Abstract

The Coefficient of Performance of an ordinary water-cooled chiller is presented as a relationship with the chiller load factor and cooling water temperature. However, the cooling water temperature fluctuates according to the processed heat of the cooling tower originating in the cooling energy of the chiller and to the outside temperature and humidity. It is therefore difficult to obtain the cooling water temperature under the processed-heat and weather conditions at the time of evaluation. This, in turn, makes it difficult to determine the Coefficient of Performance of a water-cooled chiller at the evaluation time. In this research, we formulated the Coefficient of Performance of a water-cooled chiller as a relationship with the chiller load factor and specific enthalpy of outside air. Specifically, we used the Number of Transfer Units (NTU) model of a cooling tower to calculate the cooling water temperature corresponding to the cooling-tower load factor targeting a counterflow cooling tower for a range of values of outside-air specific enthalpy. This technique makes it possible to evaluate the Coefficient of Performance of a water-cooled chiller without determining the cooling water temperature. Furthermore, for the case of installing multiple units of chillers, it becomes possible to calculate the composite Coefficient of Performance of those chillers without having to determine the cooling water temperatures for the different operation load factors of those chillers. Moreover, since the composite Coefficient of Performance can be calculated by combining the different installation capacities of these chillers, the energy consumption of multiple chillers can be calculated at the basic planning stage.

1. Introduction

In developed countries, energy consumption is reaching 20–40% in residential houses and commercial buildings topping that in the industry and transport sectors [1]. In Japan, meanwhile, energy consumption in the residential and commercial sectors for 2018 came to 38.8% (residential sector: 17.7% and commercial sector: 21.1%) [2]. Energy consumption in the commercial sector increased at an annual rate of 1.6% from 1990 to 2012 [2]. Against this background, surveys and studies on the modeling of energy consumption have been conducted to better understand energy consumption in buildings with the aim of reducing overall energy consumption [3]. Although differing according to building use, a breakdown of energy consumption in the United States has shown that the energy required by Heating, Ventilation, and Air Conditioning (HVAC) makes up 50% of a building’s energy consumption [1]. There is also a report stating that energy for heating decreased while energy for air conditioning increased in 2012 compared with 2003 [4]. In Spain, moreover, a survey found that energy for air conditioning made up 36% of overall building energy [3].

In Japan, energy consumption intensity has been improving year over year due to the introduction of energy-saving equipment and control systems and energy-saving initiatives. For example, energy consumption intensity for office buildings in Tokyo from April 2016 to March 2017 improved to 1460 MJ/m2/year (which ranks in the upper 25% of energy consumption intensity values) [5], but there are concerns that energy for air conditioning will increase due to recent rises in air temperature. Consequently, to reduce energy consumption in buildings, it is important that the demand for air conditioning be reduced and that energy efficiency in cooling supply be further improved. To this end, a chiller must be appropriately selected in accordance with the building’s cooling demand.

When selecting a chiller, it is important to consider the Coefficient of Performance (COP) of that equipment during rated operation, partial-load operation, etc. and to evaluate the amount of energy consumed by the equipment. The manufacturer of the chiller provides the COP values for different chiller load factors (referred to below as “COP characteristics”) as equipment specifications. For air-cooled chillers and water-cooled chillers, COP characteristics are given for different air temperatures and different cooling water temperatures, respectively [6,7]. A designer can calculate the amount of energy consumed by the chiller (consumed energy = cooling-demand/COP) from the COP characteristics provided by the manufacturer and from the cooling energy of the chiller and outside temperature and humidity (referred to below as “outside air conditions”). Differences in the energy consumption of different types of chillers can therefore be evaluated.

The cooling water of a water-cooled chiller is generally cooled using a cooling tower. In addition, the temperature of cooling water cooled by a cooling tower (referred to below as “cooling water temperature”) is often evaluated with reference to the wet-bulb temperature of outside air for the sake of simplicity. However, cooling water temperature fluctuates according to outside air conditions and the processed heat of the cooling tower, the latter of which originates from the cooling energy and the amount of energy consumed by the chiller. As a result, cooling water temperature of the chiller cannot be correctly determined by simply setting up a relationship between the cooling capacity of the cooling tower and the outside wet-bulb temperature or outside-air specific enthalpy. This, in turn, means that it may not be possible to correctly evaluate the COP of a water-cooled chiller. In particular, for a chiller whose COP value fluctuates greatly according to the cooling water temperature and the chiller load factor, a correct understanding of cooling water temperature at the time of evaluation is essential for calculating energy consumption of the chiller.

With this in mind, and targeting a counterflow cooling tower, we set up the cooling water temperature of the cooling tower as a relationship with outside air specific enthalpy and the chiller load factor after setting cooling tower specifications. We then formulated the COP for different load factors of the water-cooled chiller and for each outside air specific enthalpy using the relationship established between the outside air specific enthalpy and the cooling water temperature.

In this study, we report on a method for calculating the cooling water temperature of a cooling tower and present COP characteristics data of water-cooled chillers for each outside-air specific enthalpy based on theoretical calculations of cooling water temperature. We also show that composite COP when installing multiple units of water-cooled chillers or multiple units with different capacities can be evaluated using these COP characteristics data and report evaluation results.

