Experimental Investigation of Static Stall Hysteresis and 3-Dimensional Flow Structures for an NREL S826 Wing Section of Finite Span

Abstract

1. Introduction

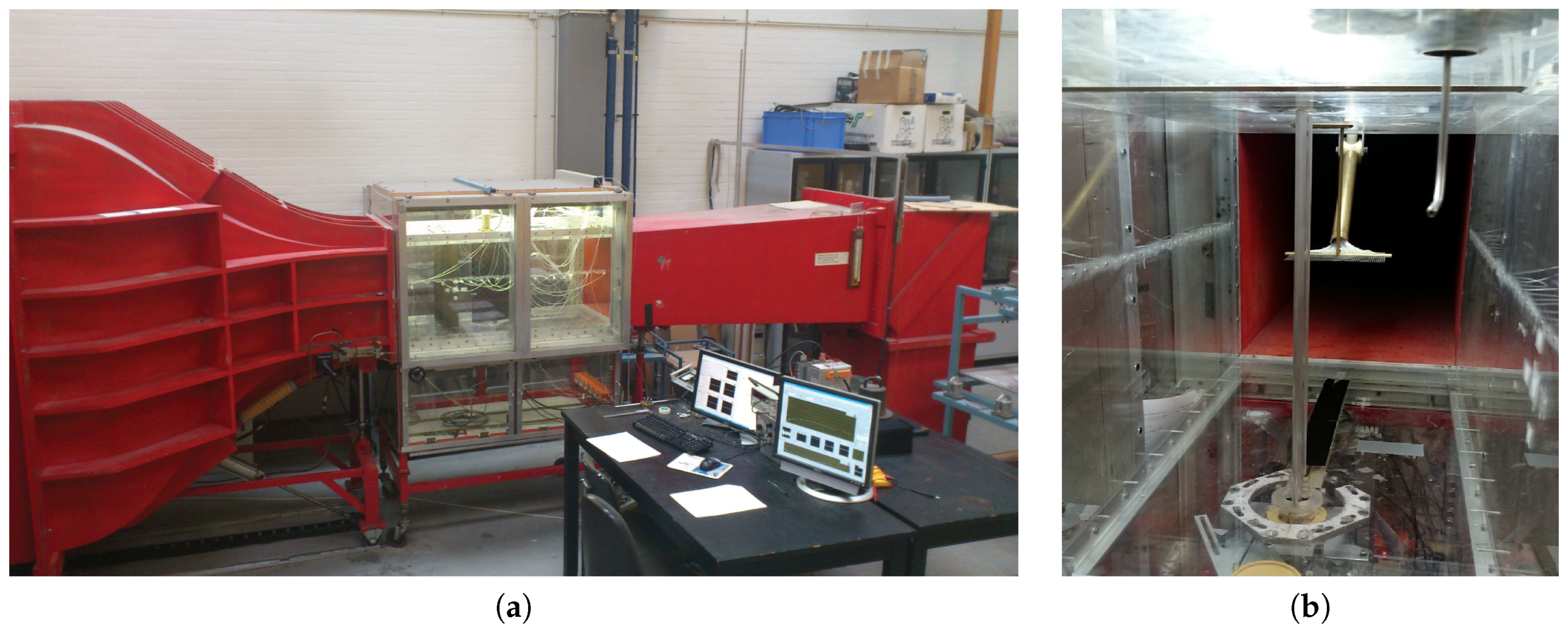

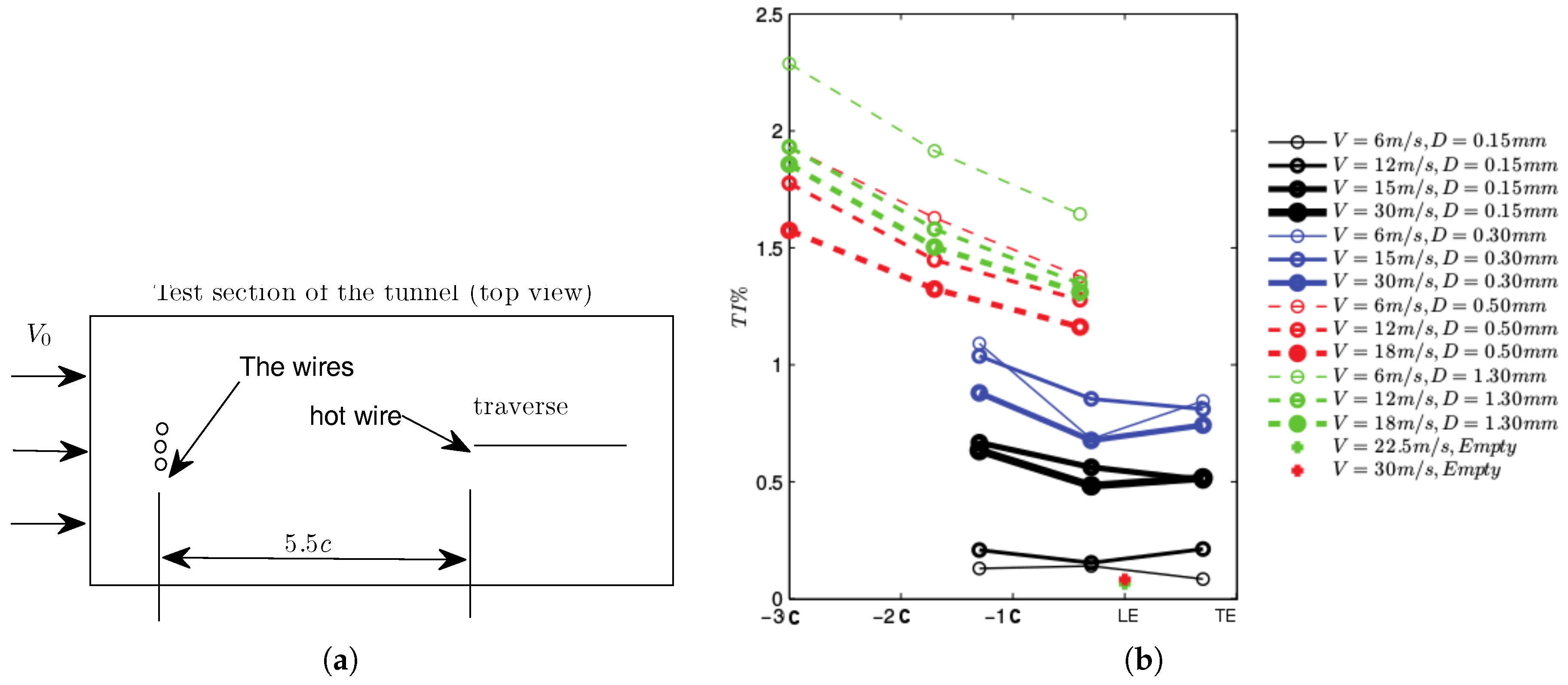

