1. Introduction

Energy demand has increased rapidly in recent years, posing myriad economic and environmental challenges worldwide, such as global warming. Accounting for over 40% of primary energy consumption and one-third of greenhouse gas (GHG) emissions, buildings are one of the most energy-intensive sectors and the top GHG emitters [

1,

2,

3]. Furthermore, 25% of global energy demand and 17% of global GHG emissions are attributed to residential buildings [

4]. A large share of this energy is consumed by heating, ventilation, and air conditioning systems to provide thermal comfort for occupants [

5,

6,

7,

8,

9]. To reduce the excessive energy consumption of buildings, the concept of nearly Zero Energy Buildings (nZEB) has been put forward. An nZEB can be defined as a high-energy performance building in which the energy demand is mostly met by on-site energy generation from renewable resources [

10,

11]. Building design features such as building typology, orientation, construction material, and HVAC systems can be optimized to minimize building energy demand. Then, renewable energy systems can be applied to meet the demand [

12,

13].

Thus far, many studies have addressed these features. For instance, the effects of several factors, including window-to-wall ratio (WWR), configuration, construction material, and the percentage of air-conditioned area, were assessed on the thermal and lighting performance of high-rise office buildings in India [

14]. It was revealed that the mixed-mode ventilation and insulated walls could effectively reduce HVAC loads. The impact of aerogel glazing on the thermal performance of a 40-story commercial building was studied, and it was indicated that the proposed glazing could conserve 8.5% of cooling energy compared to double glazing [

15]. Huang et al. investigated several insulation materials in an office building to find the optimal material and thickness in terms of cost and energy saving, showing that an optimal insulation material can reduce the heating load by 18% compared to an uninsulated wall [

16]. The scrutiny of Indonesian residential buildings indicated that natural construction material is capable of reducing the electricity consumption of dwellings [

17]. The influence of building orientation on the WWR of a single-family house was examined in temperate climates considering various U-values and g-values; the optimal WWR for Ljubljana was found to vary between 38% and 42% [

18]. Alghoul et al. analyzed the effect of window orientation and WWR on the energy use of an office building in Libya and concluded that the cooling demand increases and the heating demand decreases with an increase in WWR [

19].

The analysis of various WWRs in different European countries indicated that the optimal WWR for office buildings tends to fall between 30% and 40% for most locations [

20]. Fang et al. performed an optimization of building fenestration and envelope to improve the daylighting and energy performance of an office building in three distinctive climates, indicating that the length and width of the skylight are the most influential factors [

21]. A technical and economic study was carried out to examine and introduce building retrofitting measures for a school building in Jordan, and the findings suggested that the proposed measures could save approximately 55% of energy with a payback period of 5.5 years [

22]. Various passive solar and energy-saving techniques, including double glazing openings, shading devices, and different construction materials, were applied to a two-story detached house situated in Sydney, Australia; the findings demonstrated that the application of passive solar methods and high thermal mass in buildings can significantly reduce the energy consumption [

23]. Lan et al. adopted a holistic zero energy building design for residential buildings in Singapore and carried out a sensitivity analysis, showing that WWR, roof solar absorptance, and window status are the determining factors on indoor thermal comfort and energy efficiency [

24].

Although a large number of studies have investigated the energy efficiency of buildings in urban areas, energy conservation measures have been overlooked in rural areas, resulting in increased energy consumption [

25,

26,

27]. It is worthwhile to mention that there is a growing interest in the energy performance of rural buildings, and a few companies are presently working on them [

28,

29]. However, only a limited number of studies have examined the energy performance of rural buildings. Chi et al. studied the impact of building orientation on the thermal and daylighting performance of a traditional dwelling located in Sizhai, China, by rotating the building in 20° increments [

30]. An annual energy saving of 150 kWh (9%) was observed between the optimal and worst azimuth angles. The spatial parameters of a rural dwelling in China were studied and optimized using TRNSYS and GenOpt programs, and the optimal building shape was found to be a rectangle [

31]. The impact of spatial parameters was also investigated for a school building situated in the cold climates of China [

32]. The results indicated that the variations in spatial parameters could lead to a nearly 14% energy saving and 4% thermal comfort compared to the base case. Xue et al. [

33] examined the window-to-wall ratio of a hotel building with sunshades to enhance the daylighting and energy performance and proposed the maximum and minimum thresholds for WWR. Sun et al. assessed the thermal performance of a rural Tibetan dwelling and proposed some retrofit measures, such as the application of a solar room and insulation that can attain a nearly 75% energy saving [

34]. Mohammadi et al. analyzed the thermal comfort and energy performance of a traditional residential building in Bushehr to identify the impact of climate-responsive solutions integrated into these buildings and indicated that these solutions could effectively reduce energy consumption and enhance thermal comfort [

35].

Although urban areas are the major contributor to air pollution and excessive energy consumption, rural buildings also play a vital role due largely to their poor design. Furthermore, rural areas are located far from electricity grids, and therefore they are prone to frequent blackouts. The cost of grid extension and development can be prohibitive considering the economic conditions in developing countries, particularly in Iran. For these reasons, the design of energy-efficient buildings can be considered as a practical alternative for alleviating the peak demand pressure on the power grid. The review of pertinent literature shows that the WWR, building orientation, and construction material are among the most influential parameters on the thermal performance of a building and that there have been only a limited number of studies on the energy performance of rural buildings. Therefore, this study aims to analyze the impact of the WWR, glazing type, building orientation, and insulation material on a rural dwelling. Moreover, to achieve nZEB targets, photovoltaic modules are integrated in the building. Finally, the adopted approach is economically evaluated to ensure its feasibly. It is worthwhile to mention that, to best of the authors’ knowledge, nZEB rural buildings have not been fully investigated and that this study attempts to address both energy efficiency and renewable energy generation aspects.

2. Materials and Methods

In order to attain a sustainable building design in rural areas, this study aimed to assess the impact of multiple parameters on the thermal behavior of a building located in Palangan, Iran. The following is a detailed account of the adopted procedure.

