Complementing Syngas with Natural Gas in Spark Ignition Engines for Power Production: Effects on Emissions and Combustion

Abstract

:1. Introduction

1.1. Natural Gas in SI Engines

1.2. Syngas in SI Engines

1.3. Motivations, Focus and Research Questions

2. Materials and Methods

2.1. Experimental Set-Up

2.2. Experimental Methodology

2.3. Combustion Analysis

3. Results and Discussion

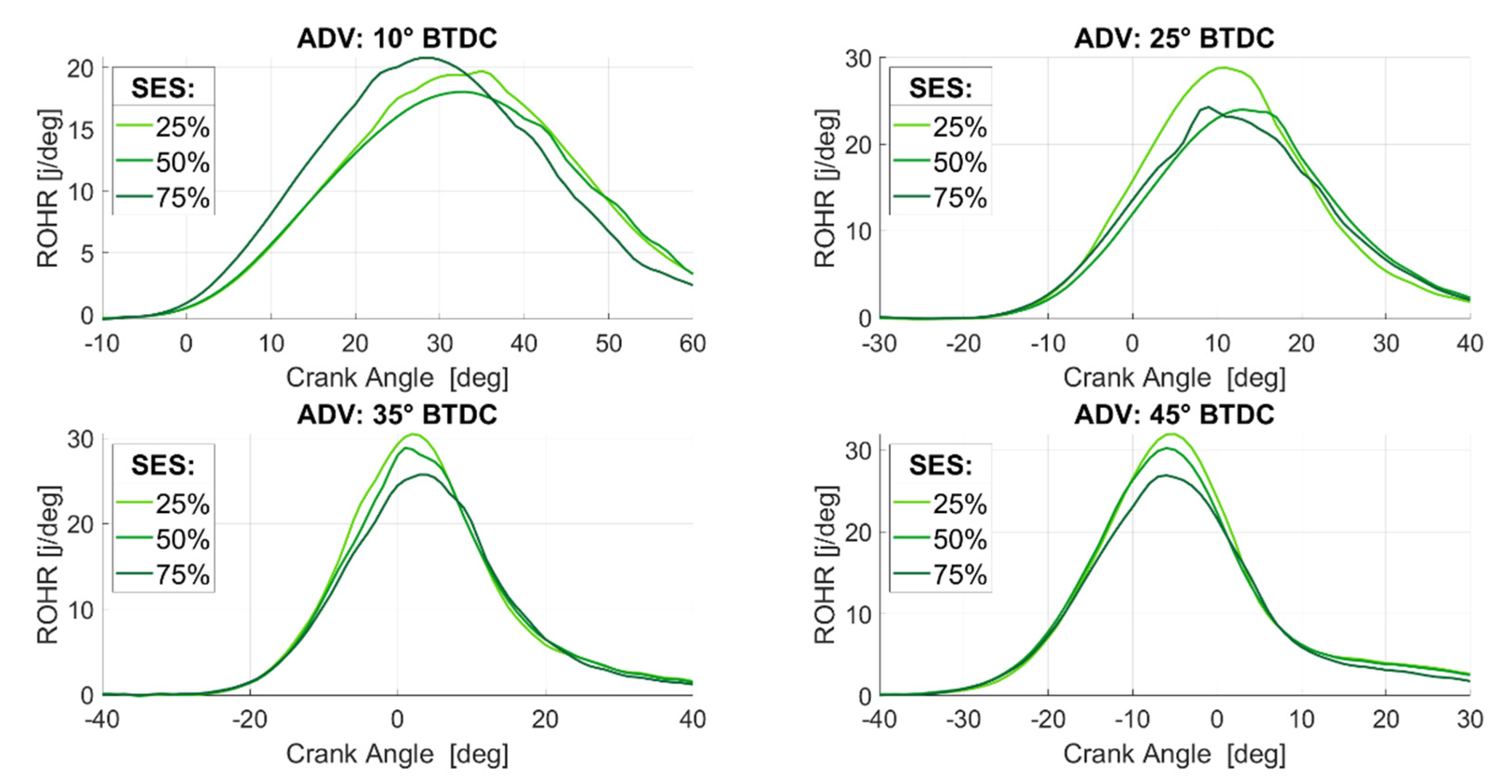

3.1. Combustion and Performance Characteristics

