An Online Data-Driven Model Identification and Adaptive State of Charge Estimation Approach for Lithium-ion-Batteries Using the Lagrange Multiplier Method

Abstract

:1. Introduction

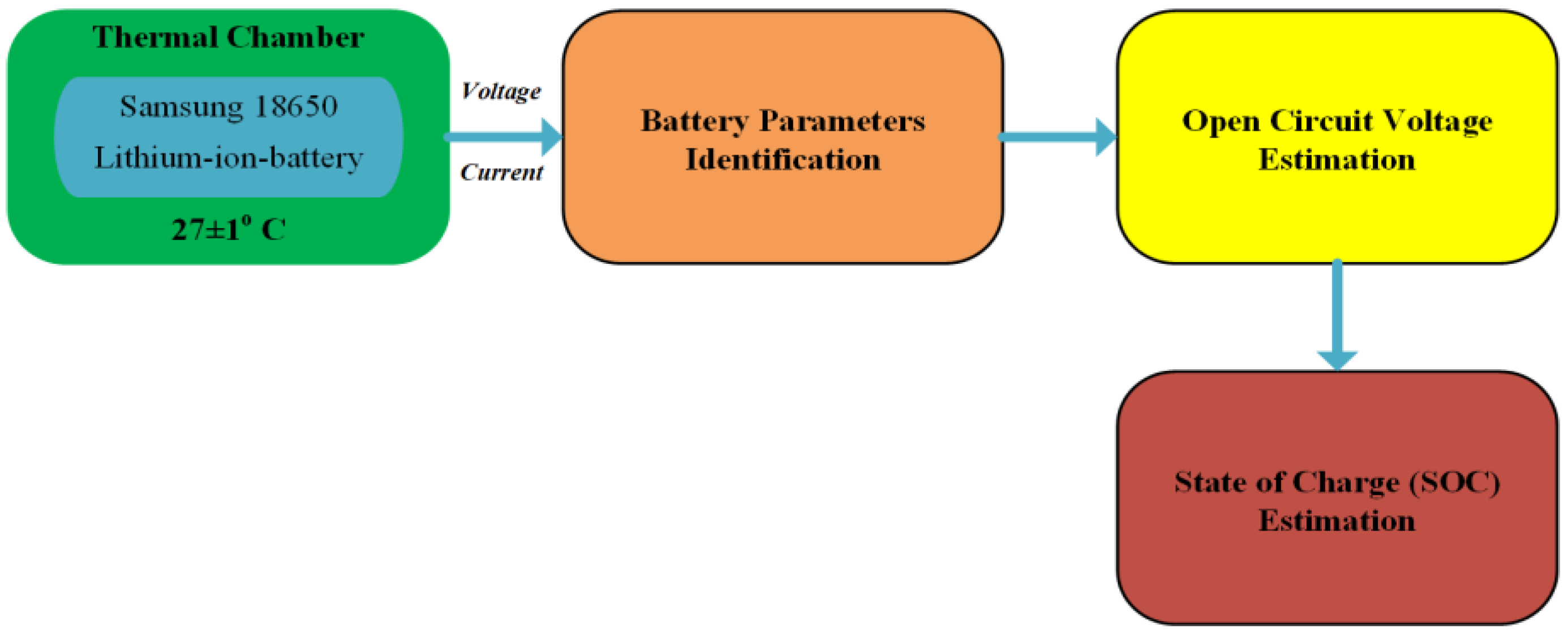

2. Battery Modelling and Parameter Estimation Technique

2.1. Modelling of Battery

2.2. Lagrange Multiplier Method for Online Model Identification

3. Adaptive SOC Estimator Design

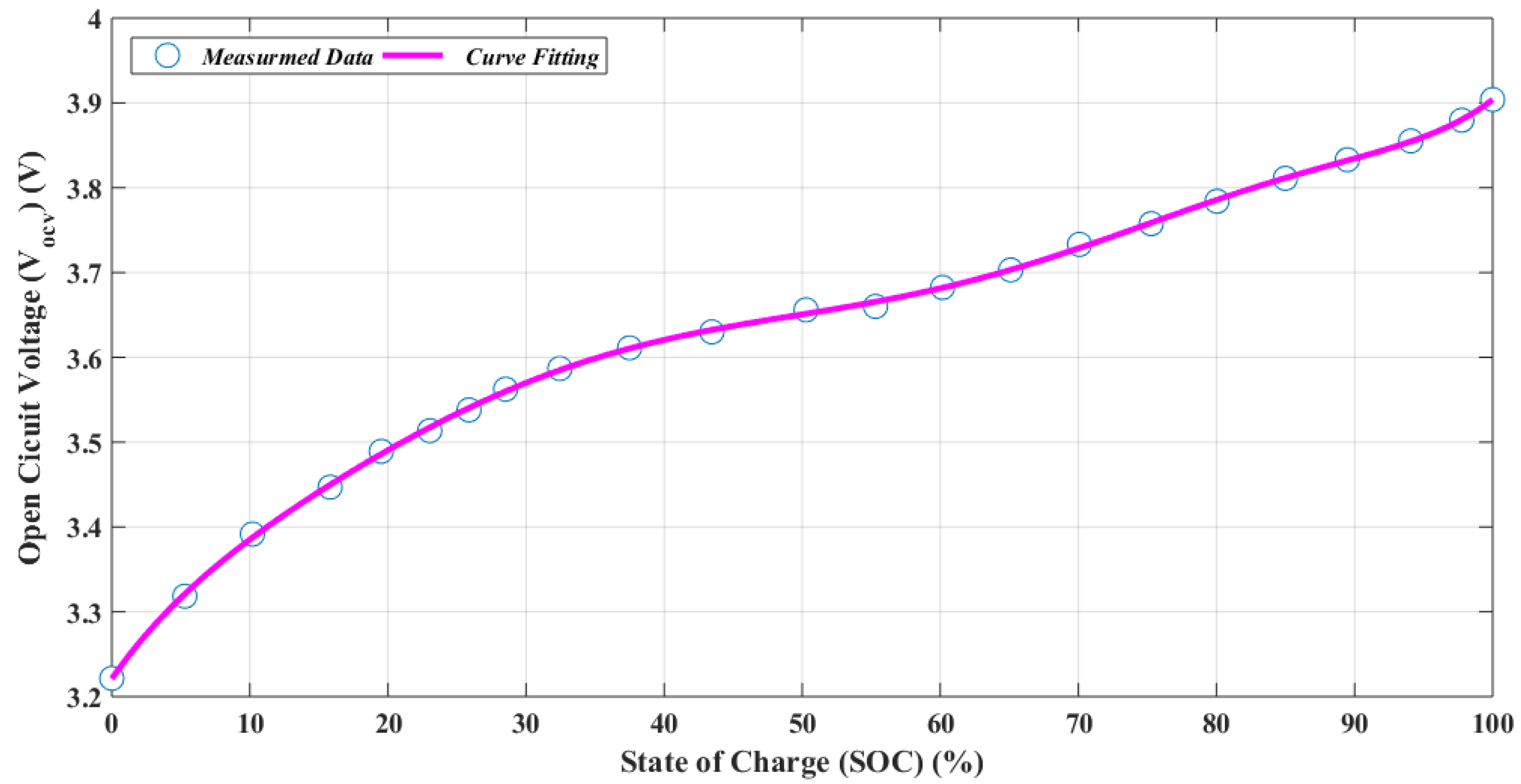

3.1. Adaptive OCV Estimator Design

3.2. Adaptive SOC Estimator Design

3.3. Algorithm Estimation Approach

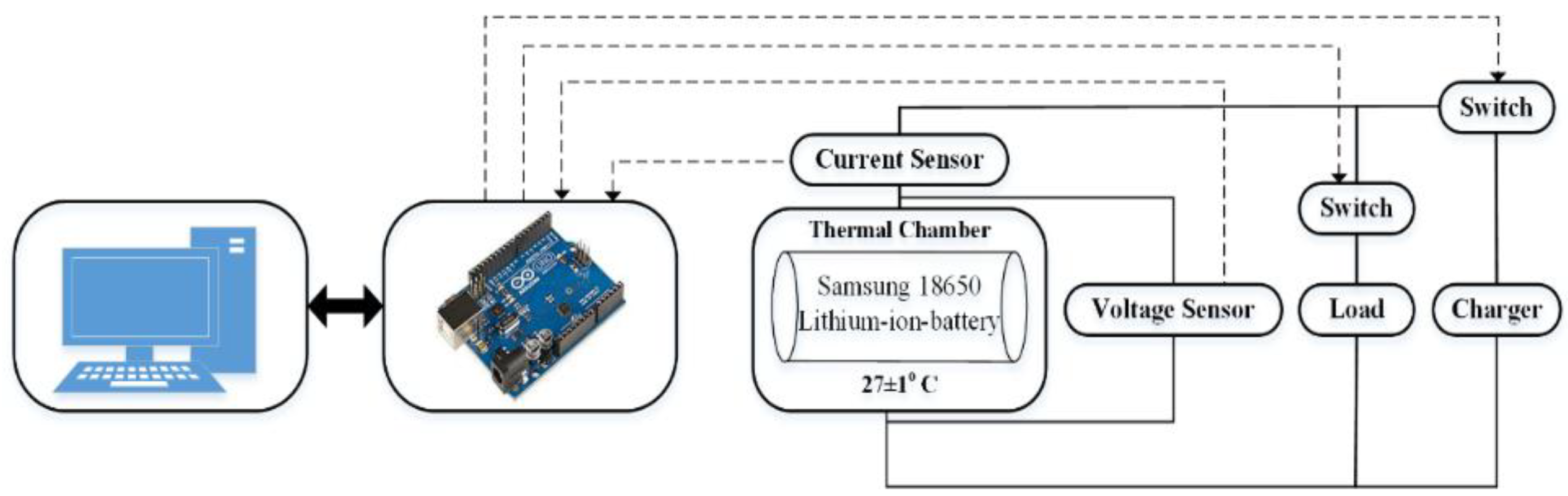

4. Experimental Setup

5. Results and Discussion

5.1. Battery Parameters Identification

5.2. Performance of SOC Estimator of Battery

5.3. Computational Time

5.4. Convergence Rate

5.5. Sensitivity Analysis

6. Conclusions

Author Contributions

Acknowledgments

Conflicts of Interest

References

- Wang, X.Y.; Hao, H.; Liu, J.L.; Huang, T.; Yu, A.S. A novel method for preparation of macroposous lithium nickel manganese oxygen as cathode material for lithium ion batteries. Electrochim. Acta 2011, 56, 4065–4069. [Google Scholar] [CrossRef]

