Research on Blade Design of Lift–Drag-Composite Tidal-Energy Turbine at Low Flow Velocity

Abstract

:1. Introduction

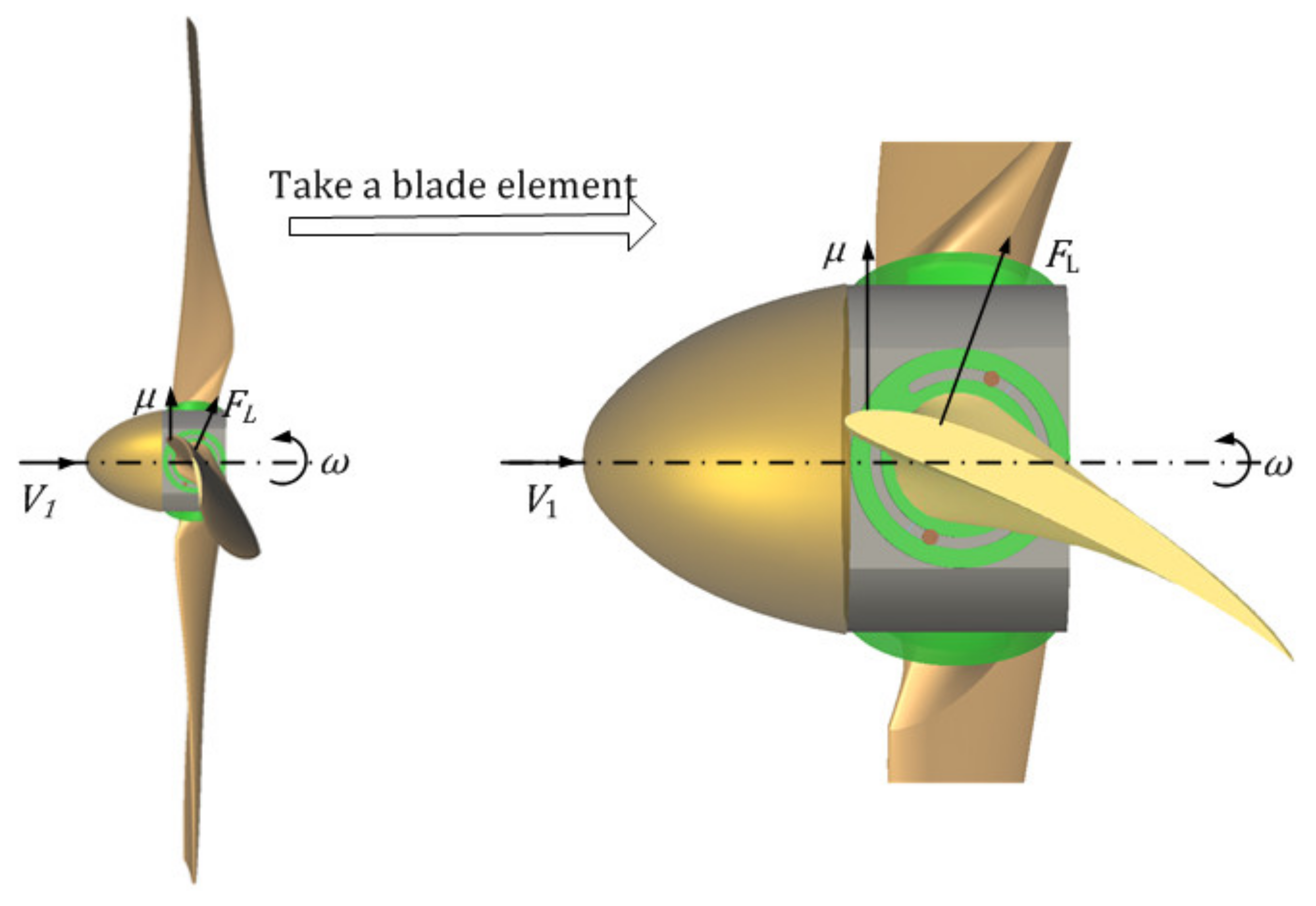

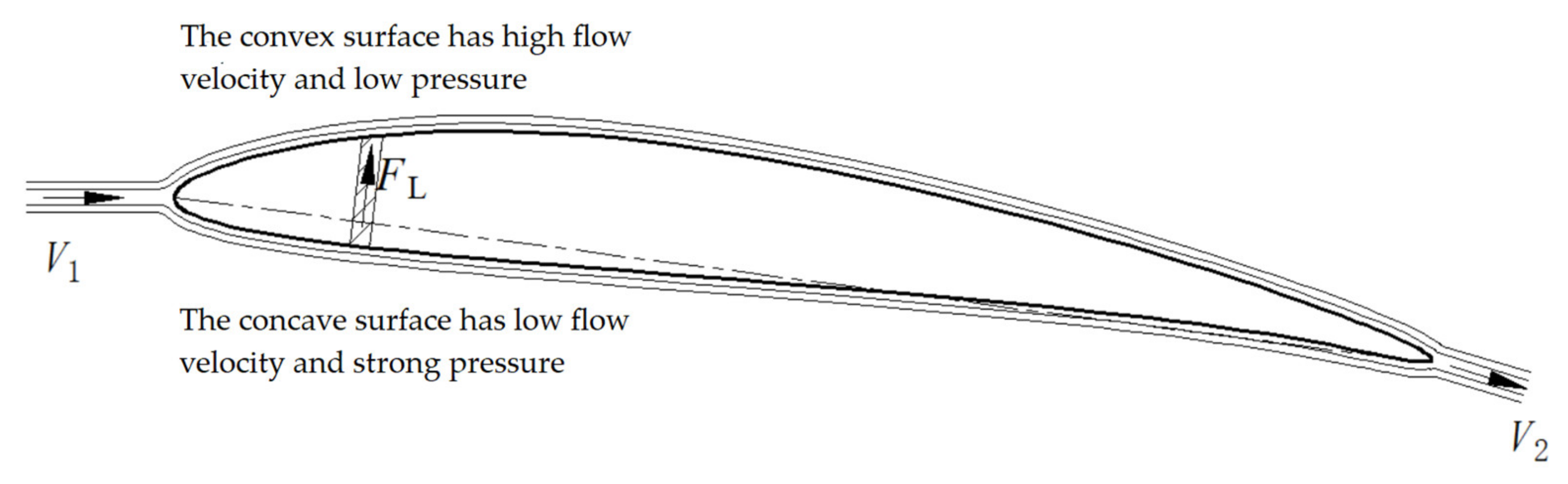

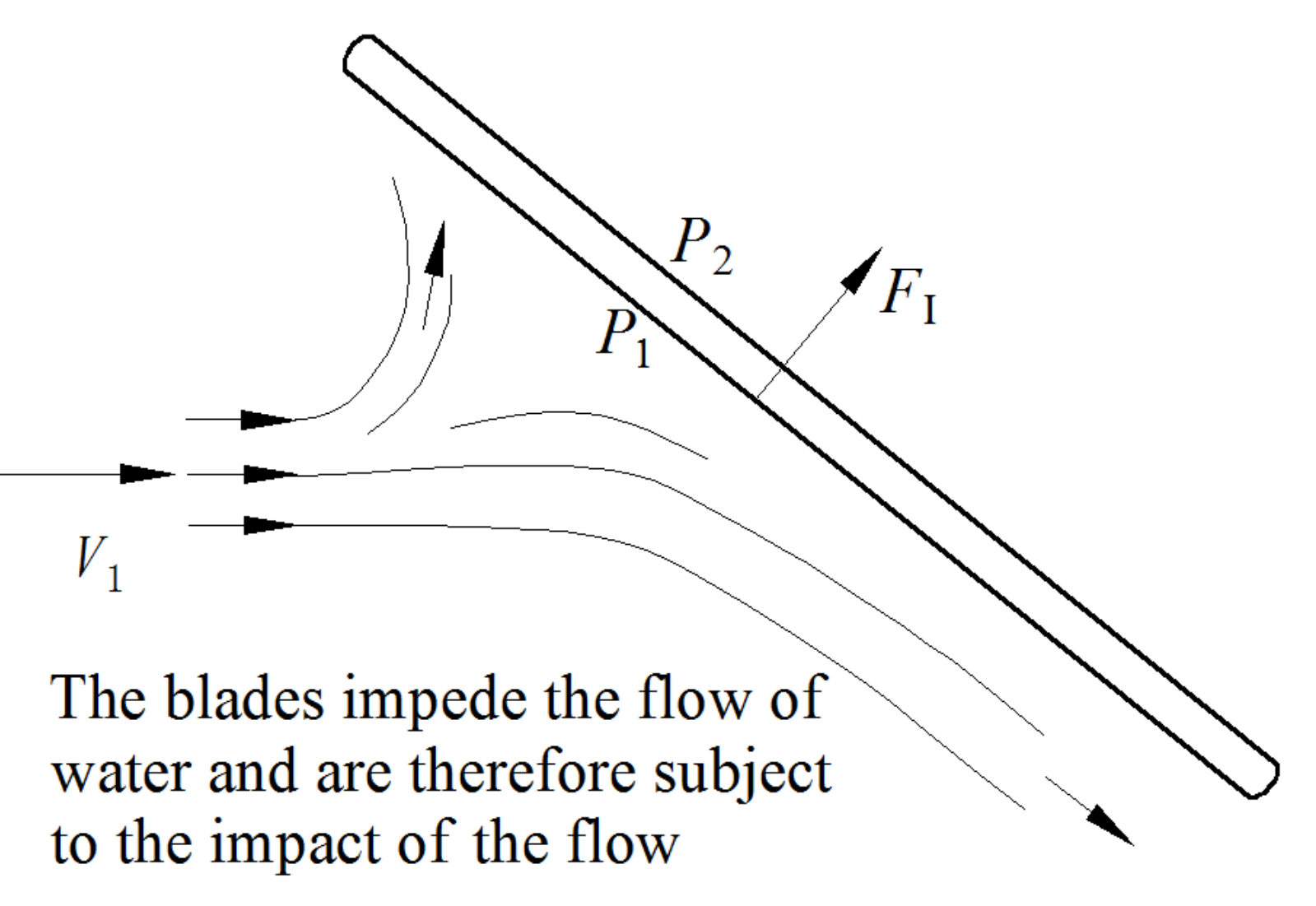

