The Challenge for Building Integration of Highly Transparent Photovoltaics and Photoelectrochromic Devices

Abstract

1. Introduction

2. Novel Technologies for Glazing: A Useful Glossary

3. Novel Technologies for Semitransparent PVs

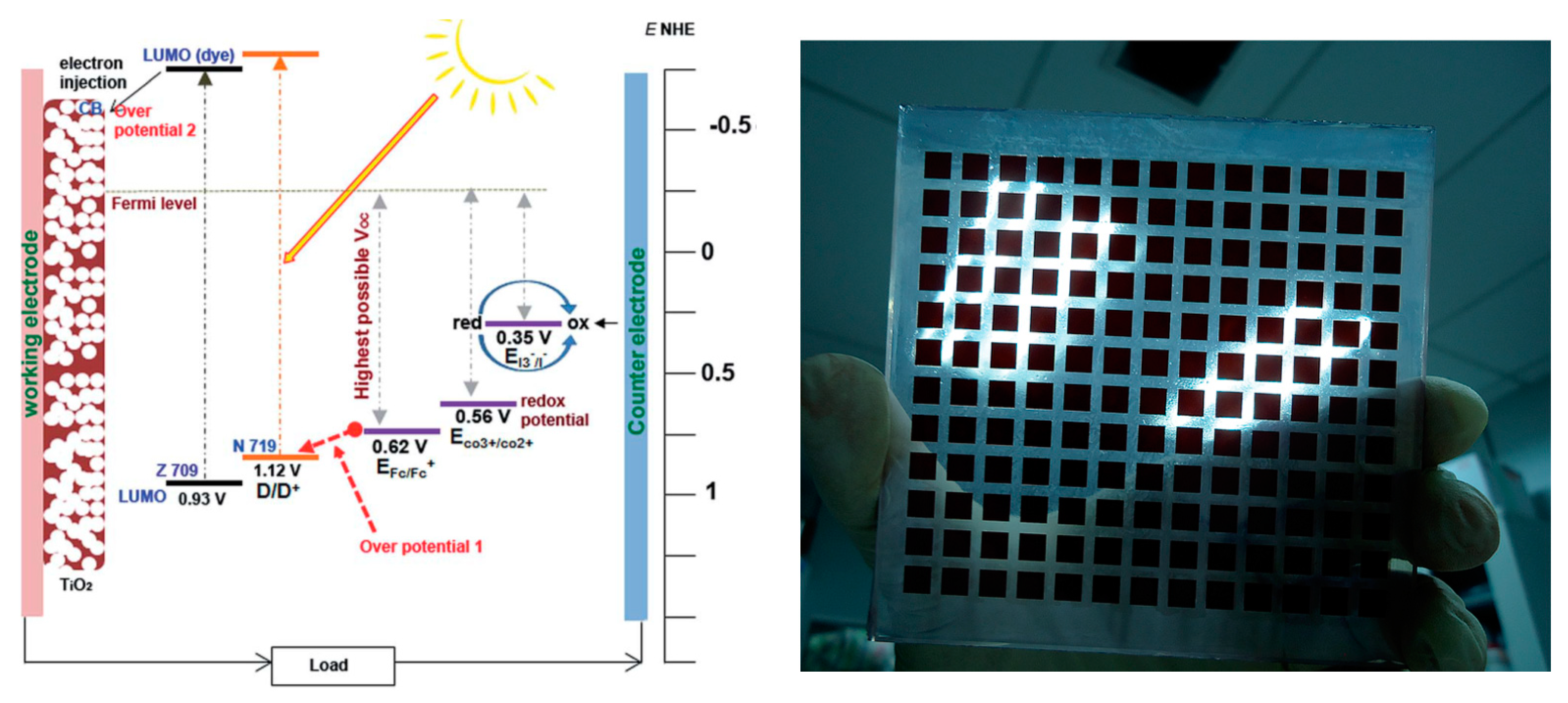

3.1. Dye Sensitized Solar Cells (DSSCs)

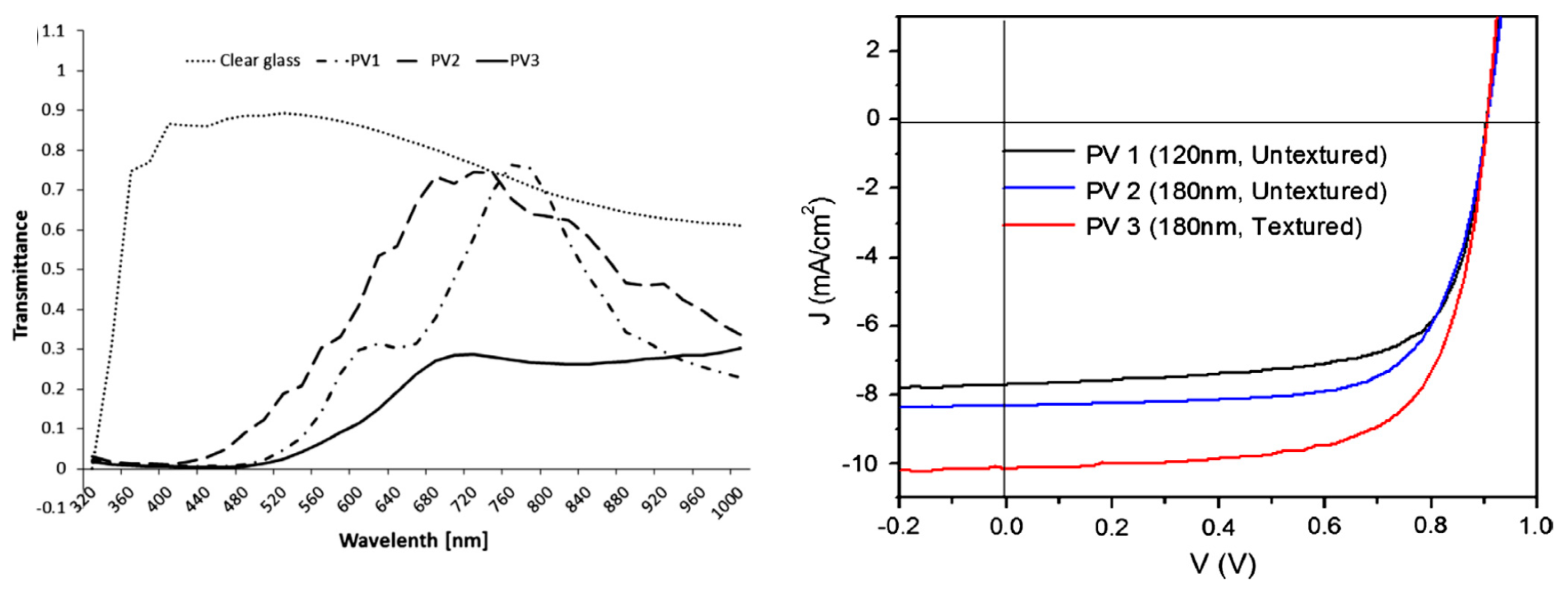

3.2. Amorphous Silicon Solar Cells and Thin Film Solar Cells

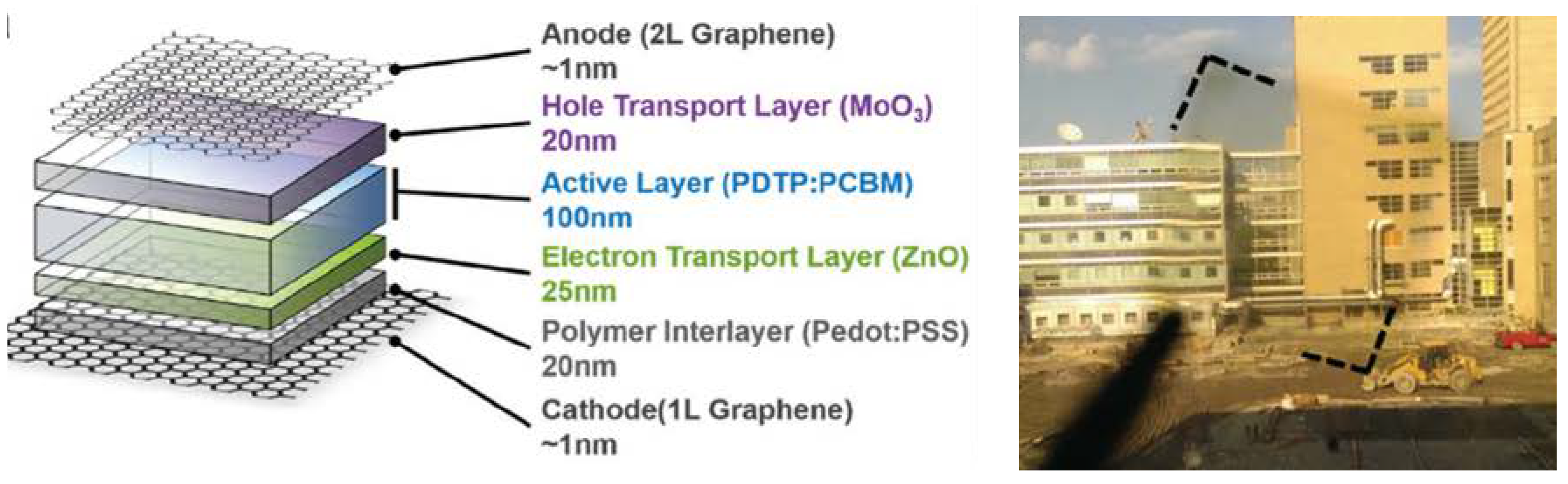

3.3. Organic Solar Cells

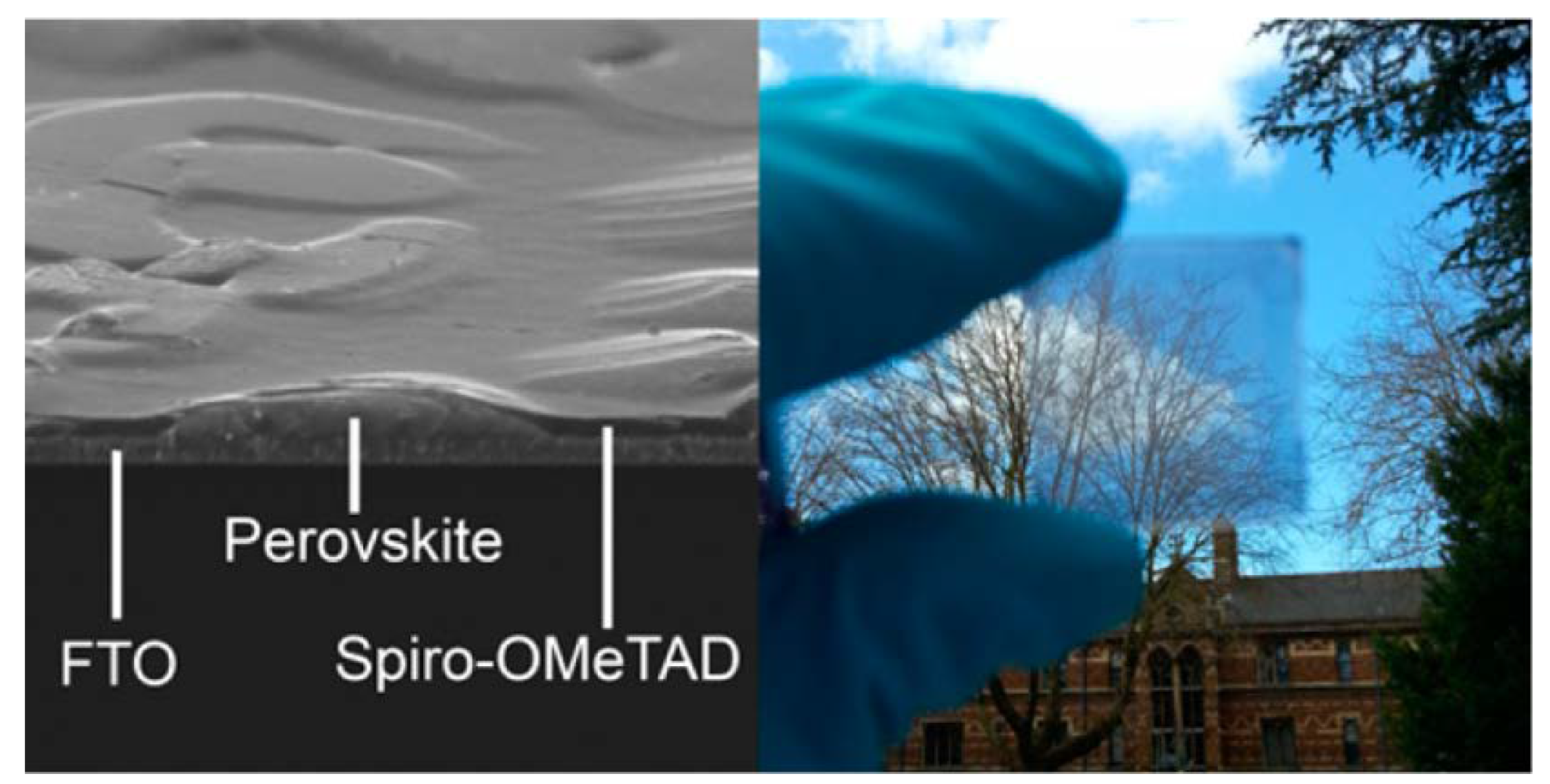

3.4. Perovskite-Based Heterojunction Solar Cells

3.5. Open issues for Building Integration of Semi-Transparent PVs

4. The Architectural Evolution of Chromogenics for Building Integration

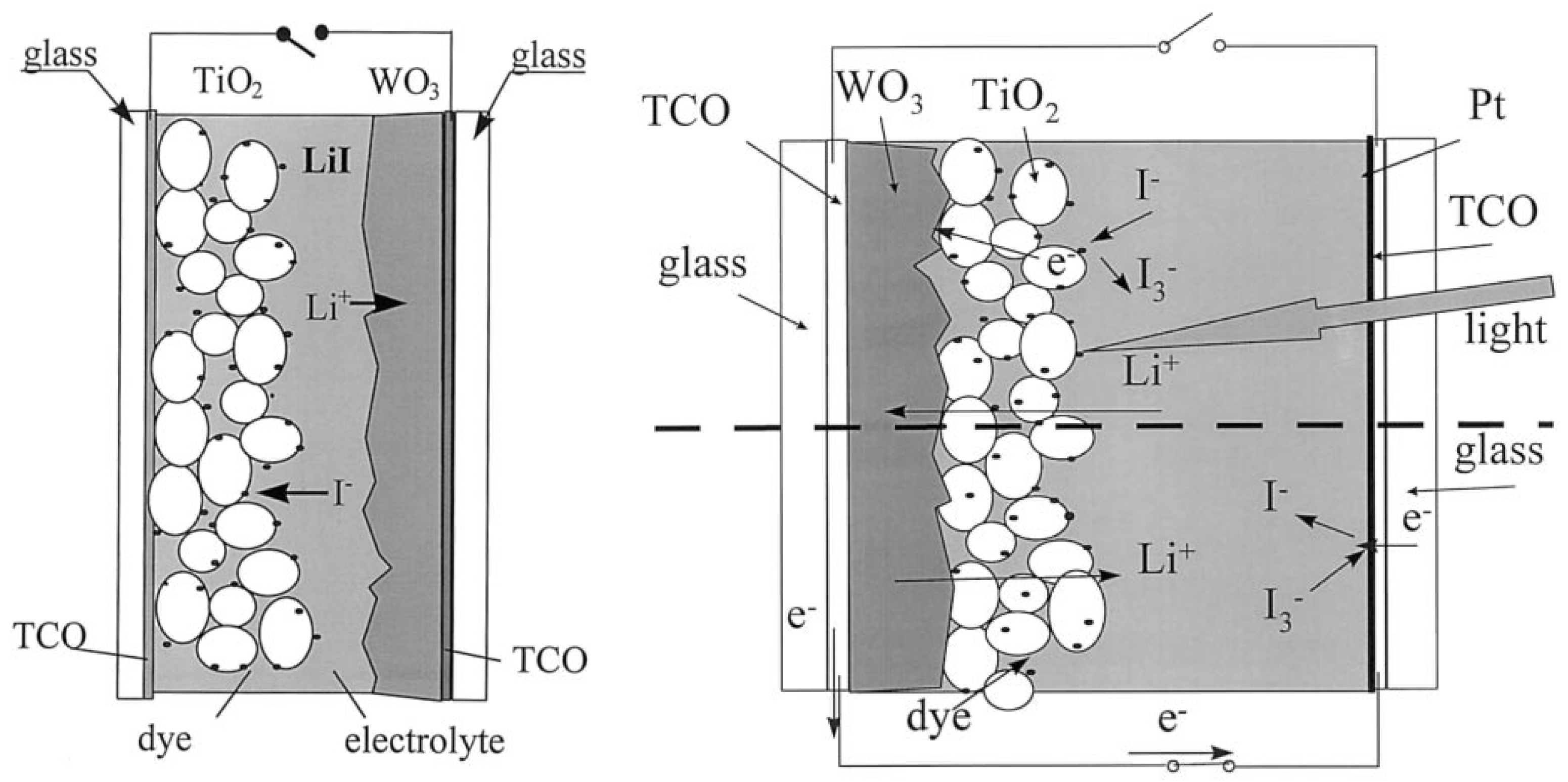

4.1. A chronological Review of PECDs

4.2. Photovoltachromic Devices: One Step Forward for PECDs

5. Building Integration of Multifunctional Devices

5.1. Effects on Visual Comfort Durability and Life-Cycle Assessment of Devices

5.2. Open Issues, Towards Smart Windows Adopting a Research-Driven Development

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Nations Unies Convention. Cadre sur les changements climatiques. Proc. Cop. 2015, 21, 39. [Google Scholar]

- Armaroli, N.; Balzani, V. Solar Electricity and Solar Fuels: Status and Perspectives in the Context of the Energy Transition. Chem. A Eur. J. 2016, 22, 32–57. [Google Scholar] [CrossRef] [PubMed]

- Armaroli, N.; Balzani, V. Towards an electricity-powered world. Energy Environ. Sci. 2011, 4, 3193. [Google Scholar] [CrossRef]

- Parliament, E. Directive 2010/31/EU of the European Parlament and of the Council of 19 May 2010 on the Energy Performance of Buildings (recast); The European Parliament: Strasbourg, France; Council of the European Union: Brussels, Belgium, 2010; pp. 13–35. [Google Scholar]

- Pichot, F.; Ferrere, S.; Pitts, R.J.; Gregg, B.A. Flexible solid-state photoelectrochromic windows. J. Electrochem. Soc. 1999, 146, 4324–4326. [Google Scholar] [CrossRef]

