Abstract

Slaughterhouse waste management is an important technological, economic, and environmental challenge. Recently, more and more attention has been paid to the possibility of obtaining biogas from waste generated by slaughterhouses. The aim of the paper was to examine the effect of an emulsifier addition in the form of a carboxymethyl cellulose solution to create animal waste fermentation media based on the quantity and quality of the generated biogas. The adopted research goal was achieved based on a laboratory experiment of methane fermenting poultry processing waste. The waste was divided into two fractions: soft (tissue) and hard (bone). A fat emulsifier in a concentration of 1%, 2.5%, 5%, and 10% of fresh weight of the substrate was added to each substrate sample made from the above fractions. The emulsifier used was a 55% carboxymethyl cellulose solution, since this emulsifier is most commonly used in food production. The experiment was conducted in order to determine how the addition of an emulsifier (55% carboxymethylcellulose solution) affects the hydration of fats during methane fermentation, as demonstrated on poultry slaughterhouse waste. The samples were subjected to static methane fermentation, according to the methodology of DIM DIN 38414(DIN Deutches Institut für Normung). The experiment lasted 30 days. The total amount of biogas obtained after fermentation was 398 mL·g−1 for the soft fraction and 402 mL·g−1 for the hard fraction. In the case of the soft waste fraction, the addition of carboxymethylcellulose at 1% of the mass to the biogas process increased the amount of obtained biogas by 16%. In the case of the hard fraction, no effect of the addition of emulsifier on the total amount of biogas obtained was identified. In each case, the biogas from substrates with added emulsifier contained less methane and slightly more carbon. The emulsifier added to the soft fraction of slaughterhouse waste from poultry processing allowed cutting the process of methanogenesis by over 50% while maintaining the efficiency of biogas production. In the case of biogasification of bone tissue, no unambiguous effect of the addition of emulsifier on the improvement of process efficiency was identified.

1. Introduction

Production of energy from biomass or organic waste materials is becoming increasingly important in developed countries. The policy on reducing greenhouse gas emissions, as well as the need to diversify energy sources, has become the foundation for the development of biomass fuel production technology [1]. One method of obtaining energy from biomass is to transform it in the process of anaerobic methane fermentation [2]. This allows obtaining energy in the form of gas, which can be used as a heat source or as a substrate for the production of electricity [3,4]. In most modern biogas plants, the input material is primarily various mixtures of manure and plants specially grown for this purpose, with the largest share of corn silage. However, the production of energy plants associated with the need to use large amounts of energy for agrotechnical treatments, to produce and use fertilizers and plant protection products, and to harvest and prepare the substrate. Therefore, the use of intentionally cultivated energy crops may be characterized by low energy efficiency and significant greenhouse gas emissions per unit of energy obtained. Therefore, the focus has recently shifted to the energy use of animal waste [5,6,7,8]. Thus far, the most common way to utilize such materials is thermal processing. However, this process is not very efficient, from both an energy and environmental point of view. The aspect of production optimization in terms of energy efficiency and environmental impact is an integral element of all modern quality management systems in primary production [9,10]. Obtaining energy from waste is a strategic element of sustainable waste management. The ecological aspect of the transformation of waste biomass using methane fermentation processes relates not only to obtaining energy from renewable sources but is also associated with the rational utilization of this waste. Moreover, it contributes to the reduction of greenhouse gas emitted from stored slaughterhouse waste and balances the production of energy from conventional sources [11,12]. The byproduct of methane fermentation is the post-fermentation sludge, which can be a valuable source of elements for plants if introduced into the soil. The use of digestate for fertilizing increases the level of carbon sequestration in the soil and is a factor supporting effective management of soil fertility. Structural and organizational changes in agriculture have led to a reduction in the use of organic fertilizers. In research related to the use of food industry waste for fertilizing purposes, special attention is paid to phosphorus, whose global resources will be exhausted by the late 21st century [13]. The use of this waste for biogas production, followed by the use of the obtained digestate for fertilization, may constitute an important link in the circulation of elements in agroecosystems as part of the implementation of rational agricultural production methods [14,15,16]. Improving the properties of the soil and enriching it with macro- and microelements reduces the demand for mineral fertilizers, the production of which also involves the emission of greenhouse gases. As a result of the methane fermentation process, the resulting digestate is free of pathogens of Salmonella and Escherichia coli bacteria, viruses, fungi, and parasites. The rate and effect of the disappearance of pathogens are affected by the parameters, such as pH, temperature, time, and level of volatile fatty acids. The sanitary aspect is an important role when the digestate is to be used for fertilizing [17].

For aquafarming and marine animal products, there is an increased risk of excessive accumulation of trace elements [18]. An important instrument supporting the development of methods of obtaining energy from waste is the EC (European Commission) legal acts, among which the most important is the Landfill Directive (1991/31/EC) [19], which imposes reduction of the amount of biodegradable waste sent to landfills, and the Framework Directive on waste (2008/98/EC) [20].

