3.1. Fuel

For auxiliary calculations of different fuels, the energy contents, volumes, and CO2 emissions of selected fossil fuels’ combustions need to be determined. Those are average values of efficiency and corresponding emissions for commonly utilized types of boilers and stoves fired by coal and wood. The energy content parameters of the combustion process for coal were determined from two sources. In general, the parameters for coal combustion may vary; however, in this work, brown coal was analysed. It may vary in parameters such as ash content, sulphur, water, and so on, but CO2 emissions should be comparable regardless of the specific source. The value for the CO2 emissions produced is, therefore, calculated from two independent sources for different types of lignite.

The first source was the coal-fired process from Umberto’s software tool library, which predicts a 70% efficiency of the burning stove. The second one was the information on the website of the Czech coal producer called Severočeské doly, a.s. According to Umberto library, 80.80 kg of coal produces 1,000,000 kJ of heat. This corresponds to 12.376 MJ/kg by taking into account the 70% efficiency of the heating system.

The primary energy input is calculated according to the formula:

where En

p represents primary energy consumption, En represents energy obtained by burning a certain volume of coal in kg, and η represents efficiency of the process.

The CO

2 emissions from the combustion of 1 MJ of primary energy, e

p, is evaluated as

where e

m represents specific emissions and η represents efficiency of the process.

For the assessment of transport effects, it is important to take into account the amount of energy that can be transported, in each particular form of fuel, in one shipment. This requires data on the density and energy contents of the transported fuels. For coal, this data is directly available [

52].

For wood, it is necessary to employ the following formula:

where ρ

w represents density of 1 m

3 of cut and chopped loose wood, M

n is the average mass of wood calculated from a combination of different tree species in 1 m

3, and v

ff represents the percentage volume of clean wood in free-flowing 1 m

3 of cut and chipped wood.

The following option is considered for wood. For calculating itself, it is necessary to set additional values, especially the energy contained in the wood

Ep. The precise type of wood, its proportion, or wood moisture is unknown both in short-term and in long-term; therefore, the value of

Ep was determined in accordance with the average calorific value of the wood and in accordance with expected moisture content based on [

53]. CO

2 emissions from the biomass burning process itself are herein considered as neutral, so they cannot be counted as total additional CO

2 emissions.

The value of the wood mass,

mw, corresponding to this volume, is calculated for the bulk space meters according to the relationship:

where the mass of wood is in kg and the volume of wood

Vw is in m

3. Analogically

mc and

mb for coal are evaluated from volume

Vc of coal respectively.

The determination of the calorific value for wood is a little bit problematic in Central European conditions. A relatively wide range of different tree species can be used, which differ both in calorific value and in density. Another problem is that the calorific value of the same wood type varies according to the volume of moisture contained. The information portal TZB info, which focuses on the issue of energy in the long term, provides data from which these typical calorific values can be derived [

54], and subsequently, adjusted for real conditions. When determining the average energy content of firewood, items that are not meaningfully usable from an economic, environmental or physical point of view have been omitted. In

Table 1 there are expected values of wood with 40–50% moisture contained, which is not possible to burn in common types of boilers, and wood with 0% moisture contained, that does not exist in normal conditions.

Let us assume in this study that wood is cultivated in the Czech Republic and it is commonly dried for a year in roofed areas; exceptionally wet wood stays there for 2 years. Let us, therefore, assume that the wood has a total calorific value of 14.215 MJ/kg, which is the average calculated from the values given in

Table 1. The selected wood types represent the most commonly used species in the Czech Republic. The final value is, therefore, average, and at the same time corresponds to a water content of 20%.

The total amount of energy included in one load was calculated based on this calculation of energy content from values shown in

Table 1 as follows:

where

Ew is the energy included in 1 m

3 of wood. Alternatively, from energies

Ec in coal, the total amount of energy included in one load

Ec1l coal was evaluated.

