Abstract

When designing the cement slurry for casing string cementing in geothermal boreholes, the appropriate thermal conductivity is selected. In the zone of geothermal water, where thermal energy is collected, cement slurry is used, from which the cement sheath has high thermal conductivity. On the other hand, the remaining part of the opening is sealed with slurry, from which the cement sheath will reduce thermal energy losses through appropriate thermal insulation. Cement slurry with appropriate thermal insulation includes light insulating materials. However, the use of such additives is very problematic as they are fractionated due to their low density. Therefore, measures should be taken to prevent fractionation of the cement slurry for sealing geothermal boreholes. This article presents the results of research on fractionation of cement slurries for sealing geothermal boreholes. 12 slurries were used for the tests. Six of them are based on class A cement, and six based on class G cement. This action shows the differences in fractionation depending on the binder used. However, the main area of research is determining the effectiveness of counteracting fractionation by the means used for this purpose. As a result of the conducted works, a very good improvement of the cement slurry stability is obtained after the introduction of xanthan gum, as well as filtration perlite. These measures prevent fractionation, so that the cement slurry has a homogeneous structure, and the cement sheath provides the required thermal insulation in the geothermal well.

1. Introduction

Geothermal energy shows constant availability and stability regardless of changing weather conditions. There is now a growing trend of interest in the use of this type of energy. Geothermal energy is a very capital intensive renewable energy source (RES) [1,2,3,4]. Due to the fact that there are many problems, they should be considered individually [5,6,7,8,9,10,11,12,13]. One such aspect is the proper sealing of boreholes in order to obtain geothermal energy. When drilling holes, in order to use geothermal energy, it is necessary to properly design the cement sheath of the borehole [14,15]. The most important thing is to ensure proper thermal insulation of the opening. This will allow minimal losses of thermal energy during the circulation of geothermal waters. To obtain a low degree of thermal conductivity, light additives are used to fill the cement slurry [16,17,18,19]. This is a challenge for engineers due to the restrictive requirements for cement slurries intended for sealing geothermal boreholes. The biggest problem in cement slurries with the addition of light fractions is obtaining a homogeneous structure of both the cement slurry and the cement sheath. Therefore, before designing a cement slurry recipe for sealing geothermal boreholes, it is necessary to analyze the possibilities of improving the cement slurry stability [16,19,20,21]. The fractionation of the light additives into the cement slurry is then reduced. This allows obtaining cement slurry that doesn’t fractionate and has a homogeneous microstructure after setting.

Cement slurry for sealing geothermal boreholes is a dispersion colloidal system. It consists of at least two phases, one of which is a finely divided material, dispersed in the other continuous phase [21,22,23,24]. Such a dispersion system is stable if it maintains the mutual arrangement of the cement particles unchanged regardless of external forces. The inverse of the cement slurry stability is the segregation of its particles (separation of dispersion to the primary system) or sedimentation (settlement of cement particles under the influence of gravity) [2,20,25]. These phenomena cause fractionation, i.e., the separation of individual fractions of the cement slurry. The reduction of cement slurry fractionation is the main condition for the effective sealing of the geothermal borehole. The use of cement slurry that fractionates causes a number of unfavourable phenomena. The fractionating cement slurry tends to delaminate and release free water. The lack of this water will weaken the setting of the hydraulic binder and cause poor or even no cementation. In addition, the fractionating cement slurry has a reduced density in the upper part of the borehole, and therefore creates a cement sheath structure of such cement slurry, which has a high anisotropy. This is very disadvantageous in geothermal boreholes, because the lower part of the borehole then has inadequate thermal insulation. Additionally, the cement sheath made of non-homogeneous hardened cement slurry has different (depending on the measurement point) values of mechanical strength, adhesion to steel pipes, porosity and permeability [20,26,27,28,29,30,31,32,33,34]. The water-cement ratio and the amount of fluidizer have a great influence on the fractionation of the cement slurry. The reduction of cement slurry fractionation can be achieved by using materials that increase the viscosity of the dispersion system [20,35,36]. However, the cement slurry must be pump under turbulent flow (Re > 2000), which requires adequate fluidity. As a consequence, more liquefied cement slurry fractionates more, which requires research and appropriate modifications.