Based on the Regulation of the European Parliament and Council No. 1069/2009/EC of 21 October 2009 (1069/2009/EC 2009) [21], waste of animal origin is considered an animal byproduct. The regulation distinguishes three categories of waste in terms of animal and public health risk. Waste classified in Category 1 must be subjected to thermal utilization. Categories 2 and 3 are waste that can be used for biogas production. Waste generated during slaughter of poultry intended for food purposes is classified in Category 3. By law, such waste can be used for biogas after pasteurization at 70 °C for 60 min. The Act passed on 14 December 2012 on waste [22] does not include the provisions of the said Regulation, with the exception of products that are “intended for the landfill, for thermal transformation, or for use in a biogas plant or composting plant, in accordance with the said Regulation.” That is why waste of animal origin intended for utilization, e.g., in a biogas plant, is still considered waste under the Act.

The aim of the paper was to examine the effect of the addition in the form of a carboxymethyl cellulose solution to create animal waste fermentation media, based on the quantity and quality of biogas generated during methane fermentation.

2. Materials and Methods

The adopted research goal was achieved based on a laboratory experiment of methane fermenting slaughterhouse waste under certain technological conditions. The waste mass used in the experiment was a waste from poultry processing, code 02 02 03, in accordance with the Regulation of the Minister of the Environment on the waste catalog [23,24]. The waste used in the experiment belonged to category 3, animal byproducts, recognized as the category not posing a safety risk to people or the environment. The waste samples were divided into two groups: hard and soft tissue. The first included bone tissues (legs, heads) and cartilage and the second included stomach contents, fat, digestive tract, epithelial tissues, and muscles. The collected mass of waste was approximately 40 kg. The collected waste was homogenized, and its moisture content and dry organic matter content were determined. In soft tissues, the content of dry mass was 25.8% and in hard tissues, 31.55%. Organic dry mass in soft tissues was 83%, compared to dry mass, and in hard tissues, 79.5%, compared to dry mass. A fat emulsifier in a concentration of 1%, 2.5%, 5%, and 10% of fresh weight of feedstock was added to each substrate prepared based on these samples. The biomass was hydrated to 90% humidity, which is the optimal humidity for wet methane fermentation, and then placed in 2 dm3 fermentors, along with the inoculum. The support material was digestate from an agricultural biogas plant. The content in each of the fermentors was identical, i.e., 10% of the dry matter. Tests with such a fermentor content applied ensured that each organic molecule was surrounded with water. Each batch prepared with the addition of 55% carboxymethylcellulose solution was placed in four fermentors. The fifth fermentor, including only the inoculum, acted as the reference fermentor, against which the output from each of the four fermentors (with a batch containing the emulsifier addition in the form of 55% carboxymethyl cellulose solution) was compared.

Thus, prepared fermentors were placed in a chamber with temperature control. Next, the samples were subjected to static methane fermentation, according to the methodology of (DIN Deutches Institut für Normung) DIM DIN 38414. It consisted of a single introduction of substrates into the fermentation chambers, carrying out the process until its completion. The pH in the fermentors was maintained at 5.8–6.2 due to the alkalinity of the fats present in the fermented biomass. The appropriate pH was maintained due to the inoculation additive. Such a pH resulted from the chosen input medium, i.e., a digestate from an agricultural biogas plant, because the use of batches made from slaughterhouse waste and the fat emulsifier addition would then be tested by the authors on an industrial scale. Humidity of the digestate was approximately 96%, and its pH was approximately 6. Generally speaking, the optimum temperature of hydrolysis is between 30–50 °C and its optimum pH ranges between 5 and 7, although there is no evidence of improved hydrolytic activity below a pH of 7 [17]. The methane fermentation process lasted 30 days. The gas resulting from methane fermentation was collected in variable volume tanks for each fermentor. The NANO SENS 60 m was used to measure the moisture content of the produced biogas and to determine its chemical composition. The results of the parameters of the process carried out were read daily at the same time and automatically saved to the computer disk using a measuring software.

The Properties of the Tested Raw Materials

The components used in the research contained large amounts of protein and fats. In the raw waste of the soft fraction, the fat and protein content was 38.44 and 22.45, respectively, calculated per dry matter (Table 1). The hard fraction contained 34.39% protein and 13.22% fat. The ratio of the C:N content in the methane fermentation process is very important from the point of view of the efficiency of the methanogenesis process. The overall C:N ratio in the input material used in the methanogenesis process was 9.96 for soft tissue and 9.32 for hard tissue; the optimal C:N ratio in the methane fermentation feedstock material. The most optimal carbon to nitrogen value in the methanogenesis process ranges from 10–30:1. Values of this parameter for feedstock used in our own research were slightly below the optimal.

Table 1.

Properties of the biogas process feedstock in individual research objects [%].

