Fault Tolerant Boost Converter with Multiple Serial Inputs and Output Voltage Regulation for Vehicle-to-Aid Services

Abstract

:1. Introduction

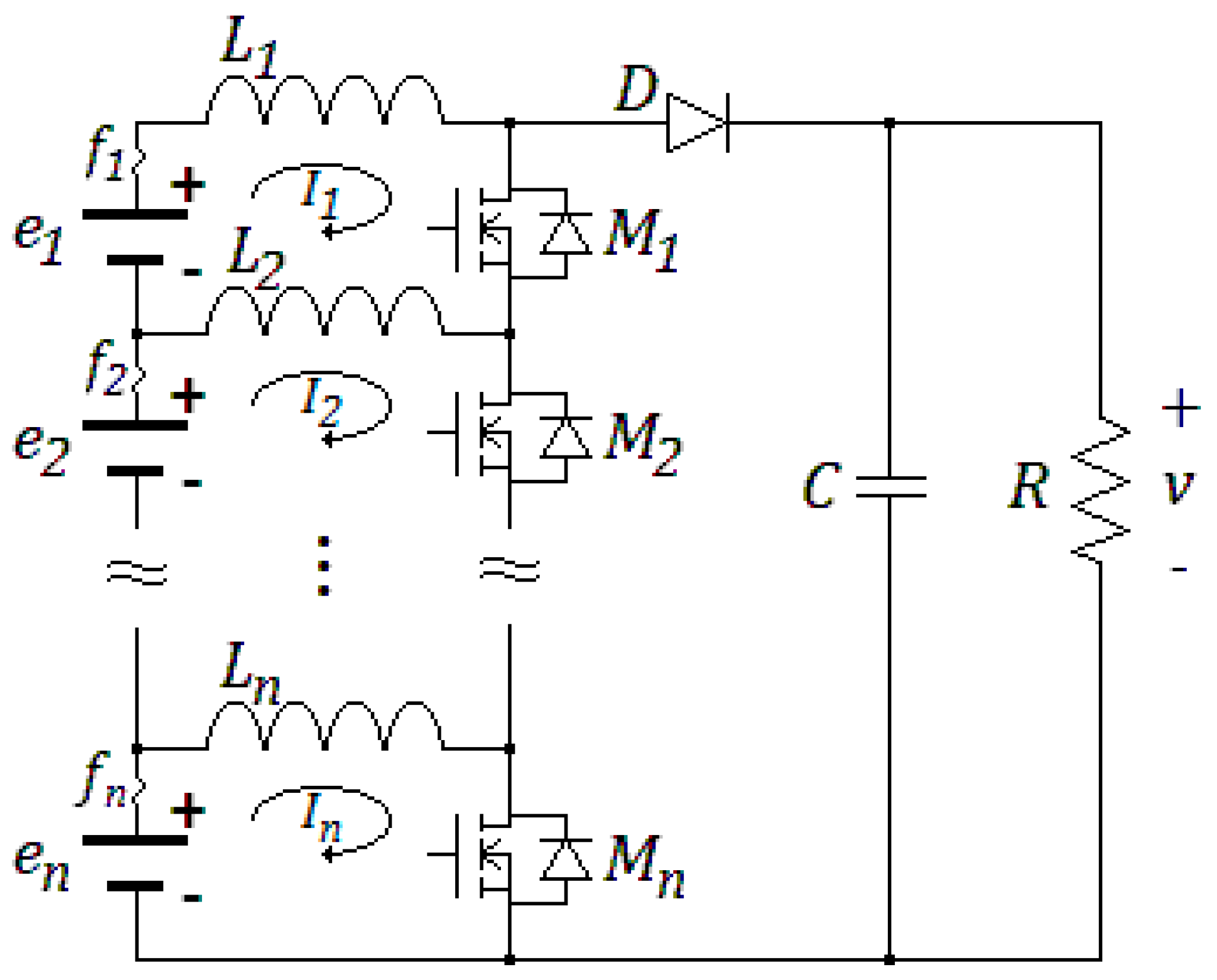

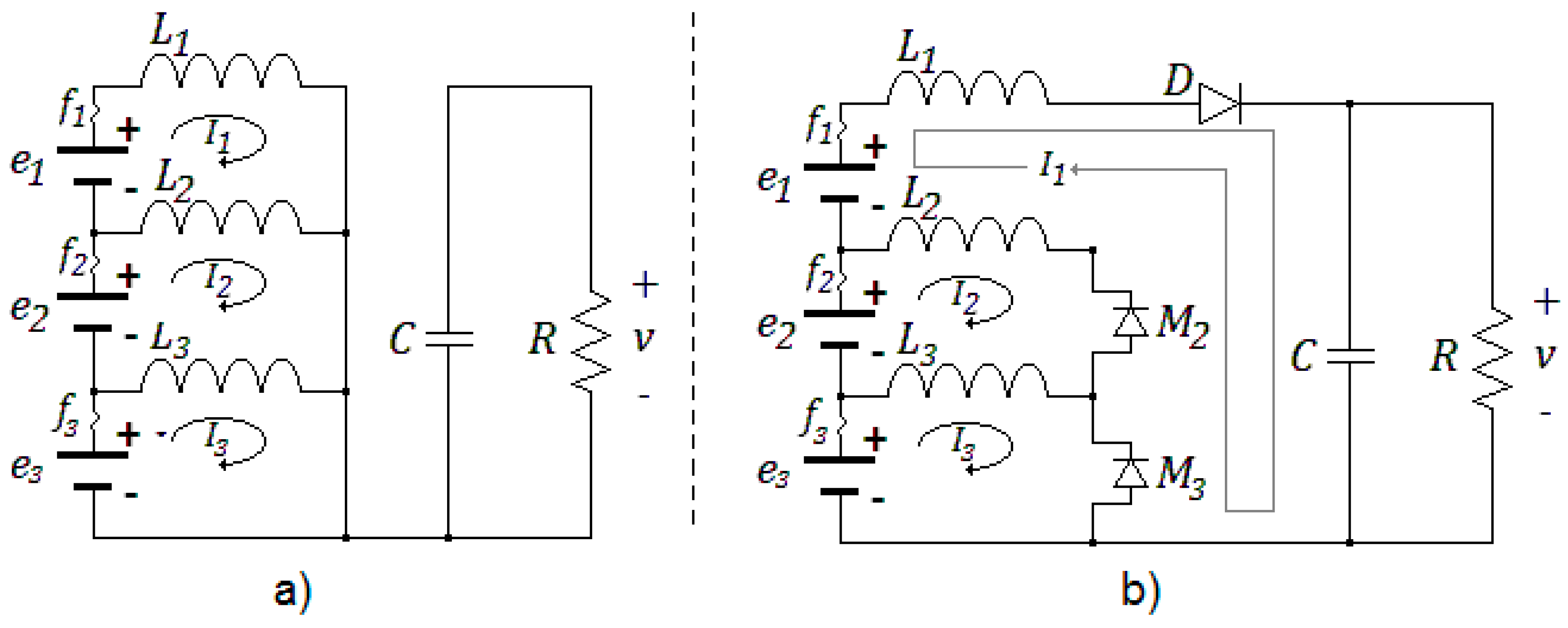

2. Modelling of the DC-DC Parallel Boost Converter

- (i)

- Some, but not all, of the n cells are discharged (zero voltage).

- (ii)

- Some, but not all, of the n cells are in open-circuit.

- (iii)

- Some, but not all, of the n inductors are in open-circuit.

- (iv)

- Some, but not all, of the n inductors are in short-circuit.

- (v)

- Some, but not all, of the n MOSFETs are damaged (Drain to Source short circuit).