2.1. Site Description

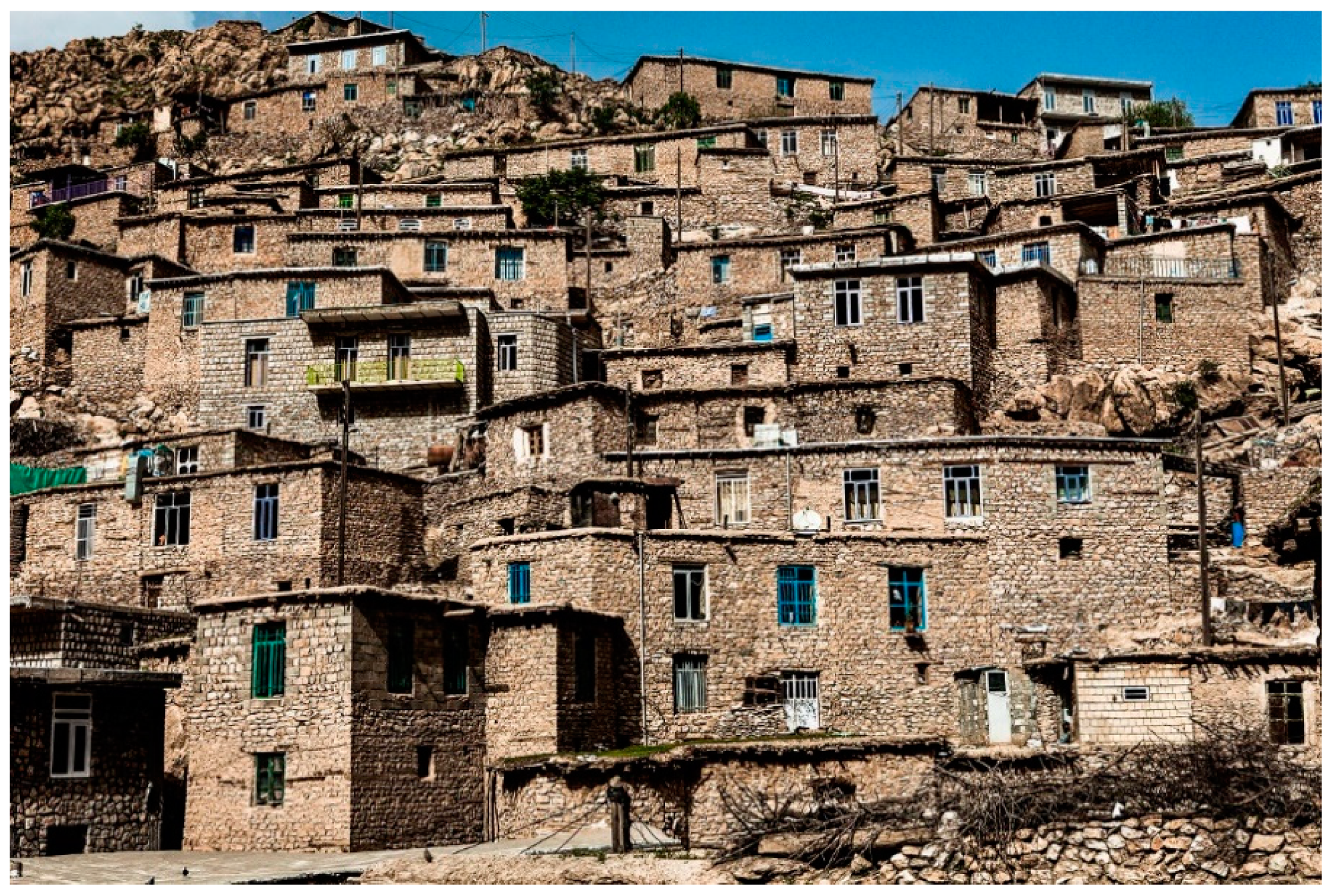

Palangan, with a coordination of 35°04′ N 46°36′ E, is a mountainous village located in the Kurdistan Province of Iran at an altitude of 1470 m. As shown in

Figure 1, this village has a stair-steps architecture, and the rooves of lower buildings are used as yards for upper buildings. The village has a Mediterranean-like climate with hot, dry summers and cold, wet winters and falls under the Csa Köppen–Geiger climate category (see

Table 1). The climatic information of the village is presented in

Table 1. The annual mean air temperature is nearly 13 °C, and the precipitation can vary from 0 mm in summer to 85 mm in winter.

