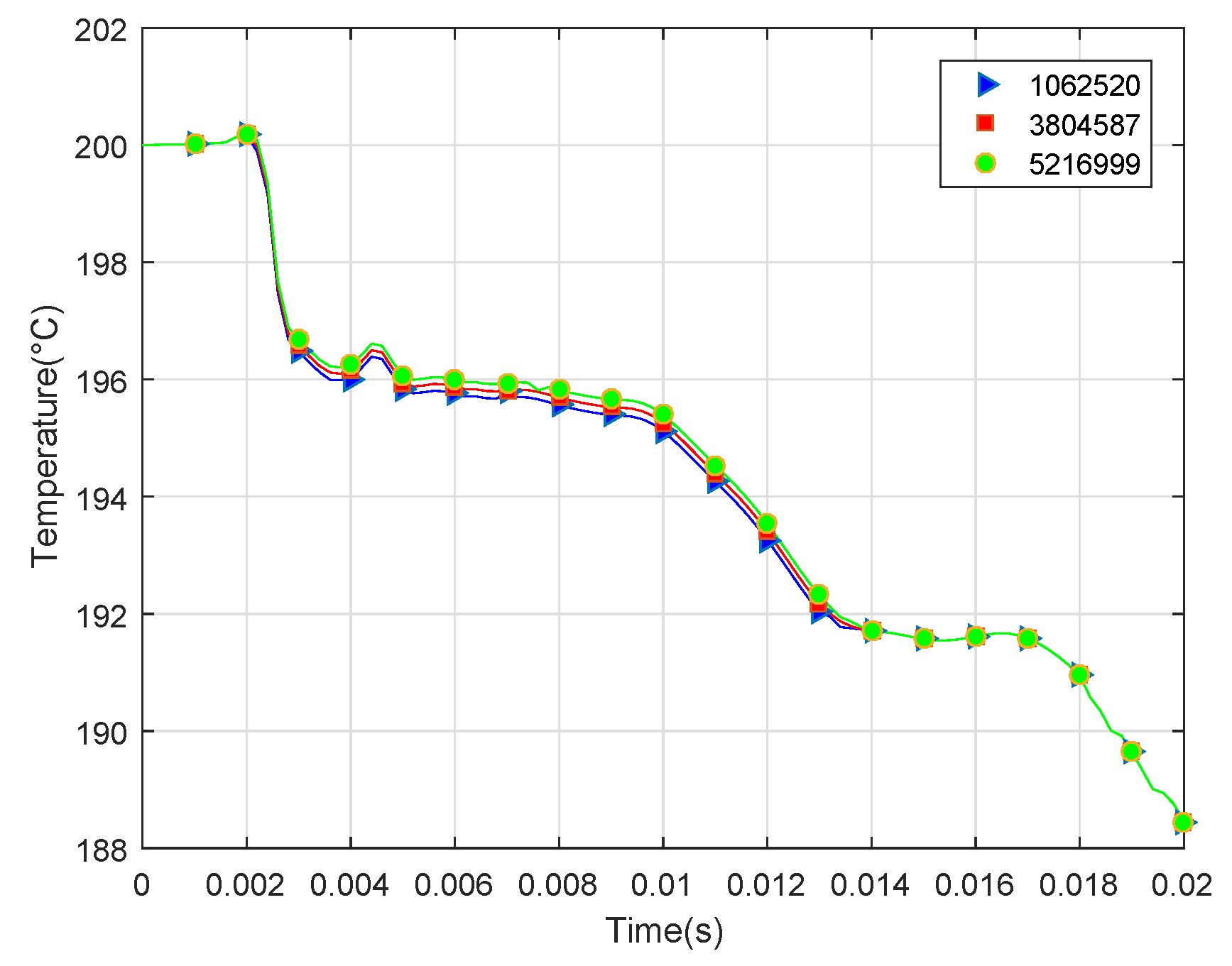

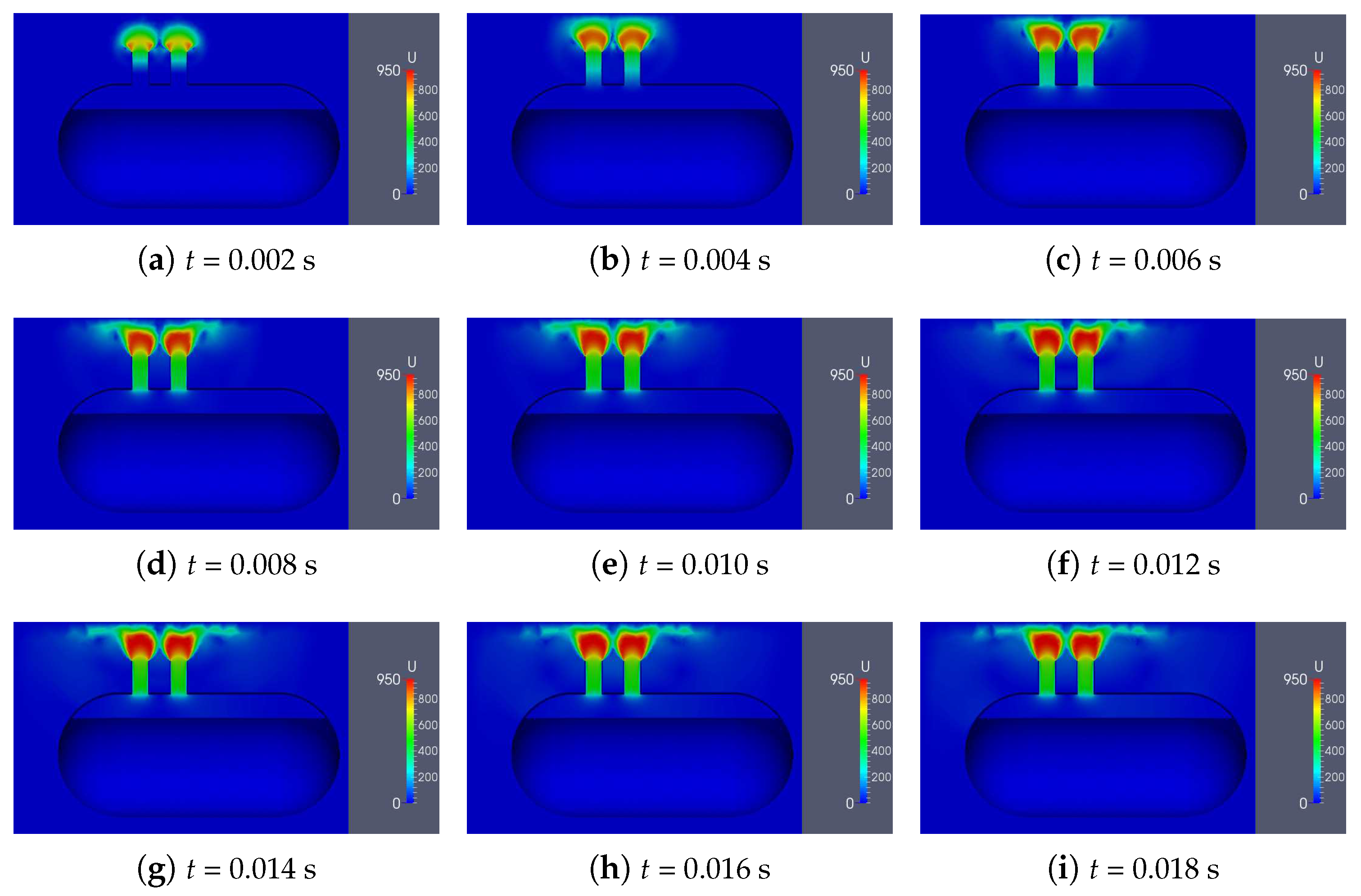

3.1. Simulation Domain and Mesh

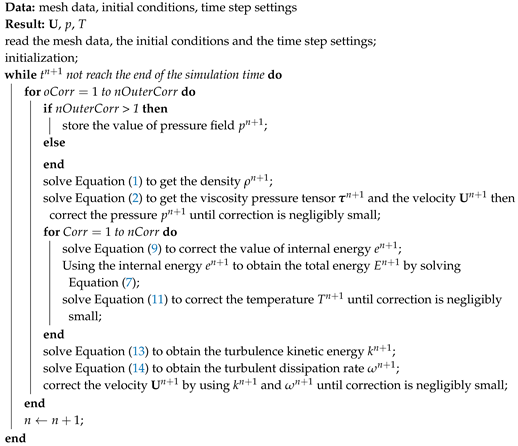

The numerical model of PRT and the shell is shown in

Figure 1; in addition, all the parameters of geometric configuration and the locations of the observation points are marked. The parameters of geometric configuration are similar to real-world building and the PRT consists of three parts: steam nozzles, air chamber, and chamber (no air). The steam nozzles are the only channel connecting PRT and interior space.