Several test methods are distinguished to determine the fractionation of the cement slurry. Very precise methods rely on laser measurement of the distribution of the number of particles in the tested liquid [20,37,38]. It is very popular to measure the amount of water released over the tested dispersion system, which in the technology of cement slurries is referred to as water separation (Figure 1). Sometimes the cement slurry shows fractionation and the cement grains fall due to the force of gravity, but the cement slurry will not have a water separation. Then, the measurement of fractionation is carried out using a column for testing the fractionation or sedimentation of the cement slurry. It allows you to determine the density of the cement slurry at individual points (top, middle, bottom). It is a very important measurement on the basis of which necessary modifications can be made to the composition of the cement slurry. This action makes it possible to reduce the fractionation of the cement slurry. As a result, cement slurry of reduced density is designed, which is homogeneous and suitable for sealing geothermal boreholes.

Figure 1.

Free water in highly fractionating cement slurry.

2. Materials and Methods

2.1. Imput Material

In order to determine the reduction of fractionation of the cement slurry to geothermal boreholes, tests are carried out for various anti-settling agents. The influence of the tested materials on the reduction of fractionation due to the improvement of the production of a homogeneous suspension in the cement slurry by the increase of the viscosity of the mixing liquid is determined. The following compares cement slurries based on class A Portland cement and class G HSR drilling cement. This is necessary due to the difference in the specific surface area of these cements. The standard water-cement ratio was used. For cement of class A w/c = 0.46, and for cement of class G w/c = 0.44.

The base cement slurry consists of cement (class A or G), water and a defoaming agent which is a mixture of unsaturated fatty acid esters and refined hydrocarbons.

The following materials are introduced into the base cement slurry in subsequent recipes, which affect the fractionation of the cement slurry: Dispersant, it’s a modified naphthalene lignosulfonate agent, with a bulk density of approx. 500 ± 50 kg/m3, and its pH is in the range of 6.6 to 8.5. Bentonite-special type of modified bentonite used to prepare water-based drilling fluids. Its bulk density is 800 to 1000 kg/m3 and a maximum moisture content of 10%. Particle residue >75 µm is max 4%. The aluminosilicate microspheres are spherical aluminate-silicate particles with a diameter of 20 to 500 µm. They are filled with carbon dioxide and nitrogen. They are characterized by a high content of SiO2 and Fe2O3 and a smaller, for microspheres, content of Al2O3. Amine polymer, which is Hexahydro-1,3,5-tris (2-hydroxyethyl)-sym-triaazine. Soda water glass, which is an aqueous solution of sodium silicate. Transparent, viscous liquid with a density of 1400 kg/m3. The XCD xanthan gum is an agent to increase the viscosity of the drilling fluid. Expanded/filter perlite EP 100F, which is a sodium potassium aluminum silicate. Its bulk density is 60–140 kg/m3, and its thermal conductivity is in the range of 0.045 to 0.059 W/m·K.

2.2. Course of Research

2.2.1. Slurry Preparation

To determine water separation, the cement slurry is prepared in accordance with point 15.6 of PN-EN ISO 10426-4 [39]. The required amount of water is measured with a measuring cylinder and poured into the mixer. It is mixed at a speed of 1600 rpm. Next, agents modifying the parameters of the cement slurry are added and the mixture is stirred for 10 min. After this time, loose additives are added to the water with the agents. The cement slurry prepared in this way is intended for further research

2.2.2. Experimental Procedures

The properties of the cement slurry are tested in accordance with the standard:

- ✓

- PN-EN ISO 10426-2. Oil and Gas Industry. Cements and materials for cementing boreholes. Lot 2: Tests for drilling cements [40].

In these tests, the following were measured: free water (at angle of 90° and 45°), cement slurry density (at top, middle, bottom of fractionation test column at angle of 90° and 45°) and rheological parameters of the tested cement slurries.

- ✓

- PN-EN ISO 10426-4 Oil and Gas Industry. Cements and materials for cementing boreholes. Part 4: Preparation and testing of cement slurries under atmospheric pressure [39].

The adhesion test is carried out according to the standard.

