A GIS Approach to Locate a Small Size Biomass Plant Powered by Olive Pruning and to Estimate Supply Chain Costs

Abstract

:1. Introduction

Recent GIS Applications in Spatial Allocation of Biomass Power Plants in Europe

2. Materials and Methods

2.1. Software and Hardware Used for the Study

2.2. Average Pruning Biomass and Harvesting Scenarios

2.3. Identification of Suitable Areas

2.4. Theoretical Small Size Biomass Plants Localization

2.5. Estimation of Supply Chain Costs

3. Results

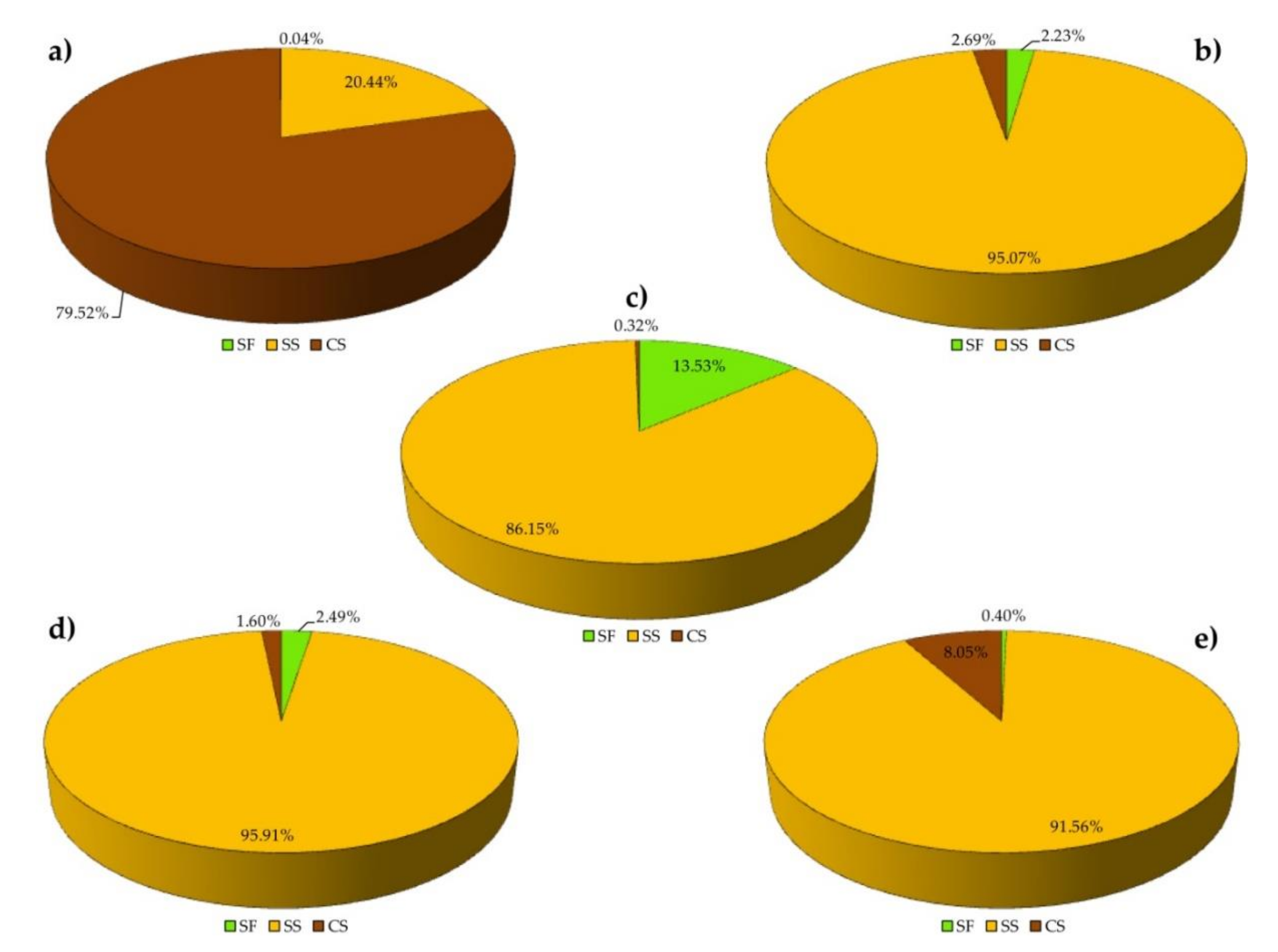

3.1. Identification of Suitable Sub-Areas and the Respective Main Characteristics

