Study of An Innovative Approach of Roof Presplitting for Gob-Side Entry Retaining in Longwall Coal Mining

Abstract

1. Introduction

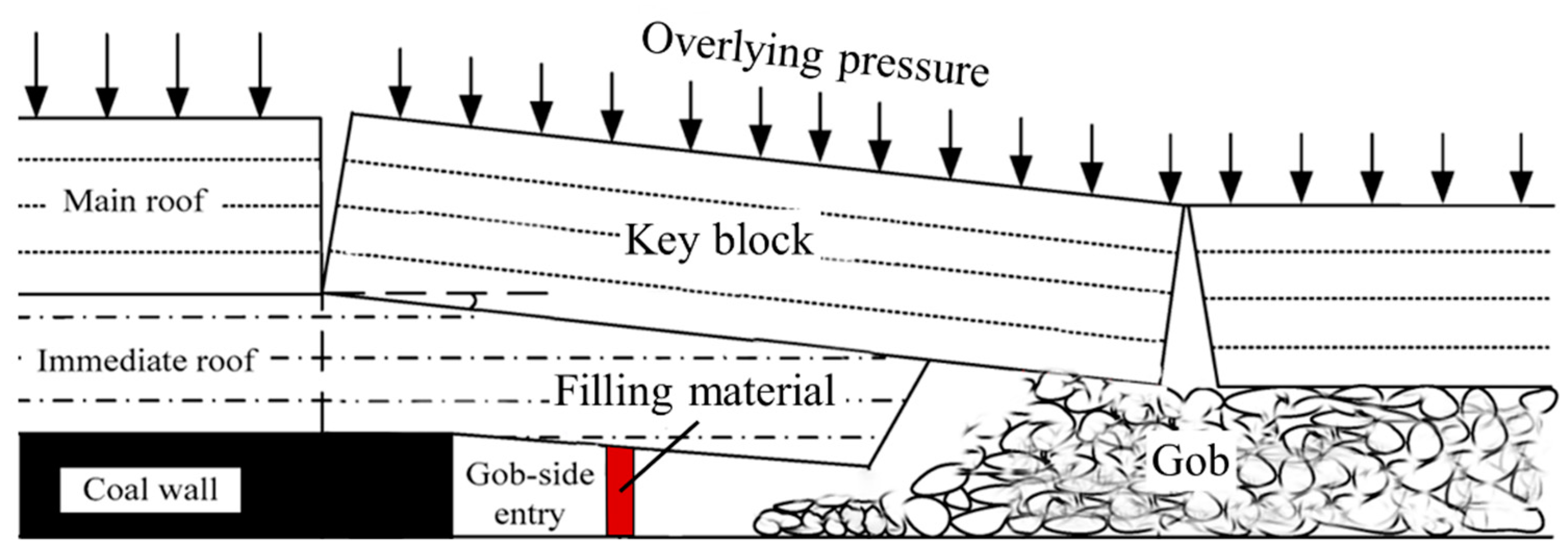

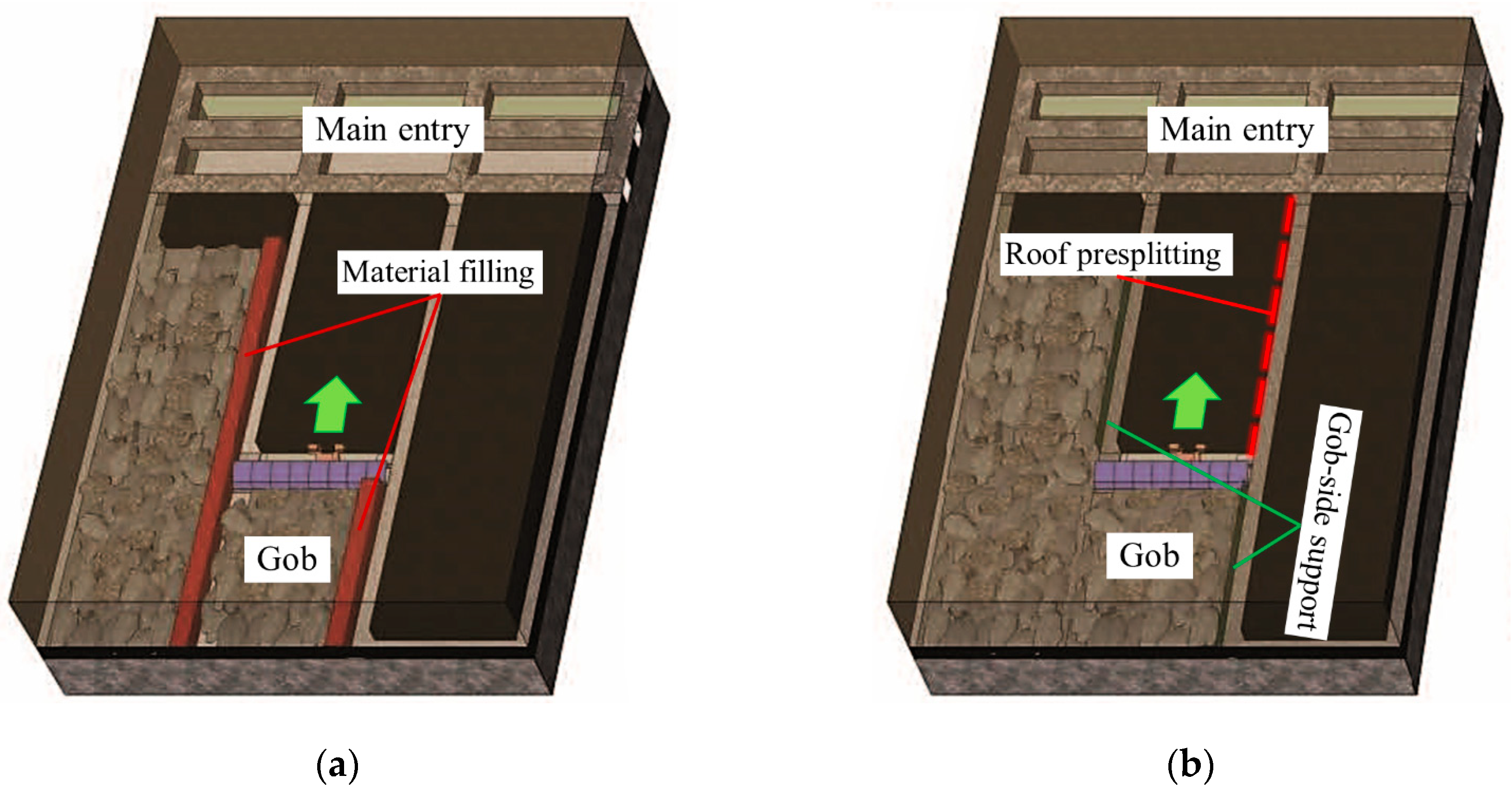

2. RPGER Approach

2.1. Roof Presplitting

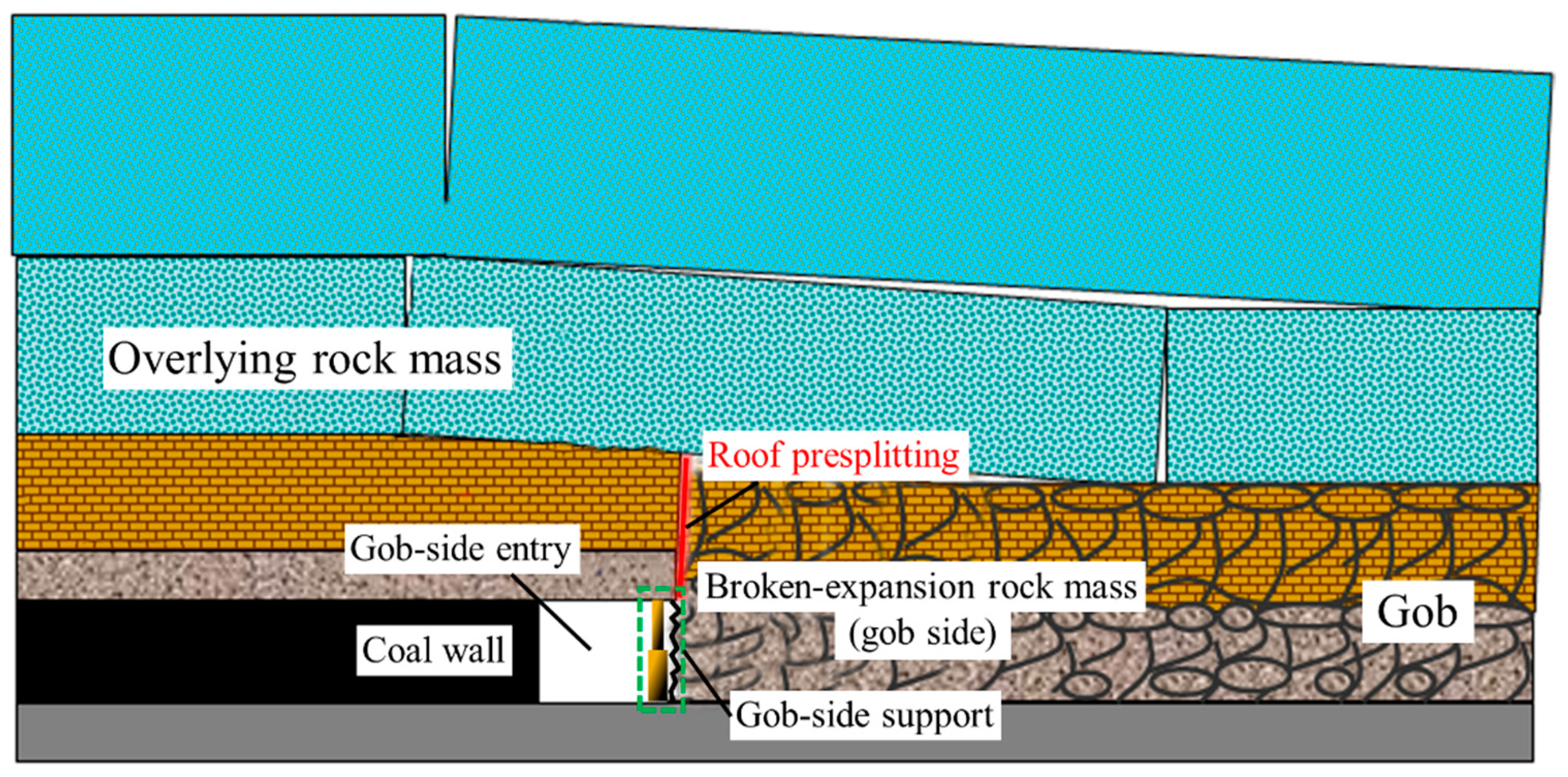

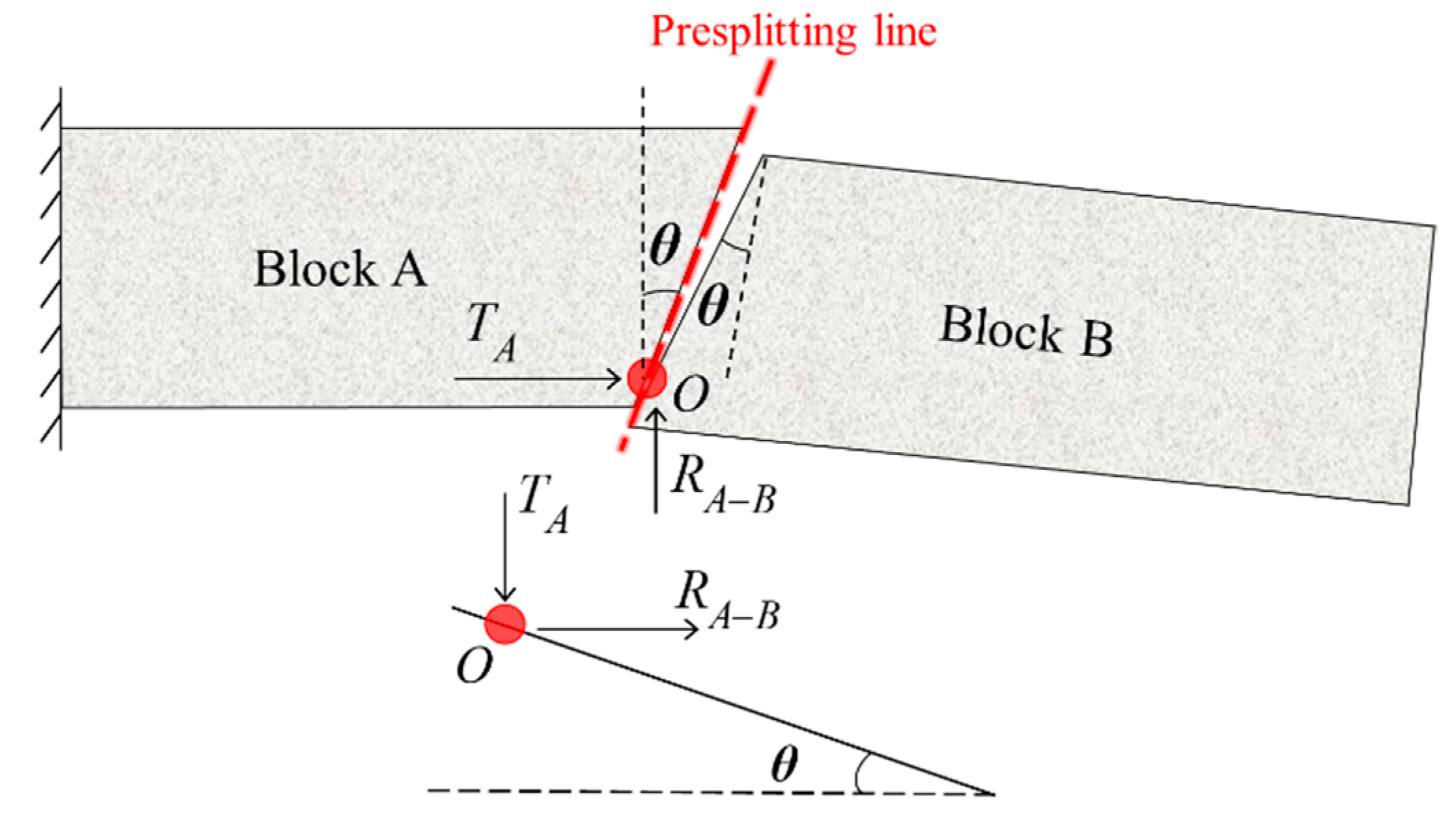

2.2. RPGER Principle

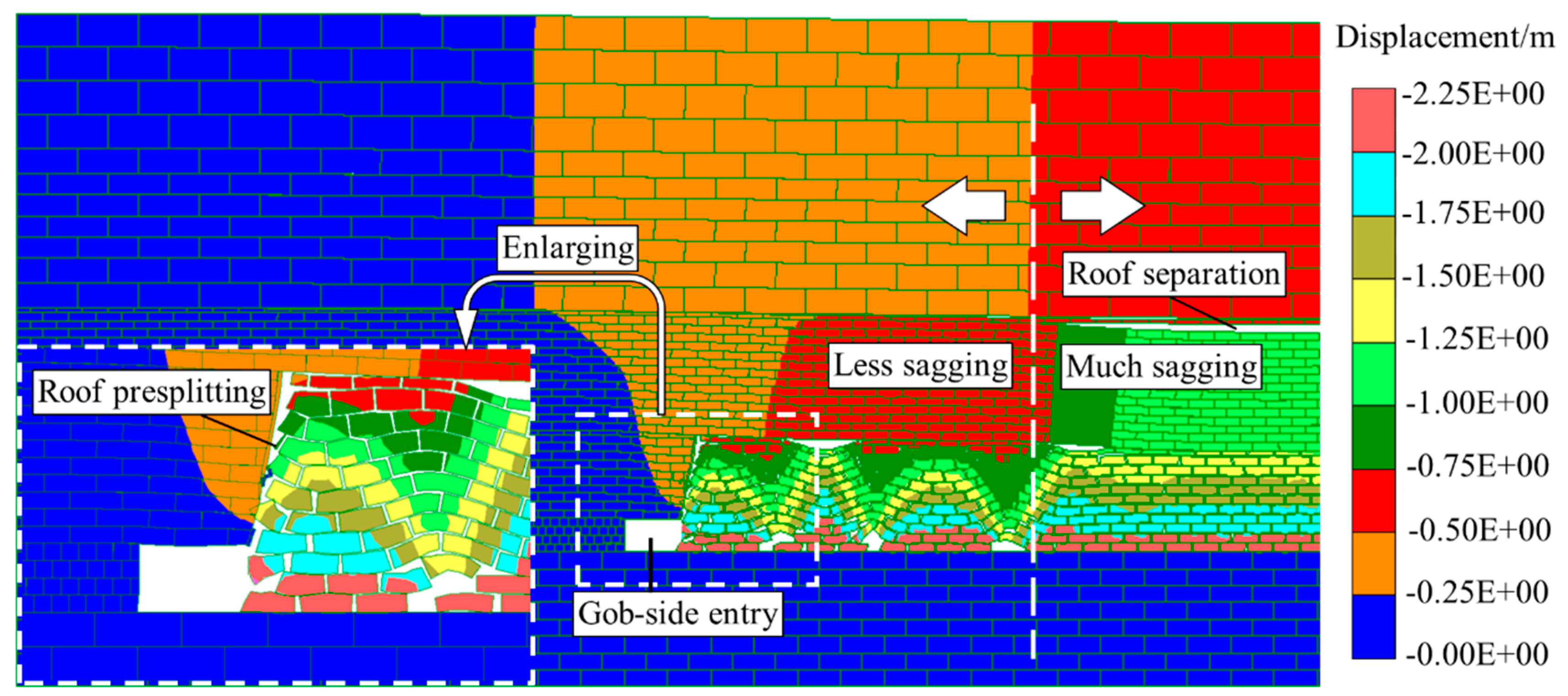

2.3. Numerical Simulating Effect of RPGER

2.3.1. Numerical Model

2.3.2. Simulation Results

3. Field Test

3.1. Geological Condition

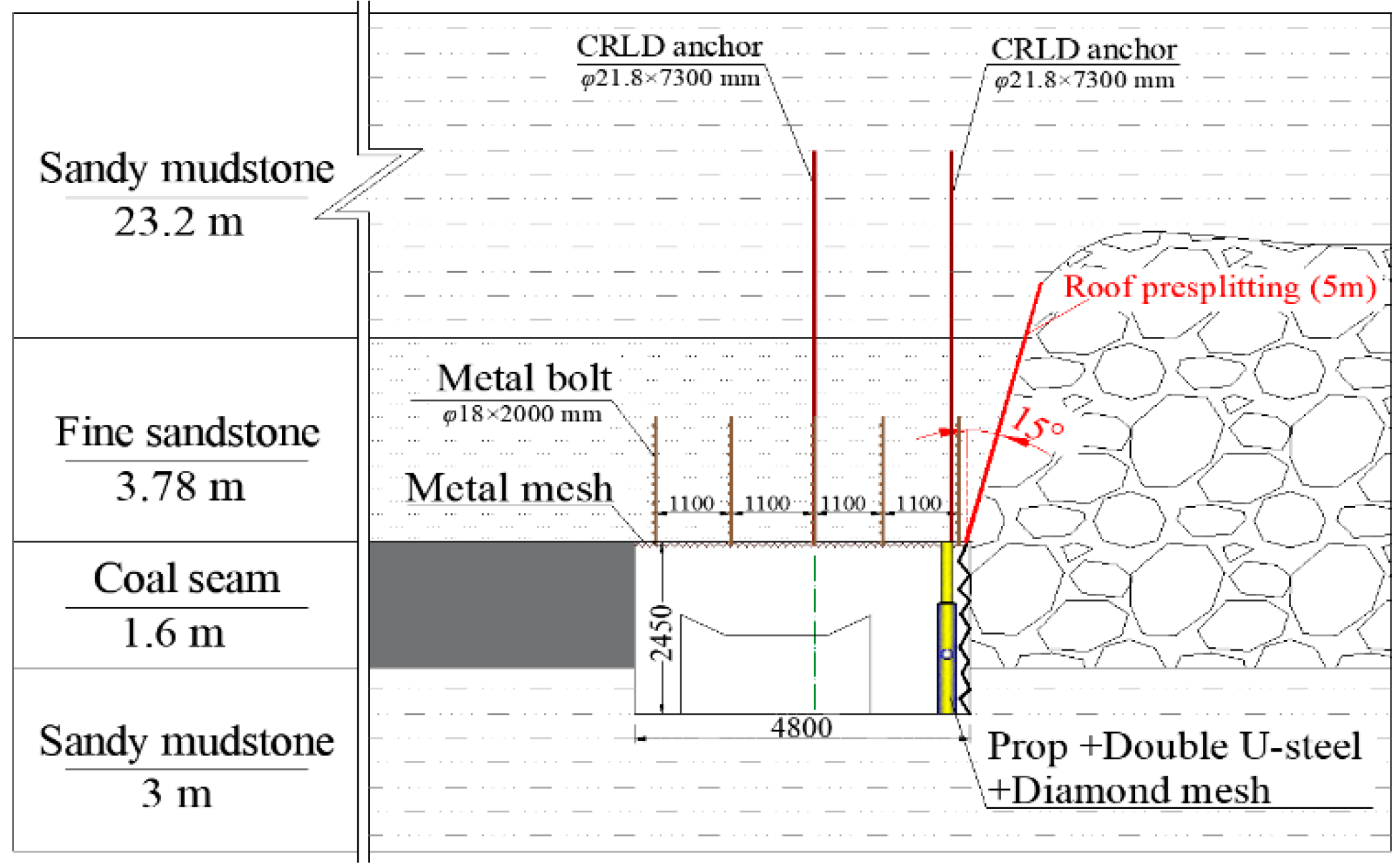

3.2. Test Design

3.2.1. Presplitting Angle

3.2.2. Presplitting Length

3.3. Test Effect

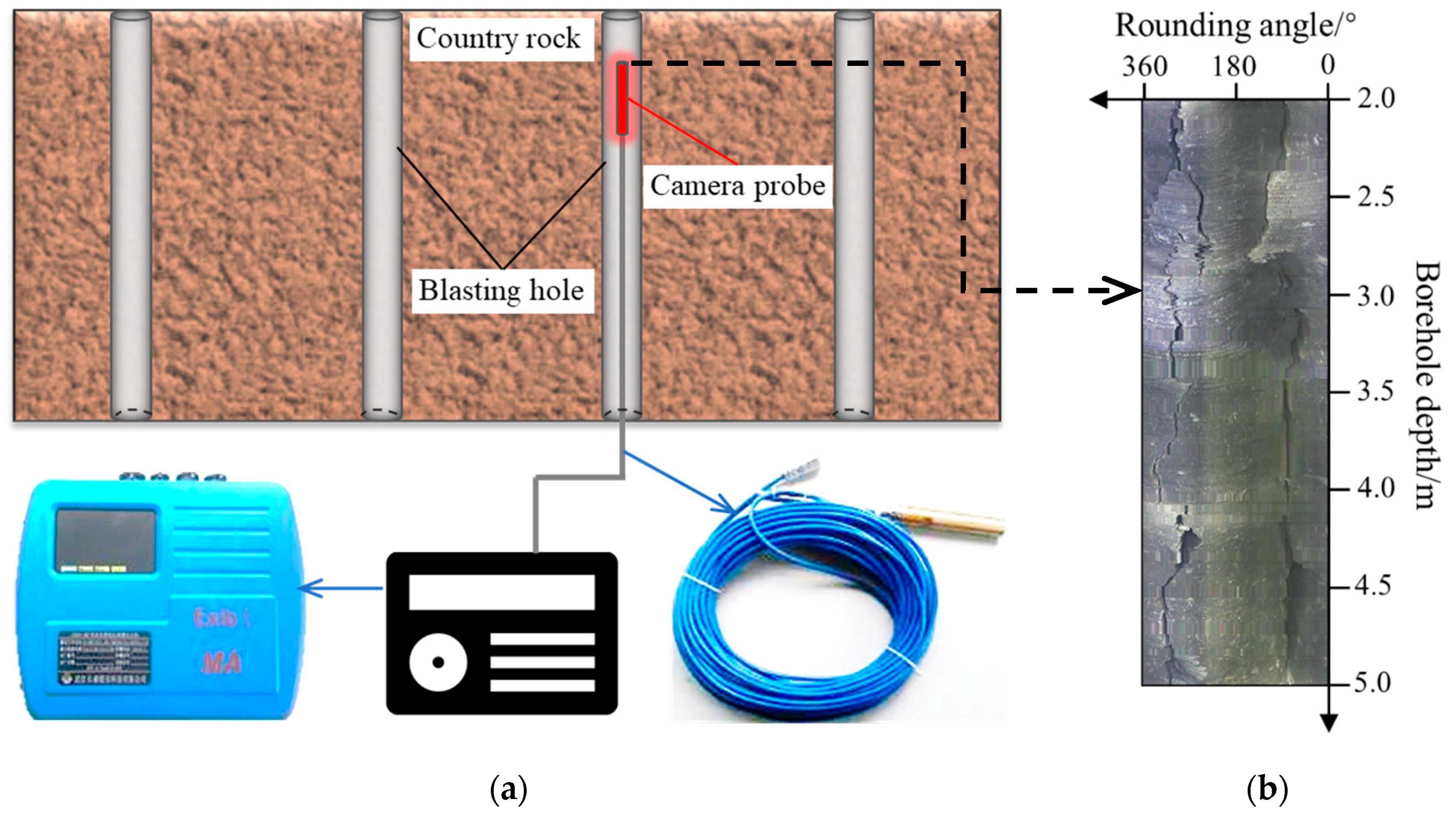

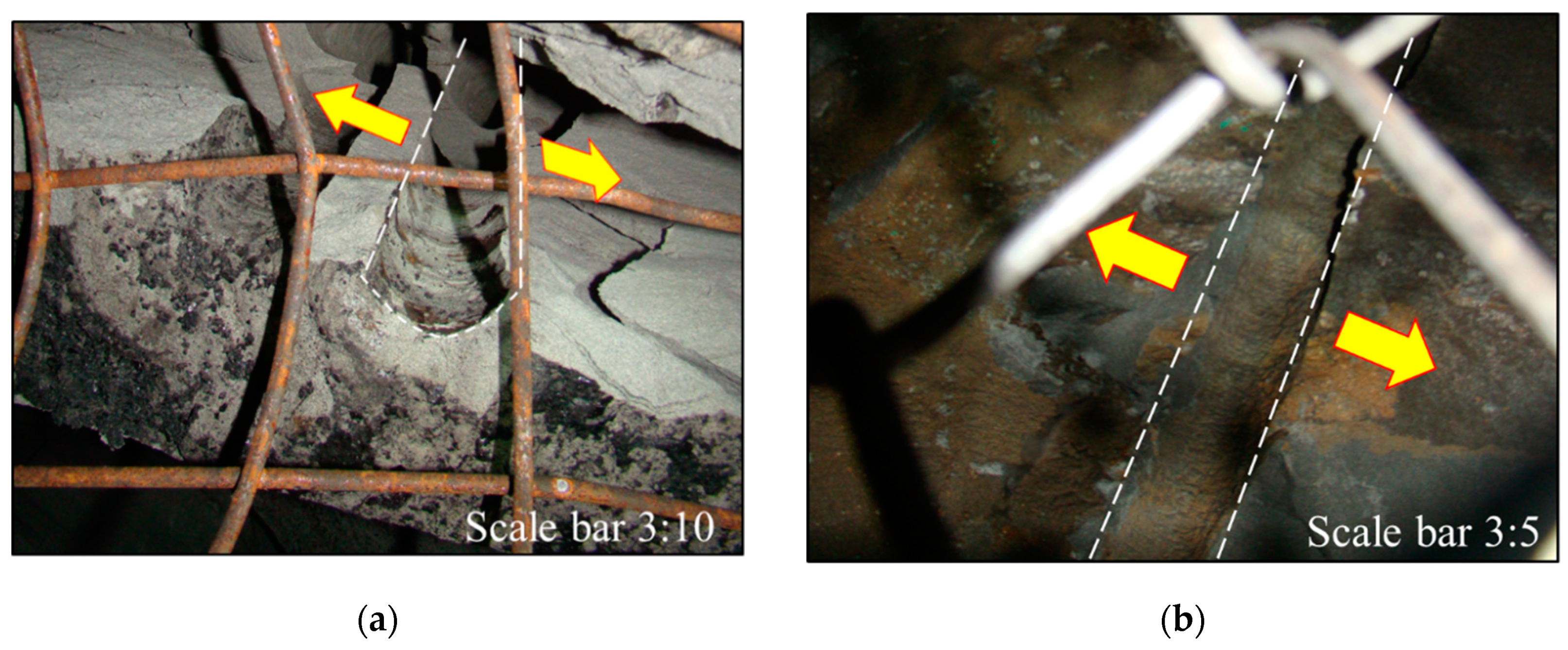

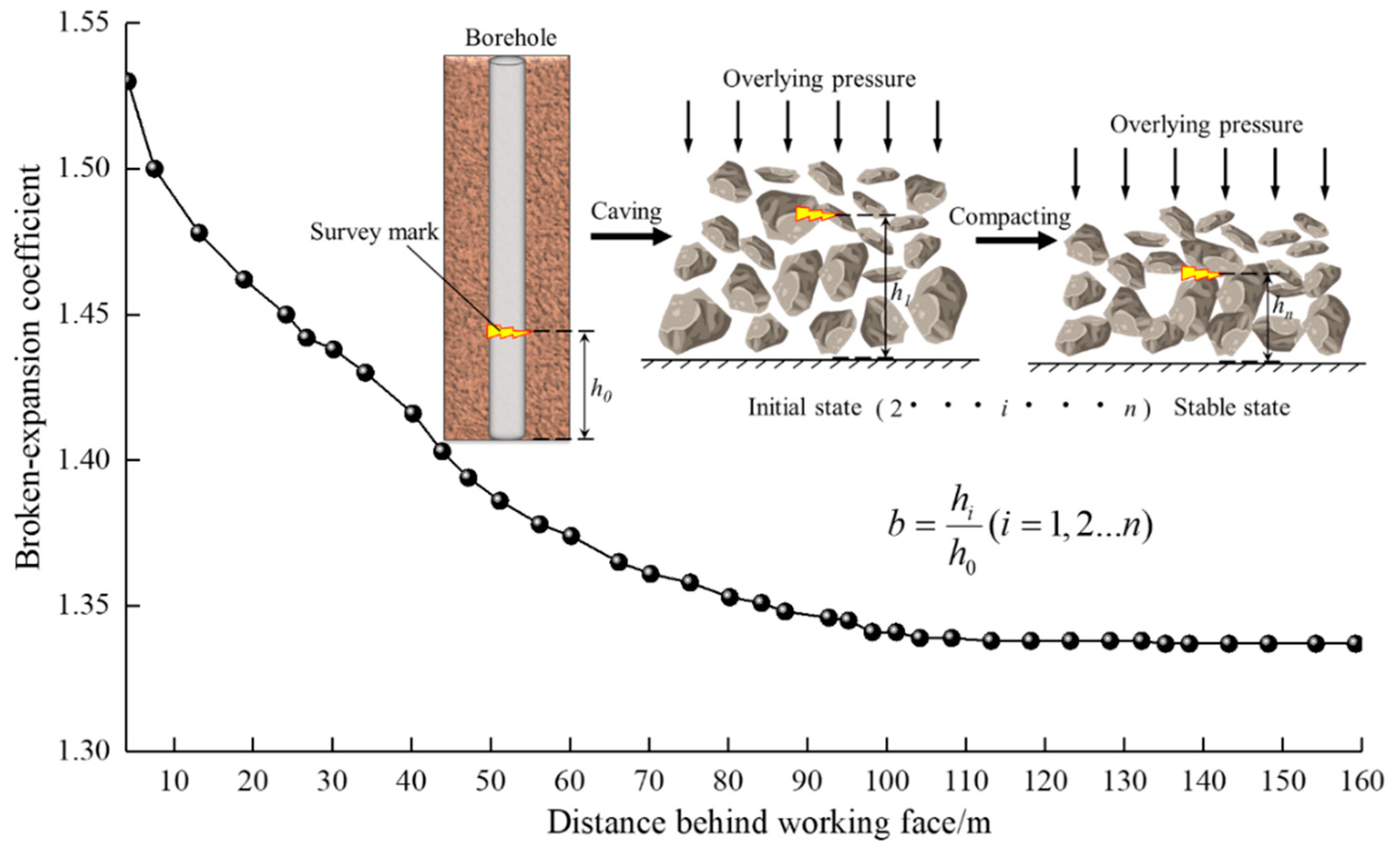

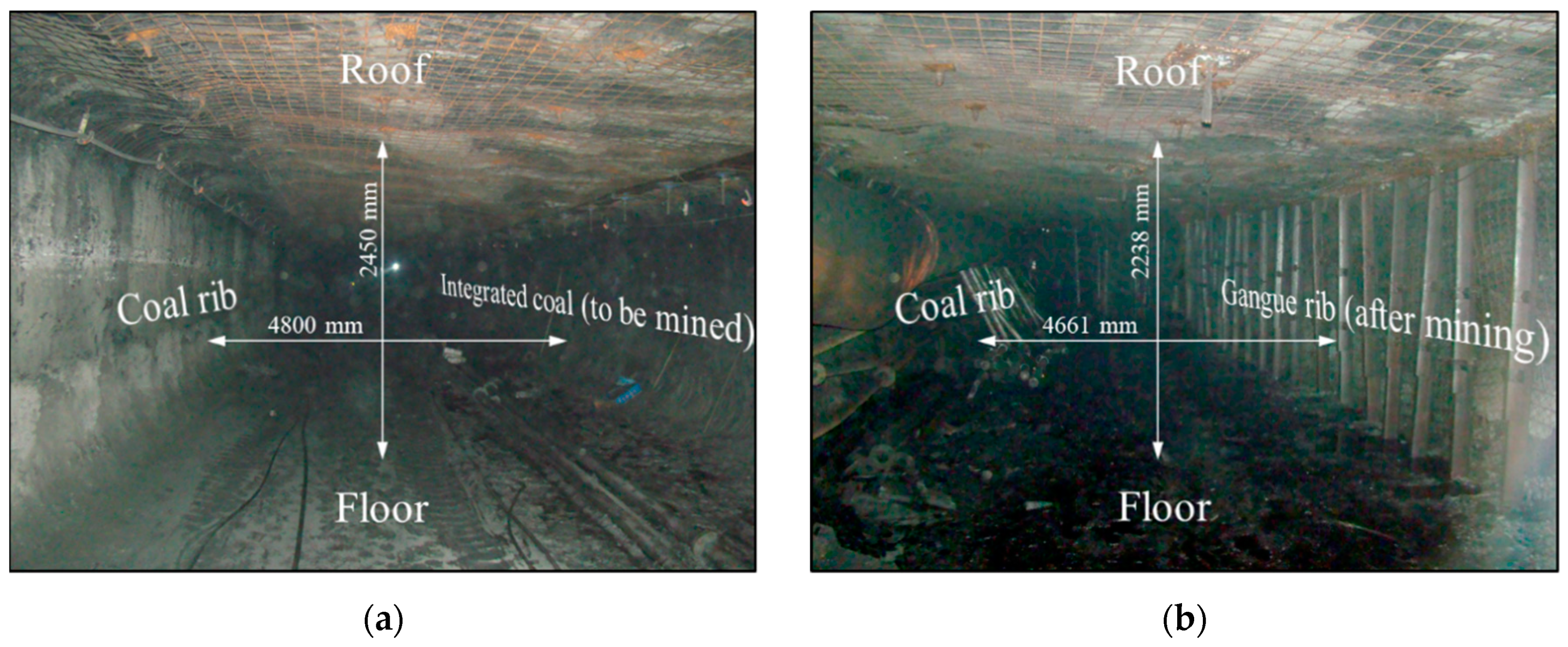

3.3.1. Roof Splitting Effect

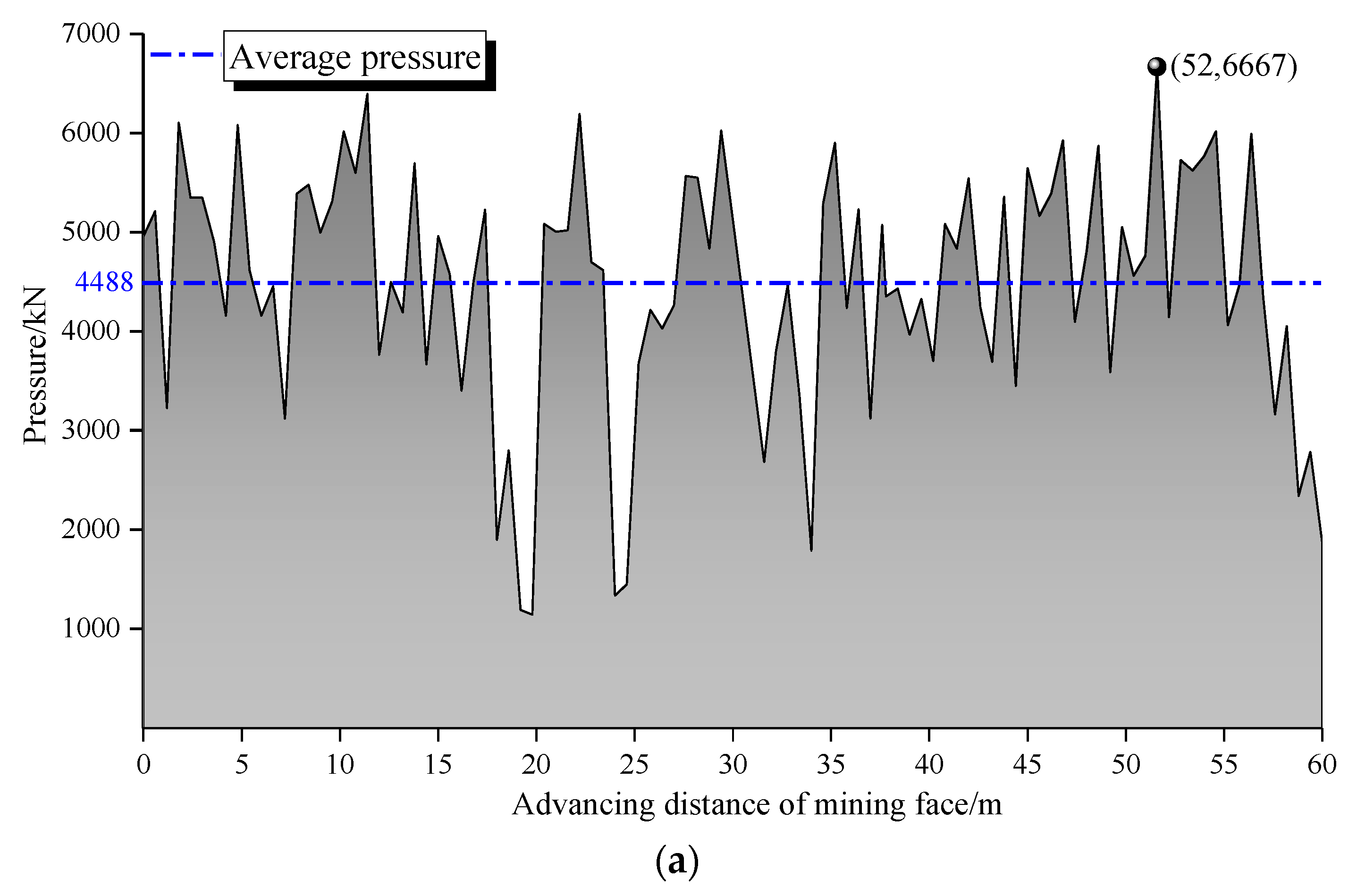

3.3.2. Mining Pressure

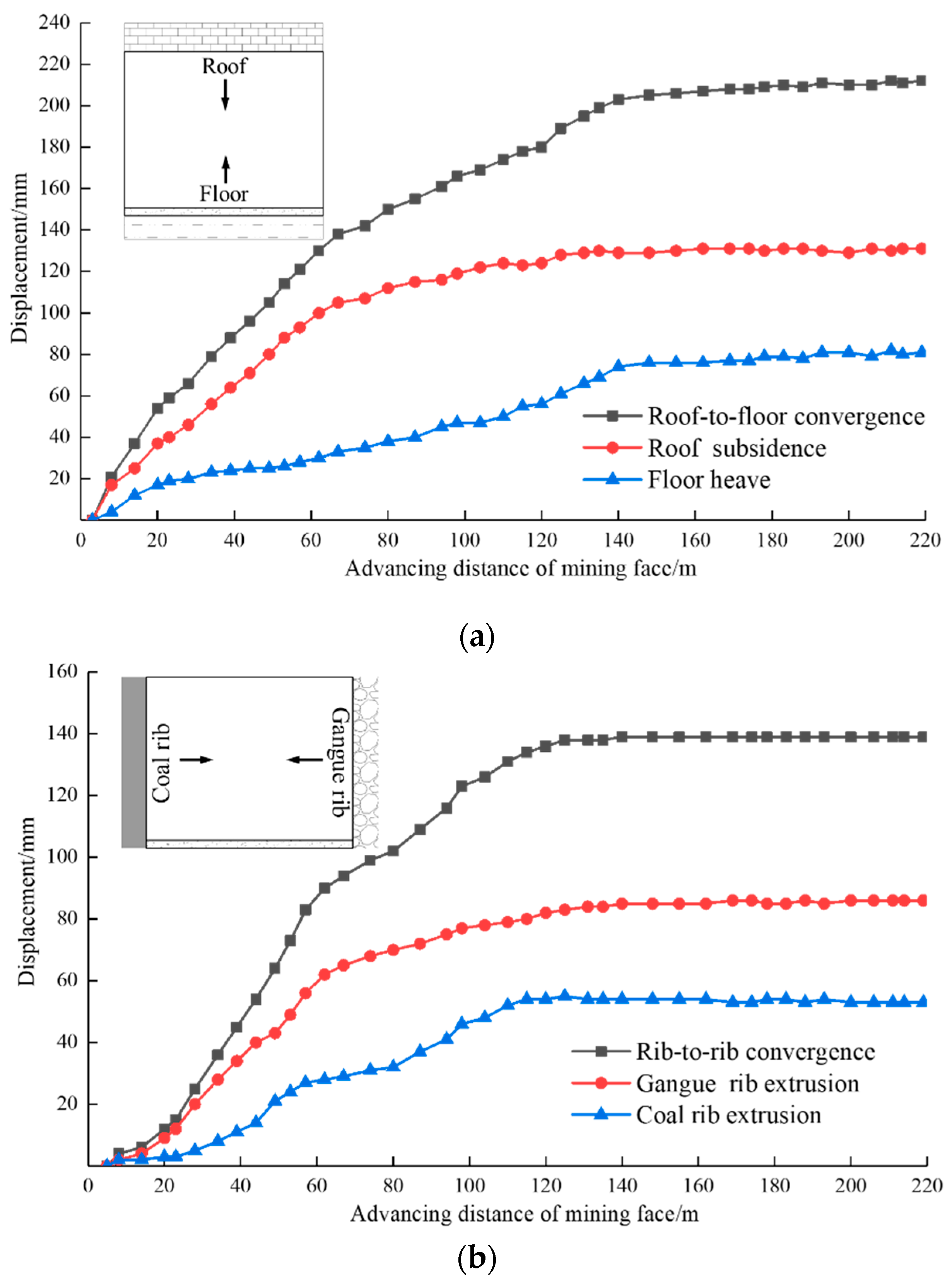

3.3.3. Gob-Side Entry Deformation

4. Discussion and Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Wolde-Rufael, Y. Coal consumption and economic growth revisited. Appl. Energ. 2010, 87, 160–167. [Google Scholar] [CrossRef]

- Suárez-Ruiz, I.; Diez, M.A.; Rubiera, F. Coal. In New Trends in Coal Conversion; Woodhead Publishing: Cambridge, UK, 2019; pp. 1–30. ISBN 978-0-0810-2201-6. [Google Scholar]

- Le Quéré, C.; Andrew, R.M.; Friedlingstein, P.; Sitch, S.; Pongratz, J.; Manning, A.C.; Korsbakken, J.I.; Peters, G.P.; Canadell, J.G.; Jackson, R.B. Global carbon budget 2017. Earth Syst. Sci. Data Discuss. 2017, 1–79. [Google Scholar] [CrossRef]

- Wang, Q.; Li, R. Decline in China’s coal consumption: An evidence of peak coal or a temporary blip? Energy Policy 2017, 108, 696–701. [Google Scholar] [CrossRef]

- Dudley, B. BP Energy Outlook; Report–BP Energy Economics: London, UK, 2018; p. 9. [Google Scholar]

- Kimura, S.; Phoumin, H. Energy Outlook and Energy Saving Potential in East Asia 2019; Economic Research Institute for ASEAN and East Asia: Jakarta, Indonesia, 2019. [Google Scholar]

- Mendelevitch, R.; Hauenstein, C.; Holz, F. The Death Spiral of Coal in the USA: Will New US Energy Policy Change the Tide? DIW Berlin Discussion Paper No. 1790; Elsevier: Amsterdam, Netherlands, 2019. [Google Scholar]

- Stougie, L.; Giustozzi, N.; van der Kooi, H.; Stoppato, A. Environmental, economic and exergetic sustainability assessment of power generation from fossil and renewable energy sources. Int. J. Energy Res. 2018, 42, 2916–2926. [Google Scholar] [CrossRef]

- Peng, S.S.; Chiang, H.S. Longwall Mining; Wiley Press: Hoboken, NJ, USA, 1984; ISBN 978-0-4292-6004-9. [Google Scholar]

- Höök, M.; Zittel, W.; Schindler, J.; Aleklett, K. Global coal production outlooks based on a logistic model. Fuel 2010, 89, 3546–3558. [Google Scholar] [CrossRef]

- Yang, H.; Cao, S.; Wang, S.; Fan, Y.; Wang, S.; Chen, X. Adaptation assessment of gob-side entry retaining based on geological factors. Eng. Geol. 2016, 209, 143–151. [Google Scholar] [CrossRef]

- Tan, Y.L.; Yu, F.H.; Ning, J.G.; Zhao, T.B. Design and construction of entry retaining wall along a gob side under hard roof stratum. Int. J. Rock Mech. Min. Sci. 2015, 77, 115–121. [Google Scholar] [CrossRef]

- Zhang, N.; Yuan, L.; Han, C.; Xue, J.; Kan, J. Stability and deformation of surrounding rock in pillarless gob-side entry retaining. Saf. Sci. 2012, 50, 593–599. [Google Scholar] [CrossRef]

- Li, X.; Ju, M.; Yao, Q.; Zhou, J.; Chong, Z. Numerical Investigation of the Effect of the Location of Critical Rock Block Fracture on Crack Evolution in a Gob-side Filling Wall. Rock Mech. Rock Eng. 2015, 49, 1041–1058. [Google Scholar] [CrossRef]

- Gong, P.; Ma, Z.; Ni, X.; Zhang, R. Floor heave mechanism of gob-side entry retaining with fully-mechanized backfilling mining. Energies 2017, 10, 2085. [Google Scholar] [CrossRef]

- Brown, E.T. Progress and challenges in some areas of deep mining. Min. Technol. 2013, 121, 177–191. [Google Scholar] [CrossRef]

- Chang, Q.L.; Tang, W.J.; Xu, Y.; Zhou, H.Q. Research on the width of filling body in gob-side entry retaining with high-water materials. Int. J. Min. Sci. Technol. 2018, 28, 519–524. [Google Scholar] [CrossRef]

- Yang, H.; Cao, S.; Li, Y.; Sun, C.; Guo, P. Soft roof failure mechanism and supporting method for gob-side entry retaining. Minerals 2015, 5, 707–722. [Google Scholar] [CrossRef]

- Xue, J.; Duan, C. Technologies of gob-side entry retaining with no-pillar in condition of overlying and thick-hard roof. J. China Coal. Soc. 2014, 39, 378–383. [Google Scholar]

- Xue, J.; Han, C. Strata behavior and control countermeasures for the gob-side entry retaining in the condition of large mining height. J. Min. Saf. Eng. 2012, 29, 466–473. [Google Scholar]

- Yan, S.; Liu, T.X.; Bai, J.B.; Wu, W.D. Key parameters of gob-side entry retaining in a gassy and thin coal seam with hard roof. Processes 2018, 6, 51. [Google Scholar] [CrossRef]

- Ma, Z.; Wang, J.; He, M.; Gao, Y.; Hu, J.; Wang, Q. Key Technologies and application test of an innovative noncoal pillar mining approach: A case study. Energies 2018, 11, 2853. [Google Scholar] [CrossRef]

- He, M.; Gao, Y.; Yang, J.; Gong, W. An innovative approach for gob-side entry retaining in thick coal seam longwall mining. Energies 2017, 10, 1785. [Google Scholar] [CrossRef]

- Hu, J.; He, M.; Wang, J.; Ma, Z.; Wang, Y.; Zhang, X. Key parameters of roof cutting of gob-side entry retaining in a deep inclined thick coal seam with hard roof. Energies 2019, 12, 934. [Google Scholar] [CrossRef]

- Fan, D.; Liu, X.; Tan, Y.; Song, S.; Gu, Q.; Yan, L.; Xu, Q. Roof cutting parameters design for gob-side entry in deep coal mine: A case study. Energies 2019, 12, 2032. [Google Scholar] [CrossRef]

- Zhang, G.; He, M.; Yu, X. Research on the technique of no-pillar mining with gobside entry formed by advanced roof caving in the protective seam in Baijiao coalmine. J. Min. Saf. Eng. 2011, 28, 511–516. [Google Scholar]

- Guo, Z.; Wang, J.; Cao, T. Study on key parameters of automatic roadway with thin coal seam topping.pressure relief. J. China Univ. Min. Technol. 2016, 45, 879–885. [Google Scholar]

- He, M.; Gao, Y.; Yang, J.; Wang, J.; Wang, Y.; Zhu, Z. Engineering experimentation of gob-side entry retaining formed by roof cutting and pressure release in a thick-seam fast-extracted mining face. Rock Soil. Mech. 2018, 39, 254–264. [Google Scholar]

- He, M.; Ma, Z.; Guo, Z.; Chen, S. Key parameters of the gob-side entry retaining formed by roof cutting and pressure release in deep medium-thickness coal seams. J. China Univ. Min. Technol. 2018, 47, 468–477. [Google Scholar]

- Itasca Consulting Group, Inc. UDEC—Universal Distinct Element Code, Version 7.0; User Manual; Itasca Consulting Group, Inc.: Minneapolis, MN, USA, 2018. [Google Scholar]

- Jia, B.; Tsau, J.S.; Barati, R. A workflow to estimate shale gas permeability variations during the production process. Fuel 2018, 220, 879–889. [Google Scholar] [CrossRef]

- Jia, B.; Tsau, J.S.; Barati, R. Role of molecular diffusion in heterogeneous, naturally fractured shale reservoirs during CO2 huff-n-puff. J. Petroleum Sci. Eng. 2018, 164, 31–42. [Google Scholar] [CrossRef]

- Labra, C.; Rojek, J.; Oñate, E.; Zarate, F. Advances in discrete element modelling of underground excavations. Acta Geotech. 2008, 3, 317–322. [Google Scholar] [CrossRef]

- Ming-Gao, C. A study of the behaviour of overlying strata in longwall mining and its application to strata control. In Developments in Geotechnical Engineering; Farmer, I.W., Ed.; Elsevier: Amsterdam, The Netherlands, 1981; Volume 32, pp. 13–17. ISBN 978-0-4444-2086-2. [Google Scholar]

| Rock Strata | Density/(kg/m3) | Elasticity Modulus (GPa) | Friction (deg) | Cohesion (MPa) | Tensile Strength (MPa) |

|---|---|---|---|---|---|

| Roof III | 2550 | 18.6 | 33 | 2.6 | 1.18 |

| Roof II | 2600 | 19.4 | 32 | 2.8 | 1.24 |

| Roof I | 2750 | 22.6 | 30 | 3.2 | 1.60 |

| Coal | 1500 | 4.0 | 22 | 0.8 | 0.36 |

| Floor | 2550 | 18.2 | 30 | 2.4 | 1.12 |

| Rock Strata | Normal Stiffness (GPa) | Sheer Stiffness (GPa) | Friction (deg) | Cohesion (MPa) |

|---|---|---|---|---|

| Roof III | 2.2 | 1.1 | 5 | 0.03 |

| Roof II | 2.7 | 1.4 | 9 | 0.04 |

| Roof I | 3.2 | 2.6 | 10 | 0.02 |

| Coal | 0.6 | 3.8 | 3 | 0 |

| Floor | 2.6 | 1.2 | 8 | 0.04 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, X.; Chen, L.; Gao, Y.; Hu, J.; Yang, J.; He, M. Study of An Innovative Approach of Roof Presplitting for Gob-Side Entry Retaining in Longwall Coal Mining. Energies 2019, 12, 3316. https://doi.org/10.3390/en12173316

Zhang X, Chen L, Gao Y, Hu J, Yang J, He M. Study of An Innovative Approach of Roof Presplitting for Gob-Side Entry Retaining in Longwall Coal Mining. Energies. 2019; 12(17):3316. https://doi.org/10.3390/en12173316

Chicago/Turabian StyleZhang, Xingyu, Liang Chen, Yubing Gao, Jinzhu Hu, Jun Yang, and Manchao He. 2019. "Study of An Innovative Approach of Roof Presplitting for Gob-Side Entry Retaining in Longwall Coal Mining" Energies 12, no. 17: 3316. https://doi.org/10.3390/en12173316

APA StyleZhang, X., Chen, L., Gao, Y., Hu, J., Yang, J., & He, M. (2019). Study of An Innovative Approach of Roof Presplitting for Gob-Side Entry Retaining in Longwall Coal Mining. Energies, 12(17), 3316. https://doi.org/10.3390/en12173316