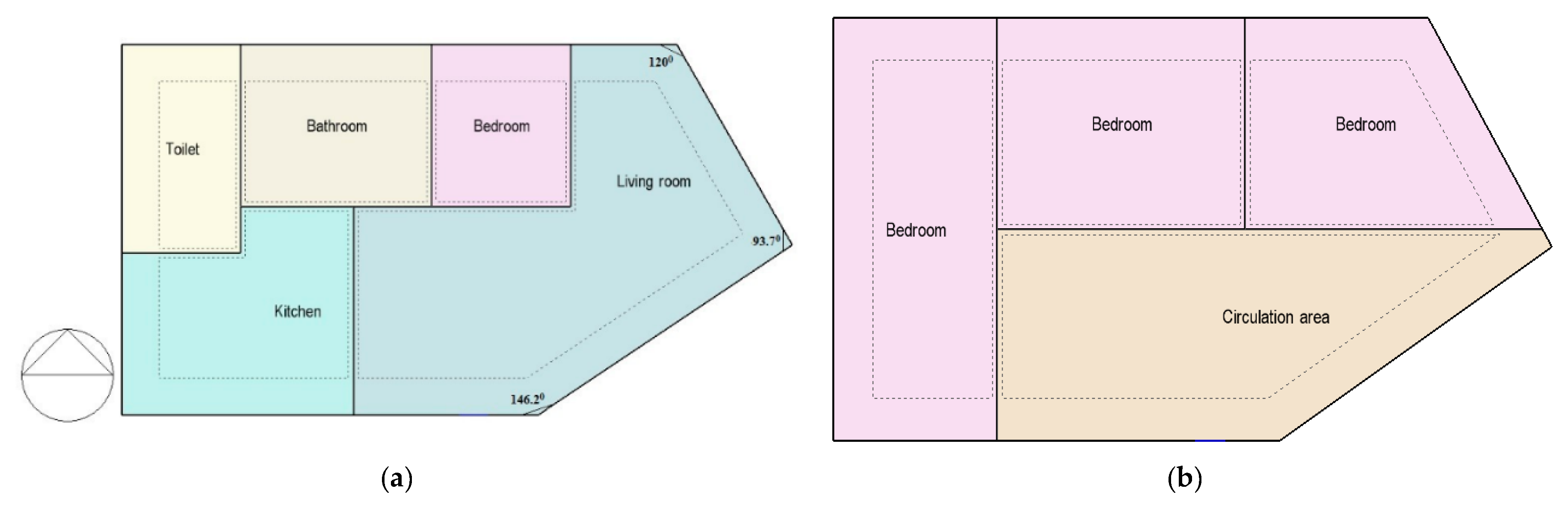

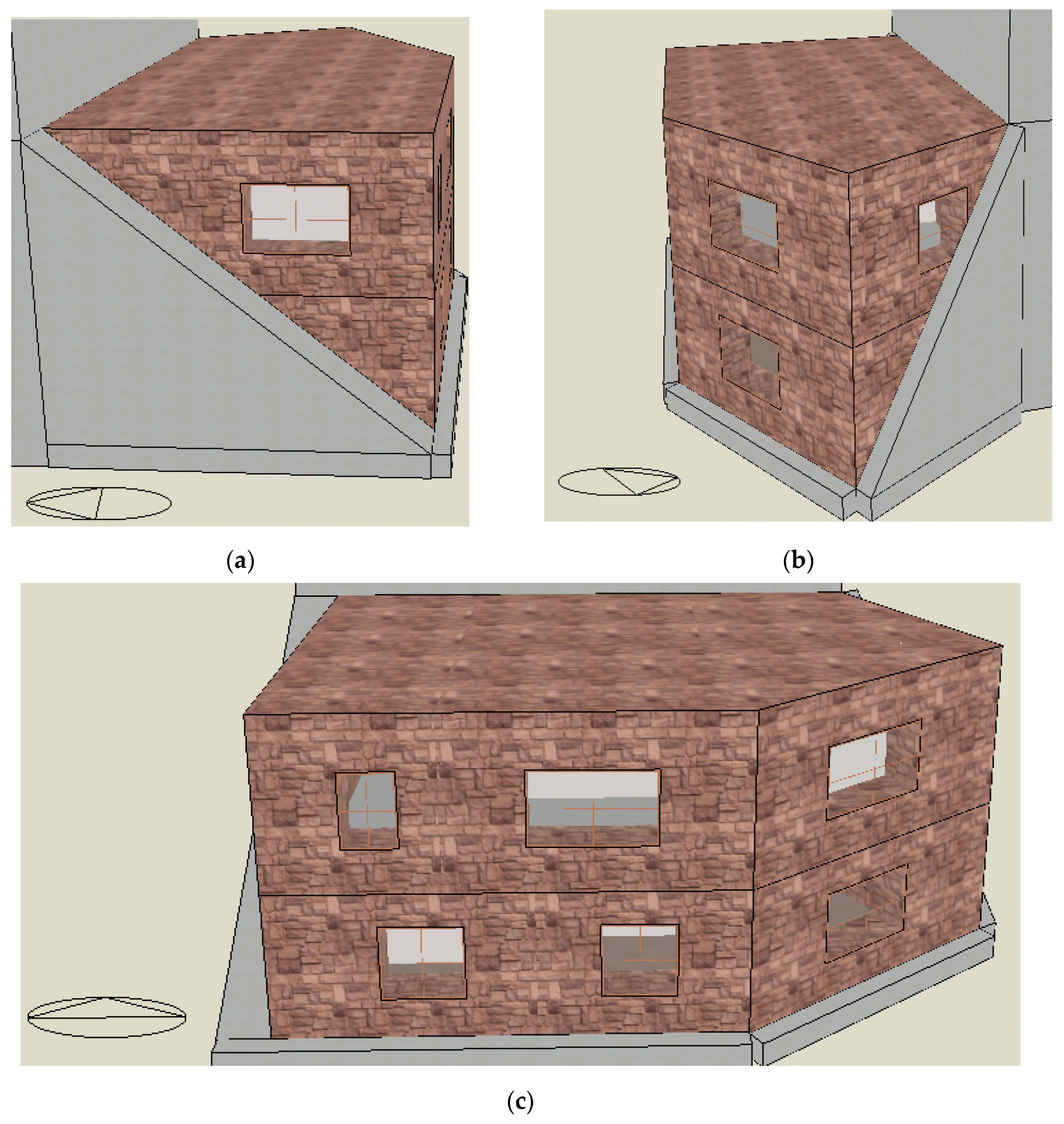

2.2. Building Description

A 2-story building with a total area of 159 m

2, as depicted in

Figure 2, typical of Palangan, was selected as the case study.

Figure 3 demonstrates the 2D plan of the building. It can be seen that the ground floor comprises a kitchen, a toilet, a bathroom, a living room, and a bedroom. There are three bedrooms on the second floor. The building walls are made of stone with a thickness of 80 cm, and 3-mm single glazing windows are considered. The details of the building envelope and windows are provided in

Table 2 and

Table 3, respectively. For heating and cooling purposes, the building is outfitted with a 4-pipe fan coil unit. The heating and cooling setpoints are taken to be 20 and 26 °C, respectively. The internal gains of the building are also summarized in

Table 4. Different views of the building are shown in

Figure 4, including right, left, and front lights.

2.3. Simulation Tool

EnergyPlus, developed by the US department of energy, is a building simulation tool that encompasses the capabilities of the DOE-2 and Blast programs [

36]. However, EnergyPlus does not have a user-friendly interface. Thus, in this study DesignBuilder (V 6.0), which uses the EnergyPlus engine for energy simulations and is an advanced user interface [

37,

38], was employed.

2.4. Studied Parameters

For minimizing the energy consumption, the impact of several parameters that include the orientation, window-to-wall ratio (WWR), glazing type, shading devices, and insulation material on the energy performance of the building were studied.

2.4.1. Orientation

To find the optimal configuration for the building, the building was rotated from 0° to 90° clockwise.

2.4.2. WWR

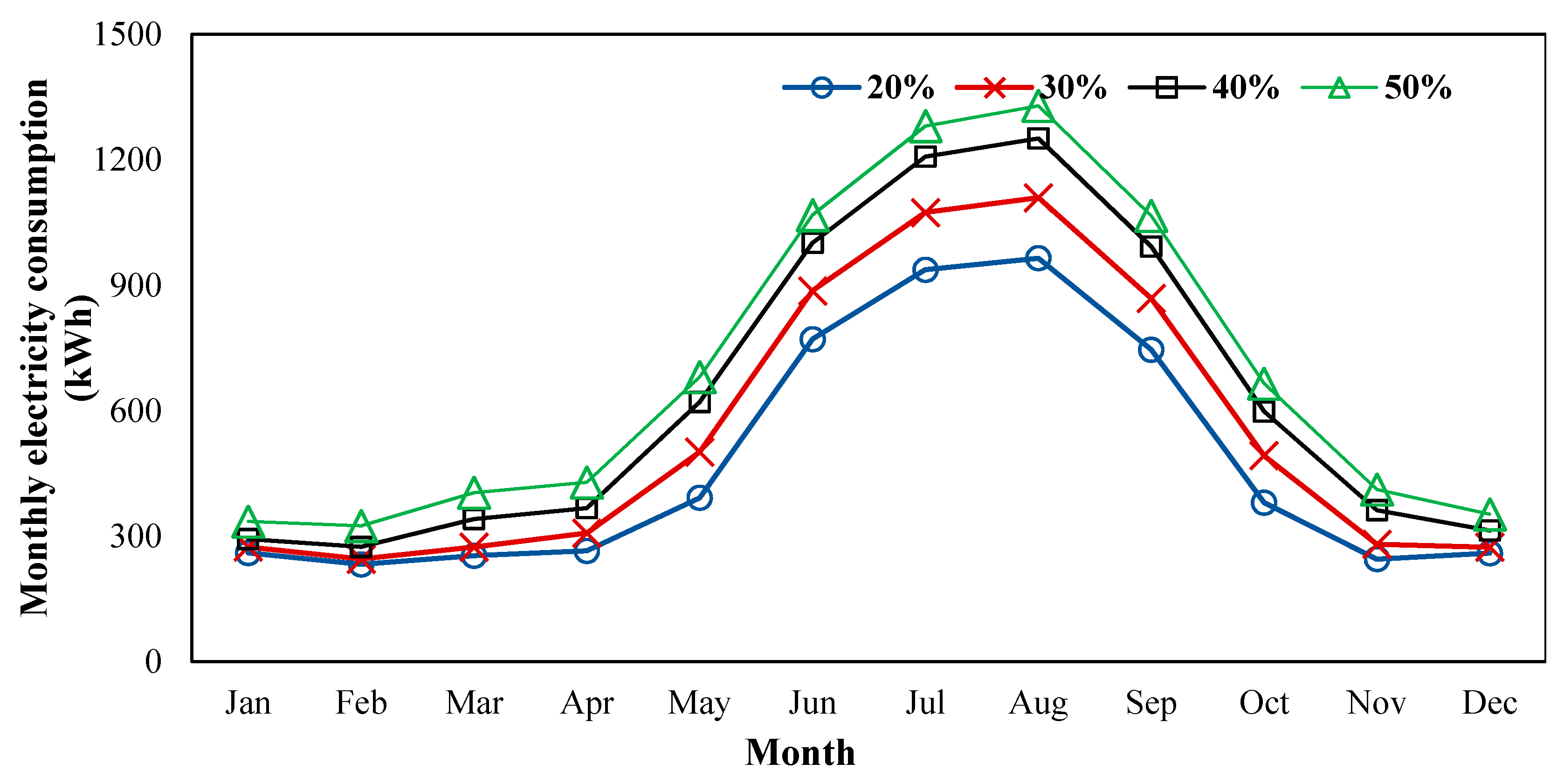

The WWR varies from 20% to 50% by 10%. This range was selected in order not to invade the local architecture of the study area.

