Study of the Application of Alkaline Extrusion to the Pretreatment of Eucalyptus Biomass as First Step in a Bioethanol Production Process

Abstract

1. Introduction

2. Materials and Methods

2.1. Raw Material

2.2. Extrusion Pretreatment

2.3. Materials Characterization

2.4. Evaluation of the Enzymatic Digestibility

2.5. Analytical Methods

3. Results and Discussion

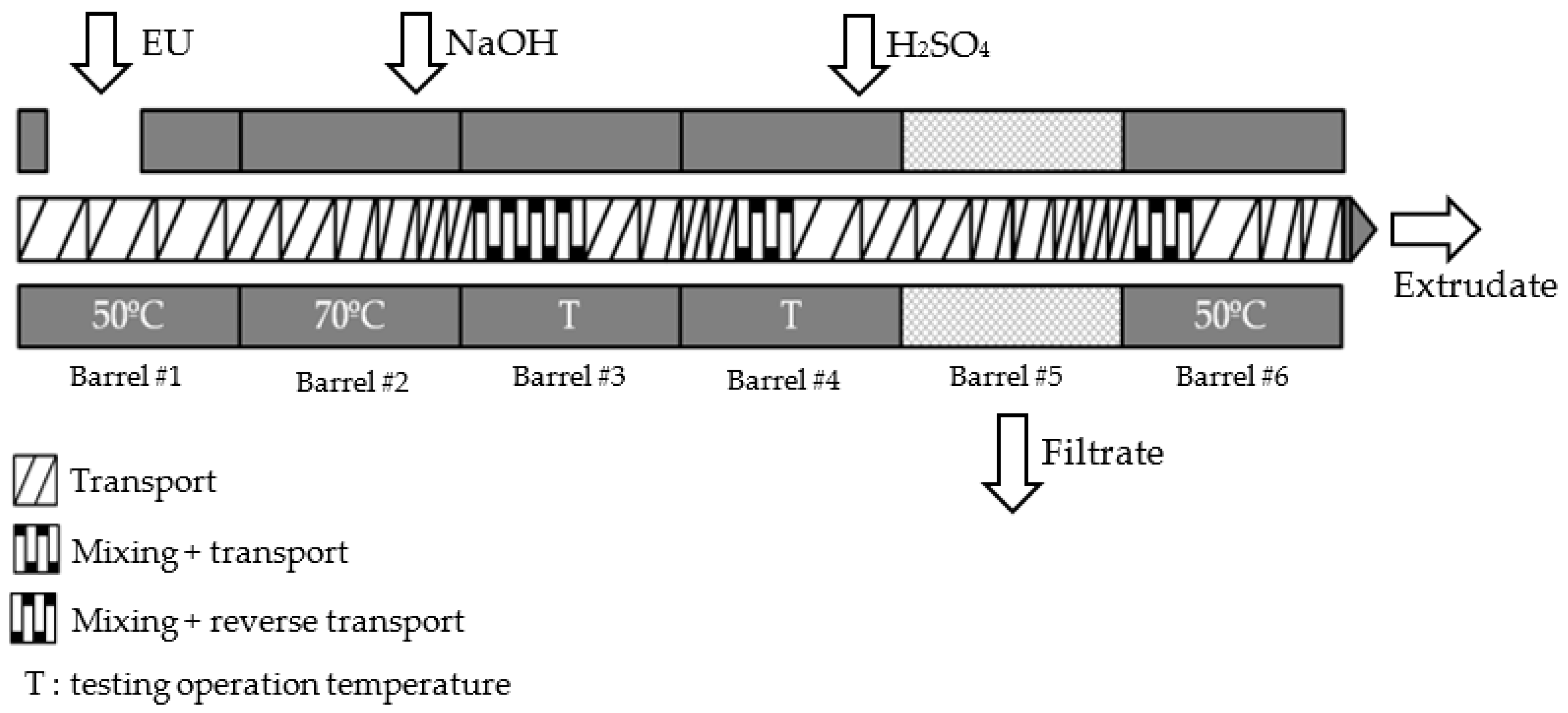

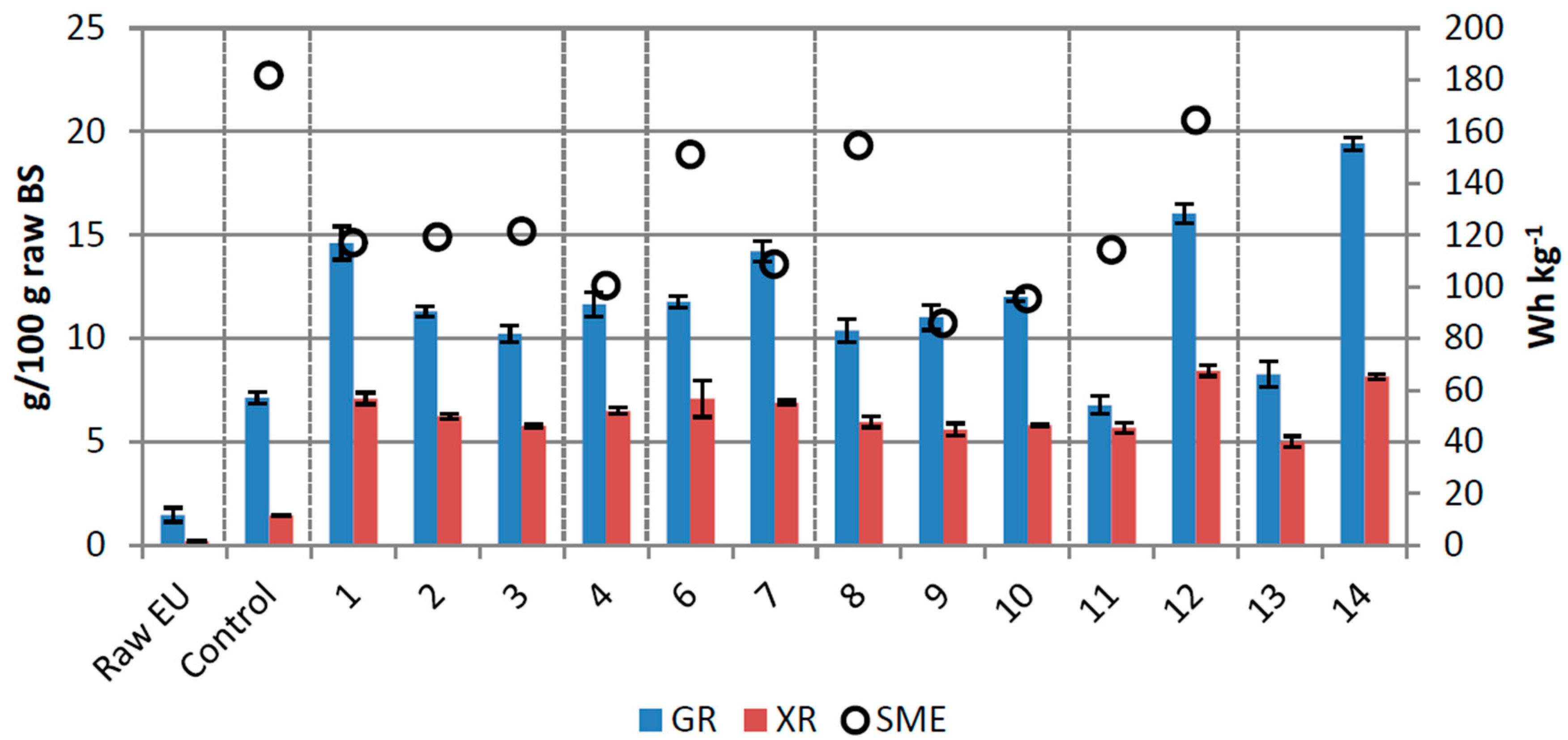

3.1. Screw Configuration

3.2. Extrusion with Water

3.3. Alkaline Extrusion with Filtration