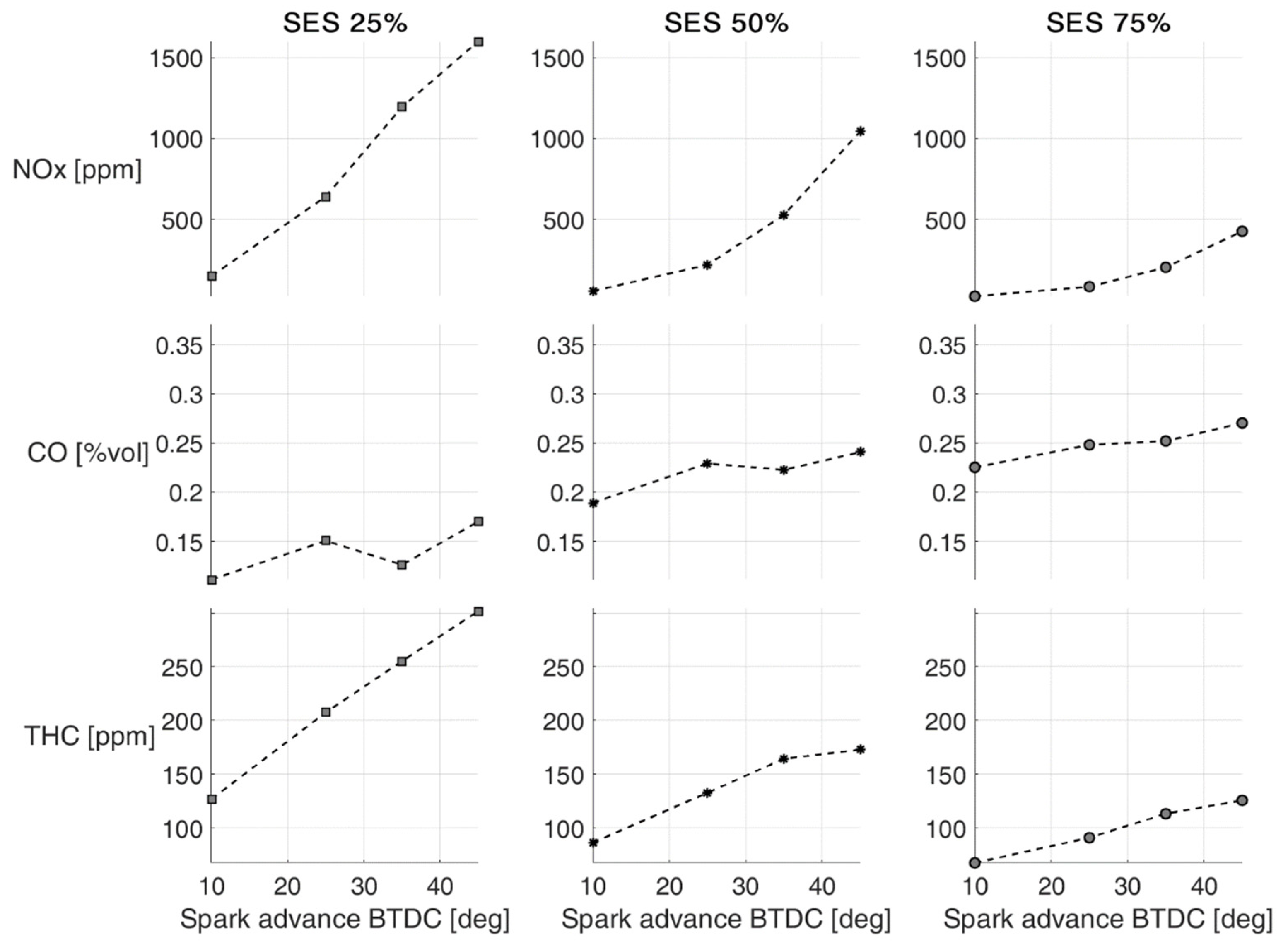

3.2. Emission Characteristics

3.2.1. NOx Emissions

3.2.2. CO Emissions

3.2.3. THC Emissions

3.2.4. CO2 Emissions

4. Conclusions

- Brake thermal efficiency (BTE) is strongly influenced by the spark advance more so than by the syngas energy share. The lowest spark advance (10° BTDC) corresponds to the lowest BTE, while the operating points with a spark advance equal to 35° BTDC show the best performance, reaching BTE values close to 28%;