- Lampert, C.M. Optical switching technology for glazings. Thin Solid Films 1993, 236, 6–13. [Google Scholar] [CrossRef]

- Reilly, S.; Arasteh, D.; Selkowitz, S. Thermal and optical analysis of switchable window glazings. Sol. Energy Mater. 1991, 22, 1–14. [Google Scholar] [CrossRef]

- Zhang, W.; Lu, L.; Peng, J.; Song, A. Comparison of the overall energy performance of semi-transparent photovoltaic windows and common energy-efficient windows in Hong Kong. Energy Build. 2016, 128, 511–518. [Google Scholar] [CrossRef]

- Olivieri, L.; Caamaño-Martín, E.; Moralejo-Vázquez, F.J.; Martín-Chivelet, N.; Olivieri, F.; Neila-Gonzalez, F.J. Energy saving potential of semi-transparent photovoltaic elements for building integration. Energy 2014, 76, 572–583. [Google Scholar] [CrossRef]

- Benemann, J.; Chehab, O.; Schaar-Gabriel, E. Building-integrated PV modules. Sol. Energy Mater. Sol. Cells 2001, 67, 345–354. [Google Scholar] [CrossRef]

- Wang, Y.; Runnerstom, E.L.; Milliron, D.J. Switchable Materials for Smart Windows. Ann. Rev. Chem. Biolmol. Eng. 2016, 7, 1–22. [Google Scholar] [CrossRef]

- Rosseinsky, D.R.; Mortimer, R.J. Electrochromic Materials and Devices; Mortimer, R.J., Rosseinsky, D.R., Monk, P.M.S., Eds.; Wiley-VCH Verlag GmbH & Co. KGaA: Weinheim, Germany, 2013; ISBN 9783527679850. [Google Scholar]

- Azens, A.; Granqvist, C.G. Electrochromic smart windows: Energy efficiency and device aspects. J. Solid State Electrochem. 2003, 7, 64–68. [Google Scholar] [CrossRef]

- Granqvist, C.G. Electrochromics and Thermochromics: Towards a New Paradigm for Energy Efficient Buildings. Mater. Today Proc. 2016, 3, S2–S11. [Google Scholar] [CrossRef]

- Granqvist, C.G.; Bayrak Pehlivan, I.; Niklasson, G.A. Electrochromics on a roll: Web-coating and lamination for smart windows. Surf. Coatings Technol. 2017, 336, 6–11. [Google Scholar]

- Jonsson, A.; Roos, A. Evaluation of control strategies for different smart window combinations using computer simulations. Sol. Energy 2010, 84, 1–9. [Google Scholar] [CrossRef]