2. The Experimental Setup

3. Results and Discussions

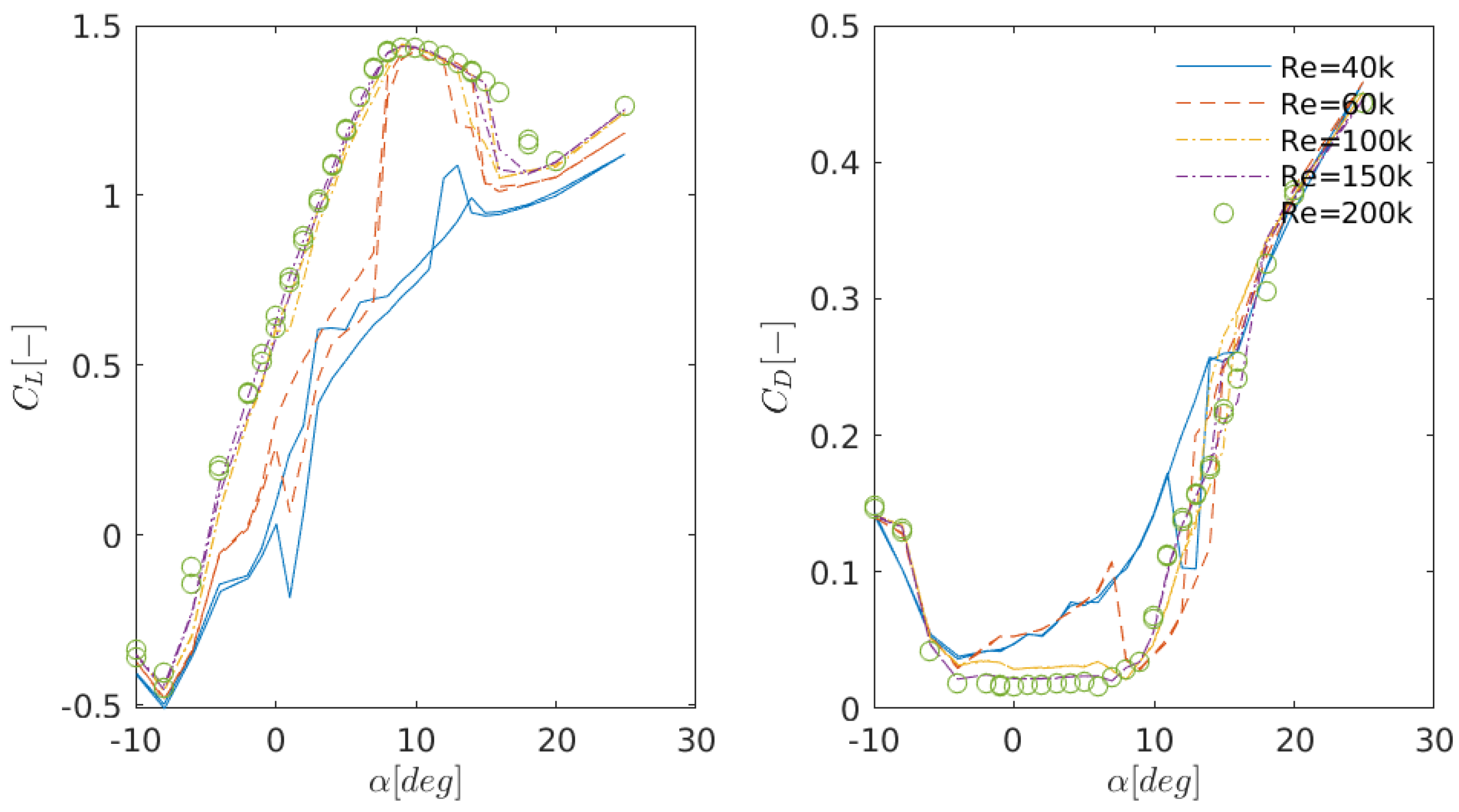

3.1. Wind Tunnel Measurement

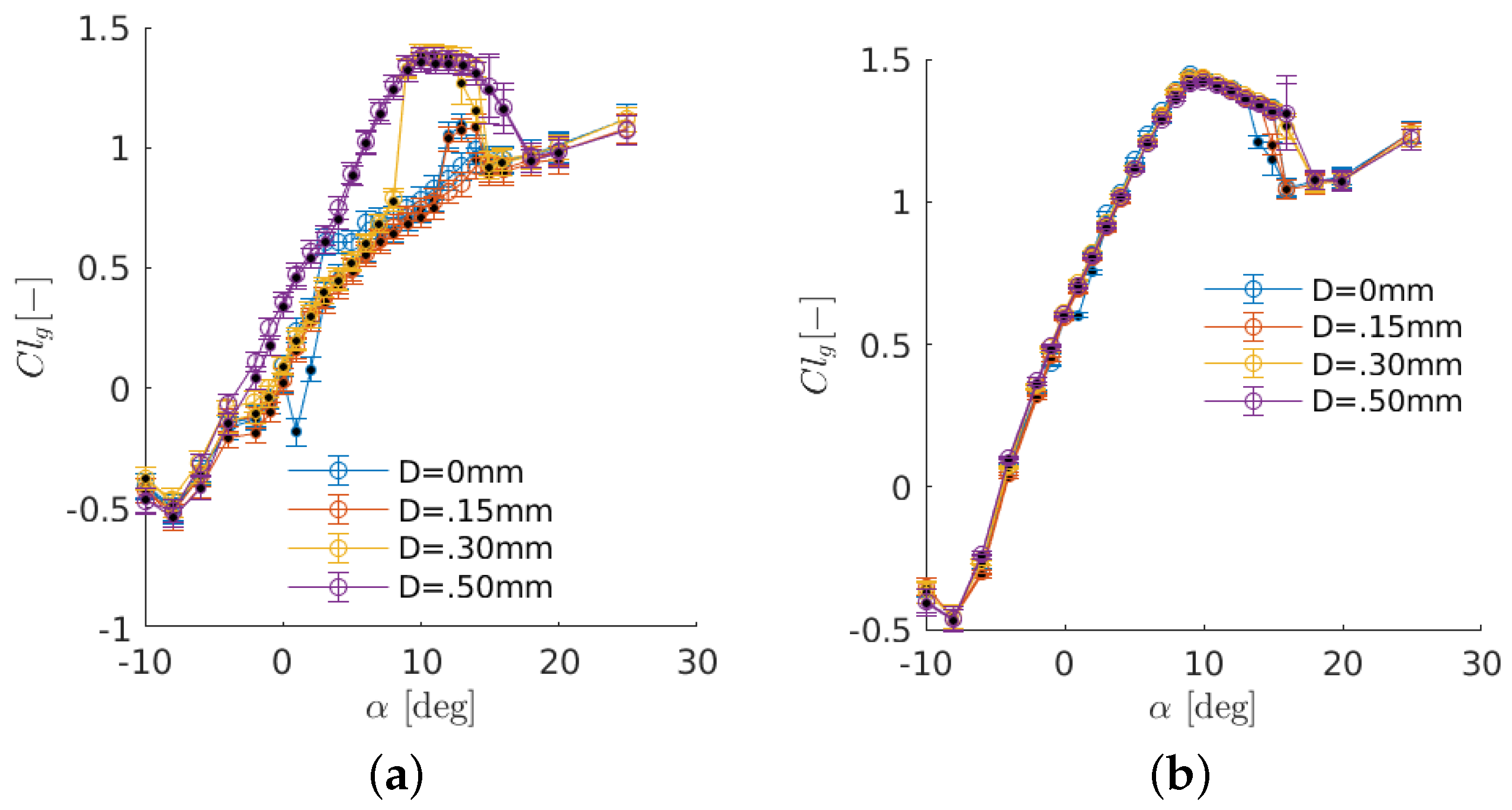

3.1.1. Polar Measurements

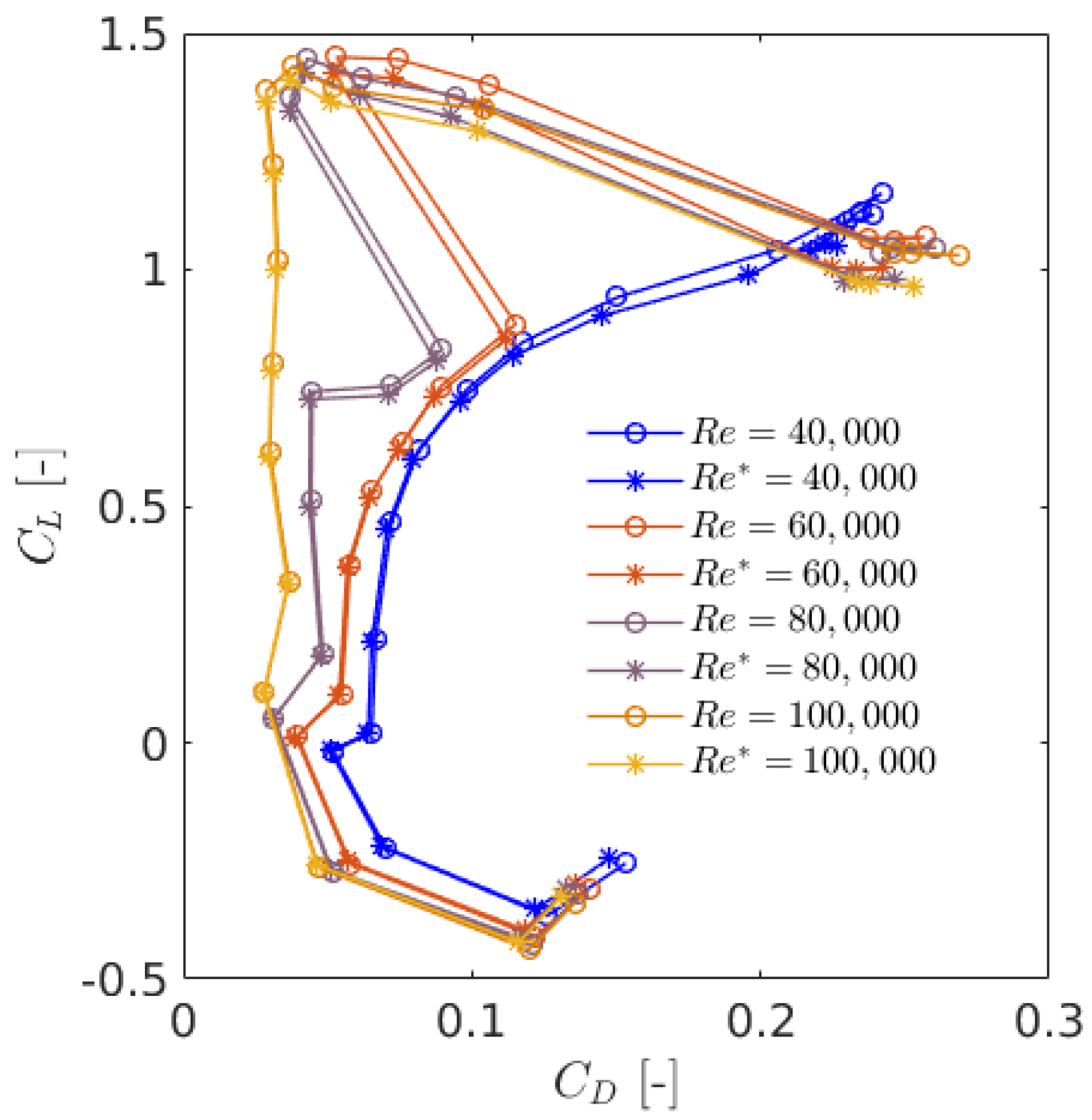

3.1.2. Wind Tunnel Correction