- Increasing the amount of syngas in the mixture creates a decrease in output power in the range of 2–6%. Hence, considering the significantly reduced volumetric energy density of the fuel, only minor power derating is experienced with the use of syngas;

- A general increase of NOx emissions is associated with advancing values of the spark advance. Such behavior is addressed to the increase of the combustion temperature created by the earlier start of ignition, confirmed by the in-cylinder pressure and ROHR analysis;

- On the other hand, the presence of syngas in the fuel mixture tends to promote a decrease in the rates of NOx formation reactions due to an increased share of CO2 and N2 in the fuel mixture;

- A general increase of CO emissions is correlated to the increasing share of syngas in the fuel mixture. The less efficient mixing of the different species might create regions with equivalence ratios outside the flammability limits, in particular, in colder regions and promotes the formation of CO. Moreover, a relevant share of CO in the exhaust gases originates from the incomplete combustion of CO already present in the syngas itself;

- THC emissions increase with advancing spark timing, while they decrease when the syngas share in the mixture increases. This can be attributed to the increased H2 content in the fuel mixture, which is responsible for promoting fast conversion of hydrocarbons;

- Increases in the CO2 emissions are measured as the syngas energy share in the fuel mixture increases, while the influence of spark advance on CO2 emissions is negligible with respect to the changes in gas composition. This clearly suggests how the increase of CO2 has a primary path, which is the presence of CO2 in the fuel mixture. However, part of this growing amount of CO2 should be considered in light of the type of syngas primary source, the bio-based origin of which is responsible for net-zero emissions.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Dhyani, V.; Subramanian, K.A. Experimental based comparative exergy analysis of a multi-cylinder spark ignition engine fuelled with different gaseous (CNG, HCNG, and hydrogen) fuels. Int. J. Hydrogy Energy 2019, 44, 20440–20451. [Google Scholar] [CrossRef]

- Elnajjar, E.; Hamdan, M.O.; Selim, M.Y.E. Experimental investigation of dual engine performance using variable LPG composition fuel. Renew. Energy 2013, 56, 110–116. [Google Scholar] [CrossRef]

- Elnajjar, E.; Selim, M.Y.E.; Hamdan, M.O. Experimental study of dual fuel engine performance using variable LPG composition and engine parameters. Energy Convers. Manag. 2013, 76, 32–42. [Google Scholar] [CrossRef]

- Wróblewski, P.; Iskra, A. Problems of Reducing Friction Losses of a Piston-Ring-Cylinder Configuration in a Combustion Piston Engine with an Increased Isochoric Pressure Gain; SAE Technical Paper 2020-01-2227; SAE International: Warrendale, PA, USA, 2020. [Google Scholar]

- European Commission. Communication from the Commission to the European Parliament, the European Council, the Council, the European Economic and Social Committee and the Committee of the Regions; The European Green Deal. COM/2019/640 Final; European Commission: Brussels, Belgium, 2019. [Google Scholar]

- Vakalis, S.; Caligiuri, C.; Moustakas, K.; Malamis, D.; Renzi, M.; Baratieri, M. Modeling the emissions of a dual fuel engine coupled with a biomass gasifier—Supplementing the Wiebe function. Environ. Sci. Pollut. Res. 2018. [Google Scholar] [CrossRef]

- Antolini, D.; Brianti, B.; Caligiuri, C.; Borooah, R.; Patuzzi, F.; Baratieri, M. Energy Valorization of Forestry Residues through a Small-Scale Open Top Gasifier. In Proceedings of the Biomass Technologies and Conversion for Bioenergy—28th European Biomass Conference and Exhibition, Virtual, 6–9 July 2020; pp. 407–410. [Google Scholar]

- Antolini, D.; Ail, S.S.; Patuzzi, F.; Grigiante, M.; Baratieri, M. Experimental investigations of air-CO2 biomass gasification in reversed downdraft gasifier. Fuel 2019, 253, 1473–1481. [Google Scholar] [CrossRef]

