVPL with roof-mounted PV system without selecting the best SP.

2. Proposed Algorithm to Select the Best Solar Panel from a List

| Algorithm 1. Proposed algorithm for optimal selection and distribution of the solar panels for a roof-mounted photovoltaic (PV) system in an electric vehicle parking lot (EVPL). | |||

| Input Data | |||

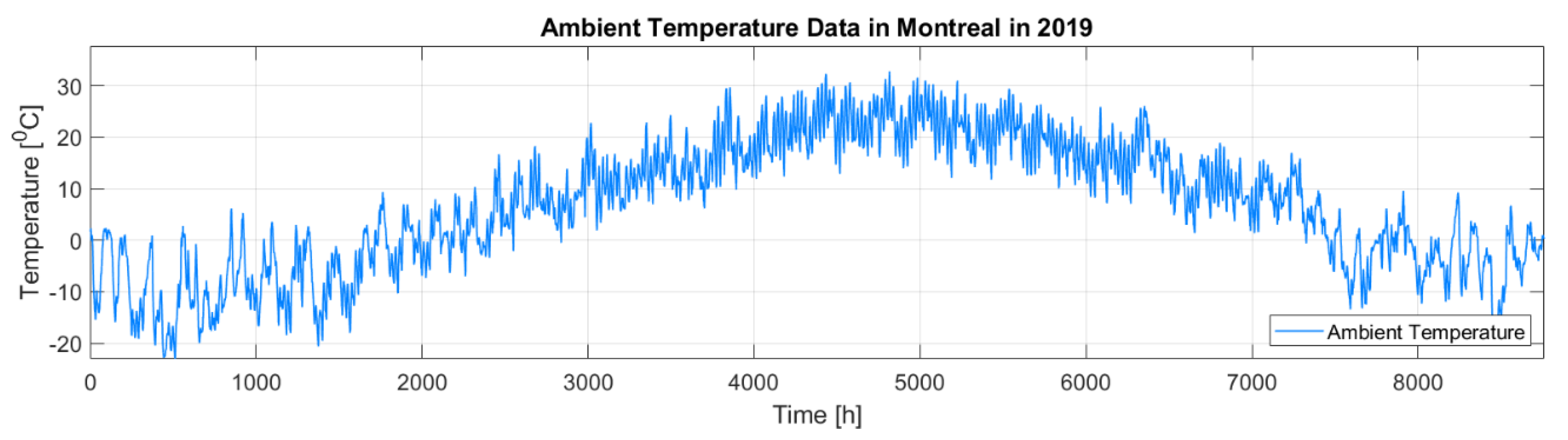

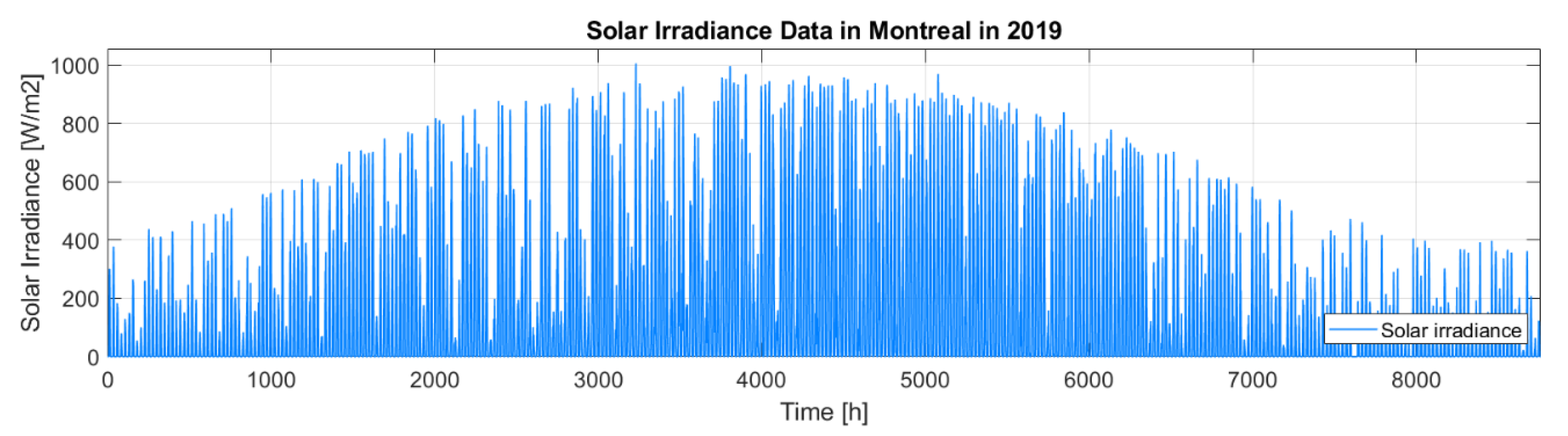

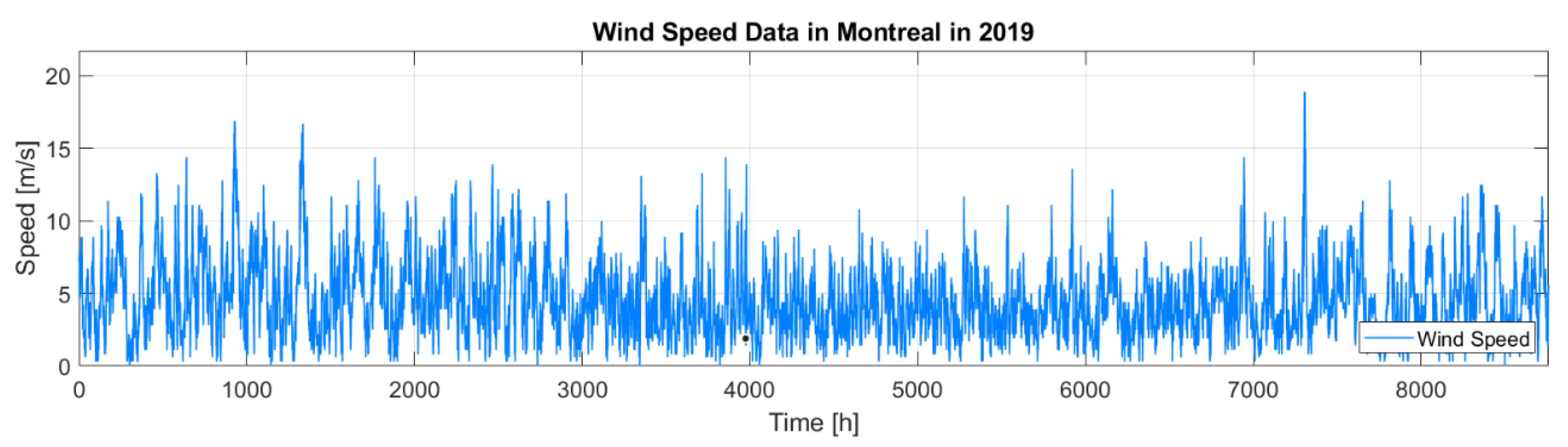

| 1 | Weather data: Solar irradiance, ambient temperature, wind speed | ||

| 2 | Historical power profiles and energy demand of the EVPL | ||

| 3 | Parking lot data, such as the maximum number of occupancies of EVs, charging rates (e.g., level 2, 6 kWp), arrival and departure time of each EV, opening and closing hours (e.g., from 8 a.m. till 11 p.m.), | ||

| 4 | Buying and selling electricity prices for the following cases: GridEV, RES→EV, RES→Grid | ||

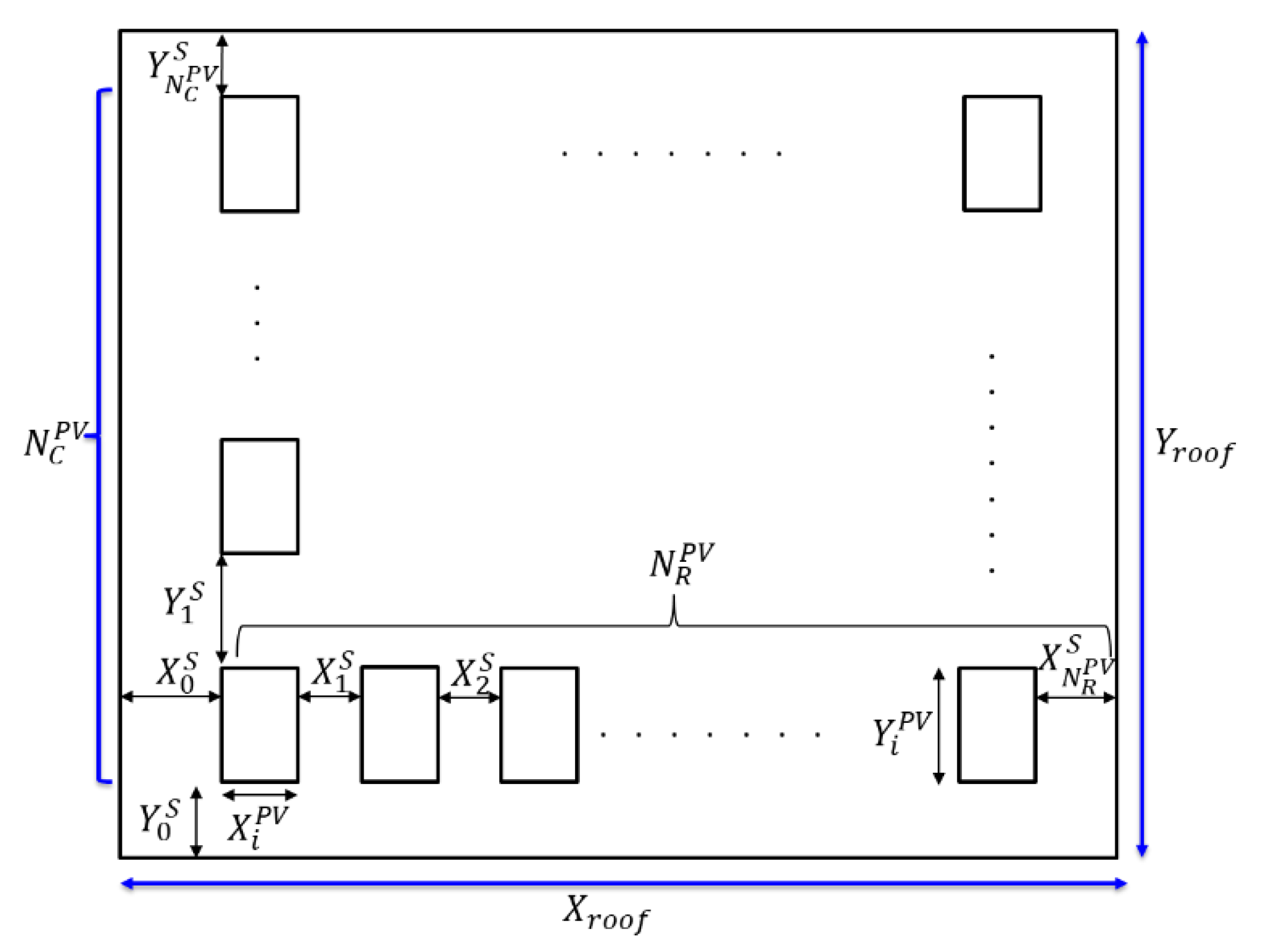

| 5 | Roof dimensions: number of roofs, their length, width, and inclination, | ||