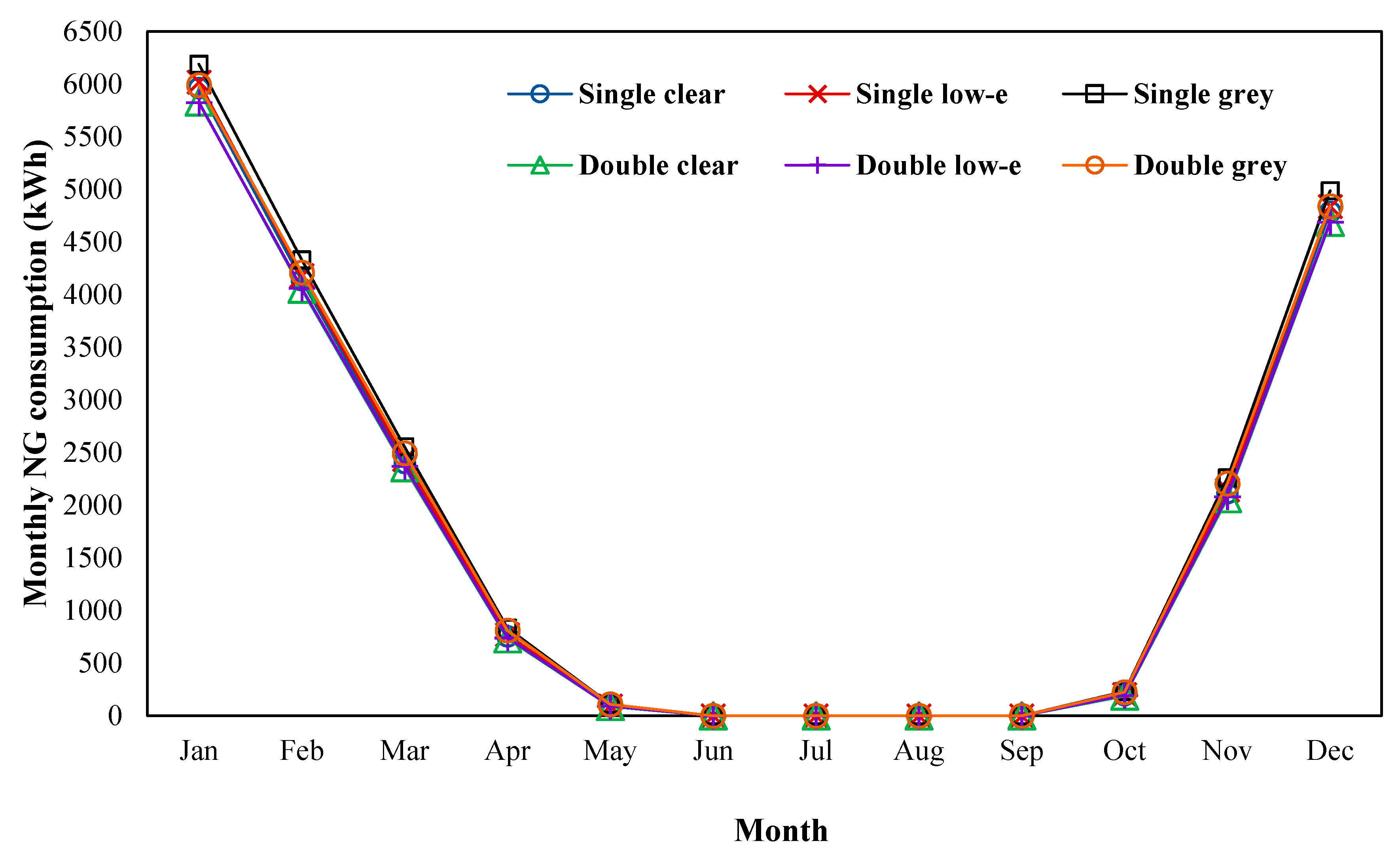

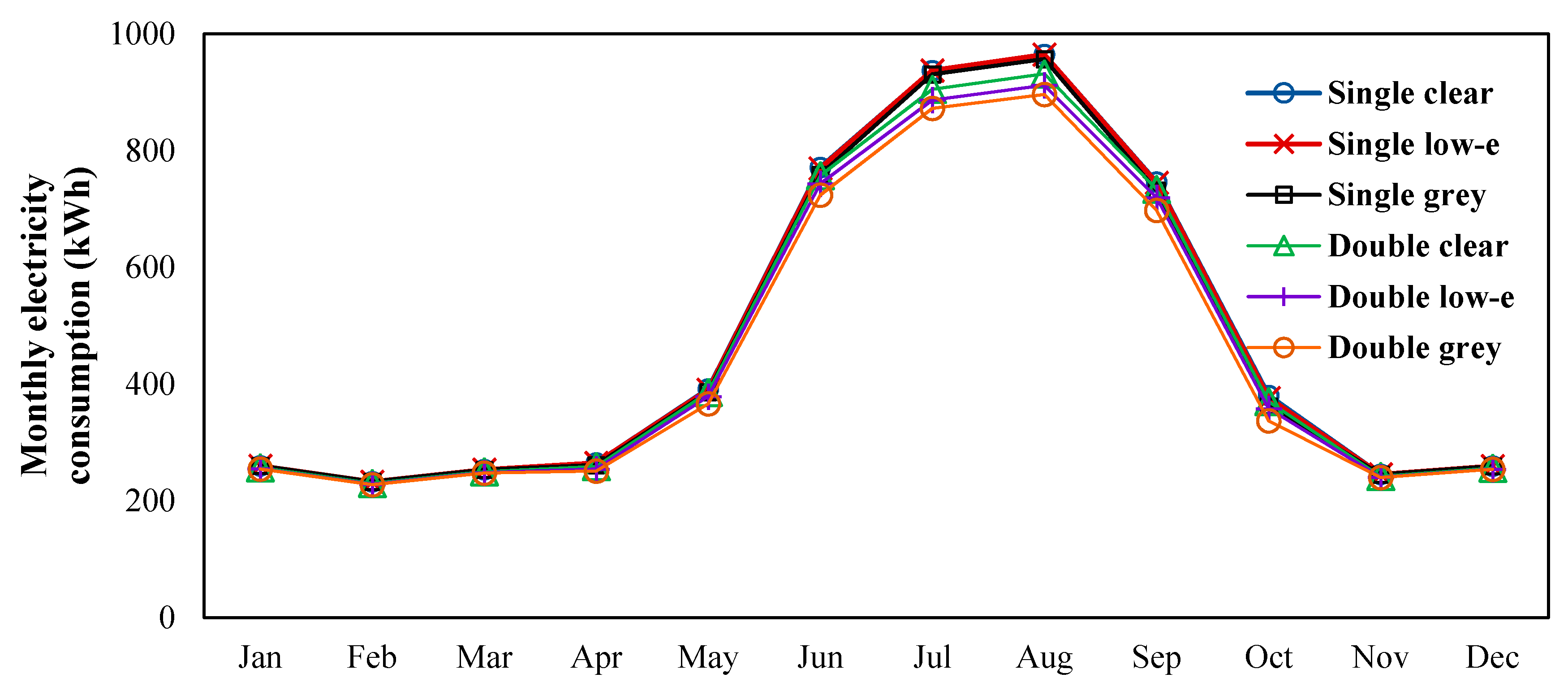

2.4.3. Glazing Type

Single and double glazing windows with various types of glass were examined. The considered glazing types and their optical properties are presented in

Table 5.