For brown coal, it was also necessary to determine the corresponding CO

2 emissions from the combustion process. Due to the neutrality of biomass emissions, CO

2 emissions for wood were set to zero (S

w = 0). The emissions for coal are determined according to the formula:

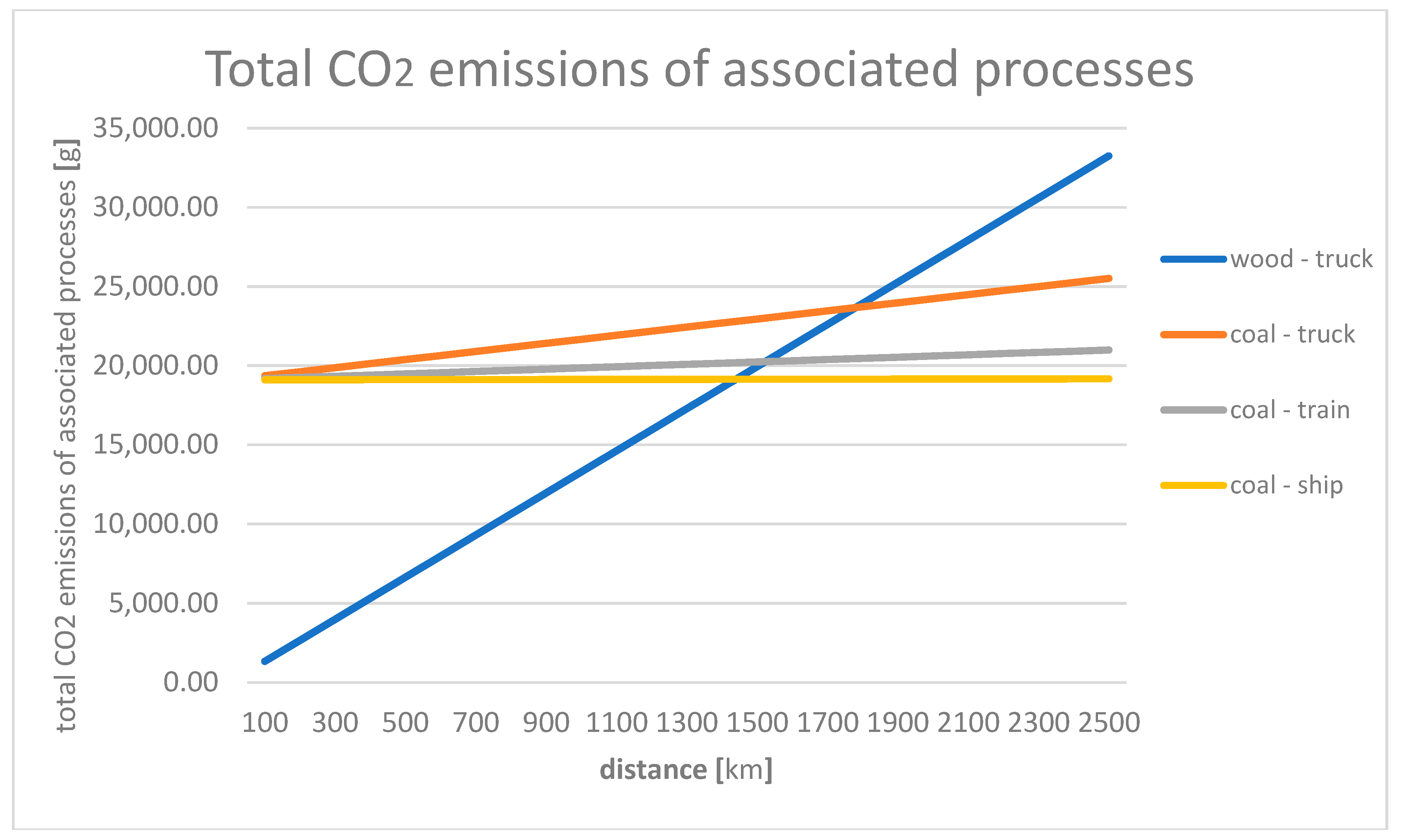

3.2. Transportation

In addition to emissions from energy consumed by transport, the associated processes, such as transport, are examined in this case also. As the means of transport were considered truck, train and ship. Data for a train is specific to the conditions of the Czech Republic, as it is based on the structure of the electric energy mix and is, therefore, not transferable. However, the data for shipping are transferable, since the propulsion of river cargo ships is similar and most of the ships in Europe that use diesel fuel.

When considering a truck with an average transport capacity of 8–10 m

3 (in our study, the Tatra 815 S3 was selected with parameters according to

Table 2. This type of truck is commonly utilized not only in the Czech Republic, but also in other countries. It has an average transport capacity of 8–10 m

3.), the increase in total transport emissions of fossil fuel and renewable energy in the form of wood is caused due to the increasing consumption of fossil fuel consumed by transporting the wood to its customer. For analysis, a truck with the parameters listed in

Table 2 was selected.

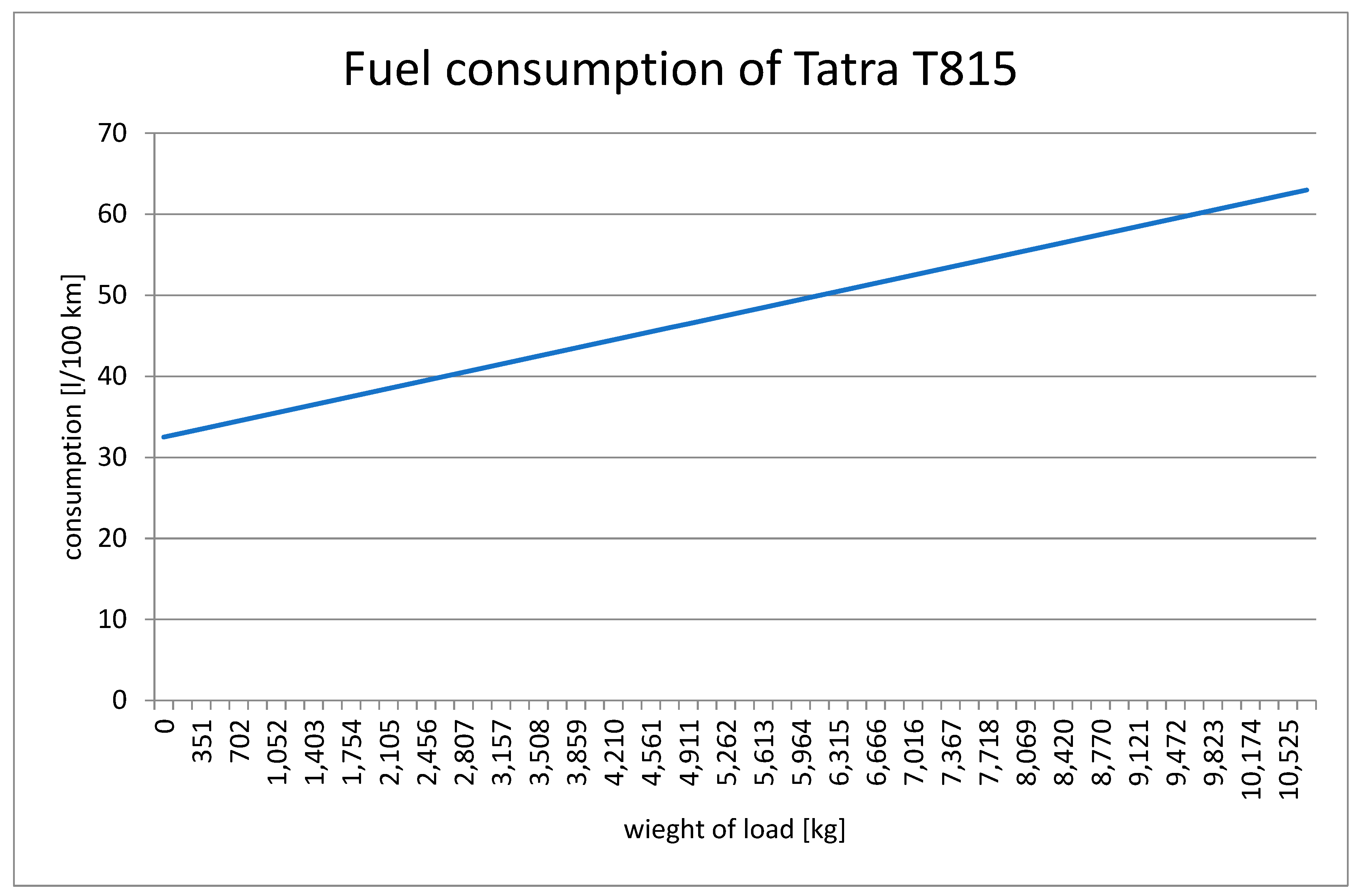

As the mass of transported fuels differs considerably, it is obvious that this effect will be reflected in the fuels’ consumption during transport. Therefore, it was necessary to establish a function that describes the relationship between the weight of the transported cargo and the fuel consumption. Let us assume for simplicity that the consumption depends on the additional mass linearly. The dependency function for selected Tatra 815 S3 vehicle is in the form:

where y represents the total consumption in l/100 km and x represents the weight of the load in kg.

Based on knowledge of fuel consumption in l/100 km, CO

2 emissions can also be determined. For CO

2 emissions produced by transport, Ekoblog.cz reports the calculation of the specific emissions of diesel fuels [

58]: “Specific emissions of CO

2 per kilometre driven by diesel combustion = 10,084/3.7584 × Specific consumption (l/100 km)/100 = Specific consumption × 26.83 (g CO

2/km)”.