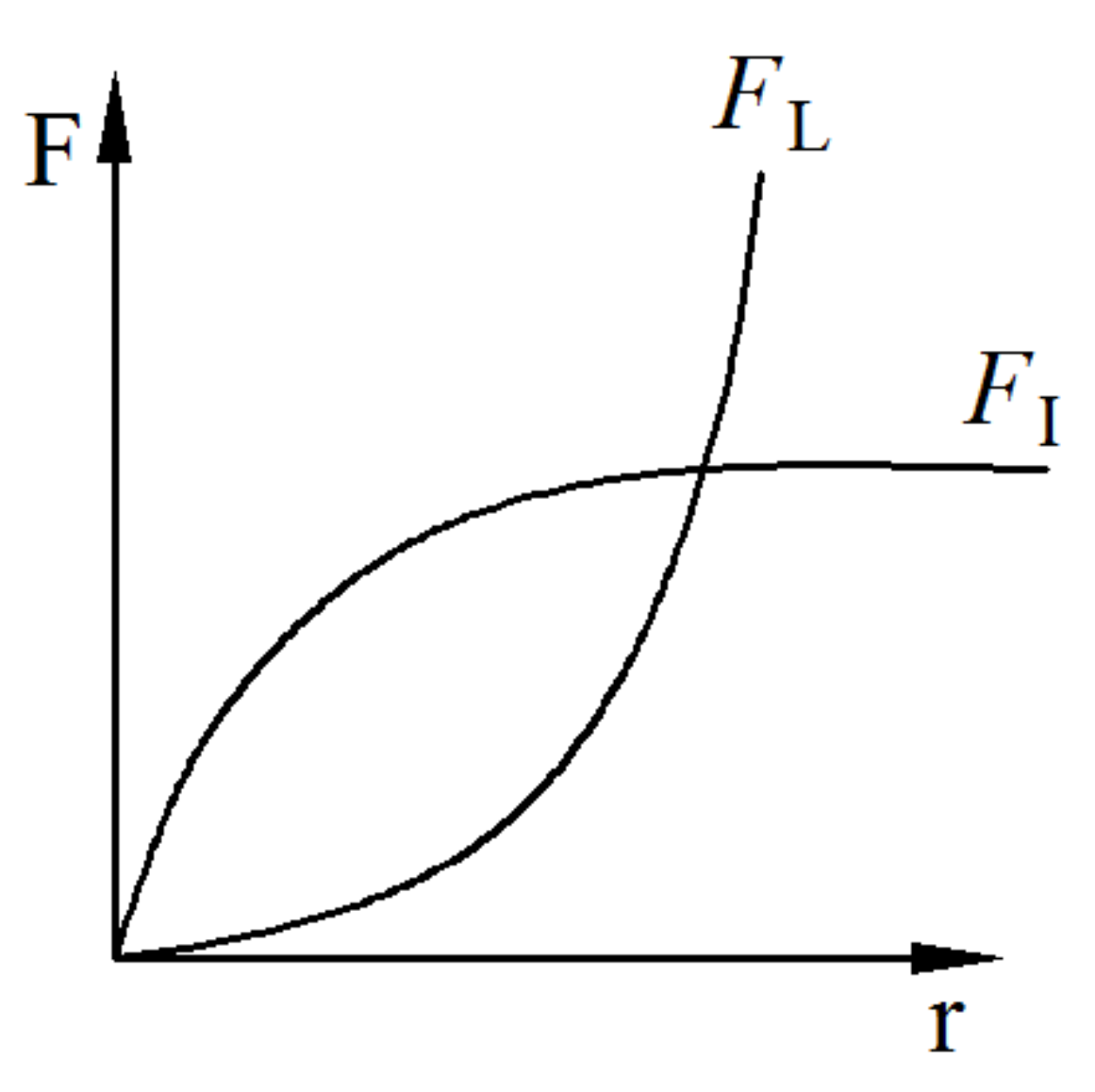

2. Analysis of Differential Pressure Lift and Impact Resistance of Water Turbine Blades

3. Design of the Arc-Shaped Blades with Lift–Drag-Composite Thin-Plate

