Journey of American Building Physics: Steps Leading to the Current Scientific Revolution

Abstract

1. Creating Building Physics (1925–1950)

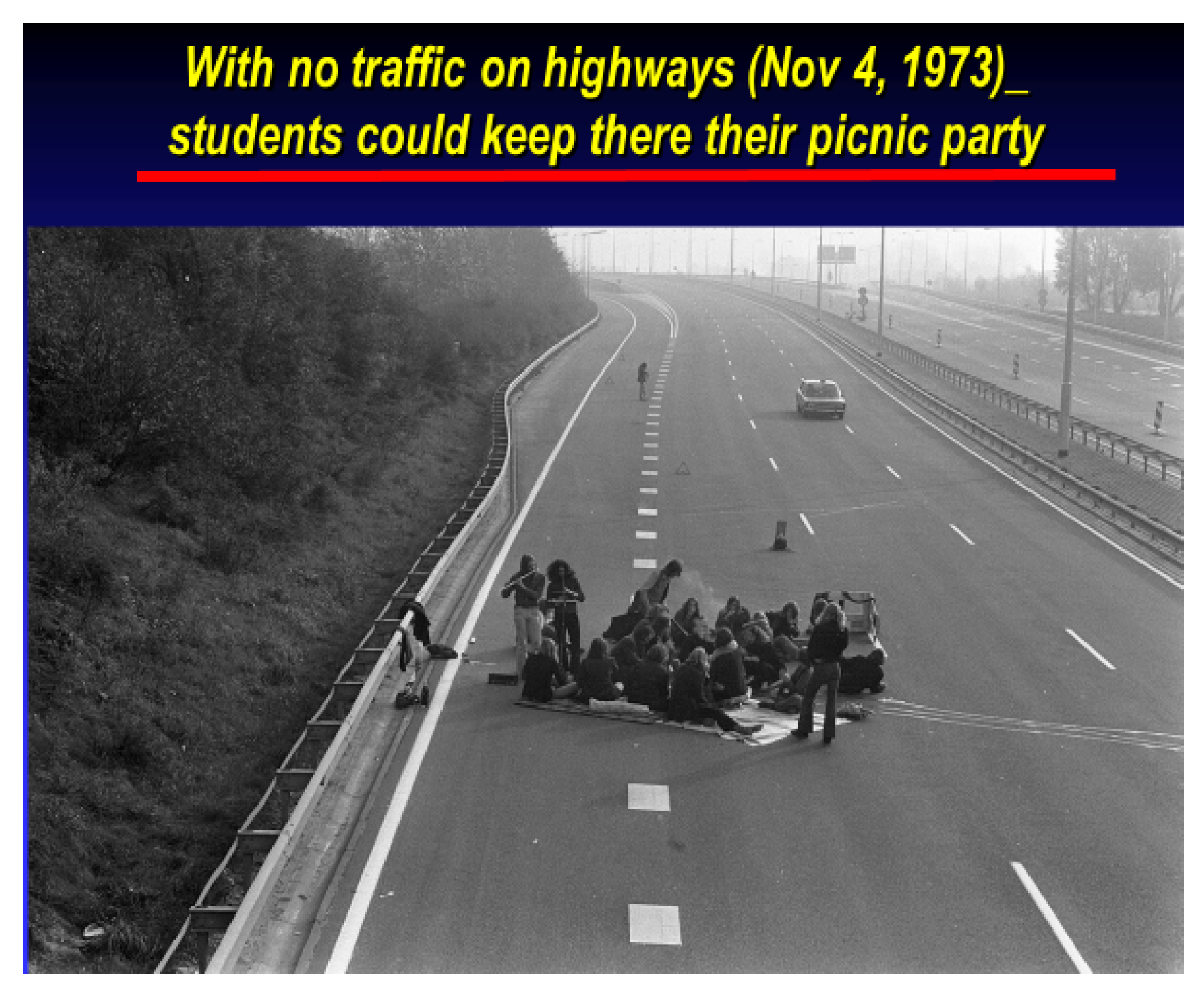

2. Simplification and Stagnation in Building Physics (1950–1975)

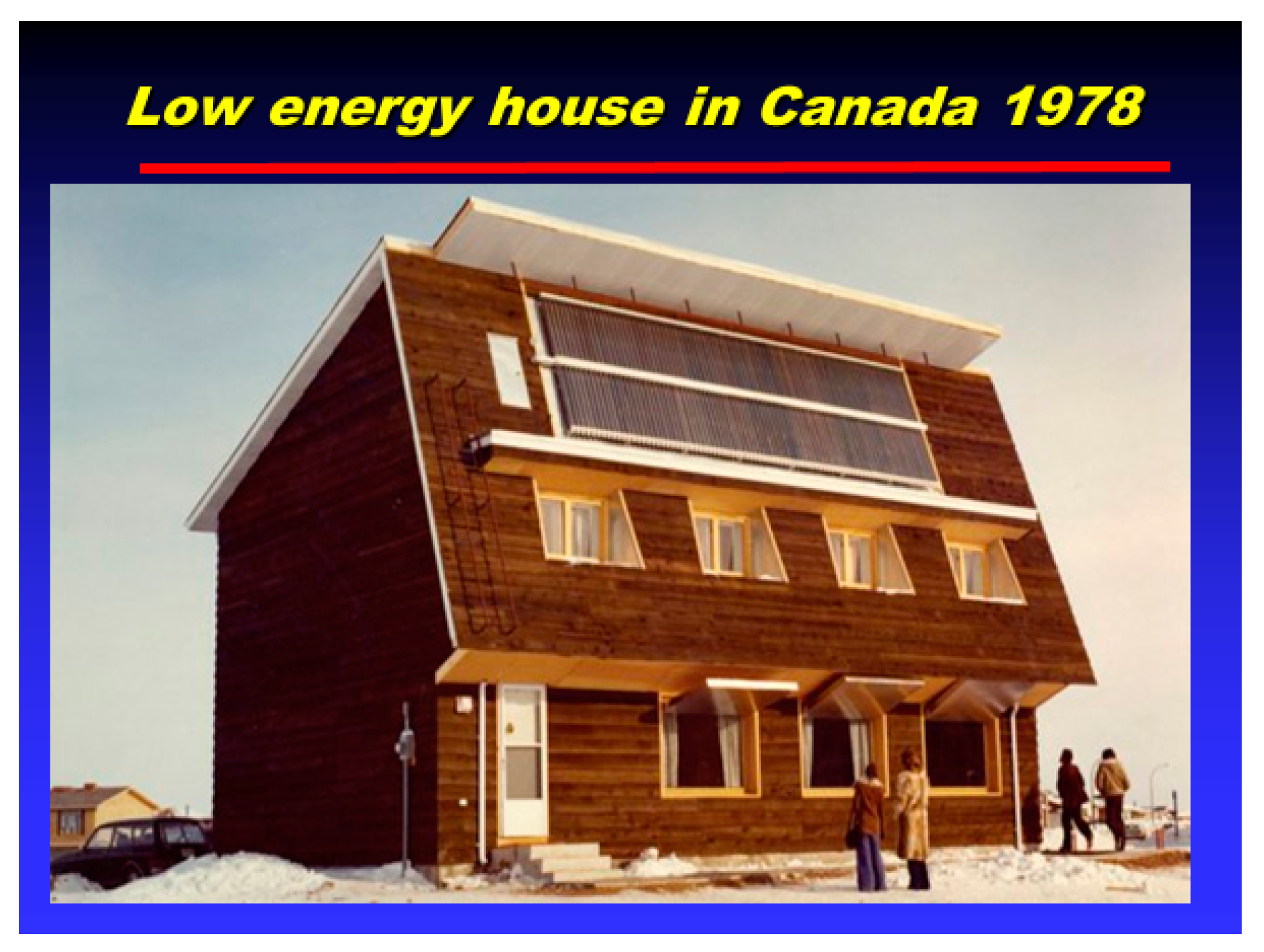

3. New Objectives Give Building Physics New Life (1975–2000)

“Knowledge about building, called, for convenience, building science is valuable largely because it is useful in predicting the outcome of the result of some building situation. Rational design is possible only when there is a capability to establish, each time a choice is made, the probability of a particular result.”

- The environment

- Adjacent materials in the assembly

- On-site factors (workmanship)

- Heat, air and moisture transports are inseparable and cannot be assessed in separation from each other. Today, we talk about “environmental control”.

- Often, when in practice one modifies materials or construction details, one finds that the cost of repairs following these minute changes is significant. This happens each time when we analyze only the detail itself and forget about its interaction with the other elements of the system [13]. In other words, we fail when we lose track of the holistic approach.

- The modification of details in the building enclosure is slow but continuing. Note that leaky and poorly insulated walls dried quickly. Airtight, insulated on exterior, walls are drying slowly. If water enters around the window frame, it will stay inside the wall. This highlights the need for an environmental control design.

- Building physics followed the evolution of practice [14] and lessons from any solution of the encountered problems enhanced understanding of construction performance.

“At the moment we are in a position where the traditional approach of learning from failures and copying what worked, has broken down. ….it is extremely difficult to accommodate all of the new information in view of the rapid changes in materials, details and performance expectations.”