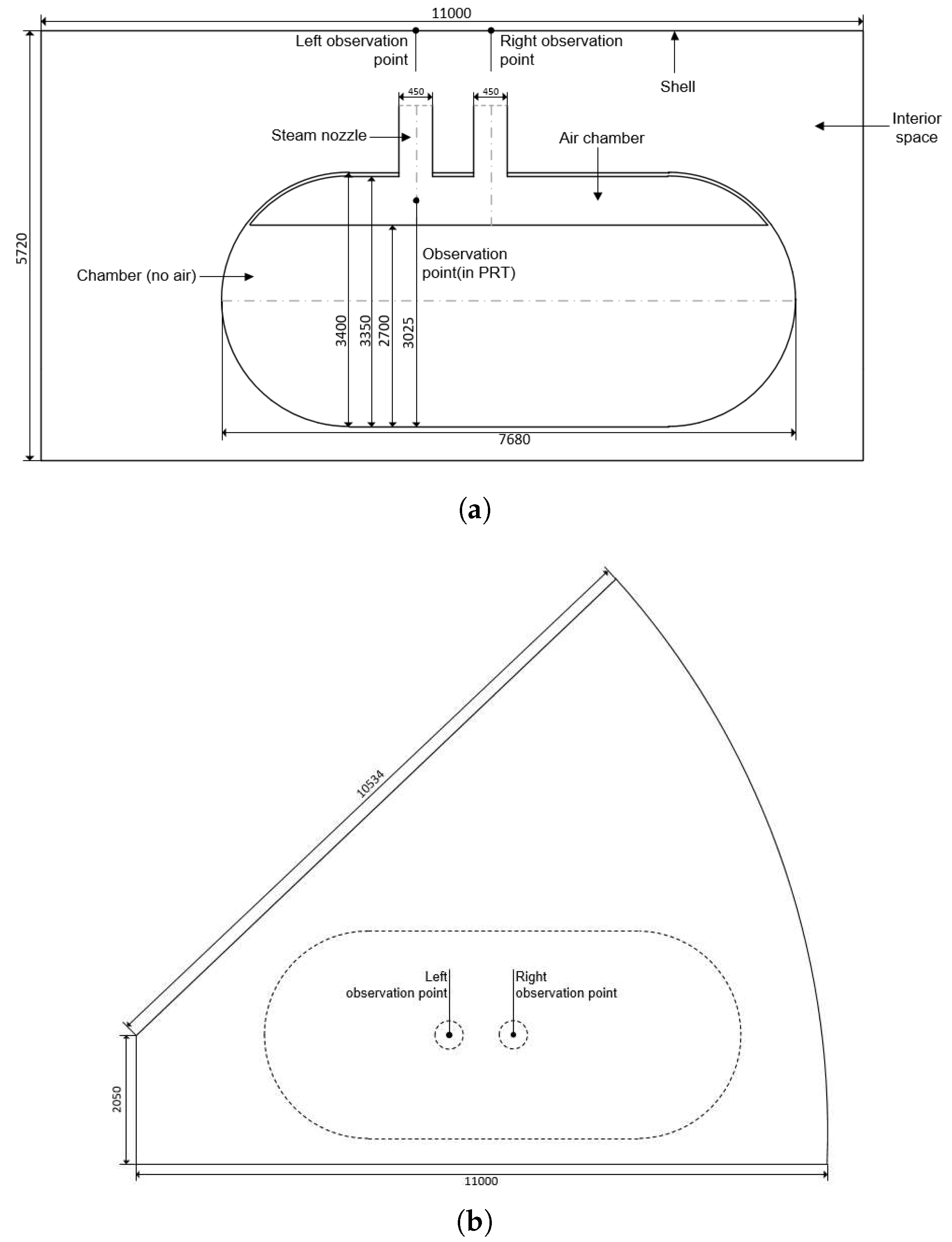

The quality and density of mesh are the vital factors of simulation accuracy and efficiency. Hybrid structured and unstructured mesh strategy are used in the meshing process. Meshes for the simulation domain are generated using ANSYS ICEM. For preserving y

at the wall, we make special refinement and use unstructured grid to reduce the generating time cost at joints, as shown in