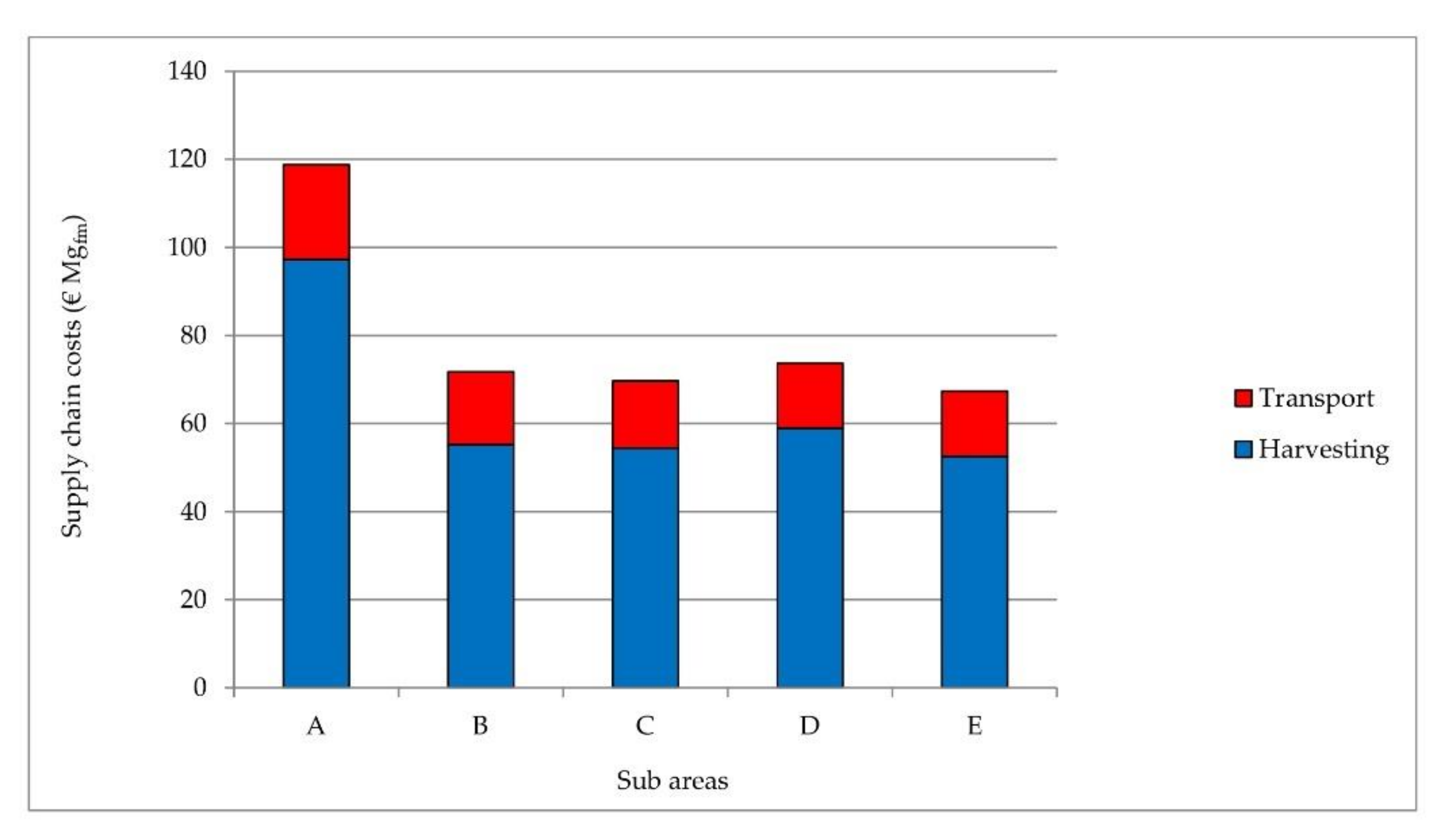

3.2. Estimation of Supply Chain Costs

4. Discussions

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Abbreviations

| GIS | Geographic Information System |

| Mgfm | Fresh matter ton |

| SF | Shredder on flat slope |

| SS | Shredder on hilly slope |

| CS | Chipper on hilly slope |

| DTM | Digital terrain Model |

| SIA | Sustainability Impact Assessment |

| LCA | Life Cycle Assessment |

| MCDA | Multi Criteria Decision Analysis |

| GHG | Green House Gases |

References

- FAO. Global agriculture towards 2050. In How to Feed World; FAO: Rome, Italy, 2009. [Google Scholar] [CrossRef]