- Xie, Z.; Ellis, S.; Xu, W.; Dye, D.; Zhao, J.; Wang, Y. A novel preparation of core–shell electrode materials via evaporation-induced self-assembly of nanoparticles for advanced li-ion batteries. Chem. Commun. 2015, 51, 15000–15003. [Google Scholar] [CrossRef] [PubMed]

- Khan, M.A.; Zeb, K.; Sathishkumar, P.; Ali, M.U.; Uddin, W.; Hussain, S.; Ishfaq, M.; Khan, I.; Cho, H.G.; Kim, H.J. A novel supercapacitor/lithium-ion hybrid energy system with a fuzzy logic-controlled fast charging and intelligent energy management system. Electronics 2018, 7, 63. [Google Scholar] [CrossRef]

- Nengroo, S.; Kamran, M.; Ali, M.; Kim, D.-H.; Kim, M.-S.; Hussain, A.; Kim, H. Dual battery storage system: An optimized strategy for the utilization of renewable photovoltaic energy in the United Kingdom. Electronics 2018, 7, 177. [Google Scholar] [CrossRef]

- Dai, H.F.; Yu, C.C.; Wei, X.Z.; Sun, Z.C. State of charge estimation for lithium-ion pouch batteries based on stress measurement. Energy 2017, 129, 16–27. [Google Scholar] [CrossRef]

- Wu, J.; Wang, Y.J.; Zhang, X.; Chen, Z.H. A novel state of health estimation method of li-ion battery using group method of data handling. J. Power Sources 2016, 327, 457–464. [Google Scholar] [CrossRef]

- Ali, M.U.; Nengroo, S.H.; Khan, M.A.; Zeb, K.; Kamran, M.A.; Kim, H.J. A real-time simulink interfaced fast-charging methodology of lithium-ion batteries under temperature feedback with fuzzy logic control. Energies 2018, 11, 1122. [Google Scholar] [CrossRef]

- Zhang, C.P.; Wang, L.Y.; Li, X.; Chen, W.; Yin, G.G.; Jiang, J.C. Robust and adaptive estimation of state of charge for lithium-ion batteries. IEEE Trans. Ind. Electr. 2015, 62, 4948–4957. [Google Scholar] [CrossRef]

- Hu, X.S.; Jiang, J.C.; Cao, D.P.; Egardt, B. Battery health prognosis for electric vehicles using sample entropy and sparse bayesian predictive modeling. IEEE Trans. Ind. Electr. 2016, 63, 2645–2656. [Google Scholar] [CrossRef]