3.3.1. Effect of Screw Speed

3.3.2. Effect of Temperature

3.3.3. Effect of L/S Ratio in the Reaction Zone

3.3.4. Effect of NaOH/DM Ratio

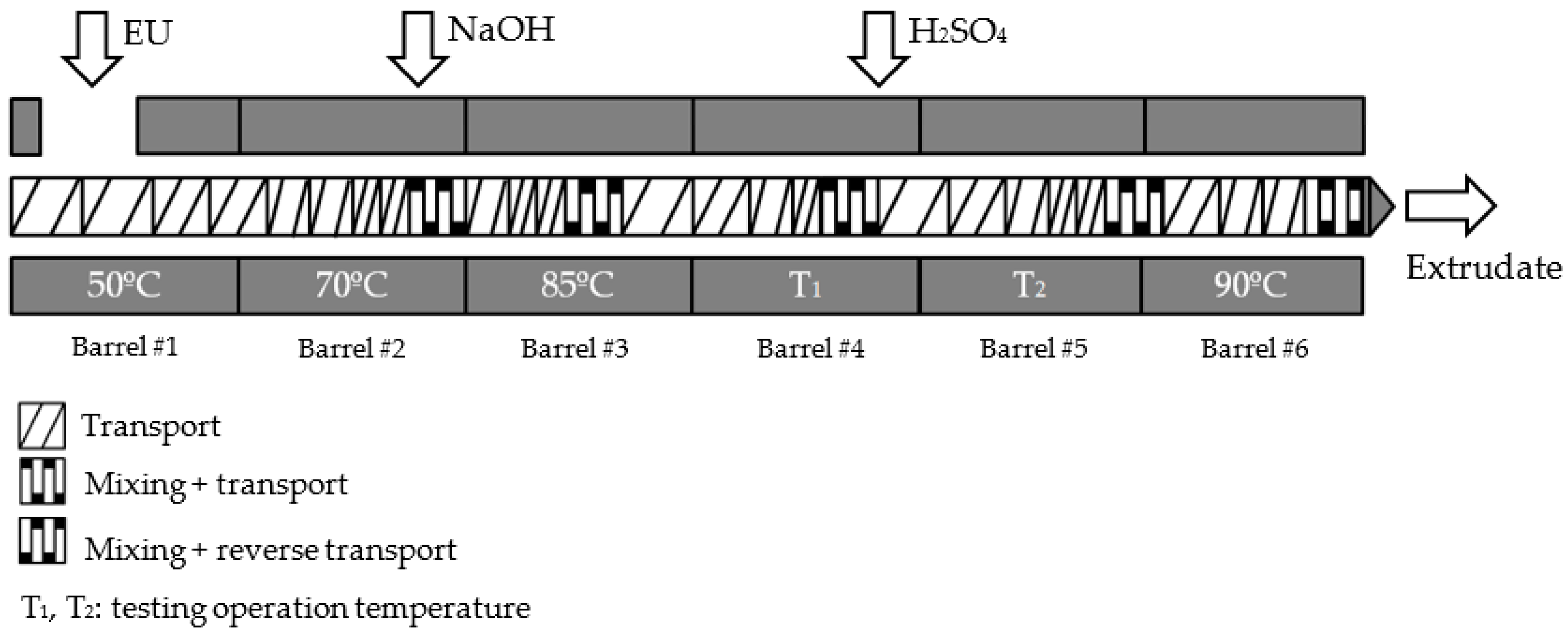

3.4. Alkaline Extrusion without Filtration

3.4.1. Modification of the Screw Configuration

3.4.2. Performance of Complete Extrudates

3.4.3. Performance of Washed Extrudates

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- REN21. Renewables 2018 Global Status Report; REN21 Secretariat: Paris, France, 2018. [Google Scholar]

- Shepherd, M.; Bartke, J.; Lee, D.J.; Brawner, J.; Bush, D.; Turnbull, P.; Macdonel, P.; Brown, T.R.; Simmons, B.; Henry, R. Eucalyptus as biofuel feedstock. Biofuels 2011, 2, 639–657. [Google Scholar] [CrossRef]

- Taherzadeh, M.J.; Karimi, K. Pretreatment of lignocellulosic wastes to improve ethanol and biogas production: A review. Int. J. Mol. Sci. 2008, 9, 1621–1651. [Google Scholar] [CrossRef] [PubMed]

- Bajpai, P. Structure of Lignocellulose. In Pretreatment of Lignocellulosic Biomass for Biofuel Production; Springer: Singapore, 2016. [Google Scholar]