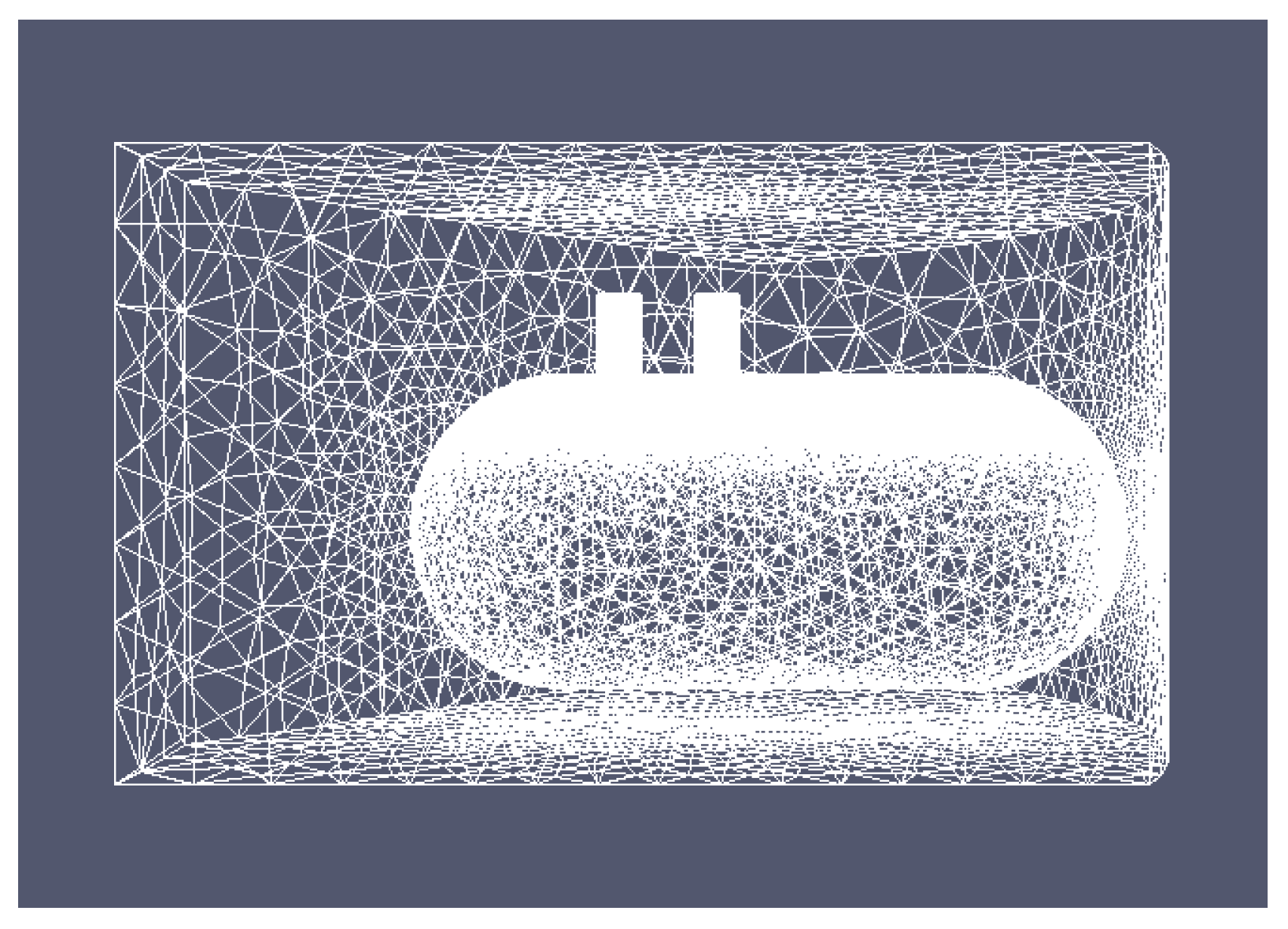

Figure 2. The overall simulation mesh is shown in

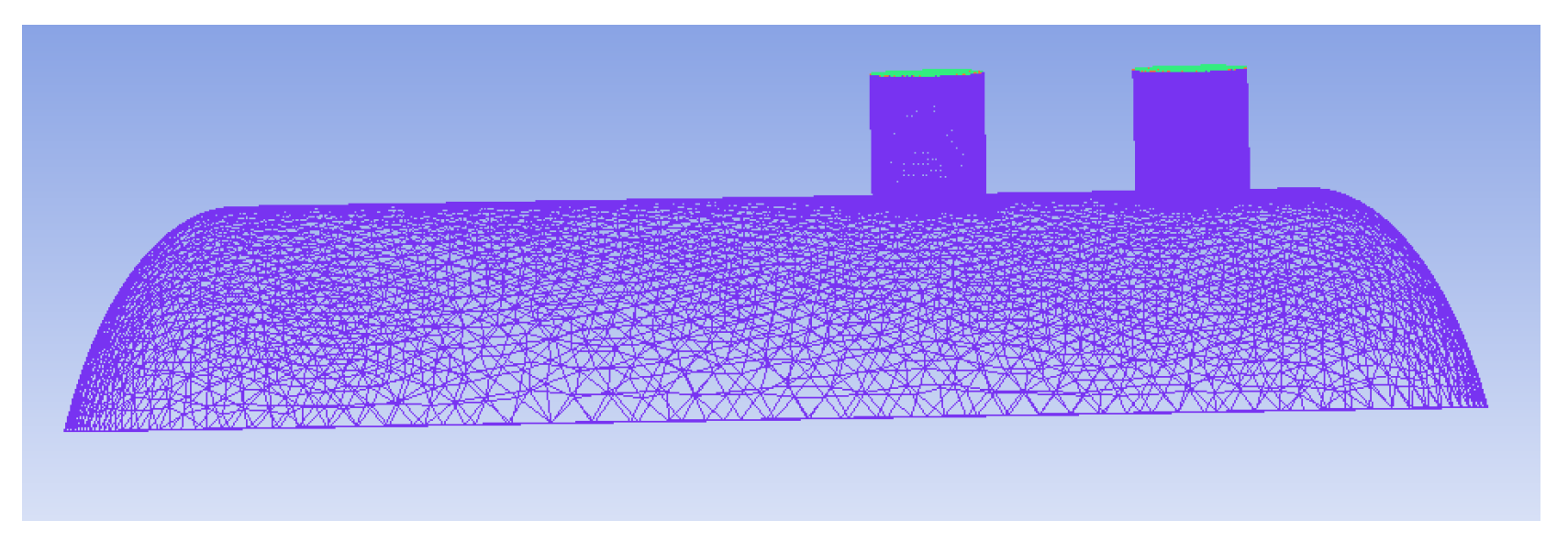

Figure 3, and the simulation mesh of air chamber is shown in

Figure 4.

Normally, a special refinement should be made at the location where the steam flow has violent changes. Successive refinement due to curvature and proximity is the key to reasonably distributing nodes along curves so as to form well shaped elements [

13]. The proximity and curvature refinement is made to solve the sector of the shell and the joints of cylinder and semicircle. The boundary layer is refined to five layers and the thickness growth rate of layer is set as 1.2. Another location we make refinement to is the joint of cylinder and vent, which is shown in

Figure 2. Actually, in this location, we use unstructured topology to accelerate the solving speed.