- Gugliermetti, F.; Bisegna, F. Visual and energy management of electrochromic windows in Mediterranean climate. Build. Environ. 2003, 38, 479–492. [Google Scholar] [CrossRef]

- Piccolo, A.; Simone, F. Energy performance of an all solid state electrochromic prototype for smart window applications. Energy Procedia 2015, 78, 110–115. [Google Scholar] [CrossRef][Green Version]

- Bechinger, C.; Ferrere, S.; Zaban, A.; Sprague, J.; Gregg, B.A. Photoelectrochromic windows and displays. Nature 1996, 383, 608–610. [Google Scholar] [CrossRef]

- Deb, S.K.; Lee, S.H.; Edwin Tracy, C.; Roland Pitts, J.; Gregg, B.A.; Branz, H.M. Stand-alone photovoltaic-powered electrochromic smart window. Electrochim. Acta 2001, 46, 2125–2130. [Google Scholar] [CrossRef]

- Gregg, B.A. Photoelectrochromic applications. Endeavour 1997, 21, 52–55. [Google Scholar] [CrossRef]

- Heinstein, P.; Ballif, C.; Perret-Aebi, L.E. Building integrated photovoltaics (BIPV): Review, potentials, barriers and myths. Green 2013, 3, 125–156. [Google Scholar] [CrossRef]

- Sprenger, W.; Wilson, H.R.; Kuhn, T.E. Electricity yield simulation for the building-integrated photovoltaic system installed in the main building roof of the Fraunhofer Institute for Solar Energy Systems ISE. Sol. Energy 2016, 135, 633–643. [Google Scholar] [CrossRef]

- Jelle, B.P.; Breivik, C.; Drolsum Røkenes, H. Building integrated photovoltaic products: A state-of-the-art review and future research opportunities. Sol. Energy Mater. Sol. Cells 2012, 100, 69–96. [Google Scholar] [CrossRef]

- Oliver, M.; Jackson, T. Energy and economic evaluation of building-integrated photovoltaics. Energy 2001, 26, 431–439. [Google Scholar] [CrossRef]

- Jelle, B.P.; Breivik, C. The path to the building integrated photovoltaics of tomorrow. Energy Procedia 2012, 20, 78–87. [Google Scholar] [CrossRef]

- Saifullah, M.; Gwak, J.; Yun, J.H. Comprehensive review on material requirements, present status, and future prospects for building-integrated semitransparent photovoltaics (BISTPV). J. Mater. Chem. A 2016, 4, 8512–8540. [Google Scholar] [CrossRef]