“We need to expand the approach of environmental control in two dimensions:

- There may be several airflow paths between any two points in a structure

- The total airflow resistance is a sum of all local airflow resistances,

- The total airflow resistance decides in which way most air goes,

- The presence of interstitial airflows permits the mechanical equipment to modify air pressure in the indoor spaces, as well as to modify the thermal performance of walls

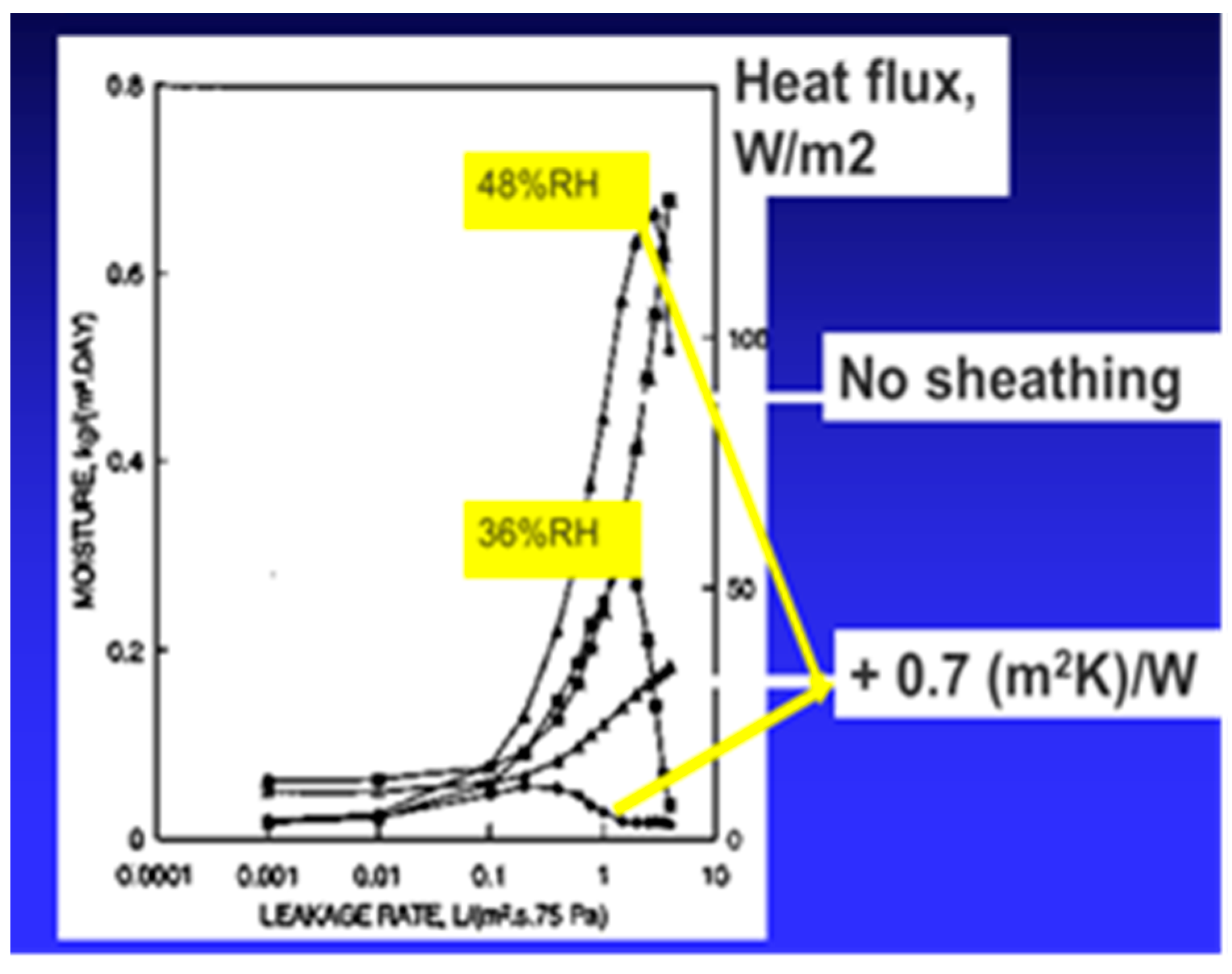

- As airflows carry water, they further impact the thermal performance of walls

- (1)

- Exterior (caused by wind)

- (2)

- Interior (HVAC operation and ducts)

- (3)

- Across the walls (stack effect)

- (4)

- Interstitial (connectivity walls, rooms, staircases, ventilation plenum)

4. Towards the Socio-Economic Impact of the Building Science (2000–2025)

- Large areas of glazing, combined with leaky wall window interfaces that increased both air and solar energy transfer across the wall

- A high precision in the control of indoor air temperature that eliminated dynamic performance

- Step 1 includes space organization, passive measures and factors affecting indoor environment such as thermal comfort, indoor air quality, acoustics, daylight, illumination, hot and sewer water management, aesthetics and building resilience.