| 6 | Solar panel data: | ||

| a. Shape of the PV module: short and long side lengths and area, and tile angle | |||

| b. Spacing between solar panels, and between solar panels and the boundaries of the roofs, | |||

| c. Internal Characteristics of the solar panels: total installation cost per module, efficiency, geometric multiplier, temperature coefficients for the current and voltage, current and voltage rating, technology, PTC, MPPT, and many others as listed in Table 1 | |||

| Calculate the following equations | |||

| Description | Equations | References | |

| 7 | Efficiency of the system | Equation (A1) | [33] |

| 8 | Number of modules in a row | Equation (A2) | (New equation) |

| 9 | Number of modules in a column | Equation (A4) | (New equation) |

| 10 | Total number of modules | Equation (A5) | (New equation derived from [33]) |

| 11 | Installed capacity of the PV system | Equation (A6) | (New equation) |

| 12 | Total installation cost of the PV system | Equation (A7) | (New equation) |

| 13 | Cost to power generation ratio (CPR) | Equation (A8) | (New equation) |

| 14 | Cost to energy generation ratio (CER) | Equation (A9) | (New equation) |

| 15 | Payback period (PBP) | Equation (A12) | (New equation) |

| 16 | Output power & energy of the PV System | Equations (A16) and (A17) | (New equation derived from [33]) |

| 17 | Energy self-sufficiency ratio | Equation (A18) | [34] |

| 18 | Power self-Sufficiency ratio | Equation (A19) | (New equation) |

| 19 | Excess and lack of energy production ratio | Equation (A20) and (A21) | (New equation) |

| 20 | Surface filling ratio | Equation (A22) | (New equation) |

| Create a decision matrix () with the following criteria (whereandare the-th alternative, and the-th criterion) | |||

| 21 | MPPT under STC | beneficial criteria | |

| 22 | Total installation cost per module | non-beneficial criteria | |

| 23 | Installed capacity of the PV system | beneficial criteria | |

| 24 | Total installation cost of the PV system | non-beneficial criteria | |

| 25 | Cost to power generation ratio | non-beneficial criteria | |

| 26 | Cost to energy generation ratio | non-beneficial criteria | |

| 27 | Efficiency of the PV system | beneficial criteria | |

| 28 | Payback period | non-beneficial criteria | |

| 29 | Energy self-sufficiency ratio | beneficial criteria | |

| Use Rank-Weigh-Rank (RWR) method to rank alternatives in the decision matrix (Our proposed MCDM algorithm) | |||

| 30 | Rank the alternatives of each criterion from the best to the worst values . The ranking can be in ascending order for the non-beneficial criteria (e.g., cost), and in descending order for the beneficial criteria (e.g., energy generation) | ||

| 31 | Create a Weighting Vector which weighs criteria using the equation , where is the weighting factor for the -th criterion, and is the normalized weighting factor, | ||

| 32 | Calculate the normalized weighted decision vector . Where, is the transposition of the vector , | ||

| 33 | Rank the obtained vector in ascending order | ||

| Results | |||

| 34 | Select the best alternative and calculate the optimal dimensioning and placement of the solar panels on the roofs of the EVPL | ||

3. Assumptions and Considerations

- Case 1: EVPLs without roof-mounted PV systems;

- Case 2: EVPLs with roof-mounted PV systems while selecting the best solar panels using our proposed RWR optimization algorithm;

- Case 3: EVPLs with roof-mounted PV system without using our proposed RWR optimization algorithm to select the best solar panels.

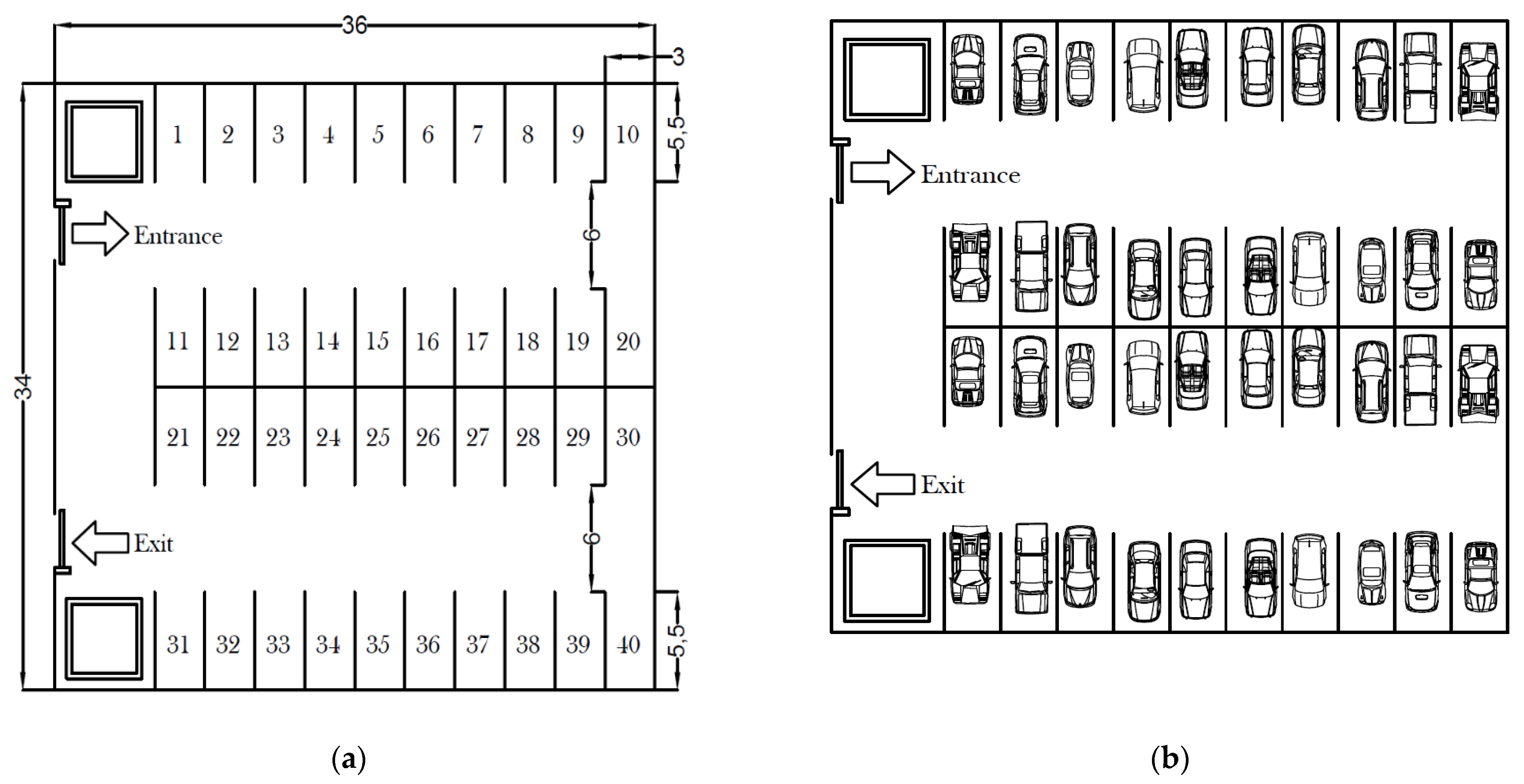

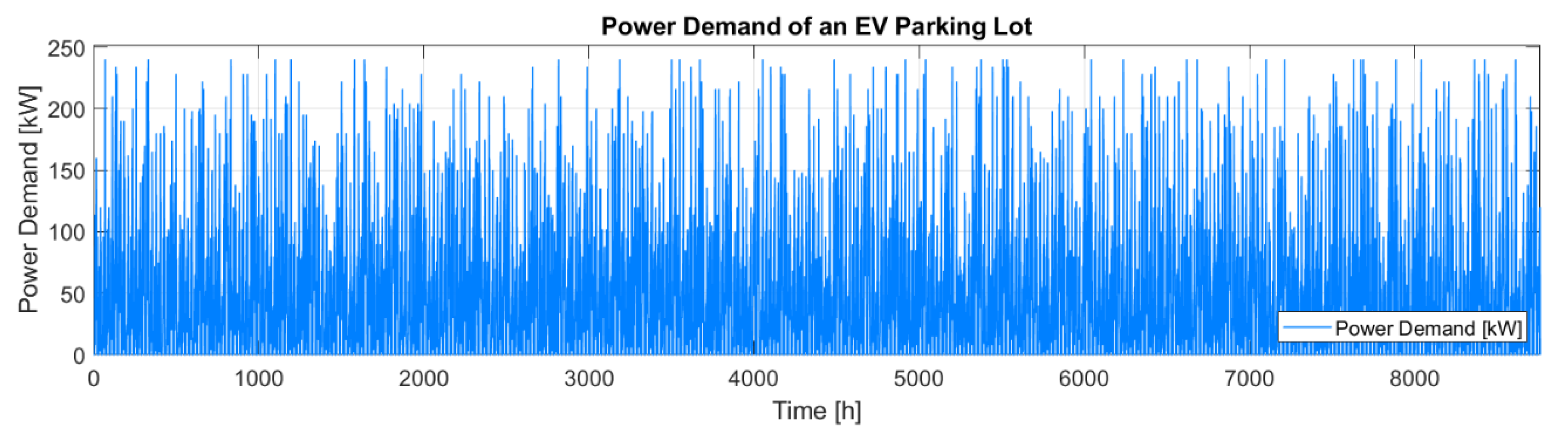

3.1. Electric Vehicle Parking Lot Data

- Parking lot is for a supermarket with an area of 1224 m2;

- Opening hours from 8:00 a.m. till 11:00 p.m.;

- AC Level 2 charger is used in which the power rate is variable between 0 and 6 kWp;

- Maximum power capacity of the parking lot is 240 kWp;

- Maximum number of EVs in the parking lot: 40;

- Rate M is applied for the parking lot in Quebec:

- ○

- $14.58 per kilowatt of billing demand (EVPL will have a maximum of 240 kWp (6 kWp × 40 EVs). Therefore, the total rate is $3499.2 (240 kWp × 14.58 $/kW),

- ○

- Plus 5.03 ¢ per kWh for the first 210,000 kilowatt-hours per month,

- ○

- And 3.73 ¢ per kWh per month for the remaining consumption.