- EUROSTAT. Supply, Transformation and Consumption-Commodity Balances. Available online: https://appsso.eurostat.ec.europa.eu/nui/show.do (accessed on 16 April 2020).

- ISTAT. Gross Electric Energy Production from Renewable Energy Sources. Available online: http://dati.istat.it/Index.aspx?QueryId=20144# (accessed on 16 April 2020).

- Bergonzoli, S.; Suardi, A.; Rezaie, N.; Alfano, V.; Pari, L. An innovative system for Maize Cob and wheat chaff harvesting: Simultaneous grain and residues collection. Energies 2020, 13, 1265. [Google Scholar] [CrossRef] [Green Version]

- Suardi, A.; Saia, S.; Stefanoni, W.; Gunnarsson, C.; Sundberg, M.; Pari, L. Admixing Chaff with Straw Increased the Residues Collected without Compromising Machinery Efficiencies. Energies 2020, 13, 1766. [Google Scholar] [CrossRef] [Green Version]

- Suardi, A.; Stefanoni, W.; Alfano, V.; Bergonzoli, S.; Pari, L. Equipping a Combine Harvester with Turbine Technology Increases the Recovery of Residual Biomass from Cereal Crops via the Collection of Chaff. Energies 2020, 13, 1572. [Google Scholar] [CrossRef] [Green Version]

- Paiano, A.; Lagioia, G. Energy potential from residual biomass towards meeting the EU renewable energy and climate targets. The Italian case. Energy Policy 2016, 91, 161–173. [Google Scholar] [CrossRef]

- European Union (EU). Renewable Energy Directive II (EU) 2018/2001 11th December 2018. Available online: https://eur-lex.europa.eu/legal-content/IT/TXT/PDF/?uri=CELEX:32018L2001&from=IT (accessed on 10 January 2020).

- Italian Ministry of Economic Development. Guidelines for The Authorization of Power Plants Powered by Renewable Energies (In Italian). Available online: https://www.gazzettaufficiale.it/eli/id/2010/09/18/10A11230/sg (accessed on 10 January 2020).

- Lazio region (Italy). Regional Energy Plan. Available online: http://www.regione.lazio.it/prl_ambiente/?vw=contenutidettaglio&id=140 (accessed on 10 January 2020).

- Suardi, A.; Latterini, F.; Alfano, V.; Palmieri, N.; Bergonzoli, S.; Pari, L. Analysis of the Work Productivity and Costs of a Stationary Chipper Applied to the Harvesting of Olive Tree Pruning for Bio-Energy Production. Energies 2020, 13, 1359. [Google Scholar] [CrossRef] [Green Version]

- ISTAT. Agriculture Statistics. Available online: https://www.istat.it/it/ (accessed on 1 March 2020).

- Magagnotti, N.; Pari, L.; Picchi, G.; Spinelli, R. Technology alternatives for tapping the pruning residue resource. Bioresour. Technol. 2013, 128, 697–702. [Google Scholar] [CrossRef]

- Spinelli, R.; Magagnotti, N.; Nati, C.; Cantini, C.; Sani, G.; Picchi, G.; Biocca, M. Integrating olive grove maintenance and energy biomass recovery with a single-pass pruning and harvesting machine. Biomass Bioenergy 2011, 35, 808–813. [Google Scholar] [CrossRef]

- Gasol, C.M.; Gabarrell, X.; Rigola, M.; González-García, S.; Rieradevall, J. Environmental assessment:(LCA) and spatial modelling (GIS) of energy crop implementation on local scale. Biomass Bioenergy 2011, 35, 2975–2985. [Google Scholar] [CrossRef]

- Dyjakon, A.; García-Galindo, D. Implementing agricultural pruning to energy in europe: Technical, economic and implementation potentials. Energies 2019, 12, 1513. [Google Scholar] [CrossRef] [Green Version]