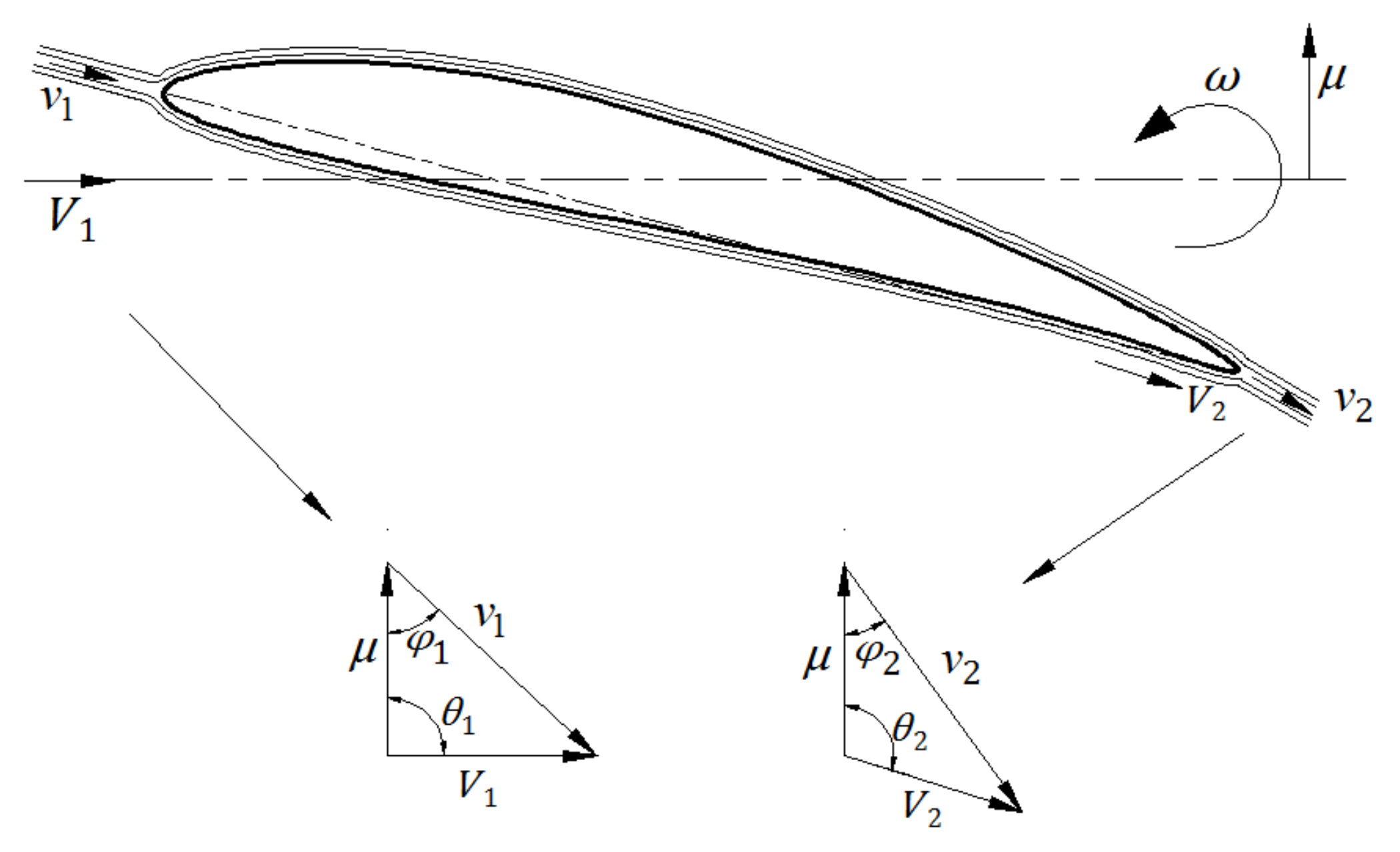

3.1. Velocity Analysis at the Inlet and Outlet of the Turbine Blade

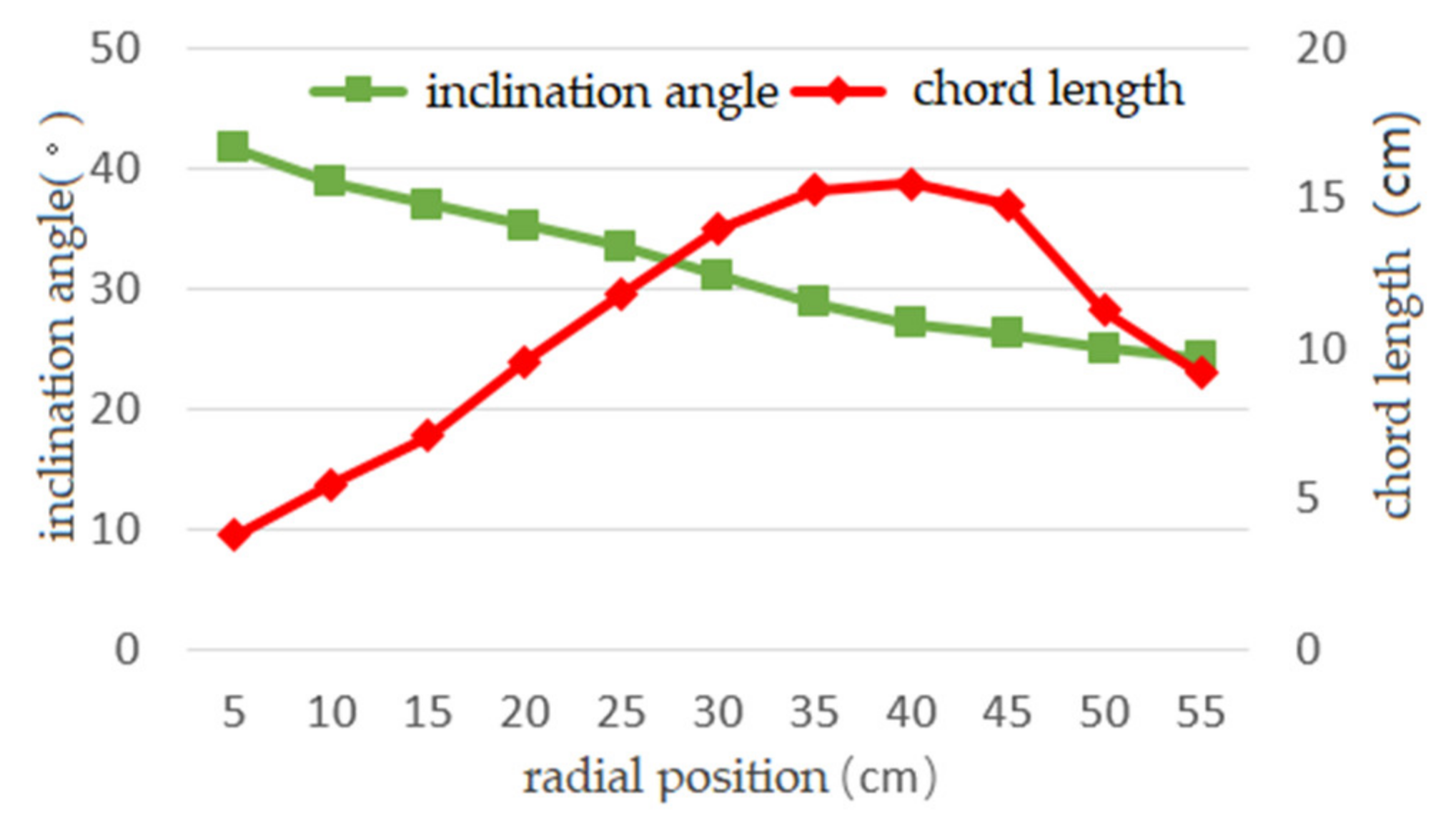

3.2. Blade-Shape Parameters of Lift–Drag-Composite Thin-Plate Arc Blade