- Korakianitis, T.; Namasivayam, A.M.; Crookes, R.J. Natural-gas fueled spark-ignition (SI) and compression-ignition (CI) engine performance and emissions. Prog. Energy Combust. Sci. 2011, 37, 89–112. [Google Scholar] [CrossRef]

- Faramawy, S.; Zaki, T.; Sakr, A.A.-E. Natural gas origin, composition, and processing: A review. J. Nat. Gas Sci. Eng. 2016, 34, 34–54. [Google Scholar] [CrossRef]

- Srinivasan, K.K.; Agarwal, A.K.; Krishnan, S.R.; Mulone, V. Natural Gas Engines—For Transportation and Power Generation; Springer: Berlin/Heidelberg, Germany, 2019; ISBN 9789811333064. [Google Scholar]

- Corbin, J.C.; Peng, W.; Yang, J.; Sommer, D.E.; Trivanovic, U.; Kirchen, P.; Miller, J.W.; Rogak, S.; Cocker, D.R.; Smallwood, G.J.; et al. Characterization of particulate matter emitted by a marine engine operated with liquefied natural gas and diesel fuels. Atmos. Environ. 2020. [Google Scholar] [CrossRef]

- Monteiro, E.; Bellenoue, M.; Sottton, J.; Roubo, A. Syngas Application to Spark Ignition Engine Working Simulations by Use of Rapid Compression Machine; IntechOpen: London, UK, 2012. [Google Scholar]

- European Parliament. Directive (EU) 2018/2001 of the European Parliament and of the Council on the promotion of the use of energy from renewable sources. Off. J. Eur. Union 2018, 2018, 82–209. [Google Scholar]

- FAO Forestry Department. Wood Gas as Engine Fuel; FAO: Rome, Italy, 1986. [Google Scholar]

- Kaupp, A.; Goss, J.R. Small Scale Gas Producer-Engine Systems; Vieweg+Teubner Verlag: Wiesbaden, Germany, 1984; ISBN 978-3-528-02001-9. [Google Scholar]

- Hagos, F.Y.; Aziz, A.R.A.; Sulaiman, S.A. Trends of Syngas as a Fuel in Internal Combustion Engines. Adv. Mech. Eng. 2014, 6, 401587. [Google Scholar] [CrossRef]

- Martínez, J.D.; Mahkamov, K.; Andrade, R.V.; Silva Lora, E.E. Syngas production in downdraft biomass gasifiers and its application using internal combustion engines. Renew. Energy 2012, 38, 1–9. [Google Scholar] [CrossRef]

- Martinez-Boggio, S.D.; Merola, S.S.; Teixeira Lacava, P.; Irimescu, A.; Curto-Risso, P.L. Effect of fuel and air dilution on syngas combustion in an optical SI engine. Energies 2019, 12, 1566. [Google Scholar] [CrossRef] [Green Version]

- Rosha, P.; Dhir, A.; Mohapatra, S.K. Influence of gaseous fuel induction on the various engine characteristics of a dual fuel compression ignition engine: A review. Renew. Sustain. Energy Rev. 2018, 82, 3333–3349. [Google Scholar] [CrossRef]

- Sridhar, G.; Sridhar, H.V.; Dasappa, S.; Paul, P.J.; Rajan, N.K.S.; Mukunda, H.S. Development of producer gas engines. Proc. Inst. Mech. Eng. Part D J. Automob. Eng. 2005, 219, 423–438. [Google Scholar] [CrossRef] [Green Version]

- Villarini, M.; Marcantonio, V.; Colantoni, A.; Bocci, E. Sensitivity Analysis of Different Parameters on the Performance of a CHP Internal Combustion Engine System Fed by a Biomass Waste Gasifier. Energies 2019, 12, 688. [Google Scholar] [CrossRef] [Green Version]

- Hagos, F.Y.; Aziz, A.R.A.; Sulaiman, S.A. Methane enrichment of syngas (H2/CO) in a spark-ignition directinjection engine: Combustion, performance and emissions comparison with syngas and Compressed Natural Gas. Energy 2015, 90, 2006–2015. [Google Scholar] [CrossRef] [Green Version]