2. Formulation of COP Characteristics of Water-Cooled Chiller

2.1. Method of Calculating Cooling Water Temperature of Cooling Tower

In the study of cooling towers, simple calculation methods have been proposed for determining the cooling water temperature, power consumption of cooling tower fan, and cooling water consumption using theoretical analysis and a computational model [8]. Experimental studies have also been carried out to extend the computational model. For example, evaluations of the thermal performance of a cooling tower based on filling layout patterns have been reported, and the heat transfer rate according to cooling tower height level [9] and cooling capacity according to differences in wet bulb temperature and in the ratio of the cooling water volume to blast volume [10,11] have been evaluated. In addition, research on cooling tower conditions has been performed to evaluate the optimization of the entire heat source system including the cooling tower [12,13].

A study using the number of transfer units (NTU) has been proposed for calculating the cooling water temperature of a cooling tower [8], but in this study, we used Tower Performance Factor (TPF) instead of NTU. Here, TPF is equal to NTU divided by ratio of cooling water volume (L: kg/h) to blast volume (G: kgDA/h; L/G). In this study, we treated the heat transfer rate for different cooling tower heights and L/G as fixed calculation conditions.

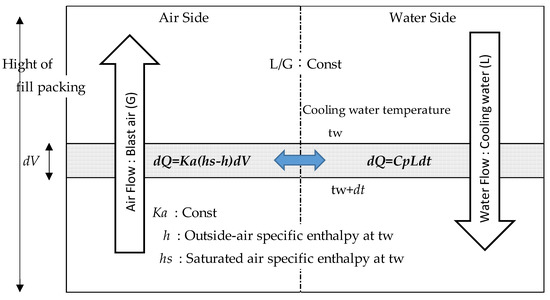

Derivation of TPF for a counterflow cooling tower is given by Equations (1)–(5). Each equation represents the relationship of heat transfer between air and water in the counterflow cooling tower. Figure 1 is a schematic diagram showing the state of each equation in the cooling tower.

Figure 1.

Schematic diagram showing the state of each equation in the cooling tower.

The amount of heat exchange between the cooling air and water in the cooling tower is proportional to the difference between the specific enthalpy of the saturated air and the outside-air specific enthalpy at the same temperature as that of the cooling water. Consequently, the amount of heat exchange in the blast air is given by Equation (1). On the other hand, the amount of heat exchange in the cooling water is given by Equation (2). Here, since the amounts of heat exchange on the air side and the cooling water side are the same, Equation (3) is obtained from Equations (1) and (2). The TPF value is obtained by integrating the height of the fill packing after transforming Equation (3) into Equation (4) and is given by Equation (5).

- : Amount of heat exchange (kJ/h).

- : Heat transfer rate (kJ/m3·h·Δh), Δh .

- : Specific enthalpy of saturated air at the same temperature as the temperature (tw) of the cooling water (kJ/kgDA).

- : Outside-air specific enthalpy at the same temperature as the temperature (tw) of the cooling water (kJ/kgDA).

- : Fill packing volume of cooling tower (m3).

- : Cooling water volume (kg/h).

- : Specific heat of water = 4.186 (kJ/kg·K).

- tw1: Design cooling water inlet temperature (°C).

- tw2: Design cooling water outlet temperature (°C).

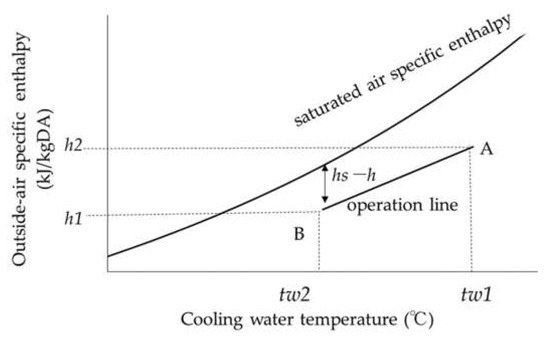

The relationship between various TPF-related quantities is shown in Figure 2 [14] as the relationship between cooling water temperature and outside-air specific enthalpy. The operation line shown in Figure 2 (t-h diagram) is the line connecting point A (intersection of cooling water inlet temperature and outlet outside-air specific enthalpy) and point B (intersection of cooling water outlet temperature and inlet outside-air specific enthalpy). The slope of this line is L/G.

Figure 2.

Operation line of the counterflow cooling tower and Tower Performance Factor (TPF)-related quantities.

From Equation (5), TPF is the integration of the inverse of the difference between outside-air specific enthalpy (denoted as h in the figure) and specific enthalpy of saturated air at that temperature (denoted as hs in the figure) along points on the operation line from the cooling-water outlet temperature to inlet temperature. The various quantities shown in Equation (5) and Figure 2, namely, inlet air temperature/humidity, rated blast volume, rated flow, outlet/inlet cooling water temperature, and rated processed heat of the cooling tower, are released as product specifications of the cooling tower. In addition, the outside-air specific enthalpy at the outlet can be calculated by dividing the rated processed heat of the cooling tower by the rated blast volume, so the TPF of the cooling tower can be calculated using Equation (5).

Furthermore, for the same cooling tower, TPF is fixed regardless of inlet air conditions and amount of processed heat as long as there is no change in cooling water flow and blast volume. Consequently, for cases in which inlet air conditions and amount of processed heat fluctuate, points A and B in Figure 2 also shift and a new operation line forms so that the TPF under the new conditions remains the same as the TPF determined from product specifications. Cooling-water outlet temperature can therefore be obtained by determining a new operation line on the t-h diagram.