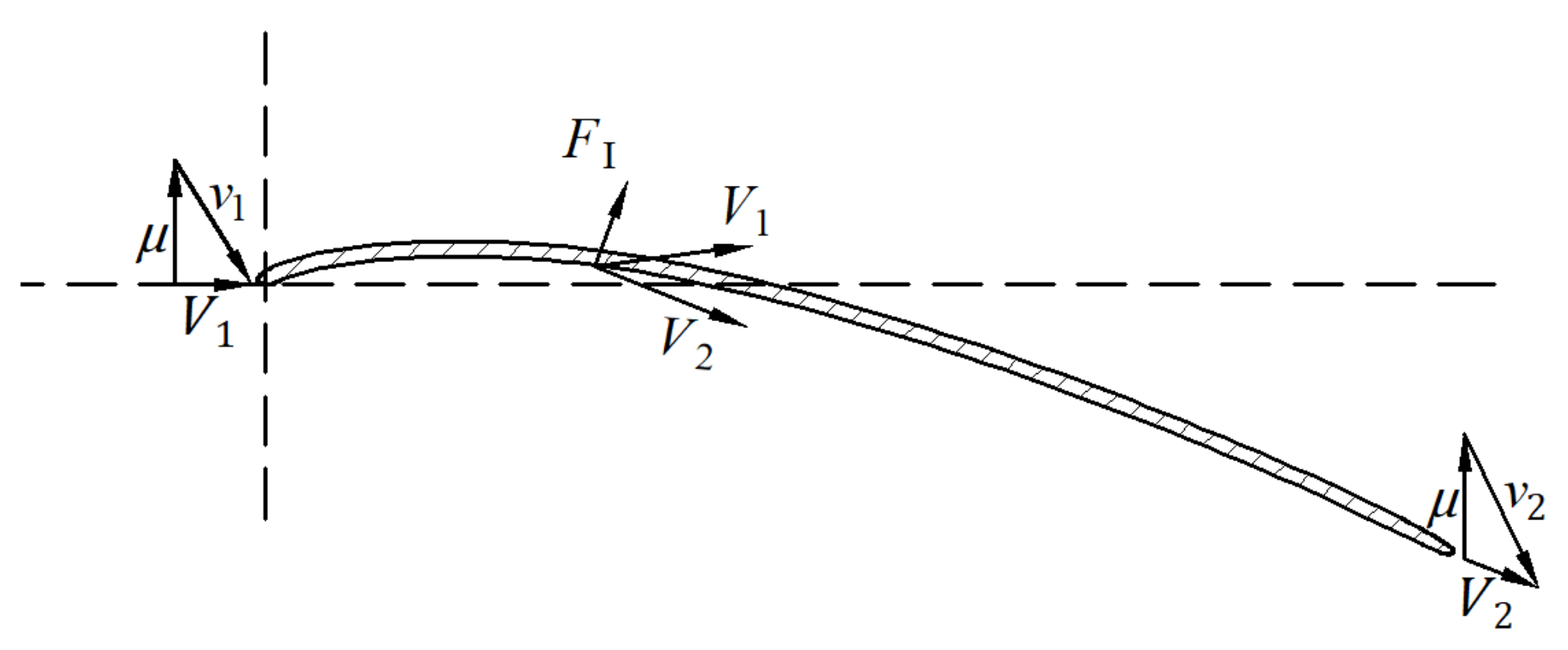

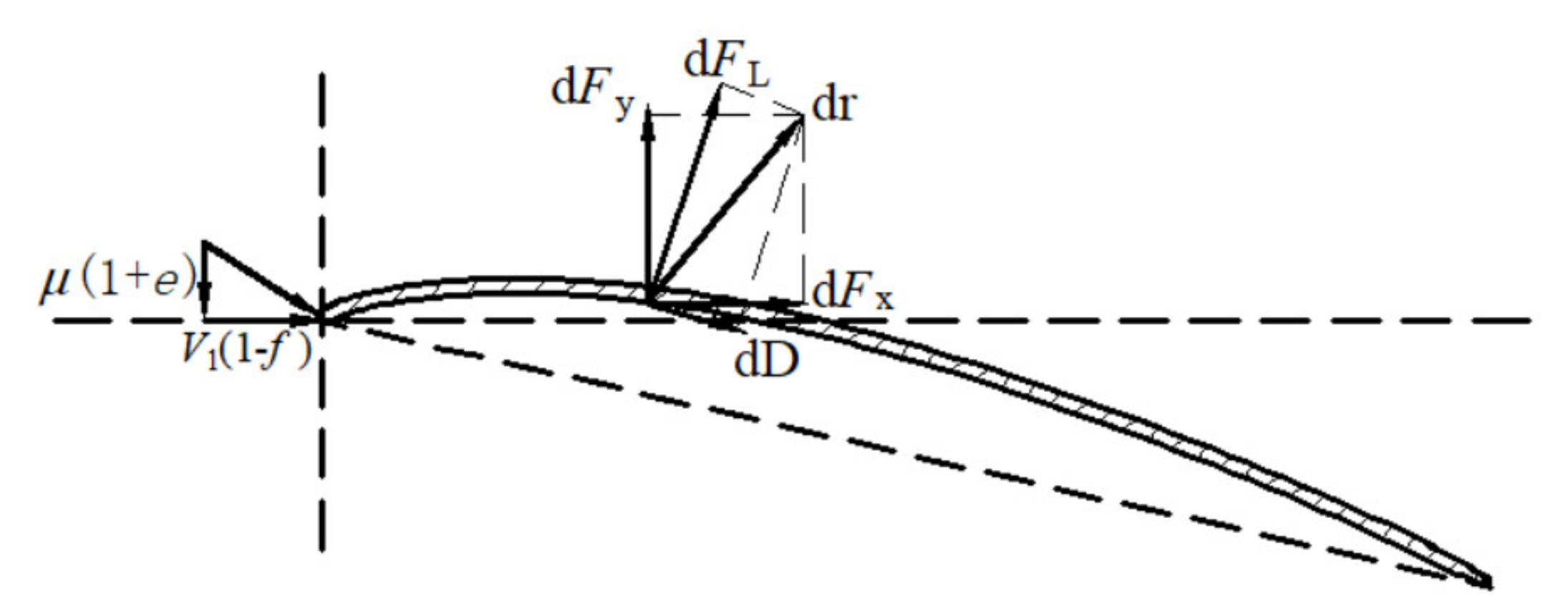

3.3. Hydrodynamic Modeling of Lift–Drag-Composite Thin-Plate Arc Blade

- (1)

- Impact resistance

- (2)

- Differential pressure lift

- (3)