- Rahimi-Eichi, H.; Ojha, U.; Baronti, F.; Chow, M.Y. Battery management system an overview of its application in the smart grid and electric vehicles. IEEE Ind. Electr. Mag. 2013, 7, 4–16. [Google Scholar] [CrossRef]

- Dong, G.Z.; Wei, J.W.; Chen, Z.H. Kalman filter for onboard state of charge estimation and peak power capability analysis of lithium-ion batteries. J. Power Sources 2016, 328, 615–626. [Google Scholar] [CrossRef]

- Hu, X.; Zou, C.; Zhang, C.; Li, Y. Technological developments in batteries: A survey of principal roles, types, and management needs. IEEE Ind. Electr. Mag. 2017, 15, 20–31. [Google Scholar] [CrossRef]

- Liu, T.H.; Chen, D.F.; Fang, C.C. Design and implementation of a battery charger with a state-of-charge estimator. Int. J. Electr. 2000, 87, 211–226. [Google Scholar] [CrossRef]

- Yang, N.X.; Zhang, X.W.; Li, G.J. State of charge estimation for pulse discharge of a lifepo4 battery by a revised ah counting. Electrochim. Acta 2015, 151, 63–71. [Google Scholar] [CrossRef]

- Hannan, M.A.; Lipu, M.S.H.; Hussain, A.; Mohamed, A. A review of lithium-ion battery state of charge estimation and management system in electric vehicle applications: Challenges and recommendations. Renew. Sustain. Energy Rev. 2017, 78, 834–854. [Google Scholar] [CrossRef]

- Fotouhi, A.; Auger, D.J.; Propp, K.; Longo, S.; Wild, M. A review on electric vehicle battery modelling: From lithium-ion toward lithium–sulphur. Renew. Sustain. Energy Rev. 2016, 56, 1008–1021. [Google Scholar] [CrossRef]

- Chang, W.-Y. The state of charge estimating methods for battery: A review. ISRN Appl. Math. 2013, 2013. [Google Scholar] [CrossRef]

- Plett, G.L. Extended kalman filtering for battery management systems of lipb-based hev battery packs—Part 1. Background. J. Power Sources 2004, 134, 252–261. [Google Scholar] [CrossRef]

- Plett, G.L. Extended kalman filtering for battery management systems of lipb-based hev battery packs—Part 2. Modeling and identification. J. Power Sources 2004, 134, 262–276. [Google Scholar] [CrossRef]

- Plett, G.L. Extended kalman filtering for battery management systems of lipb-based hev battery packs—Part 3. State and parameter estimation. J. Power Sources 2004, 134, 277–292. [Google Scholar] [CrossRef]

- Plett, G.L. Battery Management Systems, Volume II: Equivalent-Circuit Methods; Artech House: London, UK, 2015. [Google Scholar]

- Coleman, M.; Lee, C.K.; Zhu, C.; Hurley, W.G. State-of-charge determination from emf voltage estimation: Using impedance, terminal voltage, and current for lead-acid and lithium-ion batteries. IEEE Trans. Ind. Electr. 2007, 54, 2550–2557. [Google Scholar] [CrossRef]

- Quanshi, C.; Chengtao, L. Summarization of studies on performance models of batteries for electric vehicle. Autom. Technol. 2005, 3, 1–5. [Google Scholar]

- Ning, G.; White, R.E.; Popov, B.N. A generalized cycle life model of rechargeable li-ion batteries. Electrochim. Acta 2006, 51, 2012–2022. [Google Scholar] [CrossRef]

- Li, J.F.; Wang, L.X.; Lyu, C.; Pecht, M. State of charge estimation based on a simplified electrochemical model for a single licoo2 battery and battery pack. Energy 2017, 133, 572–583. [Google Scholar] [CrossRef]

- Xu, J.; Mi, C.C.; Cao, B.G.; Cao, J.Y. A new method to estimate the state of charge of lithium-ion batteries based on the battery impedance model. J. Power Sources 2013, 233, 277–284. [Google Scholar] [CrossRef]

- Zhao, X.W.; Cai, Y.S.; Yang, L.; Deng, Z.W.; Qiang, J.X. State of charge estimation based on a new dual-polarization-resistance model for electric vehicles. Energy 2017, 135, 40–52. [Google Scholar] [CrossRef]