- Talibi, M.; Hellier, P.; Ladommatos, N. Combustion and exhaust emission characteristics, and in-cylinder gas composition, of hydrogen enriched biogas mixtures in a diesel engine. Energy 2017, 124, 397–412. [Google Scholar] [CrossRef]

- Yan, F.; Xu, L.; Wang, Y. Application of hydrogen enriched natural gas in spark ignition IC engines: From fundamental fuel properties to engine performances and emissions. Renew. Sustain. Energy Rev. 2018, 82, 1457–1488. [Google Scholar] [CrossRef]

- Hagos, F.Y.; Aziz, A.R.A.; Sulaiman, S.A.; Mamat, R. Effect of fuel injection timing of hydrogen rich syngas augmented with methane in direct-injection spark-ignition engine. Int. J. Hydrogy Energy 2017, 42, 23846–23855. [Google Scholar] [CrossRef] [Green Version]

- Nadaleti, W.C.; Przybyla, G. SI engine assessment using biogas, natural gas and syngas with different content of hydrogen for application in Brazilian rice industries: Efficiency and pollutant emissions. Int. J. Hydrogy Energy 2018, 43, 10141–10154. [Google Scholar] [CrossRef]

- Cameretti, M.C.; Cappiello, A.; De Robbio, R.; Tuccillo, R. Comparison between Hydrogen and Syngas Fuels in an Integrated Micro Gas Turbine/Solar Field with Storage. Energies 2020, 13, 4764. [Google Scholar] [CrossRef]

- Elnajjar, E.; Selim, M.; Omar, F. Comparison Study of Dual Fuel Engine Performance and Overall Generated Noise under Different Dual Fuel Types and Engine Parameters. Int. J. Basic Appl. Sci. IJBAS-IJENS 2011, 11. [Google Scholar]

- Nadaleti, W.C.; Przybyla, G. Emissions and performance of a spark-ignition gas engine generator operating with hydrogen-rich syngas, methane and biogas blends for application in southern Brazilian rice industries. Energy 2018, 154, 38–51. [Google Scholar] [CrossRef]

- Kan, X.; Zhou, D.; Yang, W.; Zhai, X.; Wang, C.-H. An investigation on utilization of biogas and syngas produced from biomass waste in premixed spark ignition engine. Appl. Energy 2018, 212, 210–222. [Google Scholar] [CrossRef]

- Bates, R.; Dölle, K. Syngas Use in Internal Combustion Engines—A Review. Adv. Res. 2017, 10, 1–8. [Google Scholar] [CrossRef] [Green Version]

- Soria, J.; Li, R.; Flamant, G.; Mazza, G.D. Influence of pellet size on product yields and syngas composition during solar-driven high temperature fast pyrolysis of biomass. J. Anal. Appl. Pyrolysis 2019. [Google Scholar] [CrossRef]

- Lin, C.L.; Weng, W.C. Effects of different operating parameters on the syngas composition in a two-stage gasification process. Renew. Energy 2017. [Google Scholar] [CrossRef]

- Danardono, D.; Kim, K.S.; Lee, S.Y.; Lee, J.H. Optimization the design of venturi gas mixer for syngas engine using three-dimensional CFD modeling. J. Mech. Sci. Technol. 2011, 25, 2285–2296. [Google Scholar] [CrossRef]

- Horiba, L. On Board Emission Measurement System OBS-2200—Instruction Manual; Horiba Europe GmbH: Oberursel, Germany, 2007. [Google Scholar]

- Žvar Baškovič, U.; Vihar, R.; Seljak, T.; Katrašnik, T. Feasibility analysis of 100% tire pyrolysis oil in a common rail Diesel engine. Energy 2017, 137, 980–990. [Google Scholar] [CrossRef] [Green Version]

- Vihar, R.; Žvar Baškovič, U.; Seljak, T.; Katrašnik, T. Combustion and emission formation phenomena of tire pyrolysis oil in a common rail Diesel engine. Energy Convers. Manag. 2017, 149, 706–721. [Google Scholar] [CrossRef] [Green Version]

- Žvar Baškovič, U. Advanced Combustion Concepts with Innovative Waste Derived Fuels. Ph.D. Thesis, University of Ljubljana, Ljubljana, Slovenia, 2019. [Google Scholar]

