Experimental and Numerical Study on Flow Resistance and Bubble Transport in a Helical Static Mixer

Abstract

1. Introduction

2. Experimental Setup

2.1. Structure of the Helical Static Mixer

2.2. Experimental Setup

3. Numerical Model

3.1. Fluid Flow

3.2. Bubble Transport

3.3. Computational Domain and Mesh Generation

3.4. Flow Parameters and Boundary Conditions

4. Results and Discussion

4.1. Verification

4.2. Flow Resistance

4.2.1. Comparison of the Friction Factors

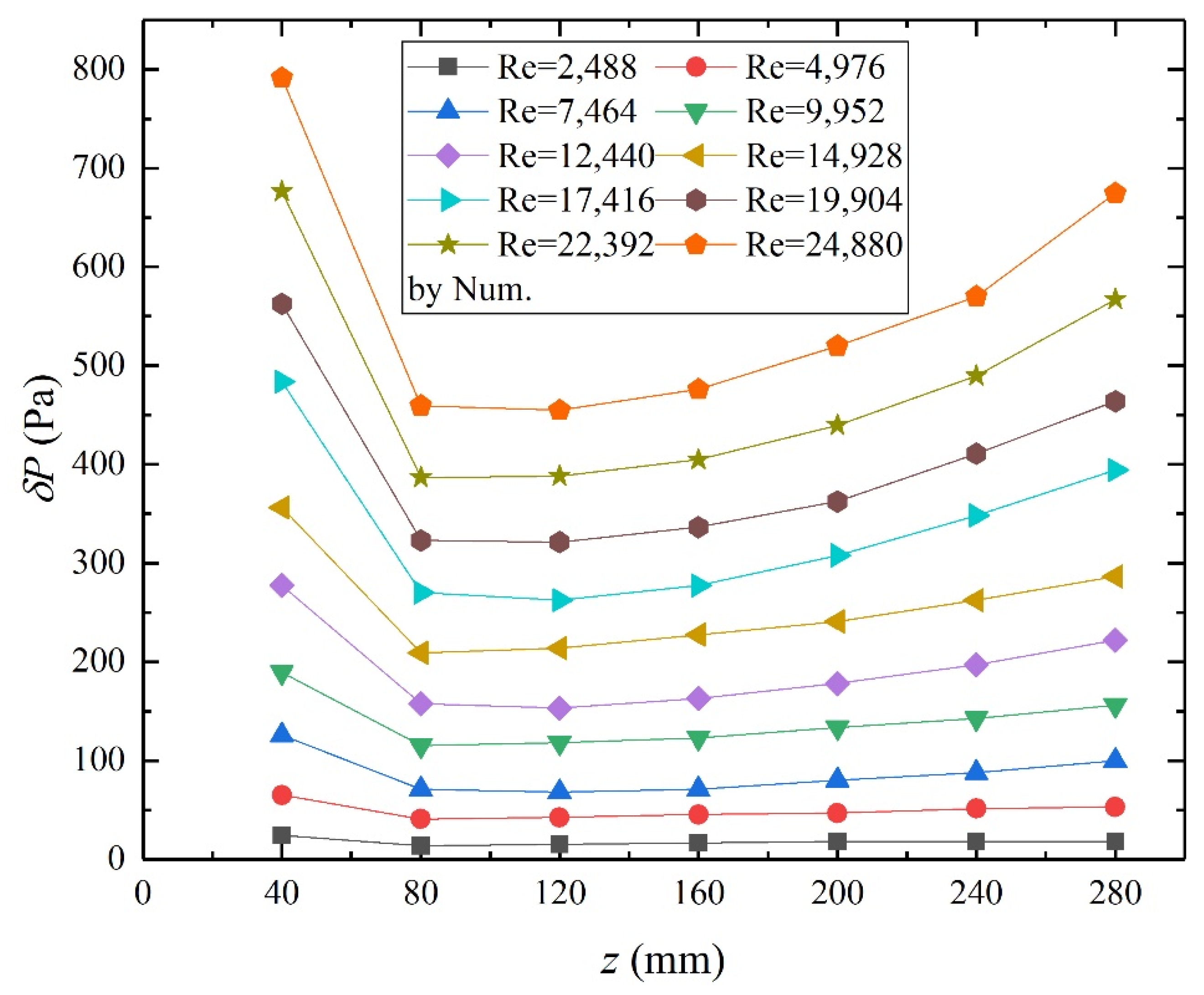

4.2.2. Effect of the Reynolds Number

4.2.3. Effect of the Variable-Pitch Coefficient

4.3. Bubble Transport

4.3.1. Change of the BSD

4.3.2. Effect of the Reynolds Number

4.3.3. Effect of the Variable-Pitch Coefficient

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

Appendix A

References

- Paul, E.L.; Atiemo-Obeng, V.A.; Kresta, S.M. Handbook of Industrial Mixing: Science and Practice; Wiley & Sons: Hoboken, NJ, USA, 2004. [Google Scholar] [CrossRef]

- Malecha, Z.M.; Malecha, K. Numerical analysis of mixing under low and high frequency pulsations at serpentine micromixers. Chem. Process. Eng. 2014, 35, 369–385. [Google Scholar] [CrossRef]

- Meng, H.; Zhu, G.; Yu, Y.; Wang, Z.; Wu, J. The effect of symmetrical perforated holes on the turbulent heat transfer in the static mixer with modified Kenics segments. Int. J. Heat Mass Transf. 2016, 99, 647–659. [Google Scholar] [CrossRef]

- Rabha, S.; Schubert, M.; Grugel, F.; Banowski, M.; Hampel, U. Visualization and quantitative analysis of dispersive mixing by a helical static mixer in upward co-current gas–liquid flow. Chem. Eng. J. 2015, 262, 527–540. [Google Scholar] [CrossRef]