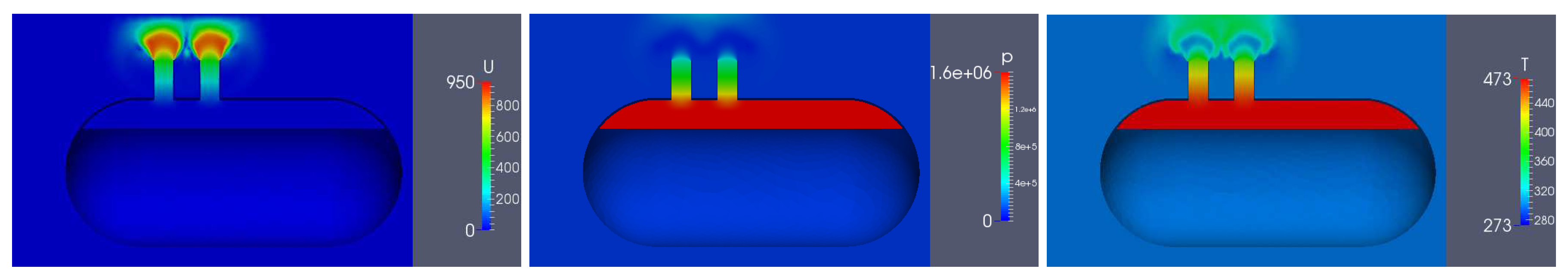

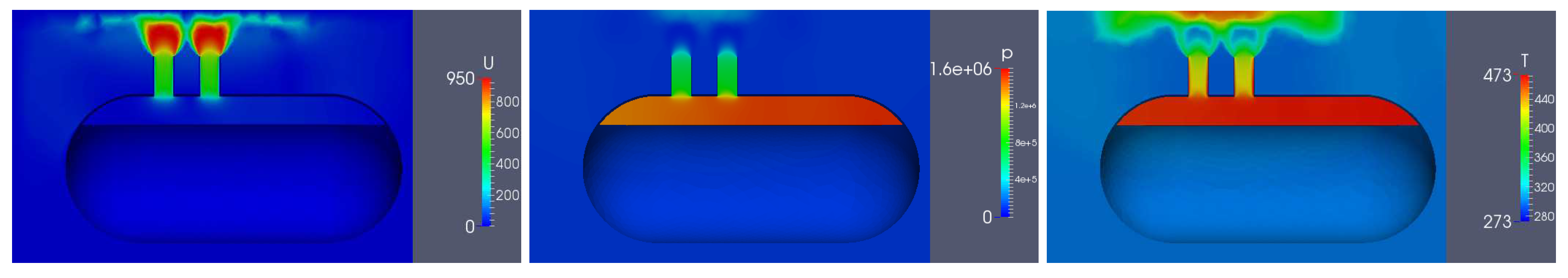

3.3. Numerical Algorithm and Scheme

The solvers in OpenFOAM have both pre- and post-processing, and it provides a variety of finite volume solvers for structured grid and unstructured gird [

14]. In order to design the solver and implement the compressible Navier–Stokes (N–S) equations, we select the PIMPLE algorithm to be implement in OpenFOAM, which is shown in Algorithm 1.

The sign of termination is the runTime to reach the endTime. Actually, there are two cycles and we input the values to nOuterCorr and nCorr. nOuterCorr is the number of pressure correction and nCorr is the number of piso algorithm solution, which is the implementation of the solution principles. Every time step, the solver will run this process.

Normally, the solution strategy is four steps, solving the velocity equation to get the velocity predicted value, using the value to correct the pressure, solving the energy conservation equation to correct the temperature, and then using pressure to correct the velocity. This strategy is used for compressible flow, incompressible flow, heat transfer and so on. The implementation is different depending on the specific object scheme.

| Algorithm 1: The iterative algorithm to solve the compressible idea gas fluid model for simulating the steam dumping process. |

![Energies 12 02276 i001]() |

Density is dynamically changed so we set the thermal setting to calculate density per unit time. The parameters of steam shown in

Table 1 are consistent with real situation.

The thermal model will help us to get the information of steam by those dynamic parameters. In the OpenFOAM file system, fvSchemes is the target file that contains the discretization schemes shown in

Table 2.

The file named fvSolution records the solver’s parameter. In addition to selecting the right solution, discrete formats have close correlation. The file content is in

Table 3.

There is no limiting conditions for density, so we choose diagonal as it is the most simple solver. Usually, time derivative and Laplace item will use the symmetric matrix to solve, but, if the convection item exists, we have to use an asymmetric matrix. Thus, PBiCG is selected for calculating pressure. Relative tolerance should be zero as tolerance is the only standard to check whether the result is accurate. For tolerance, we set the value to 1 × 10 because usually 1 × 10 is enough for normal conditions, but this may be unsteady, which is why we should set a smaller value.