- Rašić, D.; Vihar, R.; Baškovič, U.Ž.; Katrašnik, T. Methodology for processing pressure traces used as inputs for combustion analyses in diesel engines. Meas. Sci. Technol. 2017. [Google Scholar] [CrossRef]

- Žvar Baškovič, U.; Vihar, R.; Mele, I.; Katrašnik, T. A New Method for Simultaneous Determination of the TDC Offset and the Pressure Offset in Fired Cylinders of an Internal Combustion Engine. Energies 2017, 10, 143. [Google Scholar] [CrossRef] [Green Version]

- AVL LIST GmbH. BOOST—Theory (v2014.1); AVL List GmbH: Graz, Austria, 2014. [Google Scholar]

- Heywood, J.B. Internal Combustion Engine Fundamentals; McGraw-Hill Education: New York, NY, USA, 2018; ISBN 007028637X. [Google Scholar]

- Boushaki, T.; Dhué, Y.; Selle, L.; Ferret, B.; Poinsot, T. Effects of hydrogen and steam addition on laminar burning velocity of methane-air premixed flame: Experimental and numerical analysis. Int. J. Hydrogy Energy 2012. [Google Scholar] [CrossRef] [Green Version]

- Hu, E.; Huang, Z.; He, J.; Jin, C.; Zheng, J. Experimental and numerical study on laminar burning characteristics of premixed methane-hydrogen-air flames. Int. J. Hydrogy Energy 2009. [Google Scholar] [CrossRef]

- Di Sarli, V.; Benedetto, A. Di Laminar burning velocity of hydrogen–methane/air premixed flames. Int. J. Hydrogy Energy 2007, 32, 637–646. [Google Scholar] [CrossRef]

- Hu, E.; Huang, Z.; Zheng, J.; Li, Q.; He, J. Numerical study on laminar burning velocity and NO formation of premixed methane-hydrogen-air flames. Int. J. Hydrogy Energy 2009. [Google Scholar] [CrossRef]

- Hu, G.; Zhang, S.; Li, Q.F.; Pan, X.B.; Liao, S.Y.; Wang, H.Q.; Yang, C.; Wei, S. Experimental investigation on the effects of hydrogen addition on thermal characteristics of methane/air premixed flames. Fuel 2014. [Google Scholar] [CrossRef]

- Coppens, F.H.V.; De Ruyck, J.; Konnov, A.A. The effects of composition on burning velocity and nitric oxide formation in laminar premixed flames of CH4 + H2 + O2 + N2. Combust. Flame 2007. [Google Scholar] [CrossRef]

- Miao, H.; Ji, M.; Jiao, Q.; Huang, Q.; Huang, Z. Laminar burning velocity and Markstein length of nitrogen diluted natural gas/hydrogen/air mixtures at normal, reduced and elevated pressures. Int. J. Hydrogy Energy 2009. [Google Scholar] [CrossRef]

- Hermanns, R.T.E.; Konnov, A.A.; Bastiaans, R.J.M.; de Goey, L.P.H.; Lucka, K.; Köhne, H. Effects of temperature and composition on the laminar burning velocity of CH4 + H2 + O2 + N2 flames. Fuel 2010. [Google Scholar] [CrossRef]

- Salzano, E.; Basco, A.; Cammarota, F.; Di Sarli, V.; Di Benedetto, A. Explosions of Syngas/CO2 Mixtures in Oxygen-Enriched Air. Ind. Eng. Chem. Res. 2012, 51, 7671–7678. [Google Scholar] [CrossRef]

- Kim, T. Micro methanol reformer combined with a catalytic combustor for a PEM fuel cell. Int. J. Hydrogy Energy 2009, 34, 6790–6798. [Google Scholar] [CrossRef]

- Mirhashemi, F.S.; Sadrnia, H. NOx emissions of compression ignition engines fueled with various biodiesel blends: A review. J. Energy Inst. 2020, 93, 129–151. [Google Scholar] [CrossRef]

- Singh, Y.; Sharma, A.; Tiwari, S.; Singla, A. Optimization of diesel engine performance and emission parameters employing cassia tora methyl esters-response surface methodology approach. Energy 2019, 168, 909–918. [Google Scholar] [CrossRef]