- Selling electricity price:

- ○

- From PV to EV: 15 ¢/kWh,

- ○

- From PV to the grid: 5.03 ¢/kWh,

- Since we are comparing different SPs, the price of the infrastructure is not included in the calculation because it will be the same for any kind of SPs, and it will not affect the output results.

3.2. Real Data for the Montreal Case Study

3.3. Solar Panels’ Data

4. Results and Discussion

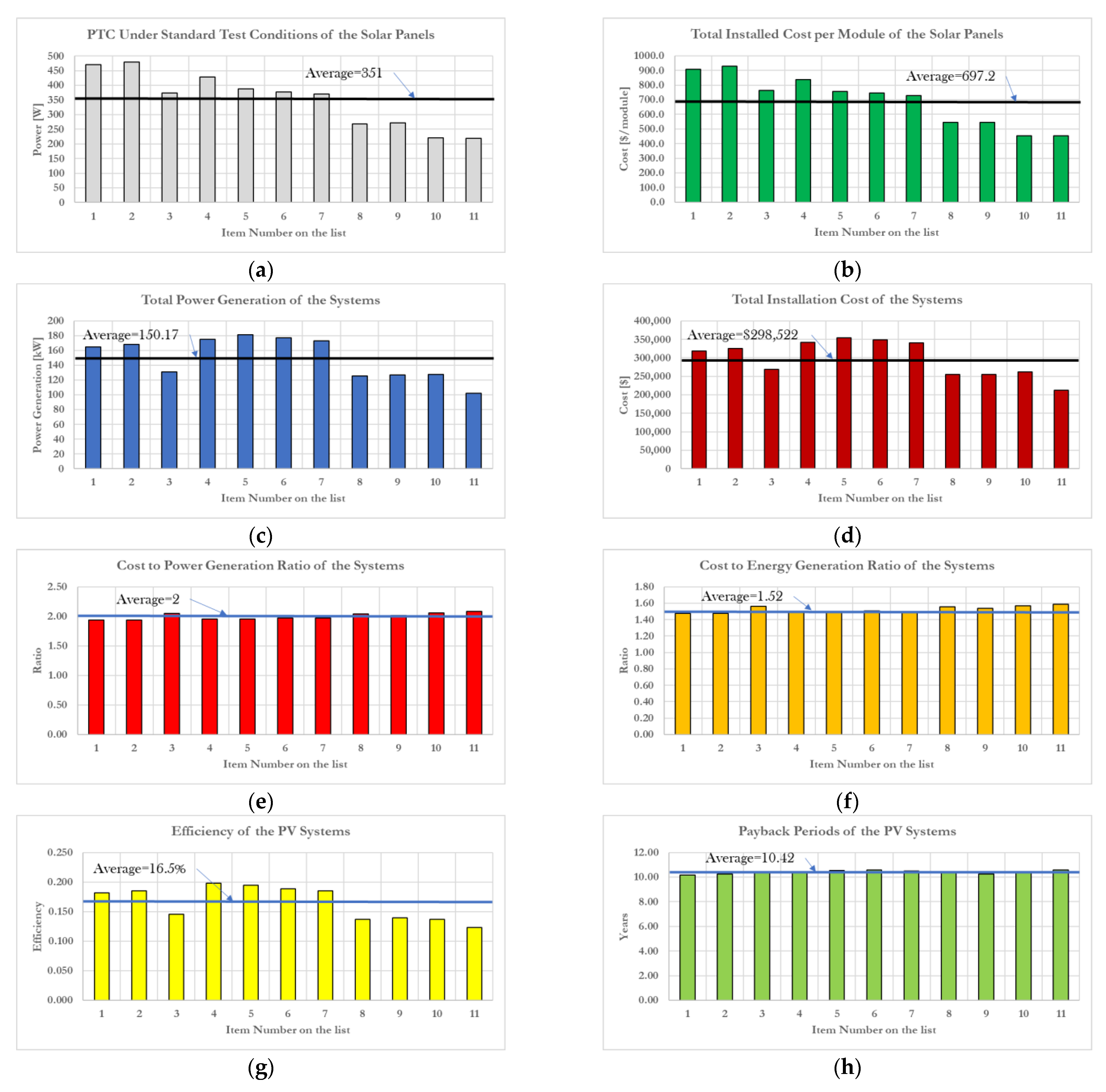

4.1. Design of the Electric Vehicle Parking Lot’s (EVPL) Roof-Mounted Photovoltaic (PV) System

4.2. Calculation of the System Performance

4.3. Decision Matrix

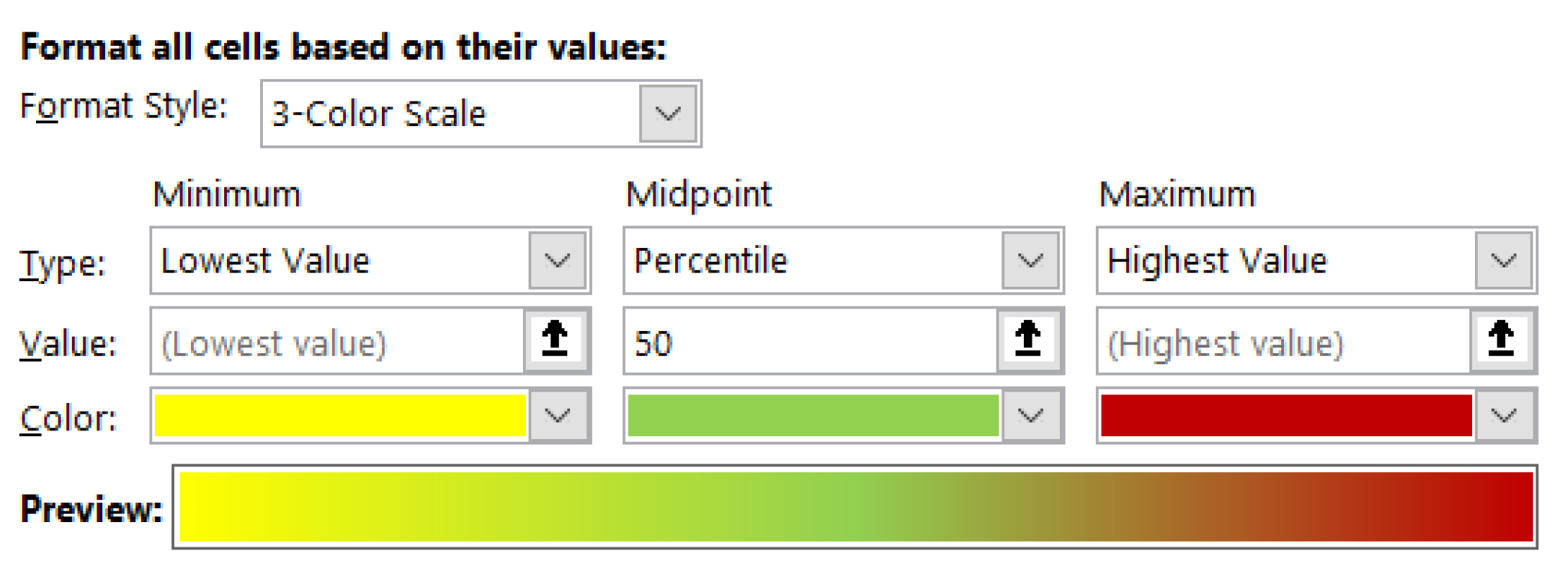

4.4. Determination of the Weighting Factors

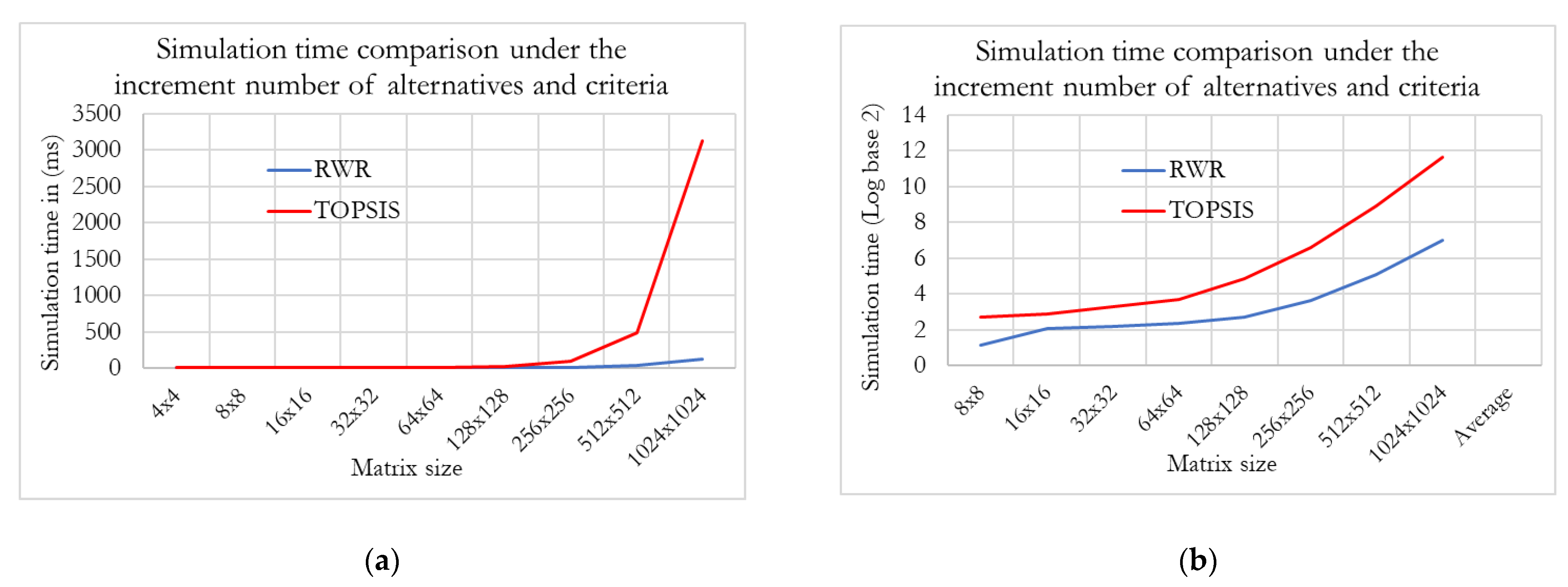

4.5. Comparing RWR and TOPSIS Methods under Different Test Conditions

- Case 1: the same dimension of the decision matrix is used while considering different weighting factors for each iteration, as in Table 6. In this case, RWR is faster than TOPSIS by 2.856 times;

- Case 2: the size of the decision matrix is doubled every iteration, as presented in Table 7 and Figure 10. The main goal is to know how much the matrix’s dimension affects the simulation time. In this case, it is remarked that RWR is much faster than TOPSIS, and the speed is exponentially increased with the increase of the decision matrix.