- Jelle, B.P. Electrochromic Smart Windows for Dynamic Daylight and Solar Energy Control in Buildings. In Electrochromic Materials and Devices; Monk, P.M.S., Mortimer, R.J., Rosseinsky, D.R., Eds.; Wiley: Hoboken, NJ, USA, 2015; pp. 419–502. [Google Scholar]

- Eperon, G.E.; Burlakov, V.M.; Goriely, A.; Snaith, H.J. Neutral color semitransparent microstructured perovskite solar cells. ACS Nano 2014, 8, 591–598. [Google Scholar] [CrossRef]

- Boyce, P.; Eklund, N.; Mangum, S.; Saalfield, C.; Tang, L. Minimum acceptable transmittance of glazing. Light. Res. Technol. 1995, 27, 145–152. [Google Scholar] [CrossRef]

- Baetens, R.; Jelle, B.P.; Gustavsen, A. Properties, requirements and possibilities of smart windows for dynamic daylight and solar energy control in buildings: A state-of-the-art review. Sol. Energy Mater. Sol. Cells 2010, 94, 87–105. [Google Scholar] [CrossRef]

- Cannavale, A.; Cossari, P.; Eperon, G.E.; Colella, S.; Fiorito, F.; Gigli, G.; Snaith, H.J.; Listorti, A. Forthcoming perspectives of photoelectrochromic devices: A critical review. Energy Environ. Sci. 2016, 9, 2682–2719. [Google Scholar] [CrossRef]

- Hagfeldt, A.; Boschloo, G.; Sun, L.; Kloo, L.; Pettersson, H.; Kalyanasundaram, E.K.; Bertoz, M.; Bisquert, J.; De Angelis, F.; Desilvestro, H.; et al. Dye-sensitized solar cells. Chem. Rev. 2010, 110, 6595–6663. [Google Scholar] [CrossRef]

- Manca, M.; Beke, S.; De Marco, L.; Pareo, P.; Qualtieri, A.; Cannavale, A.; Brandi, F.; Gigli, G. 3D photoelectrode for dye solar cells realized by laser micromachining of photosensitive glass. J. Phys. Chem. C 2014, 118, 17100–17107. [Google Scholar] [CrossRef]

- Carlson, D.E.; Wronski, C.R. Amorphous silicon solar cell. Appl. Phys. Lett. 1976, 28, 671–673. [Google Scholar] [CrossRef]

- Yalçin, L.; Öztürk, R. Performance comparison of c-Si, mc-Si and a-Si thin film PV by PVsyst simulation. J. Optoelectron. Adv. Mater. 2013, 15, 326–334. [Google Scholar]

- Song, Y.; Chang, S.; Gradecak, S.; Kong, J. Visibly-Transparent Organic Solar Cells on Flexible Substrates with All-Graphene Electrodes. Adv. Energy Mater. 2016, 6, 1600847. [Google Scholar] [CrossRef]

- Della Gaspera, E.; Peng, Y.; Hou, Q.; Spiccia, L.; Bach, U.; Jasieniak, J.J.; Cheng, Y.B. Ultra-thin high efficiency semitransparent perovskite solar cells. Nano Energy 2015, 13, 249–257. [Google Scholar] [CrossRef]

- Kim, T.; Kim, J.H.; Kang, T.E.; Lee, C.; Kang, H.; Shin, M.; Wang, C.; Ma, B.; Jeong, U.; Kim, T.S.; et al. Flexible, highly efficient all-polymer solar cells. Nat. Commun. 2015, 6, 1–7. [Google Scholar] [CrossRef]

- O’Regan, B.; Gratzel, M. A Low-Cost, High-Efficiency Solar-Cell Based on Dye-Sensitized Colloidal TiO2 Films. Nature 1991, 353, 737–740. [Google Scholar] [CrossRef]

- Gong, J.; Sumathy, K.; Qiao, Q.; Zhou, Z. Review on dye-sensitized solar cells (DSSCs): Advanced techniques and research trends. Renew. Sustain. Energy Rev. 2017, 68, 234–246. [Google Scholar] [CrossRef]

- Lee, C.; Li, C.; Ho, K. Use of organic materials in dye-sensitized solar cells. Biochem. Pharmacol. 2017, 20, 267–283. [Google Scholar] [CrossRef]

- Parisi, M.L.; Maranghi, S.; Basosi, R. The evolution of the dye sensitized solar cells from Grätzel prototype to up-scaled solar applications: A life cycle assessment approach. Renew. Sustain. Energy Rev. 2014, 39, 124–138. [Google Scholar] [CrossRef]

- Selvaraj, P.; Ghosh, A.; Mallick, T.K.; Sundaram, S. Investigation of semi-transparent dye-sensitized solar cells for fenestration integration. Renew. Energy 2019, 141, 516–525. [Google Scholar] [CrossRef]

- Fakharuddin, A.; Jose, R.; Brown, T.M.; Fabregat-Santiago, F.; Bisquert, J. A perspective on the production of dye-sensitized solar modules. Energy Environ. Sci. 2014, 7, 3952–3981. [Google Scholar] [CrossRef]

- Kitamura, T.; Okada, K.; Matsui, H.; Tanabe, N. Durability of Dye-Sensitized Solar Cells and Modules. J. Sol. Energy Eng. 2016, 132, 1–7. [Google Scholar] [CrossRef]

- Reale, A.; Cinà, L.; Malatesta, A.; De Marco, R.; Brown, T.M.; Di Carlo, A. Estimation of Energy Production of Dye-Sensitized Solar Cell Modules for Building-Integrated Photovoltaic Applications. Energy Technol. 2014, 2, 531–541. [Google Scholar] [CrossRef]

- El Chaar, L.; Lamont, L.A.; El Zein, N. Review of photovoltaic technologies. Renew. Sustain. Energy Rev. 2011, 15, 2165–2175. [Google Scholar] [CrossRef]

- Fritzsche, H. Photo-induced structural changes associated with the Staebler-Wronski effect in hydrogenated amorphous silicon. Solid State Commun. 1995, 94, 953–955. [Google Scholar] [CrossRef]

- Águas, H.; Ram, S.K.; Araújo, A.; Gaspar, D.; Vicente, A.; Filonovich, S.A.; Fortunato, E.; Martins, R.; Ferreira, I. Silicon thin film solar cells on commercial tiles. Energy Environ. Sci. 2011, 4, 4620. [Google Scholar] [CrossRef]

- Narain, J.; Jin, W.; Ghandehari, M.; Wilke, E.; Shukla, N.; Berardi, U.; El-Korchi, T.; Van Dessel, S. Design and Application of Concrete Tiles Enhanced with Microencapsulated Phase-Change Material. J. Archit. Eng. 2016, 22, 05015003. [Google Scholar] [CrossRef]

- Chae, Y.T.; Kim, J.; Park, H.; Shin, B. Building energy performance evaluation of building integrated photovoltaic (BIPV) window with semi-transparent solar cells. Appl. Energy 2014, 129, 217–227. [Google Scholar] [CrossRef]

- Krebs, F.C.; Espinosa, N.; Hösel, M.; Søndergaard, R.R.; Jørgensen, M. 25th anniversary article: Rise to power-OPV-based solar parks. Adv. Mater. 2014, 26, 29–39. [Google Scholar] [CrossRef]

- Chen, C.C.; Dou, L.; Zhu, R.; Chung, C.H.; Song, T.B.; Zheng, Y.B.; Hawks, S.; Li, G.; Weiss, P.S.; Yang, Y. Visibly transparent polymer solar cells produced by solution processing. ACS Nano 2012, 6, 7185–7190. [Google Scholar] [CrossRef] [PubMed]

- Van Der Wiel, B.; Egelhaaf, H.J.; Issa, H.; Roos, M.; Henze, N. Market readiness of organic photovoltaics for building integration. Twent. Century Music 2014, 1639. [Google Scholar] [CrossRef]

- Granqvist, C.G. Transparent conductors as solar energy materials: A panoramic review. Sol. Energy Mater. Sol. Cells 2007, 91, 1529–1598. [Google Scholar] [CrossRef]