- Alptekin, E. Emission, injection and combustion characteristics of biodiesel and oxygenated fuel blends in a common rail diesel engine. Energy 2017. [Google Scholar] [CrossRef]

- Hasegawa, T.; Sato, M.; Nakata, T. A Study of Combustion Characteristics of Gasified Coal Fuel. J. Eng. Gas Turbines Power 2001, 123, 22–32. [Google Scholar] [CrossRef]

- Lieuwen, T.C.; Yang, V.; Yetter, R. Synthesis Gas Combustion—Fundamentals and Applications; CRC Press: Boca Raton, FL, USA, 2010; ISBN 9781420085341. [Google Scholar]

- Kravos, A.; Seljak, T.; Rodman Oprešnik, S.; Katrašnik, T. Operational stability of a spark ignition engine fuelled by low H2 content synthesis gas: Thermodynamic analysis of combustion and pollutants formation. Fuel 2020, 261, 116457. [Google Scholar] [CrossRef]

- Whitty, K.J.; Zhang, H.R.; Eddings, E.G. Emissions from Syngas Combustion. Combust. Sci. Technol. 2008, 180, 1117–1136. [Google Scholar] [CrossRef]

- Sahoo, B.B.; Sahoo, N.; Saha, U.K. Effect of H2:CO ratio in syngas on the performance of a dual fuel diesel engine operation. Appl. Therm. Eng. 2012, 49, 139–146. [Google Scholar] [CrossRef]

- Shah, A.; Srinivasan, R.; To, S.D.F.; Columbus, E.P. Performance and emissions of a spark-ignited engine driven generator on biomass based syngas. Bioresour. Technol. 2010, 101, 4656–4661. [Google Scholar] [CrossRef]

- European Environment Agency. The European environment-state and outlook 2020. In Knowledge for Transition to a Sustainable Europe; European Environment Agency: Copenhagen, Denmark, 2020; Volume 60, ISBN 9789294800909. [Google Scholar]

| Technical Characteristic | Value/Type | Unit |

|---|---|---|

| Nr. Cylinders | 4 | - |

| Valves per cylinder | 2 | - |

| Displacement | 2237 | cm3 |

| Bore | 91 | Mm |

| Stroke | 86 | Mm |

| Compression ratio | 8.8 | - |

| Max. Power @2570 rpm | 42 | kW |

| Max Torque @2200 rpm | 160 | Nm |

| Cooling system | Counter-current, water-cooled | - |

| Ignition system | Electronic ignition with inductors | - |

| Component | CO | CO2 | H2 | CH4 | N2 |

| Vol. Fraction [%] | 19.59% | 12.48% | 14.99% | 2.49% | 50.35% |

| Component | CH4 | C2H6 | C3H8 | C4H10 | N2 |

| Vol. Fraction [%] | 95.65% | 2.45% | 0.78% | 0.11% | 0.65% |

| Measured Quantity | Equipment | Accuracy | Measuring Range |

|---|---|---|---|

| Air Mass Flow | Meriam 50MC2 | ±1% RD | 0 to 100 SCFM |

| Syngas Mass Flow | Emerson Micromotion Elite CMFS015 | ±0.1% FS | 0 to 330 kg/h |

| Natural Gas Mass Flow | Honeywell Elster RVG G10 | ±0.2% FS | 0.5 to 16 m3/h |

| Crank Angle | Kistler 2613B | ±0.02 °CA at 10,000 rpm | 1 to 20,000 rpm |

| In-cylinder pressure | AVL GH12D | ±0.3% FS | 0 to 300 bar |

| Torque | HBN U2B Load Cell | 0.1% FS | 0 to 2 kN |

| Exhausts composition: CO2 and NOx (NO and NO2) | Sensors Semtech DS | <±2% RD | CO2: 0 to 18% vol |

| <±2% RD | NO: 0 to 3000 ppm | ||

| <±2% RD | NO2: 0 to 1000 ppm | ||

| Exhausts composition: CO and THC | Horiba OBS-2200 | ±2.5% RD | CO: 0 to 8% vol |