3. Stability Analysis

4. Robust Stability under Failure Conditions

4.1. Some Discharged Cells

4.2. Cells in Open Circuit

- The first () cell is in open circuit. In this case, the circuit behaves has some of cells. The model remains without structural modification, and the stability properties are conserved; moreover, it is easy to demonstrate that the CLF found for n cells is also valid for cells, and therefore the stability property is retained, even during the switching between the models.

- The -th cell ( or ) is in open circuit. In such a case, the circuit behaves as some of , where the inductance in the upper mesh is now . This change is now considered within the parameter variation ranges of the model, without structural modification or changes on the stability properties.

4.3. Some but not All of the n Inductors are in Open Circuit

- The first inductor () is in open circuit. In this case, the circuit behaves has some of cells. The model remains without structural modification and the stability properties are conserved; moreover, it is easy to demonstrate that the CLF found for n cells is valid also for cells, and therefore the stability property is retained even during switching between the models.

- The -th inductor () is in open circuit. In such case, the circuit behaves as some of cells, where the equivalent voltage source in the respective mesh is now . This change is now considered within the parameter variation ranges of the model without structural modification neither changes on the stability properties.

4.4. Some but not All of the n Inductors are in Short Circuit

4.5. Drain to Source Short Circuit

4.6. Combinations of Failure Events

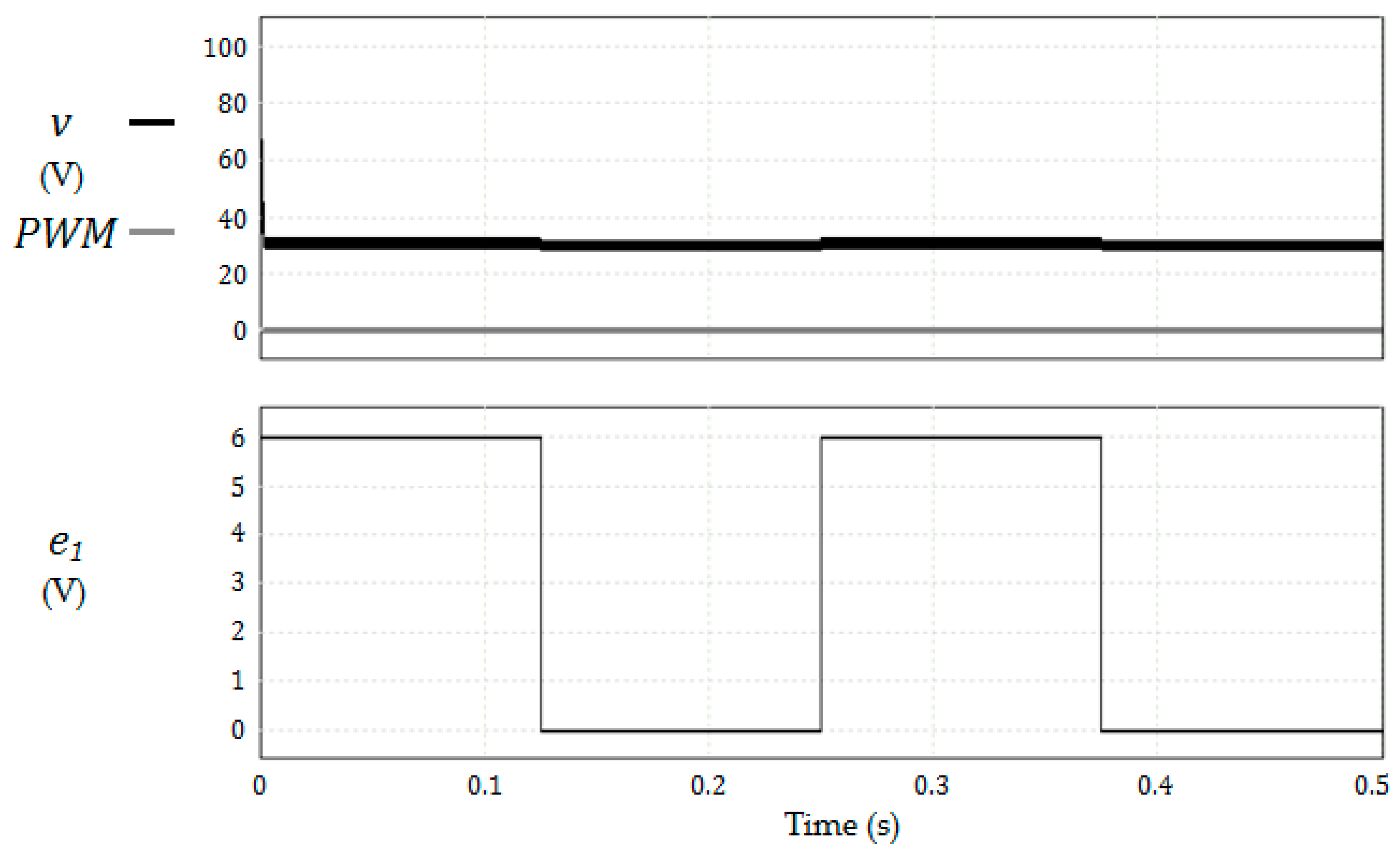

5. Simulations

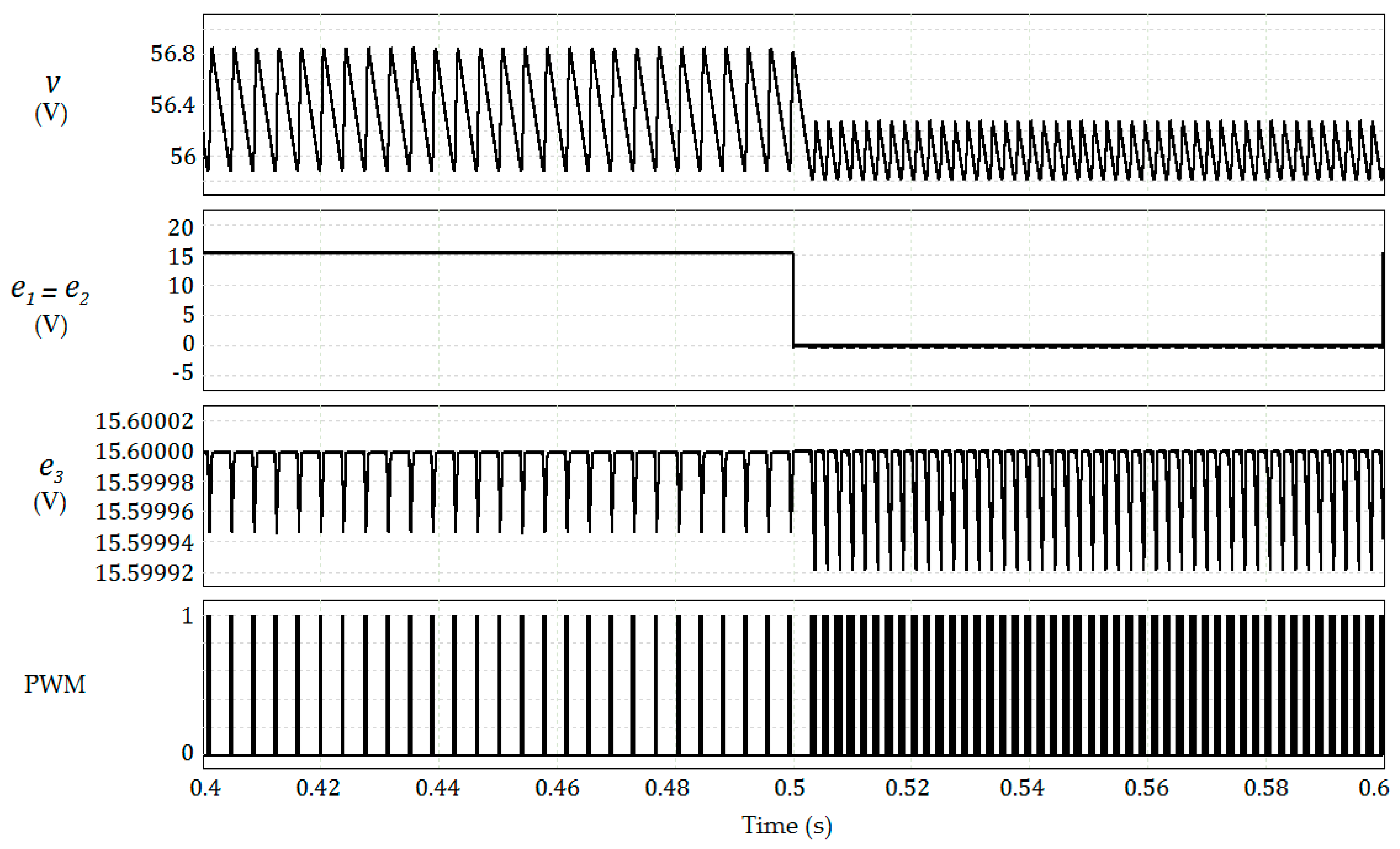

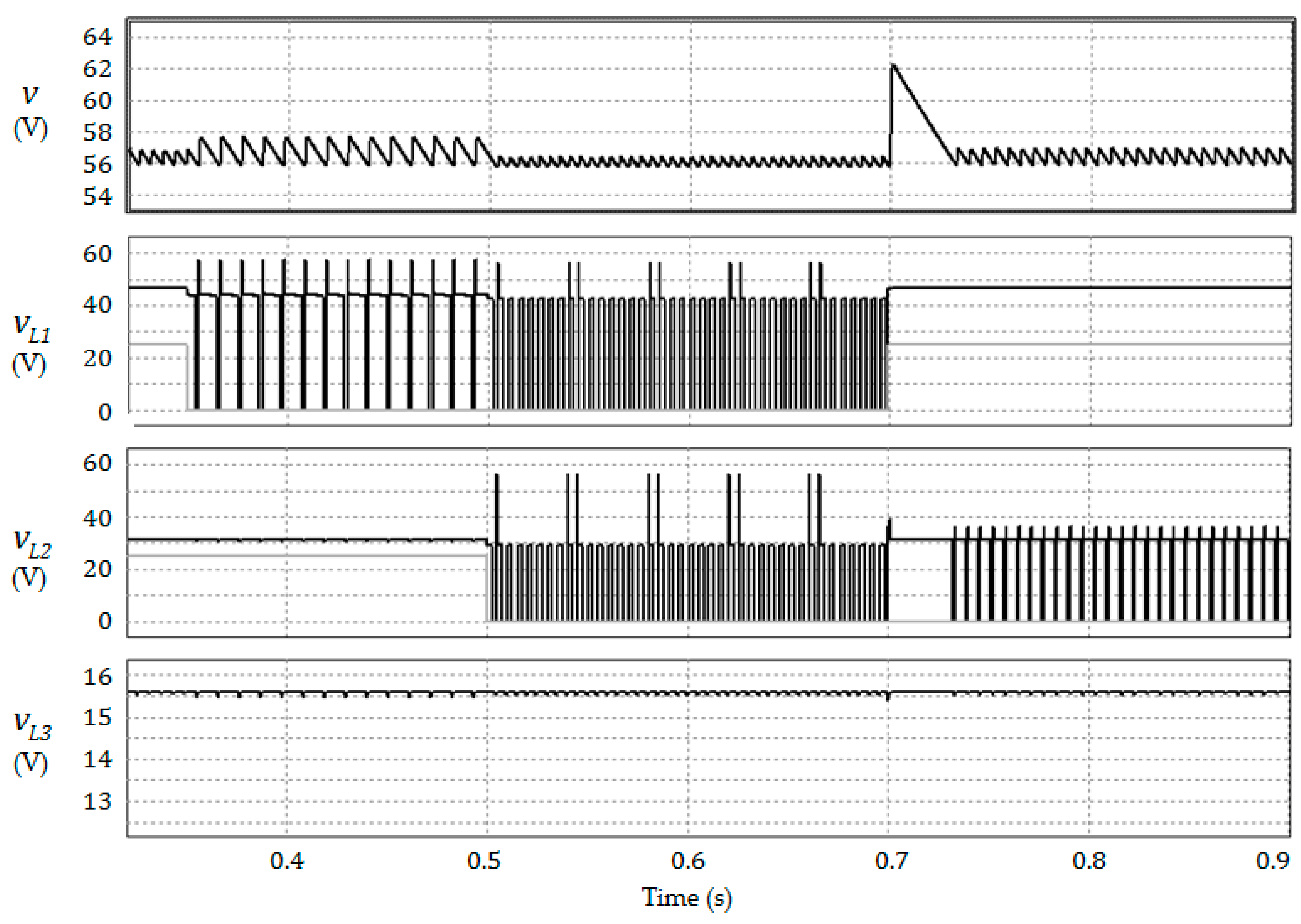

5.1. Some Discharged Cells

5.2. Cells in Open Circuit

5.3. Some but not All of the n Inductors are in Open Circuit

5.4. Some but not All of the n Inductors are in Short Circuit

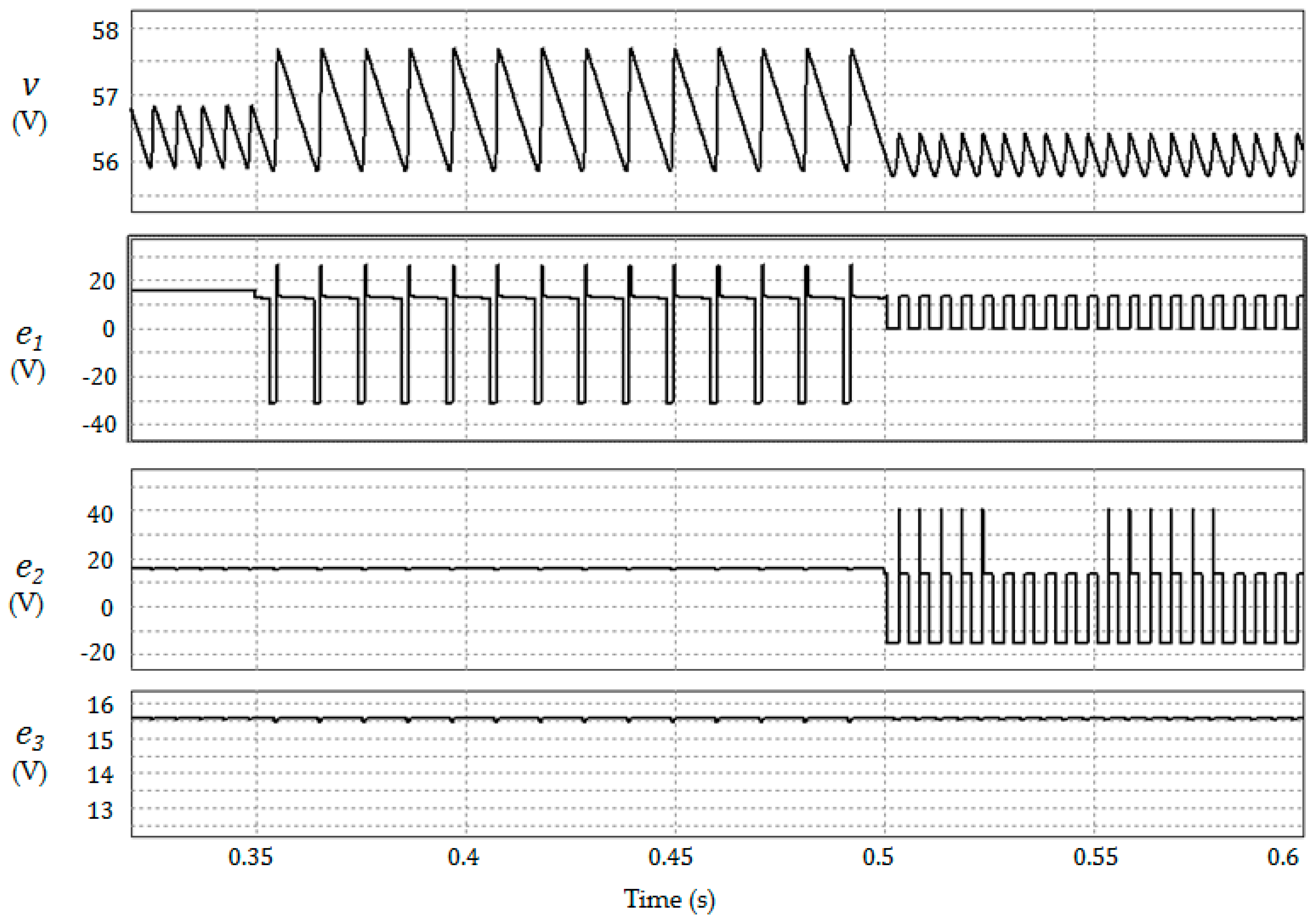

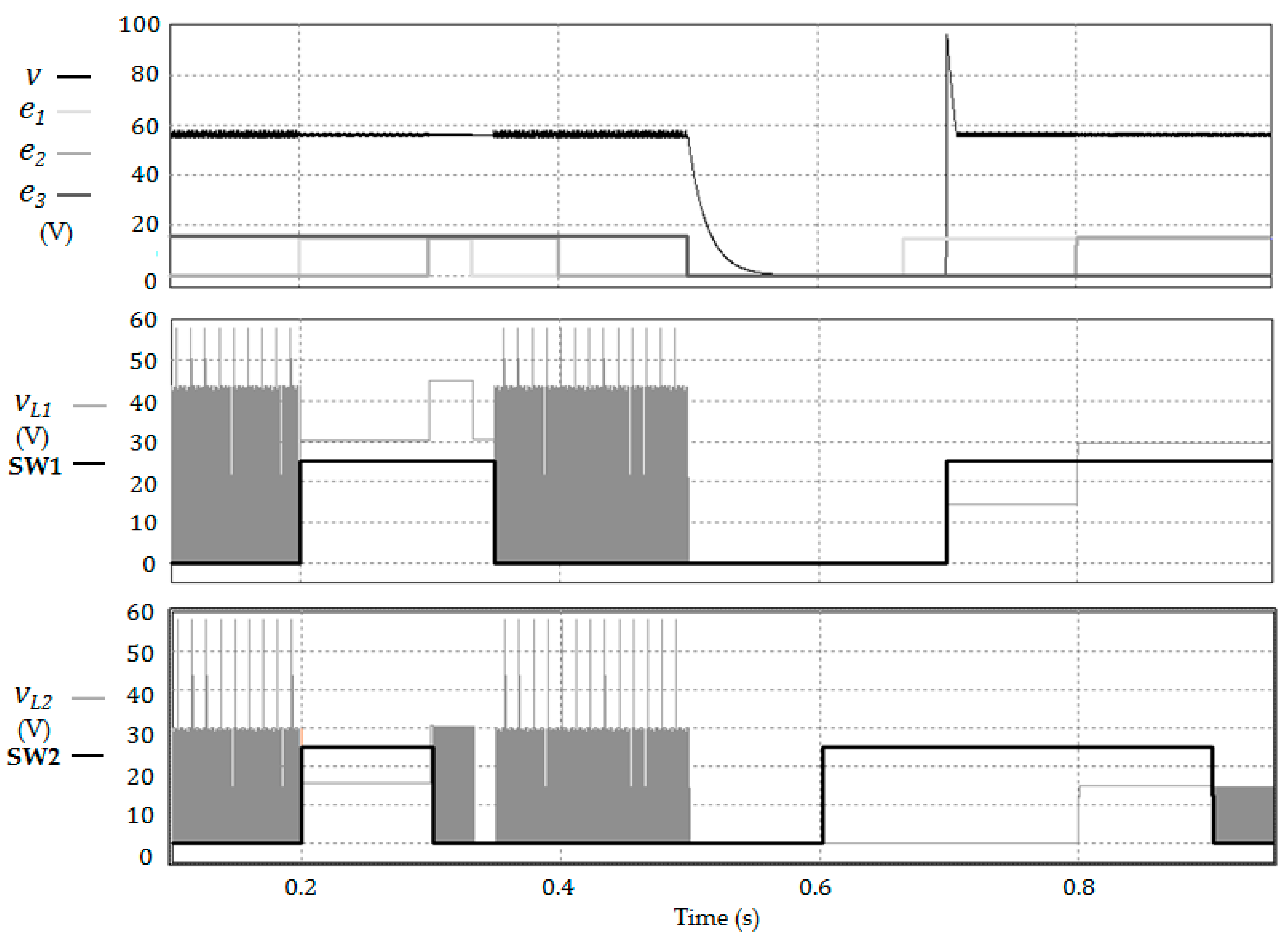

5.5. Drain to Source Short Circuit

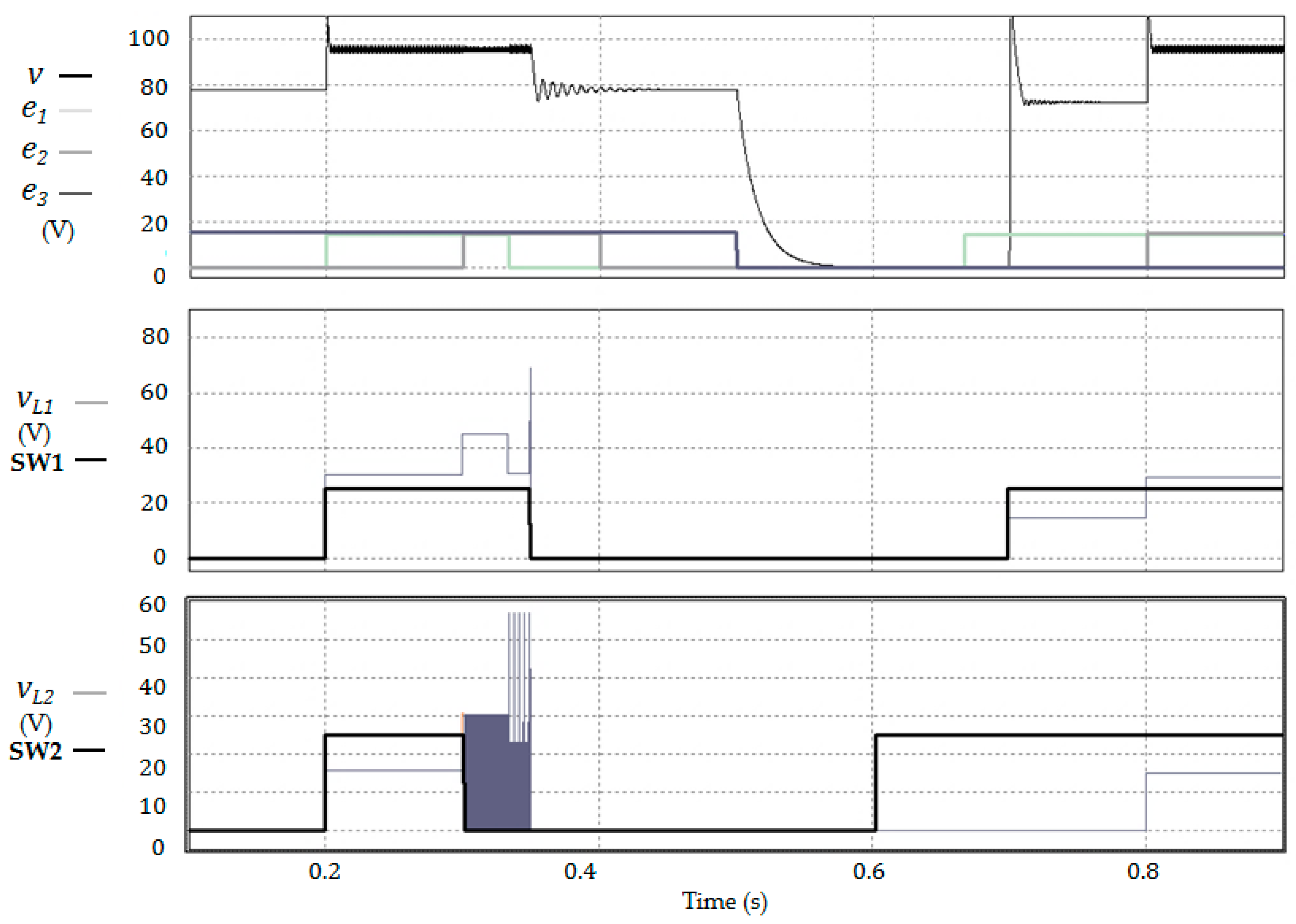

5.6. Combinations of Failure Events

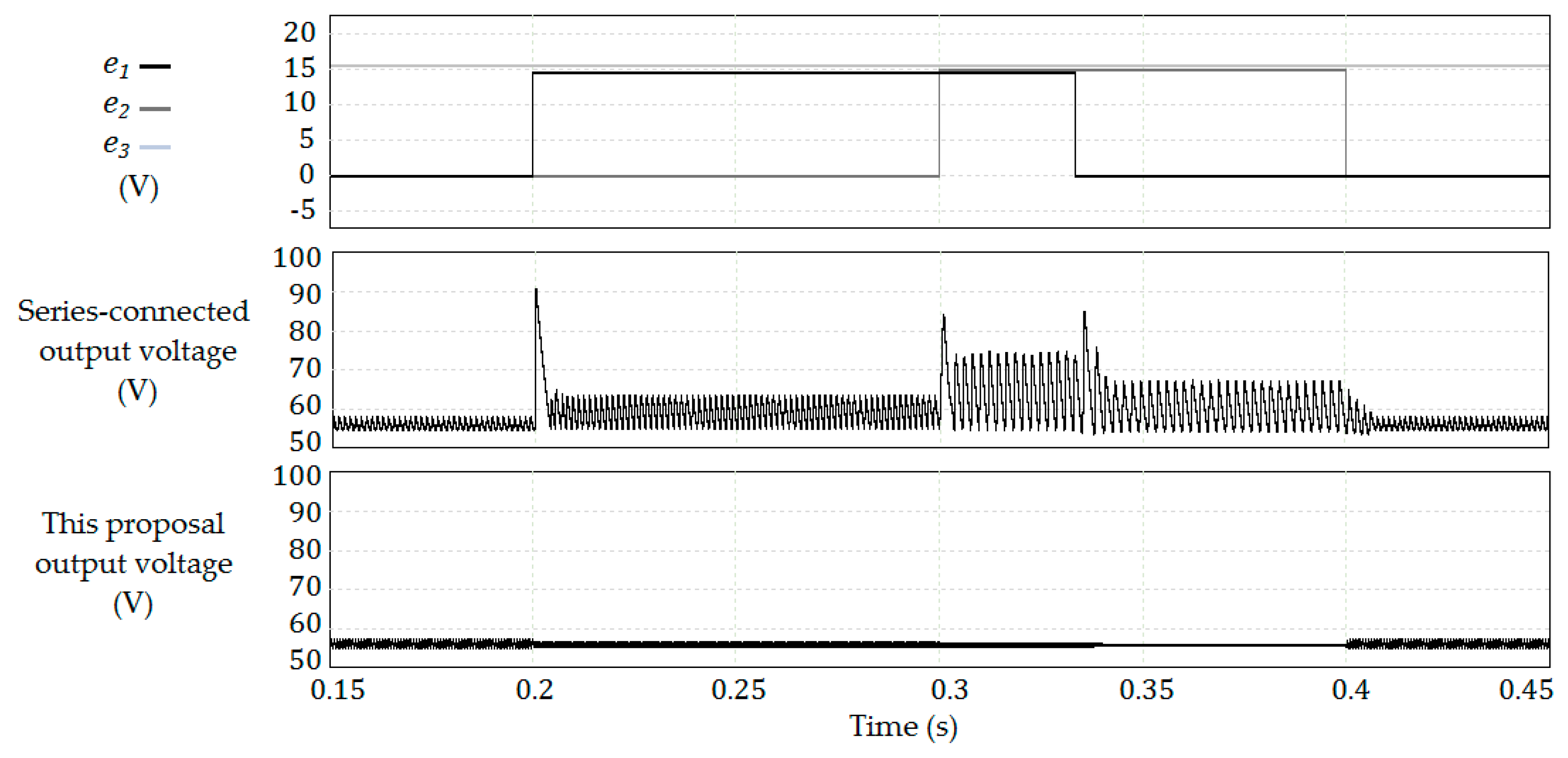

5.7. Boost Series-Connected Comparison

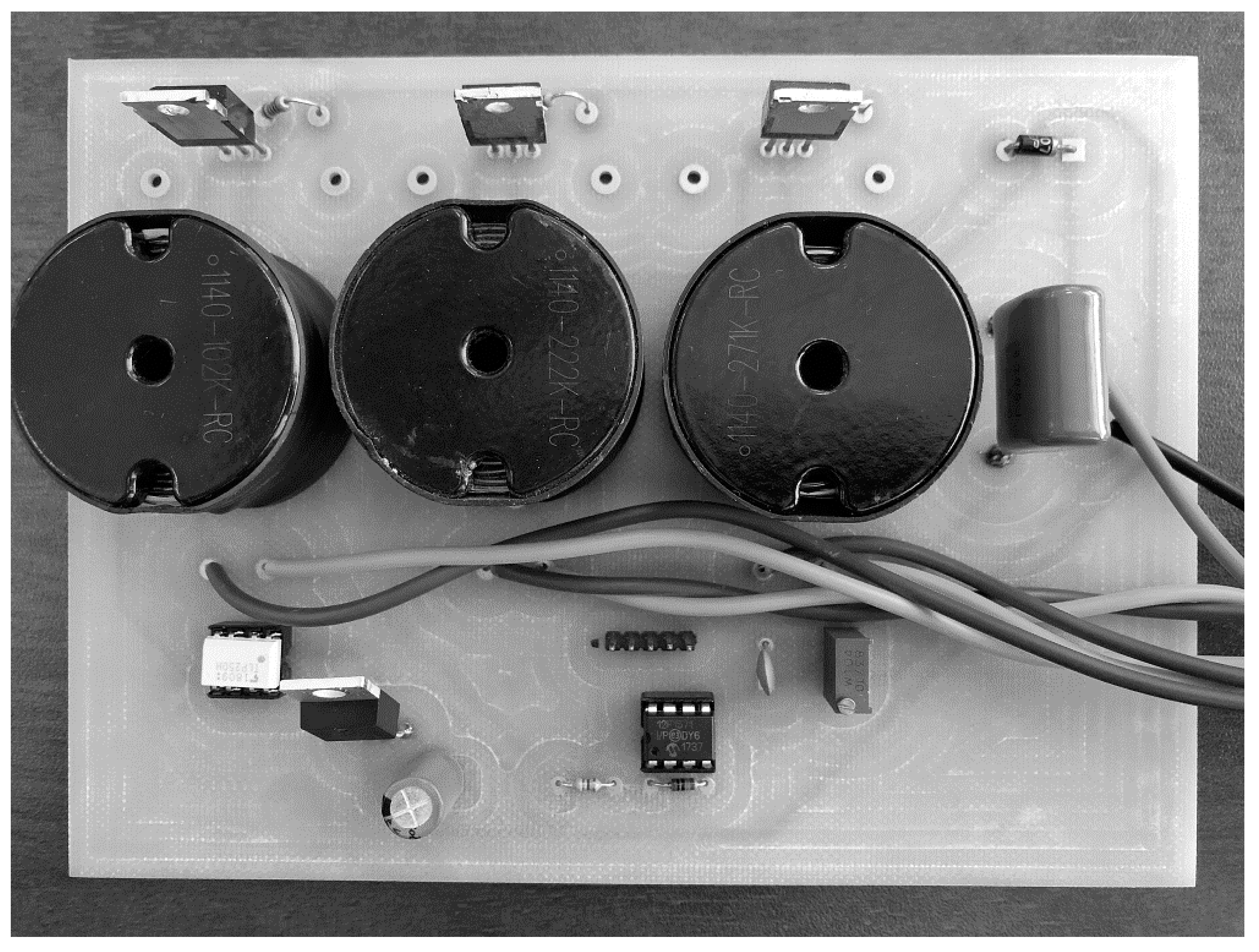

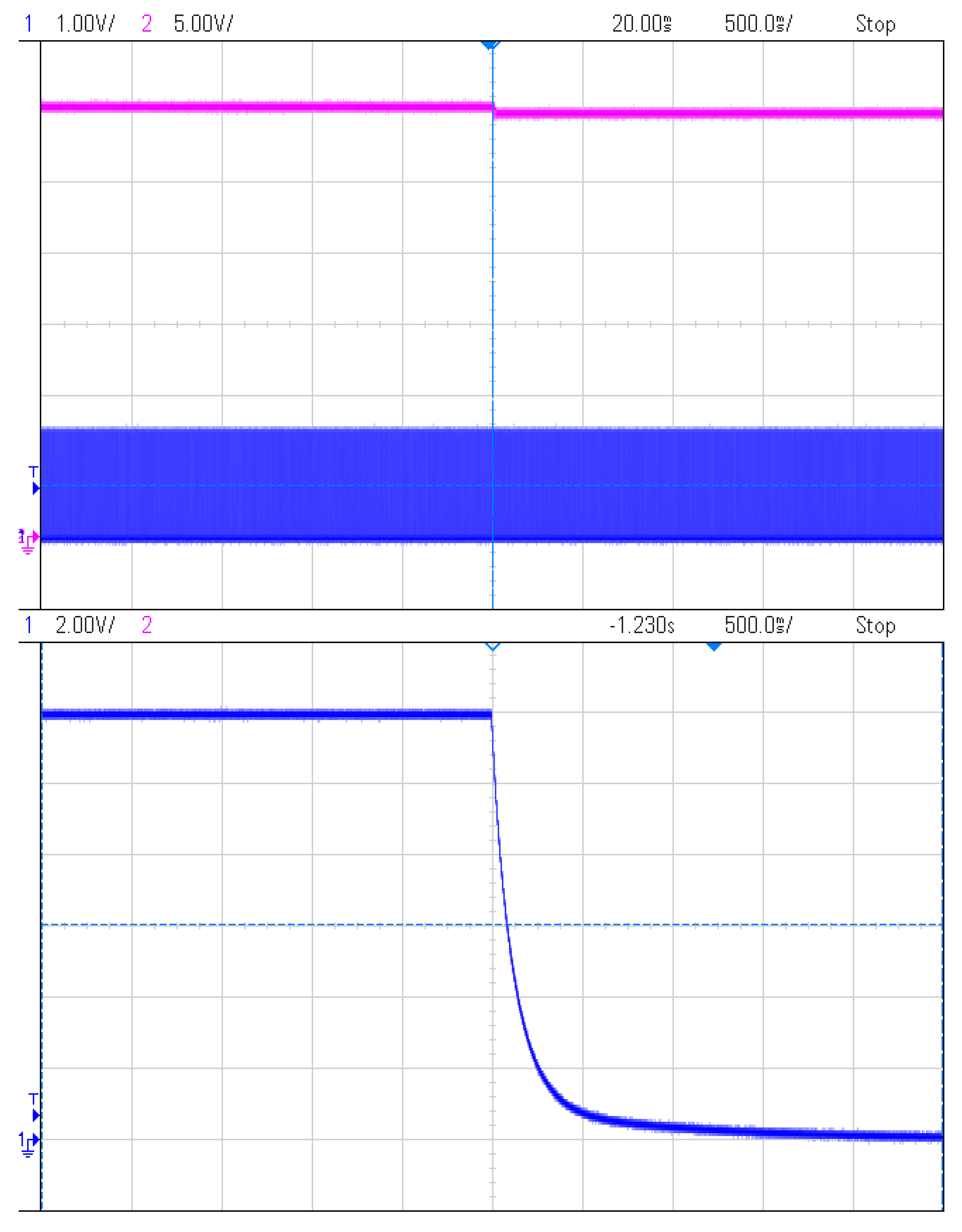

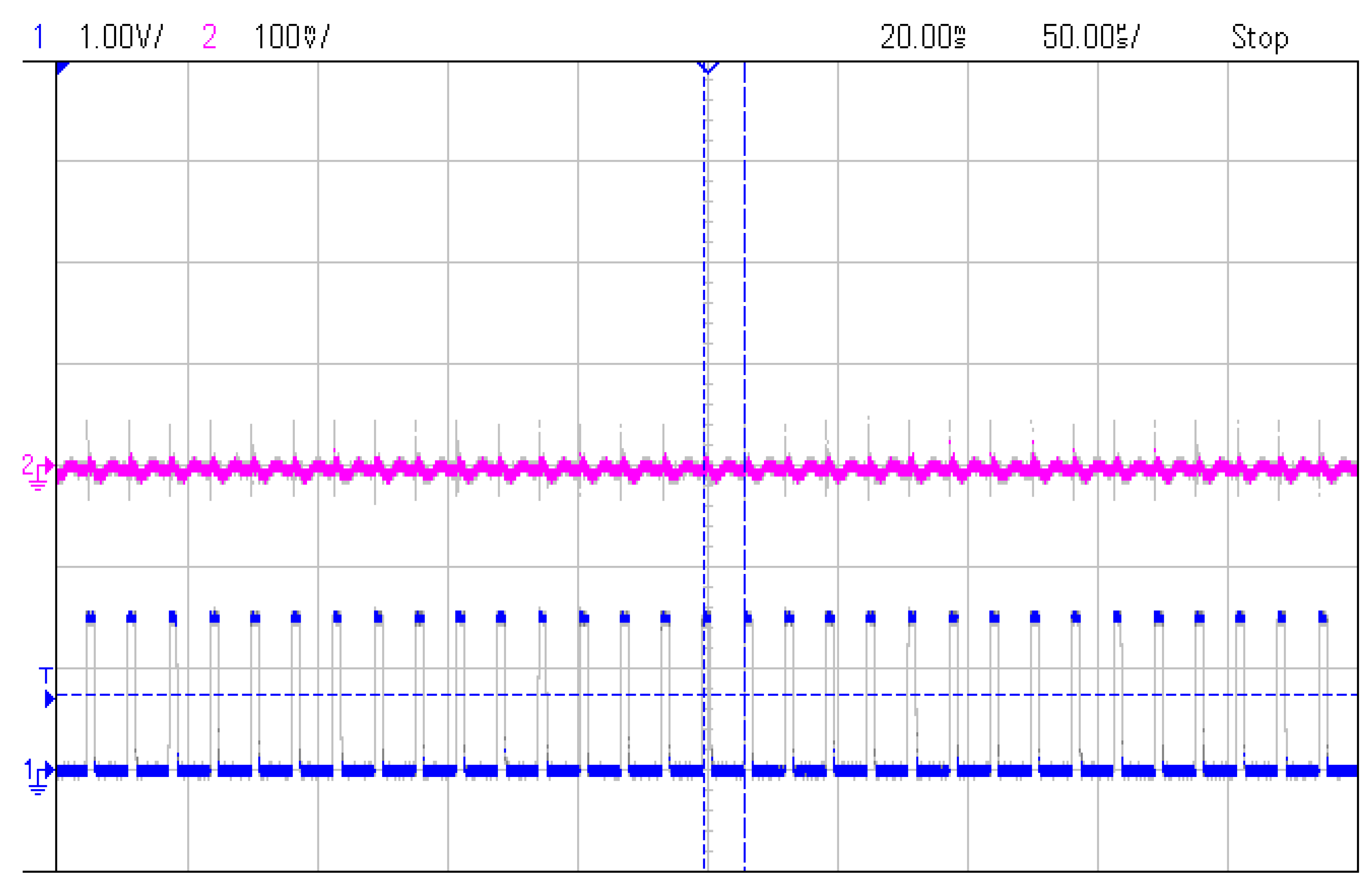

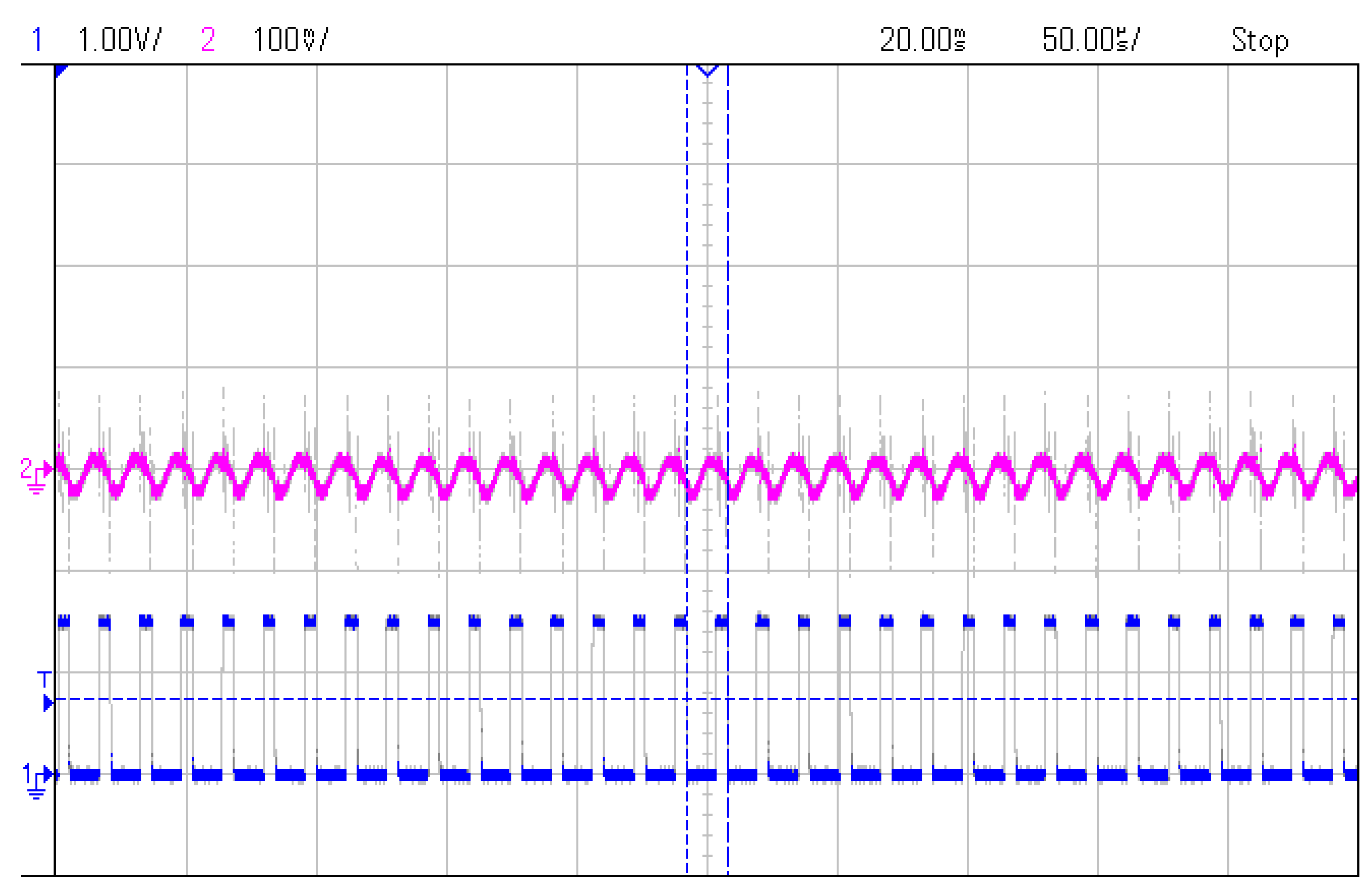

6. Experiments

7. Discussion

8. Conclusions

Funding

Acknowledgments

Conflicts of Interest

References

- Ganesan, S.; Padmanaban, S.; Varadarajan, R.; Subramaniam, U.; Mihet-Popa, L. Study and analysis of an intelligent microgrid energy management solution with distributed energy sources. Energies 2017, 10, 1419. [Google Scholar] [CrossRef] [Green Version]

- Noel, L.; Rubens, G.Z.; Kester, J.; Sovacool, B.K. Vehicle-to-Grid: A Sociotechnical Transition Beyond Electric Mobility; Springer: Cham, Switzerland, 2019; pp. 1–85. ISBN 978-3-030-04863-1. [Google Scholar]

- Corchero, C.; Sanmarti, M. Vehicle-to-Everything (V2X): Benefits and Barriers. In Proceedings of the IEEE International Conference on the European Energy Market, Łódź, Poland, 27–29 June 2018. [Google Scholar]

- Wang, B. Intelligent Control and Power Flow Optimization of Microgrid: Energy Management Strategies. Ph.D. Thesis, Sciences pour l’ingénieur, Compiègne, France, 2013. [Google Scholar]

- Jovanovic, M.M.; Crow, D.E.; Fang-Yi, L. A novel, low-cost implementation of “democratic” load-current sharing of paralleled converter modules. IEEE Trans. Power Electron. 1996, 11, 604–611. [Google Scholar] [CrossRef]

- Shebani, M.M.; Iqbal, T.; Quaicoe, J.E. Synchronous Switching for Parallel-Connected DC-DC Boost Converters. In Proceedings of the IEEE Electrical Power and Energy Conference, Saskatoon, SS, Canada, 22–25 October 2017. [Google Scholar]

- Grbovic, P.J. Master/slave control of input-series-and output-parallel-connected converters: Concept for low-cost high-voltage auxiliary power supplies. IEEE Trans. Power Electron. 2009, 24, 316–328. [Google Scholar] [CrossRef]

- Choudhary, V.; Ledezma, G.; Ayyanar, R.; Button, R.M. Fault tolerant circuit topology and control method for input-series and output-parallel modular DC-DC converters. IEEE Trans. Power Electron. 2008, 23, 402–411. [Google Scholar] [CrossRef]

- Al-Sheikh, H.; Bennouna, O.; Hoblos, G.; Moubayed, N. Modeling, Design and Fault Analysis of Bidirectional DC-DC Converter for Hybrid Electric Vehicles. In Proceedings of the IEEE 23rd International Symposium on Industrial Electronics, Istanbul, Turkey, 1–4 June 2014. [Google Scholar]

- Lee, Y.; Emadi, A. Phase Shift Switching Scheme for DC/DC Boost Converter with Switches in Parallel. In Proceedings of the IEEE Vehicle Power and Propulsion Conference, Heilongjiang, China, 3–5 September 2008. [Google Scholar]

- Stala, R.; Waradzyn, Z.; Penczek, A.; Mondzik, A.; Skała, A. A switched-capacitor DC–DC converter with variable number of voltage gains and fault-tolerant operation. IEEE Trans. Ind. Electron. 2018, 66, 3435–3445. [Google Scholar] [CrossRef]

- Mohammadpour, A.; Parsa, L.; Todorovic, H.M.; Lai, R.; Datta, R.; Garces, L. Series-input parallel-output modular-phase dc–dc converter with soft-switching and high-frequency isolation. IEEE Trans. Power Electron. 2015, 31, 111–119. [Google Scholar] [CrossRef]

- Shahbazi, M.; Jamshidpour, E.; Poure, P.; Saadate, S.; Zolghadri, M.R. Open-and short-circuit switch fault diagnosis for nonisolated DC–DC converters using field programmable gate array. IEEE Trans. Ind. Electron. 2012, 60, 4136–4146. [Google Scholar] [CrossRef] [Green Version]

- Ribeiro, E.; Cardoso, A.J.M.; Boccaletti, C. Fault-tolerant strategy for a photovoltaic DC–DC converter. IEEE Trans. Power Electron. 2012, 28, 3008–3018. [Google Scholar] [CrossRef]

- Guilbert, D.; Guarisco, M.; Gaillard, A.; N’Diaye, A. FPGA based fault-tolerant control on an interleaved DC/DC boost converter for fuel cell electric vehicle applications. Int. J. Hydrogen Energy 2015, 40, 15815–15822. [Google Scholar] [CrossRef]

- Choi, B. Comparative study on paralleling schemes of converter modules for distributed power applications. IEEE Trans. Ind. Electron. 1998, 45, 194–199. [Google Scholar] [CrossRef]

- Ribeiro, E.; Cardoso, A.J.M.; Boccaletti, C. Open-circuit fault diagnosis in interleaved DC–DC converters. IEEE Trans. Power Electron. 2013, 29, 3091–3102. [Google Scholar] [CrossRef]

- Jamshidpour, E.; Shahbazi, M.; Poure, P.; Gholipour, E.; Saadate, S. Fault Tolerant Operation of Single-Ended Non-Isolated DC-DC Converters Under Open and Short-Circuit Switch Faults. In Proceedings of the European Conference on Power Electronics and Applications, Lille, France, 4 September 2013. [Google Scholar]

- Jamshidpour, E.; Shahbazi, M.; Poure, P.; Gholipour, E.; Saadate, S. FPGA Based Fault Detection and Fault Tolerance Operation in DC-DC Converters. In Proceedings of the IEEE International Symposium on Power Electronics, Electrical Drives, Automation and Motion, Ischia, Italy, 18–20 June 2014. [Google Scholar]

- Jamshidpour, E.; Poure, P.; Gholipour, E.; Saadate, S. Single-switch DC–DC converter with fault-tolerant capability under open-and short-circuit switch failures. IEEE Trans. Power Electron. 2014, 30, 2703–2712. [Google Scholar] [CrossRef] [Green Version]

- Lin, K.; Yu, R.L.; Moo, C.S.; Juan, C.Y. Analysis on Parallel Operation of Boost-Type Battery Power Modules. In Proceedings of the IEEE International Conference on Power Electronics and Drive Systems, Kitakyushu, Japan, 22 April 2013. [Google Scholar]

- Neacsu, D.O.; Bonnice, W.; Holmansky, E. On the Small-Signal Modeling of Parallel/Interleaved Buck/Boost Converters. In Proceedings of the IEEE International Symposium on Industrial Electronics, Bari, Italy, 4–7 July 2010. [Google Scholar]

- Pei, X.; Nie, S.; Kang, Y. Switch short-circuit fault diagnosis and remedial strategy for full-bridge DC–DC converters. IEEE Trans. Power Electron. 2014, 30, 996–1004. [Google Scholar] [CrossRef]

- Sheng, H.; Wang, F.; Tipton, C.W. A fault detection and protection scheme for three-level DC–DC converters based on monitoring flying capacitor voltage. IEEE Trans. Power Electron. 2011, 27, 685–697. [Google Scholar] [CrossRef]

- De-Bernardinis, A.; Coquery, G. First Approach for a Fault Tolerant Power Converter Interface for Multi-Stack PEM Fuel Cell Generator in Transportation Systems. In Proceedings of the International Power Electronics and Motion Control Conference, Poznan, Poland, 1–3 September 2008. [Google Scholar]

- Guilbert, D.; Gaillard, A.; N’Diaye, A.; Djerdir, A. Energy Efficiency and Fault Tolerance Comparison of DC/DC Converters Topologies for Fuel Cell Electric Vehicles. In Proceedings of the IEEE Transportation Electrification Conference and Expo, Novi, MI, USA, 19–21 June 2013. [Google Scholar]

- Huangfu, Y.; Zhuo, S.; Chen, F.; Pang, S. Evaluation and Fault Tolerant Control of a Floating Interleaved Boost Converter for Fuel Cell Systems. In Proceedings of the IEEE Industry Applications Society Annual Meeting, Portland, OR, USA, 2–6 October 2016. [Google Scholar]

- Khaligh, A.; Cao, J.; Lee, Y.J. A multiple-input DC–DC converter topology. IEEE Trans. Power Electron. 2009, 24, 862–868. [Google Scholar] [CrossRef]

- Dobbs, B.G.; Chapman, P.L. A multiple-input DC-DC converter topology. IEEE Power Electron. Lett. 2003, 1, 6–9. [Google Scholar] [CrossRef]

- Tomar, A.; Mishra, S. Multi-Input Single-Output DC-DC Converter Based PV Water Pumping System. In Proceedings of the IEEE 1st International Conference on Power Electronics, Intelligent Control and Energy Systems, Delhi, India, 4–6 July 2016. [Google Scholar]

- Caricchi, F.; Crescimbini, F.; Napoli, A.D.; Honorati, O.; Santini, E. Testing of a New DC/DC Converter Topology for Integrated Wind-Photovoltaic Generating Systems. In Proceedings of the Fifth European Conference on Power Electronics and Applications, Brighton, UK, 13–16 September 1993. [Google Scholar]

- Sira, H.J.; Silva, R. Control. Design Techniques in Power Electronics Devices; Springer: Cham, Switzerland, 2006; pp. 20–25. ISBN 1-84628-458-9. [Google Scholar]

- Lay, S.R. Convex Sets and Their Applications; Courier Corporation: New York, NY, USA, 2007; pp. 2–27. ISBN 0-48645-803-2. [Google Scholar]

- Boyd, S.; Ghaoui, E.; Feron, E.; Balakrishnan, V. Linear Matrix Inequalities in System and Control Theory; SIAM: Philadelphia, PA, USA, 1994; pp. 7–27. ISBN 0-89871-334-X. [Google Scholar]

© 2020 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rodríguez Licea, M.A. Fault Tolerant Boost Converter with Multiple Serial Inputs and Output Voltage Regulation for Vehicle-to-Aid Services. Energies 2020, 13, 1694. https://doi.org/10.3390/en13071694

Rodríguez Licea MA. Fault Tolerant Boost Converter with Multiple Serial Inputs and Output Voltage Regulation for Vehicle-to-Aid Services. Energies. 2020; 13(7):1694. https://doi.org/10.3390/en13071694

Chicago/Turabian StyleRodríguez Licea, Martín Antonio. 2020. "Fault Tolerant Boost Converter with Multiple Serial Inputs and Output Voltage Regulation for Vehicle-to-Aid Services" Energies 13, no. 7: 1694. https://doi.org/10.3390/en13071694

APA StyleRodríguez Licea, M. A. (2020). Fault Tolerant Boost Converter with Multiple Serial Inputs and Output Voltage Regulation for Vehicle-to-Aid Services. Energies, 13(7), 1694. https://doi.org/10.3390/en13071694