Delta time is also a difficult problem we should think about. Normally, this parameter needs to follow the CFL condition (the CFL condition: the CFL condition is named after Courant, Friedrichs, and Lewy, which is that a numerical method can be convergent only if its numerical domain of dependence contains the true domain of dependence of the PDE(Partial differential equation), at least in the limit as dt and dx go to zero.) [

15]. The automatic adjustment in OpenFOAM can also help us to confirm and approach the most appropriate value of the DeltaT. As the result, we choose 5 × 10

s as the value of DeltaT. The file named controlDict records the content of running settings in

Table 4.

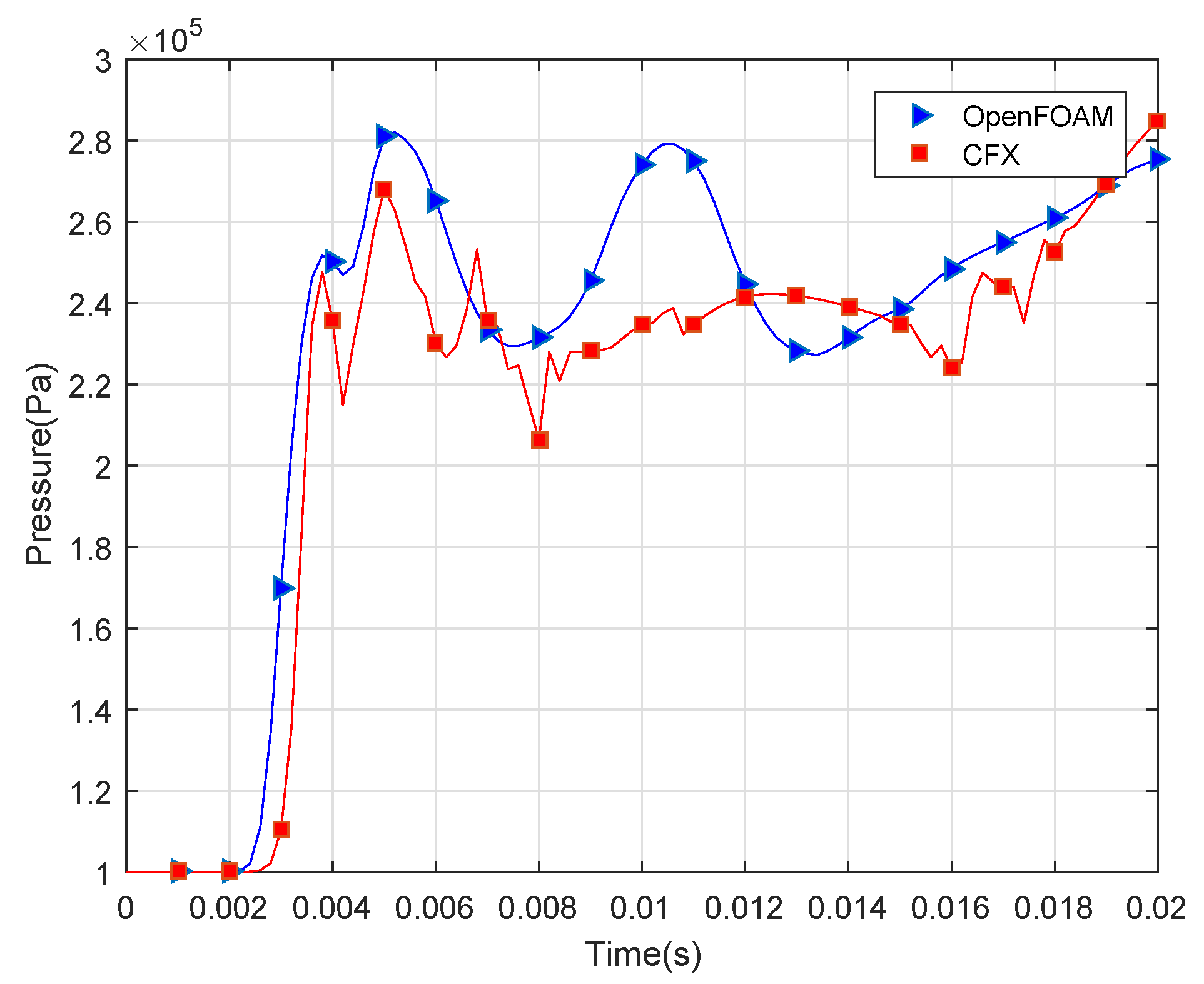

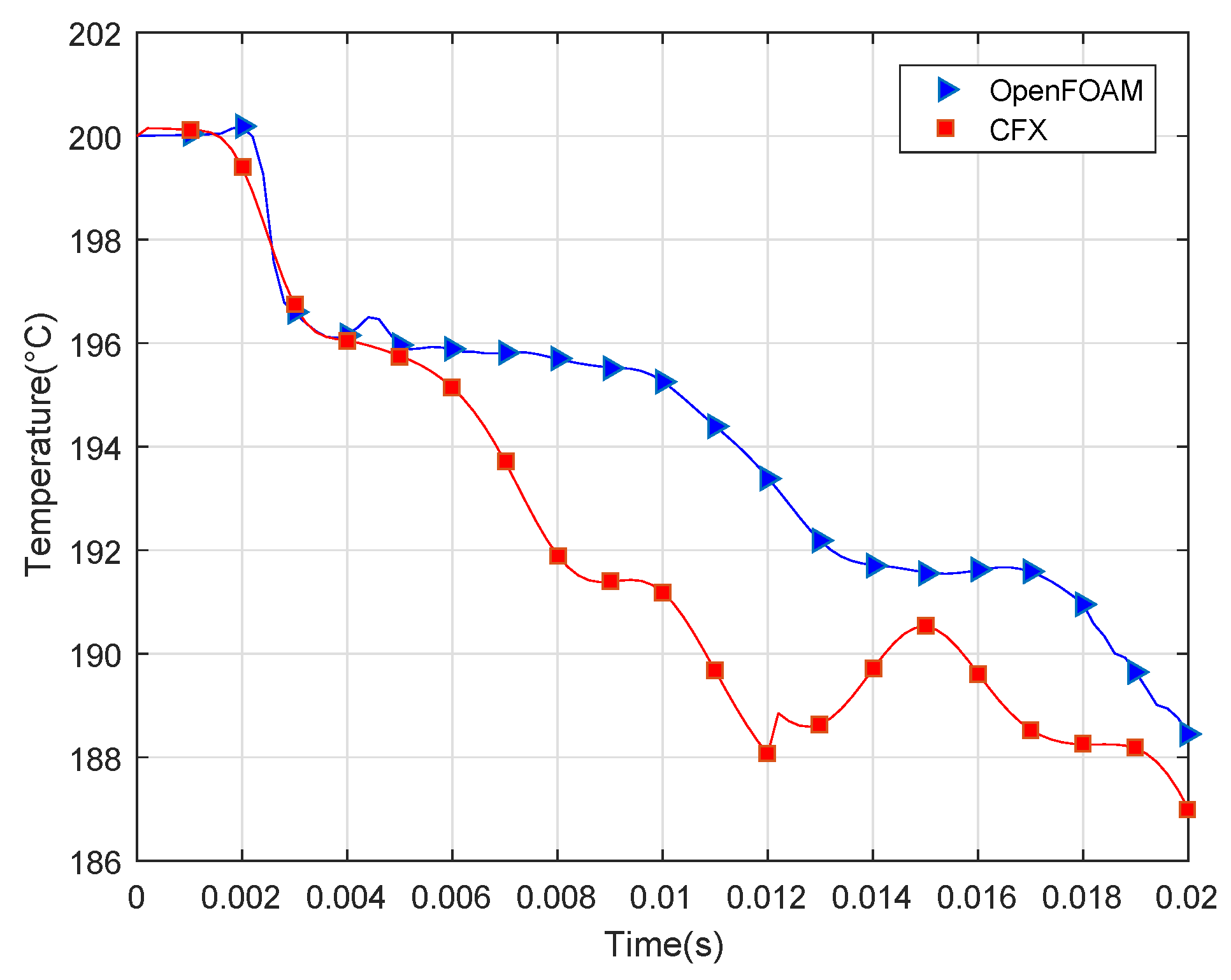

In order to make the comparison representative, the simulation in CFX is of vital significance and the similar settings and parameters are expected to reduce systematic error. As the speed is predicted to reach supersonic, the first-order upwind advection scheme is chosen for the discretization of conservation equations. The material properties including equation of state, specific heat capacity, and transport properties can be considered as a real gas model with high velocity and high temperature, which are listed in

Table 5.

The fluid models is related to heat transfer settings and turbulence model, and the details are in

Table 6.