Comparative Evaluation of Lifetime of Three-Level Inverters in Grid-Connected Photovoltaic Systems

Abstract

1. Introduction

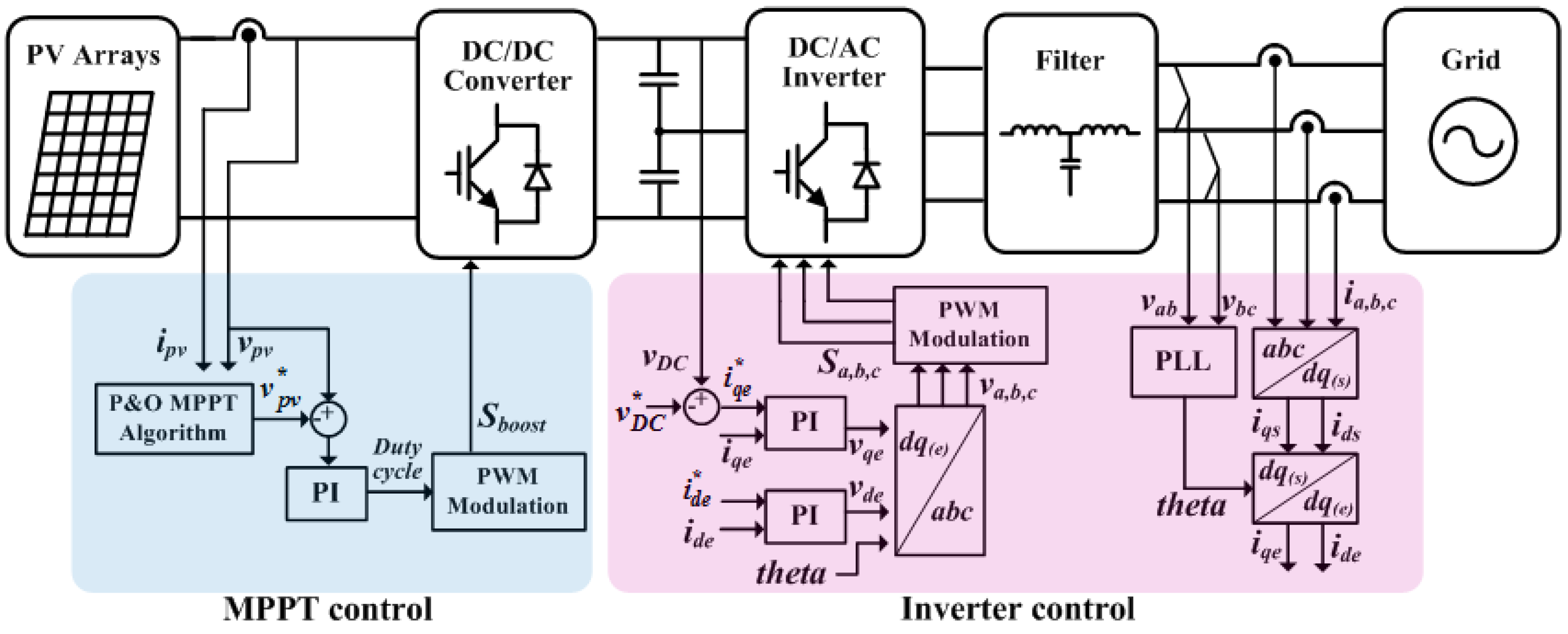

2. PV NPC and T-Type Inverters

2.1. Description of PV System Configurations of NPC and T-Type Inverters

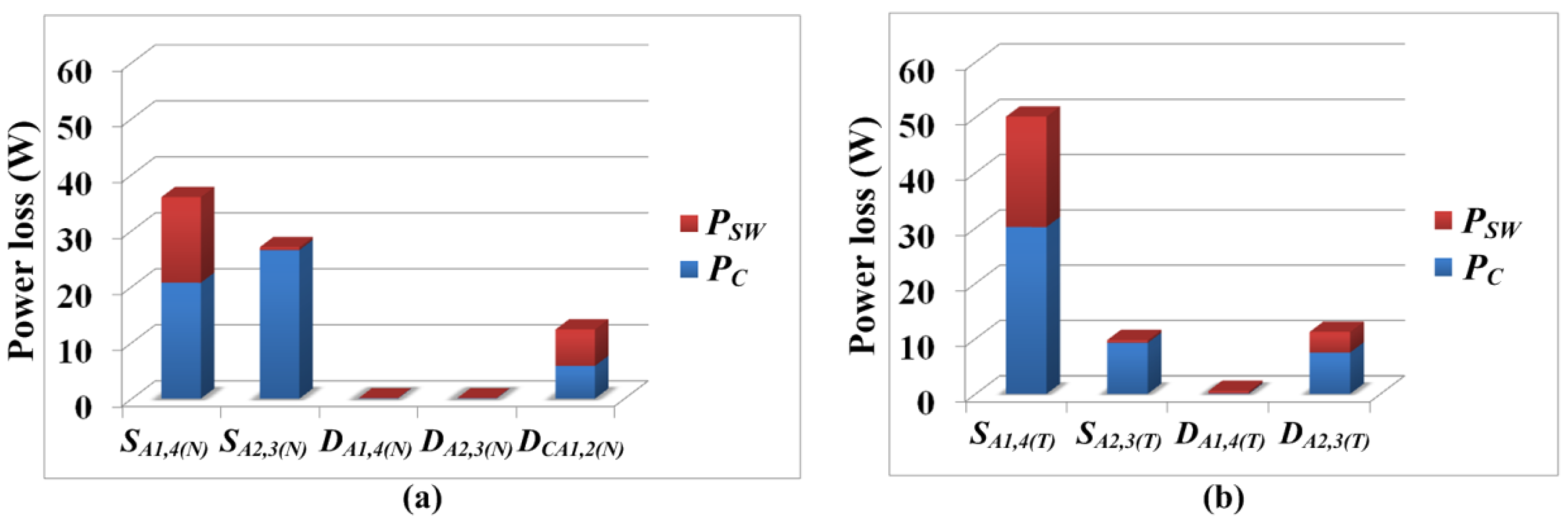

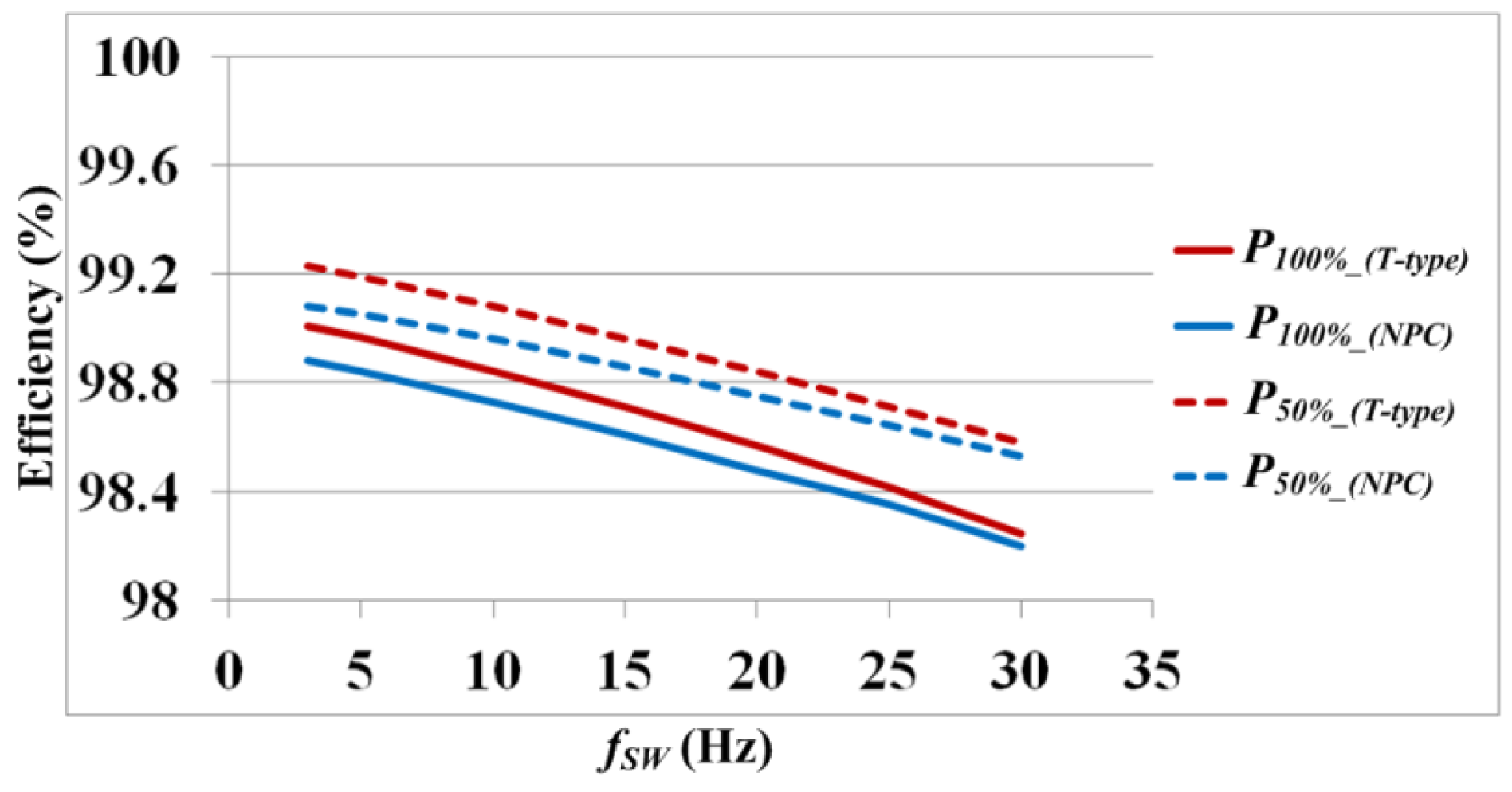

2.2. Efficiencies and Power Loss Distributions of NPC and T-Type Inverters

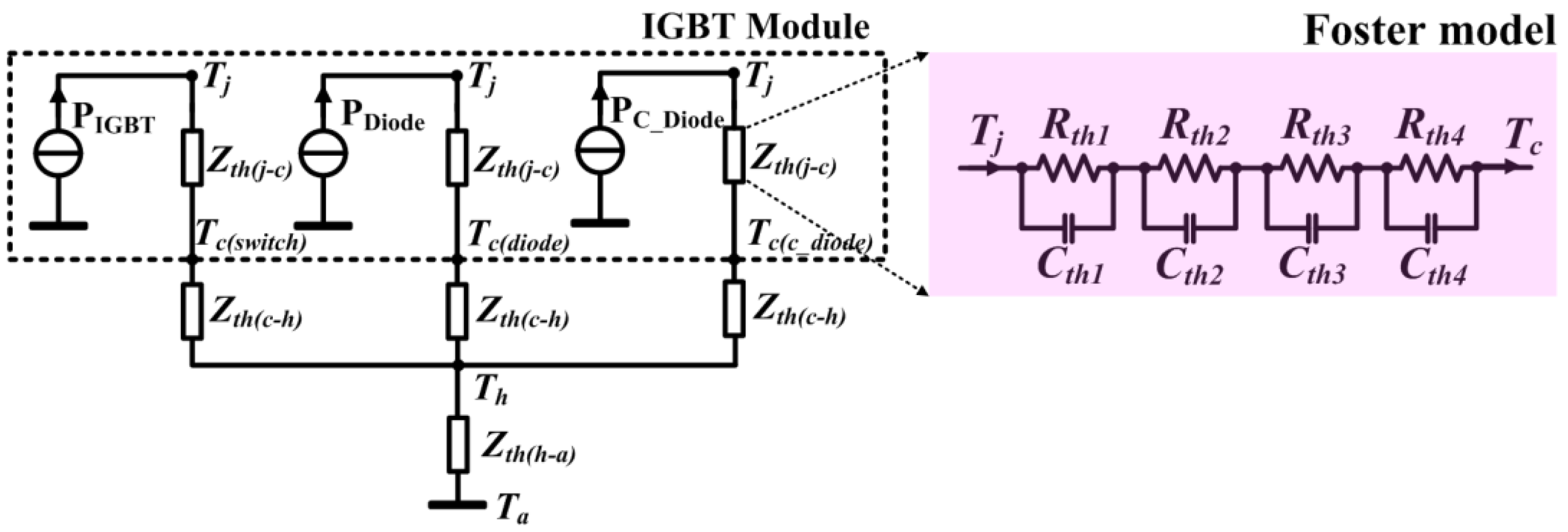

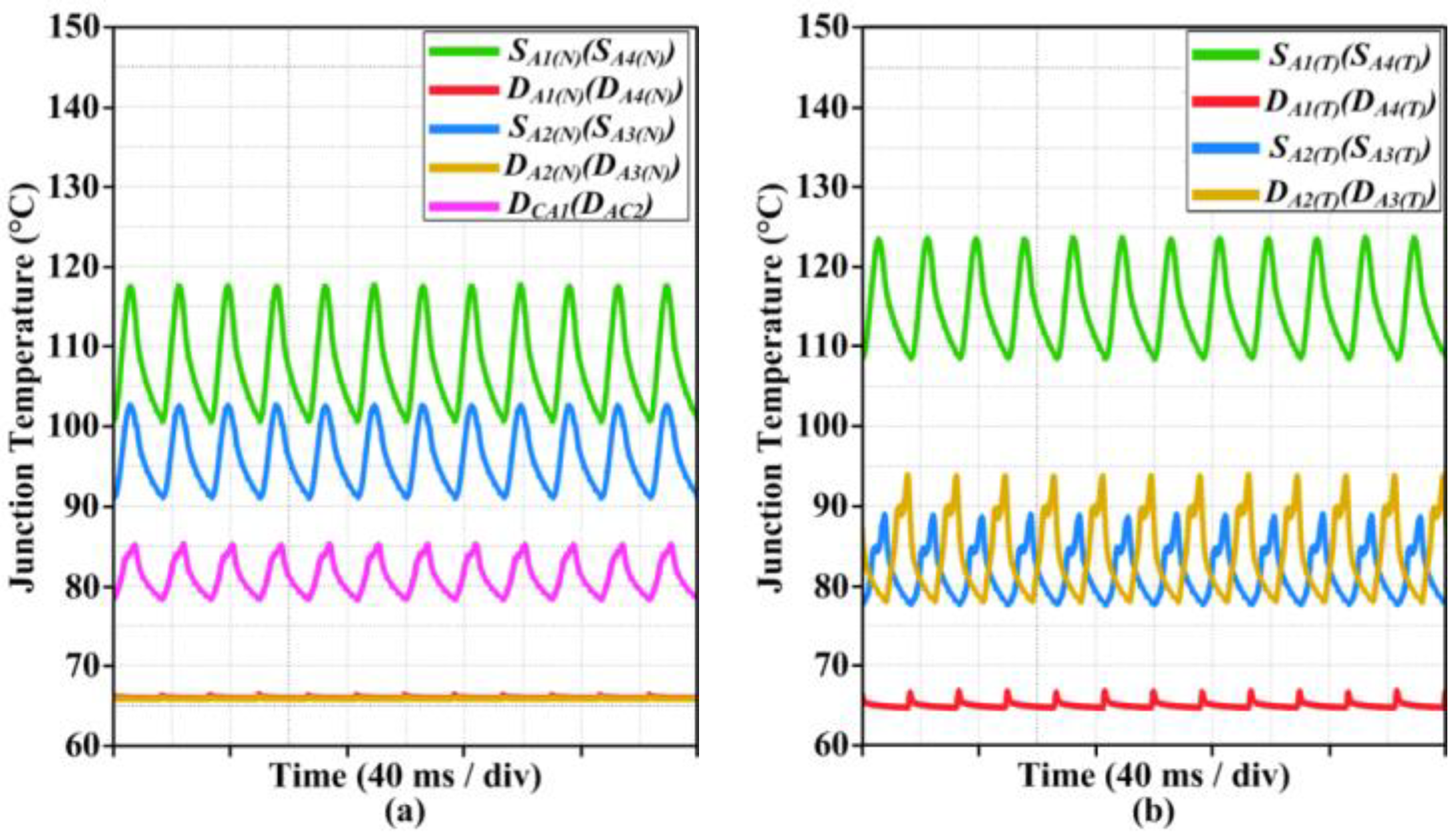