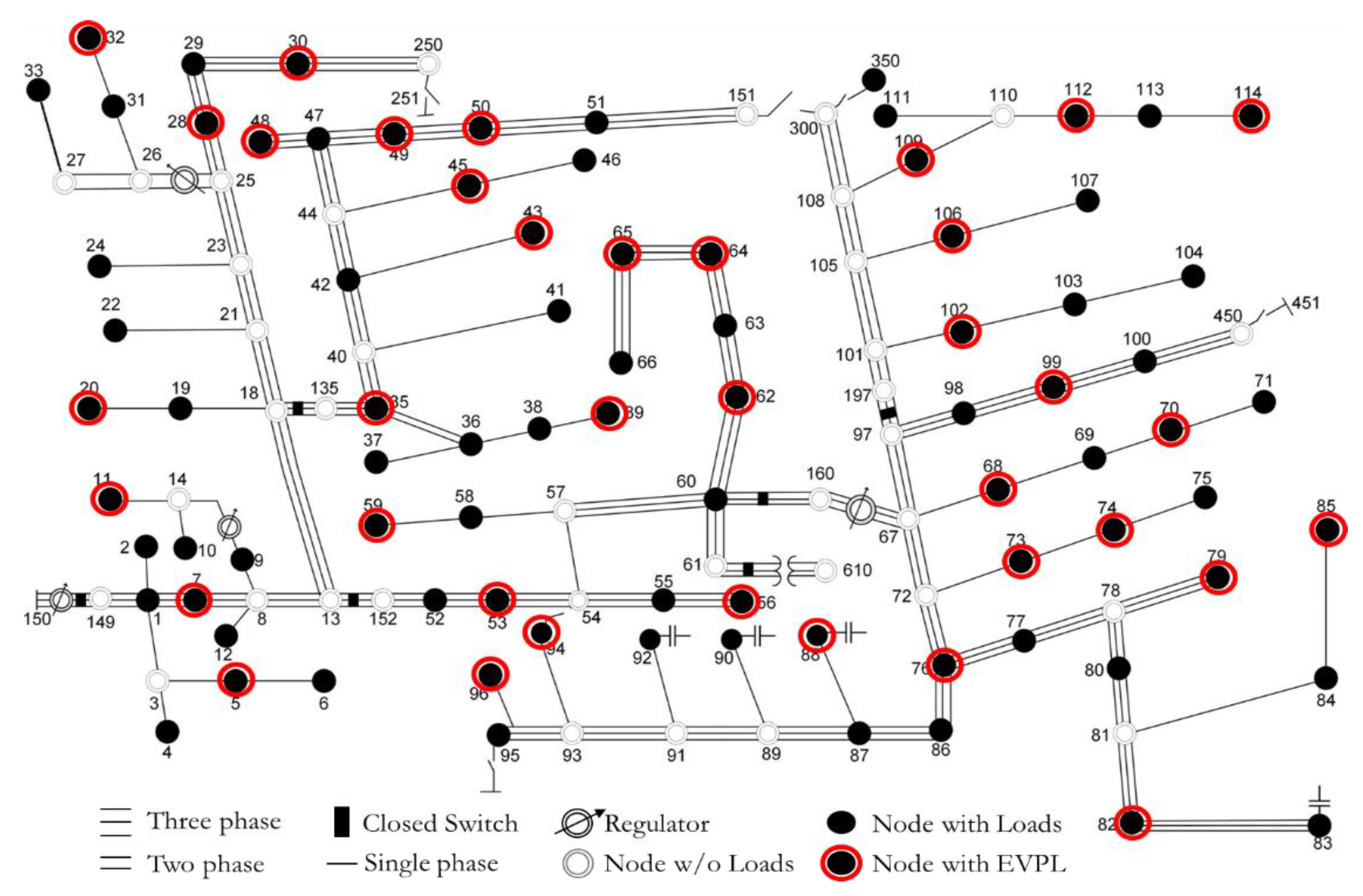

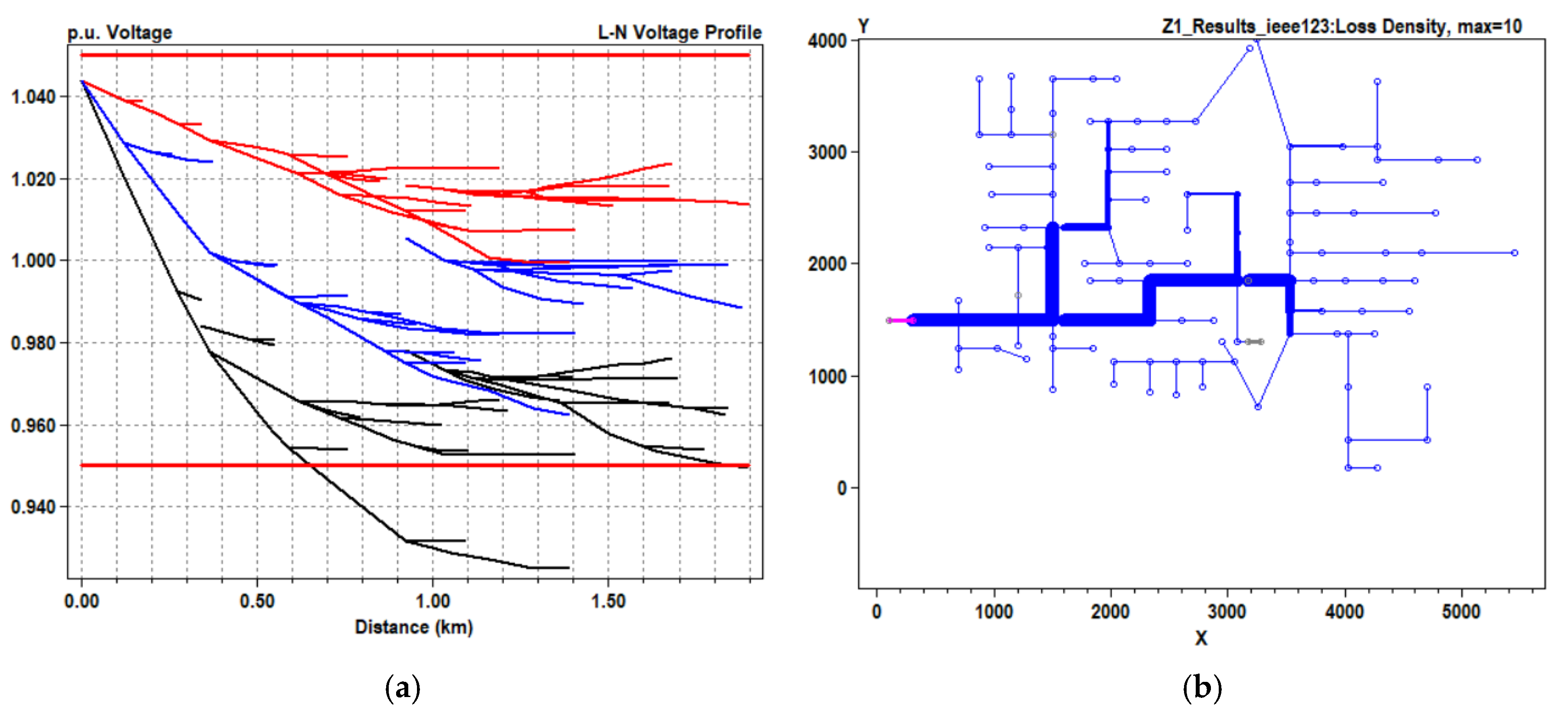

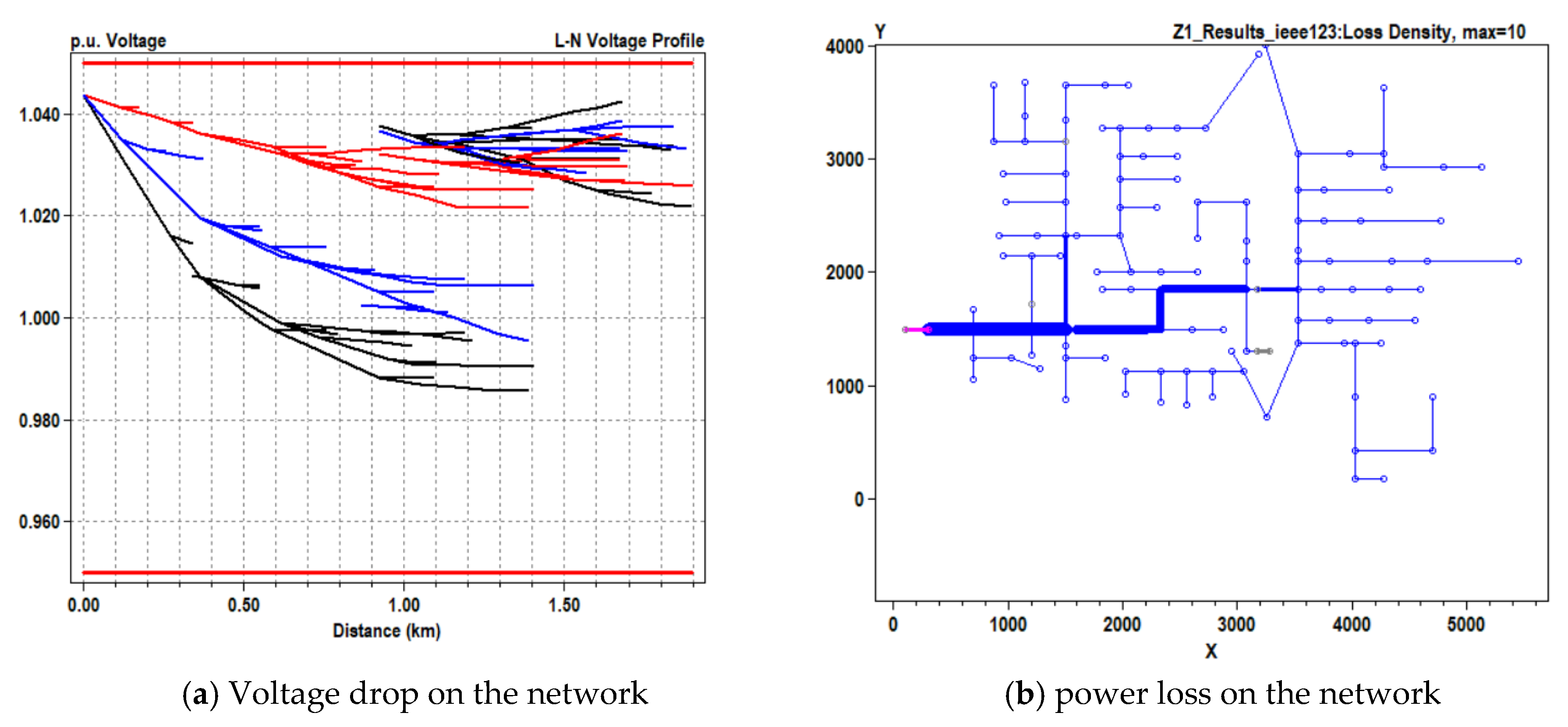

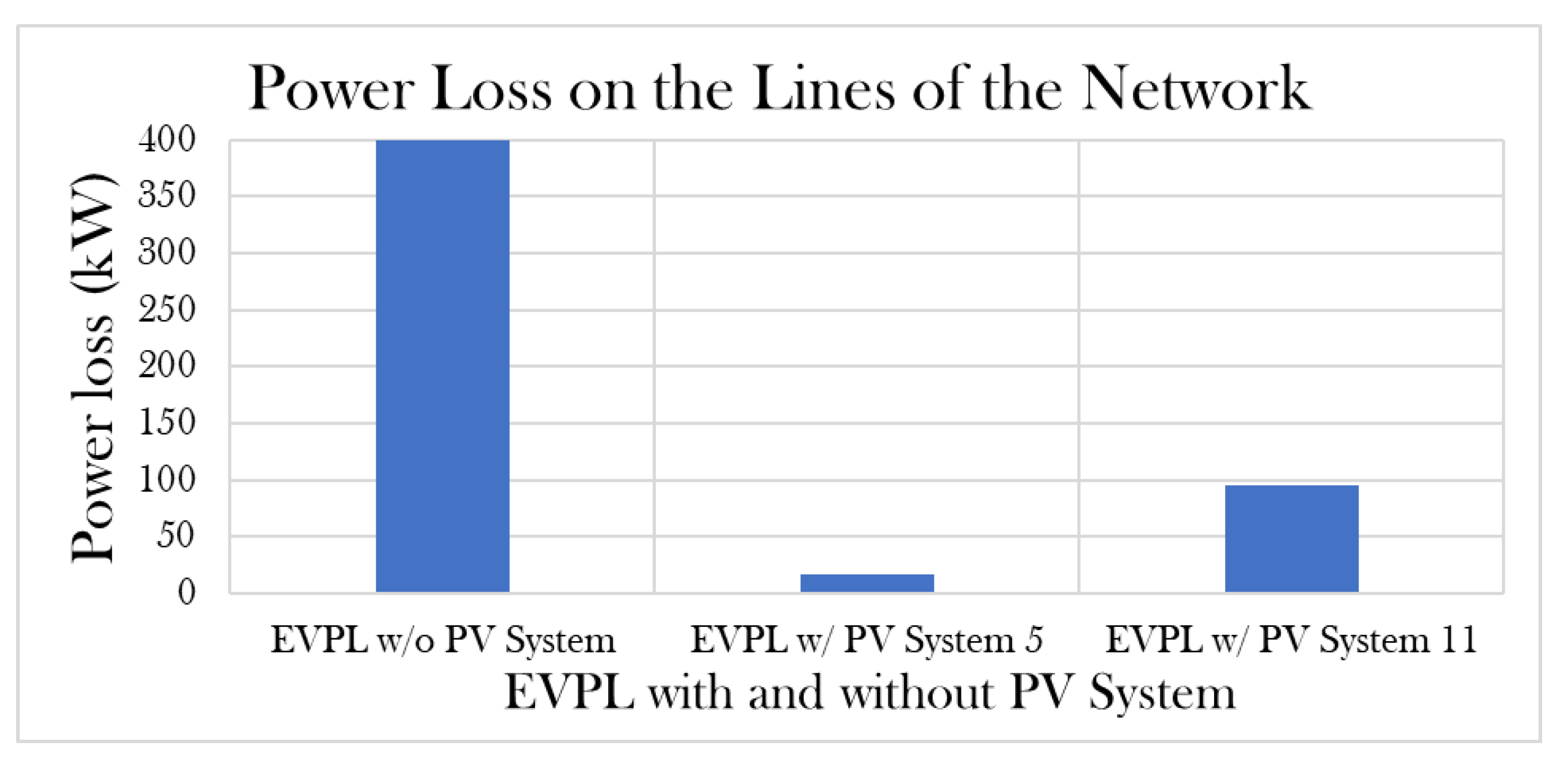

4.6. Does the Selection of Different Solar Panels Have an Impact on the Distribution System?

- IEEE 123 nodes test feeder is considered as a distribution network (as in Figure 11);

- We consider that 43% of the nodes have EVPLs (red dots in Figure 11);

- OpenDSS is used to simulate the distribution network;

- Since IEEE 123 is a standard network, we consider that the load of EVPL is added to the network.

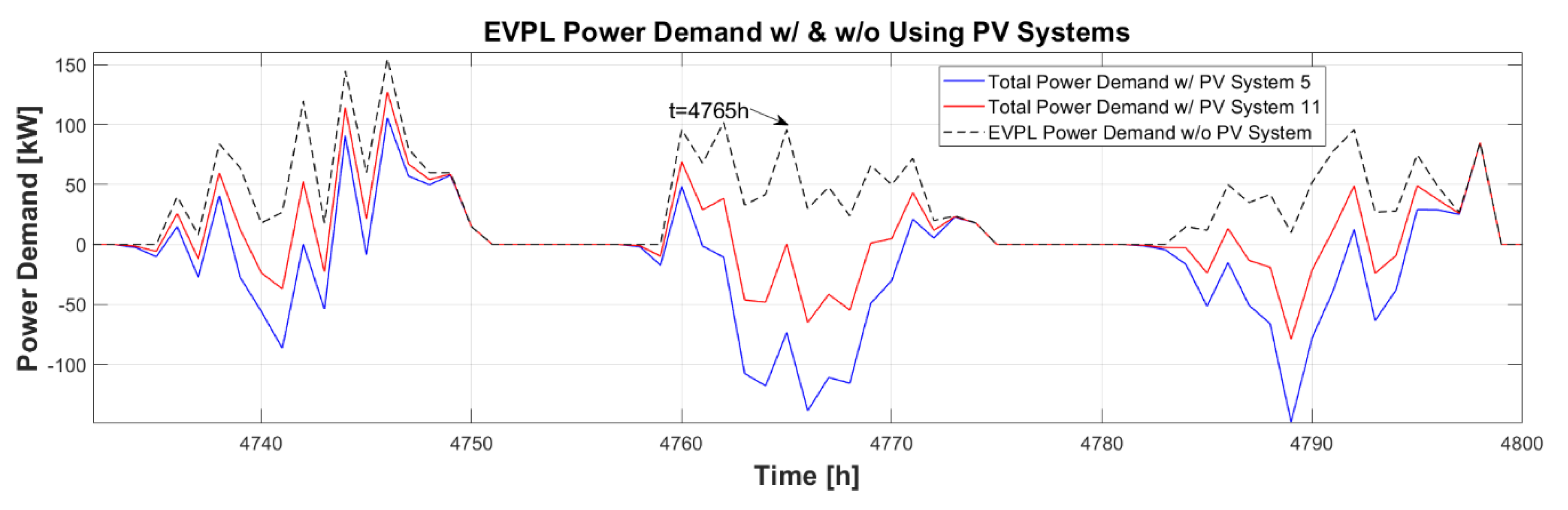

- Solar panels items 5 (Canadian Solar Inc., model: CS1U-415MS) and 11 (Gintung Energy, model: ASEC-250G6S6B) are chosen for the comparison;

- The same EVPL in the previous sections is studied with the same roof area to ensure a fair comparison;

- The comparison is made for t = 4765 h, which is on 2019-07-18 at 1 p.m. in the Montreal time zone as in Figure 12, where the local energy production is much higher than the energy demand;

- Three scenarios are studied:

4.7. The Impact of the Electricity Tariff on the Future of Electric Vehicle Parking Lot

- Reduce the subscription fees for an EVPL by considering only the energy consumption. It is possible a small monthly subscription fee can be applied;

- Encourage the EVPLs to integrate renewable energy systems such as PV and wind turbines to increase their ESSR;

- Subsidies and funding can be applied to reduce the investment cost of renewable energy sources such as PV systems, wind turbines, etc. Hence, the EVPL will be able to produce more local energy and will reduce the demand from the electrical network;

- Optimization should be used to manage the charging of EVs and minimize the peak demand. Therefore, the impact on the electrical network is reduced;

- Bidirectional chargers could also reduce the impact on the network and may increase the revenue of the EVPL owner by participating in ancillary services.