- Park, J.M.; Kim, D.S.; Kang, T.G.; Kwon, T.H. Improved serpentine laminating micromixer with enhanced local advection. Microfluid. Nanofluid. 2008, 4, 513–523. [Google Scholar] [CrossRef]

- Stroock, A.D.; Dertinger, S.K.W.; Ajdari, A.; Mezić, I.; Stone, H.A.; Whitesides, G.M. Chaotic mixer for microchannels. Science 2002, 295, 647–651. [Google Scholar] [CrossRef]

- Zhang, C.; Ferrell, A.R.; Nandakumar, K. Study of a toroidal-helical pipe as an innovative static mixer in laminar flows. Chem. Eng. J. 2019, 359, 446–458. [Google Scholar] [CrossRef]

- Ghanem, A.; Lemenand, T.; Della Valle, D.; Peerhossaini, H. Static mixers: Mechanisms, applications, and characterization methods-a review. Chem. Eng. Res. Des. 2014, 92, 205–228. [Google Scholar] [CrossRef]

- Hobbs, D.; Muzzio, F. The Kenics static mixer: A three-dimensional chaotic flow. Chem. Eng. J. 1997, 67, 153–166. [Google Scholar] [CrossRef]

- Putra, R.A.; Neumann-Kipping, M.; Schäfer, T.; Lucas, D. Comparison of gas–liquid flow characteristics in geometrically different swirl generating devices. Energies 2019, 12, 4653. [Google Scholar] [CrossRef]

- Lei, Y.G.; Zhao, C.H.; Song, C.F. Enhancement of turbulent flow heat transfer in a tube with modified twisted tapes. Chem. Eng. Technol. 2012, 35, 2133–2139. [Google Scholar] [CrossRef]

- Rahimi, M.; Shabanian, S.R.; Alsairafi, A.A. Experimental and CFD studies on heat transfer and friction factor characteristics of a tube equipped with modified twisted tape inserts. Chem. Process. Eng. 2009, 48, 762–770. [Google Scholar] [CrossRef]

- Cui, Y.-Z.; Tian, M.-C. Three-dimensional numerical simulation of thermal-hydraulic performance of a circular tube with edgefold-twisted-tape inserts. J. Hydrodyn. Ser. B 2010, 22, 662–670. [Google Scholar] [CrossRef]