- Pari, L. Agricultural waste energy exploitation in Lazio Region. In Proceedings of the 2nd World Conference on Biomass for Energy, Industry and Climate Protection, Rome, Italy, 10–14 May 2004. [Google Scholar]

- González-García, S.; Dias, A.C.; Clermidy, S.; Benoist, A.; Maurel, V.B.; Gasol, C.M.; Gabarrell, X.; Arroja, L. Comparative environmental and energy profiles of potential bioenergy production chains in Southern Europe. J. Clean. Prod. 2014, 76, 42–54. [Google Scholar] [CrossRef]

- Delivand, M.K.; Cammerino, A.R.B.; Garofalo, P.; Monteleone, M. Optimal locations of bioenergy facilities, biomass spatial availability, logistics costs and GHG (greenhouse gas) emissions: A case study on electricity productions in South Italy. J. Clean. Prod. 2015, 99, 129–139. [Google Scholar] [CrossRef]

- Jeong, J.S.; Ramírez-Gómez, Á. A multicriteria GIS-based assessment to optimize biomass facility sites with parallel environment—A case study in Spain. Energies 2017, 10, 2095. [Google Scholar] [CrossRef] [Green Version]

- García-Galindo, D.; Dyjakon, A.; Cay Villa-Ceballos, F. Building Variable Productivity Ratios for Improving Large Scale Spatially Explicit Pruning Biomass Assessments. Energies 2019, 12, 957. [Google Scholar] [CrossRef] [Green Version]

- Costa, F.R.; Ribeiro, C.A.A.S.; Marcatti, G.E.; Lorenzon, A.S.; Teixeira, T.R.; Domingues, G.F.; de Castro, N.L.M.; dos Santos, A.R.; Soares, V.P.; Mota, P.H.S.; et al. GIS applied to location of bioenergy plants in tropical agricultural areas. Renew. Energy 2020, 153, 911–918. [Google Scholar] [CrossRef]

- Charis, G.; Danha, G.; Muzenda, E. A review of the application of GIS in biomass and solid waste supply chain optimization: Gaps and opportunities for developing nations. Proc. Int. Conf. Ind. Eng. Oper. Manag. 2018, 2018, 42–52. [Google Scholar] [CrossRef]

- Abreu, M.; Reis, A.; Moura, P.; Fernando, A.L.; Luís, A.; Quental, L.; Patinha, P.; Gírio, F. Evaluation of the potential of biomass to energy in Portugal-conclusions from the CONVERTE project. Energies 2020, 13, 937. [Google Scholar] [CrossRef] [Green Version]

- López-Rodríguez, F.; Sanz-Calcedo, J.G.; Moral-García, F.J. Spatial analysis of residual biomass and location of future storage centers in the southwest of Europe. Energies 2019, 12, 1978. [Google Scholar] [CrossRef] [Green Version]

- Picchio, R.; Proto, A.R.; Civitarese, V.; Di Marzio, N.; Latterini, F. Recent Contributions of Some Fields of the Electronics in Development of Forest Operations Technologies. Electronics 2019, 8, 1465. [Google Scholar] [CrossRef] [Green Version]

- Statuto, D.; Tortora, A.; Picuno, P. A GIS approach for the quantification of forest and agricultural biomass in the Basilicata region. J. Agric. Eng. 2013, 44, 627–631. [Google Scholar] [CrossRef]

- Rodríguez, R.; Gauthier-Maradei, P.; Escalante, H. Fuzzy spatial decision tool to rank suitable sites for allocation of bioenergy plants based on crop residue. Biomass Bioenergy 2017, 100, 17–30. [Google Scholar] [CrossRef]

- Zhang, X.; Fu, J.; Lin, G.; Jiang, D.; Yan, X. Switchgrass-based bioethanol productivity and potential environmental impact from marginal lands in China. Energies 2017, 10, 260. [Google Scholar] [CrossRef] [Green Version]

- Amirante, R.; Clodoveo, M.L.; Distaso, E.; Ruggiero, F.; Tamburrano, P. A tri-generation plant fuelled with olive tree pruning residues in Apulia: An energetic and economic analysis. Renew. Energy 2016, 89, 411–421. [Google Scholar] [CrossRef]