The specific procedure for calculating the cooling water temperature is as follows:

First, the cooling water inlet temperature is given as an initial value, and the cooling water outlet temperature is obtained from the processed heat of cooling tower and the cooling water volume (Equation (7)). Then, after calculating the cooling tower outlet air specific enthalpy using the processed heat of the cooling tower and the inlet air specific enthalpy (Equation (8)), the points A and B in Figure 2 are determined and a new operation line is obtained. The TPF for the new operation line is calculated using Equation (6). The cooling-inlet-temperature is determined by a succession of calculations in the manner of the Newton iterative method until the TPF under the new conditions is the same as the TPF determined from product specifications.

- TPF_d: TPF from product specifications

- TPF at new inlet air conditions or processed heat of cooling tower

- : Cooling water inlet temperature as initial value (°C)

- Cooling water outlet temperature determined by calculation using cooling water inlet temperature (°C)

- Inlet air specific enthalpy from cooling tower at new inlet air conditions (kJ/kgDA)

- Outlet air specific enthalpy from cooling tower determined by calculation using inlet air specific enthalpy of cooling tower (kJ/kgDA)

- G: Blast volume (kgDA/h)

- Q: Processed heat of cooling tower (kJ/h)

Figure 3 and Table 1 shows the relationship between the cooling water temperature and cooling-tower load factor (cooling-tower-processed-heat/rated capacity) calculated for different values of specific enthalpy of the cooling tower inlet air. In the calculation, it is assumed that the cooling water flow and blast volume are unchanged regardless of the cooling-tower load factor.

Figure 3.

Relationship between the cooling water temperature and cooling-tower load factor.

Table 1.

Cooling water temperature in each cooling-tower load factor and outside air specific enthalpy.

Cooling tower specifications used in the calculations are listed in Table 2. However, the results shown in Figure 3 also hold for a counterflow cooling tower outside the cooling tower specifications of Table 2 as long as the cooling-tower inlet air conditions, cooling-water inlet/outlet temperatures, and L/G from the TPF formula are the same.

Table 2.

Cooling tower specifications used in the calculations.

Figure 2 and Table 1 shows the relationship between cooling water temperature and cooling-tower load factor (cooling-tower-processed-heat/rated capacity) calculated for different values of specific enthalpy of the cooling tower inlet air. In the calculation, it is assumed that the cooling water flow and blast volume are unchanged regardless of the cooling-tower load factor.

Cooling tower specifications used in the calculations are listed in Table 2. However, the results shown in Figure 2 also hold for a counterflow cooling tower outside the cooling tower specifications of Table 2 as long as the cooling-tower inlet air conditions, cooling-water inlet/outlet temperatures, and L/G from the TPF formula are the same.

The reason for calculating the cooling water temperature for different values of outside-air specific enthalpy in Figure 3 is that cooling water temperature fluctuates with outside-air temperature and humidity, but if the outside-air specific enthalpy is the same, the cooling water temperature is the same even if the outside-air temperature and humidity are different. From Figure 3, it can be seen that cooling water temperature dropped as the outside-air specific enthalpy decreased and that it approached the outside wet-bulb temperature as the load factor dropped for the same outside-air specific enthalpy. In addition, the difference in the cooling water temperature for the same cooling-tower load factor became greater as the outside-air specific enthalpy decreased. The difference in cooling water temperature between load factors of 1.0 and 0.1 came to 14.4 °C for an outside-air specific enthalpy of 10 kJ/kgDA.

2.2. Chiller Load Factor and Cooling Water Temperature

The COP characteristics of a water-cooled chiller provided by the manufacturer are presented as values with respect to chiller load factors. It is therefore necessary in the end to indicate the cooling water temperature cooled using a cooling tower in terms of its relationship with the outside-air specific enthalpy and the chiller load factor (chiller load/rated capacity). On the other hand, the processed heat of the cooling tower shown in Figure 3, while originating in the cooling energy of the chiller, includes some of the energy consumed by the chiller other than the cooling energy of that chiller (referred to below as “chiller waste heat”). The energy consumed by the chiller affects the COP based on the chiller load factor and cooling water temperature, so the cooling-tower load factor and chiller load factor differ. We therefore evaluated the difference between these two load factors after calculating the cooling energy and chiller waste heat for different chiller load factors and determining the processed heat of the cooling tower.

Using an absorption chiller as an example, the relationship between cooling-tower processed heat and chiller waste heat is shown in Figure 4. Some of the energy consumed by the chiller is discarded by machine room ventilation and other means as radiated heat from the body of the equipment while the rest is discarded through the cooling tower as chiller waste heat. The value of this waste heat fluctuates according to ventilation conditions and other factors, but it can be estimated from the ratio of the cooling-tower processed heat to rated capacity of the chiller, the former of which is determined from the rated cooling-water pump flow of the chiller and cooling-water return temperature difference.

Figure 4.

Relationship between cooling-tower processed heat and chiller waste heat.