- ✓

- PN-EN 196-1: 2006 Cement testing methods. Strength determination [41].

The tests are performed to perform fractionation analysis. The tests consist in determining the amount of free water and measuring the fractionation of the cement slury.

2.2.3. Free Water

The cement slurry is prepared in accordance with point 15.6 of the standard [40]. The cement slurry is mixed for 20 min in a consistometer and poured into a 250 cm3 cylinder. The cylinder seals at the top to prevent water evaporation. After 2 h, the amount of water above the cement slurry is measured, which is called free water.

2.2.4. Cement Slurry Fractionation

The cement slurry is prepared in the same way as for free water testing. The cement slurry is then placed in the fractionation test column (Figure 2). After 2 h, the sliders are closed and the individual cement batches are distributed (top, middle, bottom). The slurry from each part of the cylinder is mixed separately and the density is measured with a baroid mud balance. From the obtained results, the fractionation of the cement slurry is determined. Cement slurry, which doesn’t fractionate, is sedimentation stable and has the same density values at all measurement points. If the difference in density is greater than 60 kg/m3, the cement slurry excessively fractionates.

Figure 2.

The column for testing the cement slurry fractionation.

2.2.5. Rheological Parameters

Research on rheological properties is based on the determination of shear curves. Tests are performed for the following rotational speeds: 600, 300, 200, 100, 60, 30, 20, 10, 6, 3, 2 and 1 rpm. These values correspond to the following shear rates (γ): 1022; 511.2; 340.8; 170.4; 102.2; 51.1; 34.08; 17.04; 10.22; 4.11; 3.41; and 1.70 s−1. The tests were carried out at a temperature of 20 °C ± 2 °C. The dosed liquid was tap water, free of impurities. The Viscometer-Model 35 FANN with coaxial cylinders was used in the study of rheological properties. The numerical software “Rheo Solution” was used to facilitate the calculations. The software is owned by the Faculty of Drilling, Oil and Gas of the AGH University of Science and Technology and is used in research and development. The rheological parameters of the tested cement slurries later in the tekst.

3. Results and Discussion

The first to be tested is the control cement slurry. It consists of cement and water. Subsequently, fractionation reducing agents are introduced into this cement slurry. Their main activity is to increase the viscosity of the liquid. The cement slurries recipes, quantitative contents of individual additives and admixtures are shown in Table 1 for class A cement and Table 2 for class G cement. The main parameters of the cement slurries are summarized in Table 3 (class A cement) and Table 4 (class G cement).

Table 1.

Compositions of cement slurries based on class A cement.

Table 2.

Compositions of cement slurries based on class G cement.

Table 3.

Selected parameters of cement slurries based on class A cement.

Table 4.

Selected parameters of cement slurries based on class G cement.

In the first group, No. 1 to No. 6 cement slurries are made with class A cement, and contain 0.15% defoaming agent. The second cement slurry has a dispersant. The difference in the successive cement slurries is the presence of fractionation reducing additives. In the group of cement slurries presented in Table 1, bentonite, aluminosilicate microsphere, mixture of bentonite and microsphere, and mixture of microsphere and high-molecular polymer are used. The detailed test results of the cement slurries from this group are presented in Table 3. Whereas the cement slurries of the second group presented in Table 2 are made with the use of G HSR cement. They also contain 0.15% defoaming agent. To reduce fractionation, bentonite, sodium water glass, xanthan gum and filter perlite are used. The detailed results of the research on cement slurries based on G HSR drilling cement are presented in Table 4.

