Impact of Wide-Bandgap Technology on Renewable Energy and Smart-Grid Power Conversion Applications Including Storage

Abstract

:1. Introduction

2. Renewable Energy Inverters

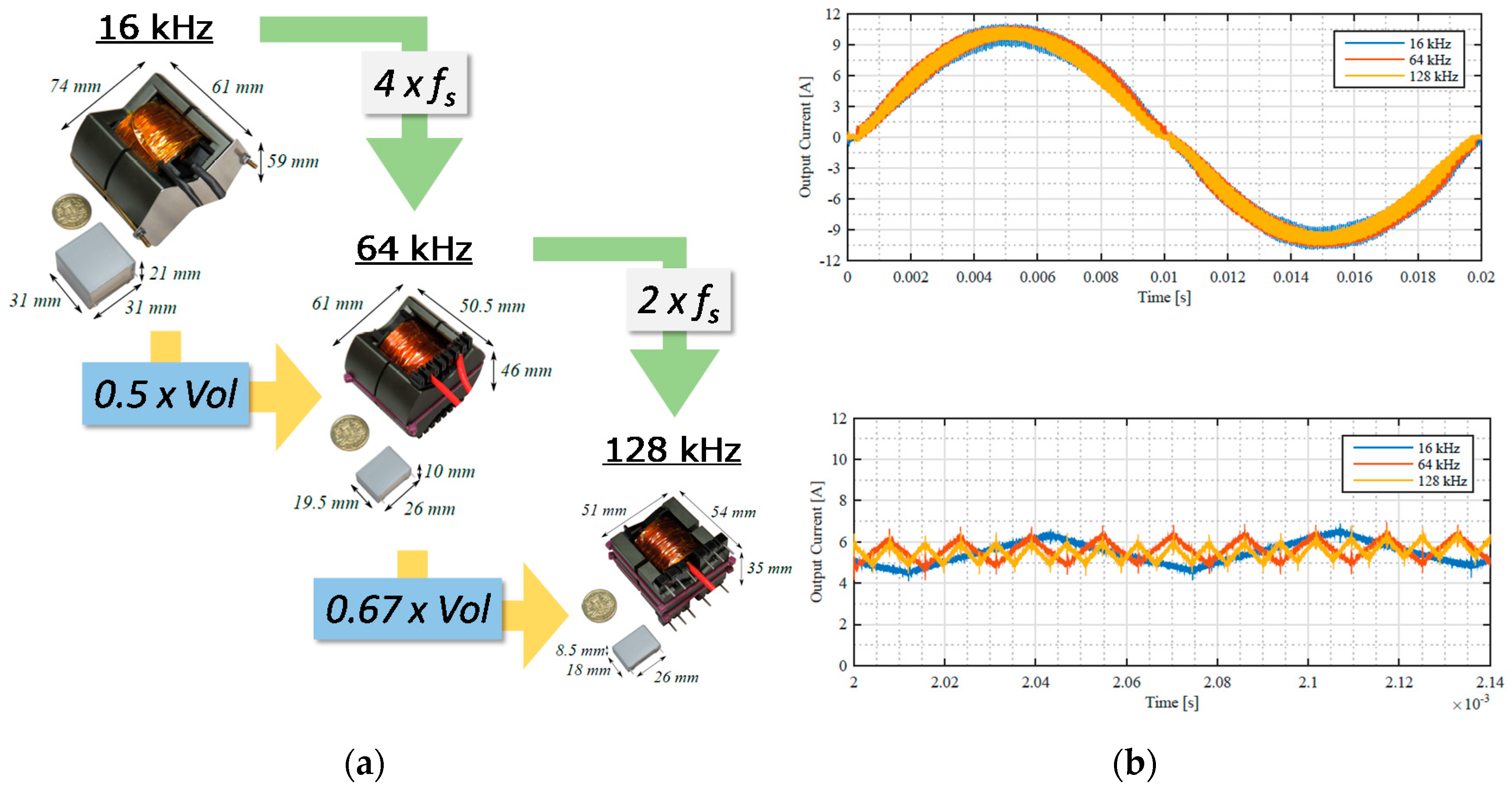

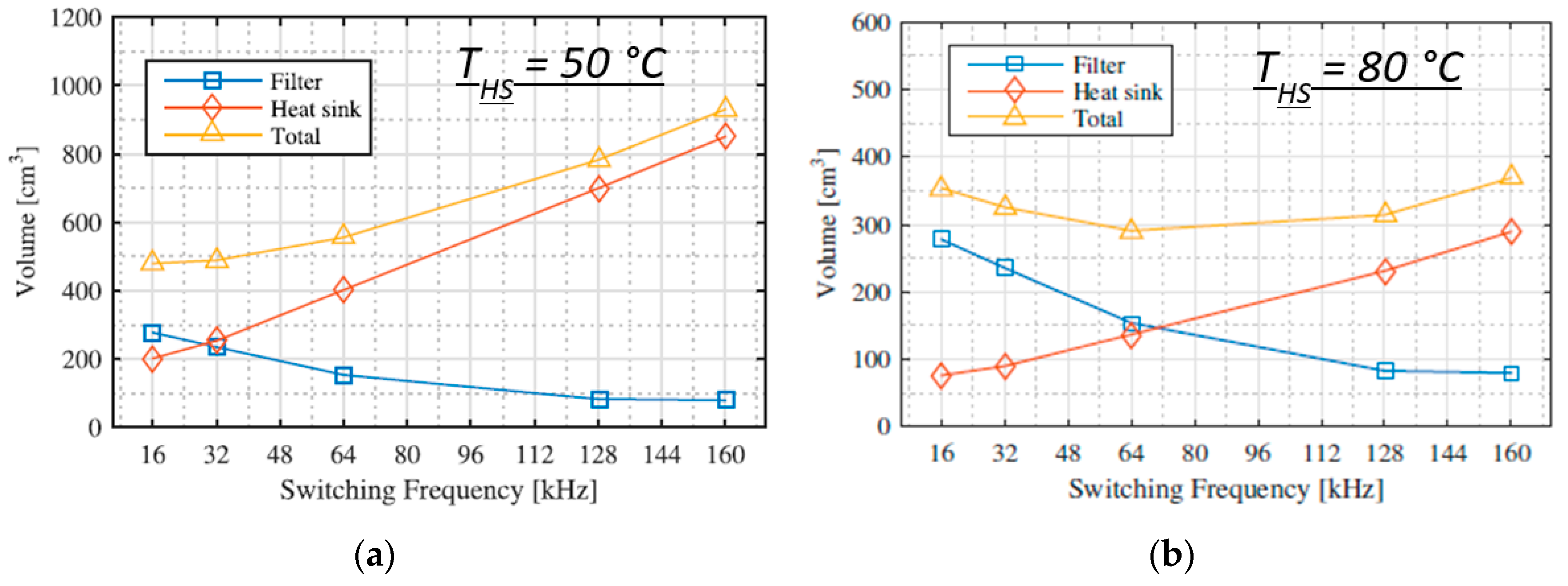