2.3. Temperature Distributions of NPC and T-Type Inverters

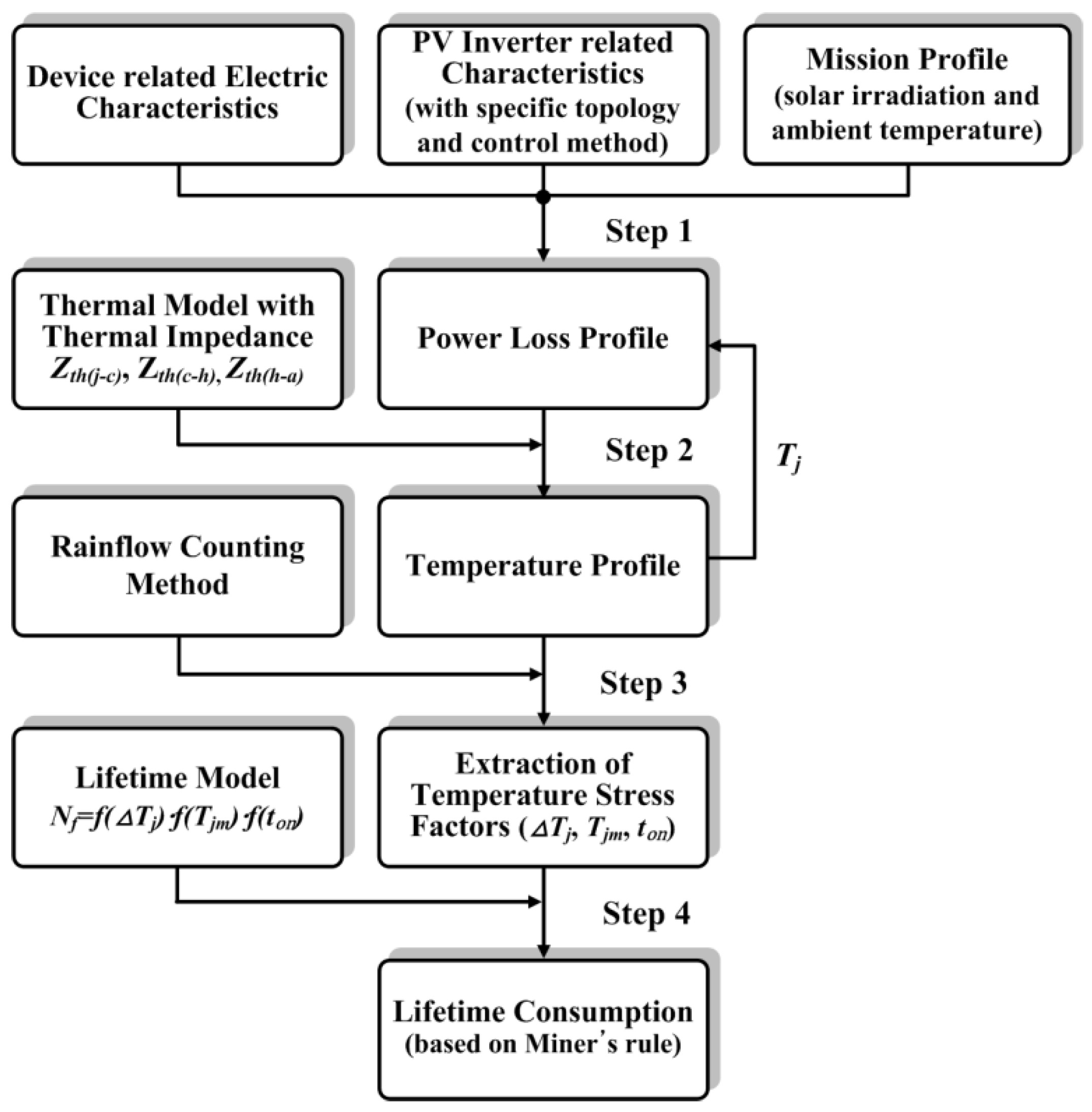

3. Lifetime Evaluation of NPC and T-Type Inverters

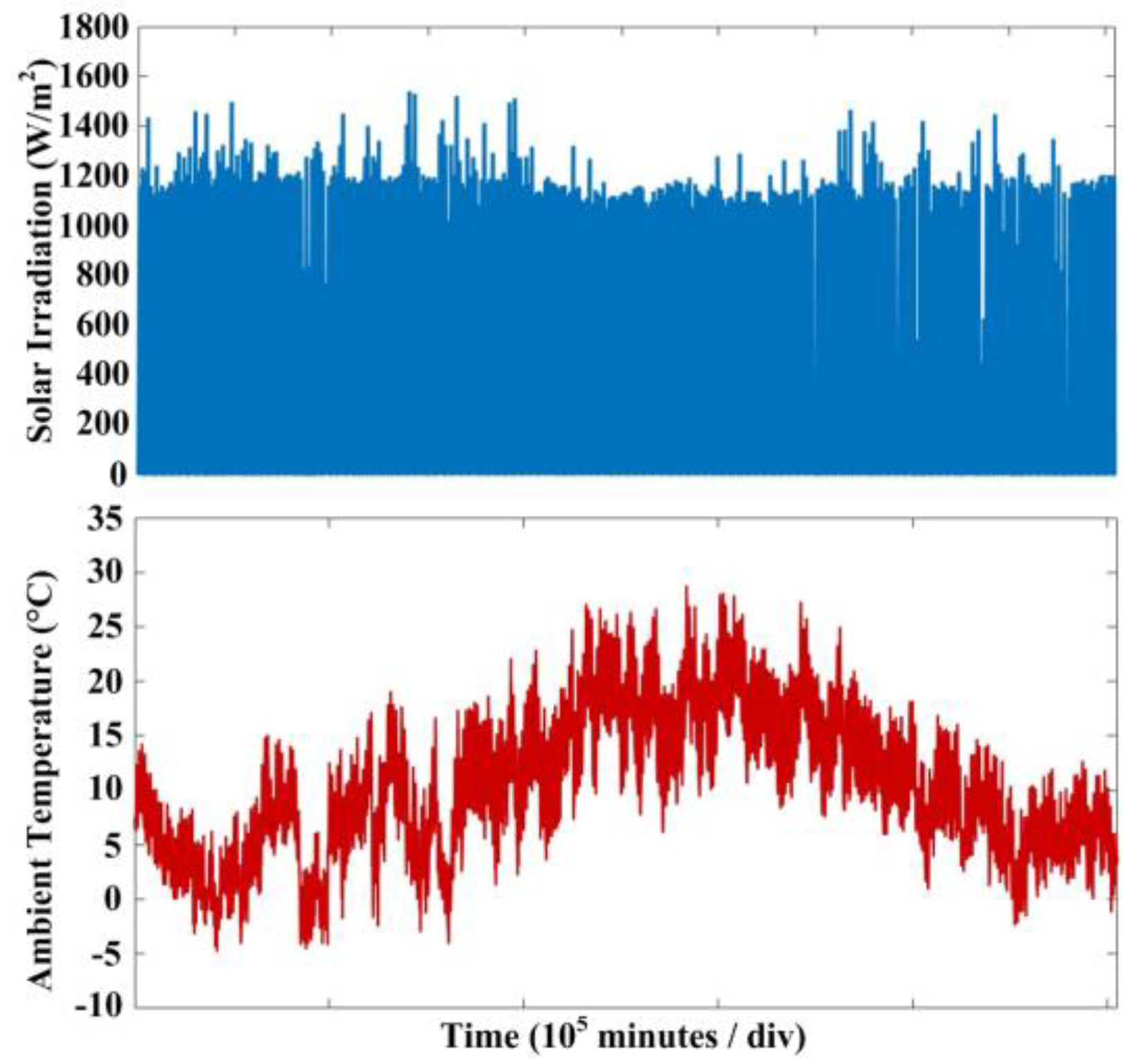

3.1. Mission Profile of PV System

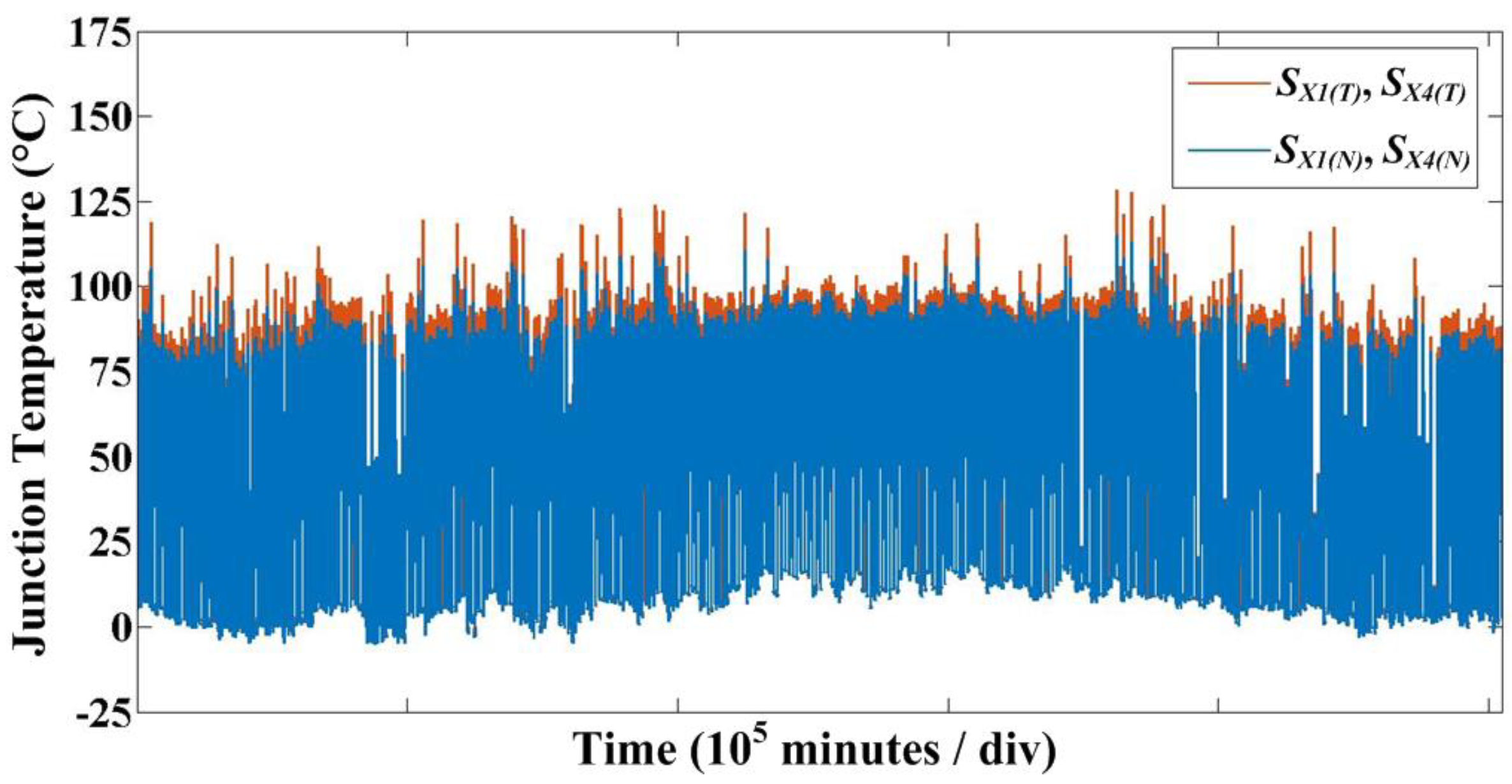

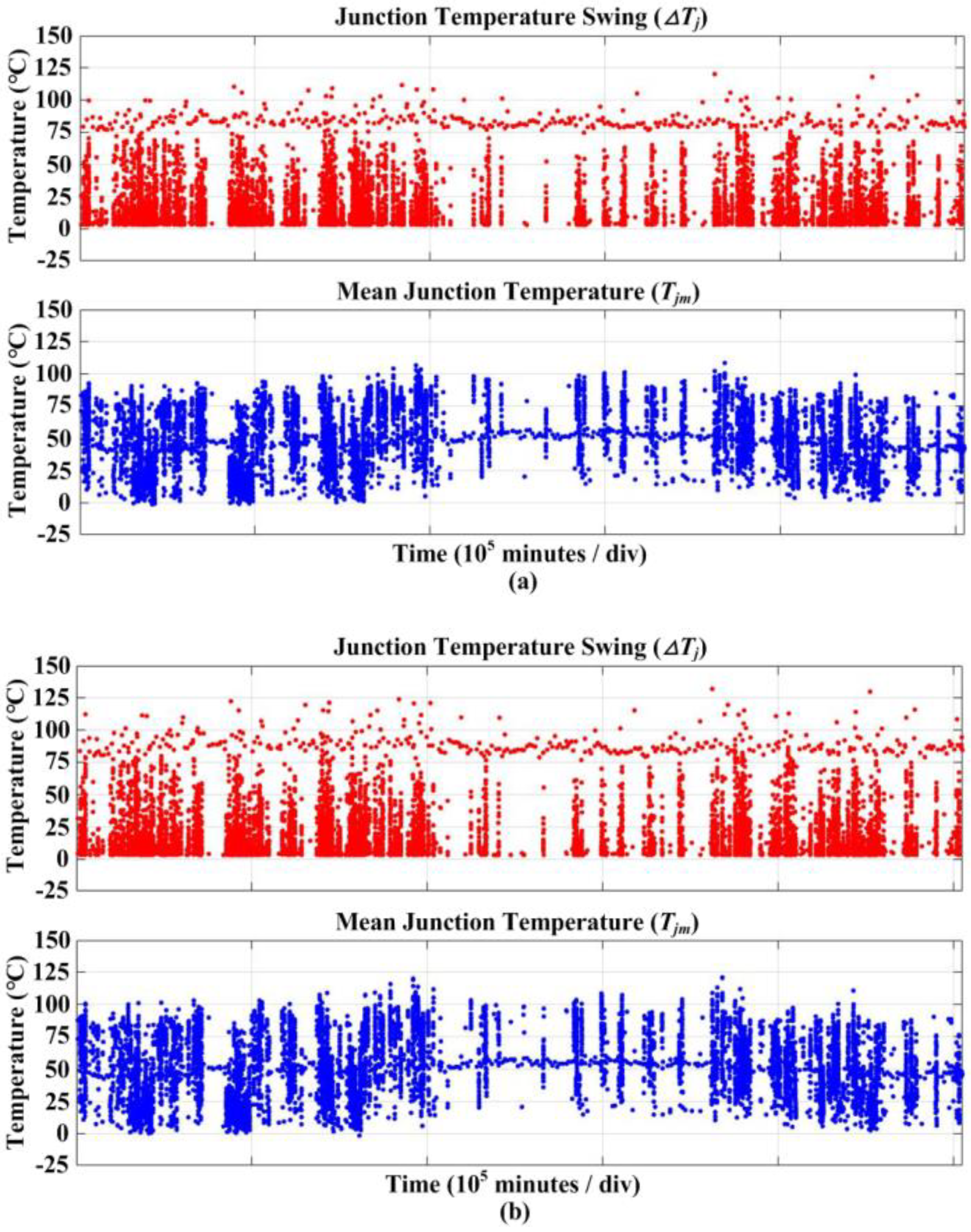

3.2. Junction Temperature Profile from Mission Profile

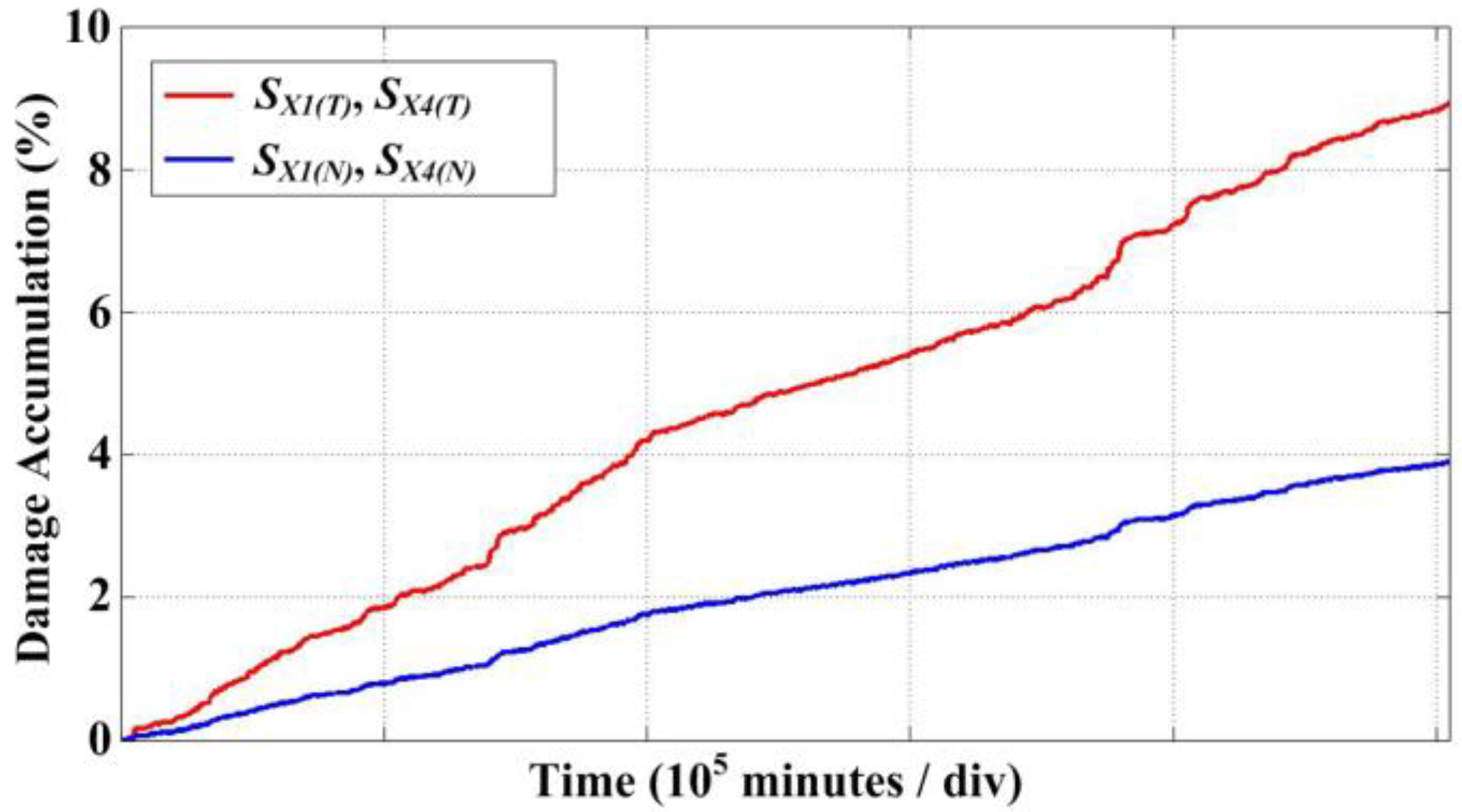

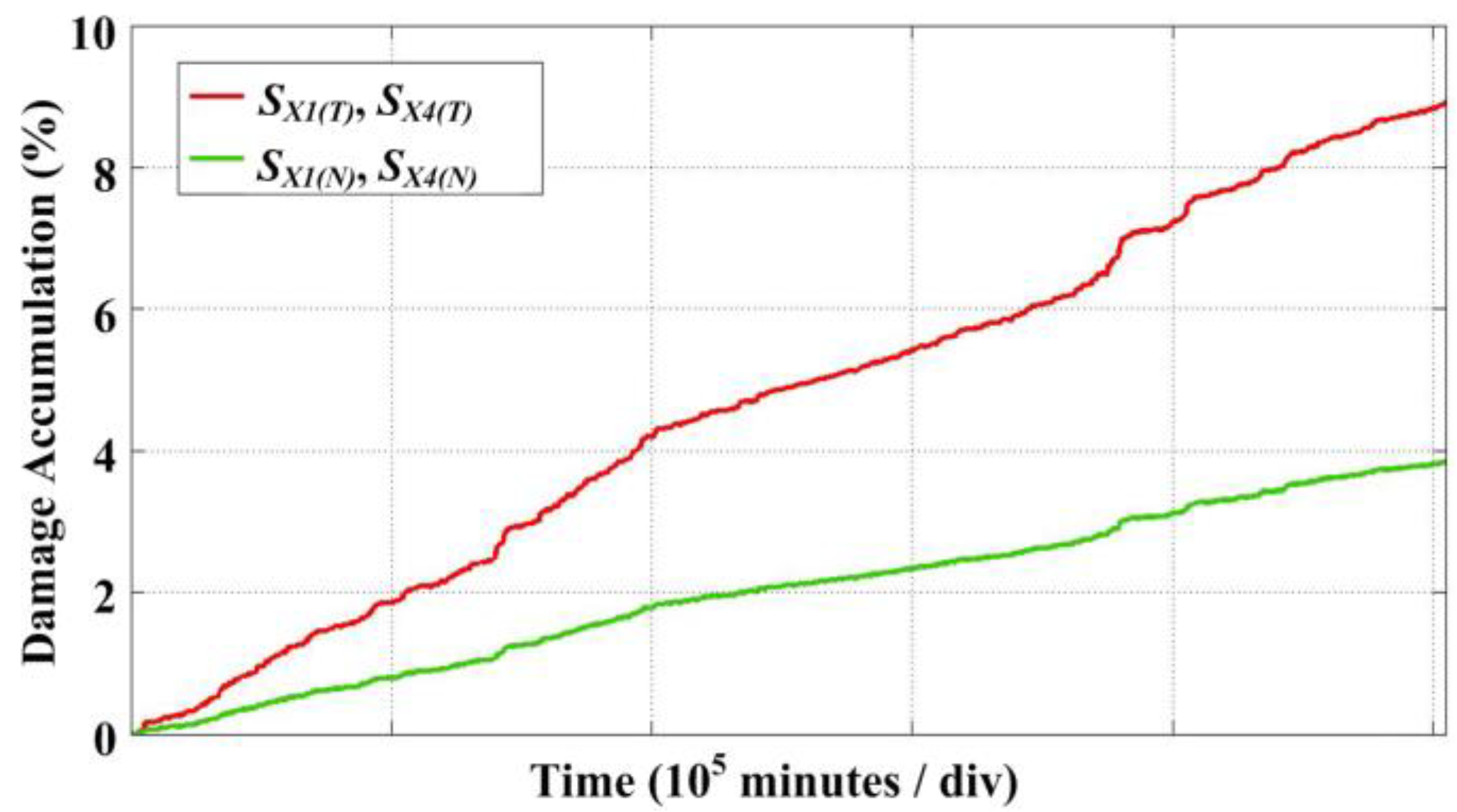

3.3. Lifetime Evaluation