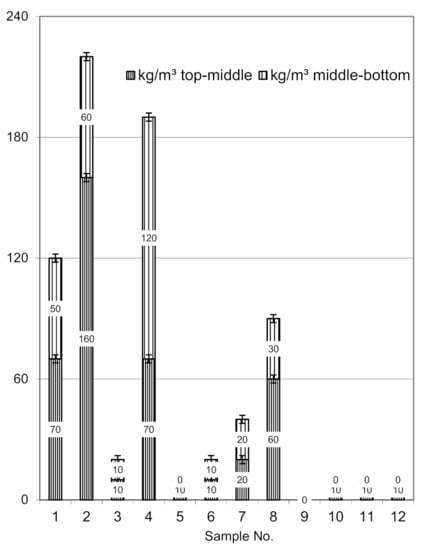

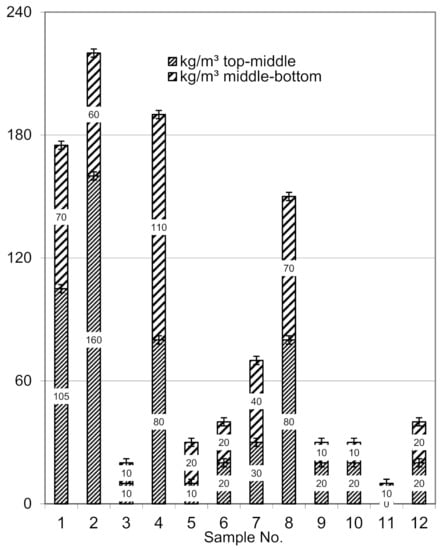

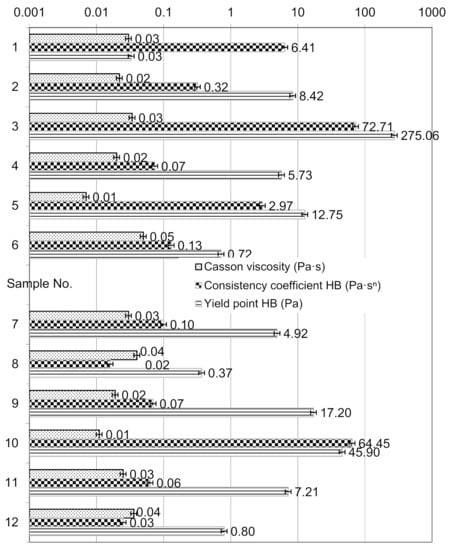

The results of the tests in Table 3 show the fractionation of the control cement slurry No. 1 in Figure 3. The difference in density between the top and center of the fractionation column is 70 kg/m3, and 50 kg/m3, between the middle and bottom, when measured at 90°. These are acceptable values. However, when measuring at an angle of 45° (Figure 4), the differences in density are much stronger. The difference in density between the top and middle parts of the column is 105 kg/m3 and 70 kg/m3 between the middle and bottom parts. The addition of a dispersant in cement slurry No. 2 causes a significant increase in fractionation. The difference in density in cement slurry No. 2 between the upper and middle measurement points in the column is 160 kg/m3 (measured at 90° and 45°, Figure 3 and Figure 4). In cement slurry No. 4 there is an aluminosilicate microsphere. This addition without modifying the viscosity of the mixing water by the addition of bentonite causes a very strong fractionation of the cement slurry, which is shown in Figure 3 and Figure 4. The strongest fractionation-retaining effect has bentonite and high-molecular polymer (sample No. 3 and 6). It can be seen that the addition of bentonite increases the rheological parameters. The HB consistency index is 72.71 Pa·sn, and the yield pointHB is 275 Pa (Figure 5). In the technology of pressing cement slurry, such parameters are not good. High values of the plastic viscosity and the yield point may cause an increase in pumping pressure, which causes the risk of depressurization of the deposit zone. Bentonite reduces the fractionation of the cement slurry, but increases the rheology of the cement slurry. A high-molecular polymer is therefore a much better anti-sedimentation agent. It keeps the rheological parameters at a good level and at the same time the cement slurry does not fractionate. It can be seen in cement slurry No. 6, the difference in density is from 10 kg/m3 to 20 kg/m3, Figure 3 and Figure 4.

Figure 3.

Density difference between the top and middle and middle and bottom of the column for the fractionation test. The measurement angle is 90°.

Figure 4.

Density difference between the top and middle and middle and bottom of the column for the fractionation test. The measurement angle is 45°.

Figure 5.

Values of rheological parameters of the tested cement slurries. Tests at a temperature of 20 °C and atmospheric pressure.

Cement slurries from the second group (Table 2) are made with G HSR drilling cement. The same as in the first group, all cement slurries have 0.1% defoaming agent. From the test results in Table 4 and in Figure 3 and Figure 4, a slight fractionation of the control cement slurry No. 7 can be seen. The difference in density is from 20 kg/m3 to 40 kg/m3. The use of a dispersant in cement slurry No. 8 increases fractionation. The difference in density is from 70 kg/m3 between the top and middle of the column to 80 kg/m3 between the middle and bottom for measuring sedimentation at an angle of 45° (Figure 4). These values are slightly above the limit value, which is 60 kg/m3. This result means that the dispersant has no effect on reducing the fractionation of the cement slurry. On the other hand, the use of the remaining additives does not cause a large difference in density in individual parts of the fractionation column. During the tests, the difference in density does not exceed 20 kg/m3. When analyzing the rheological parameters of the cement slurries, a significant increase in the value can be seen after the use of water glass in sample 10 (Figure 5). In this case, as when using bentonite, the water glass should be carefully dosed to reduce fractionation. Optionally, a small amount of dispersant can also be used. The obtained results confirm the beneficial effects of xanthan gum in cement slurry No. 10 and filter perlite in cement slurry No. 12. It is also possible to use the addition of sodium water glass, but the rheological parameters should be reduced.

Analyzing the fractionation of the control cement slurries, it was observed that the cement slurry based on G HSR class G drilling cement was much smaller. This is due to the lower standard water-cement ratio. The tested agents with the effect of reducing fractionation increase the rheological parameters. As a result, it is possible to keep fine fractions in the entire volume of the cement slurry and reduce fractionation. However, too strong an increase in the consistency coefficient and the yield point is not good and it should be taken into account when designing the cement slurry. Materials with the effect of reducing fractionation also reduce the amount of free water (Table 3 and Table 4). This can be explained by the interaction of fractionation and free water separation from the cement slurry. The increase in the amount of free water is caused by the aluminosilicate microsphere and xanthan gum.

The conducted research on the means to reduce the fractionation of the lightweight cement slurry is necessary in the technology of drilling geothermal boreholes. The selection of appropriate fractionation reducing agents allows to obtain a homogeneous structure of the cement paste that does not undergo fractionation. As a result, the cement sheath has the required thermal conductivity. Otherwise, the opening would not have adequate thermal insulation. The thermal energy would be dissipated in the cement sheath which would show an anisotropic structure. Therefore, the appropriate selection of fractionation reducing agents contributes to the achievement of the required parameters of the cement sheath. Thanks to this, it is possible to minimize thermal energy losses in the borehole during the circulation of geothermal waters, during the recovery of geothermal energy.

4. Conclusions

- Bentonite in lightweight cement slurries for geothermal boreholes reduces fractionation of the cement slurry, but also causes a significant increase in rheological parameters. The HB consistency coefficient for the slurry with bentonite is 72.71 Pa·sn, and the yield point of HB with bentonite is 275 Pa, where for the sample without bentonite the HB consistency index is 0.32 Pa·sn, and the yield point of HB without bentonite is 8.42 Pa

- Introducing a dispersing agent into the cement slurry reduces the rheological parameters. But by reducing the value of the intermolecular forces of the cement grains, the fractionation of the cement slurry increases. Therefore, the mutual amounts of dispersing agent and bentonite in the cement slurry should be optimized. The consistency coefficient is reduced from the value of 6.41 Pa·sn to 0.32 Pa·sn, and the Casson viscosity from the value of 0.03 Pa·s to 0.02 Pa·s after introducing the dispersant

- Water glass is used to significantly reduce fractionation. But because of the high concentration of the mixing water, a dispersant must be added additionally.

- A cement slurry for sealing geothermal boreholes (surface casing, intermediate casing) that is prepared using class G cement has greater fractionation resistance. It is related to the lower water-cement ratio required by the standard.

- Xanthan gum has a beneficial effect in reducing the fractionation of the cement slurry to geothermal boreholes. This material doesn’t cause a strong increase in rheological parameters, which is beneficial from the point of view of the technology of pressing the cement slurry into the borehole.

- Filtration perlite has the best properties in reducing the fractionation of the cement slurry to geothermal boreholes (surface casing, intermediate casing). The introduction of fine fractions of this material into the cement slurry results in a uniform structure of the liquid slurry while maintaining low consistency coefficient 0.03 Pa·sn and the yield point 0.8 Pa.