| ±2.5% RD | THC: 0 to 10,000 ppm |

| Label | SES [%] | Spark Advance [°BTDC] |

|---|---|---|

| OP2510 | 25 | 10 |

| OP2525 | 25 | 25 |

| OP2535 | 25 | 35 |

| OP2545 | 25 | 45 |

| OP5010 | 50 | 10 |

| OP5025 | 50 | 25 |

| OP5035 | 50 | 35 |

| OP5045 | 50 | 45 |

| OP7510 | 75 | 10 |

| OP7525 | 75 | 25 |

| OP7535 | 75 | 35 |

| OP7545 | 75 | 45 |

| Spark Advance [°BTDC] | IMEP [Bar] @SES: 25% | IMEP [Bar] @SES: 50% | IMEP [Bar] @SES: 75% |

|---|---|---|---|

| 10 | 3.4 | 3.5 | 3.9 |

| 25 | 4.1 | 3.9 | 4.2 |

| 35 | 4.4 | 4.4 | 4.4 |

| 45 | 4.6 | 4.8 | 4.7 |

| Spark Advance [°BTDC] | Torque [Nm] @SES: 25% | Torque [Nm] @SES: 50% | Torque [Nm] @SES: 75% |

|---|---|---|---|

| 10 | 55.5 | 54.1 | 53.5 |

| 25 | 68.0 | 66.6 | 65.3 |

| 35 | 67.1 | 67.0 | 66.7 |

| 45 | 65.0 | 64.4 | 64.1 |

| Label | Brake Power [kW] | CO [g/kWh] | CO2 [g/kWh] | NOx [g/kWh] | THC [g/kWh] |

|---|---|---|---|---|---|

| OP2510 | 8.72 | 0.70 | 96.97 | 1.00 | 0.37 |

| OP2525 | 10.68 | 0.77 | 83.07 | 3.51 | 0.49 |

| OP2535 | 10.54 | 0.65 | 84.15 | 6.59 | 0.61 |

| OP2545 | 10.21 | 0.91 | 83.67 | 9.23 | 0.75 |

| OP5010 | 8.50 | 1.31 | 129.65 | 0.41 | 0.28 |

| OP5025 | 10.46 | 1.28 | 106.66 | 1.30 | 0.34 |

| OP5035 | 10.52 | 1.24 | 106.34 | 3.12 | 0.42 |

| OP5045 | 10.12 | 1.41 | 111.42 | 6.54 | 0.47 |

| OP7510 | 8.40 | 1.70 | 161.32 | 0.19 | 0.24 |

| OP7525 | 10.26 | 1.53 | 133.23 | 0.54 | 0.26 |

| OP7535 | 10.48 | 1.52 | 130.21 | 1.31 | 0.32 |

| OP7545 | 10.07 | 1.69 | 135.60 | 2.85 | 0.36 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Caligiuri, C.; Žvar Baškovič, U.; Renzi, M.; Seljak, T.; Oprešnik, S.R.; Baratieri, M.; Katrašnik, T. Complementing Syngas with Natural Gas in Spark Ignition Engines for Power Production: Effects on Emissions and Combustion. Energies 2021, 14, 3688. https://doi.org/10.3390/en14123688

Caligiuri C, Žvar Baškovič U, Renzi M, Seljak T, Oprešnik SR, Baratieri M, Katrašnik T. Complementing Syngas with Natural Gas in Spark Ignition Engines for Power Production: Effects on Emissions and Combustion. Energies. 2021; 14(12):3688. https://doi.org/10.3390/en14123688

Chicago/Turabian StyleCaligiuri, Carlo, Urban Žvar Baškovič, Massimiliano Renzi, Tine Seljak, Samuel Rodman Oprešnik, Marco Baratieri, and Tomaž Katrašnik. 2021. "Complementing Syngas with Natural Gas in Spark Ignition Engines for Power Production: Effects on Emissions and Combustion" Energies 14, no. 12: 3688. https://doi.org/10.3390/en14123688

APA StyleCaligiuri, C., Žvar Baškovič, U., Renzi, M., Seljak, T., Oprešnik, S. R., Baratieri, M., & Katrašnik, T. (2021). Complementing Syngas with Natural Gas in Spark Ignition Engines for Power Production: Effects on Emissions and Combustion. Energies, 14(12), 3688. https://doi.org/10.3390/en14123688