- Volynets, B.; Ein-Mozaffari, F.; Dahman, Y. Biomass processing into ethanol: Pretreatment, enzymatic hydrolysis, fermentation, rheology, and mixing. Green Process. Synth. 2017, 6, 1–22. [Google Scholar] [CrossRef]

- Alvira, P.; Tomas-Pejó, E.; Ballesteros, M.; Negro, M.J. Pretreatment technologies for an efficient bioethanol production process based on enzymatic hydrolysis: A review. Bioresour. Technol. 2010, 101, 4851–4861. [Google Scholar] [CrossRef] [PubMed]

- Duque, A.; Manzanares, P.; Ballesteros, M. Extrusion as a pretreatment for lignocellulosic biomass: Fundamentals and applications. Renew. Energy 2017, 114, 1427–1441. [Google Scholar] [CrossRef]

- Romaní, A.; Garrote, G.; Parajó, J.C. Bioethanol production from autohydrolyzed Eucalyptus globulus by Simultaneous Saccharification and Fermentation operating at high solids loading. Fuel 2012, 94, 305–312. [Google Scholar] [CrossRef]

- McIntosh, S.; Vancov, T.; PAlmer, J.; Spain, M. Ethanol production from Eucalyptus plantation thinnings. Bioresour. Technol. 2012, 110, 264–272. [Google Scholar] [CrossRef] [PubMed]

- Lima, M.A.; Lavorente, G.B.; da Silva, H.K.P. Effects of pretreatment on morphology, chemical composition and enzymatic digestibility of eucalyptus bark: A potentially valuable source of fermentable sugars for biofuel production—Part 1. Biotechnol. Biofuels 2013, 6, 75. [Google Scholar] [CrossRef] [PubMed]

- Karunanithy, C.; Muthukumarappan, K.; Gibbons, W.R. Extrusion pretreatment of pine wood chips. Appl. Biochem. Biotechnol. 2012, 167, 81–99. [Google Scholar] [CrossRef] [PubMed]

- Lee, S.H.; Teramoto, Y.; Endo, T. Enhancement of enzymatic accessibility by fibrillation of woody biomass using batch-type kneader with twin-screw elements. Bioresour. Technol. 2010, 101, 769–774. [Google Scholar] [CrossRef] [PubMed]

- Lee, S.-H.; Teramoto, Y.; Endo, T. Enzymatic saccharification of woody biomass micro/nanofibrillated by continuous extrusion process I—Effect of additives with cellulose affinity. Bioresour. Technol. 2009, 100, 275–279. [Google Scholar] [CrossRef] [PubMed]

- Lee, S.H.; Inoue, S.; Teramoto, Y.; Endo, T. Enzymatic saccharification of woody biomass micro/nanofibrillated by continuous extrusion process II: Effect of hot-compressed water treatment. Bioresour. Technol. 2010, 101, 9645–9649. [Google Scholar] [CrossRef] [PubMed]

- Kim, T.H.; Choi, C.H.; Keun, K. Bioconversion of sawdust into ethanol using dilute sulfuric acid-assisted continuous twin screw-driven reactor pretreatment and fed-batch simultaneous saccharification and fermentation. Bioresour. Technol. 2013, 130, 306–313. [Google Scholar] [CrossRef] [PubMed]

- Senturk, S.; Gevgilili, H.; Kaylon, D.M. Biomass pretreatment strategies via control of rheoroligal behavior of biomass suspensions and reactive twin screw extrusion processing. Bioresour. Technol. 2011, 102, 9068–9075. [Google Scholar] [CrossRef] [PubMed]

- Brault, J. Développement d’un Procédé Innovant de Dégradation Enzymatique des Parois Végétales Pour la Production de Bioéthanol Seconde Génération. Ph.D. Thesis, INPT Toulouse, Toulouse, France, 2013. [Google Scholar]

- Duque, A.; Manzanares, P.; Ballesteros, I.; Negro, M.J.; Oliva, J.M.; Saez, F.; Ballesteros, M. Study of process configuration and catalyst concentration in integrated alkaline extrusion of barley straw for bioethanol production. Fuel 2014, 134, 448–454. [Google Scholar] [CrossRef]

- National Renewable Energy Laboratory (NREL). Chemical Analysis and Testing Laboratory Analytical Procedures; NREL: Golden, CO, USA, 2007.