- Cerezo, J.; Best, R.; Chan, J.J.; Romero, R.J.; Hernandez, J.I.; Lara, F. A theoretical-experimental comparison of an improved ammonia-water bubble absorber by means of a helical static mixer. Energies 2017, 11, 56. [Google Scholar] [CrossRef]

- Thianpong, C.; Eiamsa-ard, P.; Eiamsa-ard, S. Heat transfer and thermal performance characteristics of heat exchanger tube fitted with perforated twisted-tapes. Heat Mass Transf. 2012, 48, 881–892. [Google Scholar] [CrossRef]

- Eiamsa-ard, S.; Nuntadusit, C.; Promvonge, P. Effect of twin delta-winged twisted-tape on thermal performance of heat exchanger tube. Heat Transf. Eng. 2013, 34, 1278–1288. [Google Scholar] [CrossRef]

- Zidouni, F.; Krepper, E.; Rzehak, R.; Rabha, S.; Schubert, M.; Hampel, U. Simulation of gas–liquid flow in a helical static mixer. Chem. Eng. Sci. 2015, 137, 476–486. [Google Scholar] [CrossRef]

- Ushikubo, F.Y.; Furukawa, T.; Nakagawa, R.; Enari, M.; Makino, Y.; Kawagoe, Y.; Shiina, T.; Oshita, S. Evidence of the existence and the stability of nano-bubbles in water. Colloids Surf. Phys. Eng. Asp. 2010, 361, 31–37. [Google Scholar] [CrossRef]

- Turner, W.R. Microbubble persistence in fresh water. J. Acoust. Soc. Am. 1961, 33, 1223. [Google Scholar] [CrossRef]

- Lawrie, A.; Brisken, A.F.; Francis, S.E.; Cumberland, D.C.; Crossman, D.C.; Newman, C.M. Microbubble-enhanced ultrasound for vascular gene delivery. Genetherapy 2000, 7, 2023. [Google Scholar] [CrossRef]

- Sakai, O.; Kimura, M.; Shirafuji, T.; Tachibana, K. Underwater microdischarge in arranged microbubbles produced by electrolysis in electrolyte solution using fabric-type electrode. Appl. Phys. Lett. 2008, 93, 3. [Google Scholar] [CrossRef]

- Sadatomi, M.; Kawahara, A.; Matsuura, H.; Shikatani, S. Micro-bubble generation rate and bubble dissolution rate into water by a simple multi-fluid mixer with orifice and porous tube. Exp. Therm. Fluid Sci. 2012, 41, 23–30. [Google Scholar] [CrossRef]

- Heyouni, A.; Roustan, M.; Do-Quang, Z. Hydrodynamics and mass transfer in gas–liquid flow through static mixers. Chem. Eng. Sci. 2002, 57, 3325–3333. [Google Scholar] [CrossRef]

- Putra, R.A.; Schäfer, T.; Neumann, M.; Lucas, D. CFD studies on the gas–liquid flow in the swirl generating device. Nucl. Eng. Des. 2018, 332, 213–225. [Google Scholar] [CrossRef]

- Cong, T.; Zhang, X. Numerical study of bubble coalescence and breakup in the reactor fuel channel with a vaned grid. Energies 2018, 11, 256. [Google Scholar] [CrossRef]

- Falzone, S.; Buffo, A.; Vanni, M.; Marchisio, D.L. Simulation of Turbulent Coalescence and Breakage of Bubbles and Droplets in the Presence of Surfactants, Salts, and Contaminants. Adv. Chem. Eng. 2018, 52, 125–188. [Google Scholar] [CrossRef]

- Martinez, C.; Rodriguez, J.; Deane, G.; Montañes, J.; Lasheras, J. Considerations on bubble fragmentation models. J. Fluid Mech. 2010, 661, 159–177. [Google Scholar] [CrossRef]

- Tran-Cong, S.; Marié, J.-L.; Perkins, R.J. Bubble migration in a turbulent boundary layer. Int. J. Multiph. Flow 2008, 34, 786–807. [Google Scholar] [CrossRef]

- Azizi, F.; Al Taweel, A. Population balance simulation of gas–liquid contacting. Chem. Eng. Sci. 2007, 62, 7436–7445. [Google Scholar] [CrossRef]

- Coulaloglou, C.; Tavlarides, L. Description of interaction processes in agitated liquid-liquid dispersions. Chem. Eng. Sci. 1977, 32, 1289–1297. [Google Scholar] [CrossRef]

- Vyakaranam, K.V.; Kokini, J.L. Prediction of air bubble dispersion in a viscous fluid in a twin-screw continuous mixer using FEM simulations of dispersive mixing. Chem. Eng. Sci. 2012, 84, 303–314. [Google Scholar] [CrossRef]

- Nguyen, V.T.; Song, C.-H.; Bae, B.-U.; Euh, D.-J. Modeling of bubble coalescence and break-up considering turbulent suppression phenomena in bubbly two-phase flow. Int. J. Multiph. Flow 2013, 54, 31–42. [Google Scholar] [CrossRef]

- Chouippe, A.; Climent, E.; Legendre, D.; Gabillet, C. Numerical simulation of bubble dispersion in turbulent Taylor-Couette flow. Phys. Fluids 2014, 26, 043304. [Google Scholar] [CrossRef]

- Mukin, R. Modeling of bubble coalescence and break-up in turbulent bubbly flow. Int. J. Multiph. Flow 2014, 62, 52–66. [Google Scholar] [CrossRef]

- Liao, Y.; Rzehak, R.; Lucas, D.; Krepper, E. Baseline closure model for dispersed bubbly flow: Bubble coalescence and breakup. Chem. Eng. Sci. 2015, 122, 336–349. [Google Scholar] [CrossRef]

- Kumar, S.; Ramkrishna, D. On the solution of population balance equations by discretization-I. A fixed pivot technique. Chem. Eng. Sci. 1996, 51, 1311–1332. [Google Scholar] [CrossRef]

- Asiagbe, K.S.; Fairweather, M.; Njobuenwu, D.O.; Colombo, M. Large eddy simulation of microbubble transport in a turbulent horizontal channel flow. Int. J. Multiph. Flow 2017, 94, 80–93. [Google Scholar] [CrossRef][Green Version]

- Jaworski, Z.; Pianko-Oprych, P.; Marchisio, D.L.; Nienow, A.W. CFD modelling of turbulent drop breakage in a Kenics static mixer and comparison with experimental data. Chem. Eng. Res. Des. 2007, 85, 753–759. [Google Scholar] [CrossRef]

- Lobry, E.; Theron, F.; Gourdon, C.; Le Sauze, N.; Xuereb, C.; Lasuye, T. Turbulent liquid-liquid dispersion in SMV static mixer at high dispersed phase concentration. Chem. Eng. Sci. 2011, 66, 5762–5774. [Google Scholar] [CrossRef]

- Lebaz, N.; Sheibat-Othman, N. A population balance model for the prediction of breakage of emulsion droplets in SMX+ static mixers. Chem. Eng. J. 2019, 361, 625–634. [Google Scholar] [CrossRef]

- Arffman, A.; Marjamäki, M.; Keskinen, J. Simulation of low pressure impactor collection efficiency curves. J. Aerosol Sci. 2011, 42, 329–340. [Google Scholar] [CrossRef]

- Liao, Y.; Lucas, D. A literature review of theoretical models for drop and bubble breakup in turbulent dispersions. Chem. Eng. Sci. 2009, 64, 3389–3406. [Google Scholar] [CrossRef]

- Saffman, P.; Turner, J. On the collision of drops in turbulent clouds. J. Fluid Mech. 1956, 1, 16–30. [Google Scholar] [CrossRef]

- Qin, C.; Yang, N. Population balance modeling of breakage and coalescence of dispersed bubbles or droplets in multiphase systems. Prog. Chem. 2016, 28, 1207–1223. [Google Scholar] [CrossRef]

- Barthelmes, G.; Pratsinis, S.; Buggisch, H. Particle size distributions and viscosity of suspensions undergoing shear-induced coagulation and fragmentation. Chem. Eng. Sci. 2003, 58, 2893–2902. [Google Scholar] [CrossRef]

- Yu, M.; Lin, J.; Chan, T. A new moment method for solving the coagulation equation for particles in Brownian motion. Aerosol Sci. Technol. 2008, 42, 705–713. [Google Scholar] [CrossRef]

- Chan, T.L.; Liu, S.; Yue, Y. Nanoparticle formation and growth in turbulent flows using the bimodal TEMOM. Powder Technol. 2018, 323, 507–517. [Google Scholar] [CrossRef]

- Yu, P.; Jiang, J.; Cheng, K. Preparation of oxygen-enriched water by spiral cutter and its process optimization. Light Ind. Mach. 2018, 36, 41–47. [Google Scholar] [CrossRef]

- Zhi-qing, W. Study on correction coefficients of liminar and turbulent entrance region effect in round pipe. Appl. Math. Mech. Engl. 1982, 3, 433–446. [Google Scholar] [CrossRef]

- Theron, F.; Sauze, N.L. Comparison between three static mixers for emulsification in turbulent flow. Int. J. Multiph. Flow 2011, 37, 488–500. [Google Scholar] [CrossRef]

- Sugiyama, K.; Calzavarini, E.; Lohse, D. Microbubbly drag reduction in Taylor-Couette flow in the wavy vortex regime. J. Fluid Mech. 2008, 608, 21–41. [Google Scholar] [CrossRef]

- Chen, L.; Asai, K.; Nonomura, T.; Xi, G.; Liu, T. A review of backward-facing step (BFS) flow mechanisms, heat transfer and control. Therm. Sci. Eng. Prog. 2018, 6, 194–216. [Google Scholar] [CrossRef]

| Static Mixer Design | Diameter (mm) | Mixing Length (mm) | Number of Elements | Global Porosity (%) |

|---|---|---|---|---|

| KSM (Chemineer Inc., Ohio, USA) [38] | 19.1 | 687.6 | 24 | 78 |

| PKMS [3] | 40 | 960 | 12 | 90.8–93.3 |

| SMV (Sulzer Inc. Winterthur, Switzerland) [39] | 10 | 50 | 5 | 83 |

| SMX+ (Sulzer Inc.) [40] | 5 | 50 | 10 | 75 |

| TTT [16] | 19 | 1000 | 1 | 94.6 |

| Current HSM | 25 | 280 | 1 | 68.5 |

| Grid Name | Number of Elements (104) | Pressure Drop (Pa) | Relative Error of Pressure Drop (%) |

|---|---|---|---|

| Grid 1 | 1845 | 3352.4 | - |

| Grid 2 | 1074 | 3318.8 | 1.0 |

| Grid 3 | 552 | 3228.4 | 3.7 |

| Grid 4 | 385 | 3007.1 | 10.3 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yuan, F.; Cui, Z.; Lin, J. Experimental and Numerical Study on Flow Resistance and Bubble Transport in a Helical Static Mixer. Energies 2020, 13, 1228. https://doi.org/10.3390/en13051228

Yuan F, Cui Z, Lin J. Experimental and Numerical Study on Flow Resistance and Bubble Transport in a Helical Static Mixer. Energies. 2020; 13(5):1228. https://doi.org/10.3390/en13051228

Chicago/Turabian StyleYuan, Fangyang, Zhengwei Cui, and Jianzhong Lin. 2020. "Experimental and Numerical Study on Flow Resistance and Bubble Transport in a Helical Static Mixer" Energies 13, no. 5: 1228. https://doi.org/10.3390/en13051228

APA StyleYuan, F., Cui, Z., & Lin, J. (2020). Experimental and Numerical Study on Flow Resistance and Bubble Transport in a Helical Static Mixer. Energies, 13(5), 1228. https://doi.org/10.3390/en13051228