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- REN21, Paris, France, Renewables 2018: Global Status Report (GRS). 2018. Available online: http://www.ren21.net/ (accessed on 26 June 2018).

- Woodhouse, M.; Feldman, R.D.; Fu, R.; Horowitz, K.; Chung, D.; Jordan, D.; Kurtz, S. On the Path to SunShot: The Role of Advancements in Solar Photovoltaic Efficiency, Reliability, and Costs; NREL/TP-6A20-65872; National Renewable Energy Laboratory: Golden, CO, USA, 2016.

- Moore, L.M.; Post, H.N. Five years of operating experience at a large, utility-scale photovoltaic generating plant. Prog. Photovolt. Res. Appl. 2008, 16, 249–259. [Google Scholar] [CrossRef]

- Solar Bankability. Technical Risks in PV Projects: Report on Technical Risks in PV Project Development and PV Plant Operation; European Union: Brussels, Belgium, 2016. [Google Scholar]

- Choi, U.M.; Blaabjerg, F.; Jorgensen, S. Power Cycling Test Methods for Reliability Assessment of Power Device Modules in Respect to Temperature Stress. IEEE Tran. Power Electron. 2018, 33, 2531–2551. [Google Scholar] [CrossRef]

- Dbeiss, M.; Avenas, Y.; Zara, H.; Dupont, L.; Al Shakarchi, F. A Method for Accelerated Aging Tests of Power Modules for Photovoltaic Inverters Considering the Inverter Mission Profiles. IEEE Trans. Power Electron. 2019, 34, 12226–12234. [Google Scholar] [CrossRef]

- Sangwongwanich, A.; Shen, Y.; Chub, A.; Liivik, E.; Vinnikov, D.; Wang, H.; Blaabjerg, F. Mission Profile-based Accelerated Testing of DC-link Capacitors in Photovoltaic Inverters. In Proceedings of the 2019 IEEE APEC, Anaheim, CA, USA, 17–21 March 2019. [Google Scholar]