- Step 2 deals with the building automatic control system that integrates heating, cooling, ventilation, and other indoor climate controls including the geothermal and solar means for energy generation and storage.

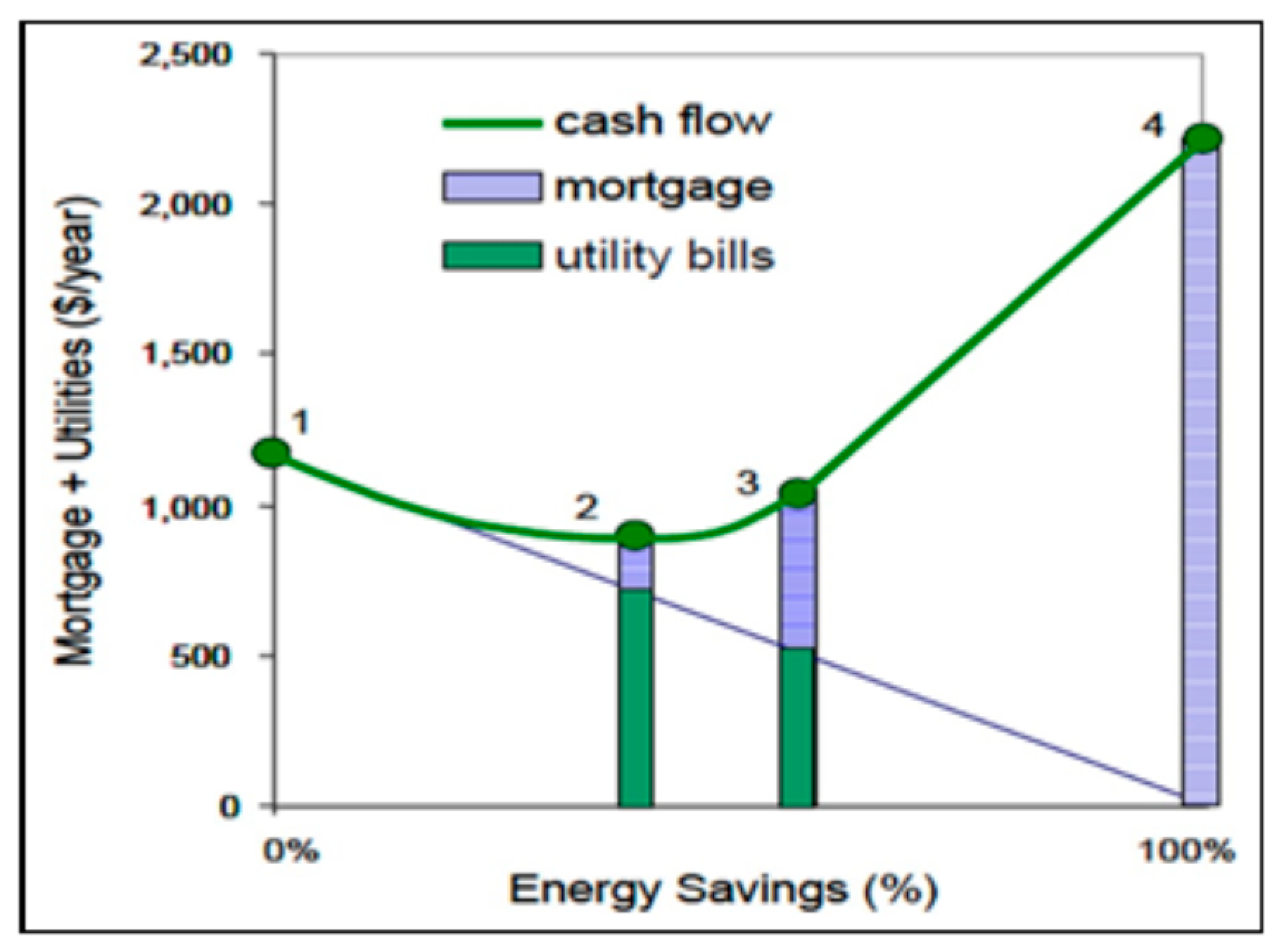

- Step 3 provides an economic analysis to determine the level of investment that limits the 1st stage of new construction or retrofitting.

- Step 4 develops a comprehensive operational manual for the building and provides the design and cost for stage 2 of the new construction or retrofitting.

4.1. Example of a New Technology

- Individual ventilation on-demand in rooms with solar heating.