3. Results

The results of the conducted research indicate that the addition of a fat emulsifier had a positive effect on the total biogas yield in the methane fermentation process, both in the fermentation of soft tissue and hard tissue, containing bone fraction, with a greater impact observed in the fermentation of the former. All the results shown in the graphs are the average of the four identical batches compared against the standard batch fermentor, in which only the inoculum was fermented. The standard deviation for all tested batches was 5 mL·g−1 TS. Such a low standard deviation is due to the fact that all the repetitions were made at the same time and under the same environmental conditions and that the batch was prepared uniformly and divided into four fermenters, according to the DIM DIN 38414 methodology. ANOVA (ANalysis Of Variance) was applied to analyze the results. The significance of mean differences among the objects was tested with the multiple comparison procedure, and Tukey’s range test was applied at a significance level of α = 0.05. Analysis was performed using the statistical software package Statistica v. 12.0. The Tukey’s test was used to identify samples with homogeneous biogas yields (StatSoft Inc., Tulsa, OK, USA).

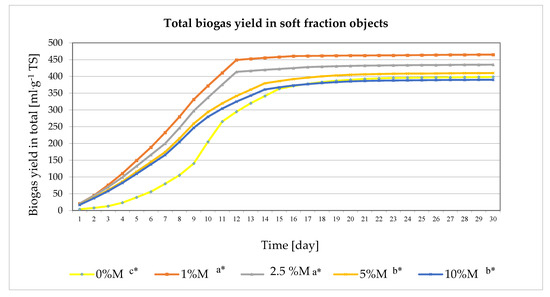

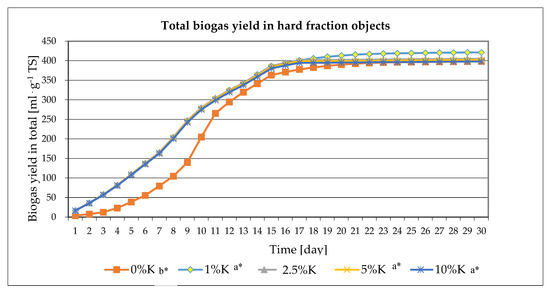

In the case of soft tissue, 398 mL of biogas per gram of dry weight of waste was obtained during a 30-day fermentation process (Figure 1). The addition of an emulsifier at 1% of the waste mass increased the total biogas yield by 16%. In this object, 465 mL of biogas per gram was obtained. Increasing the amount of emulsifier to 2.5% of the weight of the feedstock did not improve the efficiency of the process, and with the largest amount of emulsifier added, the amount of biogas was lower than in the control object. In the case of bone tissue, a smaller effect of the carboxymethylcellucose addition on the total amount of biogas obtained during methanogenesis was found (Figure 2). The total amount of biogas obtained under different amounts of the carboxymethyl cellulose addition was at a similar level.

Figure 1.

Total biogas yield in soft fraction objects. * Different letters mean statistically significant differences at the significance level p = 0.05.

Figure 2.

Total biogas yield in hard fraction objects. * Different letters mean statistically significant differences at the significance level p = 0.05.

A delay of fermentation was observed in both waste groups of objects without the added emulsifier (Figure 1 and Figure 2). Only from the 6th day, the acceleration of the biogas production process was observed. This was probably due to the start of fat emulsification in the soft fraction objects. The use of carboxymethylcellulose as a technological additive to the biogasing of slaughterhouse waste cut the methanogenesis process. On day 12 of the process, a biogas yield of 449.1 mL·g−1 of dry waste was obtained in the object with the 1% emulsifier added. In this period, only 294.7 mL·g−1 dry waste of gas was obtained from the control object. In the following days, no increase in biogas production was observed in the object, in which the technological additive was used. It can be assumed that, in the object with the smallest addition of emulsifier, the end of the methanogenesis process occurred on the 12th day. In the case of a control object, biogas production was observed until day 23, when the total biogas yield was 395.3 mL·g−1 dry weight of the waste. The results of the conducted experiment indicate that the use of a technological additive, carboxymethyl cellulose, allowed to cut the methanogenesis process of slaughterhouse waste by over 50%. In the case of the hard fraction, the addition of the emulsifier did not have such a pronounced effect on the length of the methanogenesis process. At the initial stage of the process, the process was delayed in the object with no emulsifier added, but on the 13th day of the process, the biogas yield in individual research objects was at a comparable level, regardless of the amount of emulsifier added.