- Zhang, B.; Hastings, A.; Clifton-Brown, J.C.; Jiang, D.; Faaij, A.P.C. Modelled spatial assessment of biomass productivity and technical potential of Miscanthus× giganteus, Panicum virgatum L. and Jatropha on marginal land in China. GCB Bioenergy 2020. [Google Scholar] [CrossRef] [Green Version]

- Lozano-García, D.F.; Santibañez-Aguilar, J.E.; Lozano, F.J.; Flores-Tlacuahuac, A. GIS-based modeling of residual biomass availability for energy and production in Mexico. Renew. Sustain. Energy Rev. 2020, 120. [Google Scholar] [CrossRef]

- Perpiñá, C.; Alfonso, D.; Pérez-Navarro, A.; Peñalvo, E.; Vargas, C.; Cárdenas, R. Methodology based on Geographic Information Systems for biomass logistics and transport optimisation. Renew. Energy 2009, 34, 555–565. [Google Scholar] [CrossRef]

- Sánchez-García, S.; Athanassiadis, D.; Martínez-Alonso, C.; Tolosana, E.; Majada, J.; Canga, E. A GIS methodology for optimal location of a wood-fired power plant: Quantification of available woodfuel, supply chain costs and GHG emissions. J. Clean. Prod. 2017, 157, 201–212. [Google Scholar] [CrossRef]

- Khan, S.; Mohiuddin, K. Evaluating the parameters of ArcGIS and QGIS for GIS Applications. Int. J. Adv. Res. Sci. Eng. 2018, 7, 582–594. [Google Scholar]

- Tommasi, A.; Cefalo, R.; Grazioli, A.; Pozzetto, D.; Alvarez Serrano, Y.M.; Zuliani, M. Optimization of a Co-generative Biomass Plant Location Using Open Source GIS Techniques. Technical, Economical and Environmental Validation Methodology. New Adv. GNSS 3D Spat. Tech. 2018. [Google Scholar] [CrossRef]

- Picchio, R.; Latterini, F.; Mederski, P.S.; Venanzi, R.; Karaszewski, Z.; Bembenek, M.; Croce, M. Comparing accuracy of three methods based on the gis environment for determining winching areas. Electronics 2019, 8, 53. [Google Scholar] [CrossRef] [Green Version]

- Picchio, R.; Pignatti, G.; Marchi, E.; Latterini, F.; Benanchi, M.; Foderi, C.; Venanzi, R.; Verani, S. The application of two approaches using GIS technology implementation in forest road network planning in an Italian mountain setting. Forests 2018, 9, 277. [Google Scholar] [CrossRef] [Green Version]

- Hadidi, L.A.; Omer, M.M. A financial feasibility model of gasification and anaerobic digestion waste-to-energy (WTE) plants in Saudi Arabia. Waste Manag. 2017, 59, 90–101. [Google Scholar] [CrossRef]

- Khan, M.J.; Hasan, S.A. GiS-Based Screening Model of coastal city Karachi for plantation of Biofuel Source. Sci. Rep. 2020, 10, 1–7. [Google Scholar] [CrossRef]

- Chalkias, C.; Lasaridi, K. Benefits from GIS based modelling for municipal solid waste management. In International Waste Management; Kumar, S., Ed.; INTECH Open Access Publisher: London, UK, 2011; Volume 1, pp. 417–434. ISBN 9533074698. [Google Scholar]

- Waewsak, J.; Ali, S.; Gagnon, Y. Site suitability assessment of para rubberwood-based power plant in the southernmost provinces of Thailand based on a multi-criteria decision-making analysis. Biomass Bioenergy 2020, 137, 105545. [Google Scholar] [CrossRef]

- Haase, M.; Rösch, C.; Ketzer, D. GIS-based assessment of sustainable crop residue potentials in European regions. Biomass Bioenergy 2016, 86, 156–171. [Google Scholar] [CrossRef]

- Comber, A.; Dickie, J.; Jarvis, C.; Phillips, M.; Tansey, K. Locating bioenergy facilities using a modified GIS-based location–allocation-algorithm: Considering the spatial distribution of resource supply. Appl. Energy 2015, 154, 309–316. [Google Scholar] [CrossRef] [Green Version]

- Franco, C.; Bojesen, M.; Hougaard, J.L.; Nielsen, K. A fuzzy approach to a multiple criteria and Geographical Information System for decision support on suitable locations for biogas plants. Appl. Energy 2015, 140, 304–315. [Google Scholar] [CrossRef] [Green Version]