- Choi, C.H.; Oh, K.K. Application of a continuous twin screw-driven process for dilute acid pretreatment of rape straw. Bioresour. Technol. 2012, 110, 349–354. [Google Scholar] [CrossRef] [PubMed]

- Kuster Moro, M.; Sposina, R.; Sant’Ana da Silva, A.; Fujimoto, M.D.; Melo, P.A.; Secchi, A.R.; da Silva Bon, E.P. Continuous pretreatment of sugarcane biomass using a twin-screw extruder. Ind. Crop. Prod. 2017, 97 (Suppl. C), 509–517. [Google Scholar] [CrossRef]

- Zheng, J.; Choo, K.; Rehmann, L. Xylose removal from lignocellulosic biomass via a twin-screw extruder: The effects of screw configurations and operating conditions. Biomass Bioenergy 2016, 88, 10–16. [Google Scholar] [CrossRef]

- Vandenbossche, V.; Brault, J.; Vilarem, G.; Rigal, L. Bio-catalytic action of twin-screw extruder enzymatic hydrolysis onthe deconstruction of annual plant material: Case of sweet cornco-products. Ind. Crop. Prod. 2015, 67, 239–248. [Google Scholar] [CrossRef]

- Yoo, J.; Alavi, S.; Vadlani, P.; Behnke, K.C. Soybean hulls pretreated using thermo-mechanical extrusion—Hydrolysis efficiency, fermentation inhibitors, and ethanol yield. Appl. Biochem. Biotechnol. 2012, 166, 576–589. [Google Scholar] [CrossRef] [PubMed]

- Lamsal, B.; Yoo, J.; Brijwani, K.; Alavi, S. Extrusion as a thermo-mechanical pre-treatment for lignocellulosic ethanol. Biomass Bioenergy 2010, 34, 1703–1710. [Google Scholar] [CrossRef]

- Scott, C.T.; Samaniuk, J.R.; Klingenberg, D.J. Rheology and extrusion of high-solids biomass. Tappi J. 2011, 10, 47–53. [Google Scholar]

- Duque, A.; Manzanares, P.; Ballesteros, I. Optimization of integrated alkaline-extrusion pretreatment of barley straw for sugar production by enzymatic hydrolysis. Process Biochem. 2013, 48, 775–781. [Google Scholar] [CrossRef]

- Zhang, S.; Xu, Y.; Hanna, M. Pretreatment of Corn Stover with Twin-Screw Extrusion Followed by Enzymatic Saccharification. Appl. Biochem. Biotechnol. 2012, 166, 458–469. [Google Scholar] [CrossRef] [PubMed]

- Karunanithy, C.; Muthukumarappan, K. Effect of Extruder Parameters and Moisture Content of Switchgrass, Prairie Cord Grass on Sugar Recovery from Enzymatic Hydrolysis. Appl. Biochem. Biotechnol. 2010, 162, 1785–1803. [Google Scholar] [CrossRef] [PubMed]

- Negro, M.J.; Duque, A.; Manzanares, P.; Sáez, F.; Oliva, J.M.; Ballesteros, I.; Ballesteros, M. Alkaline twin-screw extrusion fractionation of olive-treepruning biomass. Ind. Crop. Prod. 2015, 74, 336–341. [Google Scholar] [CrossRef]

- Karunanithy, C.; Muthukumarappan, K. A comparative study on torque requirement during extrusion pretreatment of different feedstocks. Bioenergy Res. 2012, 5, 263–276. [Google Scholar] [CrossRef]

- Da Silva, A.; Sposina, R.; Endo, T.; Bon, E.P.; Lee, S.H. Continuous pretreatment of sugarcane bagasse at high loading in an ionic liquid using a twin-screw extruder. Green Chem. 2013, 15, 1991–2001. [Google Scholar] [CrossRef]

- Choi, W.I.; Oh, K.K.; Park, J.Y.; Lee, J.S. Continuous sodium hydroxide-catalyzed pretreatment of empty fruit bunches (EFB) by continuous twin-screw-driven reactor (CTSR). J. Chem. Technol. Biotechnol. 2014, 89, 290–296. [Google Scholar] [CrossRef]