- Balance equation

3.4. Calculation of Blade-Shape Parameters of Hydraulic Turbine Blades

4. Experimental Verification

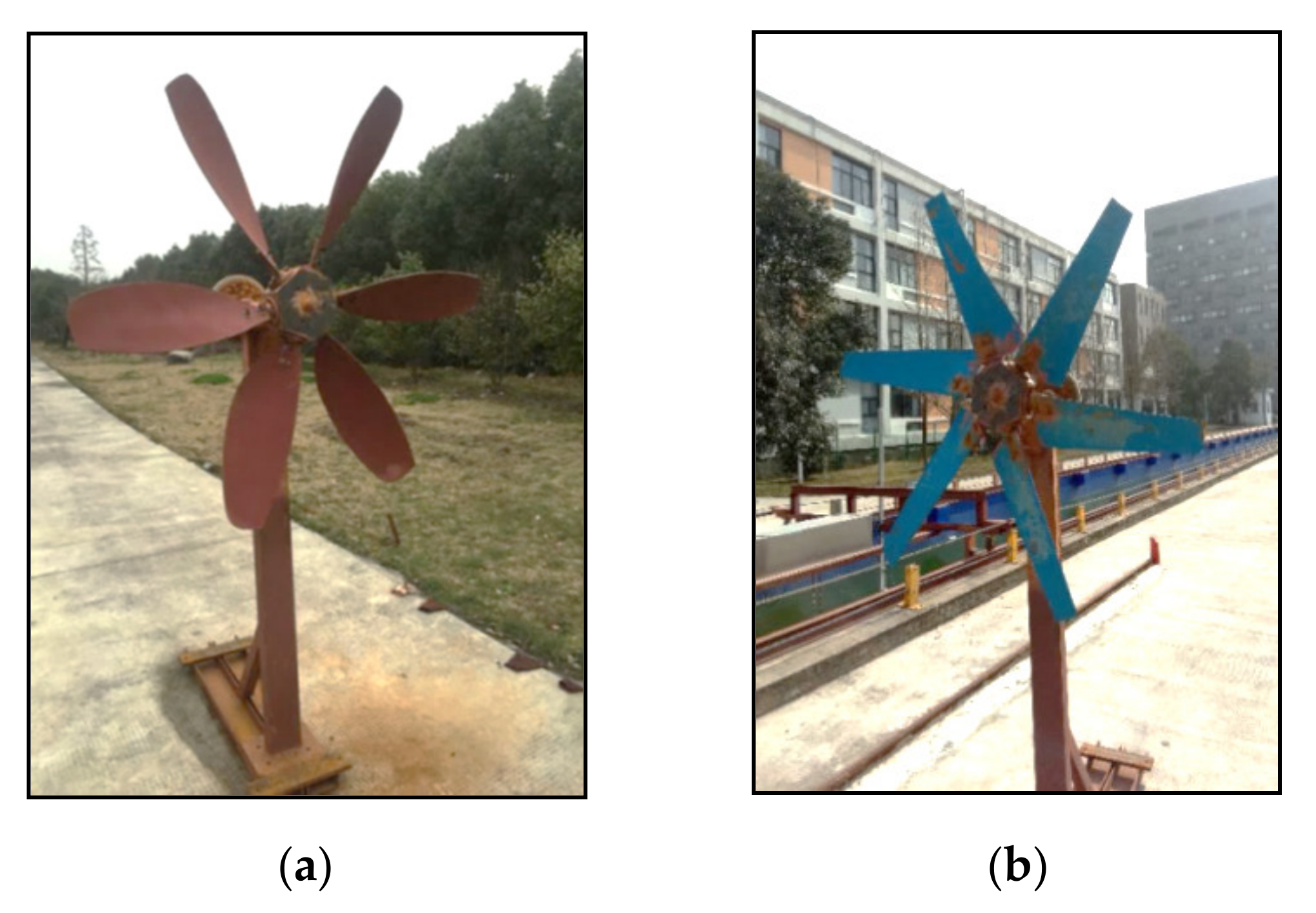

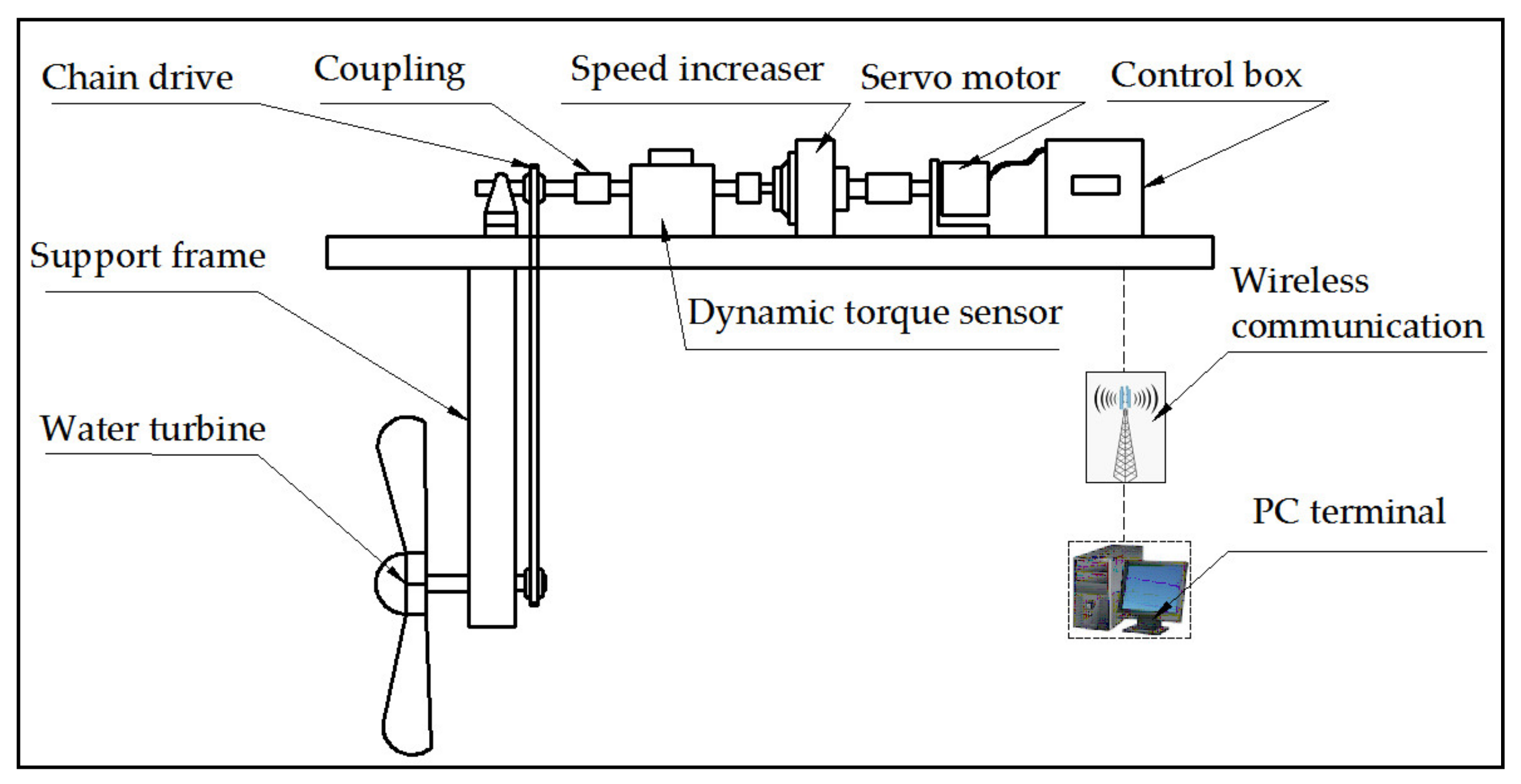

4.1. Construction of Experimental Device

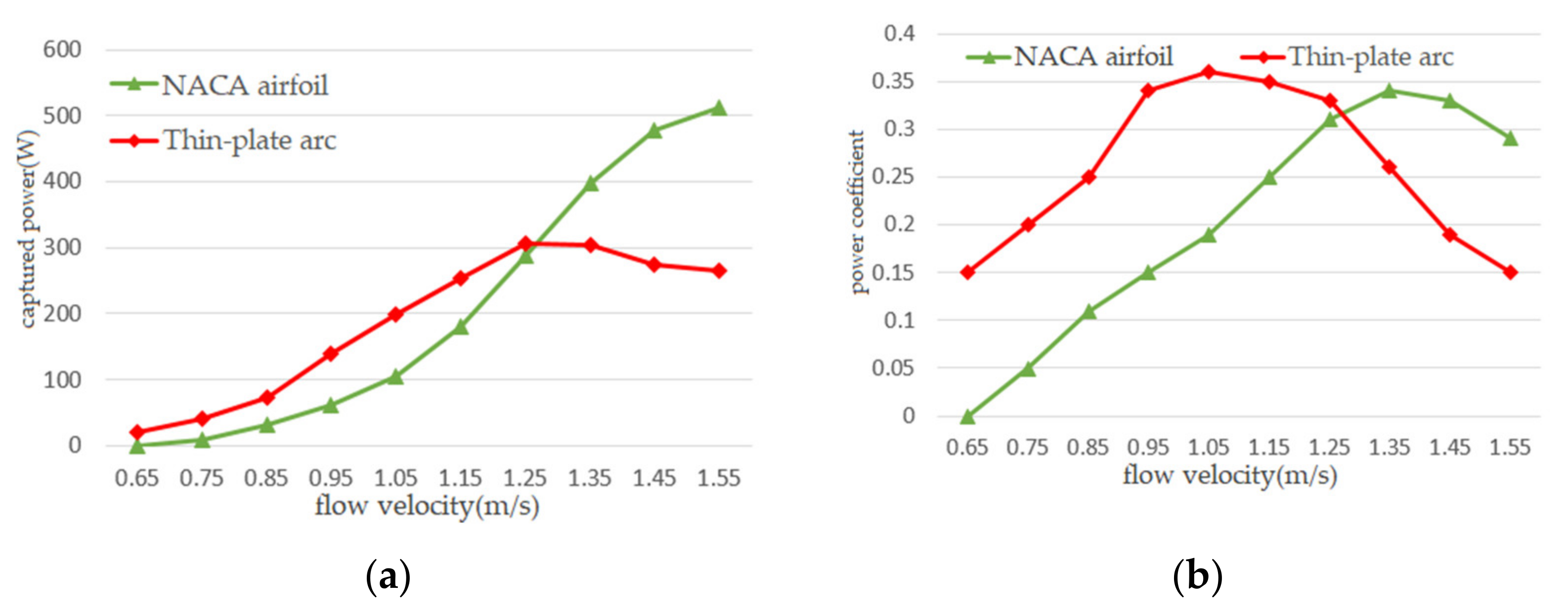

4.2. Analysis of Experimental Data

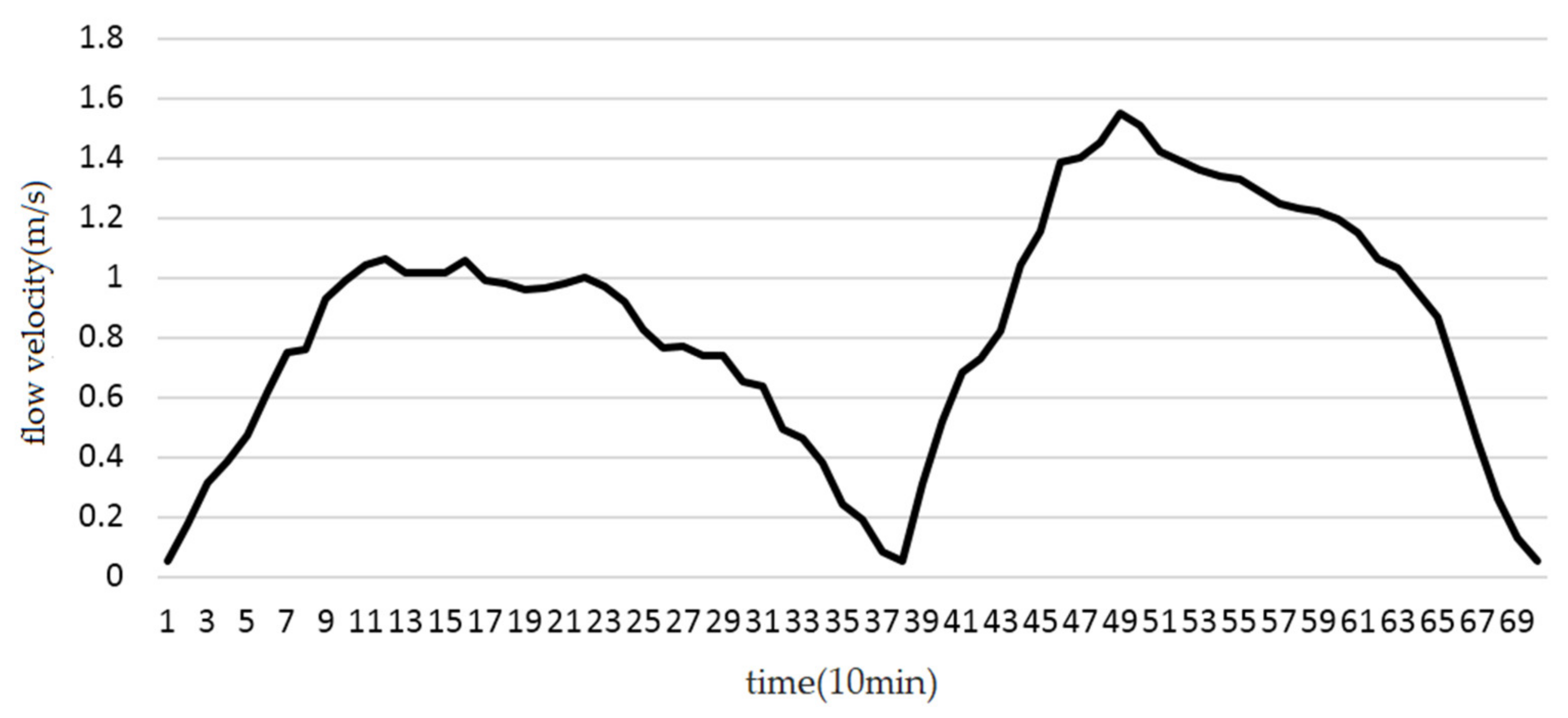

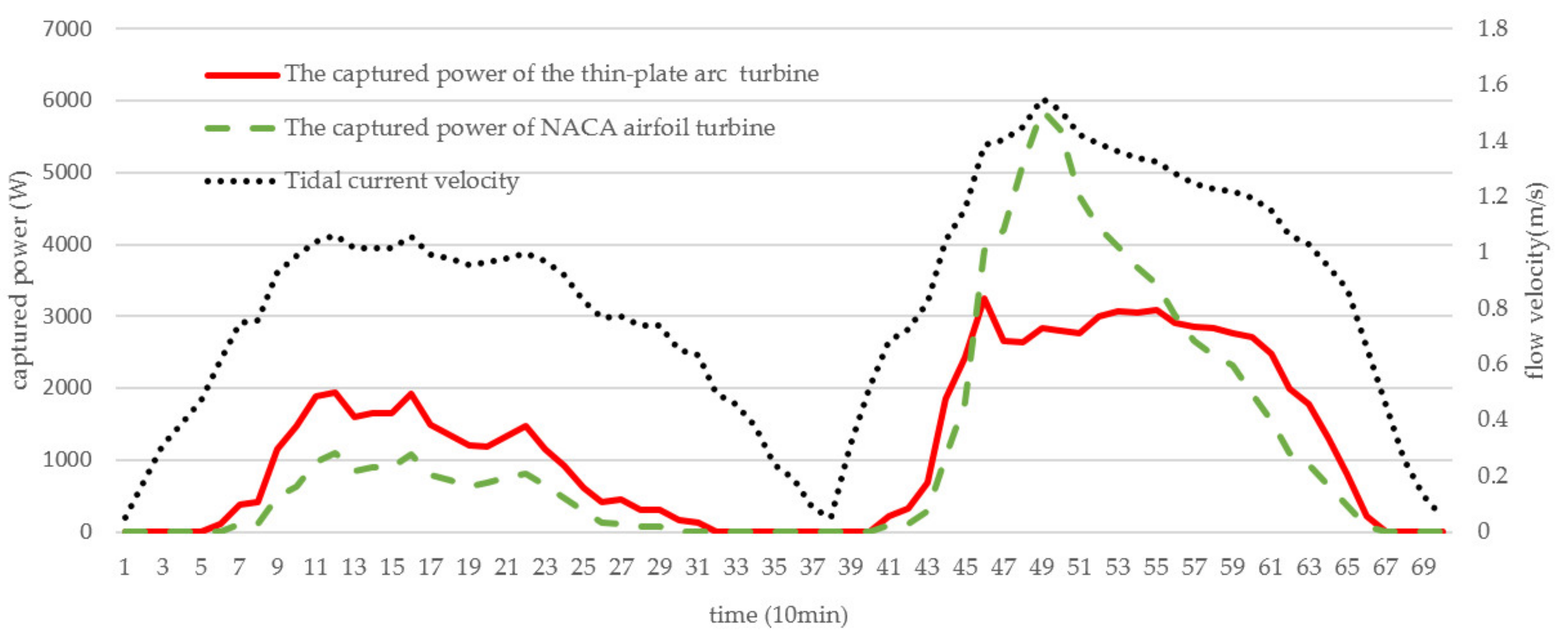

5. Marine Experimental Research

6. Conclusions

- 1.

- Through the hydrodynamic analysis of the turbine blade, the water flow around the airfoil formed a pressure difference and impact, which acted on the blade together; that is, the torque and axial force acted on the blade. Under the condition of low flow velocity and small radius, the impact resistance of the blade cannot be ignored.

- 2.

- Through the water-tank experiment and the offshore experiment, the thin-plate arc turbine blades that comprehensively used differential pressure lift and impact resistance had better performance under conditions of low flow velocity and small radius, which verified the correctness of the design method of lift–drag-composite blades.

- 3.

- In sea areas where the flow velocity was generally low, the flow velocity could be higher at certain moments, and the capture power of the lift-type blade was greater than that of the lift–drag-composite blade. However, when considering the variation period of tidal current velocity comprehensively and calculating the average power of cycle, the average capture power of the lift–drag-composite blade was larger, which was more suitable for the low-velocity sea area.