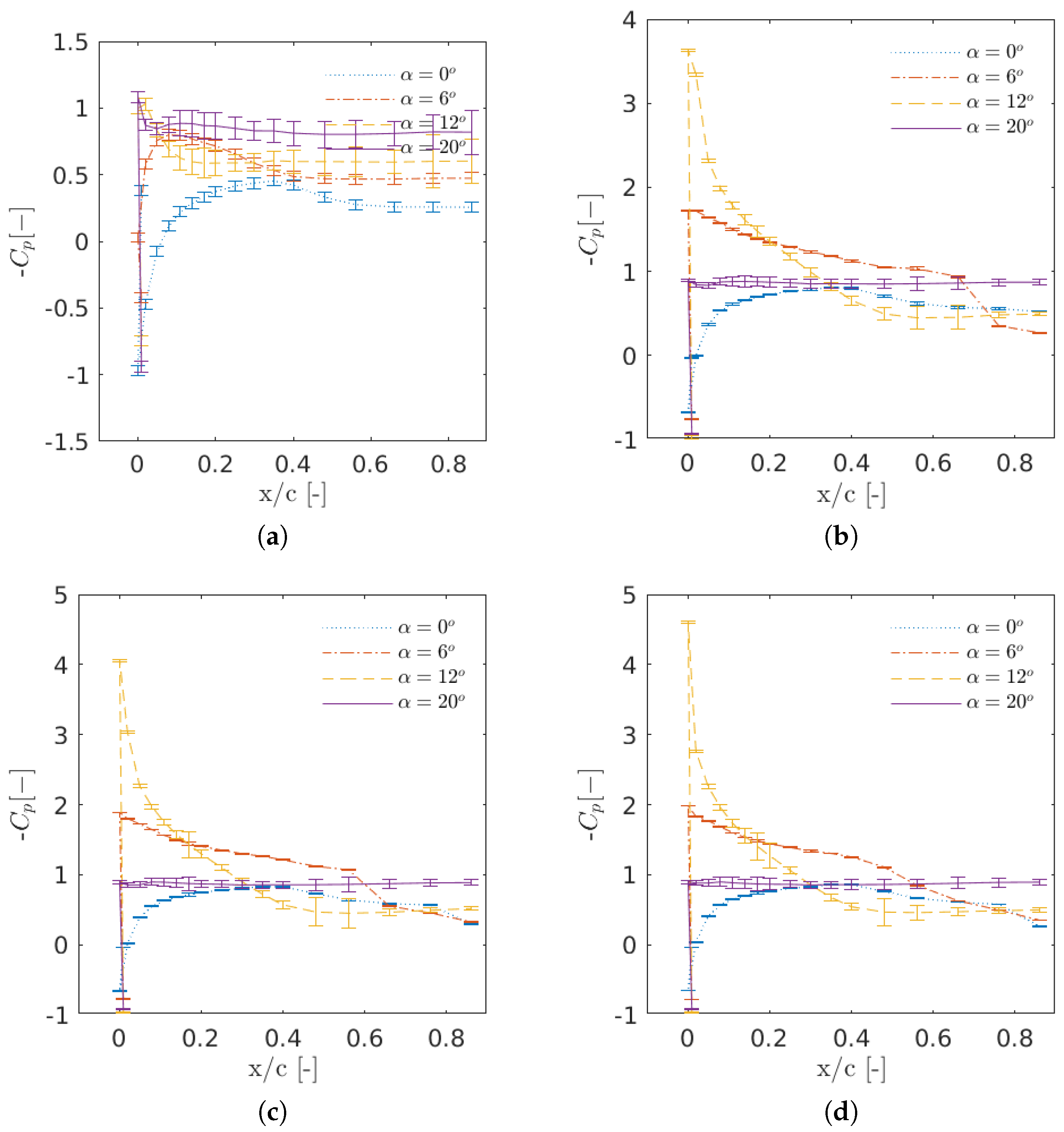

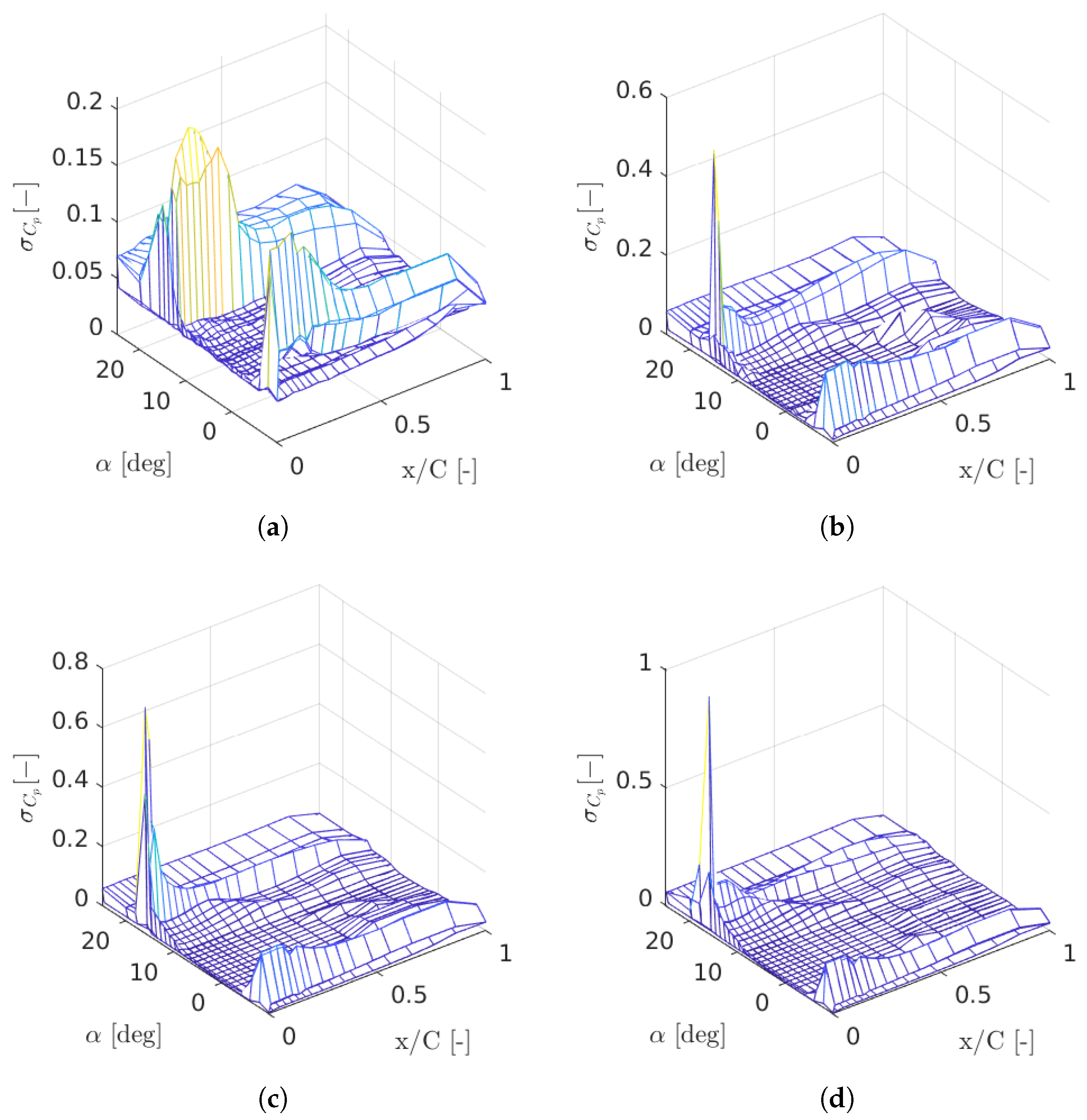

3.1.3. Pressure Distribution

3.1.4. Stall Hysteresis

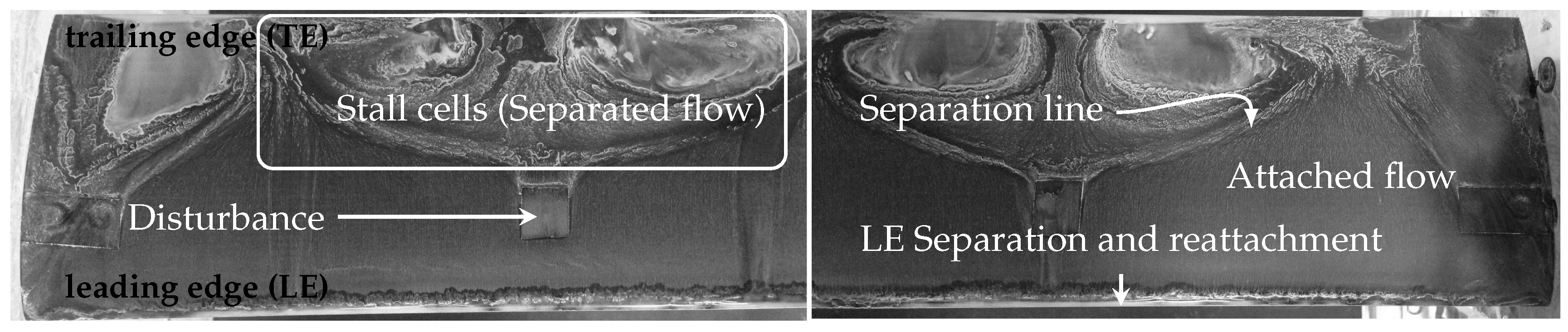

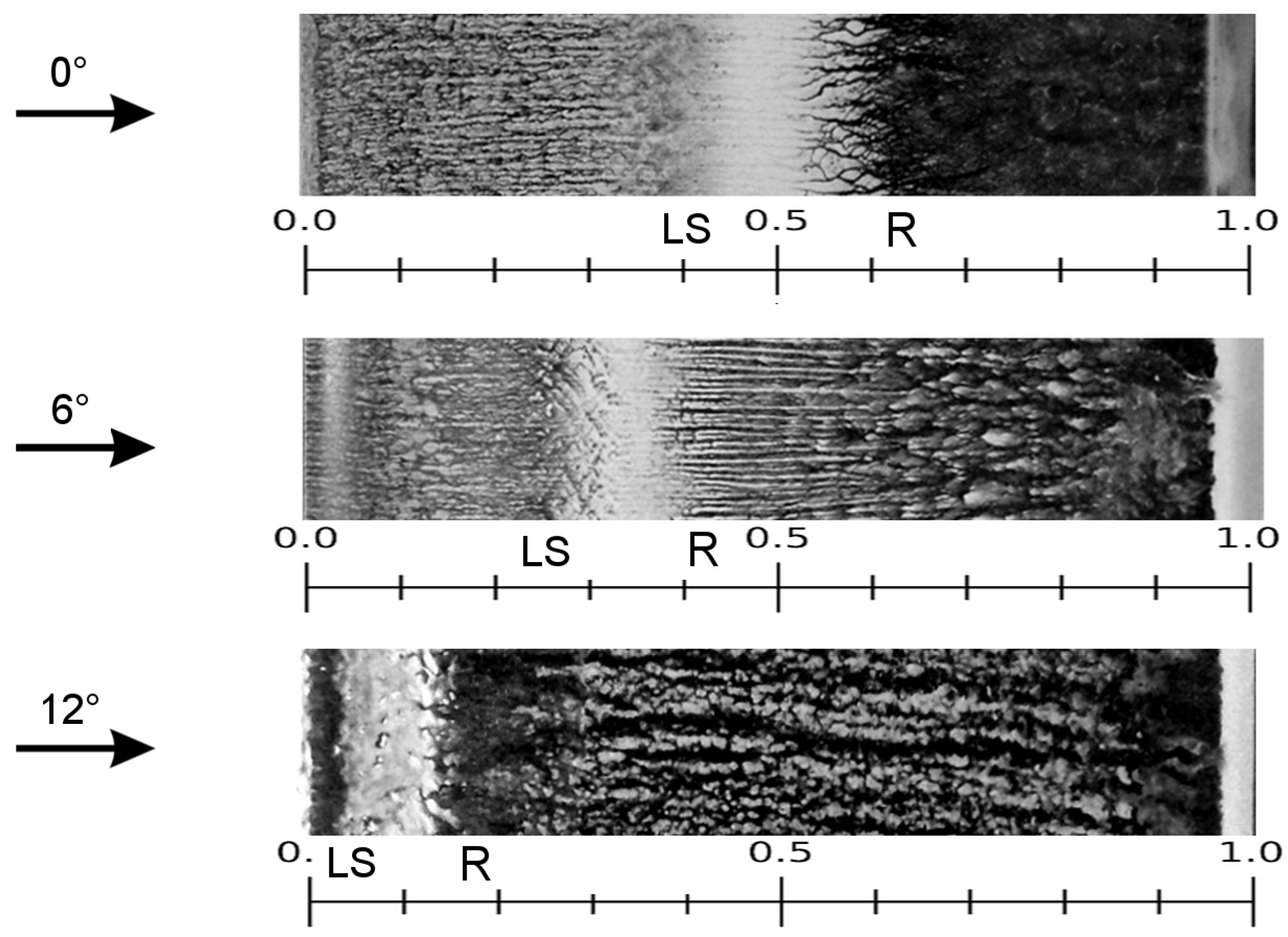