- The materials tested in order to reduce fractionation of the cement slurry for sealing geothermal boreholes increase the consistency coefficient and the slurry yield point and reduce the amount of free water. Thanks to this, it is possible to design a homogeneous cement sheath. Such cement slurry has the same values of the tested parameters at all measurement points, so it can be used for sealing geothermal boreholes (surface casing, intermediate casing).

Author Contributions

Conceptualization, M.K.; methodology, M.K. and B.J.; software, B.J.; validation, M.K., G.Z. and B.J.; formal analysis, Ł.K.; investigation, M.K., B.J.; resources, Ł.K.; data curation, B.J.; writing—original draft preparation, M.K.; writing—eview and editing, M.K.; visualization, M.K. and B.J.; supervision, M.K.; project administration, M.K., G.Z.; funding acquisition, M.K. All authors have read and agreed to the published version of the manuscript.

Funding

The work was financially supported by Ministry of Science and Higher Education Warsaw (Internal order Oil and Gas Institute—National Research Institute Project No. 0015/KW/21 and 36/KW/16).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Acknowledgments

The author thanks the anonymous reviewers for their constructive comments and the editor for handling the paper.

Conflicts of Interest

The authors declare no conflict of interest.

Nomenclature

| Symbol | Explanation |

| w/c | Twater–cement ratio—expresses the amount of water per cement unit |

| Casson viscosity | the liquid is described by Casson’s rheological model |

| HB (yield point, con-sistency coefficient) | the liquid is described by the Herschel–Bulkley rheological model |

References

- Kremieniewski, M.; Kędzierski, M. Badanie frakcjonowania lekkich materiałów obniżających gęstość jako wstępnego parametru podczas projektowania receptury zaczynu lekkiego. Nafta-Gaz 2019, 12, 35–42. [Google Scholar] [CrossRef]

- Kremieniewski, M. Ultra-Lightweight Cement Slurry to Seal Wellbore of Poor Wellbore Stability. Energies 2020, 13, 3124. [Google Scholar] [CrossRef]

- Gaurina-Međimurec, N.; Pašić, B.; Mijić, P.; Medved, I. Drilling Fluid and Cement Slurry Design for Naturally Fractured Reservoirs. Appl. Sci. 2021, 11, 767. [Google Scholar] [CrossRef]

- Aliyu, M.; Chen, H.-P. Sensitivity analysis of deep geothermal reservoir: Effect of reservoir parameters on production temperature. Energy 2017, 129, 101–113. [Google Scholar] [CrossRef]

- Operacz, A.; Chowaniec, J. Perspectives of geothermal water use in the Podhale Basin according to geothermal step distribution. Geol. Geophys. Environ. 2018, 44, 379–389. [Google Scholar] [CrossRef] [Green Version]

- Huculak, M.; Jarczewski, W.; Dej, M. Economic aspects of the use of deep geothermal heat in district heating in Poland. Renew. Sustain. Energy Rev. 2015, 49, 29–40. [Google Scholar] [CrossRef]

- Zheng, S.; Liu, T.; Jiang, G.; Fang, C.; Qu, B.; Gao, P.; Li, L.; Feng, Y. Effects of Water-to-Cement Ratio on Pore Structure Evolution and Strength Development of Cement Slurry Based on HYMOSTRUC3D and Micro-CT. Appl. Sci. 2021, 11, 3063. [Google Scholar] [CrossRef]

- Tao, C.; Kutchko, B.G.; Rosenbaum, E.; Massoudi, M. A Review of Rheological Modeling of Cement Slurry in Oil Well Applications. Energies 2020, 13, 570. [Google Scholar] [CrossRef] [Green Version]

- Kampa, Ł.; Chowaniec, A.; Królicka, A.; Sadowski, Ł. The Effect of the Addition of Polypropylene Fibers to Primer on the Pull-Off Strength of Epoxy Resin Coatings. Materials 2020, 13, 4674. [Google Scholar] [CrossRef]