- Using a hybrid ventilation system with overpressure of the supply air. In this case, one must improve the moisture management in the walls.

4.2. Two-Stage Design Process

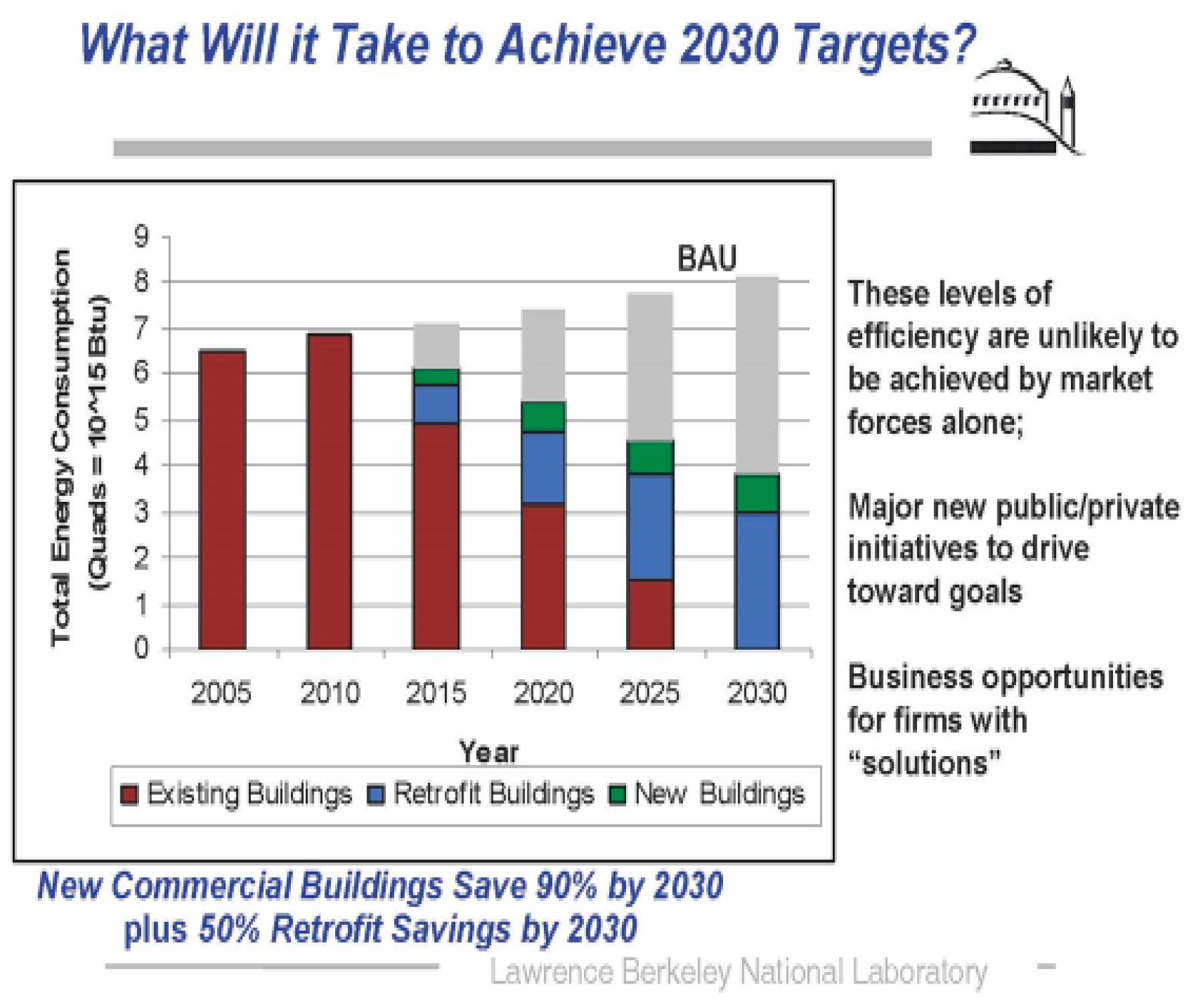

- High performance enclosure; common water loop; solar wall—36% reduction

- Gray water power, the cumulative energy reduction grows to 42%

- Heat pump heating—all passive measures give a 60% reduction

- Domestic hot water with evacuated solar panels, a further 14%

- Photovoltaic panels reduce the total energy to a total of 92%

5. Steps to the Scientific Revolution

- Discovery of interstitial air pressure fields

- Introduction of air barrier systems

- The need for exterior insulating sheathing

- An ecological complex in the field performance

- Introduction of an integrated design process

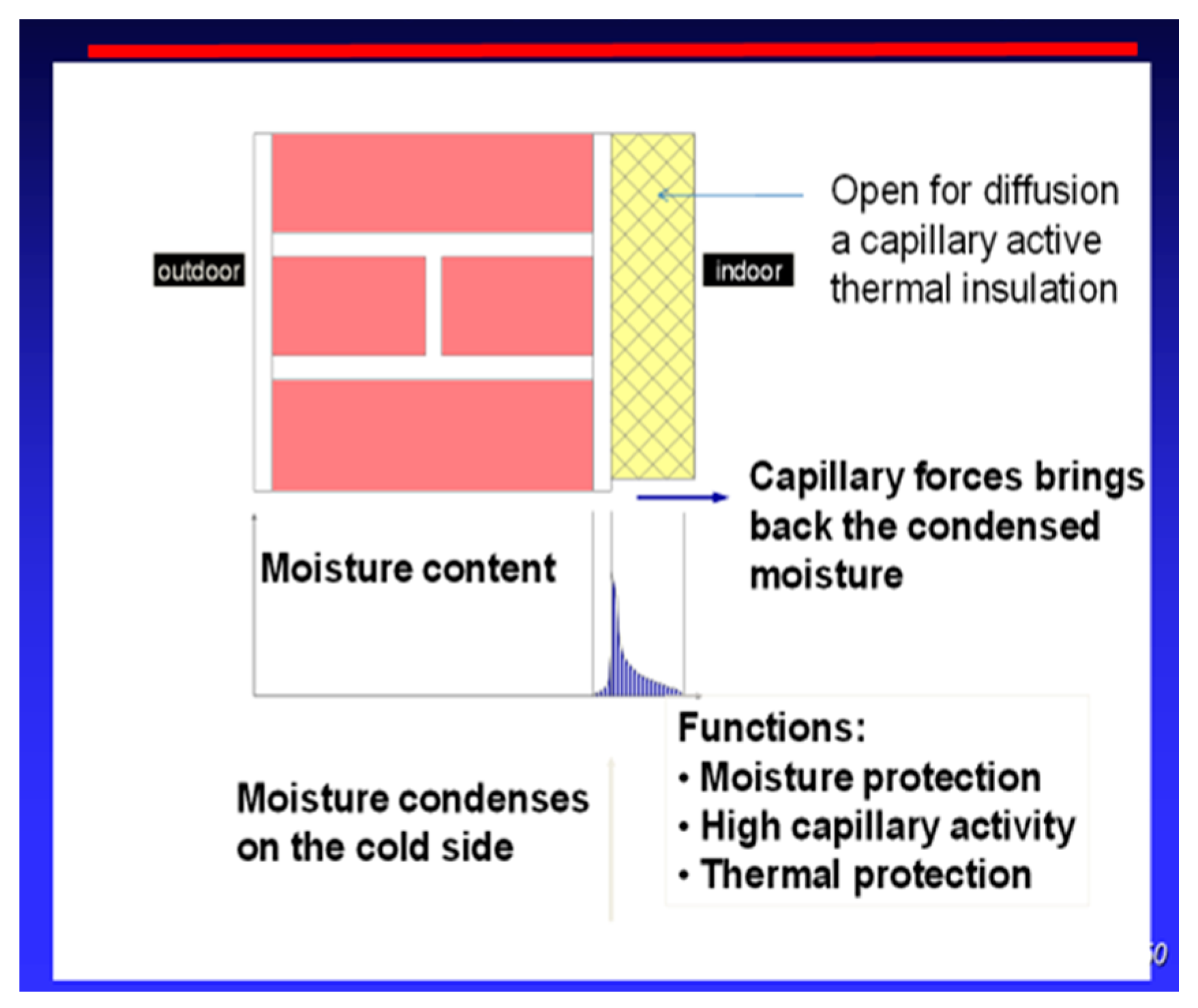

- Capillary active technology to modify humidity in indoor air

- Use of an adaptive comfort approach in the indoor environment and improved comfort measures [33]

- Use of heat pump technology for simultaneous heating and cooling

- Integration of heating, cooling and ventilation within the building fabric

- Integrated control systems to operate and optimize the HVAC operation

Author Contributions

Funding

Conflicts of Interest

References

- Kuhn, T. The Structure of Scientific Revolutions; University of Chicago Press: Chicago, IL, USA, 1970. [Google Scholar]

- Bomberg, M.; Solvason, K.R. How to ensure good thermal performance of cellulose fiber insulation. Part 1. Horizontal applications. J. Build. Phys. 1980, 4, 93. [Google Scholar] [CrossRef]

- Szklowier, A.M.; Wasiliew, B.F.; Uszkow, F.B. The Foundations of Building Thermal Science of Residential and Public Buildings; Architectural Academy of Soviet Union, 1959. (In Russian) [Google Scholar]