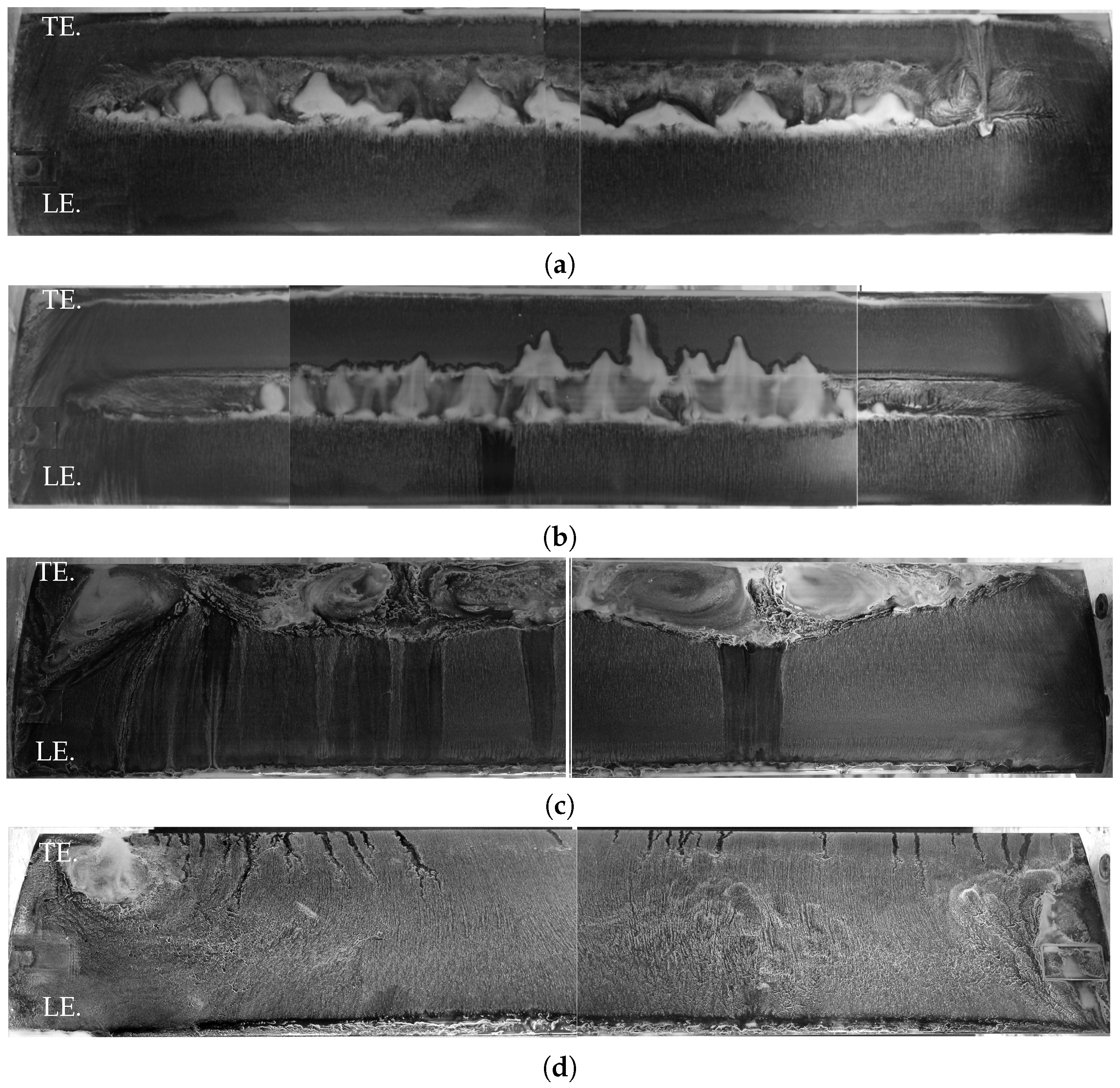

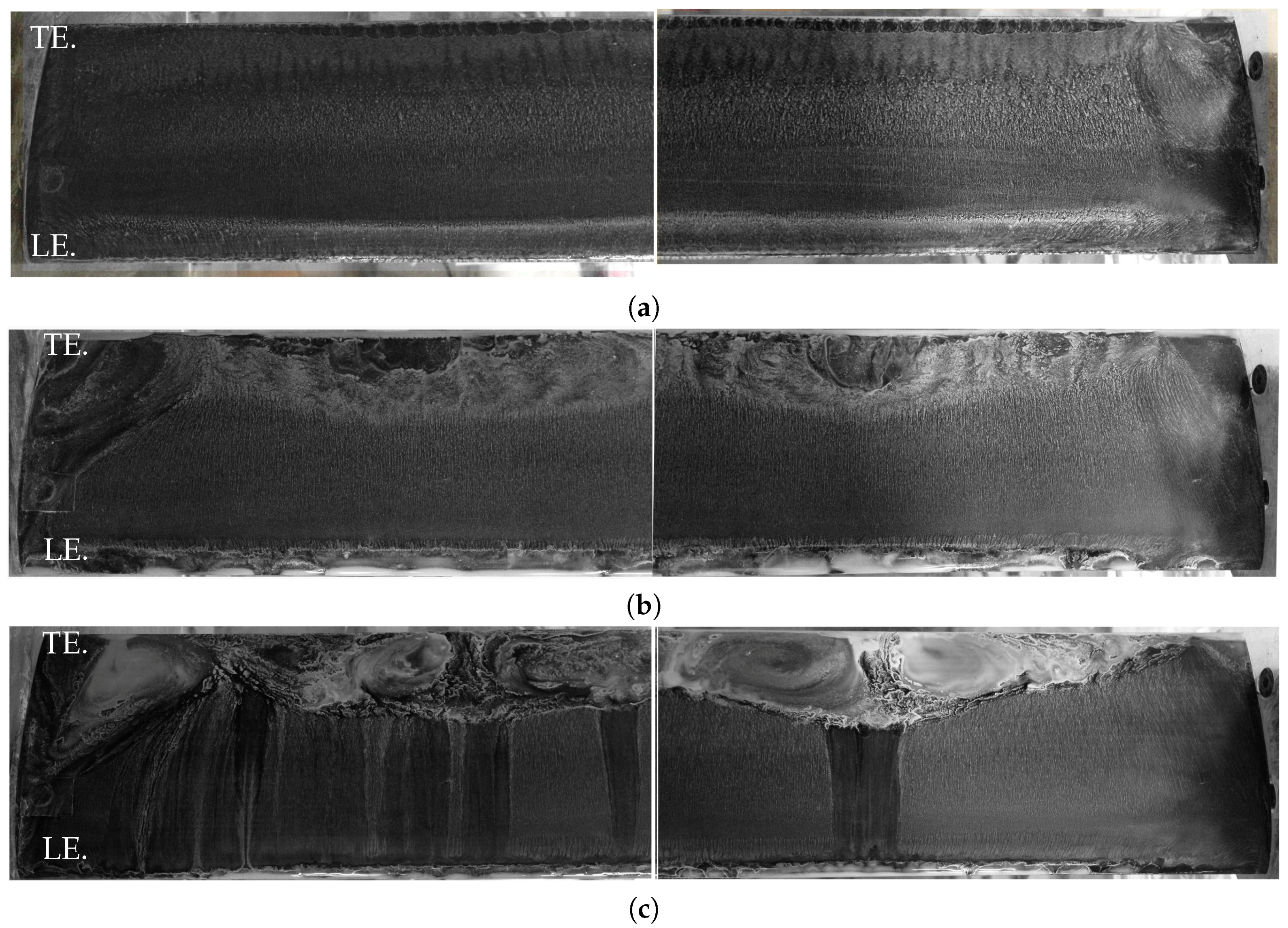

3.2. Identification of Three-Dimensional Flow over the Airfoil

Surface Oil Flow Visualization

4. Conclusions

- The NREL S826 airfoil was experimentally investigated and detailed airfoil polars, pressure distribution, as well as surface flow visualizations were documented for future use as a reference.

- It was found that the separation point moves towards the leading edge when increasing the angle of attack and Reynolds number.