2.4.4. Shading Devices

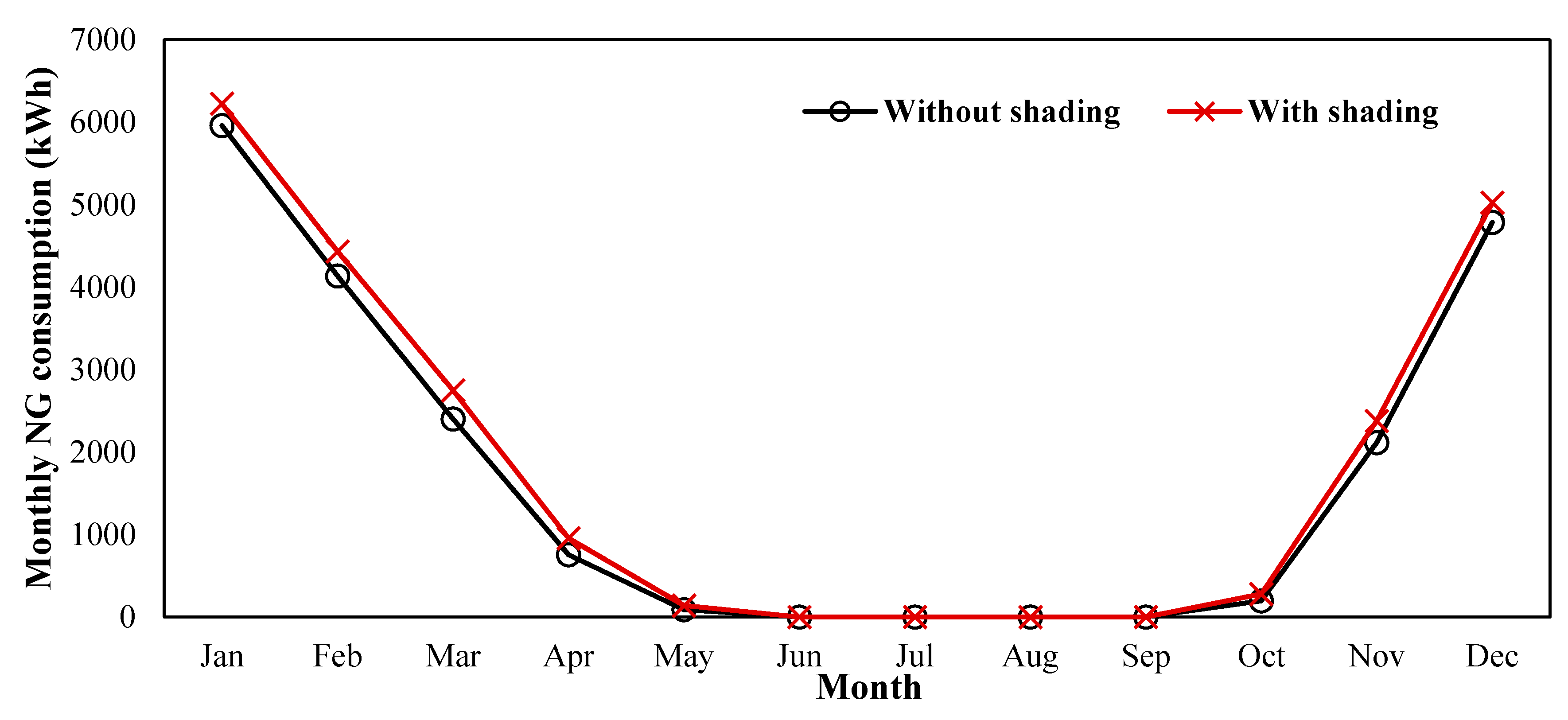

The building with and without overhangs was simulated to see its impact on energy performance. Wooden overhangs with a width of 1 m were attached to the windows.

2.4.5. Insulation Material

The inclusion of insulation material in the external walls was one of the energy-saving measures. In this regard, several insulation materials were examined, and then the one with optimal performance was proposed.

Table 6 shows the materials considered and the U-value of the external walls.

2.5. Photovoltaic

To attain nZEB features, photovoltaic (PV) modules were mounted on the roof. To asses the output power of the PV system, DesignBuilder adopted equivalent to one diode or a four-parameter-equivalent circuit method where the slope of the IV curve is zero under short circuit conditions [

18]:

The four parameters,

,

,

, and

, were obtained from manufacture’s catalogue [

18].

The equation can be defined follows.

In the above equation,

,

,

,

,

, and

are the current flowing through the PV, the load, the load voltage, the Boltzmann constant, the module temperature, the electron charge constant, and the module series constant, respectively.

is the photocurrent that correlates linearly with the incident radiation and is expressed as:

, , and are total incident radiation, incident radiation at a reference condition, and module photocurrent at a reference condition, respectively. is a constant with a value of 1000 W/m2.

The diode reverse saturation current,

, varies with the temperature and is calculated by the following equation [

18]:

is the diode reverse saturation current, and is the module temperature at standard conditions. When and are assessed by Equations (3) and (4), the Newton method is employed to calculate the PV current. Furthermore, an iterative technique is also used to give the current () and voltage () at the maximum power.

,

, and

can be separated. First, the current and voltage are replaced into Equation (2) at the open circuit (

oc), short circuit (

sc), and maximum power (

mp) conditions:

where the term −1 can be dropped, as it has an insignificant impact on the right side of the equation. The following equations that separate the three parameters can be expressed by some modifications [

18].

To determine the final parameter, the derivative of the voltage must be computed with regard to the temperature at a reference short circuit condition that is defined as follows:

In the above equation,

,

, and

demonstrate the temperature coefficient of the open circuit, the temperature coefficient of the short circuit, and the bandgap, respectively.

can be expressed as follows:

where

signifies the number of solar cells in a PV module.

The specifications of PVs are summarized in

Table 7. Fifty PV modules, each with a nominal power of 250 W, were installed. It should be noted that the total nominal power of the PV system was 12.8 kW. The modules were tilted at an angle of 36° toward the south.

2.6. Validation

Many researchers have verified and validated the EnergyPlus engine and DesignBuilder software, such as studies reported by Blanco et al. [

39], Zhuang et al. [

40], Anđelković et al. [

41], Alam et al. [

42], Fernando Garsia et al. [

43], and Shehadi [

44]. However, to be assured of the reliability of our findings, a single zone building located in Melbourne, Australia, as presented by Alam et al., was selected for validation. Further information about the building is available in Alam et al. [