5. Conclusions and Future Work

- the electricity tariff in Quebec does not encourage the decision-makers to build an EVPL in Montreal since the electricity tariff is very high, and the construction cost is also very high, which should be reconsidered;

- the PV system is insufficient to supply the EVPL’s demand, especially in Quebec, since the solar radiation is low most of the time, even in summer. Hence, other renewable energy systems should be studied, such as the integration of vertical axis wind turbines;

- the integration of renewable energy systems and EVs should always be accompanied with advanced tools to manage and schedule the energy generation and consumption to avoid problems on the network, as discussed previously;

- since RWR and TOPSIS do not always give the same results, it becomes a little bit confusing to know which method is better than the other. From this place, it is necessary to study and compare many MCDM methods in order to see which ones are the most probable to use for the case of renewable energy-based EVPLs.

Author Contributions

Funding

Institutional Review Board Statement

Conflicts of Interest

Appendix A. Mathematical Modeling and Constraints of the Proposed Algorithm

Appendix A.1. Efficiency of the Solar Panel

Appendix A.2. Total Number of the Installed Solar Panels

Appendix A.3. Installed Capacity of the Solar System

Appendix A.4. The Total Installation Cost of the PV System

Appendix A.5. Cost to Power Generation Ratio of the PV System under Standard Test Conditions (STC)

Appendix A.6. Cost to Energy Generation Ratio of the PV System under Real Weather Conditions

Appendix A.7. Payback Period

Appendix A.8. Output Power of the PV System

Appendix A.9. Energy Self-Sufficiency Ratio

Appendix A.10. Power Self-Sufficiency Ratio

- If PSSR = 0%, it means that the PV system is not able to meet the demand of the unit, whatever is t. Therefore, it might not be necessary to install batteries to store energy since there is no excess in production.

- If PSSR = X% where , it means that the PV system is able to meet the demand for X% of the time. In this case, if the excess in power production is high in some periods, the decision-maker can install a battery storage system (BSS) in order to store the excess of energy and to use it later once the unit needs it,

- If PSSR = 100%, it means that the PV system is always producing more energy than needed at any time t. Hence, the decision-maker can sell the energy to the grid without even installing a BSS.

| Algorithm A1. Proposed Algorithm |

| 1 Define: 2 %Starting time of the study e.g., 3 %Time interval, e.g., 4 %Period of the study, e.g., 24 h 5 %Initialize the number of met demand by the power production 6 Calculate: 7 ; %Number of step intervals 8 ; % ending time of the study, e.g., 9 for = 0 10 if 11 % Count the number of times when the generated power meets the power demand 12 end if 13 end for 14 %Power Self-Sufficiency Ratio End of Algorithm |

Appendix A.11. Excess and Lack of Energy Production Ratios

Appendix A.12. Surface Filling Ratio

References

- Tan, K.M.; Ramachandaramurthy, V.K.; Yong, J.Y. Integration of electric vehicles in smart grid: A review on vehicle to grid technologies and optimization techniques. Renew. Sustain. Energy Rev. 2016, 53, 720–732. [Google Scholar] [CrossRef]

- Harris, S.; Weinzettel, J.; Bigano, A.; Källmén, A. Low carbon cities in 2050? GHG emissions of European cities using production-based and consumption-based emission accounting methods. J. Clean. Prod. 2020, 248, 119206. [Google Scholar] [CrossRef]

- Ilieva-Obretenova, M. Information Model for City Monitoring by Smart Lighting. J. Min. Geol. Sci. 2018, 61, 55–59. [Google Scholar]

- Rajakaruna, S.; Shahnia, F.; Ghosh, A. Plug in Electric Vehicles in Smart Grids; Springer: Berlin/Heidelberg, Germany, 2016. [Google Scholar]

- Mohsenzadeh, A.; Pazouki, S.; Haghifam, M.R.; Chengzong, P. Optimal planning of parking lots and demand response programs in distribution network considering power loss and voltage profile. In Proceedings of the Innovative Smart Grid Technologies Conference (ISGT), 2015 IEEE Power & Energy Society, Washington, DC, USA, 18–20 February 2015; pp. 1–5. [Google Scholar]

- El-Bayeh, C.Z.; Mougharbel, I.; Asber, D.; Saad, M.; Chandra, A.; Lefebvre, S. Novel approach for optimizing the transformer’s critical power limit. IEEE Access 2018, 6, 55870–55882. [Google Scholar] [CrossRef]

- The World’s Biggest Solar Photovoltaic Cell Manufacturers. Available online: https://www.power-technology.com/features/featurethe-worlds-biggest-solar-photovoltaic-cell-manufacturers-4863800/ (accessed on 4 May 2021).

- Huang, Q.; Jia, Q.-S.; Guan, X. A Review of EV Load Scheduling with Wind Power Integration. IFAC-Pap. 2015, 48, 223–228. [Google Scholar] [CrossRef]

- Li, D.; Heimeriks, G.; Alkemade, F. The emergence of renewable energy technologies at country level: Relatedness, international knowledge spillovers and domestic energy markets. Ind. Innov. 2020, 27, 1–23. [Google Scholar] [CrossRef] [Green Version]

- Adefarati, T.; Obikoya, G. Assessment of Renewable Energy Technologies in a Standalone Microgrid System. Int. J. Eng. Res. Afr. 2020, 46, 146–167. [Google Scholar] [CrossRef]

- Moustakas, K.; Loizidou, M.; Rehan, M.; Nizami, A. A review of recent developments in renewable and sustainable energy systems: Key challenges and future perspective. Renew. Sustain. Energy Rev. 2020, 119, 109418. [Google Scholar] [CrossRef]

- Boxwell, M. Solar Electricity Handbook 2019 Edition: A Simple Practical Guide to Solar Energy: Designing and Installing Solar PV Systems; Greenstream Publishing: Coventry, UK, 2019. [Google Scholar]

- Fazelpour, F.; Vafaeipour, M.; Rahbari, O.; Rosen, M.A. Intelligent optimization to integrate a plug-in hybrid electric vehicle smart parking lot with renewable energy resources and enhance grid characteristics. Energy Convers. Manag. 2014, 77, 250–261. [Google Scholar] [CrossRef]

- Zhang, Y.; Cai, L. Dynamic Charging Scheduling for EV Parking Lots With Photovoltaic Power System. IEEE Access 2018, 6, 56995–57005. [Google Scholar] [CrossRef]

- Turan, M.T.; Ates, Y.; Erdinc, O.; Gokalp, E.; Catalão, J.P.S. Effect of electric vehicle parking lots equipped with roof mounted photovoltaic panels on the distribution network. Int. J. Electr. Power Energy Syst. 2019, 109, 283–289. [Google Scholar] [CrossRef]

- Ghazvini, A.M.; Olamaei, J. Optimal sizing of autonomous hybrid PV system with considerations for V2G parking lot as controllable load based on a heuristic optimization algorithm. Sol. Energy 2019, 184, 30–39. [Google Scholar] [CrossRef]

- Velasquez, M.; Hester, P.T. An analysis of multi-criteria decision making methods. Int. J. Oper. Res. 2013, 10, 56–66. [Google Scholar]

- Kumar, A.; Sah, B.; Singh, A.R.; Deng, Y.; He, X.; Kumar, P.; Bansal, R. A review of multi criteria decision making (MCDM) towards sustainable renewable energy development. Renew. Sustain. Energy Rev. 2017, 69, 596–609. [Google Scholar] [CrossRef]

- Ananda, J.; Herath, G. A critical review of multi-criteria decision making methods with special reference to forest management and planning. Ecol. Econ. 2009, 68, 2535–2548. [Google Scholar] [CrossRef]

- Agarwal, P.; Sahai, M.; Mishra, V.; Bag, M.; Singh, V. A review of multi-criteria decision making techniques for supplier evaluation and selection. Int. J. Ind. Eng. Comput. 2011, 2, 801–810. [Google Scholar] [CrossRef]

- Wang, J.-J.; Jing, Y.-Y.; Zhang, C.-F.; Zhao, J.-H. Review on multi-criteria decision analysis aid in sustainable energy decision-making. Renew. Sustain. Energy Rev. 2009, 13, 2263–2278. [Google Scholar] [CrossRef]

- Kabir, G.; Sadiq, R.; Tesfamariam, S. A review of multi-criteria decision-making methods for infrastructure management. Struct. Infrastruct. Eng. 2014, 10, 1176–1210. [Google Scholar] [CrossRef]

- Scott, J.A.; Ho, W.; Dey, P.K. A review of multi-criteria decision-making methods for bioenergy systems. Energy 2012, 42, 146–156. [Google Scholar] [CrossRef] [Green Version]

- Penadés-Plà, V.; García-Segura, T.; Martí, J.V.; Yepes, V. A review of multi-criteria decision-making methods applied to the sustainable bridge design. Sustainability 2016, 8, 1295. [Google Scholar] [CrossRef] [Green Version]