- Strong hysteresis effects were observed at Reynolds numbers lower than 100,000. The characteristics of the airfoil for higher Reynolds number flows are somewhat independent of the Reynolds number.

- No stall cells were found at Re = 40,000, but it was observed that increasing the Reynolds number may result in distinct vortex pairs, which are most visible around an angle of attack , close to the stall angle.

- Through upstroke and downstroke pitching of the airfoil, static stall hysteresis was found responsible for some of the complexities of the S826 airfoil at low Reynolds numbers, and a method for removing such effects based on inflow turbulence generation was tested successfully. It was found that the hysteresis strength has an inverse relation with the Reynolds number, and the effects diminish at Re = 100,000.

- The dependence of the flow patterns on the disturbances on the airfoil surface was investigated, and it was found that the presence of surface roughness results in more distinct vortex pairs on the suction side of the airfoil. However, disturbances themselves cannot promote the formation of stall cells.

- As mentioned in the Introduction, results presented in this article will be applicable to a wide range of low Reynolds number flows such as domestic and vertical axis wind turbines. Of particular interest is, nonetheless, the importance of 3D flow aerodynamics near the blade hub where the Reynolds numbers are smaller due to low speeds. The evolution of root vortices may be affected by the flow distribution and 3D effects stemming from the formation of stall cells. The interesting flow features in the root region, which consequently may affect the evolution of tip vortices, thereby influencing the wake behind turbines, have received little attention in the past, nor have they been addressed in the present article, but these flows will be studied in future research.

Author Contributions

Acknowledgments

Conflicts of Interest

Appendix A. Lift and Drag Coefficients of the NREL S826 Airfoil for Re = 40,000–400,000.

| AoA | Lift | Drag | ||||||

|---|---|---|---|---|---|---|---|---|

| TI = 0% | TI = 0.14% | TI = 0.68% | TI = 1.37% | TI = 0% | TI = 0.14% | TI = 0.68% | TI = 1.37% | |

| −9.9 | −0.306 | −0.302 | −0.315 | −0.360 | 0.140 | 0.145 | 0.149 | 0.162 |

| −8.0 | −0.459 | −0.459 | −0.459 | −0.477 | 0.101 | 0.108 | 0.122 | 0.108 |

| −6.0 | −0.330 | −0.324 | −0.327 | −0.310 | 0.052 | 0.057 | 0.068 | 0.070 |

| −4.0 | −0.149 | −0.140 | −0.108 | −0.079 | 0.036 | 0.042 | 0.046 | 0.054 |

| −2.0 | −0.159 | −0.152 | −0.131 | 0.032 | 0.041 | 0.048 | 0.060 | 0.063 |

| −1.0 | −0.060 | −0.052 | −0.036 | 0.192 | 0.043 | 0.048 | 0.061 | 0.062 |

| −0.0 | 0.034 | 0.048 | 0.062 | 0.339 | 0.046 | 0.057 | 0.064 | 0.065 |

| 1.0 | 0.166 | 0.175 | 0.172 | 0.454 | 0.054 | 0.062 | 0.070 | 0.066 |

| 2.0 | 0.288 | 0.298 | 0.280 | 0.536 | 0.053 | 0.063 | 0.074 | 0.071 |

| 3.0 | 0.371 | 0.386 | 0.384 | 0.606 | 0.062 | 0.072 | 0.074 | 0.076 |

| 4.0 | 0.440 | 0.435 | 0.421 | 0.752 | 0.074 | 0.084 | 0.076 | 0.072 |

| 5.0 | 0.494 | 0.502 | 0.482 | 0.924 | 0.078 | 0.085 | 0.087 | 0.065 |

| 6.0 | 0.559 | 0.557 | 0.550 | 1.060 | 0.077 | 0.090 | 0.097 | 0.060 |

| 7.0 | 0.584 | 0.587 | 0.615 | 1.184 | 0.090 | 0.099 | 0.109 | 0.062 |

| 8.0 | 0.629 | 0.630 | 0.720 | 1.294 | 0.105 | 0.116 | 0.123 | 0.060 |

| 9.0 | 0.657 | 0.657 | 1.343 | 1.356 | 0.118 | 0.129 | 0.051 | 0.059 |

| 9.9 | 0.677 | 0.676 | 1.348 | 1.352 | 0.140 | 0.147 | 0.055 | 0.066 |

| 10.9 | 0.702 | 0.702 | 1.341 | 1.345 | 0.169 | 0.175 | 0.067 | 0.077 |

| 11.9 | 0.727 | 0.726 | 1.325 | 1.328 | 0.199 | 0.197 | 0.088 | 0.096 |

| 12.9 | 0.760 | 0.757 | 1.306 | 1.313 | 0.225 | 0.221 | 0.111 | 0.120 |

| 14.0 | 0.838 | 0.829 | 1.290 | 1.294 | 0.257 | 0.262 | 0.125 | 0.141 |

| 14.9 | 0.862 | 0.884 | 0.907 | 1.185 | 0.253 | 0.244 | 0.246 | 0.220 |

| 16.0 | 0.907 | 0.912 | 0.909 | 1.099 | 0.261 | 0.252 | 0.267 | 0.232 |

| 18.0 | 0.936 | 0.952 | 0.939 | 0.929 | 0.321 | 0.323 | 0.339 | 0.348 |

| 20.0 | 0.974 | 0.988 | 0.972 | 0.965 | 0.364 | 0.385 | 0.393 | 0.395 |

| 24.9 | 1.103 | 1.106 | 1.114 | 1.088 | 0.458 | 0.461 | 0.464 | 0.466 |

| AoA | Re = 40,000 | Re = 60,000 | Re = 80,000 | Re = 100,000 | Re = 120,000 | Re = 150,000 | Re = 200,000 | Re = 300,000 | Re = 400,000 |

|---|---|---|---|---|---|---|---|---|---|

| Upstroke (Downstroke) | |||||||||

| −9.9 | −0.306 (−0.309) | −0.263 | −0.235 | −0.238 | −0.243 | −0.244 | −0.268 | −0.295 | −0.349 |

| −8.0 | −0.460 (−0.463) | −0.454 | −0.445 | −0.441 | −0.455 | −0.461 | −0.467 | −0.332 | −0.295 |

| −6.0 | −0.331 (−0.323) | −0.341 | −0.347 | −0.325 | −0.294 | −0.270 | −0.166 | −0.085 | −0.093 |

| −4.0 | −0.149 (−0.170) | −0.070 | −0.022 | 0.048 | 0.076 | 0.115 | 0.158 | 0.134 | 0.111 |

| −2.0 | −0.160 (−0.145) | −0.064 | 0.015 | 0.259 | 0.348 | 0.354 | 0.401 | 0.358 | 0.326 |

| −1.0 | −0.060 (−0.051) | 0.062 | 0.182 | 0.335 | 0.414 | 0.481 | 0.504 | 0.459 | 0.424 |

| −0.0 | 0.034 (0.044) | 0.224 | 0.368 | 0.533 | 0.514 | 0.539 | 0.614 | 0.564 | 0.525 |

| 1.0 | 0.166 (0.174) | 0.315 | 0.511 | 0.611 | 0.608 | 0.635 | 0.718 | 0.660 | 0.631 |

| 2.0 | 0.288 (0.294) | 0.358 | 0.612 | 0.718 | 0.732 | 0.745 | 0.831 | 0.769 | 0.735 |

| 3.0 | 0.372 (0.376) | 0.399 | 0.583 | 0.842 | 0.858 | 0.849 | 0.952 | 0.862 | 0.841 |

| 4.0 | 0.441 (0.443) | 0.451 | 0.586 | 0.947 | 0.959 | 0.965 | 1.037 | 0.947 | 0.940 |

| 5.0 | 0.494 (0.503) | 0.510 | 0.599 | 1.055 | 1.075 | 1.099 | 1.108 | 1.056 | 1.038 |

| 6.0 | 0.559 (0.563) | 0.563 | 0.660 | 1.176 | 1.185 | 1.201 | 1.211 | 1.171 | 1.135 |