For an absorption chiller, the ratio of cooling-tower processed heat to rated capacity of the chiller as determined from a manufacturer’s catalog [7] is 1.67, which means that the chiller waste heat can be estimated to be 67% of the cooling energy. Here, the ratio of cooling-tower processed heat to chiller rated capacity is fixed regardless of the chiller capacity. Referring to Figure 4, energy consumption at a rating time of an absorption chiller having a rated capacity of 5063 MJ/h was 3895 MJ/h (rated-capacity/COP, COP = 1.3), chiller waste heat was 3389 MJ/h (67% of cooling energy), and cooling-tower processed heat was 8452 MJ/h (167% of cooling energy). The chiller waste heat was 87% of the energy consumption (waste-heat/energy-consumption), so 13% of the consumed energy was discarded via ventilation, etc. On the other hand, the ratio of cooling-tower processed heat to chiller rated capacity for a turbo chiller likewise determined from a manufacturer’s catalog [6] is 1.18. As a result, energy consumption at rating time of a turbo chiller having a rated capacity of 5063 MJ/h was 1013 MJ/h (rated-capacity/COP, COP = 5.0), chiller waste heat was 911 MJ/h (18% of cooling energy), and cooling-tower processed heat was 5975 MJ/h (118% of cooling energy). The chiller waste heat was therefore 90% of the energy consumption, so the amount of heat discarded via ventilation, etc. can be estimated to be 10% of energy consumption.

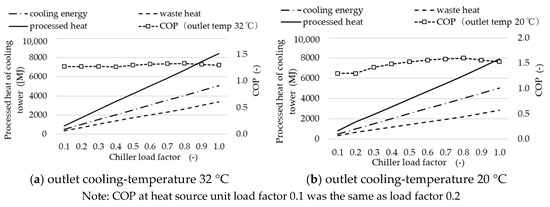

The chiller waste heat under rated operation was estimated to be 87% of the energy consumption for an absorption chiller and 90% for a turbo chiller, but the amount of energy consumed also fluctuated under partial load operation due to the fluctuation of the chiller COP at this time. For this reason, considering that the ratio of chiller waste heat to energy consumption was unchanged from that of rated operation even under partial loads, we evaluated chiller waste heat and partial-load COP and determined the cooling-tower processed heat. The cooling energy and chiller waste heat is shown together with COP [15] for different chiller load factors in Figure 5 and Figure 6 for an absorption chiller and inverter-controlled turbo chiller, respectively, both with a rated capacity of 5063 MJ/h. In the figures, the cooling energy was proportional to the chiller load factor, but energy consumption fluctuates according to the COP value based on chiller load factor and cooling water temperature.

Figure 5.

Cooling energy and chiller waste heat (absorption chiller).

Figure 6.

Cooling energy and chiller waste heat (inverter-controlled turbo chiller).

Cooling-tower load factor with respect to chiller load factor as determined from Figure 5 and Figure 6 is shown in Figure 7. The cooling-tower load factor and chiller load factor differed from each other when COP under partial load operation differed from rated COP. In other words, for the case that COP under partial load operation was lower than rated COP, energy consumption of the chiller increased with the result that the cooling-tower load factor became larger than the chiller load factor. On the other hand, for the case that partial-load COP was higher than rated COP, the cooling-tower load factor became smaller than the chiller load factor. The difference between the cooling-tower load factor and chiller load factor at maximum was 8% for the absorption chiller (cooling water temperature: 20 °C and load factor: 0.8) and 15% for the inverter-controlled turbo chiller (cooling water temperature: 32 °C and load factor: 0.2). These maximum values occurred when the difference between partial-load COP and rated COP was maximum. Even for other types of water-cooled chillers, namely, fixed-speed turbo chillers and water-cooled chillers using rotary vane pumps, the difference between partial-load COP and rated COP was smaller than that of an inverter-controlled turbo chiller, so the maximum difference between cooling-tower load factor and chiller load factor could be evaluated at 15%. With this in mind, we used Equation (5) to calculate fluctuation in cooling water temperature for a range of outside-air specific enthalpy values for the case that all cooling-tower load factors differed from the chiller load factor by 15% (Table 3). These results show that the maximum range of fluctuation in the cooling water temperature for a 15% difference between the cooling-tower load factor and chiller load factor was from −1.7 °C to 1.5 °C with an average value of −0.13 °C. We therefore assessed that error in cooling water temperature would be small even if determining the cooling-tower load factor to be the same as chiller load factor.

Figure 7.

Cooling-tower load factor with respect to chiller load factor.

Table 3.

Change in cooling water temperature from base temperature.

2.3. COP Characteristics of Water-Cooled Chiller

Based on the cooling water temperature taking outside air conditions and the chiller load factor into account, we arranged COP characteristics of a water-cooled chiller by different values of outside-air specific enthalpy. Arranging chiller COP characteristics as outside-air specific enthalpy in this way enables chiller COP to be evaluated taking into account outside air conditions in the evaluation area, and at the same time, enables this COP to be compared with COP of an air-cooled chiller provided for different values of outside air temperature. This makes it easy to calculate energy consumption for different types of chillers in basic planning, etc.