- Mardani, A.; Zavadskas, E.K.; Khalifah, Z.; Zakuan, N.; Jusoh, A.; Nor, K.M.; Khoshnoudi, M. A review of multi-criteria decision-making applications to solve energy management problems: Two decades from 1995 to 2015. Renew. Sustain. Energy Rev. 2017, 71, 216–256. [Google Scholar] [CrossRef]

- Sabaei, D.; Erkoyuncu, J.; Roy, R. A review of multi-criteria decision making methods for enhanced maintenance delivery. Procedia CIRP 2015, 37, 30–35. [Google Scholar] [CrossRef] [Green Version]

- Shao, M.; Han, Z.; Sun, J.; Xiao, C.; Zhang, S.; Zhao, Y. A review of multi-criteria decision making applications for renewable energy site selection. Renew. Energy 2020, 157, 377–403. [Google Scholar] [CrossRef]

- Balo, F.; Şağbanşua, L. The Selection of the Best Solar Panel for the Photovoltaic System Design by Using AHP. Energy Procedia 2016, 100, 50–53. [Google Scholar] [CrossRef] [Green Version]

- Wang, T.-C.; Tsai, S.-Y. Solar panel supplier selection for the photovoltaic system design by using fuzzy multi-criteria decision making (MCDM) approaches. Energies 2018, 11, 1989. [Google Scholar] [CrossRef] [Green Version]

- Kharseh, M.; Wallbaum, H. Comparing Different PV Module Types and Brands Under Working Conditions in the United Kingdom. In Reliability and Ecological Aspects of Photovoltaic Modules; Gok, A., Ed.; IntechOpen: London, UK, 2020. [Google Scholar]

- Sasikumar, G.; Ayyappan, S. Multi-criteria Decision Making for Solar Panel Selection Using Fuzzy Analytical Hierarchy Process and Technique for Order Preference by Similarity to ideal Solution (TOPSIS): An Empirical Study. J. Inst. Eng. (India) Ser. C 2019, 100, 707–715. [Google Scholar] [CrossRef]

- El-Bayeh, C.Z.; Alzaareer, K.; Brahmi, B.; Zellagui, M.; Eicker, U. An original multi-criteria decision-making algorithm for solar panels selection in buildings. Energy 2021, 217, 119396. [Google Scholar] [CrossRef]

- Eicker, U. Solar Technologies for Buildings; Wiley Online Library: Hoboken, NJ, USA, 2003; Volume 341. [Google Scholar]

- El-Bayeh, C.Z.; Alzaareer, K.; Laraki, M.-H.; Brahmi, B.; Panchabikesan, K.; Venturini, W.A.; Eicker, U. A Comparison between PV and Dish Stirling Systems Towards Self-Sufficient Energy Building in Lebanon. In Proceedings of the 2020 5th International Conference on Renewable Energies for Developing Countries (REDEC), Marrakech, Morocco, 24–26 March 2020; pp. 1–6. [Google Scholar]

- Data Download for Montréal. Available online: https://montreal.weatherstats.ca/download.html (accessed on 22 April 2021).

- El-Bayeh, C.Z.; Eicker, U.; Alzaareer, K.; Brahmi, B.; Zellagui, M. A Novel Data-Energy Management Algorithm for Smart Transformers to Optimize the Total Load Demand in Smart Homes. Energies 2020, 13, 4984. [Google Scholar] [CrossRef]

- El-Bayeh, C.Z.; Alzaareer, K.; Brahmi, B.; Zellagui, M. A Novel Algorithm for Controlling Active and Reactive Power Flows of Electric Vehicles in Buildings and Its Impact on the Distribution Network. World Electr. Veh. J. 2020, 11, 43. [Google Scholar] [CrossRef]

- El-Bayeh, C.Z.; Mougharbel, I.; Saad, M.; Chandra, A.; Lefebvre, S.; Asber, D. Novel multilevel soft constraints at homes for improving the integration of plug-in electric vehicles. In Proceedings of the 2018 4th International Conference on Renewable Energies for Developing Countries (REDEC), Beirut, Lebanon, 1–2 November 2018; pp. 1–9. [Google Scholar]

- El-Bayeh, C.Z.; Mougharbel, I.; Saad, M.; Chandra, A.; Asber, D.; Lenoir, L.; Lefebvre, S. Novel Soft-Constrained Distributed Strategy to meet high penetration trend of PEVs at homes. Energy Build. 2018, 178, 331–346. [Google Scholar] [CrossRef]

- Kagan, J. Payback Period. Available online: https://www.investopedia.com/terms/p/paybackperiod.asp (accessed on 28 April 2021).

- Bayeh, C.Z. Introduction to the Infomath function in mathematics and its application in electrical and electronic engineering. WSEAS Trans. Adv. Eng. Educ. 2013, 10, 24–36. [Google Scholar]

| i (Item Number) | Manufacturer | Model Number | Nameplate Pmax (W) | PTC (W) | Technology | Total Installed Cost per Module ($/Module) | A_c (m2) | N_s | N_p | Nameplate Isc (A) | Nameplate Voc (V) | Nameplate Ipmax (A) | Nameplate Vpmax (V) | Average NOCT (°C) | Short Side (m) | Long Side (m) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | Sunpreme Inc. | SNPM-GxB-500 | 500 | 470.0 | Thin Film | 908.4 | 2.591 | 96 | 1 | 9.20 | 72.90 | 8.70 | 57.40 | 45.5 | 1.308 | 1.981 |

| 2 | Sunpreme Inc. | SNPM-GxB-510 | 510 | 479.6 | Thin Film | 927.6 | 2.591 | 96 | 1 | 9.40 | 74.70 | 8.90 | 57.30 | 45.5 | 1.308 | 1.981 |

| 3 | Topsun | TS-S420SA1 | 420 | 373.2 | Mono-c-Si | 764.1 | 2.564 | 96 | 1 | 9.12 | 60.65 | 8.62 | 48.73 | 48.3 | 1.308 | 1.960 |

| 4 | SunPower | SPR-X22-460-COM | 460 | 428.4 | Mono-c-Si | 837.1 | 2.162 | 128 | 1 | 6.40 | 90.50 | 6.00 | 76.70 | 45.7 | 1.046 | 2.067 |

| 5 | Canadian Solar Inc. | CS1U-415MS | 415 | 387.7 | Mono-c-Si | 756.2 | 1.990 | 81 | 6 | 9.75 | 53.7 | 9.3 | 44.7 | 45.1 | 1.000 | 1.990 |

| 6 | LG Electronics Inc. | LG410N2C-A5 | 410 | 377.9 | Mono-c-Si | 746.3 | 2.000 | 72 | 1 | 10.55 | 49.50 | 9.91 | 41.40 | 47.7 | 1.000 | 2.000 |

| 7 | LG Electronics Inc. | LG400N2K-A5 | 400 | 369.7 | Mono-c-Si | 727.9 | 2.000 | 72 | 1 | 10.29 | 49.40 | 9.76 | 41.00 | 47.2 | 1.000 | 2.000 |

| 8 | Advance Power | API-M300 | 300 | 267.8 | Mono-c-Si | 545.7 | 1.951 | 72 | 1 | 8.58 | 44.71 | 8.17 | 36.72 | 47.9 | 0.995 | 1.961 |

| 9 | Recom | RCM-300-6PA | 300 | 270.8 | Multi-c-Si | 545.9 | 1.940 | 72 | 1 | 8.69 | 44.80 | 8.20 | 36.60 | 46.2 | 0.992 | 1.956 |

| 10 | KISCO | GETWATT 250M-A1U | 250 | 220.9 | Mono-c-Si | 454.9 | 1.615 | 60 | 1 | 8.60 | 37.60 | 8.20 | 30.50 | 47.5 | 0.983 | 1.643 |

| 11 | Gintung Energy | ASEC-250G6S6B | 250 | 218.4 | Mono-c-Si | 454.8 | 1.773 | 66 | 1 | 8.37 | 40.4 | 7.85 | 31.85 | 51.4 | 0.99 | 1.79 |

| Input Data of the Algorithm | Output Results of the Algorithm | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| i | Short Side (m) | Long Side (m) | PTC under STC (W) | Total Installed Cost per Module ($/Module) | Total Power Generation of the System (W) | Total Installation Cost of the System ($) | CPR of the System ($/W) | CER of the System ($/kWh) | Efficiency of the System | PBP of the System (Year) | Energy Self-Sufficiency Ratio (%) | Power Self-Sufficiency Ratio (%) | Total Nb of PV Modules on the Roof | Surface Filling Ratio (%) |

| 1 | 1.31 | 1.98 | 470 | 908.4 | 164,970 | 318,848 | 1.93 | 1.47 | 0.181 | 10.18 | 69.0 | 59.6 | 351 | 90 |

| 2 | 1.31 | 1.98 | 480 | 927.6 | 168,340 | 325,588 | 1.93 | 1.47 | 0.185 | 10.24 | 70.4 | 59.9 | 351 | 90 |

| 3 | 1.31 | 1.96 | 373 | 764.1 | 130,993 | 268,199 | 2.05 | 1.56 | 0.146 | 10.41 | 54.7 | 56.6 | 351 | 89 |

| 4 | 1.05 | 2.07 | 428 | 837.1 | 174,787 | 341,537 | 1.95 | 1.49 | 0.198 | 10.44 | 73.1 | 60.4 | 408 | 88 |

| 5 | 1.00 | 1.99 | 388 | 756.2 | 181,444 | 353,902 | 1.95 | 1.49 | 0.195 | 10.54 | 75.8 | 60.9 | 468 | 92 |

| 6 | 1.00 | 2.00 | 378 | 746.3 | 176,857 | 349,268 | 1.97 | 1.51 | 0.189 | 10.59 | 73.9 | 60.5 | 468 | 93 |

| 7 | 1.00 | 2.00 | 370 | 727.9 | 173,020 | 340,657 | 1.97 | 1.50 | 0.185 | 10.50 | 72.3 | 60.2 | 468 | 93 |

| 8 | 1.00 | 1.96 | 268 | 545.7 | 125,330 | 255,388 | 2.04 | 1.55 | 0.137 | 10.36 | 52.4 | 56.1 | 468 | 91 |

| 9 | 0.99 | 1.96 | 271 | 545.9 | 126,734 | 255,481 | 2.02 | 1.54 | 0.140 | 10.25 | 53.0 | 56.1 | 468 | 90 |