| 7.0 | 0.584 (0.595) | 0.624 | 1.222 | 1.266 | 1.275 | 1.278 | 1.287 | 1.254 | 1.225 |

| 8.0 | 0.630 (0.622) | 1.312 | 1.330 | 1.326 | 1.331 | 1.332 | 1.326 | 1.286 | 1.276 |

| 9.0 | 0.657 (0.654) | 1.363 | 1.353 | 1.334 | 1.319 | 1.308 | 1.298 | 1.314 | 1.303 |

| 9.9 | 0.678 (0.674) | 1.345 | 1.306 | 1.273 | 1.258 | 1.250 | 1.235 | 1.315 | 1.298 |

| 10.9 | 0.702 (0.696) | 1.321 | 1.259 | 1.228 | 1.215 | 1.199 | 1.183 | 1.242 | 1.231 |

| 11.9 | 0.727 (0.987) | 1.299 | 1.227 | 1.196 | 1.182 | 1.161 | 1.143 | 1.183 | 1.165 |

| 12.9 | 0.760 (1.060) | 1.273 | 1.201 | 1.172 | 1.156 | 1.137 | 1.123 | 1.131 | 1.114 |

| 14.0 | 0.839 (0.826) | 1.221 | 1.182 | 1.150 | 1.136 | 1.115 | 1.102 | 1.078 | 1.055 |

| 14.9 | 0.862 (0.876) | 1.000 | 1.208 | 1.126 | 1.113 | 1.091 | 1.058 | 1.025 | 0.987 |

| 16.0 | 0.908 (0.910) | 0.998 | 0.913 | 0.908 | 0.992 | 1.043 | 1.007 | 0.977 | 0.956 |

| 18.0 | 0.937 (0.939) | 0.944 | 0.954 | 0.954 | 0.950 | 0.950 | 1.064 | 1.068 | 1.166 |

| 20.0 | 0.974 (0.971) | 0.981 | 0.983 | 0.989 | 0.993 | 0.995 | 1.107 | 0.930 | 0.945 |

| 24.9 | 1.103 (1.103) | 1.130 | 1.152 | 1.165 | 1.170 | 1.168 | 1.168 | 1.013 | 0.985 |

| AoA | Re = 40,000 | Re = 60,000 | Re = 80,000 | Re = 100,000 | Re = 120,000 | Re = 150,000 | Re = 200,000 | Re = 300,000 | Re = 400,000 |

|---|---|---|---|---|---|---|---|---|---|

| Upstroke (Downstroke) | |||||||||

| −9.9 | 0.141 (0.143) | 0.140 | 0.140 | 0.142 | 0.143 | 0.142 | 0.148 | 0.170 | 0.175 |

| −8.0 | 0.102 (0.101) | 0.128 | 0.130 | 0.134 | 0.130 | 0.133 | 0.130 | 0.087 | 0.086 |

| −6.0 | 0.053 (0.054) | 0.053 | 0.054 | 0.052 | 0.050 | 0.047 | 0.038 | 0.026 | 0.026 |

| −4.0 | 0.036 (0.038) | 0.029 | 0.028 | 0.033 | 0.029 | 0.021 | 0.019 | 0.016 | 0.013 |

| −2.0 | 0.042 (0.042) | 0.046 | 0.047 | 0.035 | 0.029 | 0.025 | 0.019 | 0.013 | 0.011 |

| −1.0 | 0.043 (0.042) | 0.053 | 0.046 | 0.034 | 0.026 | 0.023 | 0.017 | 0.012 | 0.011 |

| −0.0 | 0.047 (0.048) | 0.053 | 0.043 | 0.029 | 0.026 | 0.022 | 0.017 | 0.013 | 0.011 |

| 1.0 | 0.054 (0.055) | 0.055 | 0.042 | 0.030 | 0.025 | 0.022 | 0.018 | 0.013 | 0.011 |

| 2.0 | 0.054 (0.053) | 0.058 | 0.044 | 0.029 | 0.025 | 0.022 | 0.018 | 0.014 | 0.012 |

| 3.0 | 0.063 (0.062) | 0.064 | 0.059 | 0.030 | 0.026 | 0.022 | 0.019 | 0.015 | 0.013 |

| 4.0 | 0.075 (0.078) | 0.070 | 0.068 | 0.031 | 0.026 | 0.024 | 0.019 | 0.015 | 0.014 |

| 5.0 | 0.078 (0.075) | 0.078 | 0.079 | 0.031 | 0.027 | 0.024 | 0.020 | 0.016 | 0.014 |

| 6.0 | 0.078 (0.082) | 0.088 | 0.088 | 0.034 | 0.028 | 0.024 | 0.017 | 0.016 | 0.015 |

| 7.0 | 0.091 (0.094) | 0.108 | 0.032 | 0.028 | 0.022 | 0.020 | 0.024 | 0.014 | 0.013 |

| 8.0 | 0.105 (0.102) | 0.035 | 0.025 | 0.021 | 0.027 | 0.030 | 0.029 | 0.020 | 0.019 |

| 9.0 | 0.119 (0.121) | 0.029 | 0.033 | 0.035 | 0.035 | 0.034 | 0.034 | 0.027 | 0.025 |

| 9.9 | 0.141 (0.142) | 0.040 | 0.041 | 0.047 | 0.053 | 0.056 | 0.066 | 0.033 | 0.032 |

| 10.9 | 0.170 (0.172) | 0.051 | 0.057 | 0.076 | 0.088 | 0.101 | 0.112 | 0.062 | 0.060 |

| 11.9 | 0.200 (0.103) | 0.069 | 0.085 | 0.111 | 0.125 | 0.134 | 0.139 | 0.111 | 0.111 |

| 12.9 | 0.226 (0.102) | 0.093 | 0.105 | 0.139 | 0.148 | 0.155 | 0.155 | 0.144 | 0.143 |

| 14.0 | 0.257 (0.255) | 0.118 | 0.133 | 0.163 | 0.173 | 0.177 | 0.182 | 0.179 | 0.178 |

| 14.9 | 0.254 (0.260) | 0.249 | 0.150 | 0.190 | 0.206 | 0.209 | 0.219 | 0.214 | 0.221 |

| 16.0 | 0.262 (0.261) | 0.268 | 0.295 | 0.291 | 0.274 | 0.225 | 0.248 | 0.247 | 0.242 |

| 18.0 | 0.322 (0.322) | 0.330 | 0.336 | 0.341 | 0.342 | 0.343 | 0.300 | 0.291 | 0.270 |

| 20.0 | 0.364 (0.374) | 0.372 | 0.376 | 0.376 | 0.376 | 0.379 | 0.326 | 0.430 | 0.402 |

| 24.9 | 0.459 (0.459) | 0.459 | 0.452 | 0.451 | 0.450 | 0.446 | 0.448 | 0.379 | 0.369 |

References

- Bastankhah, M.; Porté-Agel, F. Wind tunnel study of the wind turbine interaction with a boundary-layer flow: Upwind region, turbine performance, and wake region. Phys. Fluids 2017, 29, 065105. [Google Scholar] [CrossRef]

- Pierella, F.; Krogstad, P.Å.; Sætran, L. Blind Test 2 calculations for two in-line model wind turbines where the downstream turbine operates at various rotational speeds. Renew. Energy 2014, 70, 62–77. [Google Scholar] [CrossRef]

- Bartl, J.; Sætran, L. Blind test comparison of the performance and wake flow between two in-line wind turbines exposed to different turbulent inflow conditions. Wind Energy Sci. 2017, 2, 55–76. [Google Scholar] [CrossRef]

- Hu, H.; Yang, Z. An experimental study of the laminar flow separation on a low-Reynolds-number airfoil. J. Fluids Eng. 2008, 130, 051101. [Google Scholar] [CrossRef]

- Choudhry, A.; Arjomandi, M.; Kelso, R. A study of long separation bubble on thick airfoils and its consequent effects. Int. J. Heat Fluid Flow 2015, 52, 84–96. [Google Scholar] [CrossRef]