We selected as water-cooled chillers an absorption chiller, fixed-speed turbo chiller, inverter-controlled turbo chiller, and water-cooled chiller using a rotary vane pump. We also arranged COP for different load factors of a water-cooled chiller using “COP ratio”, which is the ratio of COP at the time of operation to rated COP. In this regard, COP characteristics by the chiller load factor and outside air conditions differ for each type of chiller [15]. On the other hand, rated COP can differ even for the same model of chiller owing to differences in rated capacity. As a result, arranging chiller COP as COP ratio enables COP to be determined even for a chiller with various rated capacities. The COP ratio for different types of water-cooled chillers by the load factor and cooling water temperature is shown in Figure 8 [15].

Figure 8.

Coefficient of Performance (COP) ratio by the load factor for water-cooled chillers.

Figure 9 shows the schematic diagram of the procedure (Steps 1–3) for obtaining Figure 10. Figure 10 shows the COP ratio characteristics for water-cooled chillers in relationship to the chiller load factor and outside-air specific enthalpy. To obtain the COP ratio characteristics, we applied the relationship between outside-air specific enthalpy and cooling water temperature determined in Figure 3 and Table 1 to the COP ratio for each load factor shown in Figure 8.

Figure 9.

Schematic diagram of the procedure for obtaining Figure 10.

Figure 10.

COP ratio characteristics of the water-cooled chillers.

In more detail, we determined the cooling water temperature based on the combination of outside-air specific enthalpy and load factor shown in Table 1 (Step 1 in Figure 9) and referenced the COP ratio corresponding to the cooling water temperature and load factor using Figure 8 (Step 2 in Figure 9). Here, the COP ratio between cooling water temperatures for each load factor shown in Figure 8 was taken to change in a linear manner. Consequently, given a cooling water temperature not shown in Figure 8, the COP ratio for that temperature could be determined from a linear expression between the adjacent cooling water temperatures (Equation (9); Step 2 in Figure 9). Finally, the relationship between the load factor and the COP ratio characteristics in the outside-air specific enthalpy was established (Step 3 in Figure 9). In the figure, an applicable range of cooling water temperature was set for each type of chiller, and the COP ratio applied for the cooling water temperature below the lower limit of this range was that corresponding to that lower limit value while the COP ratio applied for cooling water temperature above the upper limit of this range was that corresponding to the upper limit value. Specifically, the lower and upper limits of cooling water temperature were 20 °C and 32 °C, respectively, for the absorption chiller, 12 °C and 32 °C, respectively, for the turbo chillers (fixed-speed and inverter-controlled), and 20 °C and 30 °C, respectively, for the water-cooled chiller using a rotary vane pump.

Additionally, since differences in chiller models such as absorption and turbo chillers result in differences in the cooling-tower processed heat shown in Figure 4 even for the same cooling energy, the cooling-tower load factor also differs according to the model. However, the capacity of an actual cooling tower to be installed is selected according to the chiller waste heat of each chiller model, so Figure 3 and Table 1 used the same values for different chiller models.

COP_ratio = (COP_r1 − COP_r2)/(T2 − T1) × cooling-water temperature + C

- COP_r1: COP ratio at cooling water temperature immediately lower than target cooling water temperature

- COP_r2: COP ratio at cooling water temperature immediately higher than target cooling water temperature

- T1: Cooling water temperature immediately lower than target cooling water temperature

- T2: Cooling water temperature immediately higher than target cooling water temperature

- C: constant value

For all chiller models, cooling water temperature dropped as the outside-air specific enthalpy decreased with the result that the COP ratio increased. In addition, cooling water temperature dropped with a drop in the chiller load factor, so the COP ratio for low loads improved. However, for the absorption chiller, fixed-speed turbo chiller, and water-cooled chiller using a rotary vane pump, the COP ratio dropped for low loads, so the change in COP for different chiller load factors behaved in the manner of Figure 8. For the inverter-controlled turbo chiller, however, the COP ratio was high for a cooling water temperature of 16 °C or lower, so the COP ratio improved as the load factor dropped for outside-air specific enthalpy in the range of 10–30 kJ/kgDA. Here, though, the cooling water temperature for load factors of 0.5 or less at an outside-air specific enthalpy of 10 kJ/kgDA and for load factors of 0.3 or less at an outside-air specific enthalpy of 20 kJ/kgDA dropped below the applied lower limit of 12 °C, which simply reflects a change in the COP ratio according to load factor.

3. Evaluation of Composite COP Characteristics of Chillers

3.1. Composite COP of Water-Cooled Chillers

Multiple units of chillers may be installed with the aim of improving chiller COP at times of low cooling demand or providing a chiller backup. It is also common for the capacity of each chiller to be the same for the sake of easy maintenance. However, given that cooling energy varies with season and time slot, the introduction of chillers with different capacities should also be studied. To this end, we determined composite COP for water-cooled chillers when installing multiple units using the data that we formulated on the COP ratio of a water-cooled chiller for different values of outside-air specific enthalpy. When installing multiple units of chillers, the cooling water temperature of each chiller will differ even for the same outside-air specific enthalpy since the operation load factor of each chiller differs. However, since the COP ratio characteristics shown in Figure 10 were calculated using cooling water temperature that takes into account the chiller load factor and outside-air specific enthalpy, composite COP for chillers with different operation load factors can be calculated.