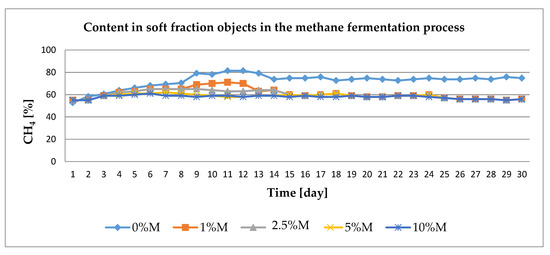

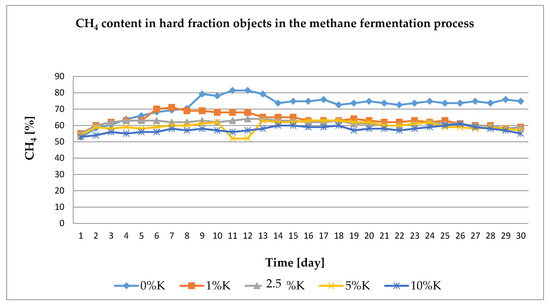

The methane content is the most important parameter impacting the quality of produced biogas. The results of the conducted research indicate that the highest methane content was obtained in biogas produced from waste without the addition of an emulsifier. For both types of waste, the biogas content on the last day of the process was 75%. In the case of objects with emulsifier additives, the methane content was approximately 50%, regardless of the amount of emulsifier added (Figure 3 and Figure 4). From the point of view of the quality of the obtained biogas, the best effects were observed on day 12 of the process. The methane content in the biogas obtained in the object without the added emulsifier was approximately. 81% at the time, while in the experimental object with 1% emulsifier added the value was approximately. 70% (Figure 3 and Figure 4). With larger emulsifier additions, a lower methane content in biogas was found on the 12th day of the process, which was determined as the completion of the methanogenesis process in objects with the addition of carboxymethylcellulose.

Figure 3.

Methane content in soft fraction objects in the methane fermentation process.

Figure 4.

Methane content in soft fraction objects in the methane fermentation process.

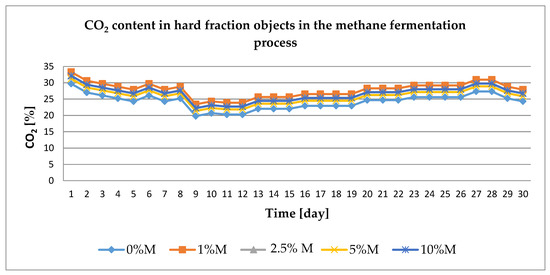

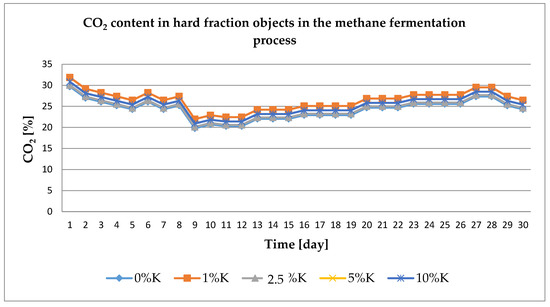

The dynamics of carbon dioxide content in individual research objects was similar, regardless of the amount of additive. The content of this gas in the obtained biogas decreased until the 9th day of the process. Afterwards, its amount increased slightly until the end of the experiment. The lowest content of this gas was found in the biogas obtained from waste without a technological additive, while the highest was identified in the object with a 1% addition of carboxymethyl cellulose (Figure 5 and Figure 6). There were slight differences in the carbon dioxide content in individual technological variants. On the 12th day of the process, which was considered strategic for the assessment of the proposed biogas technology, 20% CO2 was identified in the biogas from the control facility, while in the object with added carboxymethyl cellulose, this value was 23%. For bone tissue, the lowest amount of CO2 on the 12th day of the process was found in the object with 2.5% carboxymethyl cellulose addition per feedstock weight and in the control object, 21%, respectively. In biogas obtained from the object with 1% emulsifier, this value was 22%. The carbon dioxide content impaired the quality of biogas both from the energy point of view and in terms of the process’ carbon footprint.

Figure 5.

Carbon dioxide content in soft fraction objects in the methane fermentation process.

Figure 6.

Carbon dioxide content in hard fraction objects in the methane fermentation process.

4. Discussion

Waste of animal origin is characterized by a high content of protein and fats. Fermentation of fat-containing waste is associated with technological problems affecting the methane fermentation process [25]. The inhibition of the methane fermentation process of slaughter waste may be impacted by long chain fatty acids, which may have a detrimental effect on the development of methanogenic bacteria, especially acetogens and methanogens, responsible for the dynamics of the process [26,27]. Long chain fatty acids exhibit surfactant properties, inhibiting the fermentation process by adsorbing the microorganisms that are involved in it. Due to the low solubility of fat-containing waste, there is a risk of clogging of fermentation chambers and the formation of foams during the fermentation process [28]. Luostarinen et al. [29] confirm that methane fermentation of animal waste can be problematic, but the possibility of using such waste as a co-substrate should be considered [30]. In terms of efficiency of the animal waste management process, mixing it with a plant substrate is not beneficial. Animal waste comes from slaughterhouses or other meat processing plants, which are often distant from the sources of agricultural substrates. In addition, the use of a digestive created from a biogased animal-derived substrate may be subject to specific legal or technological requirements [31,32]. In the past, animal waste was mostly processed into bone meal. For sanitary reasons, these possibilities are currently limited, and, therefore, the main method of utilizing bone meal is currently to combust it with hard coal. From the point of view of energy yield, this is a good raw material, which is pointed out by Fryda et al. [33] and Vilvert et al. [34]. This way of managing animal waste leads to loss of elements that are contained in it. Ash from coal combustion with an organic component added is generally not used in agriculture. Animal products contain large amounts of plant nutrients and organic carbon compounds, so attempting to reuse them in the production process of plants is recommended. Proper fertilization is one of the most important factors affecting soil fertility and the quality of plant products [1,9].