- Kim, J.S.; Lee, Y.Y.; Kim, T.H. A review on alkaline pretreatment technology for bioconversion of lignocellulosic biomass. Bioresour. Technol. 2016, 199, 42–48. [Google Scholar] [CrossRef] [PubMed]

- Van Walsum, G.P.; Um, B.H. Effect of pretreatment severity on accumulation of major degradation products from dilute acid pretreated corn stover and subsequent inhibition of enzymatic hydrolysis of cellulose. Appl. Biochem. Biotechnol. 2012, 168, 406–420. [Google Scholar]

- Han, M.; Kang, K.E.; Kim, Y.; Choi, G.W. High efficiency bioethanol production from barley straw using a continuous pretreatment reactor. Process Biochem. 2013, 48, 488–495. [Google Scholar] [CrossRef]

- Liu, C.; van der Heide, E.; Wang, H.; Li, B.; Yu, G.; Mu, X. Alkaline twin-screw extrusion pretreatment for fermentable sugar production. Biotechnol. Biofuels 2013, 6, 97. [Google Scholar] [CrossRef] [PubMed]

- Um, B.-H.; Choi, C.H.; Oh, K.K. Chemicals effect on the enzymatic digestibility of rape straw over the thermo-mechanical pretreatment using a continuous twin screw-driven reactor (CTSR). Bioresour. Technol. 2013, 130, 38–44. [Google Scholar] [CrossRef] [PubMed]

- Kang, K.E.; Han, M.; Moon, S.K.; Kang, H.W.; Kim, Y.; Cha, Y.L.; Choi, G.W. Optimization of alkali-extrusion pretreatment with twin-screw for bioethanol production from Mischantus. Fuel 2013, 109, 520–526. [Google Scholar] [CrossRef]

| Experiment | Assays | R (%w/w) | L/S (w/w) | T (°C) | SS (rpm) | Filter | Washed |

|---|---|---|---|---|---|---|---|

| W | Control | - | 1.2 | 75 | 200 | Yes | No |

| SS | 1 | 8.5 | 1.2 | 75 | 100 | Yes | No |

| 2 | 8.5 | 1.2 | 75 | 200 | Yes | No | |

| 3 | 8.5 | 1.2 | 75 | 300 | Yes | No | |

| T | 4 | 8.5 | 1.2 | 100 | 200 | Yes | No |

| 5 | 8.5 | 1.2 | 125 | 200 | [1] | [1] | |

| L/S | 6 | 8.5 | 0.6 | 75 | 200 | Yes | No |

| 7 | 8.5 | 1.5 | 75 | 200 | Yes | No | |

| NaOH | 8 | 5 | 0.7 | 100 | 150 | Yes | No |

| 9 | 10 | 1.2 | 100 | 150 | Yes | No | |

| 10 | 20 | 1.2 | 100 | 250 | Yes | No | |

| NF | 11 | 8.5 | 1.2 | 125 | 300 | No | No |

| 12 | 8.5 | 1.2 | 150 | 300 | No | No | |

| NFW | 13 | 8.5 | 1.2 | 125 | 300 | No | Yes |

| 14 | 8.5 | 1.2 | 150 | 300 | No | Yes |

| Experiment | Cellulose (%) | Hemicellulose (%) | Lignin (%) | Ash (%) |

|---|---|---|---|---|

| Raw EU | 46.90 ± 1.21 a | 12.87 ± 0.35 a,b,c,d | 31.15 ± 0.40 a,b | 0.86 ± 0.00 a |

| Control | 44.90 ± 1.86 a,b,c | 13.71 ± 0.32 a,c,d,e | 32.97 ± 0.86 c,d | 0.57 ± 0.05 a |