- Zhang, S.; Lanty, G.; Lauret, J.S.; Deleporte, E.; Audebert, P.; Galmiche, L. Synthesis and optical properties of novel organic-inorganic hybrid nanolayer structure semiconductors. Acta Mater. 2009, 57, 3301–3309. [Google Scholar] [CrossRef]

- Green, M.; Ho-baillie, A. The emergence of perovskite solar cells. Nat. Photonics 2014, 8, 506–514. [Google Scholar] [CrossRef]

- Kim, H.S.; Lee, C.R.; Im, J.H.; Lee, K.B.; Moehl, T.; Marchioro, A.; Moon, S.J.; Humphry-Baker, R.; Yum, J.H.; Moser, J.E.; et al. Lead iodide perovskite sensitized all-solid-state submicron thin film mesoscopic solar cell with efficiency exceeding 9%. Sci. Rep. 2012, 2, 1–7. [Google Scholar] [CrossRef] [PubMed]

- Chang, N.L.; Yi Ho-Baillie, A.W.; Basore, P.A.; Young, T.L.; Evans, R.; Egan, R.J. A manufacturing cost estimation method with uncertainty analysis and its application to perovskite on glass photovoltaic modules. Prog. Photovolt. Res. Appl. 2017, 25, 390–405. [Google Scholar] [CrossRef]

- Qin, P.; Tanaka, S.; Ito, S.; Tetreault, N.; Manabe, K.; Nishino, H.; Nazeeruddin, M.K.; Grätzel, M. Inorganic hole conductor-based lead halide perovskite solar cells with 12.4% conversion efficiency. Nat. Commun. 2014, 5, 1–6. [Google Scholar] [CrossRef]

- Eperon, G.E.; Leijtens, T.; Bush, K.A.; Prasanna, R.; Green, T.; Wang, J.T.; Mcmeekin, D.P.; Volonakis, G.; Milot, R.L.; May, R.; et al. Perovskite-perovskite tandem photovoltaics with optimized bandgaps. Science 2016, 9717, 1–10. [Google Scholar]

- NREL Best Research-Cell Efficiency Chart. Available online: https://www.nrel.gov/pv/cell-efficiency.html (accessed on 19 November 2019).

- Park, N.G. Research Direction toward Scalable, Stable, and High Efficiency Perovskite Solar Cells. Adv. Energy Mater. 2019, 1903106, 1–14. [Google Scholar] [CrossRef]

- Noel, N.K.; Stranks, S.D.; Abate, A.; Wehrenfennig, C.; Guarnera, S.; Haghighirad, A.-A.; Sadhanala, A.; Eperon, G.E.; Pathak, S.K.; Johnston, M.B.; et al. Lead-free organic–inorganic tin halide perovskites for photovoltaic applications. Energy Environ. Sci. 2014, 7, 3061–3068. [Google Scholar] [CrossRef]

- Christians, J.A.; Schulz, P.; Tinkham, J.S.; Schloemer, T.H.; Harvey, S.P.; Tremolet De Villers, B.J.; Sellinger, A.; Berry, J.J.; Luther, J.M. Tailored interfaces of unencapsulated perovskite solar cells for 1000 hour operational stability. Nat. Energy 2018, 3, 68–74. [Google Scholar] [CrossRef]

- Park, N.-G.; Grätzel, M.; Miyasaka, T.; Zhu, K.; Emery, K. Towards stable and commercially available perovskite solar cells. Nat. Energy 2016, 1, 16152. [Google Scholar] [CrossRef]

- Song, Z.; McElvany, C.L.; Phillips, A.B.; Celik, I.; Krantz, P.W.; Watthage, S.C.; Liyanage, G.K.; Apul, D.; Heben, M.J. A technoeconomic analysis of perovskite solar module manufacturing with low-cost materials and techniques. Energy Environ. Sci. 2017, 10, 1297–1305. [Google Scholar] [CrossRef]

- Eperon, G.E.; Stranks, S.D.; Menelaou, C.; Johnston, M.B.; Herz, L.M.; Snaith, H.J. Formamidinium lead trihalide: A broadly tunable perovskite for efficient planar heterojunction solar cells. Energy Environ. Sci. 2014, 7, 982. [Google Scholar] [CrossRef]

- Zhang, W.; Anaya, M.; Lozano, G.; Calvo, M.E.; Johnston, M.B.; Míguez, H.; Snaith, H.J. Highly efficient perovskite solar cells with tunable structural color. Nano Lett. 2015, 15, 1698–1702. [Google Scholar] [CrossRef]

- Hörantner, M.T.; Nayak, P.K.; Mukhopadhyay, S.; Wojciechowski, K.; Beck, C.; McMeekin, D.; Kamino, B.; Eperon, G.E.; Snaith, H.J. Shunt-Blocking Layers for Semitransparent Perovskite Solar Cells. Adv. Mater. Interfaces 2016, 3, 1–7. [Google Scholar] [CrossRef]

- Aharon, S.; Layani, M.; Cohen, B.E.; Shukrun, E.; Magdassi, S.; Etgar, L. Self-Assembly of Perovskite for Fabrication of Semitransparent Perovskite Solar Cells. Adv. Mater. Interfaces 2015, 2, 1–6. [Google Scholar] [CrossRef]

- Ramírez Quiroz, C.O.; Levchuk, I.; Bronnbauer, C.; Salvador, M.; Forberich, K.; Heumüller, T.; Hou, Y.; Schweizer, P.; Spiecker, E.; Brabec, C.J. Pushing efficiency limits for semitransparent perovskite solar cells. J. Mater. Chem. A 2015, 3, 24071–24081. [Google Scholar] [CrossRef]

- Yang, R.J.; Zou, P.X.W. Building integrated photovoltaics (BIPV): Costs, benefits, risks, barriers and improvement strategy. Int. J. Constr. Manag. 2016, 16, 39–53. [Google Scholar] [CrossRef]

- Eke, R.; Senturk, A. Monitoring the performance of single and triple junction amorphous silicon modules in two building integrated photovoltaic (BIPV) installations. Appl. Energy 2013, 109, 154–162. [Google Scholar] [CrossRef]

- Kapsis, K.; Athienitis, A.K. A study of the potential benefits of semi-transparent photovoltaics in commercial buildings. Sol. Energy 2015, 115, 120–132. [Google Scholar] [CrossRef]

- Zomer, C.; Nobre, A.; Cassatella, P.; Reindl, T.; Rüther, R. The balance between aesthetics and performance in building-integrated photovoltaics in the tropics. Prog. Photovoltaics Res. Appl. 2013, 22, 744–756. [Google Scholar] [CrossRef]

- Lim, J.W.; Lee, S.H.; Lee, D.J.; Lee, Y.J.; Yun, S.J. Performances of amorphous silicon and silicon germanium semi-transparent solar cells. Thin Solid Films 2013, 547, 212–215. [Google Scholar] [CrossRef]

- Martellotta, F.; Cannavale, A.; Ayr, U. Comparing energy performance of different semi-transparent, building-integrated photovoltaic cells applied to “reference” buildings. Energy Procedia 2017, 126, 219–226. [Google Scholar] [CrossRef]

- Cannavale, A.; Hörantner, M.; Eperon, G.E.; Snaith, H.J.; Fiorito, F.; Ayr, U.; Martellotta, F. Building integration of semitransparent perovskite-based solar cells: Energy performance and visual comfort assessment. Appl. Energy 2017, 194, 94–107. [Google Scholar] [CrossRef]

- Nabil, A.; Mardaljevic, J. Useful daylight illuminances: A replacement for daylight factors. Energy Build. 2006, 38, 905–913. [Google Scholar] [CrossRef]

- Nabil, A.; Mardaljevic, J. Useful daylight illuminance: A new paradigm for assessing daylight in buildings. Light. Res. Technol. 2005, 37, 41–59. [Google Scholar] [CrossRef]

- Wienold, J.; Christoffersen, J. Evaluation methods and development of a new glare prediction model for daylight environments with the use of CCD cameras. Energy Build. 2006, 38, 743–757. [Google Scholar] [CrossRef]