As conditions for calculating composite COP, we assumed the installation of two chiller units and evaluated COP for different cooling load factors while varying the ratio of each chiller’s installation capacity. We also assumed that a cooling tower would be installed for each chiller. In the evaluation, one chiller (base machine) performed the base operation while the other chiller (peak machine) was put into operation if the cooling load factor exceeded the operation capacity of the base machine. To compute chiller composite COP, we first determined COP at the cooling load factor of each chiller, then calculated the energy consumption of each chiller, and finally divided the cooling energy by the total energy consumption of the two chiller units. Here, the chiller composite COP was taken to be the COP of the main body of a chiller with no auxiliary power and COP was calculated by multiplying the COP ratio at each operation load factor by rated COP. Values of the operation load factor with respect to the cooling load factor for different chiller installation capacity ratios between the base and peak machines are listed in Table 4. Here the chiller installation capacity ratio indicates the ratio of chiller installation capacity to maximum cooling energy. For example, the capacity ratio 2:8 shown in Table 4 means that the installation capacities of the base machine and peak machine were 0.2 and 0.8, respectively of the maximum cooling energy. In addition, for rated COP of a water-cooled chiller that uses electric power for energy, we applied COP calculated using the amount of primary converted heat (9.76 MJ/kWh) to the calorific value of electric power (Table 5).

Table 4.

Operation load factor of chiller with respect to cooling load.

Table 5.

COP in each chiller.

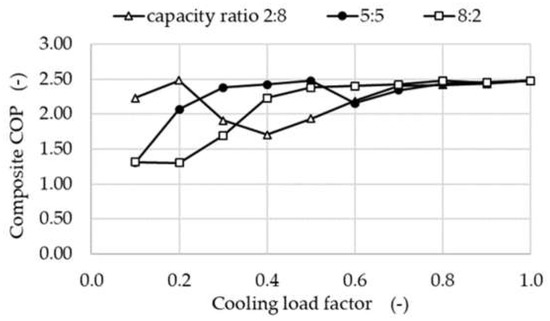

Composite COP values of a fixed-speed turbo chiller given an outside-air specific enthalpy of 70 kJ/kgDA are shown in Figure 11. For a base machine with a small installation capacity ratio (2:8), the base machine operates at a high load factor and composite COP takes on high values at cooling load factors of 0.2 or less. On the other hand, composite COP dropped at cooling load factors corresponding to two-unit operation with the peak machine, and at load factors of 0.3–0.5, it was lower than that of the other installation capacity ratios. On the other hand, for a base machine with a high installation capacity ratio (8:2), the base machine operated at a low load factor at cooling load factors of 0.3 or less resulting in low values of composite COP. However, for cooling load factors of 0.4 or greater, composite COP rose above that for an installation capacity ratio of 2:8. Consequently, when setting chiller capacities to different ratios, it can be seen that selecting base-machine and peak-machine operation such that composite COP was high for each cooling load factor would contribute to reducing energy consumption in all of the chillers. At cooling load factors of 0.6 or greater, the base-machine and peak-machine load factors were high so that the difference in composite COP owing to different installation capacity ratios was small. In this way, it is important at the basic planning stage to evaluate chiller operation time for various cooling load factors and to study chiller installation capacity ratios and composite COP.

Figure 11.

Composite COP of fixed-speed turbo chiller (air specific enthalpy 70 kJ/kgDA).

The above operating trends hold for various values of outside-air specific enthalpy. In addition, though COP ratios could also differ in water-cooled chillers using a rotary vane pump, the change in COP for the different installation capacity ratios behaved in a manner similar to that of a fixed-speed turbo chiller (Figure 12).

Figure 12.

Composite COP of water-cooled chiller using a rotary vane pump (air specific enthalpy 70 kJ/kgDA).

Now, for an absorption chiller, differences in composite COP owing to different installation capacity ratios were small (Figure 13), and the change in composite COP behaved the same at each value of outside-air specific enthalpy. Moreover, for values of outside-air specific enthalpy of 80 kJ/kgDA or greater, cooling water temperature was 28 °C or higher, and as a result, differences in composite COP owing to different installation capacity ratios were practically unchanged.

Figure 13.

Composite COP of absorption chiller (air specific enthalpy 70 kJ/kgDA).

Next, for an inverter-controlled turbo chiller (Figure 14), change in composite COP for different chiller load factors at outside-air specific enthalpy values of 50 kJ/kgDA or greater behaved similarly to that of a fixed-speed turbo chiller. However, at outside-air specific enthalpy values of 40 kJ/kgDA or less, composite COP values at cooling load factors of 0.4 or less were the highest for a base machine with a high installation capacity ratio (8:2). This is because the operation load factor of the base machine was 0.5 or less at cooling load factors of 0.4 or less and because cooling water temperature was 20.5 °C at an outside-air specific enthalpy of 40 kJ/kgDA, all of which makes for a chiller operation with high COP.

Figure 14.

Composite COP of an inverter-controlled turbo chiller.

Methods have been proposed for operating chillers by selecting load factors with high COP, but it has become common to use methods of controlling and operating multiple chillers in accordance with cooling load. Here, however, differences in composite COP owing to different installation capacity ratios was large, so it is important from the viewpoint of reducing energy consumption to find conditions for high-efficiency operation taking into account installation location, outside air conditions, installation capacity, etc.