- Luikow, A.W. Stroitielna Teplotiechnika (Building Thermal Technology), 1966. (In Russian)

- Uszkow, F.B. Methods for Calculation of Wetting of Components of the Exterior Enclosure in Buildings; Ministry of Communal Matters: Moscow, Russia, 1955. (In Russian) [Google Scholar]

- Rowley, F.B.; Algren, A.B.; Lund, C.E. Condensation within walls. ASHVE Trans. 1938, 44. [Google Scholar]

- Bomberg, M. Moisture Flow through Porous Building Materials. Ph.D. Thesis, Lund Institute of Technology, Lund, Sweden, Report 52. 1974; pp. 1–188. [Google Scholar]

- Sandberg, P.I. Water Vapor Transport Calculations. Ph.D. Thesis, Lund Institute of Technology, Lund, Sweden, 1973. [Google Scholar]

- Kuenzel, H.M. Simultaneous Heat and Moisture Transport in Building Components, One- and TWo- Dimensional Calculations Using Simple Parameters; Fraunhofer IRB Verlag: Stuttgart, Germany, 1995. [Google Scholar]

- Hutcheon, N.B. The utility of building science, reprint of the 1971 lecture. J. Build. Phys. 1998, 22, 4. [Google Scholar]

- Romanska-Zapala, A.; Bomberg, M.; Yarbrough, D. Towards reduction of the impact of residential buildings on climate change. Unpublished work.

- Bomberg, M.; Onysko, D. (Eds.) Energy Efficiency and Durability of Buildings at the Crossroads. 2008. Available online: http://thebestconference.org/BEST1 (accesed on 25 February 2020).

- Kwasnowski, P.; Fedorczak-Cisak, M.; Knap, K. Problems of technology of energy-saving buildings and their impact on energy efficiency in buildings. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2017; Volume 245, p. 072043. [Google Scholar]

- Kisilewicz, T.; Fedorczak-Cisak, M.; Barkanyi, T. Active thermal insulation as an element limiting heat loss through external walls. Energy Build. 2019, 205, 109541. [Google Scholar] [CrossRef]

- Bomberg, M.; Kisilewicz, T.; Mattock, C. Methods of Building Physics; Timusk 1992; Cracow University Press: Cracow, Poland, 2016; pp. 1–300. [Google Scholar]

- Sasaki, J.R.; Wilson, A.G. Air leakage for residential windows. ASHRAE Trans. 1965, 71, 81–88. [Google Scholar]

- Bomberg, M.; Kisilewicz, T.; Nowak, K. Is there an optimum range of airtightness for a building? J. Build. Phys. 2016, 39, 395–420. [Google Scholar] [CrossRef]

- Lstiburek, J.W. Toward an Understanding and Prediction of Air Flow in Buildings. Ph.D. Thesis, University of Toronto, Toronto, ON, Canada, 1999. [Google Scholar]

- Quirouette, R.L. The difference between a vapor barrier and an air barrier. In Building Practice Note 54; IRC; NRC: Ottawa, ON, Canada, 1985. [Google Scholar]

- Perrault, J.C. Air barrier systems: Construction applications. In An Air Barrier for the Building Envelope; Building Science Insight; NRC: Ottawa, ON, Canada, 1986; pp. 20–24. [Google Scholar]

- Kumaran, M.K.; Ojanen, T.R. Effect of exfiltration on hygrothermal behavior of a residential wall assembly. J. Build. Phys. 1996, 19, 215–228. [Google Scholar]

- Hutcheon, N.B.; Handegord, G.O. Building Science for A Cold Climate; Construction Technology Centre Atlantic Inc.: Ottawa, ON, Canada, 1983. [Google Scholar]

- IDP. Available online: https://www.stategiaconseil.ca/en/2018/ (accessed on 2 February 2020).

- Bomberg, M. A concept of capillary active, dynamic insulation integrated with heating, cooling and ventilation, air conditioning system. Front. Architect. Civ. Eng. China 2010, 4, 431–437. [Google Scholar] [CrossRef]

- Häupl, P.; Grunewald, J.; Fechner, H. Moisture behavior of a “Gründerzeit”-house by means of a capillary active interior insulation. In Proceedings of the Building Physics in the Nordic Countries, Gothenburg, Sweden, 24–26 August 1999; pp. 225–232. [Google Scholar]

- Mattock, C.H. Harmony House EquilibriumTM project, Canada Green Building Council. In Proceedings of the Annual Conference, Vancouver, BC, Canada, 8–10 June 2010. [Google Scholar]

- Brennan, T.; Henderson, H.; Stack, K.; Bomberg, M. Quality Assurance and Commissioning Process in High Environmental Performance (HEP) Demonstration House in NY State. 2008. Available online: www.thebestconference.org/best1 (accessed on 12 October 2019).