- Choi, U.M.; Blaabjerg, F. Separation of Wear-Out Failure Modes of IGBT Modules in Grid-Connected Inverter Systems. IEEE Trans. Power Electron. 2018, 33, 6217–6223. [Google Scholar] [CrossRef]

- Agarwal, N.; Ahmad, M.W.; Anand, S. Quasi-Online Technique for Health Monitoring of Capacitor in Single-Phase Solar Inverter. IEEE Trans. Power Electron. 2018, 33, 5283–5291. [Google Scholar] [CrossRef]

- Huang, H.; Mawby, P.A. A Lifetime Estimation Technique for Voltage Source Inverters. IEEE Trans. Power Electron. 2013, 28, 4113–4119. [Google Scholar] [CrossRef]

- Yang, Y.; Wang, H.; Blaabjerg, F.; Kerekes, T. A Hybrid Power Control Concept for PV Inverters With Reduced Thermal Loading. IEEE Trans. Power Electron. 2014, 29, 6271–6275. [Google Scholar] [CrossRef]

- Aly, M.; Ahmed, E.M.; Shoyama, M. Modulation Method for Improving Reliability of Multilevel T-type Inverter in PV Systems. IEEE J. Emerg. Sel. Top. Power Electron. 2019. [Google Scholar] [CrossRef]