2.1. Inverter Performance and Power Density Trade-Off

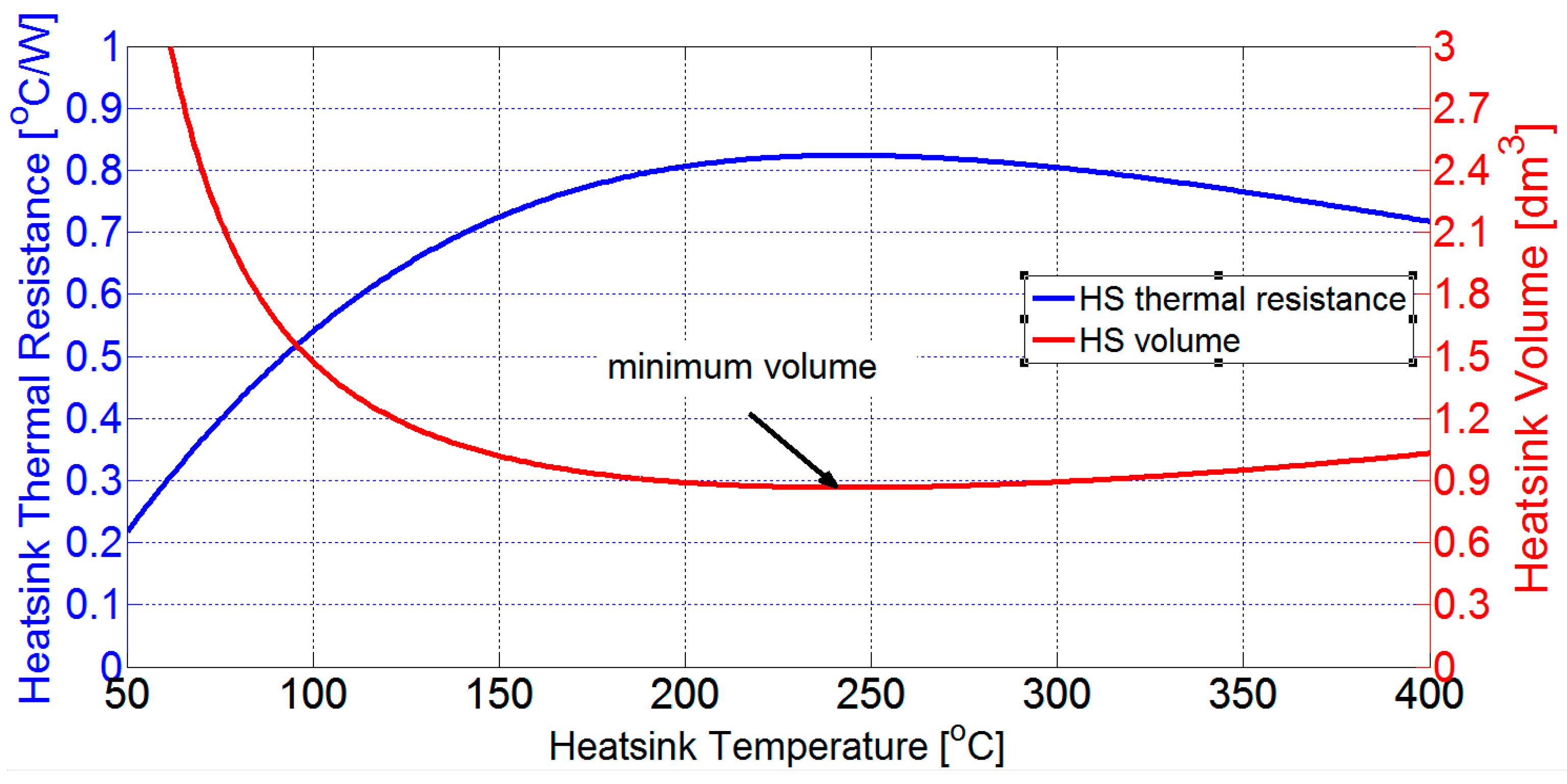

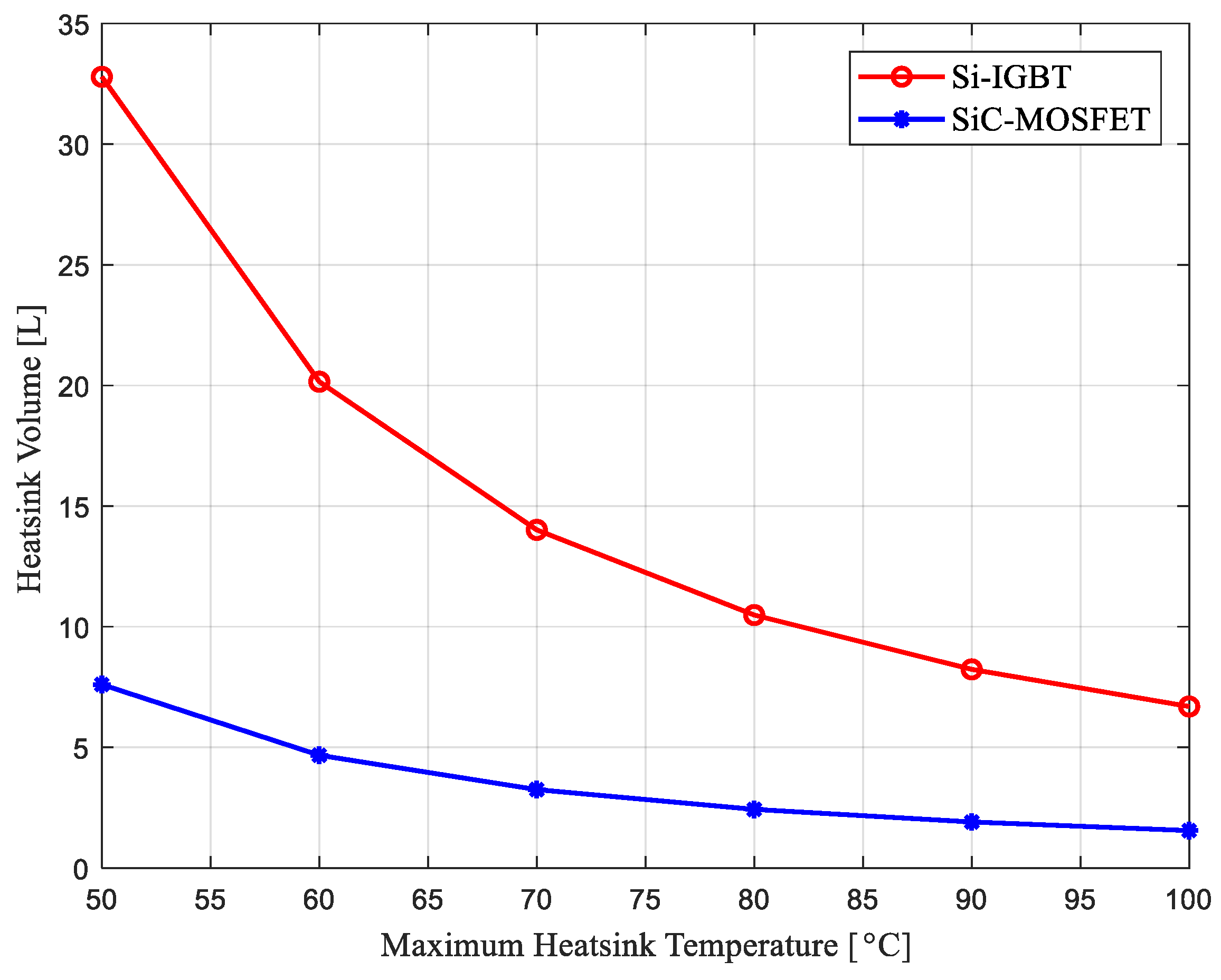

2.2. Higher-Temperature Capability Exploitation

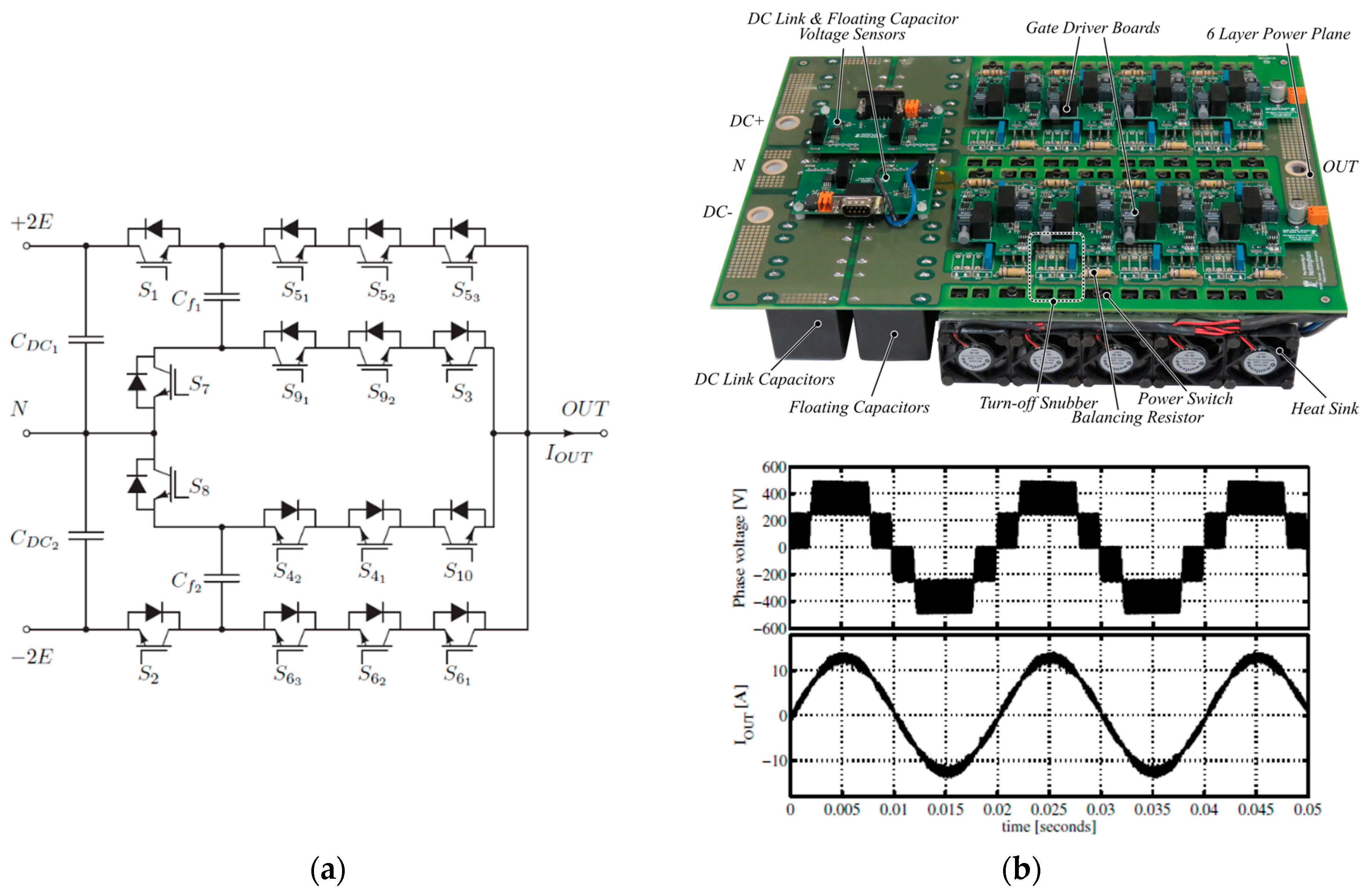

2.3. Multilevel Solutions and Higher-Voltage Rating Devices: Tranfer to High-Power Applications

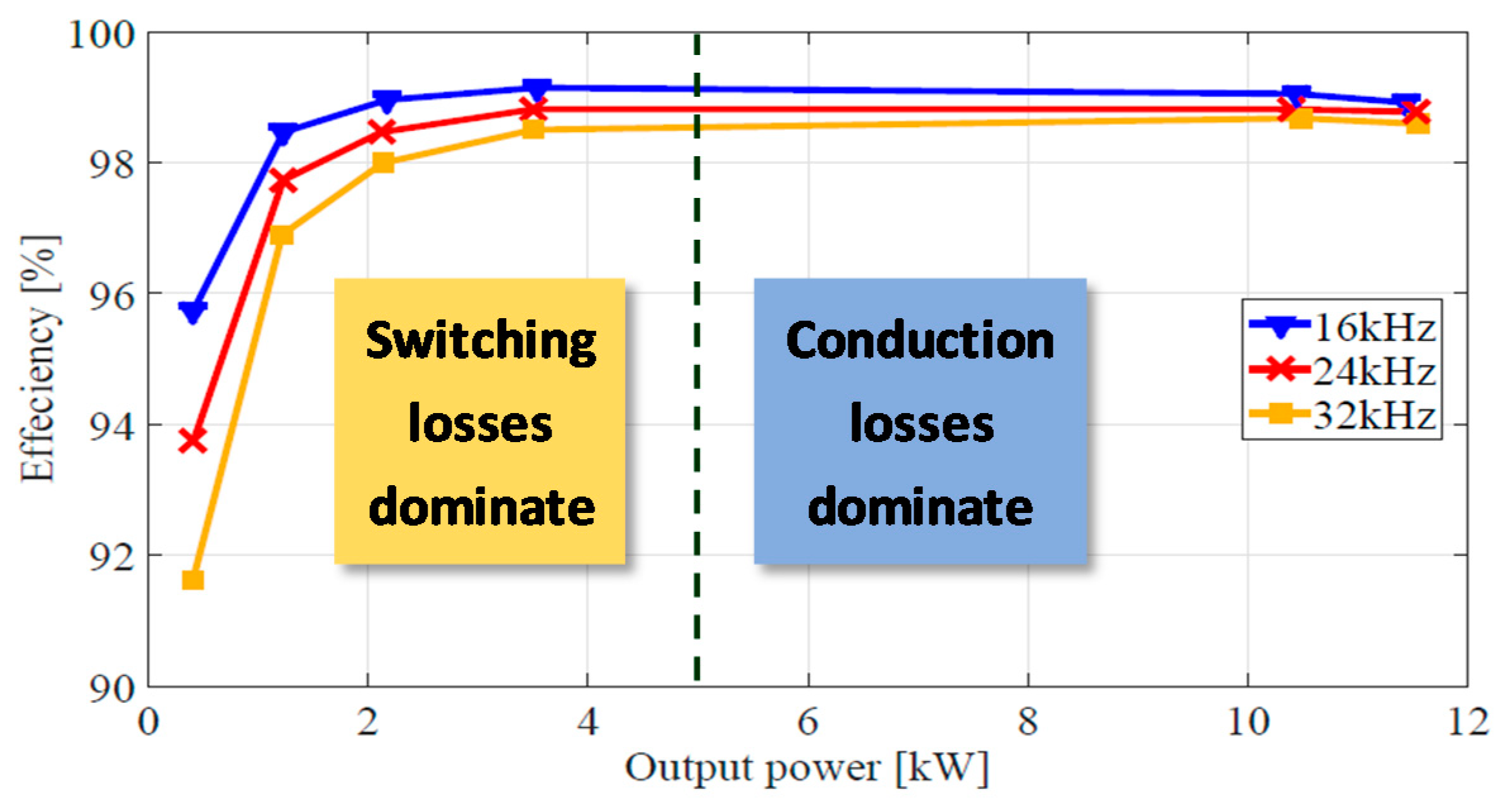

2.4. Low-Load Efficiency Penalty at High Switching Frequencies: Energy Versus Power Efficiency Optimisation

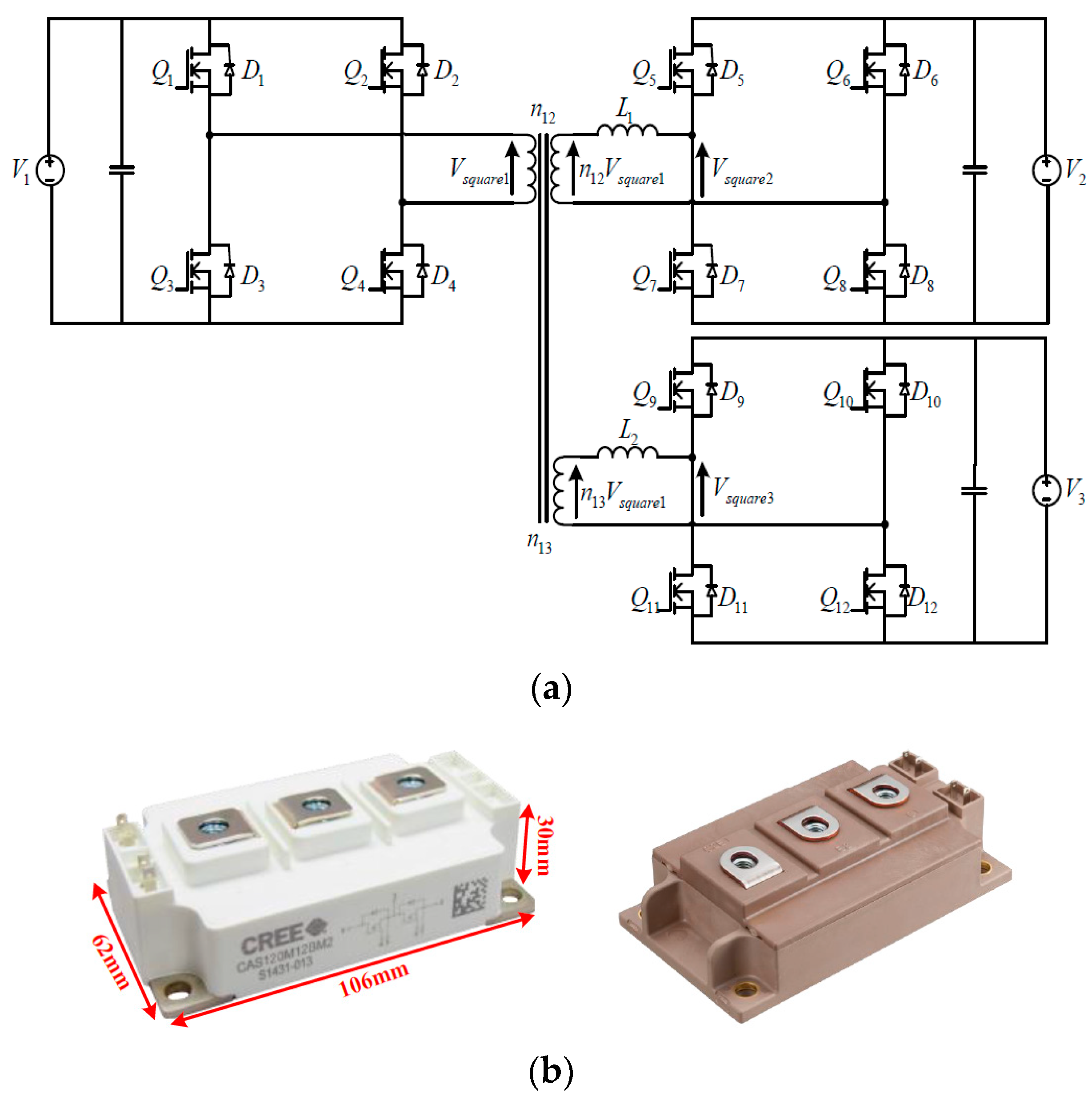

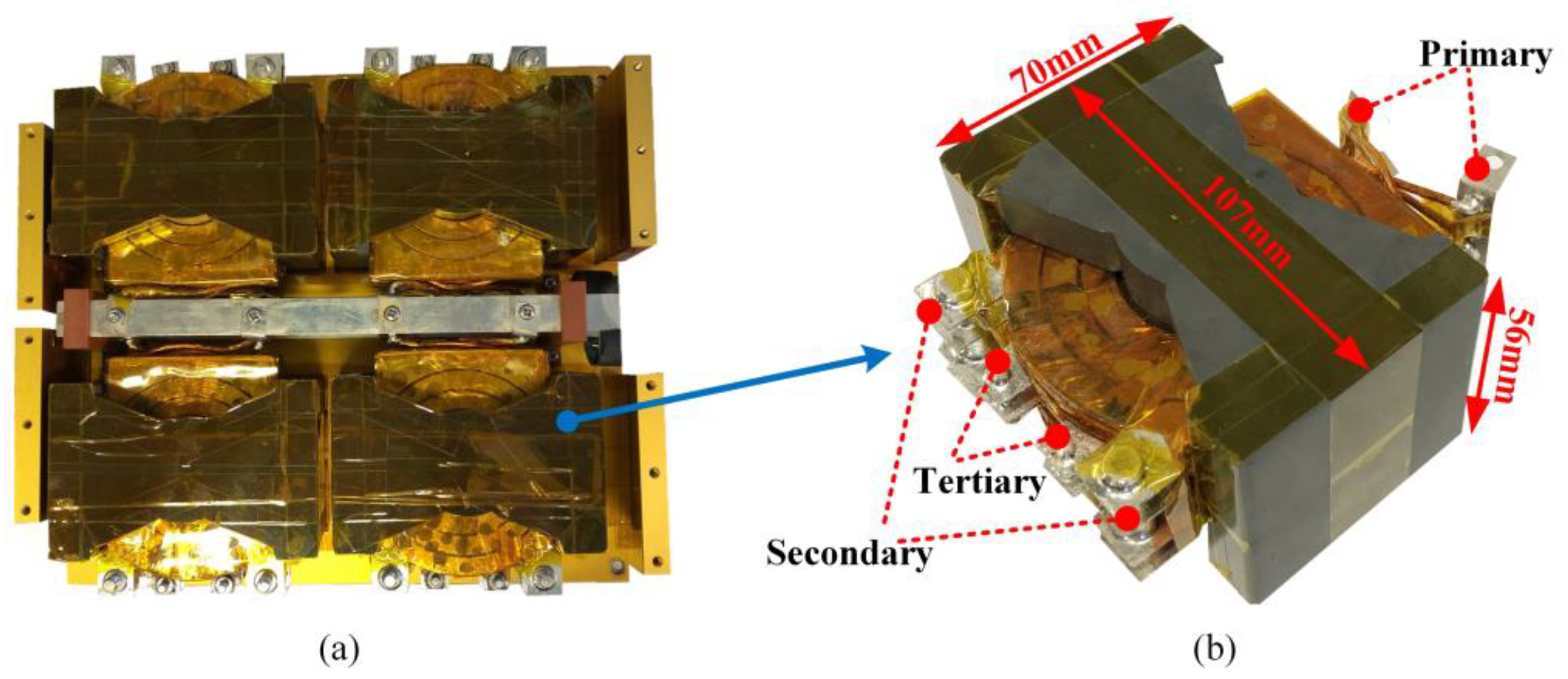

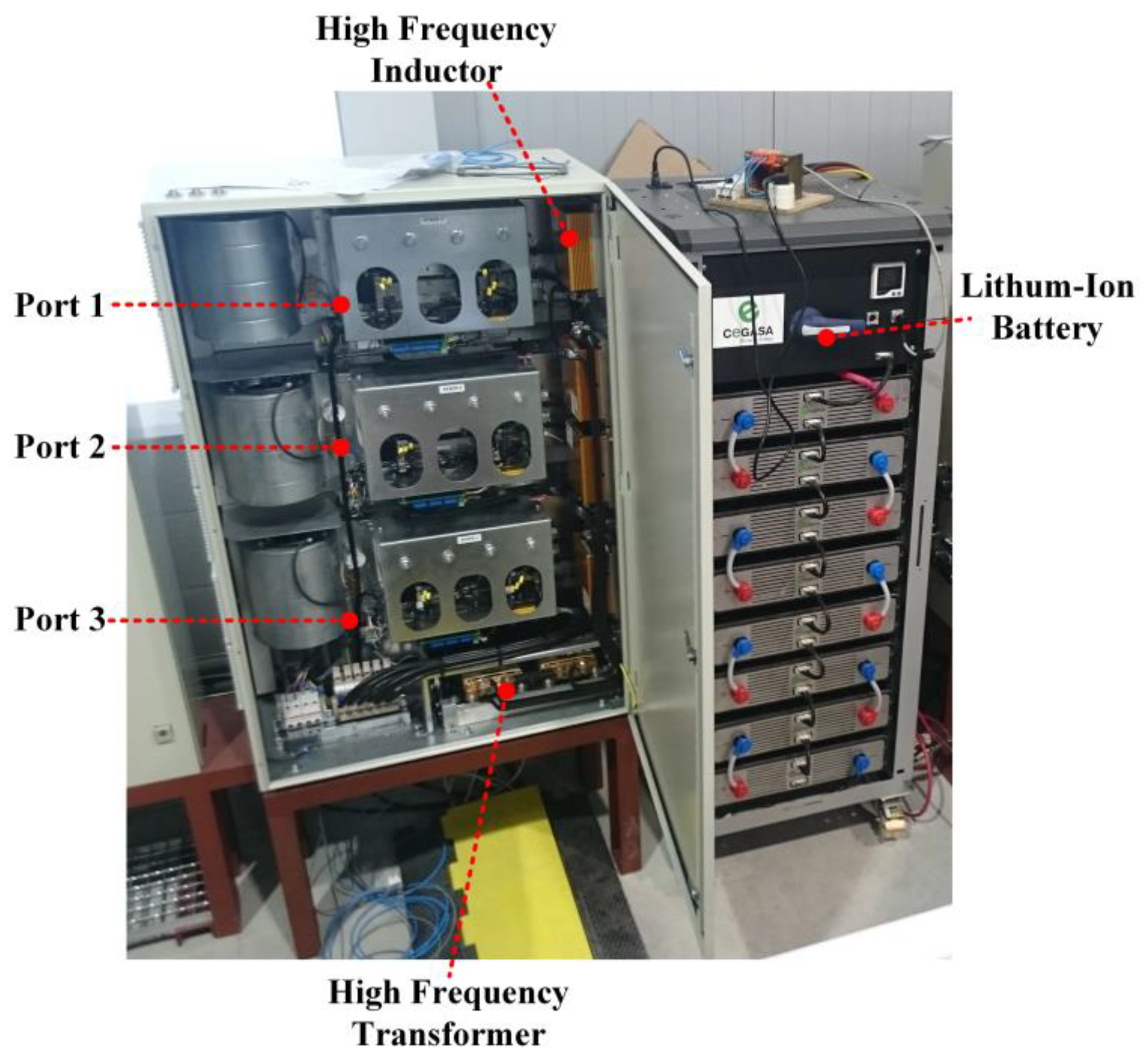

3. Solid-State Transformer (3-Port Dual-Active Bridge DC-DC Converter)

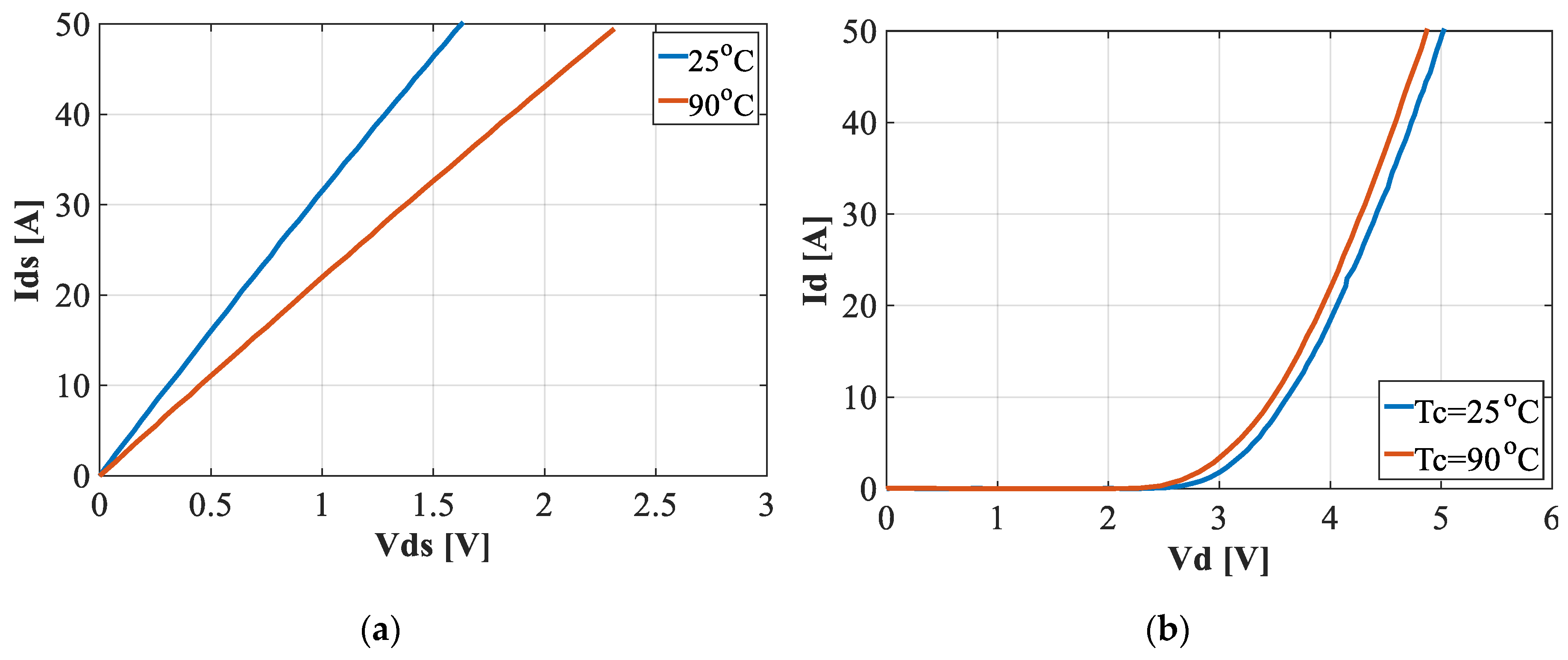

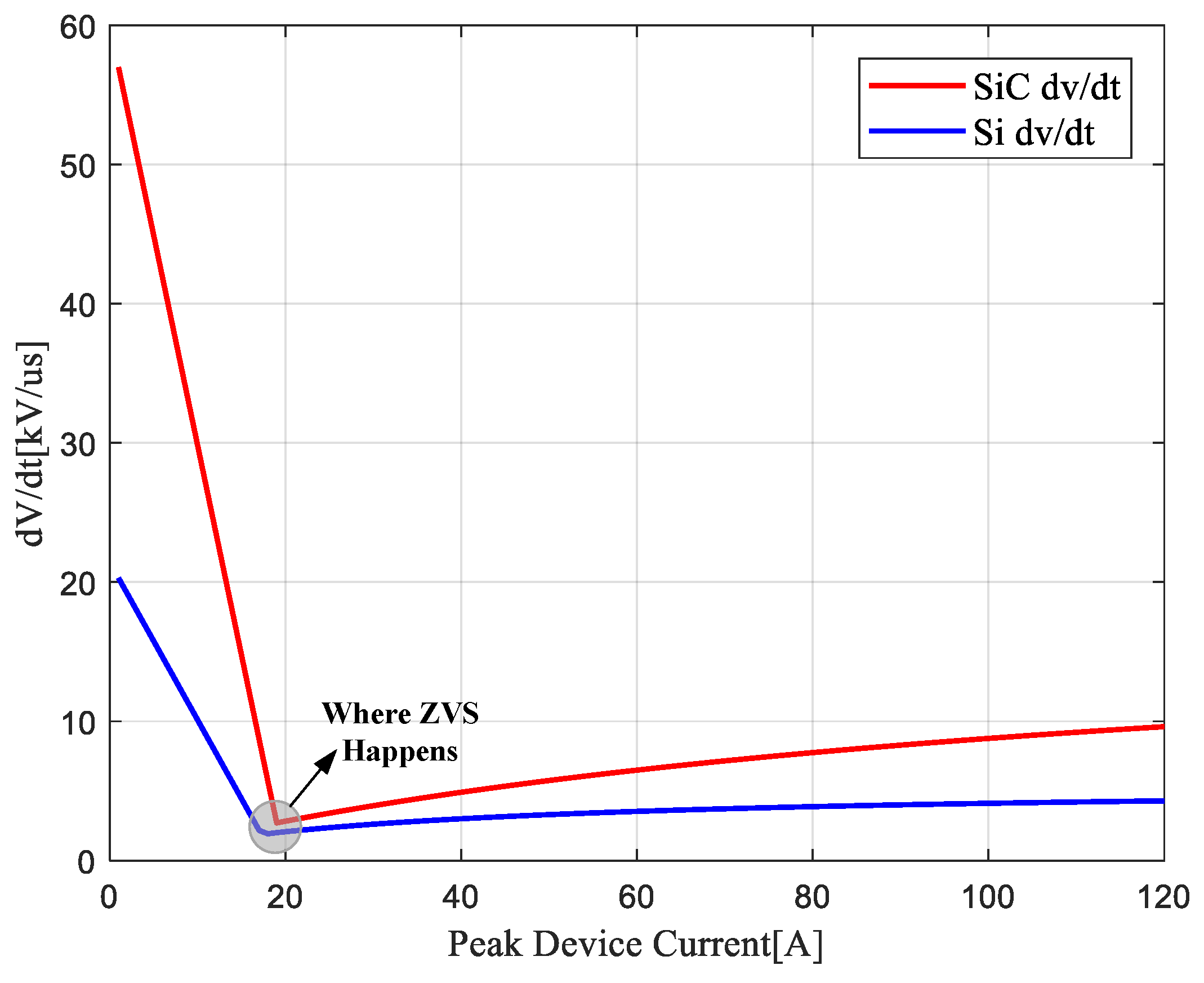

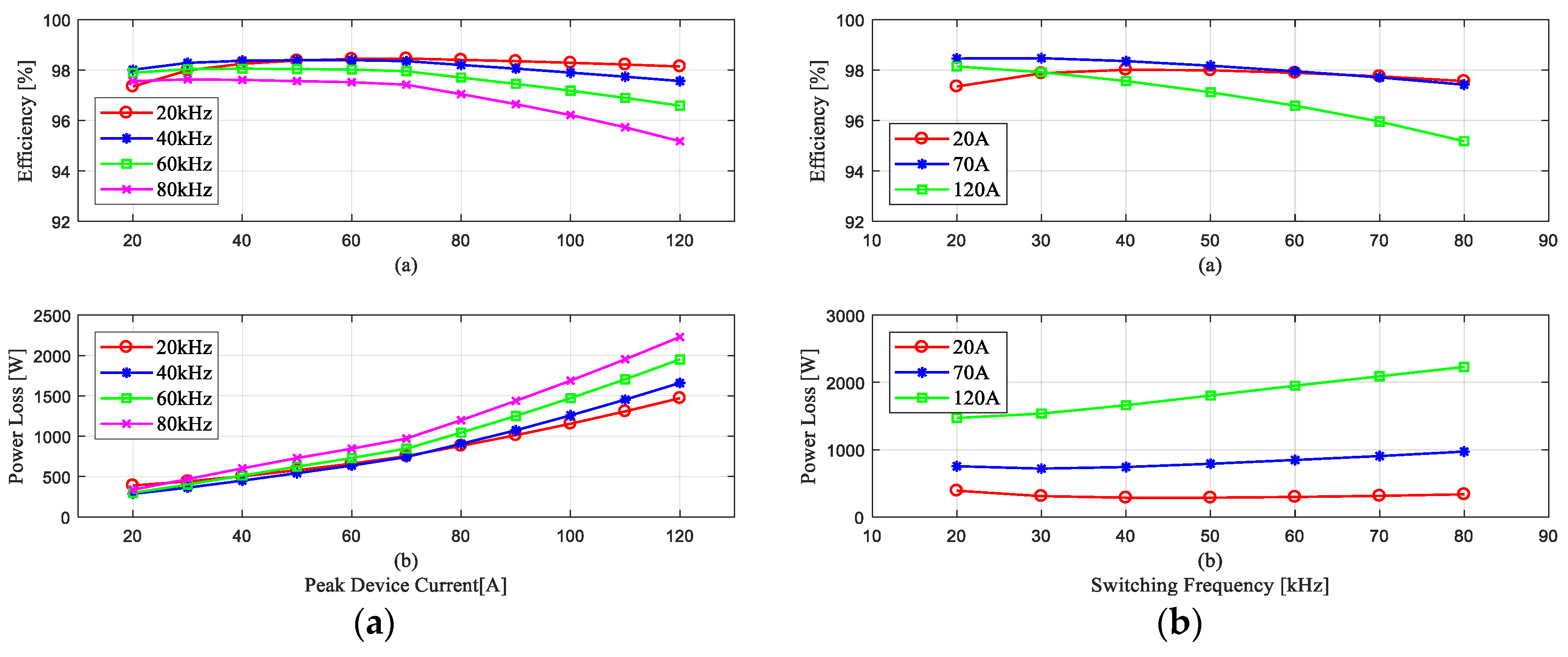

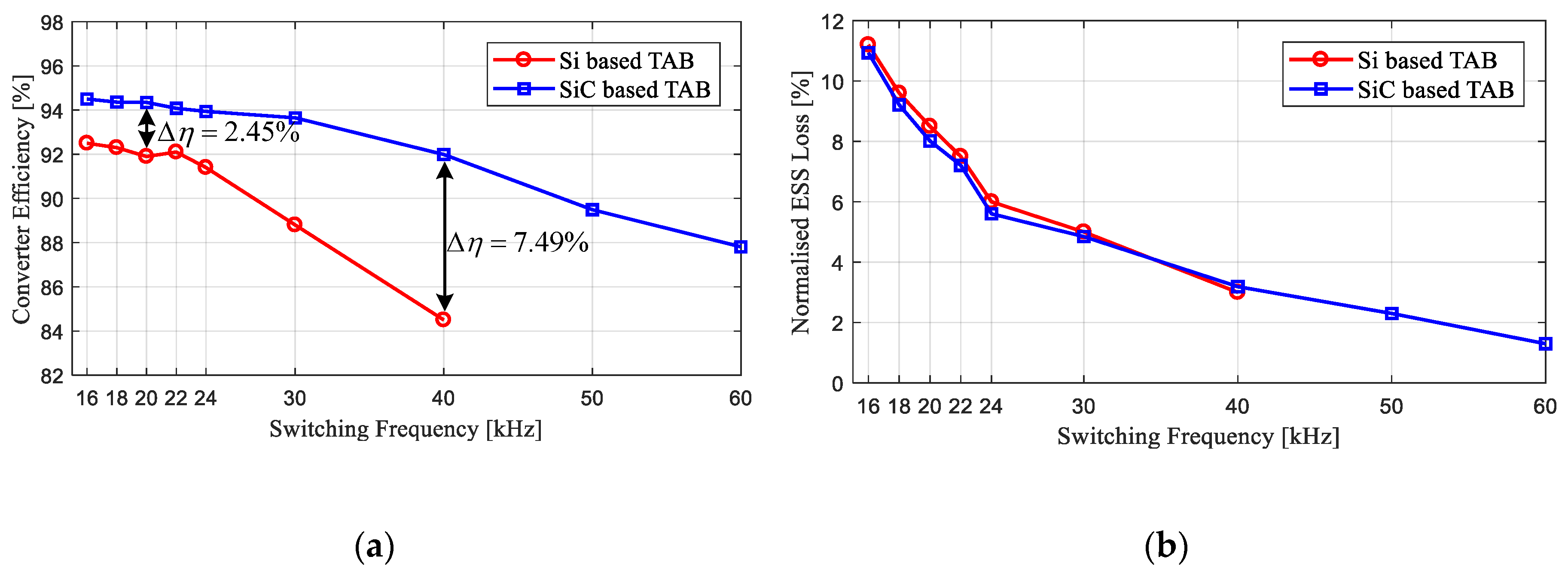

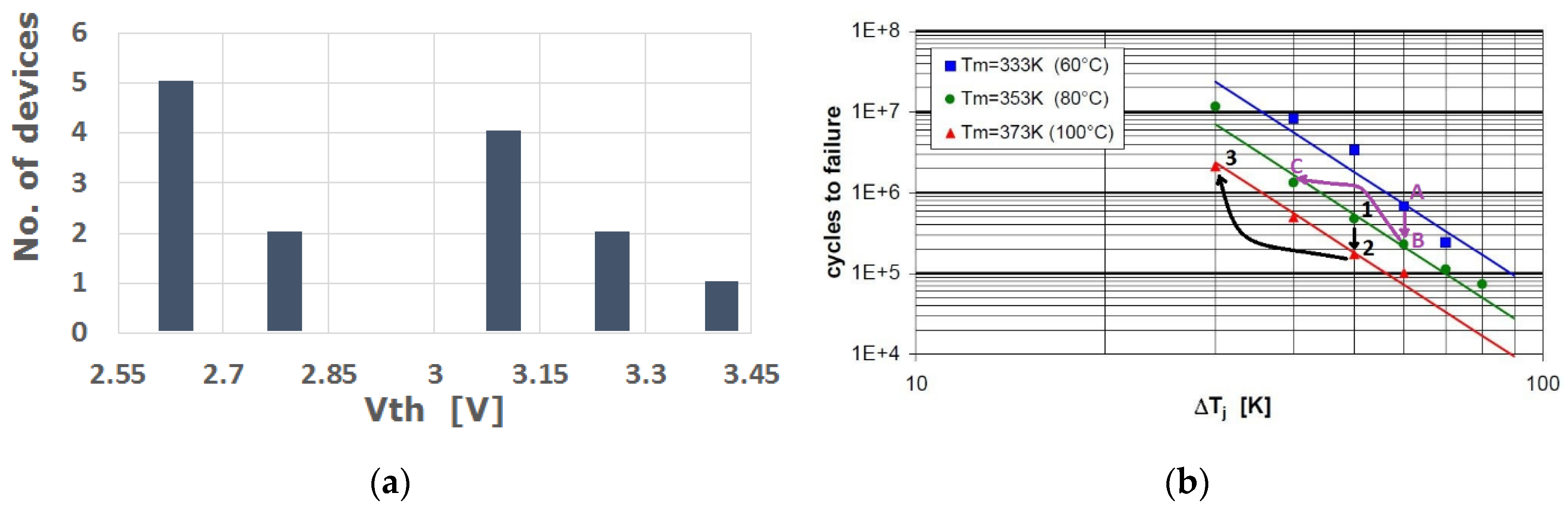

3.1. Converter Performance and Power Density Trade-Off

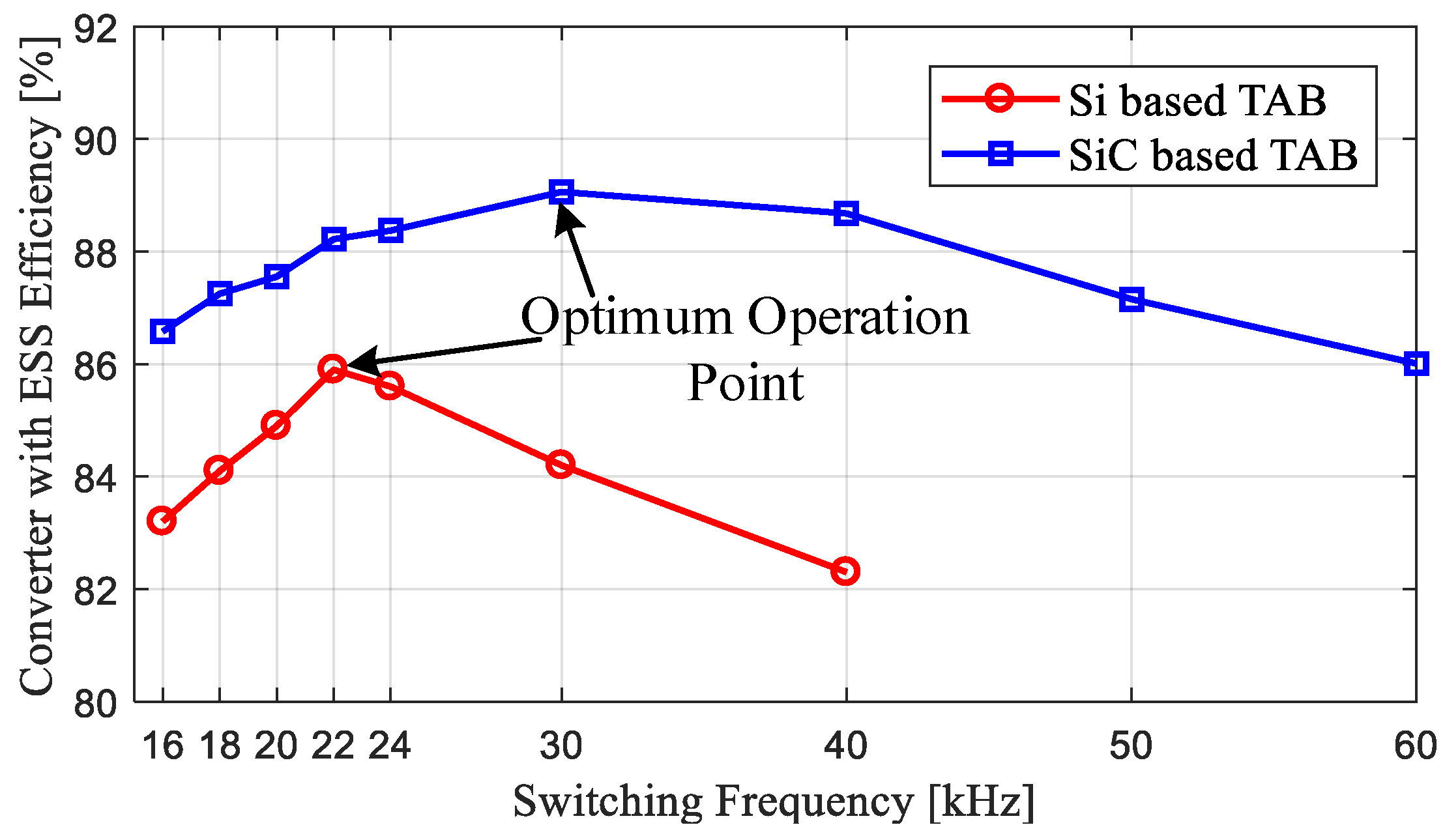

3.2. Impact of the Technology on Storage Device Utilization

4. Discussion and Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Kimoto, T.; Yamada, K.; Niwa, H.; Suda, J. Promise and Challenges of High-Voltage SiC Bipolar Power Devices. Energies 2016, 9, 908. [Google Scholar] [CrossRef]

- Gurpinar, E.; Castellazzi, A. Single-Phase T-Type Inverter Performance Benchmark Using Si IGBTs, SiC MOSFETs, and GaN HEMTs. IEEE Trans. Power Electron. 2016, 31, 7148–7160. [Google Scholar] [CrossRef]