- Yildirim, N.; Parmanto, S.; Akkurt, G.G. Thermodynamic assessment of downhole heat exchangers for geothermal power generation. Renew. Energy 2019, 141, 1080–1091. [Google Scholar] [CrossRef]

- Górecki, W.; Sowiżdżał, A.; Hajto, M.; Wachowicz-Pyzik, A. Atlases of geothermal waters and energy resources in Poland. Environ. Earth Sci. 2014, 74, 7487–7495. [Google Scholar] [CrossRef] [Green Version]

- Bujakowski, W.; Tomaszewska, B.; Miecznik, M. The Podhale geothermal reservoir simulation for long-term sustainable production. Renew. Energy 2016, 99, 420–430. [Google Scholar] [CrossRef]

- Jeleński, T.; Dendys, M.; Tomaszewska, B.; Pająk, L.; Tomasz, J. The Potential of RES in the Reduction of Air Pollution: The SWOT Analysis of Smart Energy Management Solutions for Krakow Functional Area (KrOF). Energies 2020, 13, 1754. [Google Scholar] [CrossRef] [Green Version]

- Cao, S.; Yilmaz, E.; Song, W. Evaluation of Viscosity, Strength and Microstructural Properties of Cemented Tailings Backfill. Minerals 2018, 8, 352. [Google Scholar] [CrossRef] [Green Version]

- Kremieniewski, M. Zmiana wczesnej wytrzymałości na ściskanie pod wpływem wybranych środków poprawiających stabilność sedymentacyjną. Nafta-Gaz 2020, 76, 446–473. [Google Scholar] [CrossRef]

- Kremieniewski, M.; Kędzierski, M. Wpływ wybranych domieszek obniżających gęstość na parametry zaczynu cementowego. Nafta-Gaz 2020, 76, 143–153. [Google Scholar] [CrossRef]

- Kremieniewski, M. Recipe of Lightweight Slurry with High Early Strength of the Resultant Cement Sheath. Energies 2020, 13, 1583. [Google Scholar] [CrossRef] [Green Version]

- Elkatatny, S.; Gamal, H.; Ahmed, A.; Sarmah, P.; Sangaru, S.; Alohaly, M. A Novel Solution for Severe Loss Prevention While Drilling Deep Wells. Sustainability 2020, 12, 1339. [Google Scholar] [CrossRef] [Green Version]

- Almalkawi, A.T.; Salem, T.; Hamadna, S.; Darsanasiri, A.G.N.D.; Soroushian, P.; Balchandra, A.; Al-Chaar, G. Physio-Microstructural Properties of Aerated Cement Slurry for Lightweight Structures. Materials 2018, 11, 597. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kremieniewski, M. Poprawa stabilności sedymentacyjnej zaczynu cementowego. Nafta-Gaz 2017, 73, 242–249. [Google Scholar] [CrossRef]

- Kremieniewski, M.; Pikłowska, A. Receptura zaczynu lekkiego do uszczelniania otworów w strefie niskich ciśnień złożowych. Nafta-Gaz 2020, 76, 577–584. [Google Scholar] [CrossRef]

- Bhatty, J.I.; Banfill, P.F.G. Sedimentation behaviour in cement pastes subjected to continuous shear in rotational viscometers. Cem. Concr. Res. 1982, 12, 69–78. [Google Scholar] [CrossRef]

- Stryczek, S.; Wiśniowski, R.; Gonet, A.; Złotkowski, A. The influence of time of rheological parameters of fresh cement slurries. AGH Drill. Oil Gas 2014, 31, 123–133. [Google Scholar] [CrossRef]

- Tao, C.; Kutchko, B.G.; Rosenbaum, E.; Wu, W.-T.; Massoudi, M. Steady Flow of a Cement Slurry. Energies 2019, 12, 2604. [Google Scholar] [CrossRef] [Green Version]

- Kremieniewski, M. Badania środków poprawiających stabilność sedymentacyjną zaczynów cementowych. Nafta-Gaz 2020, 76, 387–395. [Google Scholar] [CrossRef]

- Kremieniewski, M.; Stryczek, S.; Kotwica, Ł. Zmiany w mikrostrukturze płaszcza cementowego w zależności od warunków hydratacji zaczynu. Nafta-Gaz 2014, 12, 918–926. [Google Scholar]