The rise of anaerobic digestion research was facilitated by a drive for environmentally sustainable methods for waste management, and anaerobic digestion has already demonstrated its promise as a technology with a diverse range of applications from food waste and agriculture to wastewater treatment [35,36].

Due to the aforementioned complications affecting the independent process of methane fermentation of animal waste, it is necessary to introduce measures to increase its efficiency. Wang et al. [5] indicate a significant potential to increase the efficiency of the animal waste methanogenesis process by using two-stage biogas and the use of technological additives improving the physical properties of the feedstock. In our own research, it was proposed to use technological additives responsible for emulsifying fats contained in the used substrates, which should also improve the physical parameters of the process. Many authors point to the significant potential of using slaughterhouse waste as a source of biogas, while stressing the need to use process modification to optimize it. Bücker et al. [37] stated that waste from fish processing can be a valuable input to the methanogenesis process. These authors obtained 540.5 mL of methane from 1 g of fish processing waste and 426.3 mL CH4 from 1 g of fish oil. The authors found no inhibitory effect of large amounts of fat in the feedstock within the accepted system boundaries. Amounts smaller than the above were reported by Sikora et al. [7] who biogased waste from carp processing. The authors identified a methane yield of 475 mL of biogas, with an average of 67.45% methane content in biogas. Bulak et al. [38] conducted research on the biogasing efficiency of mealworm waste. The process feedstock had a very low C:N value, 7.77, as well as a protein content of 31.98% and fat content of 4.13%, with the possibility of biogasing. Under the above conditions, the authors obtained a biogas yield of 451 mL of methane from 1 g of waste mass and an average methane content of 53.6%. Our own research found biogas yield similar to that of the authors in the object with 1% emulsifier. The results of the conducted experiments indicate a positive effect of carboxymethylcellulose on the amount of biogas obtained from the methanogenesis process. Wang et al. [39] proposed optimization of the methanogenesis process of slaughter waste with large amounts of fat by adding bamboo carriers. Due to the improvement in the conditions for microorganisms, i.e., the available surface, the efficiency of the process increased by 104%. With the introduction of a process innovation, i.e., the use of bamboo carriers, the maximum yield of biogas from blood reached 651 mL·g−1. The value of the C:N ratio for blood subjected to methanogenesis was 4.1. These authors emphasize that the use of bamboo carriers improved the ability of microorganisms to break down fat. Martí-Herrero et al. [40] increased the efficiency of biogas production from slaughterhouse waste by over 100% by increasing the surface of the walls of tubular fermentors. Earlier thermal processing may be a factor in improving the efficiency of the anaerobic digestion of animal waste [41,42,43,44,45,46,47,48]. These authors reported an approximate 300 mL methane yield in biogas from poultry slaughterhouse waste processing. Thermal processing of the feedstock at 190 °C resulted in an approximately 25% increase in biogas production efficiency. In our own research, the total amount of biogas in the control for the soft fraction was approximately 314 mL of methane per 1 g on the 30th day of the process, while for the hard fraction this value was 300 mL of methane per 1 g. With the addition of 1% carboxymethyl cellulose per weight of the feedstock, the total methane yield for the soft and hard fraction calculated on day 12 of the process was 315 and 216 mL·g−1 of CH4 per dry weigh of the waste, respectively. In the case of biogasing the soft fraction of slaughterhouse waste, the use of carboxymethyl cellulose enabled the process to be cut by 18 days while maintaining the methane yield. In the case of the hard fraction, cutting the process resulted in a reduction of the total amount of methane produced by 28%.

5. Conclusions

1. The total amount of biogas obtained after methane fermentation of slaughterhouse waste was 398 mL·g−1 for the soft fraction and 402 mL·g−1 for the hard fraction.

2. In the case of the soft waste fraction, the addition of carboxymethylcellulose at 1% of the mass to the biogas process increased the amount of obtained biogas by 16%. In the case of the hard fraction, no effect of the addition of emulsifier on the total amount of biogas obtained was identified.

3. The addition of an emulsifier reduced the methane content of biogas and increased the amount of carbon dioxide after the eighth day of fermentation, but in the media, including the carboxymethylcellulose addition, the highest daily increase of biogas was observed in the first 10 days. This decrease was caused by the mixing of nutrients for microorganisms.

4. Introduced to the soft fraction of slaughterhouse waste from poultry processing, the emulsifier, in the form of a carboxymethylcellulose addition, allowed cutting the process of methanogenesis by over 50% while maintaining the efficiency of biogas production. In the case of biogasification of bone tissue, no unambiguous effect of the addition of emulsifier on the improvement of process efficiency was identified.

5. The best biogas production effects were obtained with the addition of an emulsifier at 1% per dry weight of the feedstock. Larger concentrations of the addition did not affect the efficiency of the process or it slightly decreased it.