- Barater, D.; Concari, C.; Buticchi, G.; Gurpinar, E.; De, D.; Castellazzi, A. Performance Evaluation of a Three-Level ANPC Photovoltaic Grid-Connected Inverter With 650-V SiC Devices and Optimized PWM. IEEE Trans. Ind. Appl. 2016, 52, 2475–2485. [Google Scholar] [CrossRef]

- Gurpinar, E.; Yang, Y.; Iannuzzo, F.; Castellazzi, A.; Blaabjerg, F. Reliability-Driven Assessment of GaN HEMTs and Si IGBTs in 3L-ANPC PV Inverters. IEEE J. Emerg. Sel. Top. Power Electron. 2016, 4, 965–969. [Google Scholar] [CrossRef]

- Gurpinar, E.; Castellazzi, A. Tradeoff Study of Heat Sink and Output Filter Volume in a GaN HEMT Based Single-Phase Inverter. IEEE Trans. Power Electron. 2017, 33, 5226–5239. [Google Scholar] [CrossRef]

- Hussein, A.; Castellazzi, A.; Wheeler, P.; Klumpner, C. Performance Benchmark of Si IGBTs vs. SiC MOSFETs in Small-Scale Wind Energy Conversion Systems. In Proceedings of the IEEE International Power Electronics and Motion Control Conference (PEMC), Varna, Bulgaria, 25–28 September 2016. [Google Scholar]

- Hussein, A.; Castellazzi, A. Optimization of Thermal Management and Power Density of Small-Scale wind Turbine Applications Using SiC-MOSFETs. In Proceedings of the IEEE 3rd International Future Energy Electronics Conference and ECCE Asia (IFEEC 2017–ECCE Asia), Kaohsiung, Taiwan, 3–7 June 2017. [Google Scholar]

- Hussein, A.; Castellazzi, A. Variable Frequency Control and Filter Design for Optimum Energy Extraction from a SiC Wind Inverter. In Proceedings of the International Power Electronics Conference (IPEC-Niigata 2018–ECCE Asia), Niigata, Japan, 20–24 May 2018. [Google Scholar]

- Castellazzi, A.; Fayyaz, A.; Gurpinar, E.; Hussein, A.; Li, J.; Mouawad, B. Multi-Chip SiC MOSFET Power Modules for Standard Manufacturing, Mounting and Cooling. In Proceedings of the International Power Electronics Conference (IPEC-Niigata 2018 -ECCE Asia), Niigata, Japan, 20–24 May 2018. [Google Scholar]

- Hussein, A.; Mouawad, B.; Castellazzi, A. Dynamic Performance Analysis of a 3.3 kV SiC MOSFET Half-Bridge Module with Parallel Chips and Body-Diode Freewheeling. In Proceedings of the IEEE 30th International Symposium on Power Semiconductor Devices and ICs (ISPSD), Chicago, IL, USA, 13–17 May 2018. [Google Scholar]

- Castellazzi, A.; Fayyaz, A.; Kraus, R. SiC MOSFET Device Parameter Spread and Ruggedness of Parallel Multichip Structures. Mater. Sci. Forum 2018, 924, 811–817. [Google Scholar] [CrossRef]

- Borghese, A.; Riccio, M.; Fayyaz, A.; Castellazzi, A.; Maresca, L.; Breglio, G.; Irace, A. Statistical Analysis of the Electrothermal Imbalances of Mismatched Parallel SiC Power MOSFETs. IEEE J. Emerg. Sel. Top. Power Electron. 2019, 7, 1527–1528. [Google Scholar] [CrossRef]

- Chowdhury, S.; Gurpinar, E.; Castellazzi, A. Full SiC Version of the EDA5 Inverter. In Proceedings of the IEEE 3rd Intern. Future Energy Electronics Conference and ECCE Asia (IFEEC2017-ECCE Asia), Kaohsiung, Taiwan, 3–7 June 2017. [Google Scholar]

- Hussein, A.; Castellazzi, A. Comprehensive Design Optimization of a Wind Power Converter Using SiC Technology. In Proceedings of the International Conference on Smart Grid (icSmartGrid), Nagasaki, Japan, 4–6 December 2018. [Google Scholar]

- Wang, Z.; Castellazzi, A.; Saeed, S.; Navarro-Rodríguez, Á.; Garcia-Fernandez, P. Impact of SiC Technology in a Three-Port Active Bridge Converter for Energy Storage Integrated Solid State Transformer Applications. In Proceedings of the IEEE 4th Workshop on Wide Bandgap Power DEVICES and Applications (WiPDA), Fayetteville, AR, USA, 7–9 November 2016. [Google Scholar]

- Wang, Z.; Castellazzi, A. SiC-based Triple Active Bridge Converter for Shipboard Micro-grid Applications with Efficient Energy Storag. In Proceedings of the International Conference on Smart Grid (icSmartGrid), Nagasaki, Japan, 4–6 December 2018. [Google Scholar]

- Wang, Z.; Castellazzi, A. Device Loss Model of a Fully SiC Based Dual Active Bridge Considering the effect of Synchronous Rectification and Deadtime. In Proceedings of the IEEE Southern Power Electronics Conference (SPEC), Puerto Varas, Chile, 4–7 December 2017. [Google Scholar]

- García, P.; Saeed, S.; Navarro-Rodríguez, Á.; Garcia, J.; Schneider, H. Switching Frequency Optimization for a Solid State Transformer With Energy Storage Capabilities. IEEE Trans. Ind. Appl. 2018, 54, 6223–6233. [Google Scholar] [CrossRef]

- Wang, X.; Castellazzi, A.; Zanchetta, P. Observer based temperature control for reduced thermal cycling in power electronic cooling. Appl. Therm. Eng. 2014, 64, 10–18. [Google Scholar] [CrossRef]

- Wang, X.; Wang, Y.; Castellazzi, A. Reduced Active and Passive Thermal Cycling Degradation by Dynamic Active Cooling of Power Modules. In Proceedings of the IEEE 27th International Symposium on Power Semiconductor Devices & IC’s (ISPSD), Hong Kong, China, 10–14 May 2015. [Google Scholar]

| Old | New | |

|---|---|---|

| Dimensions (mm) | 375 × 327 × 73 | 280 × 200 × 75 |

| Volume (L) | 8.952 | 4.2 |

| Mass (kg) | 22.6 | 10.8 |

| Power Density (kW/L) | 11.17 | 23.8 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Castellazzi, A.; Gurpinar, E.; Wang, Z.; Suliman Hussein, A.; Garcia Fernandez, P. Impact of Wide-Bandgap Technology on Renewable Energy and Smart-Grid Power Conversion Applications Including Storage. Energies 2019, 12, 4462. https://doi.org/10.3390/en12234462

Castellazzi A, Gurpinar E, Wang Z, Suliman Hussein A, Garcia Fernandez P. Impact of Wide-Bandgap Technology on Renewable Energy and Smart-Grid Power Conversion Applications Including Storage. Energies. 2019; 12(23):4462. https://doi.org/10.3390/en12234462

Chicago/Turabian StyleCastellazzi, Alberto, Emre Gurpinar, Zhenyu Wang, Abdallah Suliman Hussein, and Pablo Garcia Fernandez. 2019. "Impact of Wide-Bandgap Technology on Renewable Energy and Smart-Grid Power Conversion Applications Including Storage" Energies 12, no. 23: 4462. https://doi.org/10.3390/en12234462

APA StyleCastellazzi, A., Gurpinar, E., Wang, Z., Suliman Hussein, A., & Garcia Fernandez, P. (2019). Impact of Wide-Bandgap Technology on Renewable Energy and Smart-Grid Power Conversion Applications Including Storage. Energies, 12(23), 4462. https://doi.org/10.3390/en12234462