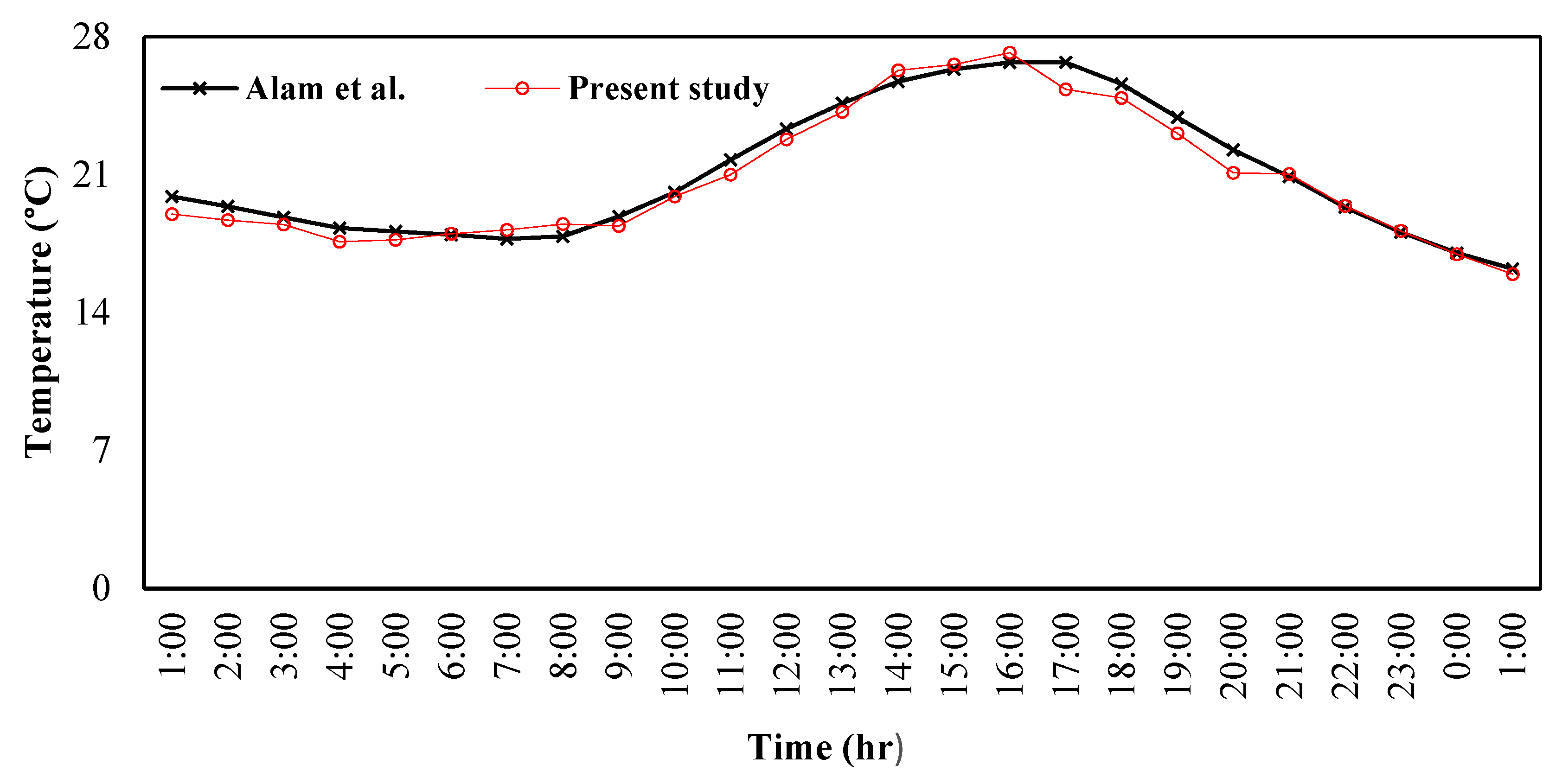

42]. As shown in

Figure 5, the building is modeled and simulated in DesignBuilder from 1 April to 2 April.

Figure 6 depicts the hourly results reported by Alam et al. and the current study. It can be seen that the findings of the present study are in agreement with those presented by Alam et al.

4. Conclusions

Buildings are responsible for a large fraction of primary energy consumption. In this regard, many studies have proposed various energy-saving measures. However, the energy performance of buildings located in rural areas that have relatively higher energy consumption due to lack of proper design has not yet been fully investigated. The purpose of this study was to examine the impact of several factors, namely orientation, WWR, glazing type, shading devices, and insulation, on the energy performance of a two-story building located in Palangan village in Iran. The building was then outfitted with PV modules, and finally an economic assessment was conducted to see whether or not the proposed design was economically viable. The following is a brief account of the findings:

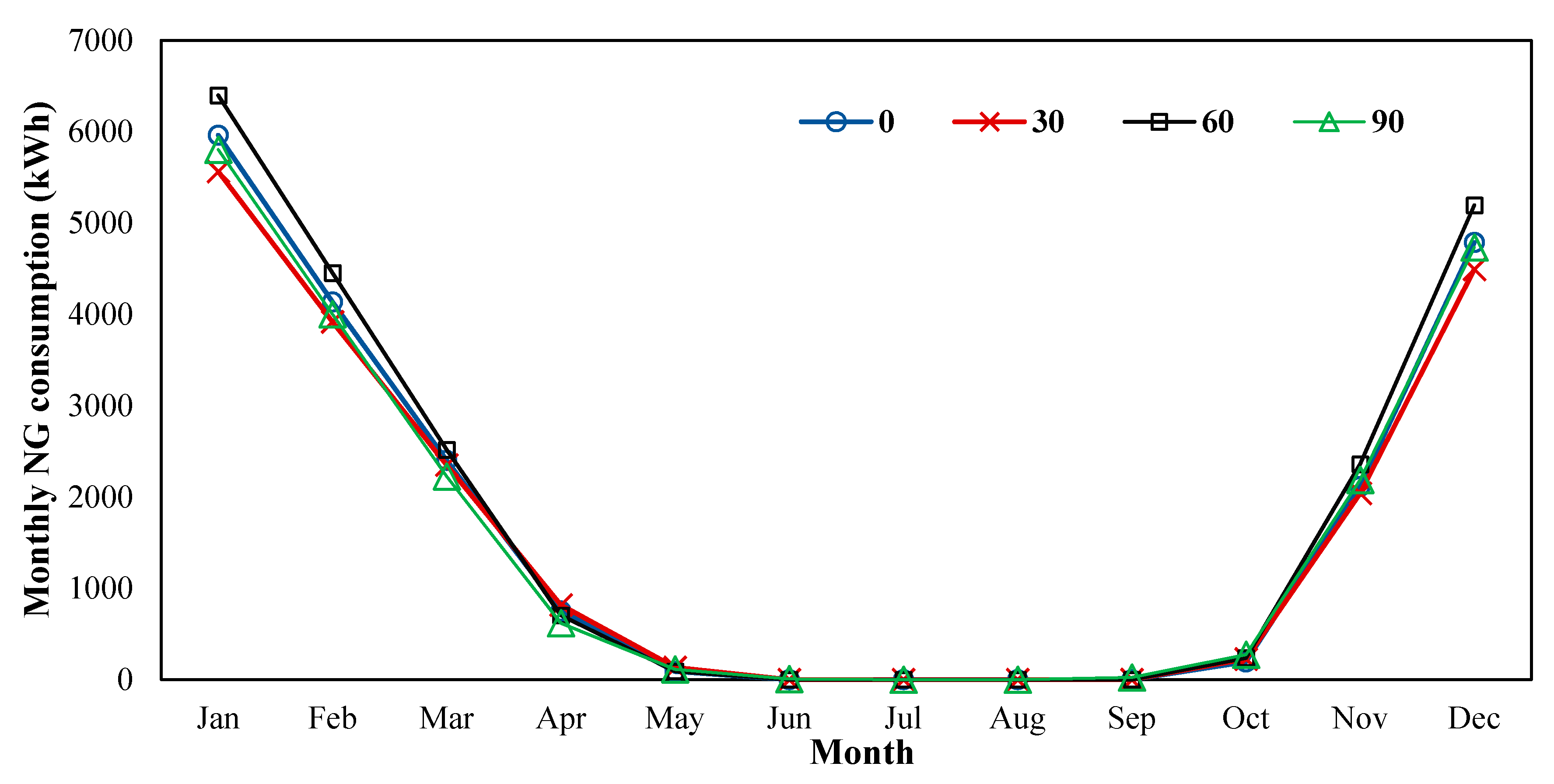

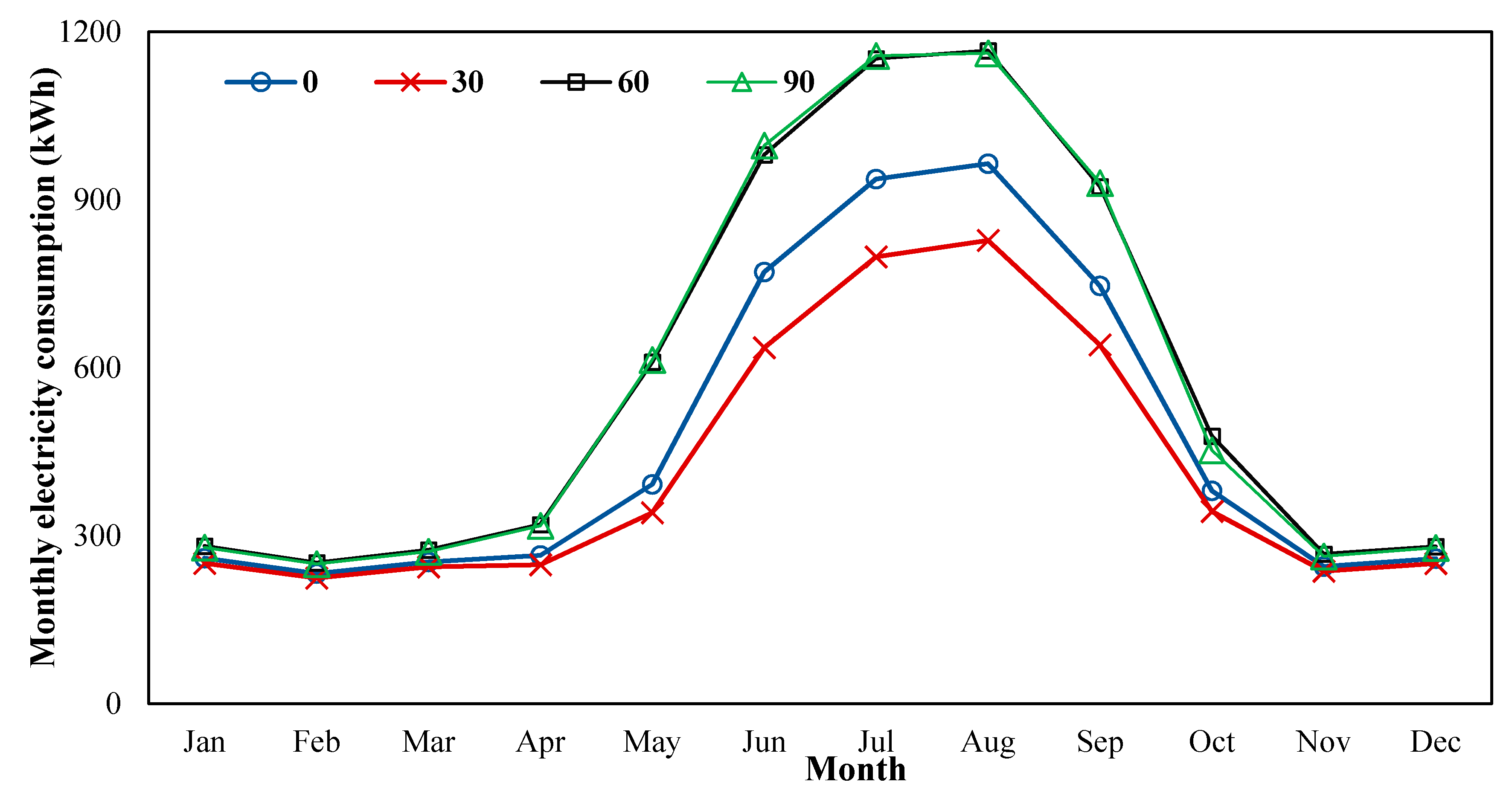

The building rotated 30° clockwise could reduce the NG and electricity use by 4.4% and 11.6%, respectively.

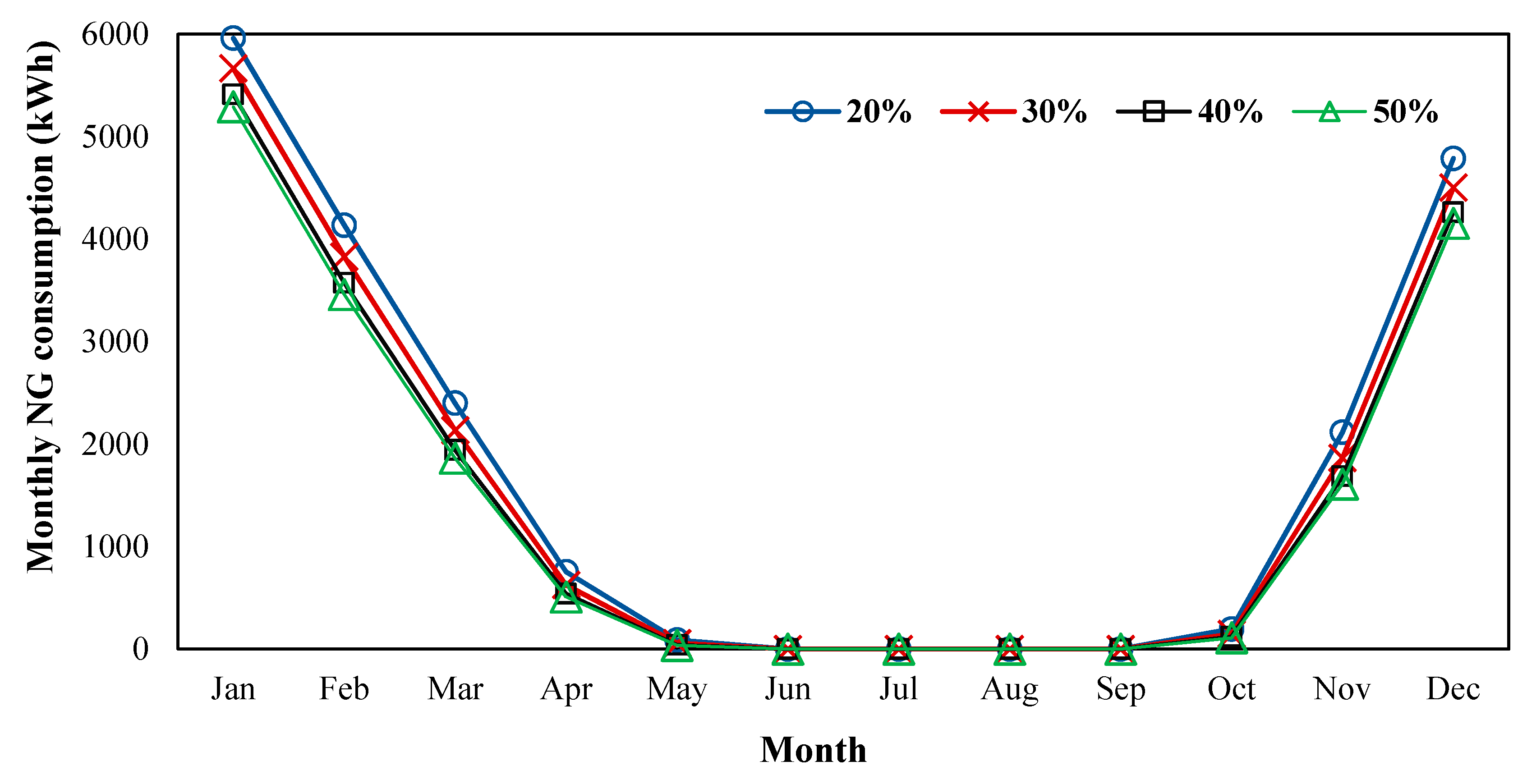

As the WWR increased, the NG consumption declined and the electricity use increased. The optimal WWR was found to be 40%.

The double low-e glazing could minimize both NG and electricity consumption by 1.9% and 4%, respectively.

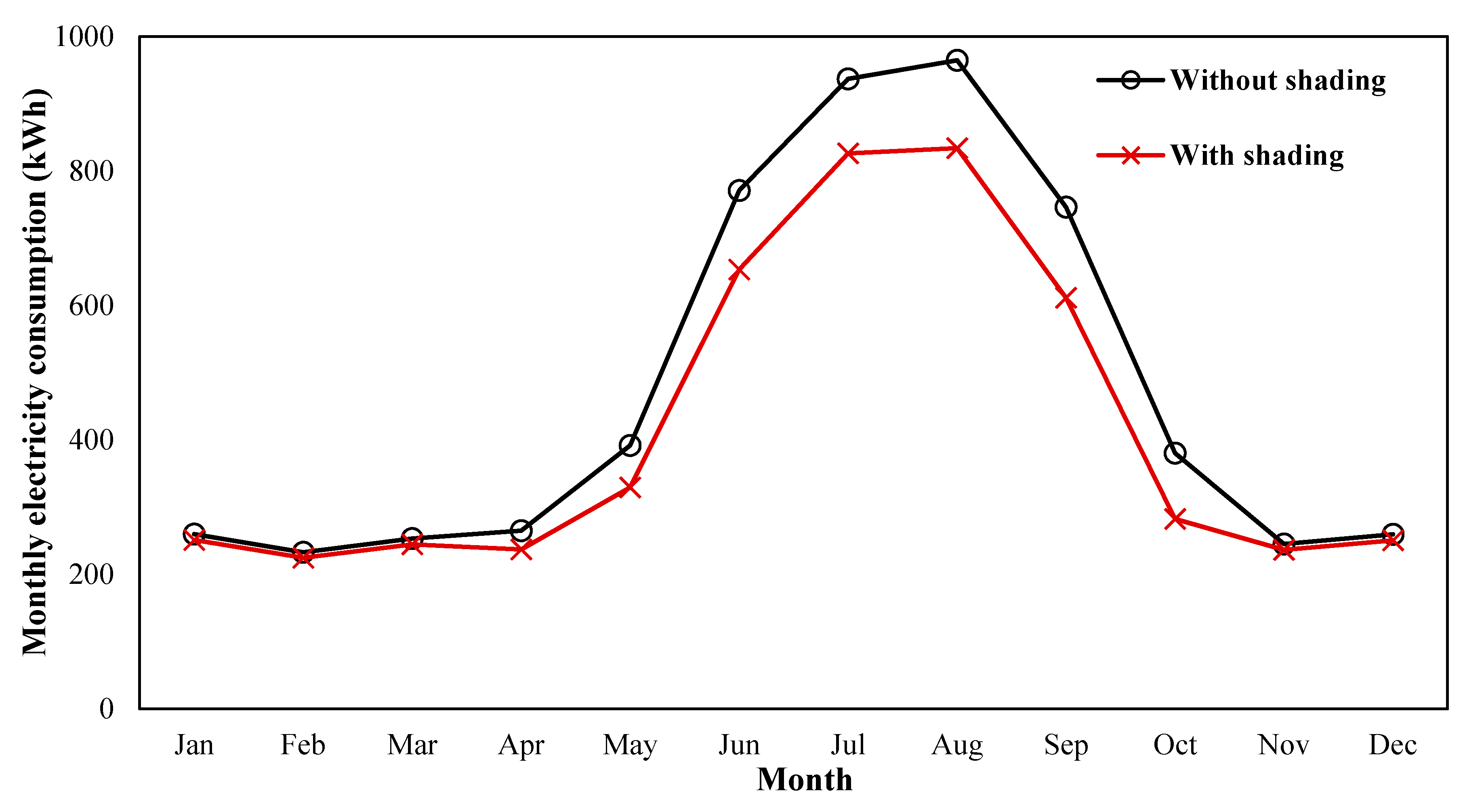

The application of the overhangs increased the NG use by 8.5% and the total energy by 3.9%.

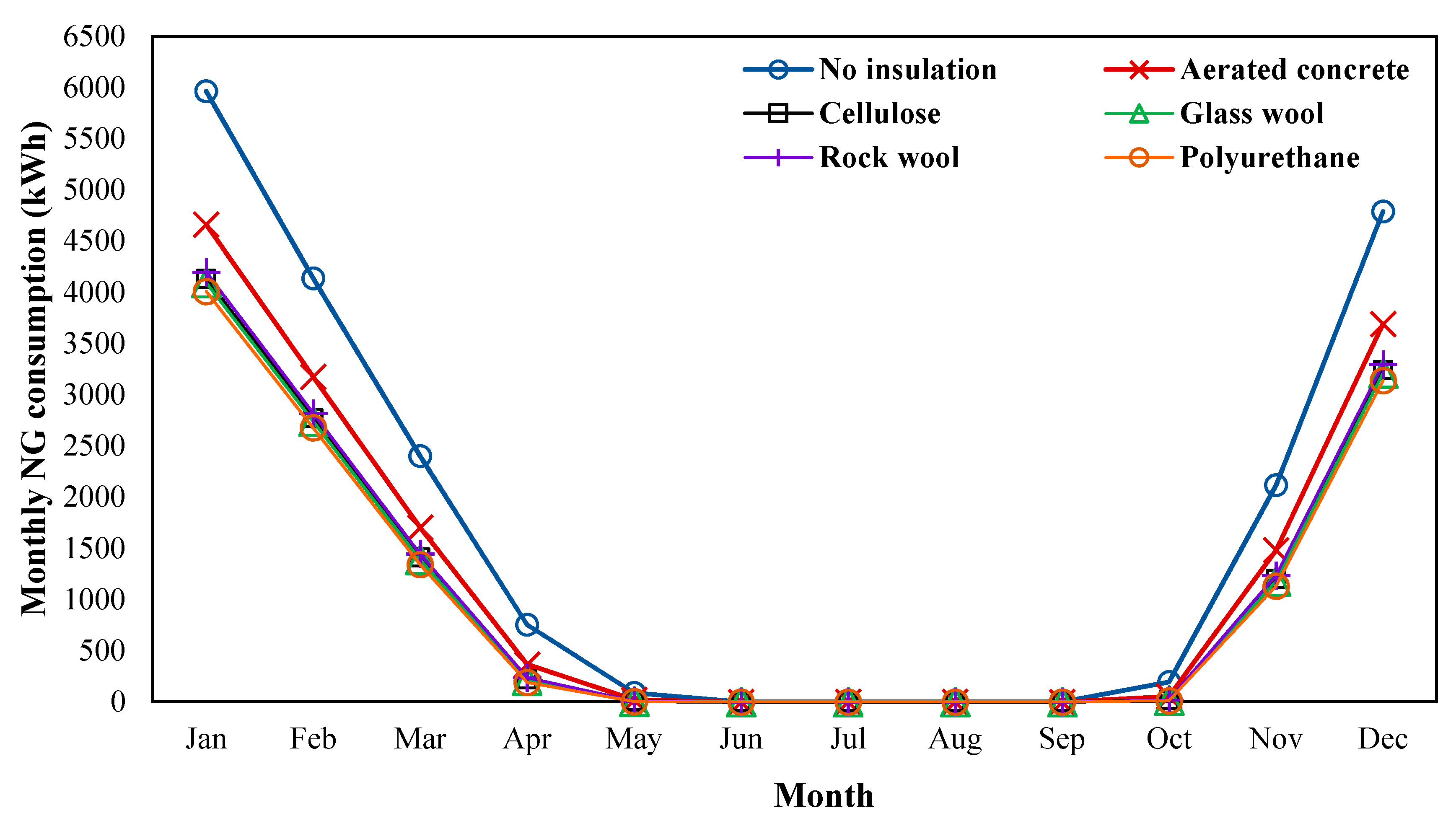

Polyurethane was identified as the best insulation material among the studied cases, since it reduced the total building energy by 27.8%.

The optimal case could save 32.2% of the total energy compared to the conventional building, and the PV system could generate over 22 MWh of electricity annually. The payback period for the building with PV was 21.7 years.

For future studies, the impact of energy-saving measures in various climatic conditions can be investigated. Moreover, advanced building materials such as phase change materials can be incorporated in building walls to further improve energy performance.