Author Contributions

Conceptualization, J.S., M.N. and M.K.; methodology, M.K., A.S.-S. and Z.G.-S.; software, J.S. and M.N.; validation, A.S.-S. and Z.G.-S.; formal analysis, M.K., M.K. and J.S.; resources, Z.G.-S., A.S.-S. and M.K.; writing—original draft preparation: M.N., J.S. and M.K., visualization, Z.G.-S., A.S.-S. and M.K. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Szeląg-Sikora, A.; Niemiec, M.; Sikora, J.; Chowaniak, M. Possibilities of Designating Swards of Grasses and Small-Seed Legumes From Selected Organic Farms in Poland for Feed. In Proceedings of the IX International Scientific Symposium “Farm Machinery and Processes Management in Sustainable Agriculture”, Lublin, Poland, 22–24 November 2017; pp. 365–370. [Google Scholar]

- Alkanok, G.; Demirel, B.; Onay, T.T. Determination of biogas generation potential as a renewable energy source from supermarket wastes. Waste Manage. 2014, 34, 134–140. [Google Scholar] [CrossRef]

- De Souza, S.N.M.; Wernacke, I.; Marques, C.A.; Bariccatti, R.A.; Santos, R.F.S.; Nogueira, C.E.C.; Bassegio, D. Electric energy micro-production in a rural property using biogas as primary source. Renew. Sust. Energ. Rev. 2013, 28, 385–391. [Google Scholar] [CrossRef]

- Lijó, L.; González-García, S.; Bacenetti, J.; Moreira, M.T. The environmental effect of substituting energy crops for food waste as feedstock for biogas production. Energy 2017, 137, 1130–1143. [Google Scholar] [CrossRef]

- Wang, S.; Hawkins, G.L.; Kiepper, H.K.; Das, K.C. Treatment of slaughterhouse blood waste using pilot scale two-stage anaerobic digesters for biogas production. Renew. Energy 2018, 126, 552–562. [Google Scholar] [CrossRef]

- Loganath, R.; Mazumder, D. Performance study on organic carbon, total nitrogen, suspended solids removal and biogas production in hybrid UASB reactor treating real slaughterhouse wastewater. J. Environ. Chem. Eng. 2018, 6, 3474–3484. [Google Scholar] [CrossRef]

- Sikora, J.; Niemiec, M.; Szeląg-Sikora, A.; Kuboń, M.; Olech, E.; Marczuk, A. Zgazowanie odpadów z przemysłowego przetwórstwa karpia. Przem. Chem. 2017, 96, 2275–2278. [Google Scholar] [CrossRef]

- Cupiał, M.; Szeląg-Sikora, A.; Niemiec, M. Farm Machinery and Processes Management in Sustainable Agriculture Location: 7th International Scientific Symposium: Symposium proceedings, Gembloux, Belgium, 25–27 November 2015. Agric. Agric. Sci. Procedia 2015, 7, 64–69. [Google Scholar]

- Szeląg-Sikora, A.; Sikora, J.; Niemiec, M.; Gródek-Szostak, Z.; Kapusta-Duch, J.; Kuboń, M.; Komorowska, M.; Karcz, J. Impact of Integrated and Conventional Plant Production on Selected Soil Parameters in Carrot Production. Sustainability 2019, 11, 5612. [Google Scholar] [CrossRef]

- Niemiec, M.; Komorowska, M.; Szeląg-Sikora, A.; Sikora, J.; Kuboń, M.; Gródek-Szostak, Z.; Kapusta-Duch, J. Risk Assessment for Social Practices in Small Vegetable farms in Poland as a Tool for the Optimization of Quality Management Systems. Sustainability 2019, 11, 3913. [Google Scholar] [CrossRef]

- Lorenz, H.; Fischer, P.; Schumacher, B.; Adler, P. Current EU-27 technical potential of organic waste streams for biogas and energy production. Waste Manage. 2013, 3, 2434–2448. [Google Scholar] [CrossRef]

- Granada, C.E.; Hasan, C.; Marder, M.; Konrad, O.; Vargas, L.K.; Passaglia, L.M.P.; Giongo, A.; de Oliveira, R.R.; de Pereira, L.M.; Trindade, F.J.; et al. Biogas from slaughterhouse wastewater anaerobic digestion is driven by the archaeal family Methanobacteriaceae and bacterial families Porphyromonadaceae and Tissierellaceae. Renew. Energy 2018, 118, 840–846. [Google Scholar] [CrossRef]

- Vilalba, G.; Liu, Y.; Schroder, H.; Ayres, R.U. Global phosphorus flows in the industrial economy from a production perspective. J. Ind. Ecol. 2008, 12, 557–569. [Google Scholar] [CrossRef]

- Mangwandi, C.; Tao, L.J.; Albadarin, A.B.; Allen, S.J.; Walker, G.M. Alternative method for producing organic fertiliser from anaerobic digestion liquor and limestone powder: High Shear wet granulation. Powder Technol. 2013, 233, 245–254. [Google Scholar] [CrossRef]

- Kuźnia, M.; Wojciech, J.; Łyko, P.; Sikora, J. Analysis of the combustion products of biogas produced from organic municipal waste. J. Power Technol. 2015, 95, 158–165. [Google Scholar]

- Kasprzak, K.; Wojtunik-Kulesza, K.; Oniszczuk, T.; Kuboń, M.; Oniszczuk, A. Secondary Metabolites, Dietary Fiber and Conjugated Fatty Acids as Functional Food Ingredients against Overweight and Obesity. Nat. Prod. Commun. 2018, 13, 1073–1082. [Google Scholar] [CrossRef]

- Weiland, P. Biomass digestion in agriculture: A successfull pathway for the energy production and waste treatment in Germany. Eng. Life Sci. 2006, 6, 302–309. [Google Scholar] [CrossRef]

- Niemiec, M.; Komorowska, M.; Szeląg-Sikora, A.; Sikora, J.; Kuzminova, N. Content of Ba, B, Sr and As in water and fish larvae of the genus Atherinidae, L. sampled in three bays in the Sevastopol coastal area. J. Elem. 2018, 23, 1009–1020. [Google Scholar] [CrossRef]

- Council of the European Union. Council Directive 1999/31/EC of 26 April 1999 on the landfill of waste. Off. J. Eur. Commun. 1999, 182, 1–19.

- Directive 2008/98/EC of the European Parliament and of the Council of 19 November 2008 on waste and repealing certain Directives. Off. J. Eur. Union L 2008, 312.

- Regulation (EC) No 1069/2009 of the European Parliament and of the Council of 21 October 2009, Laying Down Sanitary Provisions for Animal by-Products Not Intended for Human Consumption, and Repealing Regulation (EC) No 1774/2002 [Regulation on Animal by-Products]; European Union: Brussels, Belgium, 2009.

- The Act of 14 December 2012 on Waste. 2013. Available online: http://prawo.sejm.gov.pl/isap.nsf/DocDetails.xsp?id=wdu20130000021 (accessed on 7 April 2020).

- Resolution of Minister of Environment Issued on December 9, 2014 on Waste Catalogue. 2014. Available online: http://isap.sejm.gov.pl/DetailsServlet?id=WDU20140001923 (accessed on 7 April 2020).

- The Regulation of the Minister of the Environment of 20 January 2015 on the Process of R10 Recovery. 2015. Available online: http://prawo.sejm.gov.pl/isap.nsf/DocDetails.xsp?id=WDU20150000132 (accessed on 7 April 2020).

- Cripa, F.B.; Arantes, M.K.; Sequinel, R.; Fiorini, A.; Rogério, F.; Rosado, F.R.; Alves, H.J. Poultry slaughterhouse anaerobic ponds as a source of inoculum for biohydrogen production. J. Biosci. Bioeng. 2020, 129, 77–85. [Google Scholar] [CrossRef] [PubMed]

- Almomani, F.; Shawaqfah, M.; Bhosale, R.R.; Kumara, A.; Khraisheh, M.A.M. Intermediate ozonation to enhance biogas production in batch and continuous systems using animal dung and agricultural waste. Int. Biodeterior. Biodegrad. 2017, 119, 176–187. [Google Scholar] [CrossRef]

- Gródek-Szostak, Z.; Malik, G.; Kajrunajtys, D.; Szeląg-Sikora, A.; Sikora, J.; Kuboń, M.; Niemiec, M.; Kapusta-Duch, J. Modeling the Dependency between Extreme Prices of Selected Agricultural Products on the Derivatives Market Using the Linkage Function. Sustainability 2019, 11, 4144. [Google Scholar] [CrossRef]

- Salminen, E.; Rintala, J. Anaerobic digestion of organic solid poultry slaughterhouse waste- a review. Bioresour. Technol. 2002, 83, 17–18. [Google Scholar] [CrossRef]

- Luostarinen, S.; Luste, S.; Sillanpää, M. Increased biogas production at wastewater treatment plants through co-digestion of sewage sludge with grease trap sludge from a meat processing plant. Bioresour. Technol. 2009, 100, 79–85. [Google Scholar] [CrossRef]

- Latifi, P.; Karrabi, M.; Danesh, S. Anaerobic co-digestion of poultry slaughterhouse wastes with sewage sludge in batch-mode bioreactors (effect of inoculum-substrate ratio and total solids). Renew. Sustain. Energy Rev. 2019, 107, 288–296. [Google Scholar] [CrossRef]

- Russo, V.; von Blottnitz, H. Potentialities of biogas installation in South African meat value chain for environmental impacts reduction. J. Clean. Prod. 2017, 153, 465–473. [Google Scholar] [CrossRef]

- Gródek-Szostak, Z.; Szeląg-Sikora, A.; Sikora, J.; Korenko, M. Prerequisites for the cooperation between enterprises and business supportinstitutions for technological development. Bus. Nonprofit Organ. Facing Increased Compet. Grow. Cust. Demand 2017, 16, 427–439. [Google Scholar]

- Fryda, L.; Panopoulos, K.; Vourliotis, P.; Pavlidou, E.; Kakaras, E. Experimental investigation of fluidised bed co-combustion of meat and bone meal with coals and olive bagasse. Fuel 2006, 85, 1685–1699. [Google Scholar] [CrossRef]

- Vilvert, A.J.; Saldeira Junior, J.C.; Bautitz, I.R.; Zenatti, D.C.; Andrade, M.G.; Hermes, E. Minimization of energy demand in slaughterhouses: Estimated production of biogas generated from the effluent. Renew. Sustain. Energy Rev. 2020, 120, 109613. [Google Scholar] [CrossRef]

- Azman, S. Anaerobic Digestion of Cellulose and Hemiceullose in the Presence of Humic Acids. Ph.D. Thesis, Wageningen University, Wageningen, The Netherlands, 2016. [Google Scholar]

- Meegoda, J.N.; Li, B.; Patel, K.; Wang, L.B. A Review of the Processes, Parameters, and Optimization of Anaerobic Digestion. Int. J. Environ. Res. Public Health 2018, 15, 2224. [Google Scholar] [CrossRef]

- Bücker, F.; Marder, M.; Peiter, M.R.; Lehn, D.N.; Esquerdo, V.M.; Luiz Antonio de Almeida Pinto, L.A.; Konrad, O. Fish waste: An efficient alternative to biogas and methane production in an anaerobic mono-digestion system. Renew. Energy 2020, 147, 798–805. [Google Scholar] [CrossRef]

- Bulak, P.; Proc, K.; Pawłowska, M.; Kasprzycka, A.; Berus, W.; Bieganowski, A. Biogas generation from insects breeding post production wastes. J. Clean. Prod. 2020, 244, 118777. [Google Scholar] [CrossRef]

- Wang, S.; Jena, U.; Das, K.C. Biomethane production potential of slaughterhouse waste in the United States. Energy Convers. Manage. 2018, 173, 143–157. [Google Scholar] [CrossRef]

- Martí-Herrero, J.; Alvarez, R.; Floresd, T. Evaluation of the low technology tubular digesters in the production of biogas from slaughterhouse wastewater treatment. J. Clean. Prod. 2018, 199, 633–642. [Google Scholar] [CrossRef]

- Park, S.; Yoon, Y.-M.; Han, S.K.; Kim, D.; Kim, H. Effect of hydrothermal pre-treatment (HTP) on poultry slaughterhouse waste (PSW) sludge for the enhancement of the solubilization, physical properties, and biogas production through anaerobic digestion. Waste Manage. 2017, 64, 327–332. [Google Scholar] [CrossRef]

- Bustamante, M.A.; Restrepo, A.P.; Alburquerque, J.A.; Pérez-Murcia, M.D.; Paredes, C.; Moral, R.; Bernal, M.P. Recycling of anaerobic digestates by composting: Effect of the bulking agent used. J. Clean. Prod. 2013, 47, 61–69. [Google Scholar] [CrossRef]

- Sikora, J.; Niemiec, M.; Szeląg-Sikora, A. Evaluation of the chemical composition of raw common duckweed (Lemna minor L.) and pulp after methane fermentation. J. Elem. 2018, 23, 685–695. [Google Scholar] [CrossRef]

- Kapusta-Duch, J.; Szeląg-Sikora, A.; Sikora, J.; Niemiec, M.; Gródek-Szostak, Z.; Kuboń, M.; Leszczyńska, T.; Borczak, B. Health-Promoting Properties of Fresh and Processed Purple Cauliflower. Sustainability 2019, 11, 4008. [Google Scholar] [CrossRef]

- Khalil, M.; Berawi, M.A.; Heryanto, R.; Rizalie, A. Waste to energy technology: The potential of sustainable biogas production from animal waste in Indonesia. Renew. Sustain. Energy Rev. 2019, 105, 323–331. [Google Scholar] [CrossRef]

- Niemiec, M.; Chowaniak, M.; Sikora, J.; Szeląg-Sikora, A.; Gródek-Szostak, Z.; Komorowska, M. Selected Properties of Soils for Long-Term Use in Organic Farming. Sustainability 2020, 12, 2509. [Google Scholar] [CrossRef]

- Sikora, J.; Niemiec, M.; Tabak, M.; Gródek-Szostak, Z.; Szeląg-Sikora, A.; Kuboń, M.; Komorowska, M. Assessment of the Efficiency of Nitrogen Slow-Release Fertilizers in Integrated Production of Carrot Depending on Fertilization Strategy. Sustainability 2020, 12, 1982. [Google Scholar] [CrossRef]

- Kuboń, M.; Niemiec, M.; Tabak, M.; Komorowska, M.; Gródek-Szostak, Z. Ocena zasobności gleby w przyswajalne związki siarki z wykorzystaniem ekstrahentów o zróżnicowanej zdolności ekstrakcji. Przem. Chem. 2020, 99, 581–584. [Google Scholar] [CrossRef]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).