- Zhang, C.; Li, K.; Deng, J.; Song, S.J. Improved realtime state-of-charge estimation of lifepo4 battery based on a novel thermoelectric model. IEEE Trans. Ind. Electr. 2017, 64, 654–663. [Google Scholar] [CrossRef]

- Wu, G.; Zhu, C.; Chan, C.C. Comparison of the first order and the second order equivalent circuit model applied in state of charge estimation for battery used in electric vehicles. J. Asian Electr. Veh. 2010, 8, 1357–1362. [Google Scholar] [CrossRef]

- Xiong, R.; Sun, F.C.; Gong, X.Z.; Gao, C.C. A data-driven based adaptive state of charge estimator of lithium-ion polymer battery used in electric vehicles. Appl. Energy 2014, 113, 1421–1433. [Google Scholar] [CrossRef]

- Buller, S.; Thele, M.; De Doncker, R.W.A.A.; Karden, E. Impedance-based simulation models of supercapacitors and li-ion batteries for power electronic applications. IEEE Trans. Ind. Appl. 2005, 41, 742–747. [Google Scholar] [CrossRef]

- Hageman, S.C. Simple pspice models let you simulate common battery types. Electr. Des. News 1993, 38, 117–129. [Google Scholar]

- Xiong, R.; Sun, F.C.; He, H.W.; Nguyen, T.D. A data-driven adaptive state of charge and power capability joint estimator of lithium-ion polymer battery used in electric vehicles. Energy 2013, 63, 295–308. [Google Scholar] [CrossRef]

- Hu, X.S.; Sun, F.C.; Zou, Y.A. Estimation of state of charge of a lithium-ion battery pack for electric vehicles using an adaptive luenberger observer. Energies 2010, 3, 1586–1603. [Google Scholar] [CrossRef]

- Zou, C.F.; Manzie, C.; Nesic, D.; Kallapur, A.G. Multi-time-scale observer design for state-of-charge and state-of-health of a lithium-ion battery. J. Power Sour. 2016, 335, 121–130. [Google Scholar] [CrossRef]

- Gao, M.; Liu, Y.; He, Z. Battery state of charge online estimation based on particle filter. In Proceedings of the 2011 4th International Congress on Image and Signal Processing, Shanghai, China, 15–17 October 2011; pp. 2233–2236. [Google Scholar] [CrossRef]

- Chen, X.P.; Shen, W.X.; Dai, M.X.; Cao, Z.W.; Jin, J.; Kapoor, A. Robust adaptive sliding-mode observer using rbf neural network for lithium-ion battery state of charge estimation in electric vehicles. IEEE Trans. Veh. Technol. 2016, 65, 1936–1947. [Google Scholar] [CrossRef]

- Lin, C.; Mu, H.; Xiong, R.; Shen, W.X. A novel multi-model probability battery state of charge estimation approach for electric vehicles using h-infinity algorithm. Appl. Energy 2016, 166, 76–83. [Google Scholar] [CrossRef]

- Zou, C.F.; Manzie, C.; Nesic, D. A framework for simplification of pde-based lithium-ion battery models. IEEE Trans. Control Syst. Technol. 2016, 24, 1594–1609. [Google Scholar] [CrossRef]

- Salkind, A.J.; Fennie, C.; Singh, P.; Atwater, T.; Reisner, D.E. Determination of state-of-charge and state-of-health of batteries by fuzzy logic methodology. J. Power Sources 1999, 80, 293–300. [Google Scholar] [CrossRef]

- Chin, C.; Gao, Z. State-of-charge estimation of battery pack under varying ambient temperature using an adaptive sequential extreme learning machine. Energies 2018, 11, 711. [Google Scholar] [CrossRef]

- Piao, C.H.; Fu, W.L.; Lei, G.H.; Cho, C.D. Online parameter estimation of the ni-mh batteries based on statistical methods. Energies 2010, 3, 206–215. [Google Scholar] [CrossRef]

- Rahimi-Eichi, H.; Baronti, F.; Chow, M.Y. Online adaptive parameter identification and state-of-charge coestimation for lithium-polymer battery cells. IEEE Trans. Ind. Electr. 2014, 61, 2053–2061. [Google Scholar] [CrossRef]

- Wei, Z.B.; Lim, T.M.; Skyllas-Kazacos, M.; Wai, N.; Tseng, K.J. Online state of charge and model parameter co-estimation based on a novel multi-timescale estimator for vanadium redox flow battery. