Carbon Capture for CO2 Emission Reduction in the Cement Industry in Germany

Abstract

:1. Introduction

2. CO2 Capture in Cement Production

2.1. State of the Art Cement Plant

2.2. Literature Review about CO2 Capture for Cement Plants

3. Modeling of the CO2 Capture

3.1. Energy Modeling

3.2. Economic Modeling

3.3. Analyzed Cases for CO2 Capture

4. Results and Analyses

4.1. Energetic and Economic Performance

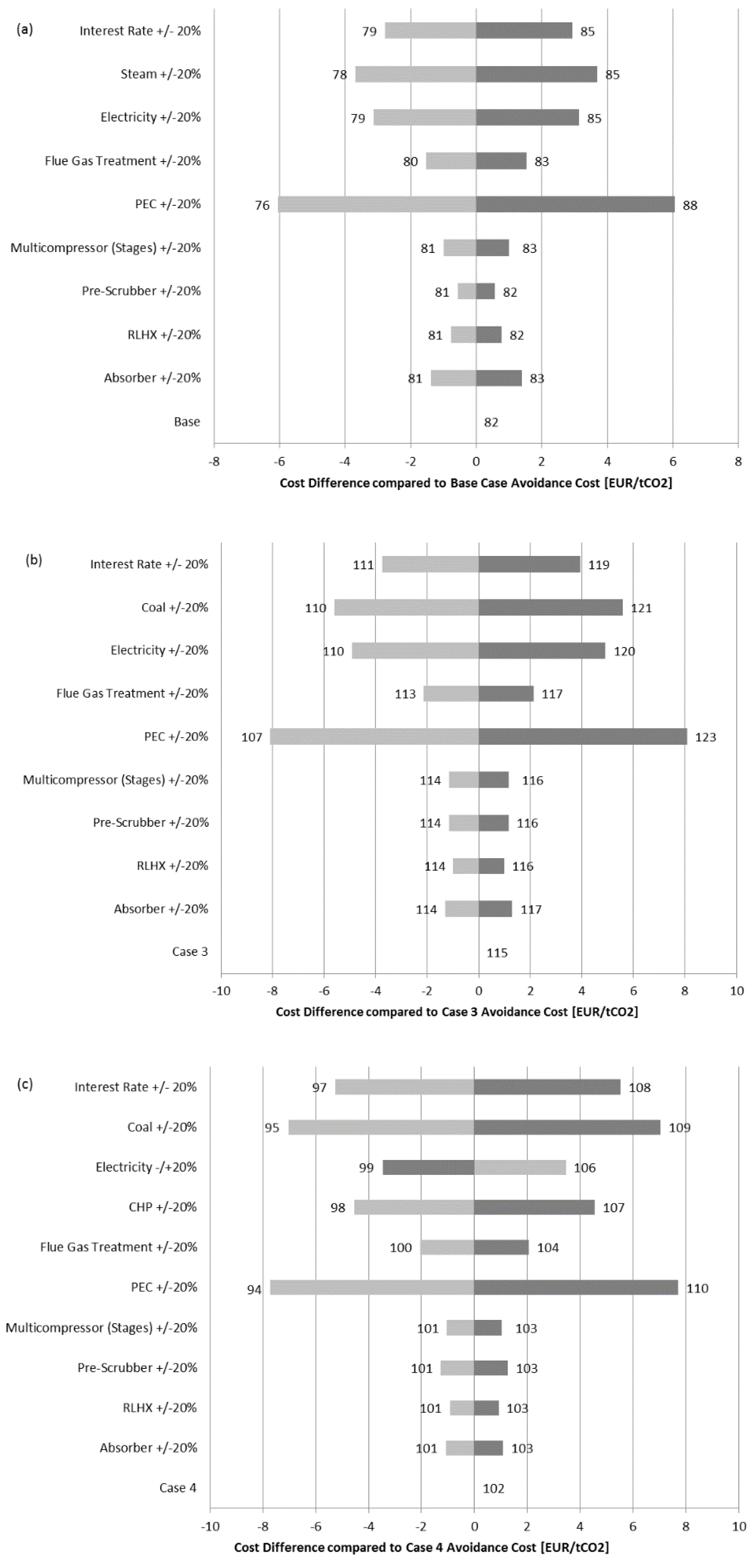

4.2. Sensitivity Analysis

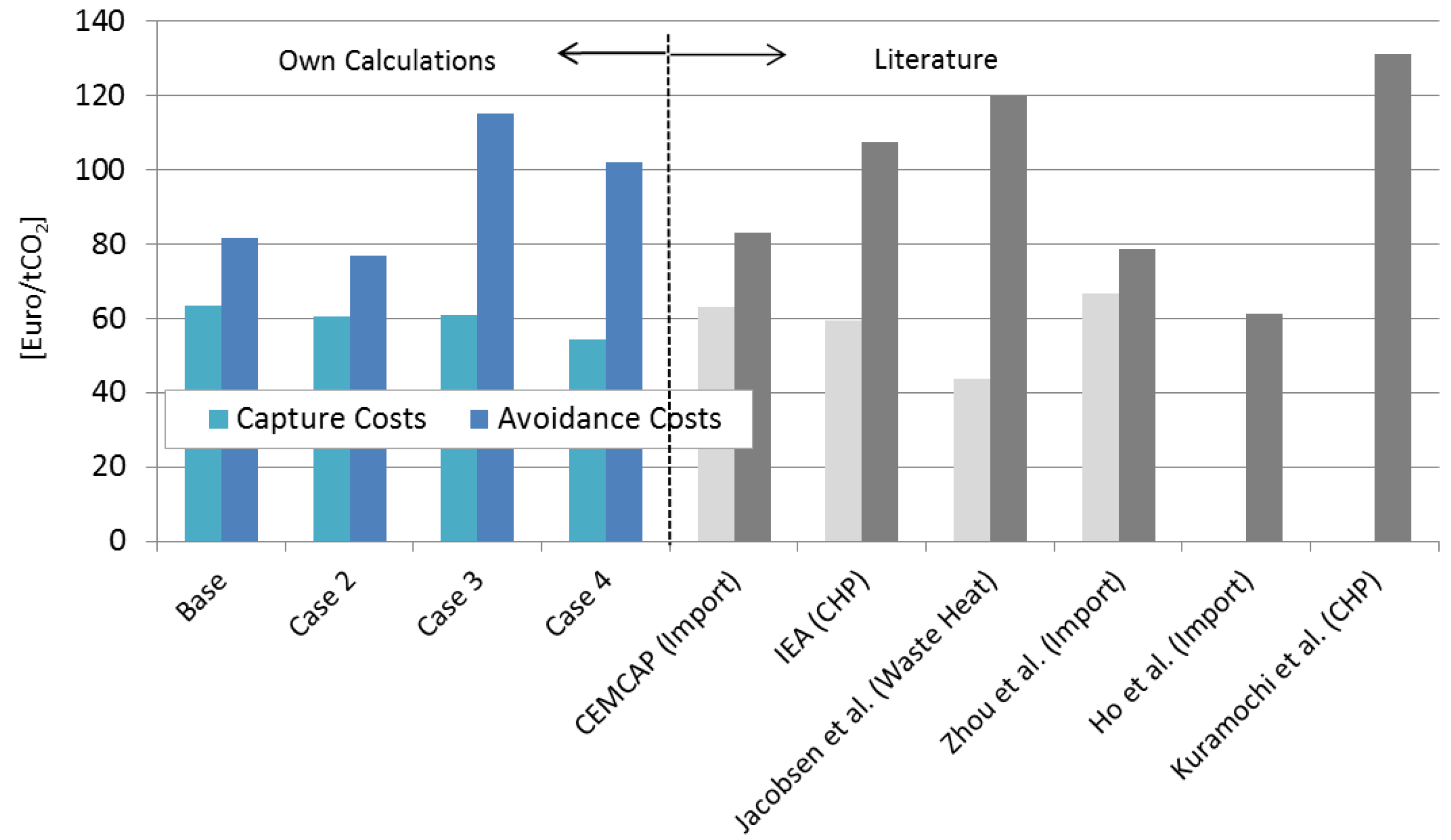

4.3. Comparison with Literature

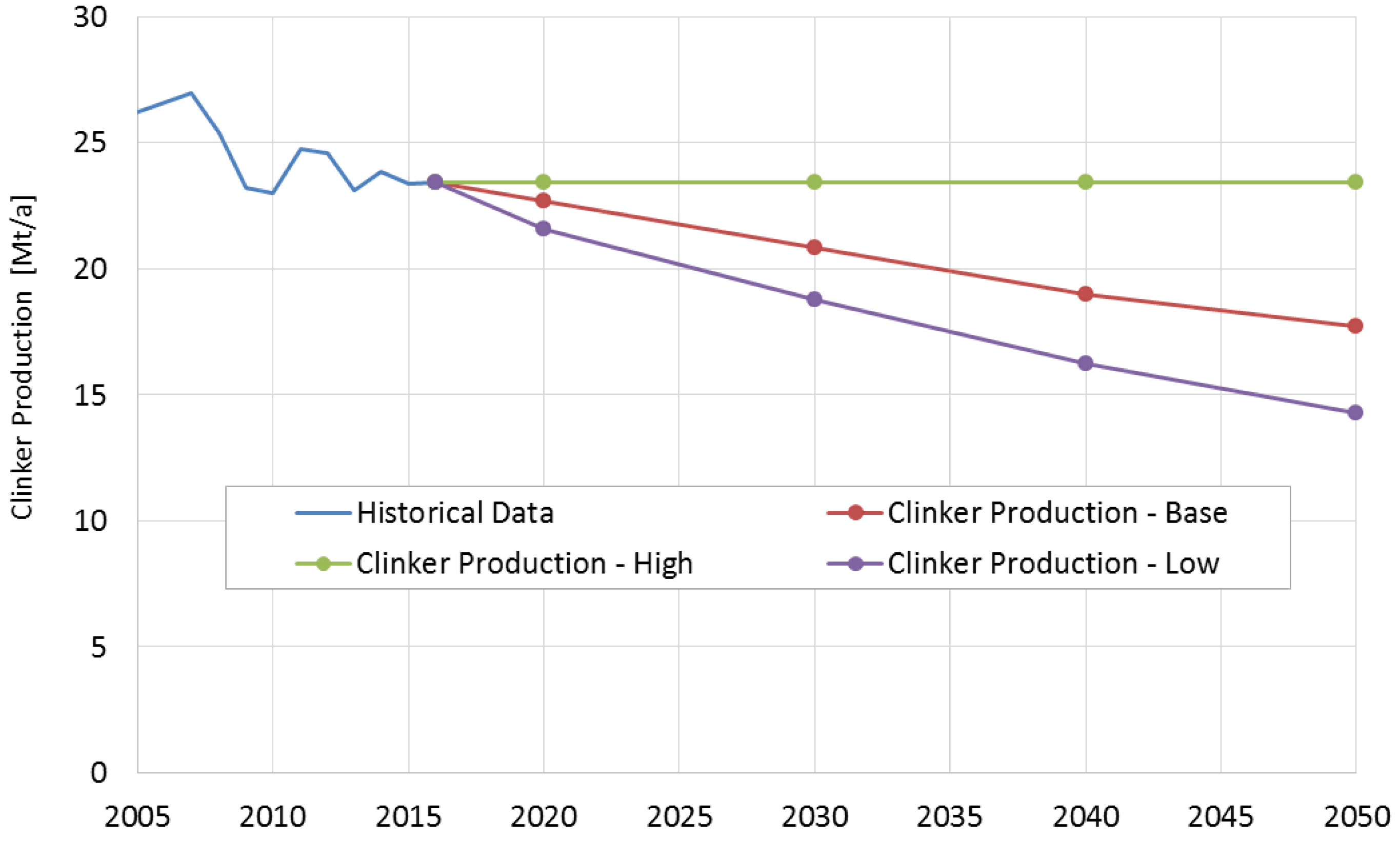

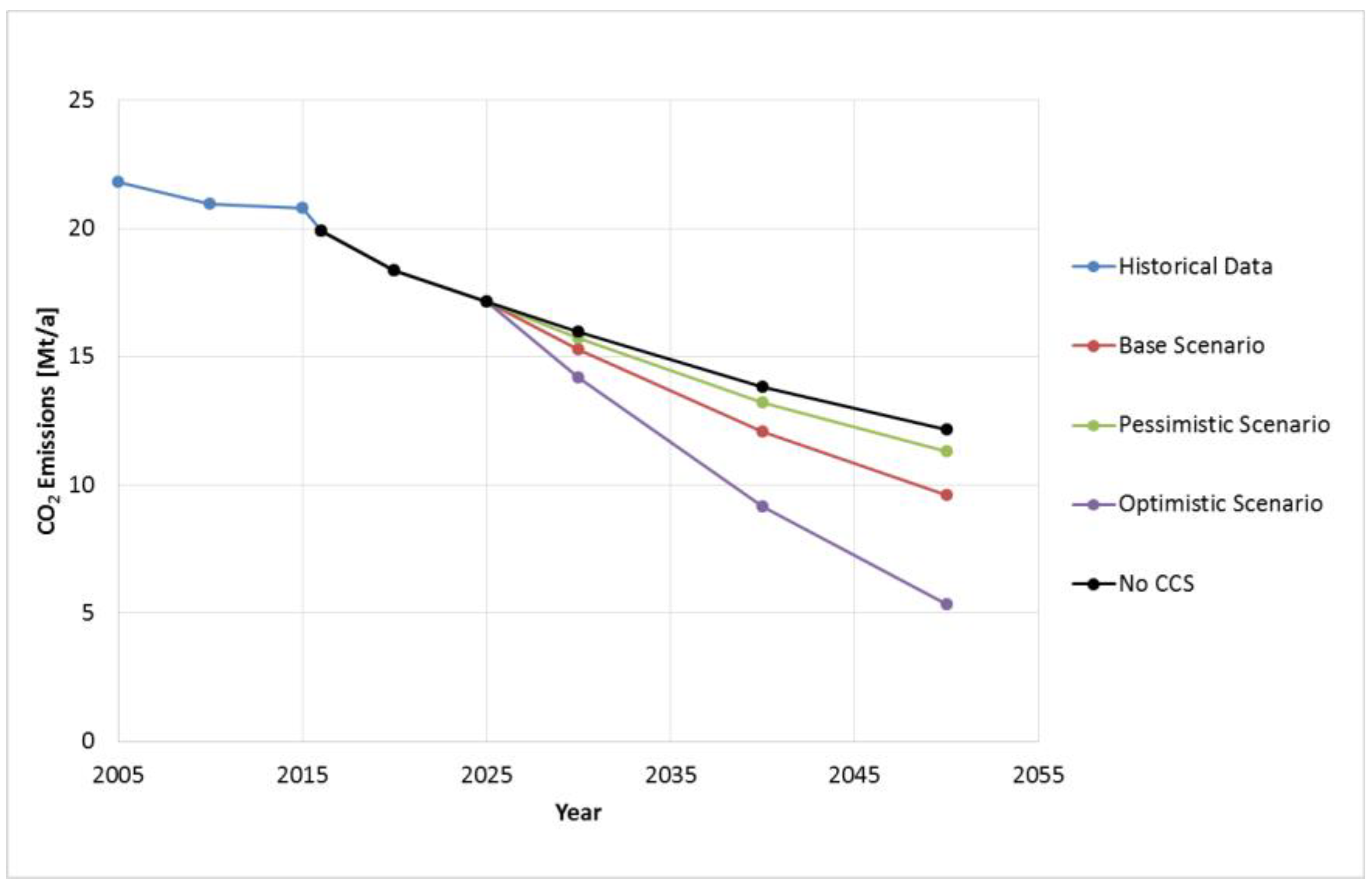

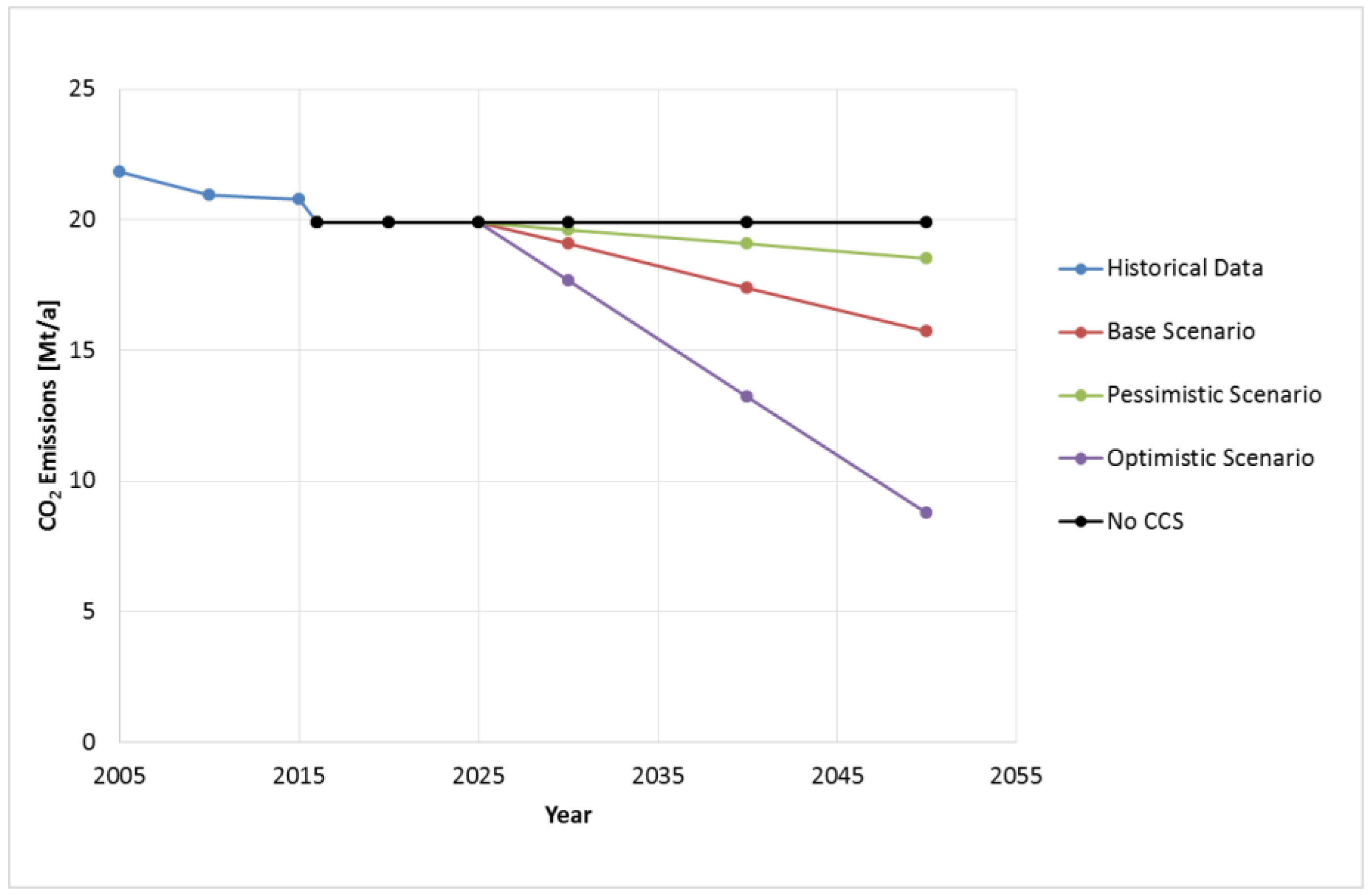

4.4. CO2 Emissions Reduction Potential in Germany

- Base Scenario: CCUS is applied to 30% of German clinker production capacities.

- Pessimistic Scenario: CCUS is applied to 10% of German clinker production capacities.

- Optimistic Scenario: CCUS is applied to 80% of German clinker production capacities.

5. Summary and Conclusions

Author Contributions

Funding

Conflicts of Interest

Nomenclature

| Symbol | SI-Unit | Name |

| Annuity | ||

| J/K | Specific heat | |

| % | Overall CO2 reduction rate | |

| EUR | Investment costs | |

| EUR/unit | Specific costs per unit | |

| EUR/a | Annual costs | |

| kg/s | Mass Flow | |

| Symbol | Name | |

| an | Annual | |

| BAT | Best available technology | |

| BECCS | Bioenergy with carbon capture and storage | |

| CaL | Calcium looping | |

| CAPEX | Capital expenditure | |

| CCUS | Carbon capture, utilization and storage | |

| CEMCAP | CO2 capture from cement production | |

| CEPCI | Chemical engineering plant cost index | |

| CHP | Combined heat and power | |

| CO2,av | CO2 avoided | |

| CO2,cap | CO2 captured | |

| el | Electric | |

| FGD | Flue gas desulphurization | |

| GHG | Greenhouse gas | |

| IEA | International energy agency | |

| MDEA | Methyldiethanolamin | |

| MEA | Monoethanolamin | |

| NG | Natural gas | |

| NGCC | Natural gas combined cycle | |

| OPEX | Operational expenditure | |

| PCC | Post combustion capture | |

| PEC | Purchased equipment costs | |

| RLHX | Rich lean heat exchangers | |

| SCR | Selective catalytic reduction | |

| USD | US dollar | |

| VDZ | Verein Deutscher Zementwerke | |

Appendix A. Literature Review

| CEMCAP [20,23] | Jakobsen et al. [32] | Zhou et al. [33] | Summers et al. [35] | Ho et al. [34] | Kuramochi et al. [31] | Barker et al. [30] | Hassan [29] | |

|---|---|---|---|---|---|---|---|---|

| Cement capacity | 1.36 Mt/a | 1.2 Mt/a | / | 1 Mt/a | 1 Mt/a | / | 1 Mt/a | 0.68 Mt/a |

| Clinker capacity | 3000 t/d; | / | 5000 t/d | / | / | / | / | 2400 t/d |

| 1 Mt/a | / | / | 1 Mt/a/ | 0.91 Mt/a | / | |||

| Process type | 5-stage preheater with precalciner | / | / | / | / | Dry process with precalciner | 5-stage preheater with precalciner | / |

| Solvent type | MEA | MEA/advanced solvent | MEA | MDEA | MEA | Adv. Solv./KS1/MEA | MEA | MEA |

| Flue gas treatment | FGD, SCR | / | / | FGD, SCR | FGD, SCR | / | FGD, SCR | FGD, bag filters |

| CO2 lean loading molCO2/mol MEA | 0.27 | / | / | / | / | / | 0.22 | 0.3 |

| CO2 rich loading molCO2/molMEA | 0.49 | / | / | / | / | / | 0.45 | / |

| Steam source | NG boiler; NG CHP; waste heat recovery; external coal power plant | Waste heat (31 MW) and NG boiler | Steam import; CHP | NG boiler | External NGCC | Steam import (Coal plant, boiler); Onsite CHP | CHP plant; import from power plant; NG boiler | Steam (imported) |

| Scenarios | Capture rates of 0.9 and 0.6; 7 steam source scenarios | Different transport and storage scenarios | Different steam scenarios | Retrofit and greenfield plant | Different prices and fuels for external steam supply | Short-mid-term (ST/MT) and long term (LT) technologies | 3 million ton cement plant | Different operational cases |

| Thermal Energy requirement [MJ/kgCO2] | 3.83 | 3.2 (MEA)/2.1 (advanced solvent) | 3.7 | / | 1.5 | 2.7 (ST/MT, MEA; 3.7 (LT, Adv. Solvent) | 3.38 | / |

| CO2 capture rate | 90% (base case), 60% | 42% (base case); max. 85% | 85% 62% | 95% | 90% | / | 85% | 85% |

| Economic lifetime | 25 a | 25 a | 25 a | 30 a | 25 a | 20 a | 25 a | 20 a |

| Interest rate | 8% | 8% | 10% | 8% | 7% | 10% | 10% | 7% |

| Investment costs for CCUS plant | 79.3 MEUR (90% capture) and 62.2 MEUR (60% capture) in comp. to cement plant | / | 110 MUSD | 145 MUSD | 91 MUSD | / | 295 MEUR | 298 MUSD (average load) |

| Operating costs for CCUS plant | 26.7 EUR/tcement (90% capt.); 18.6 EUR/tcement (60% capt.) | / | 7.9 MUSD | 60 MUSD | 43 MUSD | / | 30.4 MEUR | 25.1 MUSD (average load) |

| Costs of CO2 captured | 63.2 EUR/t (base case); 41-65 €/tCO2 in alternative scenarios | / | 74.1/t USD (imp. steam); 72.3/t USD (CHP) | / | / | / | 59.6/t EUR/t | 51 USD/t (average load) |

| Costs of CO2 avoided | 83.2 EUR/t (base case); 54-86 €/tCO2 in alternative scenarios | 40-70 EUR/t (capture + conditioning) | 87.6 USD/t (imp. steam); 100 USD/t (CHP) | 96/121 USD/t (greenfield excl./incl. FGD, SCR) | 68 USD/t | 37 EUR/t (Adv. solvent, steam import) to 131 EUR/t (MEA, onsite CHP) | 107.4 EUR/t | / |

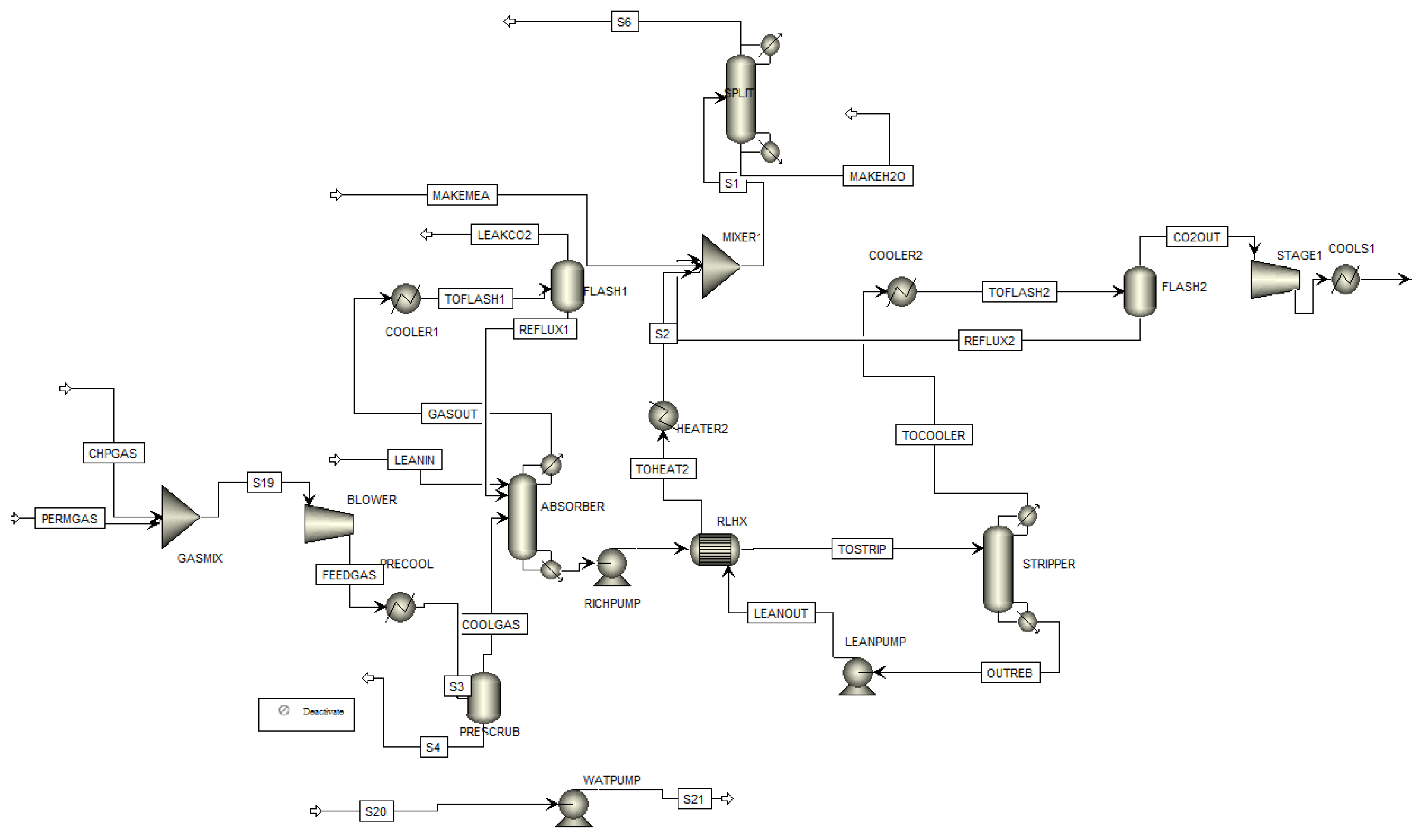

Appendix B. Post-Combustion Model

| Block | Type | Economic Analysis |

|---|---|---|

| BLOWER | Compressor | Yes |

| GASMIX | Mixer | No |

| PRECOOL | Scrubber | Yes, as single equipment |

| PRESCRUB | ||

| ABSORBER | Absorber | Yes |

| COOLER1 | Scrubber | Yes, as single equipment |

| FLASH1 | ||

| RICHPUMP | Pump | Yes |

| RLHX | Heat Exchanger | Yes |

| STRIPPER | Stripper | Yes |

| COOLER2 | Condenser/Cooler | Yes |

| FLASH2 | Knockout Drum | No |

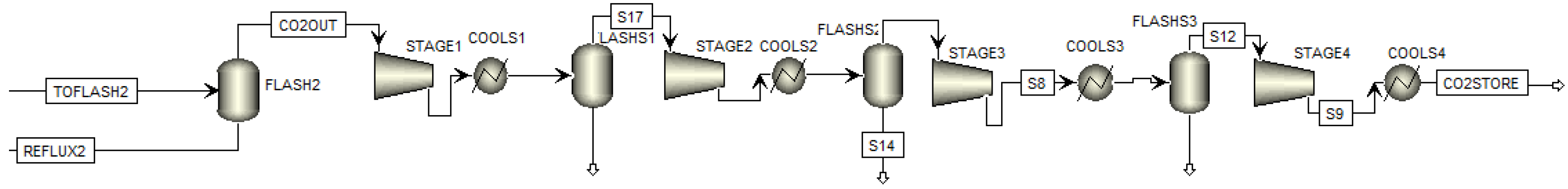

| STAGE1/STAGE2/STAGE3/STAGE4 | Compressor | Yes |

| COOLS1/COOLS2/COOLS3/COOLS4 | Cooler | Yes |

| FLASHS1/FLASHS2/FLASHS3 | Knockout Drum | Yes |

| LEANPUMP | Pump | Yes |

| HEATER2 | Cooler | Yes |

| MIXER | Mixer | No |

| SPLIT | Separator | No |

| WATPUMP | Pump | Yes |

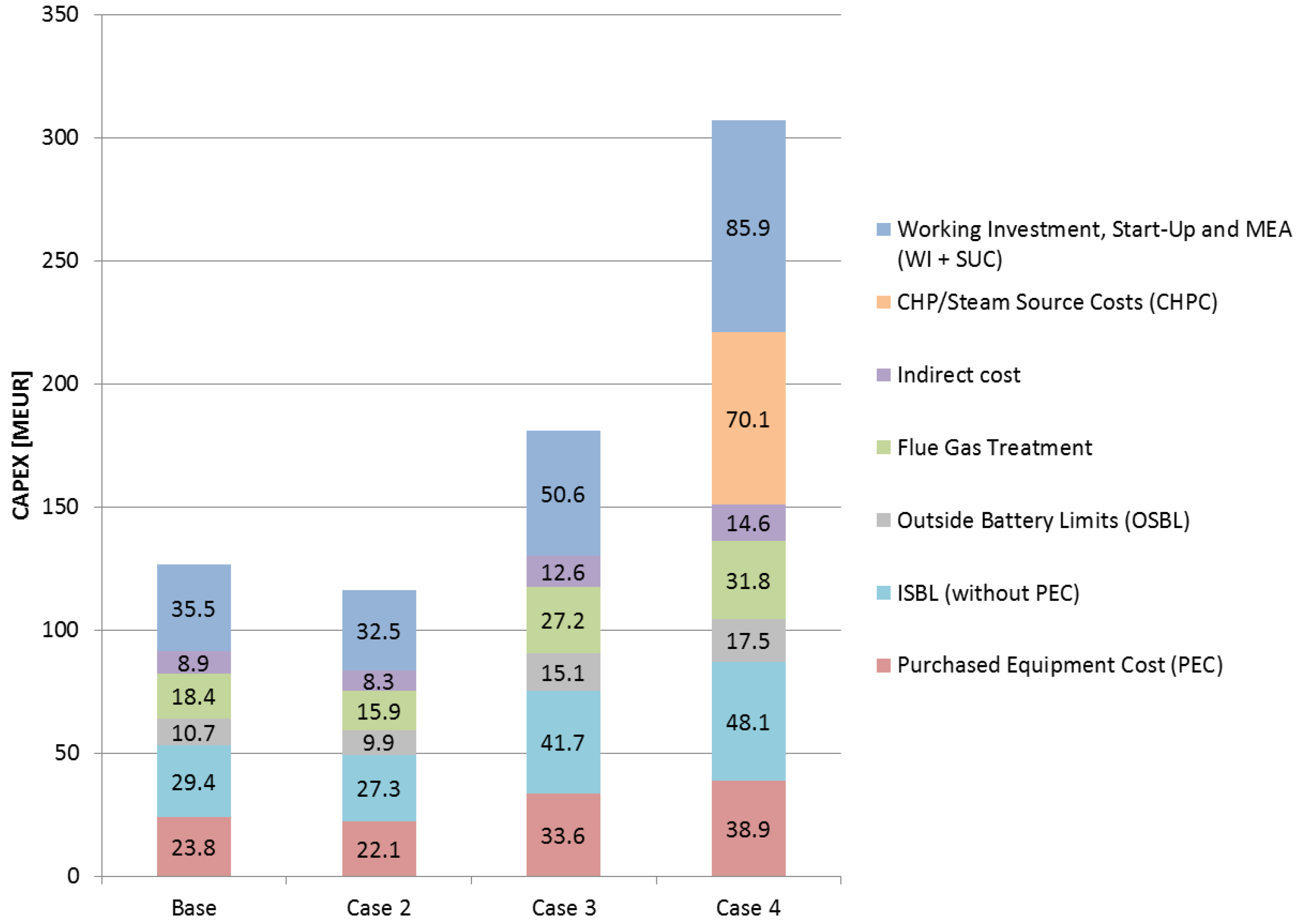

Appendix C. CAPEX Data

| Factor | Used percentage |

|---|---|

| Percentage of PEC | |

| Direct cost | |

| Inside Battery Limits (ISBL) | |

| Purchased Equipment Cost (PEC) | 100 |

| Purchased Equipment Installation | 53 |

| Instrumentation and Control | 20 |

| Piping | 40 |

| Electrical | 11 |

| Outside Battery Limits (OSBL) | |

| Building and Building Services | 10 |

| Yard Improvements | 10 |

| Service Facilities | 20 |

| Land | 5 |

| Flue Gas Treatment | |

| FGD Unit | scaled and adopted from [18] |

| SCR Unit | scaled and adopted from [18] |

| Indirect cost | |

| Engineering | 10 |

| Construction Expenses | 10 |

| Contractor’s Fee | 0.5 |

| Contingency | 17 |

| CHP/Steam Source Costs (CHPC) | scaled and adopted from [18] |

| Fixed Capital Investment (FCI) = Indirect cost + Direct cost + CHPC | |

| Percentage of FCI | |

| Fixed Capital Investment (FCI) | 100 |

| Working Investment (WI) | 25 |

| Percentage of CAPEX | |

| Start-up Cost and Initial MEA Cost (SUC) | 10 |

| CAPEX = FCI + WI + SUC | |

| Equipment | Capacity Measure [Unit] | Base Size QB | Base Costs CB [EUR2016] | Size Range | Exponent M |

|---|---|---|---|---|---|

| Shall-and-Tube Heat Exchanger | Area [m2] | 80 | 4.06 × 104 | 80–4000 | 0.68 |

| Compressor, incl. motor | Power [kW] | 250 | 1.22 × 104 | 250–10,000 | 0.46 |

| (Large) Centrifugal Pump, incl. motor | Power [kW] | 4 | 1.22 × 103 | 4–700 | 0.55 |

| Equipment | Capacity Measure [Unit] | K1 | K2 | K3 | Size Range |

|---|---|---|---|---|---|

| Process vessel (vertical) | Volume [m3] | 3.4974 | 0.4485 | 0.1074 | 0.3–520 |

| Packing (for towers) | Volume [m3] | 2.4493 | 0.9744 | 0.0055 | 0.03–628 |

| Parameter | Value |

|---|---|

| Flue gas stream, wet [kg/s] | 162.5 |

| Electricity demand [kW] | 1790 |

| Limestone consumption [t/a] | 12,830 |

| Capital costs [MEUR2016] | 21.2 |

| Parameter | Value |

|---|---|

| Flue gas stream, wet [kg/s] | 65.5 |

| Electricity demand [kW] | 300 |

| Limestone consumption [t/a] | 1855 |

| Capital costs [MEUR2016] | 4.3 |

Appendix D. OPEX Data

| Factor | Calculation Method |

|---|---|

| Fixed Charge | |

| Local taxes | 2% of FCI |

| Insurance | 1% of FCI |

| Direct Production Cost | |

| Resource Consumption | |

| Cooling Water | Cooling water make up [m3/GJ] × Cooling Duty [GJ] × Cooling water costs |

| Coal | Fuel Costs [EUR/t] × Consumption |

| Steam | Steam costs [EUR/t] × Consumption |

| Electricity | Electricity costs [EUR/MWh] × Consumption |

| MEA Make Up | MEA cost x MEA degradation |

| Limestone | adopted from [18] |

| Ammonia | adopted from [18] |

| SCR Catalyst | adopted from [18] |

| Activated Carbon | Activated Carbon Cost × Consumption |

| Maintenance, Labor, Supplies, Laboratory | |

| Maintenance (MA) | 4% of FCI |

| Operating Labor (OL) | No. of Shifts × Labor Cost [EUR/h] |

| Supervision and Support Labor (SL) | 30% of OL |

| Operating Supplies | 15% of MA |

| Laboratory Charges | 10% of OL |

| Plant Overhead Cost | |

| Plant Overhead Cost | 60% of (MA + OL + SL) |

| General Expenses | |

| Administrative Cost | 15% of OL |

| Distribution and Marketing | 0.5% of OPEX |

| R&D Cost | 5% of OPEX |

| OPEX = General Expenses + Plant Overhead Cost + Direct Production Cost + Fixed Charge | |

Appendix E. CAPEX Results

| Base | Case 2 | Case 3 | Case 4 | |

|---|---|---|---|---|

| Direct cost | 82.2 | 75.2 | 117.6 | 136.3 |

| Inside Battery Limits (ISBL) | 53.2 | 49.4 | 75.3 | 87.0 |

| Purchased Equipment Cost (PEC) | 23.8 | 22.1 | 33.6 | 38.9 |

| Purchased Equipment Installation | 12.5 | 11.7 | 17.8 | 20.5 |

| Instrumentation and Control | 4.8 | 4.4 | 6.7 | 7.8 |

| Piping | 9.5 | 8.8 | 13.5 | 15.5 |

| Electrical | 2.6 | 2.4 | 3.7 | 4.3 |

| Outside Battery Limits (OSBL) | 10.7 | 9.9 | 15.1 | 17.5 |

| Building and Building Services | 2.4 | 2.2 | 3.4 | 3.9 |

| Yard Improvements | 2.4 | 2.2 | 3.4 | 3.9 |

| Service Facilities | 4.8 | 4.4 | 6.7 | 7.8 |

| Land | 1.2 | 1.1 | 1.7 | 1.9 |

| Flue Gas Treatment | 18.4 | 15.9 | 27.2 | 31.8 |

| FGD Unit | 14.1 | 11.5 | 22.9 | 27.4 |

| SCR Unit | 4.3 | 4.3 | 4.3 | 4.3 |

| Indirect cost | 8.9 | 8.3 | 12.6 | 14.6 |

| Engineering | 2.4 | 2.2 | 3.4 | 3.9 |

| Construction Expenses | 2.4 | 2.2 | 3.4 | 3.9 |

| Contractor’s Fee | 0.1 | 0.1 | 0.2 | 0.2 |

| Contingency | 4.0 | 3.8 | 5.7 | 6.6 |

| CHP/Steam Source Costs (CHPC) | / | / | / | 70.1 |

| Fixed Capital Investment (FCI) | 91.1 | 83.5 | 130.2 | 220.9 |

| Working Investment (WI) | 22.8 | 20.9 | 32.5 | 55.2 |

| Start-up Cost and Initial MEA Cost (SUC) | 12.7 | 11.6 | 18.1 | 30.7 |

| CAPEX | 126.6 | 115.9 | 180.8 | 306.8 |

Appendix F. OPEX Results

| Base | Case 2 | Case 3 | Case 4 | |

|---|---|---|---|---|

| Fixed Charge | 2.73 | 2.50 | 3.91 | 6.63 |

| Local taxes | 1.82 | 1.67 | 2.60 | 4.42 |

| Insurance | 0.91 | 0.83 | 1.30 | 2.21 |

| Direct Production Cost | 27.0 | 25.8 | 41.7 | 29.7 |

| Cooling Water | 0.63 | 0.62 | 1.02 | 1.24 |

| Coal | 0.00 | 0.00 | 15.91 | 24.20 |

| Steam | 9.88 | 9.43 | 0.00 | 0.00 |

| Electricity | 8.40 | 8.09 | 13.97 | −11.90 * |

| MEA Make Up | 1.09 | 1.08 | 1.90 | 2.05 |

| Limestone | 0.03 | 0.02 | 0.04 | 0.05 |

| Ammonia | 0.37 | 0.37 | 0.37 | 0.37 |

| SCR Catalyst | 1.19 | 1.19 | 1.19 | 1.19 |

| Activated Carbon | 0.19 | 0.19 | 0.33 | 0.36 |

| Maintenance (M) | 3.65 | 3.34 | 5.21 | 8.84 |

| Operating Labor (OL) | 0.72 | 0.72 | 0.72 | 1.44 |

| Supervision and Support Labor | 0.22 | 0.22 | 0.22 | 0.43 |

| Operating Supplies | 0.55 | 0.50 | 0.78 | 1.33 |

| Laboratory Charges | 0.07 | 0.07 | 0.07 | 0.14 |

| Plant Overhead Cost | 2.75 | 2.57 | 3.69 | 6.42 |

| General Expenses | 2.00 | 1.91 | 2.99 | 2.72 |

| Administrative Cost | 0.11 | 0.11 | 0.11 | 0.22 |

| Distribution and Marketing | 0.17 | 0.16 | 0.26 | 0.23 |

| R&D Cost | 1.72 | 1.64 | 2.62 | 2.27 |

| OPEX | 34.46 | 32.83 | 52.31 | 45.50 |

References

- Federal Ministry for the Environment, Nature Conservation, Building and Nuclear Safety (BMUB). Climate Action Plan 2050—Principles and Goal of the German Government’s Policy. 2016. Available online: https://www.bmu.de/fileadmin/Daten_BMU/Pools/Broschueren/klimaschutzplan_2050_en_bf.pdf (accessed on 18 April 2019).

- Robinius, M.; Otto, A.; Heuser, P.; Welder, L.; Syranidis, K.; Ryberg, D.; Grube, T.; Markewitz, P.; Peters, R. Linking the Power and Transport Sectors—Part 1: The Principle of Sector Coupling. Energies 2017, 10, 957. [Google Scholar] [CrossRef]

- Otto, A.; Robinius, M.; Grube, T.; Schiebahn, S.; Praktiknjo, A.; Stolten, D. Power-to-Steel: Reducing CO2 through the Integration of Renewable Energy and Hydrogen into the German Steel Industry. Energies 2017, 10, 451. [Google Scholar] [CrossRef]

- Andrew, R.M. Global CO2 emissions from cement production. Earth Syst. Sci. Data 2018, 10, 195–217. [Google Scholar] [CrossRef]

- Le Quere, C.; Andrew, R.M.; Friedlingstein, P.; Sitch, S.; Hauck, J.; Pongratz, J.; Pickers, P.; Korsbakken, J.I.; Peters, G.P.; Canadell, J.G.; et al. Global Carbon Budget 2018. Earth Syst. Sci. Data 2018, 10, 2141–2194. [Google Scholar] [CrossRef] [Green Version]

- Deutsche Emissionshandelsstelle (DEHSt). Treibhausgasemissionen 2017—Emissionshandelspflichtige Stationäre Anlagen und Luftverkehr in Deutschland (VET-Bericht 2017). 2018. Available online: https://www.dehst.de/SharedDocs/downloads/DE/publikationen/VET-Bericht-2017.pdf?__blob=publicationFile&v=5 (accessed on 5 August 2018).

- Verein Deutscher Zementwerke (VDZ). Zementindustrie im Überblick 2017/2018. Berlin, 2017. Available online: https://www.vdz-online.de/fileadmin/gruppen/vdz/3LiteraturRecherche/Zementindustie_im_Ueberblick/VDZ_Zementindustrie_im_Ueberblick_2017_2018.pdf (accessed on 17 April 2019).

- Ishak, S.A.; Hashim, H. Low carbon measures for cement plant—A review. J. Clean. Prod. 2015, 103, 260–274. [Google Scholar] [CrossRef]

- Verband Deutscher Zementindustrie (VDZ). Environmental Data of the German Cement Industry 2016; VDZ: Düsseldorf, Germany, 2017; Available online: https://www.vdz-online.de/en/latest-news/press-releases-detail/news/environmental-data-of-the-german-cement-industry-2016-high-investments-in-environmental-protection/cobj/20680/ (accessed on 23 April 2019).

- BDI. Klimapfade für Deutschland. BDI, 2018. Available online: https://bdi.eu/media/publikationen/?publicationtype=Studien#/publikation/news/klimapfade-fuer-deutschland/ (accessed on 29 April 2019).

- dena. dena-Leitstudie—Integrierte Energiewende. Deutsche Energieagentur(dena), 2018. Available online: https://www.dena.de/newsroom/publikationsdetailansicht/pub/dena-leitstudie-integrierte-energiewende-ergebnisbericht/ (accessed on 28 April 2019).

- Pfluger, B.; Tersteegen, B.; Franke, B. Langfristszenarien für die Transformation des Energiesystems in Deutschland—Modul 3: Referenzszenario und Basisszenario, Studie im Auftrag des Bundesministeriums für Wirtschaft und Energie. September 2017. Available online: https://www.bmwi.de/Redaktion/DE/Downloads/B/berichtsmodul-3-referenzszenario-und-basisszenario.pdf?_blob=publicationFile&v=4 (accessed on 27 April 2019).

- Billig, E.; Decker, M.; Benzinger, W.; Ketelsen, F.; Pfeifer, P.; Peters, R.; Stolten, D.; Thrän, D. Non-fossil CO2 recycling—The technical potential for the present and future utilization for fuels in Germany. J. CO2 Utilizat. 2019, 30, 130–141. [Google Scholar] [CrossRef]

- Otto, A.; Grube, T.; Schiebahn, S.; Stolten, D. Closing the loop: Captured CO2 as a feedstock in the chemical industry. Energy Environ. Sci. 2015, 8, 3283–3297. [Google Scholar] [CrossRef]

- Naims, H. Economics of carbon dioxide capture and utilization-a supply and demand perspective. Environ. Sci. Pollut. Res. Int. 2016, 23, 22226–22241. [Google Scholar] [CrossRef]

- Schorcht, F.; Kourti, I.; Scalet, B.M.; Roudier, S.; Sancho, L.G. Best Available Techniques (BAT) Reference Document for the Production of Cement, Lime and Magnesium Oxide—Industrial Emissions Directive 2010/75/EU. 2013. Available online: http://eippcb.jrc.ec.europa.eu/reference/BREF/CLM_Published_def.pdf (accessed on 28 April 2019). [CrossRef]

- VDZ. Zement-Taschenbuch 2002; Verlag Bau+Technik: Düsseldorf, Germany, 2002. [Google Scholar]

- IEAGHG. CO2 Capture in the Cement Industry—Technical Study Report Number: 2008/3. IEA Greenhouse Gas R&D Programme (IEAGHG), 2008. Available online: https://ieaghg.org/docs/General_Docs/Reports/2008-3.pdf (accessed on 17 April 2019).

- CEMCAP. CO2 Capture from Cement Production. D 8.1 Status Report on Calciner Technology Revision 2. 2016. Available online: https://www.sintef.no/globalassets/sintef-energi/cemcap/d8.1-cemcap-deliverable-8_1_rev2.pdf (accessed on 18 April 2019).

- CEMCAP. CO2 Capture from Cement Production. D3.2 CEMCAP Framework for Comparative Techno-Economic Analysis of CO2 Capture from Cement Plants. 2017. Available online: https://www.sintef.no/globalassets/sintef-energi/cemcap/d3.2-cemcap-framework-for-comparative-techno-economic-analysis-of-co2-capture-from-cement-plants_.pdf (accessed on 17 April 2019).

- Verband der Deutschen Zementindustrie (VDZ). Wichtige Daten auf einen Blick. Available online: https://www.vdz-online.de/publikationen/zahlen-und-daten/a-wichtige-daten-auf-einen-blick/ (accessed on 28 April 2019).

- Cement Sustainibility Initiative (CSI). Getting the Numbers Right GNR-Project. 2019. Available online: https://www.wbcsdcement.org/GNR-2016/ (accessed on 17 April 2019).

- CEMCAP. CO2 Capture from Cement Production. D4.2 Design and Performance of CEMCAP Cement Plant with MEA Post Combustion Capture. 2016. Available online: https://www.sintef.no/globalassets/sintef-energi/cemcap/d4.2-design-and-performance-of-cemcap-cement-plant-with-mea-post-combustion-capture_rev1~1.pdf (accessed on 17 April 2019).

- CEMCAP. CO2 Capture from Cement Production. Design and Performance of CEMCAP Cement Plant without CO2 Capture. 2016. Available online: https://www.sintef.no/globalassets/sintef-energi/cemcap/d4.1-cemcap-cement-plant-without-co2-capture_rev2.pdf (accessed on 18 April 2019).

- CEMCAP. CEMCAP Framework for Comparative Techno-Economic Analysis of CO2 Capture from Plants. 2018. Available online: https://www.zenodo.org/record/1257112#.XOvdev7grRa (accessed on 28 May 2019).

- Hilz, J.; Haaf, M.; Helbig, M.; Ströhle, B.; Epple, B. Calcium carbonate Looping: CO2 capture by using limestone in the cement industry. Cement Int. 2017, 15, 52–63. [Google Scholar]

- Puxty, G.; Maeder, M. The fundamentals of post-combustion capture. In Absorption-Based Post-Combustion Capture of Carbon Dioxide; Feron, P.H.M., Ed.; Elsevier Woodhead Publishing: Heidelberg, Germany, 2016; pp. 13–33. [Google Scholar]

- Roussanaly, S.; Fu, C.; Voldsund, M.; Anantharaman, R.; Spinelli, M.; Romano, M. Techno-economic Analysis of MEA CO2 Capture from a Cement Kiln—Impact of Steam Supply Scenario. Energy Procedia 2017, 114, 6229–6239. [Google Scholar] [CrossRef]

- Hassan, S.M.N. Techno-Economic Study of CO2 Capture Process for Cement Plants; University of Waterloo: Waterloo, ON, Canada, 2005; Available online: http://hdl.handle.net/10012/925 (accessed on 18 April 2019).

- Barker, D.J.; Turner, S.A.; Napier-Moore, P.A.; Clark, M.; Davison, J.E. CO2 Capture in the Cement Industry. Energy Procedia 2009, 1, 87–94. [Google Scholar] [CrossRef]

- Kuramochi, T.; Ramírez, A.; Turkenburg, W.; Faaij, A. Comparative assessment of CO2 capture technologies for carbon-intensive industrial processes. Prog. Energy Combust. Sci. 2012, 38, 87–112. [Google Scholar] [CrossRef]

- Jakobsen, J.; Roussanaly, S.; Anantharaman, R. A techno-economic case study of CO2 capture, transport and storage chain from a cement plant in Norway. J.Clean. Prod. 2017, 144, 523–539. [Google Scholar] [CrossRef]

- Zhou, W.; Jiang, D.; Chen, D.; Griffy-Brown, C.; Jin, Y.; Zhu, B. Capturing CO2 from cement plants: A priority for reducing CO2 emissions in China. Energy 2016, 106, 464–474. [Google Scholar] [CrossRef]

- Ho, M.T.; Allinson, G.W.; Wiley, D.E. Comparison of MEA capture cost for low CO2 emissions sources in Australia. Int. J. Greenh. Gas Control 2011, 5, 49–60. [Google Scholar] [CrossRef]

- Summers, W.M.; Herron, S.E.; Zoelle, A. Cost of Capturing CO2 from Industrial Sources; NETL: Albany, OR, USA, 2014.

- Atsonios, K.; Grammelis, P.; Antiohos, S.K.; Nikolopoulos, N.; Kakaras, E. Integration of calcium looping technology in existing cement plant for CO2 capture: Process modeling and technical considerations. Fuel 2015, 153, 210–223. [Google Scholar] [CrossRef]

- Bosoaga, A.; Masek, O.; Oakey, J.E. CO2 Capture Technologies for Cement Industry. Energy Procedia 2009, 1, 133–140. [Google Scholar] [CrossRef]

- IEAGHG. Deployment of CCS in the Cement Industry-Report 2013/19. 2013. Available online: https://ieaghg.org/docs/General_Docs/Reports/2013-19.pdf (accessed on 28 April 2019).

- Knudsen, J.N.; Bade, O.M.; Askestad, I.; Gorset, O.; Mejdell, T. Pilot Plant Demonstration of CO2 Capture from Cement Plant with Advanced Amine Technology. Energy Procedia 2014, 63, 6464–6475. [Google Scholar] [CrossRef]

- Abu-Zahra, M.R.M.; Niederer, J.P.M.; Feron, P.H.M.; Versteeg, G.F. CO2 capture from power plants. Int. J. Greenh. Gas Control 2007, 1, 135–142. [Google Scholar] [CrossRef]

- Smith, R. Chemical Process Design and Integration, 2nd ed.; Wiley: Chichester, UK, 2016; p. XXIII. 896p. [Google Scholar]

- Economic Indicators. Chemical Engineering Plant Cost Index (CEPCI); ChemEngOnline, 2017; p. 80. Available online: https://de.scribd.com/document/352561651/CEPCI-June-2017-Issue (accessed on 18 April 2019).

- Peters, M.S.; Timmerhaus, K.D.; West, R.E. Plant Design and Economics for Chemical Engineers, 5th ed.; McGraw-Hill: Boston, MA, USA, 2004; p. XVII. 988p. [Google Scholar]

- EPA. The Social Cost of Carbon. EPA, 2017. Available online: https://19january2017snapshot.epa.gov/climatechange/social-cost-carbon_.html, (accessed on 15 May 2019).

- Pezzey, J.C.V. Why the social cost of carbon will always be disputed. Wiley Interdiscip. Rev. Clim. Chang. 2019, 10, e558. [Google Scholar] [CrossRef]

- Pindyck, R.S. Climate Change Policy: What Do the Models Tell Us? J. Econ. Lit. 2013, 51, 860–872. [Google Scholar] [CrossRef]

- Howarth, R.B.; Gerst, M.D.; Borsuk, M.E. Risk mitigation and the social cost of carbon. Glob. Environ. Chang. 2014, 24, 123–131. [Google Scholar] [CrossRef]

- Stilglitz, J.E.; Stern, N.; Duan, M.; Edenhofer, O.; Giraud, G.; Heal, G.; la Rovere, E.; Moris, A.; Moyer, E.; Pangestu, M.; et al. Report on the High-Level Comission on Carbon Prices. 2017. Available online: https://www.carbonpricingleadership.org/report-of-the-highlevel-commission-on-carbon-prices (accessed on 20 May 2019).

- Carattini, S.; Kallbekken, S.; Orlov, A. How to win public support for a global tax. Nature 2019, 565, 289–291. [Google Scholar] [CrossRef]

- Öko-Institut; Fraunhofer-ISI. Klimaschutzszenario 2050. 2. Endbericht. Studie im Auftrag des Bundesministeriums für Umwelt, Naturschutz, Bau und Reaktorsicherheit. 2015. Available online: https://www.oeko.de/oekodoc/2451/2015-608-de.pdf (accessed on 20 May 2019).

- UBA. Treibhausgasneutrales Deutschland im Jahr 2050; UBA: Dessau-Roßlau, Germany, 2014; Available online: http://www.umweltbundesamt.de/publikationen/treibhausgasneutrales-deutschland-im-jahr-2050-0 (accessed on 20 May 2019).

- Turton, R. Analysis, Synthesis, and Design of Chemical Processes [E-Book], 3rd ed.; Prentice Hall: Upper Saddle River, NJ, USA, 2009. [Google Scholar]

| Air Leak in Raw Mill | Medium | Low |

|---|---|---|

| Air leak in raw mill, flow rate [kg/h] | 139,806 | 69,903 |

| Total flow rate [kg/h] | 388,098 | 318,192 |

| Temperature [°C] | 110 | 130 |

| Gas composition, wet basis [mol%] | ||

| CO2 | 18 | 22 |

| N2 | 63 | 60 |

| O2 | 10 | 7 |

| H2O | 9 | 11 |

| Equation | ||

|---|---|---|

| Specific Thermal Energy Requirement | ||

| Specific Cooling Duty | ||

| Specific Compression Work | ||

| Specific Electricity Consumption |

| Symbol | Equation | ||

|---|---|---|---|

| Total Annual Costs | |||

| CO2 Avoidance | |||

| Additional CO2 Emissions | |||

| CO2 Avoidance Costs | |||

| CO2 Capture Costs | |||

| Clinker Costs |

| Parameter | Base | Case 2 | Case 3 | Case 4 |

|---|---|---|---|---|

| Flue Gas Air Leak | Medium | Low | Medium | Medium |

| Electricity Source | Import | Import | Import | Generation in CHP |

| Steam Source | Import | Import | Generation in Boiler | Generation in CHP |

| Parameter | Unit | Base | Case 2 | Case 3 | Case 4 |

|---|---|---|---|---|---|

| Heat Demand (Reboiler) | MWth | 92 | 89 | 150 | 181 |

| Electricity Demand CCUS Plant | MWel | 11.9 | 11.5 | 19.8 | 23.7 |

| Flue Gas Flow Cement | kg/h | 388,098 | 318,192 | 388,098 | 388,098 |

| Flue Gas Flow Boiler/CHP | kg/h | / | / | 243,360 | 369,878 |

| CO2 Content Boiler/CHP Flue Gas | mol% | / | / | 15.7 | 15.7 |

| CO2 Content in the Flue Gas (Cement + Boiler/CHP) | mol% | 18 | 22 | 17 | 17 |

| CO2 Capture Rate | % | 90 | 90 | 90 | 90 |

| CO2 Captured | kt/a | 728 | 722 | 1137 | 1364 |

| Specific Thermal Energy Requirement | MJth/kgCO2 | 3.6 | 3.5 | 3.8 | 3.8 |

| Specific Cooling Duty | MJth/kgCO2 | 4.3 | 4.3 | 4.5 | 4.5 |

| Specific Compression Work | MJel/kgCO2 | 0.30 | 0.30 | 0.30 | 0.29 |

| Specific Electricity Consumption | MJel/kgCO2 | 0.41 | 0.41 | 0.44 | 0.44 |

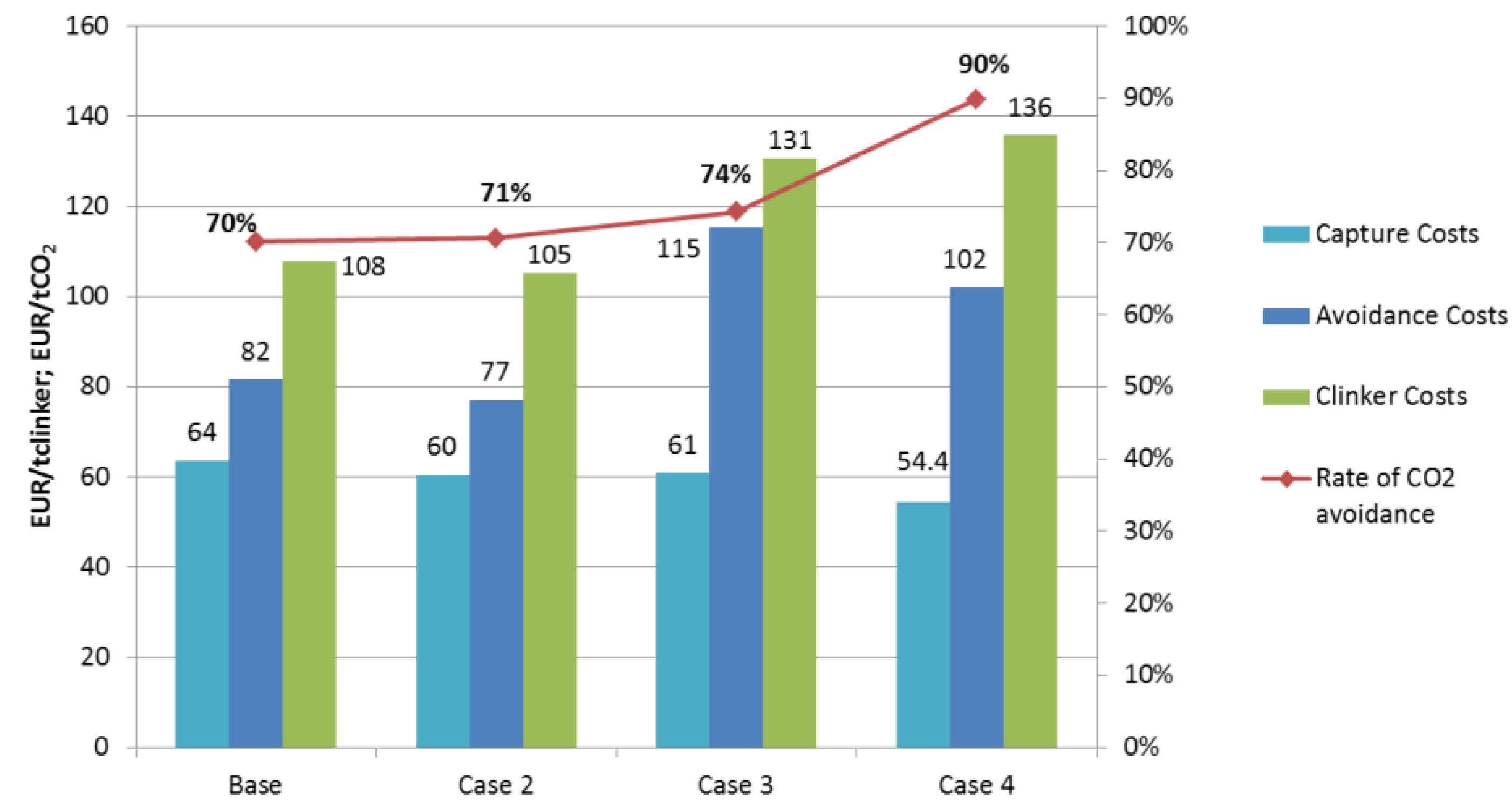

| Parameter | Unit | w/o CCS | Base | Case 2 | Case 3 | Case 4 |

|---|---|---|---|---|---|---|

| Total Annual Costs | MEUR/a | / | 46.3 | 43.7 | 69.3 | 74.2 |

| CO2 Avoidance Rate | % | / | 70 | 71 | 74 | 90 |

| CO2 Avoidance | kt/a | / | 567 | 567 | 601 | 727 |

| CO2 Capture Costs | EUR/t | / | 63.6 | 60.5 | 60.9 | 54.4 |

| CO2 Avoidance Costs | EUR/t | / | 81.7 | 77.1 | 115 | 102 |

| Clinker Costs | EUR/t | 61.7 | 108 | 105 | 131 | 136 |

| Cement Costs | EUR/t | 45.3 | 77.8 | 75.6 | 94.3 | 97.9 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Markewitz, P.; Zhao, L.; Ryssel, M.; Moumin, G.; Wang, Y.; Sattler, C.; Robinius, M.; Stolten, D. Carbon Capture for CO2 Emission Reduction in the Cement Industry in Germany. Energies 2019, 12, 2432. https://doi.org/10.3390/en12122432

Markewitz P, Zhao L, Ryssel M, Moumin G, Wang Y, Sattler C, Robinius M, Stolten D. Carbon Capture for CO2 Emission Reduction in the Cement Industry in Germany. Energies. 2019; 12(12):2432. https://doi.org/10.3390/en12122432

Chicago/Turabian StyleMarkewitz, Peter, Li Zhao, Maximilian Ryssel, Gkiokchan Moumin, Yuan Wang, Christian Sattler, Martin Robinius, and Detlef Stolten. 2019. "Carbon Capture for CO2 Emission Reduction in the Cement Industry in Germany" Energies 12, no. 12: 2432. https://doi.org/10.3390/en12122432