- Valenti, F.; Liao, W.; Porto, S.M.C. A GIS-based spatial index of feedstock-mixture availability for anaerobic co-digestion of Mediterranean by-products and agricultural residues. Biofuels Bioprod. Biorefining 2018, 12, 362–378. [Google Scholar] [CrossRef]

- Valenti, F.; Porto, S.M.C.; Dale, B.E.; Liao, W. Spatial analysis of feedstock supply and logistics to establish regional biogas power generation: A case study in the region of Sicily. Renew. Sustain. Energy Rev. 2018, 97, 50–63. [Google Scholar] [CrossRef]

- QGIS Geographic Information System. Open Source Geospatial Foundation Project. Available online: http://qgis.org (accessed on 6 June 2020).

- Indian National Centre for Ocean Information Services. Available online: https://io50.incois.gov.in/documents/ITCOocean//Installation_Manuals_QGIS.pdf (accessed on 1 June 2020).

- Pari, L.; Alfano, V.; Garcia-Galindo, D.; Suardi, A.; Santangelo, E. Pruning biomass potential in Italy related to crop characteristics, agricultural practices and agro-climatic conditions. Energies 2018, 11, 1365. [Google Scholar] [CrossRef] [Green Version]

- EU Agroinlog - Integrated Biomass Logistic Centres fo the Agro-Industry. Available online: http://agroinlog-h2020.eu/en/home/ (accessed on 16 April 2020).

- Suardi, A.; Latterini, F.; Alfano, V.; Palmieri, N.; Bergonzoli, S.; Karampinis, E.; Kougioumtzis, M.A.; Grammelis, P.; Pari, L. Machine Performance and Hog Fuel Quality Evaluation in Olive Tree Pruning Harvesting Conducted Using a Towed Shredder on Flat and Hilly Fields. Energies 2020, 13, 1713. [Google Scholar] [CrossRef] [Green Version]

- Italian Ministry of Environment Territory and Sea. Italian National Geoportal. Available online: http://www.pcn.minambiente.it/mattm/servizio-di-scaricamento-wcs/ (accessed on 10 January 2020).

- Lazio Region. Lazio Region Geoportal. Available online: https://geoportale.regione.lazio.it/geoportale/ (accessed on 10 January 2020).

- Palmieri, N.; Suardi, A.; Alfano, V.; Pari, L. Circular Economy Model: Insights from a Case Study in South Italy. Sustainability 2020, 12, 3466. [Google Scholar] [CrossRef] [Green Version]

- Cundiff, J.S.; Grisso, R.D.; Shapouri, H. Economic Analysis of two Receiving Facility Designs for a Bioenergy Plant. In Proceedings of the 2007 ASAE Annual Meeting 2007, Minneapolis, MN, USA, 17–20 June 2007; American Society of Agricultural and Biological Engineers: St. Joseph, MI, USA, 2007. [Google Scholar]

- QGIS plugin repository, Network Analysis Tool. Available online: https://docs.qgis.org/3.4/en/docs/training_manual/vector_analysis/network_analysis.html (accessed on 19 June 2020).

- Acampora, A.; Croce, S.; Assirelli, A.; Del Giudice, A.; Spinelli, R.; Suardi, A.; Pari, L. Product contamination and harvesting losses from mechanized recovery of olive tree pruning residues for energy use. Renew. Energy 2013, 53, 350–353. [Google Scholar] [CrossRef]

- Pari, L.; Suardi, A.; Santangelo, E.; García-Galindo, D.; Scarfone, A.; Alfano, V. Current and innovative technologies for pruning harvesting: A review. Biomass Bioenergy 2017, 107, 398–410. [Google Scholar] [CrossRef]

- Toscano, G.; Alfano, V.; Scarfone, A.; Pari, L. Pelleting vineyard pruning at low cost with a mobile technology. Energies 2018, 11, 2477. [Google Scholar] [CrossRef] [Green Version]

- Nati, C.; Boschiero, M.; Picchi, G.; Mastrolonardo, G.; Kelderer, M.; Zerbe, S. Energy performance of a new biomass harvester for recovery of orchard wood wastes as alternative to mulching. Renew. Energy 2018, 124, 121–128. [Google Scholar] [CrossRef]