- Cannavale, A.; Ayr, U.; Martellotta, F. Energetic and visual comfort implications of using perovskite-based building-integrated photovoltaic glazings. Energy Procedia 2017, 126, 636–643. [Google Scholar] [CrossRef]

- Cannavale, A.; Ierardi, L.; Hörantner, M.; Eperon, G.E.; Snaith, H.J.; Ayr, U.; Martellotta, F. Improving energy and visual performance in offices using building integrated perovskite-based solar cells: A case study in Southern Italy. Appl. Energy 2017, 205, 834–836. [Google Scholar] [CrossRef]

- Jelle, B.P. Building integrated photovoltaics: A concise description of the current state of the art and possible research pathways. Energies 2016, 9, 21. [Google Scholar] [CrossRef]

- Attoye, D.E.; Aoul, K.A.T.; Hassan, A. A review on building integrated photovoltaic façade customization potentials. Sustainability 2017, 9, 2287. [Google Scholar] [CrossRef]

- Li, Y.; Hagen, J.; Haarer, D. Novel photoelectrochromic cells containing a polyaniline layer and a dye-sensitized nanocrystalline TiO2 photovoltaic cell. Synth. Met. 1998, 94, 273–277. [Google Scholar] [CrossRef]

- Hauch, A.; Georg, A.; Baumgärtner, S.; Opara Krašovec, U.; Orel, B. New photoelectrochromic device. Electrochim. Acta 2001, 46, 2131–2136. [Google Scholar] [CrossRef]

- Liao, J.Y.; Ho, K.C. A photoelectrochromic device using a PEDOT thin film. J. New Mater. Electrochem. Syst. 2005, 8, 37–47. [Google Scholar]

- Krašovec, U.O.; Georg, A.; Georg, A.; Wittwer, V.; Luther, J.; Topič, M. Performance of a solid-state photoelectrochromic device. Sol. Energy Mater. Sol. Cells 2004, 84, 369–380. [Google Scholar] [CrossRef]

- Georg, A.; Georg, A.; Opara Krašovec, U. Photoelectrochromic window with Pt catalyst. Thin Solid Films 2006, 502, 246–251. [Google Scholar] [CrossRef]

- Santa-Nokki, H.; Kallioinen, J.; Korppi-Tommola, J. A dye-sensitized solar cell driven electrochromic device. Photochem. Photobiol. Sci. 2007, 6, 63–66. [Google Scholar] [CrossRef] [PubMed]

- Hsu, C.Y.; Lee, K.M.; Huang, J.H.; Justin Thomas, K.R.; Lin, J.T.; Ho, K.C. A novel photoelectrochromic device with dual application based on poly(3,4-alkylenedioxythiophene) thin film and an organic dye. J. Power Sources 2008, 185, 1505–1508. [Google Scholar] [CrossRef]

- Leftheriotis, G.; Syrrokostas, G.; Yianoulis, P. Development of photoelectrochromic devices for dynamic solar control in buildings. Sol. Energy Mater. Sol. Cells 2010, 94, 2304–2313. [Google Scholar] [CrossRef]

- Leftheriotis, G.; Syrrokostas, G.; Yianoulis, P. Partly covered photoelectrochromic devices with enhanced coloration speed and efficiency. Sol. Energy Mater. Sol. Cells 2012, 96, 86–92. [Google Scholar] [CrossRef]

- Dokouzis, A.; Theodosiou, K.; Leftheriotis, G. Assessment of the long-term performance of partly covered photoelectrochromic devices under insolation and in storage. Sol. Energy Mater. Sol. Cells 2018, 182, 281–293. [Google Scholar] [CrossRef]

- Theodosiou, Κ.; Dokouzis, A.; Antoniou, I.; Leftheriotis, G. Gel electrolytes for partly covered photoelectrochromic devices. Sol. Energy Mater. Sol. Cells 2019, 202, 110124. [Google Scholar] [CrossRef]

- Lin, C.-L.; Chen, C.-Y.; Yu, H.-F.; Ho, K.-C. Comparisons of the electrochromic properties of Poly(hydroxymethyl 3,4-ethylenedioxythiophene) and Poly(3,4- ethylenedioxythiophene) thin films and the photoelectrochromic devices using these thin films. Sol. Energy Mater. Sol. Cells 2019, 202, 110132. [Google Scholar] [CrossRef]

- Dokouzis, A.; Bella, F.; Theodosiou, K.; Gerbaldi, C.; Leftheriotis, G. Photoelectrochromic devices with cobalt redox electrolytes. Mater. Today Energy 2020, 15, 100365. [Google Scholar] [CrossRef]

- Shen, K.; Luo, G.; Liu, J.; Zheng, J.; Xu, C. Highly transparent photoelectrochromic device based on carbon quantum dots sensitized photoanode. Sol. Energy Mater. Sol. Cells 2019, 193, 372–378. [Google Scholar] [CrossRef]

- Guo, X.; Xu, Z.; Huang, J.; Zhang, Y.; Liu, X.; Guo, W. Photoelectrochromic smart windows powered by flexible dye-sensitized solar cell using CuS mesh as counter electrode. Mater. Lett. 2019, 244, 92–95. [Google Scholar] [CrossRef]

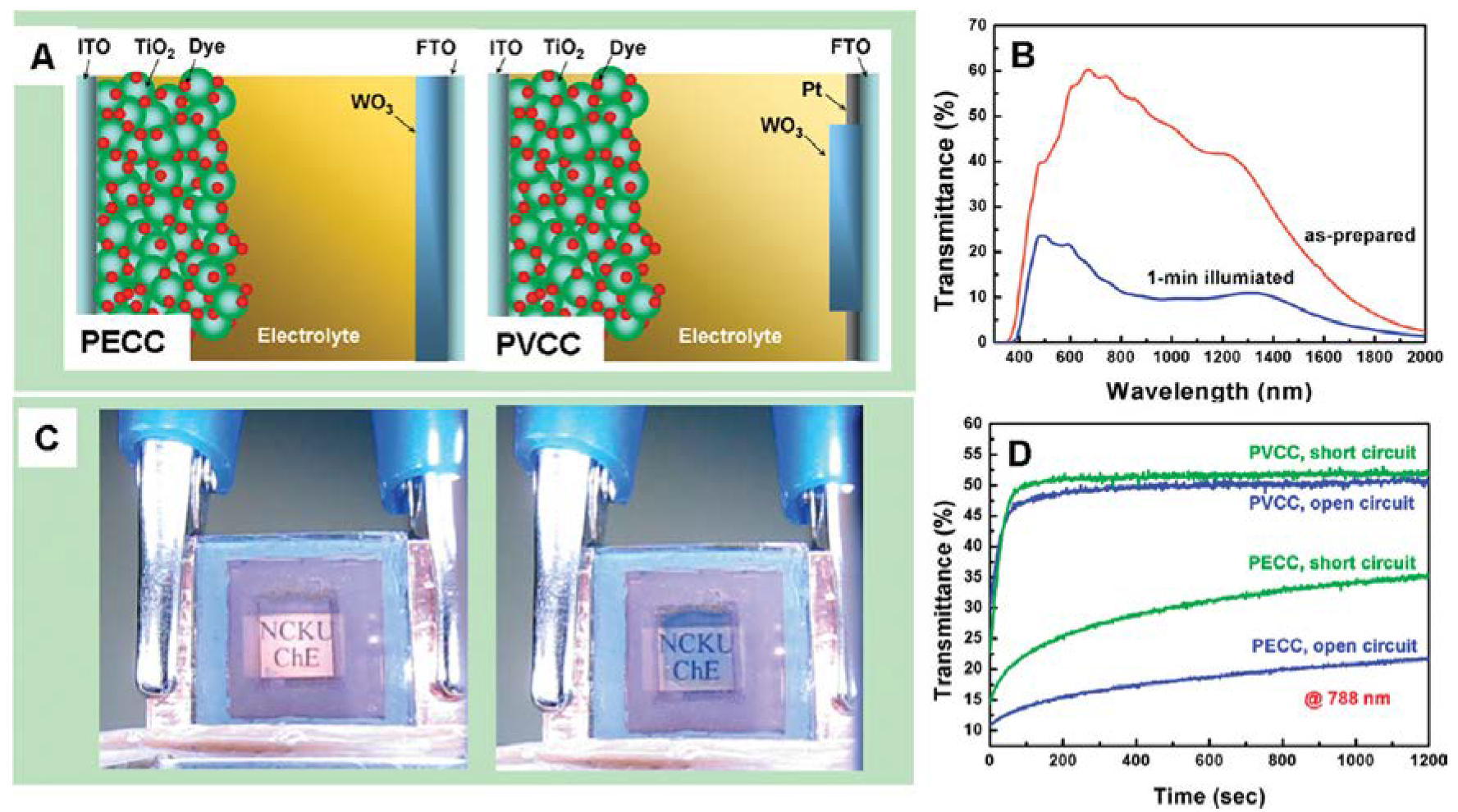

- Wu, J.J.; Hsieh, M.D.; Liao, W.P.; Wu, W.T.; Chen, J.S. Fast-switching photovoltachromic cells with tunable transmittance. ACS Nano 2009, 3, 2297–2303. [Google Scholar] [CrossRef]