- 4.

- The lift–drag hydraulic turbine was characterized by low speed and heavy load, while the lift-type turbine was characterized by high speed and light load.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Liu, H.; Ma, S.; Li, W.; Hai, G. A review on the development of tidal current energy in China. Renew. Sustain. Energy Rev. 2011, 15, 1141–1146. [Google Scholar] [CrossRef]

- Wang, S.; Peng, Y.; Dong, L.; Jiao, Y. An overview of ocean renewable energy in China. Renew. Sustain. Energy Rev. 2011, 15, 91–111. [Google Scholar] [CrossRef]

- Deng, G.; Zhang, Z.; Li, Y.; Liu, H.; Pan, Y. Prospective of development of large-scale tidal current turbine array: An example numerical investigation of Zhejiang, China. Appl. Energy 2020, 264, 114621. [Google Scholar] [CrossRef]

- Fan, W.; Xiao, C.; Li, P.; Zhang, Z.; Lin, T.; Pan, Y.; Di, Y.; Chen, Y. Intelligent Control System of an Ecological Engineering Project for Carbon Sequestration in Coastal Mariculture Environments in China. Sustainability 2020, 12, 5227. [Google Scholar] [CrossRef]

- Li, D.; Li, C. Intelligent aquaculture. J. World Aquac. Soc. 2020, 51, 808–814. [Google Scholar] [CrossRef]

- Wei, Y.; Wei, Q.; An, D. Intelligent monitoring and control technologies of open sea cage culture: A review. Comput. Electron. Agric. 2020, 169, 105119. [Google Scholar] [CrossRef]

- Zhou, H.; Lin, Y.; Li, W.; Liu, H. Design and sea test of a marine current energy prototype pecialized for low current speed condtion. Acta Energ. Sol. Sin. 2019, 40, 2509–2514. [Google Scholar]

- Westwood, A. SeaGen installation moves forward. Renew. Energy Focus 2009, 9, 26–27. [Google Scholar] [CrossRef]

- Liu, H.; He, J.; Li, W.; Lin, Y.; Gu, Y.; Wang, C. Asymmetric Load Control Method for Individual Pitch of Horizontal Axis Marine Current Turbine. J. Mech. Eng. 2018, 54, 89–95. [Google Scholar] [CrossRef]

- Wang, B.; Zhang, Y.; Guo, Y.; Cai, Y. Analysis of influence of pitch mechanism performance on power limit for tidal energy device. Acta Energ. Sol. Sin. 2020, 41, 27–34. [Google Scholar]

- Greenwood, C.; Vogler, A.; Venugopal, V. On the Variation of Turbulence in a High-Velocity Tidal Channel. Energies 2019, 12, 672. [Google Scholar] [CrossRef] [Green Version]

- Sellar, B.; Wakelam, G.; Sutherland, D.; Ingram, D.; Venugopal, V. Characterisation of Tidal Flows at the European Marine Energy Centre in the Absence of Ocean Waves. Energies 2018, 11, 176. [Google Scholar] [CrossRef] [Green Version]

- Liu, Z.; Huguenard, K. Hydrodynamic Response of a Floating Aquaculture Farm in a Low Inflow Estuary. J. Geophys. Res. Ocean. 2020, 125. [Google Scholar] [CrossRef]

- Yao, J.; Li, F.; Chen, J.; Yuan, Z.; Mai, W. Parameter Analysis of Savonius Hydraulic Turbine Considering the Effect of Reducing Flow Velocity. Energies 2019, 13, 24. [Google Scholar] [CrossRef] [Green Version]

- Chen, J.; Wang, X.; Li, H.; Jiang, C.; Bao, L. Design of the Blade under Low Flow Velocity for Horizontal Axis Tidal Current Turbine. J. Mar. Sci. Eng. 2020, 8, 989. [Google Scholar] [CrossRef]

- Liu, H.; Gu, Y.; Lin, Y.; Li, Y.; Li, W.; Zhou, H. Improved Blade Design for Tidal Current Turbines. Energies 2020, 13, 2642. [Google Scholar] [CrossRef]

- Ma, Y.; Hu, C.; Zhou, B.; Li, L.; Ka, Y. Hydrodynamic Analysis of a Semi-submersible Wind-Tidal Combined Power Generation Device. J. Mar. Sci. Appl. 2019, 18, 72–81. [Google Scholar] [CrossRef] [Green Version]

- Vaz, J.; Pinho, J.; Mesquita, A. An extension of BEM method applied to horizontal-axis wind turbine design. Renew. Energy 2011, 36, 1734–1740. [Google Scholar] [CrossRef] [Green Version]

| Parameter | Numerical | Parameter | Numerical |

|---|---|---|---|

| Design flow velocity (m/s) | 0.9 | Hub diameter (m) | 0.1 |

| Rated power (W) | 200 | Impact-capture coefficient | 0.5 |

| Blade radius (m) | 0.55 | Number of blades | 6 |

| Section | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 |

|---|---|---|---|---|---|---|---|---|---|---|---|

| f | 0.232 | 0.251 | 0.281 | 0.305 | 0.322 | 0.345 | 0.370 | 0.382 | 0.351 | 0.364 | 0.323 |

| e | 0.071 | 0.080 | 0.103 | 0.122 | 0.131 | 0.145 | 0.125 | 0.117 | 0.134 | 0.125 | 0.132 |

| Parameter | Numerical | Parameter | Numerical |

|---|---|---|---|

| Blade radius (m) | 1.8 | Hub diameter (m) | 0.37 |

| Number of blades | 6 | Pitch angle (°) | 12° |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jiang, C.; Shu, X.; Chen, J.; Bao, L.; Xu, Y. Research on Blade Design of Lift–Drag-Composite Tidal-Energy Turbine at Low Flow Velocity. Energies 2021, 14, 4258. https://doi.org/10.3390/en14144258

Jiang C, Shu X, Chen J, Bao L, Xu Y. Research on Blade Design of Lift–Drag-Composite Tidal-Energy Turbine at Low Flow Velocity. Energies. 2021; 14(14):4258. https://doi.org/10.3390/en14144258

Chicago/Turabian StyleJiang, Chuhua, Xuedao Shu, Junhua Chen, Lingjie Bao, and Yawen Xu. 2021. "Research on Blade Design of Lift–Drag-Composite Tidal-Energy Turbine at Low Flow Velocity" Energies 14, no. 14: 4258. https://doi.org/10.3390/en14144258

APA StyleJiang, C., Shu, X., Chen, J., Bao, L., & Xu, Y. (2021). Research on Blade Design of Lift–Drag-Composite Tidal-Energy Turbine at Low Flow Velocity. Energies, 14(14), 4258. https://doi.org/10.3390/en14144258