- Khan, M.N.H.; Forouzesh, M.; Siwakoti, Y.P.; Li, L.; Kerekes, T.; Blaabjerg, F. Transformerless Inverter Topologies for Single-Phase Photovoltaic Systems: A Comparative Review. IEEE J. Emerg. Sel. Top. Power Electron. 2020, 8, 805–835. [Google Scholar] [CrossRef]

- Yang, Y.; Wang, H.; Blaabjerg, F.; Ma, K. Mission Profile based Multi-Disciplinary Analysis of Power Modules in Single-Phase Transformerless Photovoltaic Inverters. In Proceedings of the 15th European Conference on Power Electronics and Applications (EPE), Lille, France, 2–6 September 2013. [Google Scholar]

- Schweizer, M.; Kolar, J.W. Design and Implementation of a Highly Efficient Three-Level T-Type Converter for Low-Voltage Applications. IEEE Trans. Power Electron. 2013, 28, 899–907. [Google Scholar] [CrossRef]

- Choi, U.M.; Ma, K.; Blaabjerg, F. Validation of Lifetime Prediction of IGBT Modules Based on Linear Damage Accumulation by Means of Superimposed Power Cycling Tests. IEEE Trans. Ind. Electron. 2018, 65, 3520–3529. [Google Scholar] [CrossRef]

- Schweizer, M.; Friedli, T.; Kolar, J.W. Comparative Evaluation of Advanced Three-Phase Three-Level Inverter/Converter Topologies Against Two-Level Systems. IEEE Trans. Ind. Electron. 2013, 60, 5515–5527. [Google Scholar] [CrossRef]

- Kouro, S.; Leon, J.I.; Vinnikov, D.; Franquelo, L.G. Grid-Connected Photovoltaic Systems: An Overview of Recent Research and Emerging PV Converter Technology. IEEE Ind. Electron. Mag. 2015, 9, 47–61. [Google Scholar] [CrossRef]

- Mitsubishi Electric, Power Module Reliability. pp. 1–13. Available online: www.mitsubishielectric.com/semiconductors/products/pdf/reliability/0512_e.pdf (accessed on 25 December 2019).

- Choi, U.M.; Blaabjerg, F.; Lee, K.B. Study and Handling Methods of Power IGBT Module Failures in Power Electronic Converter Systems. IEEE Trans. Power Electron. 2015, 30, 2517–2533. [Google Scholar] [CrossRef]

- Choi, U.M.; Vernica, I.; Blaabjerg, F. Effect of Asymmetric Layout of IGBT Modules on Reliability of Motor Drive Inverters. IEEE Trans. Power Electron. 2019, 34, 1765–1772. [Google Scholar] [CrossRef]

- Musallam, M.; Johnson, C.M. An Efficient Implementation of the Rainflow Counting Algorithm for Life Consumption Estimation. IEEE Trans. Reliab. 2012, 61, 978–986. [Google Scholar] [CrossRef]

- Bayerer, R.; Herrmann, T.; Licht, T.; Lutz, J.; Feller, M. Model for Power Cycling lifetime of IGBT Modules—Various factors influencing lifetime. In Proceedings of the 5th International Conference on Integrated Power Electronics Systems, Nuremberg, Germany, 11–13 March 2008. [Google Scholar]

- Scheuermann, U.; Schmidt, R. A New Lifetime Model for Advanced Power Modules with Sintered Chips and Optimized Al Wire Bonds. In Proceedings of the International Exhibition and Conference for Power Electronics, Intelligent Motion, Renewable Energy and Energy Management, Nuremberg, Germany, 1–10 May 2013. [Google Scholar]

| Parameters | Value |

|---|---|

| Rated output power (P) | 30 kW |

| DC-link voltage (VDC) | 650 V |

| Grid phase voltage (Vg) | 220 Vrms |

| Output current (I) | 45.45 Arms |

| Grid frequency (fgrid) | 60 Hz |

| Power factor | 1 |

| IGBT module (NPC) | F3L75R07W2E3_B11 |

| IGBT module (T-type) | F3L75R12W1H3_B27 |

| Topology | Thermal Impedance | Point (i) | ||||

|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | |||

| NPC IGBT Module (F3L75R07W2E3_B11) | R(j−h) (K/W) | IGBT (SX1,2,3,4) | 0.051 | 0.117 | 0.426 | 0.506 |

| Diode (DX1,2,3,4) | 0.097 | 0.219 | 0.576 | 0.508 | ||

| Diode (DCX1,2,3,4) | 0.062 | 0.145 | 0.444 | 0.449 | ||

| τ (s) | - | 0.0005 | 0.005 | 0.05 | 0.2 | |

| T-type IGBT Module (F3L75R12W1H3_B27) | R(j−h) (K/W) | IGBT (SX1,4) | 0.032 | 0.062 | 0,312 | 0.543 |

| IGBT (SX2,3) | 0.142 | 0.309 | 0.719 | 0.58 | ||

| Diode (DX1,4) | 0.15 | 0.323 | 0.739 | 0.588 | ||

| Diode (DX2,3) | 0.25 | 0.3 | 0.5 | 0.65 | ||

| τ (s) | - | 0.0005 | 0.005 | 0.05 | 0.2 | |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Choi, U.-M.; Lee, J.-S. Comparative Evaluation of Lifetime of Three-Level Inverters in Grid-Connected Photovoltaic Systems. Energies 2020, 13, 1227. https://doi.org/10.3390/en13051227

Choi U-M, Lee J-S. Comparative Evaluation of Lifetime of Three-Level Inverters in Grid-Connected Photovoltaic Systems. Energies. 2020; 13(5):1227. https://doi.org/10.3390/en13051227

Chicago/Turabian StyleChoi, Ui-Min, and June-Seok Lee. 2020. "Comparative Evaluation of Lifetime of Three-Level Inverters in Grid-Connected Photovoltaic Systems" Energies 13, no. 5: 1227. https://doi.org/10.3390/en13051227

APA StyleChoi, U.-M., & Lee, J.-S. (2020). Comparative Evaluation of Lifetime of Three-Level Inverters in Grid-Connected Photovoltaic Systems. Energies, 13(5), 1227. https://doi.org/10.3390/en13051227