- Windte, J.; Scholz, U.; Radespiel, R. Validation of the RANS-simulation of laminar separation bubbles on airfoils. Aerosp. Sci. Technol. 2006, 10, 484–494. [Google Scholar] [CrossRef]

- Selig, M. Low Reynolds number airfoil design lecture notes. In VKI Lecture Series; von Karman Institute for Fluid Dynamics: Sint-Genesius-Rode, Belgium, 2003; pp. 24–28. [Google Scholar]

- Horton, H. Laminar Separation Bubbles in Two and Three Dimensional Incompressible Flow. Ph.D. Thesis, Queen Mary University of London, London, UK, 1968. [Google Scholar]

- Sarlak, H. Large Eddy Simulation of an SD7003 Airfoil: Effects of Reynolds number and Subgrid-scale modeling. J. Phys. Conf. Ser. 2017, 854, 012040. [Google Scholar] [CrossRef]

- Tani, I. Boundary-layer transition. Ann. Rev. Fluid Mech. 1969, 1, 169–196. [Google Scholar] [CrossRef]

- Gaster, M. The Structure and Behaviour of Laminar Separation Bubbles; HM Stationery Office: Richmond, UK, 1969. [Google Scholar]

- Winkelman, A.; Barlow, J. Flowfield model for a rectangular planform wing beyond stall. AIAA J. 1980, 18, 1006–1008. [Google Scholar] [CrossRef]

- Rodríguez, D.; Theofilis, V. On the birth of stall cells on airfoils. Theor. Comput. Fluid Dyn. 2011, 25, 105–117. [Google Scholar] [CrossRef]

- Manolesos, M.; Papadakis, G.; Voutsinas, S.G. Experimental and computational analysis of stall cells on rectangular wings. Wind Energy 2014, 17, 939–955. [Google Scholar] [CrossRef]

- Manolesos, M.; Voutsinas, S.G. Geometrical characterization of stall cells on rectangular wings. Wind Energy 2014, 17, 1301–1314. [Google Scholar] [CrossRef]

- Boiko, A.; Dovgal, A.; ZANIN, B.; Kozlov, V. Three-dimensional structure of separated flows on wings (review). Thermophys. Aeromech. 1996, 3, 1–13. [Google Scholar]

- Yon, S.; Katz, J. Study of the unsteady flow features on a stalled wing. AIAA J. 1998, 36, 305–312. [Google Scholar] [CrossRef]

- Broeren, A.P.; Bragg, M.B. Spanwise variation in the unsteady stalling flowfields of two-dimensional airfoil models. AIAA J. 2001, 39, 1641–1651. [Google Scholar] [CrossRef]

- Ragni, D.; Ferreira, C. Effect of 3D stall-cells on the pressure distribution of a laminar NACA64-418 wing. Exp. Fluids 2016, 57, 127. [Google Scholar] [CrossRef][Green Version]

- Zarutskaya, T.; Arieli, R. On vortical flow structures at wing stall and beyond. In Proceedings of the 35th AIAA Fluid Dynamics Conference and Exhibit, Toronto, ON, Canada, 6–9 June 2005; pp. 1–10. [Google Scholar]

- Shur, M.; Spalart, P.R.; Squires, K.D.; Strelets, M.; Travin, A. Three dimensionality in Reynolds-averaged Navier–Stokes solutions around two-dimensional geometries. AIAA J. 2005, 43, 1230–1242. [Google Scholar] [CrossRef]

- Manni, L.; Nishino, T.; Delafin, P.L. Numerical study of airfoil stall cells using a very wide computational domain. Comput. Fluids 2016, 140, 260–269. [Google Scholar] [CrossRef]

- Sarlak, H.; Nishino, T.; Sørensen, J.N.; Simos, T.; Tsitouras, C. URANS simulations of separated flow with stall cells over an NREL S826 airfoil. AIP Conf. Proc. 2016, 1738, 030039. [Google Scholar] [CrossRef]

- Sarlak, H.; Meneveau, C.; Sørense, J. Role of subgrid-scale modelling in large eddy simulation of wind turbine wake interactions. Renewable Energy 2015, 77, 386–399. [Google Scholar] [CrossRef]

- Frère, A.; Hillewaert, K.; Sarlak, H.; Mikkelsen, R.; Chatelain, P. Cross-validation of numerical and experimental studies of transitional airfoil performance. In Proceedings of the 33rd Wind Energy Symposium, Kissimmee, FL, USA, 5–9 Janurary 2015; American Institute of Aeronautics & Astronautics: Reston, VA, USA, 2015. [Google Scholar]

- Sagmo, K.; Bartl, J.; Sætran, L. Numerical simulations of the NREL S826 airfoil. J. Phys. Conf. Ser. 2016, 753, 082036. [Google Scholar] [CrossRef]

- Sarlak, H. Large Eddy Simulation of Turbulent Flows in Wind Energy. Ph.D. Thesis, Technical University of Denmark, Lyngby, Denmark, 2014. [Google Scholar]

- Sarlak, H.; Mikkelsen, R.; Sarmast, S.; Sørensen, J. Aerodynamic behaviour of NREL S826 at Re = 100,000. J. Phys. Conf. Ser. 2014, 524, 012027. [Google Scholar] [CrossRef]

- Ross, I.; Altman, A. Wind tunnel blockage corrections: Review and application to Savonius vertical-axis wind turbines. J. Wind Eng. Ind. Aerodyn. 2011, 99, 523–538. [Google Scholar] [CrossRef]

- Barlow, J.; Rae, W.; Pope, A. Low-Speed Wind Tunnel Testing; Wiley: New York, NY, USA, 1999. [Google Scholar]

- Sumer, B.M. Hydrodynamics Around Cylindrical Strucures; World Scientific: Singapore, 2006; Volume 26. [Google Scholar]

- Mittal, S.; Saxena, P. Prediction of hysteresis associated with static stall of an airfoil. AIAA J. 2000, 38, 933–935. [Google Scholar] [CrossRef]

| U [m/s] | Re | Re | ||||

|---|---|---|---|---|---|---|

| D = 0.15 mm | D = 0.3 mm | D = 0.5 mm | D = 1.3 mm | |||

| 6 | 0.0057 | 40,000 | 60 | 120 | 200 | 520 |

| 15 | 0.0054 | 100,000 | 150 | 300 | 500 | 1300 |

| 30 | 0.0063 | 200,000 | 300 | 600 | 1000 | 2600 |

| Material | Composition | Amount |

|---|---|---|

| Titanium dioxide | TiO | 9 g |

| Talcum powder | MgSiO(OH) | 3 g |

| Kerosene | CH | 40 g |

| Linseed oil * | 16 g | |

| Petroleum | CH | 31 g |

| Oleic acid | CHO | 5 drops |

| Total | ≈100 g |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sarlak, H.; Frère, A.; Mikkelsen, R.; Sørensen, J.N. Experimental Investigation of Static Stall Hysteresis and 3-Dimensional Flow Structures for an NREL S826 Wing Section of Finite Span. Energies 2018, 11, 1418. https://doi.org/10.3390/en11061418

Sarlak H, Frère A, Mikkelsen R, Sørensen JN. Experimental Investigation of Static Stall Hysteresis and 3-Dimensional Flow Structures for an NREL S826 Wing Section of Finite Span. Energies. 2018; 11(6):1418. https://doi.org/10.3390/en11061418

Chicago/Turabian StyleSarlak, Hamid, Ariane Frère, Robert Mikkelsen, and Jens N. Sørensen. 2018. "Experimental Investigation of Static Stall Hysteresis and 3-Dimensional Flow Structures for an NREL S826 Wing Section of Finite Span" Energies 11, no. 6: 1418. https://doi.org/10.3390/en11061418

APA StyleSarlak, H., Frère, A., Mikkelsen, R., & Sørensen, J. N. (2018). Experimental Investigation of Static Stall Hysteresis and 3-Dimensional Flow Structures for an NREL S826 Wing Section of Finite Span. Energies, 11(6), 1418. https://doi.org/10.3390/en11061418