- Cannavale, A.; Manca, M.; Malara, F.; De Marco, L.; Cingolani, R.; Gigli, G. Highly efficient smart photovoltachromic devices with tailored electrolyte composition. Energy Environ. Sci. 2011, 4, 2567–2574. [Google Scholar] [CrossRef]

- Yang, S.; Zheng, J.; Li, M.; Xu, C. A novel photoelectrochromic device based on poly(3,4-(2,2- dimethylpropylenedioxy)thiophene) thin film and dye-sensitized solar cell. Sol. Energy Mater. Sol. Cells 2012, 97, 186–190. [Google Scholar] [CrossRef]

- Huang, L.M.; Kung, C.P.; Hu, C.W.; Peng, C.Y.; Liu, H.C. Tunable photovoltaic electrochromic device and module. Sol. Energy Mater. Sol. Cells 2012, 107, 390–395. [Google Scholar] [CrossRef]

- Cannavale, A.; Manca, M.; De Marco, L.; Grisorio, R.; Carallo, S.; Suranna, G.P.; Gigli, G. Photovoltachromic device with a micropatterned bifunctional counter electrode. ACS Appl. Mater. Interfaces 2014, 6, 2415–2422. [Google Scholar] [CrossRef] [PubMed]

- Amasawa, E.; Sasagawa, N.; Kimura, M.; Taya, M. Design of a new energy-harvesting electrochromic window based on an organic polymeric dye, a cobalt couple, and PProDOT-Me2. Adv. Energy Mater. 2014, 4, 1–9. [Google Scholar] [CrossRef]

- Malara, F.; Cannavale, A.; Carallo, S.; Gigli, G. Smart windows for building integration: A new architecture for photovoltachromic devices. ACS Appl. Mater. Interfaces 2014, 6, 9290–9297. [Google Scholar] [CrossRef]

- Jensen, J.; Dam, H.F.; Reynolds, J.R.; Dyer, A.L.; Krebs, F.C. Manufacture and demonstration of organic photovoltaic-powered electrochromic displays using roll coating methods and printable electrolytes. J. Polym. Sci. Part B Polym. Phys. 2012, 50, 536–545. [Google Scholar] [CrossRef]

- Dyer, A.L.; Bulloch, R.H.; Zhou, Y.; Kippelen, B.; Reynolds, J.R.; Zhang, F. A vertically integrated solar-powered electrochromic window for energy efficient buildings. Adv. Mater. 2014, 26, 4895–4900. [Google Scholar] [CrossRef]

- Yang, M.-C.; Cho, H.-W.; Wu, J.-J. Fabrication of stable photovoltachromic cells using a solvent-free hybrid polymer electrolyte. Nanoscale 2014, 6, 9541–9544. [Google Scholar] [CrossRef]

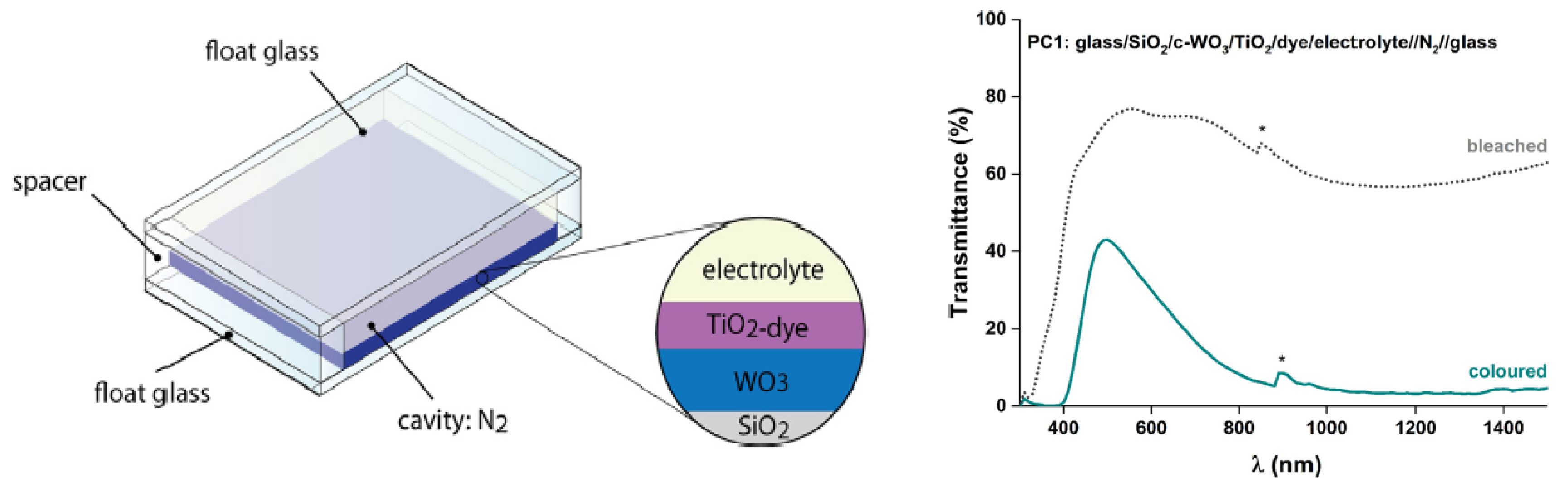

- Hočevar, M.; Opara Krašovec, U. A photochromic single glass pane. Sol. Energy Mater. Sol. Cells 2018, 186, 111–114. [Google Scholar] [CrossRef]

- Cannavale, A.; Eperon, G.E.; Cossari, P.; Abate, A.; Snaith, H.J.; Gigli, G. Perovskite photovoltachromic cells for building integration. Energy Environ. Sci. 2015, 8, 1578–1584. [Google Scholar] [CrossRef]

- Favoino, F.; Fiorito, F.; Cannavale, A.; Ranzi, G.; Overend, M. Optimal control and performance of photovoltachromic switchable glazing for building integration in temperate climates. Appl. Energy 2016, 178, 943–961. [Google Scholar] [CrossRef]

- Piccolo, A.; Simone, F. Effect of switchable glazing on discomfort glare from windows. Build. Environ. 2009, 44, 1171–1180. [Google Scholar] [CrossRef]

- Xie, Z.; Jin, X.; Chen, G.; Xu, J.; Chen, D.; Shen, G. Integrated smart electrochromic windows for energy saving and storage applications. Chem. Commun. 2014, 50, 608–610. [Google Scholar] [CrossRef] [PubMed]

- Cannavale, A.; Fiorito, F.; Resta, D.; Gigli, G. Visual comfort assessment of smart photovoltachromic windows. Energy Build. 2013, 65, 137–145. [Google Scholar] [CrossRef]

- Tavares, P.F.; Gaspar, A.R.; Martins, A.G.; Frontini, F. Evaluation of electrochromic windows impact in the energy performance of buildings in mediterranean climates. Energy Policy 2014, 67, 68–81. [Google Scholar] [CrossRef]