- Wallburger, A.; Brennan, T.; Bomberg, M.; Henderson, H. Energy Prediction and Monitoring in a High-Performance Syracuse House. 2010. Available online: http://thebestconference.org/BEST2 (accessed on 2 October 2019).

- Karagiozis, A.K.; Kumaran, M.K. Computer Model Calculation of the Performance of Vapor Barriers in Canadian Residential Buildings. ASHRAE Trans. 1993, 99, 991–1003. [Google Scholar]

- Klingenberg, K.; Kernagis, M.; Knezovich, M. Zero energy & carbon buildings based on climate specific passive building standards for North America. J. Build. Phys. 2016, 39, 503–521. [Google Scholar]

- Wright, G.; Klingenberg, K. Climate-Specific Passive Building Standards; U.S. Department of Energy, Building America, Office of Energy Efficiency and Renewable Energy: Washington, DC, USA, 2015.

- Rosemount, A. Information Notesp; Canadian Mortgage and Housing Corporation: Ottawa, ON, Canada, 2016.

- Piasecki, M.; Fedorczak-Cisak, M.; Furtak, M.; Biskupski, J. Experimental confirmation of the reliability of Fanger’s thermal comfort model—Case study of a near-zero energy building office building. Sustainability 2019, 11, 2461. [Google Scholar] [CrossRef]

- Bomberg, M.; Yarbrough, D.; Furtak, M. Buildings with environmental quality management (EQM), part 1: Designing multi-functional construction materials. J. Build. Phys. 2017, 41, 193–208. [Google Scholar] [CrossRef]

- Romanska-Zapala, A.; Bomberg, M.; Fedorczak-Cisak, M.; Furtak, M.; Yarbrough, D.; Dechnik, M. Buildings with environmental quality management (EQM), part 2: Integration of hydronic heating/cooling with thermal mass. J. Build. Phys. 2018, 41, 397–417. [Google Scholar] [CrossRef]

- Yarbrough, D.W.; Bomberg, M.; Romanska-Zapala, A. Buildings with environmental quality management (EQM), part 3: From log houses to zero-energy buildings. J. Build. Phys. 2018, 42, 672–691. [Google Scholar] [CrossRef]

- Romanska-Zapala, A.; Bomberg, M.; Yarbrough, D. Buildings with environmental quality management (EQM), part 4: A path to the future NZEB. J. Build. Phys. 2018, 43, 3–21. [Google Scholar] [CrossRef]

- Gadek, K.; Dudzik, M.; Strek, A. A Novel Three-Head Ultrasonic System for Distance Measurements Based on the Correlation Method. Meas. Sci. Rev. 2014, 14, 331–336. [Google Scholar] [CrossRef]

- Dudzik, M.; Jagiello, A.; Drapik, S.; Prusak, J. The selected real tramway substation overload analysis using the optimal structure of an artificial neural network. In Proceedings of the 2018 International Symposium on Power Electronics, Electrical Drives, Automation and Motion (Speedam), Amalfi, Italy, 20–22 June 2018. WOS:000445031300069. [Google Scholar]

- Dudzik, M.; Mielnik, R.; Wróbel, Z. Preliminary analysis of the effectiveness of the use of artificial neural networks for modelling time-voltage and time-current signals of the combination wave generator. In Proceedings of the 2018 International Symposium on Power Electronics, Electrical Drives, Automation and Motion (Speedam), Amalfi, Italy, 20–22 June 2018. WOS:000445031300179. [Google Scholar]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bomberg, M.; Romanska-Zapala, A.; Yarbrough, D. Journey of American Building Physics: Steps Leading to the Current Scientific Revolution. Energies 2020, 13, 1027. https://doi.org/10.3390/en13051027

Bomberg M, Romanska-Zapala A, Yarbrough D. Journey of American Building Physics: Steps Leading to the Current Scientific Revolution. Energies. 2020; 13(5):1027. https://doi.org/10.3390/en13051027

Chicago/Turabian StyleBomberg, Mark, Anna Romanska-Zapala, and David Yarbrough. 2020. "Journey of American Building Physics: Steps Leading to the Current Scientific Revolution" Energies 13, no. 5: 1027. https://doi.org/10.3390/en13051027

APA StyleBomberg, M., Romanska-Zapala, A., & Yarbrough, D. (2020). Journey of American Building Physics: Steps Leading to the Current Scientific Revolution. Energies, 13(5), 1027. https://doi.org/10.3390/en13051027