| 1 | 42.56 ± 3.51 b,c | 12.13 ± 0.94 a,b,c | 32.03 ± 1.00 a,c | 3.78 ± 0.37 b |

| 2 | 42.56 ± 1.19 b,c | 11.76 ± 1.51 a,b | 31.22 ± 0.41 a,b | 7.35 ± 0.15 c |

| 3 | 41.79 ± 0.88 c | 12.16 ± 0.20 a,b,c | 28.86 ± 0.10 e | 9.28 ± 0.01 d |

| 4 | 43.14 ± 1.54 a,b | 11.47 ± 0.68 d,e | 29.67 ± 0.65 f | 7.01 ± 0.10 c |

| 6 | 41.71 ± 0.56 b,c | 12.04 ± 0.43 c,d,e | 30.43 ± 0.67 d | 7.37 ± 0.06 e |

| 7 | 46.97 ± 1.21 a | 15.59 ± 2.61 e | 31.21 ± 0.31 a,b | 5.65 ± 0.10 f |

| 8 | 45.66 ± 0.10 a,b | 14.95 ± 1.70 d,e | 32.90 ± 0.61 c,d | 4.16 ± 0.07 g |

| 9 | 45.48 ± 0.82 a,b,c | 11.36 ± 0.21 a,b | 31.70 ± 0.18 a | 5.22 ± 0.03 h |

| 10 | 44.60 ± 1.77 a,b,c | 11.02 ± 1.26 b | 30.32 ± 0.22 b,f | 11.17 ± 0.08 i |

| 11 | 39.23 ± 2.31 a,b,c | 11.78 ± 0.47 a,b | 27.69 ± 0.45 g | 14.91 ± 0.12 j |

| 12 | 38.76 ± 0.36 b,c | 11.24 ± 0.16 b | 27.99 ± 0.22 g | 14.54 ± 0.10 j |

| 13 | 50.05 ± 0.38 d | 12.72 ± 0.13 a,b,c | 32.60 ± 0.15 e,f | 2.04 ± 0.02 k |

| 14 | 49.33 ± 0.71 d | 11.55 ± 0.23 a,b | 31.98 ± 0.20 e | 2.62 ± 0.07 l |

| Experiment | Filtration Efficiency | L/S Filtration | Total Glucose | Total Xylose | Acetic Acid |

|---|---|---|---|---|---|

| g Filtrate/100 g Total Output | % of Gluc in Raw EU | % of xyl in Raw EU | % of ac Acid in Raw EU | ||

| Control | 19.0 | 3.9 | 0.0 | 0.3 | 0.8 |

| 1 | 69.6 | 3.9 | 0.4 | 8.0 | 27.3 |

| 2 | 55.1 | 3.9 | 0.1 | 5.9 | 30.8 |

| 3 | 58.2 | 3.9 | 0.1 | 5.6 | 27.3 |

| 4 | 59.2 | 3.9 | 0.2 | 8.0 | 24.0 |

| 6 | 48.3 | 3.4 | 0.2 | 5.3 | 36.0 |

| 7 | 50.8 | 4.2 | 0.3 | 6.9 | 35.5 |

| 8 | 43.0 | 2.9 | 0.3 | 2.0 | 36.0 |

| 9 | 68.8 | 4.8 | 0.4 | 8.7 | 64.5 |

| 10 | 64.6 | 5.0 | 0.3 | 11.1 | 58.5 |

| 13 | Washing liquid | 0.0 | 2.2 | 42.6 | |

| 14 | Washing liquid | 0.1 | 3.2 | 33.4 | |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Duque, A.; Manzanares, P.; González, A.; Ballesteros, M. Study of the Application of Alkaline Extrusion to the Pretreatment of Eucalyptus Biomass as First Step in a Bioethanol Production Process. Energies 2018, 11, 2961. https://doi.org/10.3390/en11112961

Duque A, Manzanares P, González A, Ballesteros M. Study of the Application of Alkaline Extrusion to the Pretreatment of Eucalyptus Biomass as First Step in a Bioethanol Production Process. Energies. 2018; 11(11):2961. https://doi.org/10.3390/en11112961

Chicago/Turabian StyleDuque, Aleta, Paloma Manzanares, Alberto González, and Mercedes Ballesteros. 2018. "Study of the Application of Alkaline Extrusion to the Pretreatment of Eucalyptus Biomass as First Step in a Bioethanol Production Process" Energies 11, no. 11: 2961. https://doi.org/10.3390/en11112961

APA StyleDuque, A., Manzanares, P., González, A., & Ballesteros, M. (2018). Study of the Application of Alkaline Extrusion to the Pretreatment of Eucalyptus Biomass as First Step in a Bioethanol Production Process. Energies, 11(11), 2961. https://doi.org/10.3390/en11112961