| 10 | 0.98 | 1.64 | 221 | 454.9 | 127,238 | 262,022 | 2.06 | 1.57 | 0.137 | 10.47 | 53.2 | 56.2 | 576 | 92 |

| 11 | 0.99 | 1.79 | 218 | 454.8 | 102,211 | 212,846 | 2.08 | 1.59 | 0.123 | 10.59 | 42.7 | 53.3 | 468 | 82 |

| i | PTC under STC (W) | Total Installed Cost per Module ($/Module) | Total Power Generation of the System (W) | Total Installation Cost of the System ($) | CPR of the System ($/W) | CER of the System ($/kWh) | Efficiency of the System | PBP of the System (Year) | Energy Self-Sufficiency Ratio (%) |

|---|---|---|---|---|---|---|---|---|---|

| 1 | 470 | 908.4 | 164,970 | 318,848 | 1.93 | 1.47 | 0.181 | 10.18 | 69.0 |

| 2 | 480 | 927.6 | 168,340 | 325,588 | 1.93 | 1.47 | 0.185 | 10.24 | 70.4 |

| 3 | 373 | 764.1 | 130,993 | 268,199 | 2.05 | 1.56 | 0.146 | 10.41 | 54.7 |

| 4 | 428 | 837.1 | 174,787 | 341,537 | 1.95 | 1.49 | 0.198 | 10.44 | 73.1 |

| 5 | 388 | 756.2 | 181,444 | 353,902 | 1.95 | 1.49 | 0.195 | 10.54 | 75.8 |

| 6 | 378 | 746.3 | 176,857 | 349,268 | 1.97 | 1.51 | 0.189 | 10.59 | 73.9 |

| 7 | 370 | 727.9 | 173,020 | 340,657 | 1.97 | 1.50 | 0.185 | 10.50 | 72.3 |

| 8 | 268 | 545.7 | 125,330 | 255,388 | 2.04 | 1.55 | 0.137 | 10.36 | 52.4 |

| 9 | 271 | 545.9 | 126,734 | 255,481 | 2.02 | 1.54 | 0.140 | 10.25 | 53.0 |

| 10 | 221 | 454.9 | 127,238 | 262,022 | 2.06 | 1.57 | 0.137 | 10.47 | 53.2 |

| 11 | 218 | 454.8 | 102,211 | 212,846 | 2.08 | 1.59 | 0.123 | 10.59 | 42.7 |

| Scenarios | Weighting Factor for Each Criterion | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| j | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 |

| Scenario 1: Same weighting factor for all criteria (same importance) | 10 | 10 | 10 | 10 | 10 | 10 | 10 | 10 | 10 |

| Scenario 2: Priority is for maximizing the power generation from PV system | 1 | 1 | 10 | 2 | 2 | 2 | 5 | 5 | 10 |

| Scenario 3: Priority is for minimizing the installation cost of the PV system | 1 | 10 | 1 | 10 | 5 | 5 | 1 | 2 | 2 |

| Information | Criteria | Scenario 1 | Scenario 2 | Scenario 3 | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Alternatives | Manufacturer | Model Number | PTC under STC (W) | Total Installed Cost per Module ($/Module) | Total Power Generation of the System (W) | Total Installation Cost of the System ($) | CPR of the System ($/W) | CER of the System ($/kWh) | Efficiency of the System | PBP of the System (Year) | Energy Self-Sufficiency Ratio (%) | Weighting factor: [10, 10, 10, 10, 10, 10, 10, 10, 10] | RWR | TOPSIS | Weighting factor: [1, 10, 1, 10, 5, 5, 1, 2, 2] | RWR | TOPSIS | Weighting factor: [1, 1, 1, 10, 5, 5, 1, 10, 2] | RWR | TOPSIS |

| i/j | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | |||||||||||

| 1 | Sunpreme Inc. | SNPM-GxB-500 | 2 | 10 | 6 | 6 | 1 | 1 | 6 | 1 | 6 | 1 | 6 | 5 | 6 | 1 | 6 | |||

| 2 | Sunpreme Inc. | SNPM-GxB-510 | 1 | 11 | 5 | 7 | 2 | 2 | 4 | 2 | 5 | 2 | 5 | 4 | 5 | 2 | 7 | |||

| 3 | Topsun | TS-S420SA1 | 6 | 8 | 7 | 5 | 9 | 9 | 7 | 5 | 7 | 8 | 7 | 7 | 7 | 7 | 5 | |||

| 4 | SunPower | SPR-X22-460-COM | 3 | 9 | 3 | 9 | 4 | 4 | 1 | 6 | 3 | 4 | 2 | 2 | 3 | 5 | 8 | |||

| 5 | Canadian Solar Inc. | CS1U-415MS | 4 | 7 | 1 | 11 | 3 | 3 | 2 | 9 | 1 | 3 | 1 | 1 | 1 | 8 | 10 | |||

| 6 | LG Electronics Inc. | LG410N2C-A5 | 5 | 6 | 2 | 10 | 6 | 6 | 3 | 10 | 2 | 6 | 3 | 3 | 2 | 10 | 11 | |||

| 7 | LG Electronics Inc. | LG400N2K-A5 | 7 | 5 | 4 | 8 | 5 | 5 | 5 | 7 | 4 | 5 | 4 | 6 | 4 | 6 | 9 | |||

| 8 | Advance Power | API-M300 | 9 | 3 | 10 | 2 | 8 | 8 | 9 | 4 | 10 | 9 | 10 | 10 | 10 | 4 | 3 | |||

| 9 | Recom | RCM-300-6PA | 8 | 4 | 9 | 3 | 7 | 7 | 8 | 3 | 9 | 7 | 8 | 8 | 9 | 3 | 2 | |||

| 10 | KISCO | GETWATT 250M-A1U | 10 | 2 | 8 | 4 | 10 | 10 | 10 | 8 | 8 | 10 | 9 | 9 | 8 | 9 | 4 | |||

| 11 | Gintung Energy | ASEC-250G6S6B | 11 | 1 | 11 | 1 | 11 | 11 | 11 | 11 | 11 | 11 | 11 | 11 | 11 | 11 | 1 | |||

| Iteration | Simulation Time in (ms) | Weighting Factors | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| RWR | TOPSIS | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | |

| 1 | 2.734 | 7.974 | 5 | 6 | 7 | 4 | 4 | 10 | 0 | 9 | 10 |

| 2 | 1.867 | 3.834 | 8 | 1 | 2 | 3 | 7 | 1 | 7 | 1 | 7 |

| 3 | 2.67 | 7.924 | 5 | 0 | 7 | 0 | 0 | 5 | 1 | 8 | 8 |

| 4 | 2.744 | 8.057 | 7 | 1 | 7 | 5 | 10 | 7 | 8 | 4 | 4 |

| 5 | 2.698 | 7.745 | 9 | 0 | 1 | 1 | 4 | 9 | 8 | 0 | 4 |

| 6 | 2.716 | 7.895 | 5 | 4 | 7 | 6 | 3 | 4 | 0 | 10 | 1 |

| 7 | 2.745 | 7.841 | 1 | 4 | 2 | 5 | 3 | 10 | 10 | 0 | 8 |

| 8 | 2.687 | 7.963 | 2 | 4 | 6 | 10 | 4 | 10 | 3 | 7 | 7 |

| 9 | 2.716 | 7.902 | 5 | 7 | 7 | 1 | 1 | 10 | 1 | 0 | 6 |

| 10 | 2.697 | 7.904 | 9 | 7 | 2 | 4 | 5 | 10 | 1 | 9 | 7 |

| Average | 2.627 | 7.504 | |||||||||

| Speed ratio | 2.856 | RWR is faster than TOPSIS by 2.856 times | |||||||||

| Matrix Size | Simulation Time in (ms) | Speed Ratio (TOPSIS/RWR) RWR Is Faster by: | |

|---|---|---|---|

| RWR | TOPSIS | ||

| 4 × 4 | 1.60 | 5.48 | 3.43 |

| 8 × 8 | 2.17 | 6.56 | 3.03 |

| 16 × 16 | 4.18 | 7.25 | 1.74 |

| 32 × 32 | 4.50 | 9.71 | 2.16 |

| 64 × 64 | 5.18 | 12.75 | 2.46 |

| 128 × 128 | 6.61 | 28.65 | 4.34 |

| 256 × 256 | 12.21 | 94.68 | 7.75 |

| 512 × 512 | 34.15 | 481.31 | 14.1 |

| 1024 × 1024 | 126.69 | 3128.89 | 24.7 |

| TOPSIS | Our Method (RWR) | |

|---|---|---|

| Complexity of calculation | More complex | Very simple |

| Similarities | Considered as a benchmark method | More than 77% for a difference of less than 20% |

| Simulation time | Slower than RWR | Very fast |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

El-Bayeh, C.Z.; Zellagui, M.; Shirzadi, N.; Eicker, U. A Novel Optimization Algorithm for Solar Panels Selection towards a Self-Powered EV Parking Lot and Its Impact on the Distribution System. Energies 2021, 14, 4515. https://doi.org/10.3390/en14154515

El-Bayeh CZ, Zellagui M, Shirzadi N, Eicker U. A Novel Optimization Algorithm for Solar Panels Selection towards a Self-Powered EV Parking Lot and Its Impact on the Distribution System. Energies. 2021; 14(15):4515. https://doi.org/10.3390/en14154515

Chicago/Turabian StyleEl-Bayeh, Claude Ziad, Mohamed Zellagui, Navid Shirzadi, and Ursula Eicker. 2021. "A Novel Optimization Algorithm for Solar Panels Selection towards a Self-Powered EV Parking Lot and Its Impact on the Distribution System" Energies 14, no. 15: 4515. https://doi.org/10.3390/en14154515

APA StyleEl-Bayeh, C. Z., Zellagui, M., Shirzadi, N., & Eicker, U. (2021). A Novel Optimization Algorithm for Solar Panels Selection towards a Self-Powered EV Parking Lot and Its Impact on the Distribution System. Energies, 14(15), 4515. https://doi.org/10.3390/en14154515