- Szeląg, M. Mechano-Physical Properties and Microstructure of Carbon Nanotube Reinforced Cement Paste after Thermal Load. Nanomaterials 2017, 7, 267. [Google Scholar] [CrossRef] [Green Version]

- Liu, J.; Tang, K.; Qiu, Q.; Pan, D.; Lei, Z.; Xing, F. Experimental Investigation on Pore Structure Characterization of Concrete Exposed to Water and Chlorides. Materials 2014, 7, 6646–6659. [Google Scholar] [CrossRef] [Green Version]

- Mahmoud, A.A.; Elkatatny, S.; Ahmed, A.; Gajbhiye, R. Influence of Nanoclay Content on Cement Matrix for Oil Wells Subjected to Cyclic Steam Injection. Materials 2019, 12, 1452. [Google Scholar] [CrossRef] [Green Version]

- Rahman, S.H.A.; Zulkarnain, N.N.; Shafiq, N. Experimental Study and Design of Experiment Using Statistical Analysis for the Development of Geopolymer Matrix for Oil-Well Cementing for Enhancing the Integrity. Crystals 2021, 11, 139. [Google Scholar] [CrossRef]

- Kremieniewski, M. Korelacja wyników badań wytrzymałości na ściskanie i przyczepności do rur stalowych płaszcza cementowego z zaczynu o obniżonej gęstości. Nafta-Gaz 2019, 75, 613–624. [Google Scholar] [CrossRef]

- Kremieniewski, M. Zaczyny do uszczelniania otworów w warunkach niskich wartości gradientów ciśnienia szczelinowania skał oraz do prac rekonstrukcyjnych. Nafta-Gaz 2020, 76, 102–109. [Google Scholar] [CrossRef]

- Sliwa, T.; Sapińska-Śliwa, A.; Wysogląd, T.; Kowalski, T.; Konopka, I. Strength Tests of Hardened Cement Slurries for Energy Piles, with the Addition of Graphite and Graphene, in Terms of Increasing the Heat Transfer Efficiency. Energies 2021, 14, 1190. [Google Scholar] [CrossRef]

- Lee, S.; Kim, B.; Seo, J.; Cho, S. Beneficial Use of MIBC in Metakaolin-Based Geopolymers to Improve Flowability and Compressive Strength. Materials 2020, 13, 3663. [Google Scholar] [CrossRef] [PubMed]

- Liu, X.; Wang, Z.; Zheng, Y.; Cui, S.; Lan, M.; Li, H.; Zhu, J.; Liang, X. Preparation, Characterization and Performances of Powdered Polycarboxylate Superplasticizer with Bulk Polymerization. Materials 2014, 7, 6169–6183. [Google Scholar] [CrossRef] [Green Version]

- Cheng, B.; Yao, C.; Xiong, J.; Liu, X.; Zhang, H.; Zhang, S. Effects of Sodium Hexametaphosphate Addition on the Dispersion and Hydration of Pure Calcium Aluminate Cement. Materials 2020, 13, 5229. [Google Scholar] [CrossRef]

- Carpenter, R.B. Matrix Control Cementing Slurry. U.S. Patent No. 4,569,395, 11 February 1986. [Google Scholar]

- Chatterji, S. On the properties of freshly made Portland cement paste. Part 2. Sedimentation and strength of flocculation. Cem. Concr. Res. 1988, 18, 615–620. [Google Scholar] [CrossRef]

- ISO. Cements and Materials for Cementing Holes. In Part 4: Preparation and Testing of Cement Slurries under Atmospheric Pressure; PN-EN ISO 10426-4:2006 Oil and Gas Industry; ISO: Geneva, Switzerland, 2006. [Google Scholar]

- ISO. Cements and Materials for Cementing Holes. In Lot 2: Testing of Drilling Cements; PN–EN ISO 10426-2:2006 Oil and Gas Industry; ISO: Geneva, Switzerland, 2006. [Google Scholar]

- ISO. Cement Testing Methods. In Compressive Strength Determination; PN–EN 196-1:2016-07; ISO: Geneva, Switzerland, 2016. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).