- Forleo, M.B.; Palmieri, N.; Suardi, A.; Coaloa, D.; Pari, L. The eco-efficiency of rapeseed and sunflower cultivation in Italy. Joining environmental and economic assessment. J. Clean. Prod. 2018, 172, 3138–3153. [Google Scholar] [CrossRef]

- Schweier, J.; Blagojević, B.; Venanzi, R.; Latterini, F.; Picchio, R. Sustainability assessment of alternative strip clear cutting operations for wood chip production in renaturalization management of pine stands. Energies 2019, 12, 3306. [Google Scholar] [CrossRef] [Green Version]

- Schweier, J.; Magagnotti, N.; Labelle, E.R.; Athanassiadis, D. Sustainability Impact Assessment of Forest Operations: A Review. Curr. For. Reports 2019, 5, 101–113. [Google Scholar] [CrossRef] [Green Version]

- Spinelli, R.; Lombardini, C.; Pari, L.; Sadauskiene, L. An alternative to field burning of pruning residues in mountain vineyards. Ecol. Eng. 2014, 70, 212–216. [Google Scholar] [CrossRef]

- Avraamides, M.; Fatta, D. Resource consumption and emissions from olive oil production: A life cycle inventory case study in Cyprus. J. Clean. Prod. 2008, 16, 809–821. [Google Scholar] [CrossRef]

- Jacometti, M.A.; Wratten, S.D.; Walter, M. Management of understorey to reduce the primary inoculum of Botrytis cinerea: Enhancing ecosystem services in vineyards. Biol. Control 2007, 40, 57–64. [Google Scholar] [CrossRef]

- Testa, R.; Foderà, M.; Di Trapani, A.M.; Tudisca, S.; Sgroi, F. Choice between alternative investments in agriculture: The role of organic farming to avoid the abandonment of rural areas. Ecol. Eng. 2015, 83, 227–232. [Google Scholar] [CrossRef]

| Slope Range (%) | Harvesting Scenario | Machineries and Operations | Harvesting Costs per Surface Unit (EUR ha−1) | Harvesting Loss (%) | References | |

|---|---|---|---|---|---|---|

| 0–5% | SF | Raking | Shredding, handling and loading | 72.90 | 25 | [11,52] |

| pruning rake + 44kW tractor | towed shredder + 96 kW tractor + 90 kW lifter | |||||

| 5–25% | SS | Raking | Shredding, handling and loading | 87.60 | 25 | [11,52] |

| pruning rake + 44kW tractor | towed shredder + 96 kW tractor + 90 kW lifter | |||||

| 25–30% | CS | Bunching | Comminuting, handling and loading | 230.38 | 0 | [11] |

| 66 kW tractor | stationary chipper + hydraulic loader + 126 kW tractor + 90 kW lifter | |||||

| Sub-Area | Yearly Harvestable Pruning Availability (Mgfm·year−1) | Total Olive Groves Surface (ha) |

|---|---|---|

| A | 11,162.18 | 5396.01 |

| B | 17,246.13 | 10,448.09 |

| C | 19,838.51 | 12,062.10 |

| D | 9664.76 | 5753.62 |

| E | 8979.98 | 5483.13 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Latterini, F.; Stefanoni, W.; Suardi, A.; Alfano, V.; Bergonzoli, S.; Palmieri, N.; Pari, L. A GIS Approach to Locate a Small Size Biomass Plant Powered by Olive Pruning and to Estimate Supply Chain Costs. Energies 2020, 13, 3385. https://doi.org/10.3390/en13133385

Latterini F, Stefanoni W, Suardi A, Alfano V, Bergonzoli S, Palmieri N, Pari L. A GIS Approach to Locate a Small Size Biomass Plant Powered by Olive Pruning and to Estimate Supply Chain Costs. Energies. 2020; 13(13):3385. https://doi.org/10.3390/en13133385

Chicago/Turabian StyleLatterini, Francesco, Walter Stefanoni, Alessandro Suardi, Vincenzo Alfano, Simone Bergonzoli, Nadia Palmieri, and Luigi Pari. 2020. "A GIS Approach to Locate a Small Size Biomass Plant Powered by Olive Pruning and to Estimate Supply Chain Costs" Energies 13, no. 13: 3385. https://doi.org/10.3390/en13133385