The results shown in Figure 11, Figure 12, Figure 13 and Figure 14 were for the case of installing multiple chillers all of the same model, but composite COP for multiple chillers of different models could also be evaluated by a similar procedure. In addition, formulating COP ratio characteristics for water-cooled chillers on the basis of outside air conditions makes it possible to evaluate composite COP when installing multiple chillers of different models, namely, water-cooled chillers and air-cooled chillers.

3.2. Application to Evaluation of Chiller COP in Basic Planning

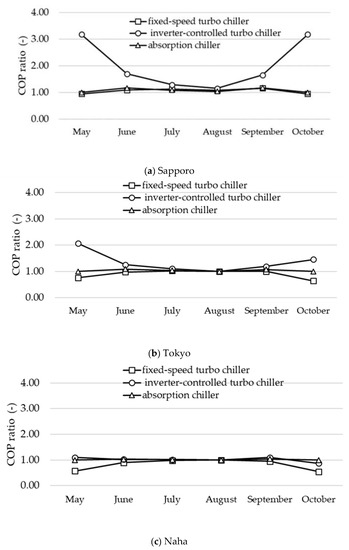

With the aim of evaluating differences in energy consumption at the basic planning stage, we evaluated the COP ratio by month for a fixed-speed turbo chiller, inverter-controlled turbo chiller, and absorption chiller targeting office buildings. In the evaluation, we selected Sapporo, Tokyo, and Naha as locations with different outside air conditions and made our calculations using the data in Figure 10 showing the COP ratio characteristics for a range of outside-air specific enthalpy values. Given a cooling period running from May to October, cooling load factor and outside-air specific enthalpy [16] for each of these months are listed in Table 6 for Japan. Here, the cooling load factor for each of these months correlates with the outside air temperature, but a similar change in the load factor over time also occurs in Korea.

Table 6.

Cooling load factor of office building and outside-air specific enthalpy in each evaluation location.

The COP ratio by month for these different types of chillers for each evaluation location is shown in Figure 15. In Naha where outside-air specific enthalpy was relatively high in each month, there was little difference in chiller COP ratio across these months but the COP ratio of the fixed-speed turbo chiller dropped in May and October that corresponded to small cooling load factors. In Sapporo, meanwhile, outside-air specific enthalpy was low and the cooling load factor was small in months other than July and August. As a result, the COP ratio of the inverter-controlled turbo chiller was high in those months and was more advantageous than that of the other types of chillers across all months. Finally, in Tokyo, COP ratio of the inverter-controlled turbo chiller was high in May and October but the difference in the COP ratio between these chillers was otherwise small in the other months.

Figure 15.

COP ratio in each cooling period.

The energy consumption of each chiller type could be calculated from the monthly cooling demand, chiller COP, and monthly operation time after first determining the chiller COP by multiplying COP ratio data by rated COP for that chiller. In this way, the energy consumption of a chiller could be evaluated even at the basic planning stage by taking into account building purpose, evaluation location, and other conditions and using COP ratio data for different values of outside-air specific enthalpy.

4. Conclusions

We formulated COP characteristics of water-cooled chillers as COP ratio characteristics using the chiller load factor and outside-air specific enthalpy. In this effort, we used a calculation model employing the TPF model of a cooling tower and determined cooling water temperature corresponding to the outside-air specific enthalpy for a range of cooling-tower load factors. Furthermore, taking into account the relationship between the cooling-tower load factor and chiller load factor, we evaluated the error in the cooling water temperature when viewing the chiller load factor as the cooling-tower load factor. Finally, by arranging the cooling water temperature against the chiller load factor for a range of values of outside-air specific enthalpy, we were able to obtain COP characteristics caused by outside air conditions without having to directly compute the cooling water temperature.

This was a theoretical study assuming a counterflow cooling tower, but we need to further study to demonstrate with experiment our methodology. In particular it will be necessary to verify the cooling water temperature at the outside-air specific enthalpy and the cooling tower load factor in the future. We will also perform theoretical calculations on the cooling water temperature for different values of L/G and verify those results as a future research topic.

Although trials on improving COP in absorption and air-cooled chillers have been performed with the aim of reducing energy consumption in chillers, it is also important to reduce chiller energy consumption by selecting equipment that matches cooling-demand characteristics or by appropriately combining multiple units of chillers. At the basic planning stage, while it is necessary to select and evaluate chiller models under constraints such as design location and building use, arranging the COP characteristics of water-cooled chillers in terms of outside air conditions makes it easy to compare energy consumption with that of air-cooled chillers. Additionally, on studying the installation of multiple units of water-cooled chillers, it was found that the composite COP of multiple chillers could be calculated even if their load factors differed according to the operation control method of each chiller. It was also found that composite COP for combined installation of different models of chillers including air-cooled chillers could be calculated. We considered that these capabilities would make it easy to select the appropriate models of chillers and to evaluate the number of and capacities of chillers to be installed at the basic planning stage.

At the same time, while a variety of simulations are used at the basic planning stage, using the formulated COP characteristics of water-cooled chillers as data makes it possible to omit simulations for determining cooling water temperature thereby improving calculation speed. In particular, in simulations using the linear programming method [17], the chiller load factor is unfortunately calculated based on the value of an established partial-load linear approximation formula. However, this is a characteristics formula under certain cooling water temperatures, and a conflict arises in which the cooling water temperature at the load factor determined by calculations lies outside those certain cooling water temperatures. However, by preparing data on linear approximations of partial-load characteristics based on the COP characteristics for different specific enthalpies of outside air shown in Figure 10 and by selecting a linear approximation formula according to outside air conditions, it becomes possible to avoid the conflict between the cooling water temperature and a partial-load linear approximation formula even in simulations using the linear programming method.