Transport-related emissions from transport by truck as the second component of the total CO

2 emissions S

t(truck), can thus be evaluated based on formula:

where q

t is the coefficient of diesel fuel CO

2 emission (26.83 in this case) and y represents the consumption in litres per 100 km. Last but not least, the total number of trips to transport the same amount of energy, Nt, should be evaluated. This number can be determined as the ratio of the amount of energy transported per carriage relative to the brown coal according to the formula:

where Nt

w represents the number of trips needed to transport the same amount of energy in the form of wood, which corresponds to one fully loaded car with a coal. The value Nt

c is less than always 1, because it is given by relation Nt

c = E

c1l/E

c1l. Consumers will primarily demand a certain amount of energy, not fuel; however, when a specific fuel volume is demanded in the order, estimation of the amount of energy is required.

The data are available in a different form for train and ship transport. According to the original study, which was conducted in 2004 under the conditions of the Czech Republic [

59].

The following values were researched for rail transport. It is true that the study may not be perceived to be completely up-to-date, but given the developments in the field of automobile transport, significant changes in energy consumption cannot be expected, since the measures being considered, especially recovery, have not yet been implemented. In addition, these are average values.

Since similar studies are rare in this field and the data structure exactly matches the purpose of the research, we consider these data to be sufficient.

Shipping transports according to

Table 3. 410,000,000 t of cargo over a distance of 1 km, consumes 128,000 GJ. It uses 0.312 MJ for the transport of one ton of cargo per km. Emissions were calculated analogously.

Railway motor transport transports 1,690,000,000 tons of cargo per km and consumes 2,272,000 GJ. It therefore consumes 2,272,000 GJ/1,690,000,000 tkm for the transport of one ton of cargo per km, which is 1.344 MJ.

Therefore, we need 1.344 MJ of diesel to transport one ton of cargo over a distance of 1 km using diesel railways.

In case of electric railway transport, we calculated the outputs according to the same formula. Railway electric transport transports 13,040,000,000 t of cargo per 1 km and consumes 2,761,000 GJ. It therefore consumes 2,761,000 GJ/13,040,000,000 tkm for the transport of one ton of cargo per km, which is 0.212 MJ.

Therefore, we need 0.212 MJ of electricity to transport one ton of cargo over a distance of 1 km using an electrified railway.

The cargo volume according the

Table 3 for electric and motor railway transport is a ratio of 88.53/11.47%. Therefore, the resulting emissions calculated for rail transport were combined from those two items, which together constitute the weighting for the weighted average calculation.

Specific CO2 emissions can be calculated in a similar way as for truck by substituting into the formula (there).

Under the conditions of the current electric energy mix, according to a decree of the Ministry of Trade and Industry [

60], 1 kWh (3600 kJ) of electricity is produced with 1.17 kg of CO

2 in case of the Czech Republic.

Total emissions from river transport (shipping) are also calculated by substituting for Equation (8). The auxiliary calculation that had to be performed here is to convert the tonne/kilometre data according to

Table 3 and to specific CO

2 emissions according to the formula.

where E

tkm represents the energy consumption for transport of 1 t cargo for distance 1 km by ship, E

d represents the amount of energy included in 1 L of diesel fuel, and the number 2.683 is the weight of CO

2 emitted by combustion of 1 L of diesel in kg.

Total rail transport emissions can be also calculated from ton-kilometers, but according to Formula (8) CO

2 emissions can only be calculated for that part of rail transport which is realized using diesel locomotives. Under the conditions of the Czech Republic, this represents 11.47% of freight rail transport, while the remaining 88.53% is transport on electrified lines. To calculate CO

2 emissions, it is therefore, necessary to use data from the Ministry of Industry and Trade, which states an emission coefficient of 1.17 CO

2 per kJ [

60].

Emissions for freight transport on electrified lines were calculated by multiplying the amount of energy per ton transported over a kilometer by an electrified railway by the amount of emissions determined by the Ministry of Industry and Trade. The formula used was:

where E

tkm represents amount of energy for transport of 1 ton cargo over distance 1 km on an electrified line, and Ef is the emission coefficient according the directive 425/2004 Coll. of the Ministry of Industry and Trade ČR. The 3600 is the conversion factor from kWh to J, and multiplication by 1000 was necessary to express the result in grams.

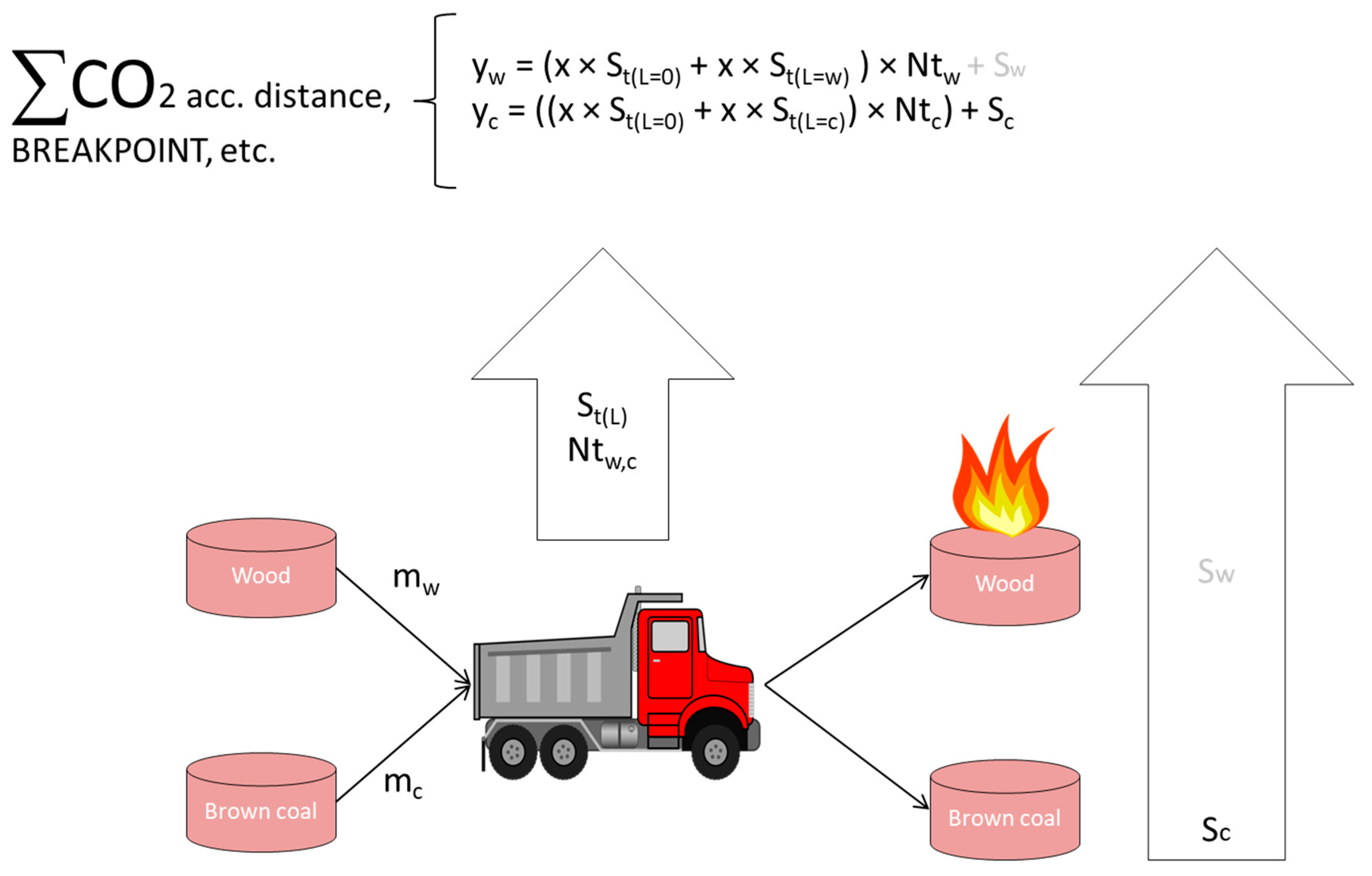

The following three relationships are original and key results of proposed methodology. These functions define the relationship between CO

2 emissions and monitored process parts. The total amount of wood CO

2 emissions, y

w, for transport and combustion together is given by:

Equations (12) and (13) characterize the total CO2 emission of wood and the total CO2 emission of brown coal yc. Analogously2, CO2 emissions for other modes of transport are calculated.

The whole methodology can be illustrated as depicted in

Figure 1. The first arrow symbolises transportation and the second one corresponds to the combustion process. The variable S

w is not considered in the Equation (11), because of its zero value. But for the completeness and better clarity of proposed procedure, it is shown in

Figure 1 and distinguished by the grey text colour. This model can then be further extended to other transport types.