- Tavares, P.; Bernardo, H.; Gaspar, A.; Martins, A. Control criteria of electrochromic glasses for energy savings in mediterranean buildings refurbishment. Sol. Energy 2016, 134, 236–250. [Google Scholar] [CrossRef]

- Zinzi, M. Office worker preferences of electrochromic windows: A pilot study. Build. Environ. 2006, 41, 1262–1273. [Google Scholar] [CrossRef]

- Llordés, A.; Garcia, G.; Gazquez, J.; Milliron, D.J. Tunable near-infrared and visible-light transmittance in nanocrystal-in-glass composites. Nature 2013, 500, 323–326. [Google Scholar] [CrossRef]

- DeForest, N.; Shehabi, A.; Selkowitz, S.; Milliron, D.J. A comparative energy analysis of three electrochromic glazing technologies in commercial and residential buildings. Appl. Energy 2017, 192, 95–109. [Google Scholar] [CrossRef]

- Lee, E.S.; Dibartolomeo, D.L.; Selkowitz, S.E. Daylighting control performance of a thin-film ceramic electrochromic window: Field study results. Energy Build. 2006, 38, 30–44. [Google Scholar] [CrossRef]

- Lampert, C.M. Chromogenic smart materials. Mater. Today 2004, 7, 28–35. [Google Scholar] [CrossRef]

- Leftheriotis, G.; Syrrokostas, G.; Yianoulis, P. Photocoloration efficiency and stability of photoelectrochromic devices. Solid State Ionics 2013, 231, 30–36. [Google Scholar] [CrossRef]

- Pierucci, A.; Cannavale, A.; Martellotta, F.; Fiorito, F. Smart windows for carbon neutral buildings. A Life Cycle approach. Energy Build. 2018, 165, 160–171. [Google Scholar] [CrossRef]

- Traverse, C.J.; Pandey, R.; Barr, M.C.; Lunt, R.R. Emergence of highly transparent photovoltaics for distributed applications. Nat. Energy 2017, 2, 849–860. [Google Scholar] [CrossRef]

- Davy, N.C.; Sezen-edmonds, M.; Gao, J.; Lin, X.; Liu, A.; Yao, N.; Kahn, A. Pairing of near-ultraviolet solar cells with electrochromic windows for smart management of the solar spectrum. Nat. Energy 2017, 17104, 1–10. [Google Scholar]

- Gong, J.; Darling, S.B.; You, F. Perovskite photovoltaics: Life-cycle assessment of energy and environmental impacts. Energy Environ. Sci. 2015, 8, 1953–1968. [Google Scholar] [CrossRef]

- Ho, K.C.; Chen, H.W.; Hsu, C.Y. Photoelectrochromic Materials and Devices. Electrochromic Mater. Devices 2015, 593–622. [Google Scholar]

- Casini, M. Sustainable Solutions for Energy Efficiency of Buildings. In Proceedings of the 15th International Multidisciplinary Scientific GeoConference & EXPO SGEM 2015, Albena, Bulgaria, 16–25 June 2015; Volume 2, pp. 303–310. [Google Scholar]

- Cannavale, A.; Martellotta, F.; Cossari, P.; Gigli, G. Energy savings due to building integration of innovative solid-state electrochromic devices. Appl. Energy 2018, 225, 975–985. [Google Scholar] [CrossRef]

- Gorgolis, G.; Karamanis, D. Solar energy materials for glazing technologies. Sol. Energy Mater. Sol. Cells 2016, 144, 559–578. [Google Scholar] [CrossRef]

- Lee, E. Application issues for large-area electrochromic windows in commercial buildings. Sol. Energy Mater. Sol. Cells 2002, 71, 465–491. [Google Scholar] [CrossRef]

- Piccolo, A.; Simone, F. Performance requirements for electrochromic smart window. J. Build. Eng. 2015, 3, 94–103. [Google Scholar] [CrossRef]

- Pérez-Lombard, L.; Ortiz, J.; Pout, C. A review on buildings energy consumption information. Energy Build. 2008, 40, 394–398. [Google Scholar] [CrossRef]

- Granqvist, C.G.; Lansåker, P.C.; Mlyuka, N.R.; Niklasson, G.A.; Avendaño, E. Progress in chromogenics: New results for electrochromic and thermochromic materials and devices. Sol. Energy Mater. Sol. Cells 2009, 93, 2032–2039. [Google Scholar] [CrossRef]

- Tällberg, R.; Jelle, B.P.; Loonen, R.; Gao, T.; Hamdy, M. Comparison of the energy saving potential of adaptive and controllable smart windows: A state-of-the-art review and simulation studies of thermochromic, photochromic and electrochromic technologies. Sol. Energy Mater. Sol. Cells 2019, 200, 109828. [Google Scholar] [CrossRef]

- Costanzo, V.; Evola, G.; Marletta, L. Thermal and visual performance of real and theoretical thermochromic glazing solutions for office buildings. Sol. Energy Mater. Sol. Cells 2016, 149, 110–120. [Google Scholar] [CrossRef]

- Cipolloni, M.; Heynderickx, A.; Maurel, F.; Perrier, A.; Jacquemin, D.; Siri, O.; Ortica, F.; Favaro, G. Multiswitchable acidichromic and photochromic bisdiarylethene. An experimental and theoretical study. J. Phys. Chem. C 2011, 115, 23096–23106. [Google Scholar] [CrossRef]

- Zhang, J.; Zou, Q.; Tian, H. Photochromic materials: More than meets the eye. Adv. Mater. 2013, 25, 378–399. [Google Scholar] [CrossRef] [PubMed]

- Ke, Y.; Chen, J.; Lin, G.; Wang, S.; Zhou, Y.; Yin, J.; Lee, P.S.; Long, Y. Smart Windows: Electro-, Thermo-, Mechano-, Photochromics, and Beyond. Adv. Energy Mater. 2019, 9, 1–38. [Google Scholar] [CrossRef]

- Ortica, F. The role of temperature in the photochromic behaviour. Dye. Pigment. 2012, 92, 807–816. [Google Scholar] [CrossRef]

- Pal, S.K.; Alanne, K.; Jokisalo, J.; Siren, K. Energy performance and economic viability of advanced window technologies for a new Finnish townhouse concept. Appl. Energy 2016, 162, 11–20. [Google Scholar] [CrossRef]

| Technology | Device (or Material) Complexity | Modulation of Spectral Properties | Energy Consumption for Operation | User’s Control and Overriding | Energy Yield |

|---|---|---|---|---|---|

| Thermochromic | Single film deposition | Yes | No | No | No |

| Photochromic | Single film deposition | Yes | No | No | No |

| Electrochromic | Multilayer device; external circuitry and electronic control | Yes | Yes | Yes | No |

| Photoelectrochromic (PECD) | Multilayer device; external circuitry | Yes | No | Yes | No |

| Photovoltachromic (PVCD) | Multilayer device, external circuitry. Grid-connected. | Yes | No | Yes | Yes |

| Semi-transparent PVs | Multilayer device, external circuitry. Grid-connected. | No | No | Yes * | Yes |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cannavale, A.; Martellotta, F.; Fiorito, F.; Ayr, U. The Challenge for Building Integration of Highly Transparent Photovoltaics and Photoelectrochromic Devices. Energies 2020, 13, 1929. https://doi.org/10.3390/en13081929

Cannavale A, Martellotta F, Fiorito F, Ayr U. The Challenge for Building Integration of Highly Transparent Photovoltaics and Photoelectrochromic Devices. Energies. 2020; 13(8):1929. https://doi.org/10.3390/en13081929

Chicago/Turabian StyleCannavale, Alessandro, Francesco Martellotta, Francesco Fiorito, and Ubaldo Ayr. 2020. "The Challenge for Building Integration of Highly Transparent Photovoltaics and Photoelectrochromic Devices" Energies 13, no. 8: 1929. https://doi.org/10.3390/en13081929

APA StyleCannavale, A., Martellotta, F., Fiorito, F., & Ayr, U. (2020). The Challenge for Building Integration of Highly Transparent Photovoltaics and Photoelectrochromic Devices. Energies, 13(8), 1929. https://doi.org/10.3390/en13081929