It is well known that configuring chiller equipment requires multifaceted studies that include energy expenditure, installation space, ease-of-maintenance, etc. in addition to energy consumption. However, given that chiller equipment is normally used over the long term, it is the responsibility of those in charge to use energy in a rational manner and reduce CO2 emissions while giving sufficient concern to social needs now and into the future such as the need to reduce “heat island” effects. There are many types and combinations of chillers that can be implemented, so it is important that policies be established at the basic planning stage that consider future demand, climate change, efficiency of chiller equipment, etc.

Author Contributions

Methodology, formal analyses and writing, T.Y.; review and editing, H.H. and T.H. All authors have read and agreed to the published version of the manuscript.

Funding

This work was supported by JSPS KAKENHI (Research representative: Hirofumi Hayama, Grant number: 18H0159109).

Conflicts of Interest

The authors declare no conflict of interest.

References

- Pérez-Lombard, L.; Ortiz, J.; Pout, C. A review on buildings energy consumption information. Energy Build. 2008, 40, 394–398. [Google Scholar] [CrossRef]

- “General Energy Statistics”, Agency for Natural Resources and Energy Home Page. Available online: https://www.enecho.meti.go.jp/statistics/total_energy/results.html#headline2 (accessed on 21 January 2020).

- Rey-Hernández, J.M.; Velasco-Gómez, E.; San José-Alonso, J.F.; Tejero-González, A.; González-González, S.L.; Rey-Martínez, F.J. Monitoring Data Study of the Performance of Renewable Energy Systems in a Near Zero Energy Building in Spain: A Case Study. Energies 2018, 11, 2979. [Google Scholar] [CrossRef]

- U.S. Energy Information Administration, Commercial Building Energy Consumption Survey. Available online: https://www.eia.gov/consumption/commercial (accessed on 21 January 2020).

- Energy Saving Chart (FY2016 Results) (Division I), Tokyo Metropolitan Government Home Page. Available online: http://www.kankyo.metro.tokyo.jp/climate/large_scale/data/karte.html (accessed on 21 January 2020).

- Turbo Chiller Catalog, Manufacturer Home Page. Available online: https://www.mhi-mth.co.jp/catalogue/index.php?mode=browse&contentsNumber=468 (accessed on 21 January 2020).

- Absorption Chiller Catalog, Manufacturer Home Page. Available online: http://esctlg.panasonic.biz/iportal/CatalogViewInterfaceStartUpAction.do?method=startUp&mode=PAGE&catalogCategoryId=&catalogId=4889660000&pageGroupId=&volumeID=PEWJ0001&designID=&nonFlash=true&redirect=true (accessed on 21 January 2020).

- Cutillas, C.G.; Ramírez, J.R.; Miralles, M.L. Optimum Design and Operation of an HVAC Cooling Tower for Energy and Water Conservation. Energies 2017, 10, 299. [Google Scholar] [CrossRef]

- Khan, J.U.R.; Yaqub, M.; Zubair, S.M. Performance characteristics of counter flow wet cooling towers. Energy Convers. Manag. 2003, 44, 2073–2091. [Google Scholar] [CrossRef]

- Hajidavalloo, E.; Shakeri, R.; Mehrabian, M.A. Thermal performance of cross flow cooling towers in variable wet bulb temperature. Energy Convers. Manag. 2010, 51, 1298–1303. [Google Scholar] [CrossRef]

- Sarker, M.M.A.; Kim, E.; Moon, C.G.; Yoon, J.I. Performance characteristics of the hybrid closed circuit cooling tower. Energy Build. 2008, 40, 1529–1535. [Google Scholar] [CrossRef]

- Hasan, A.; Sirén, K. Theoretical and computational analysis of closed wet cooling towers and its applications in cooling of buildings. Energy Build. 2002, 34, 477–486. [Google Scholar] [CrossRef]

- Gan, G.; Riffat, S.B. Numerical simulation of closed wet cooling towers for chilled ceiling systems. Appl. Therm. Eng. 1999, 19, 1279–1296. [Google Scholar] [CrossRef]

- SHASE (The Society of Heating, Air-Conditioning and Sanitary Engineers of Japan) Handbook, 14th ed.; The Society of Heating, Air-conditioning and Sanitary Engineers of Japan: Tokyo, Japan, 2010; Chapter 8; p. 265.

- BEST Program (BEST-P), Equipment Characteristics Manual 2014.06, Institute for Building Environment and Energy Conservation Home Page. Available online: http://www.ibec.or.jp/best/program/m_131_kikitokusei.pdf (accessed on 21 January 2020).

- Past Weather Data Search, Japan Meteorological Agency Home Page. Available online: http://www.data.jma.go.jp/obd/stats/etrn/index.php (accessed on 21 January 2020).

- Cao, K.; von Krbek, K.; Wetzel, M.; Cebulla, F.; Schreck, S. Classification and Evaluation of Concepts for Improving the Performance of Applied Energy System Optimization Models. Energies 2019, 12, 4656. [Google Scholar] [CrossRef]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).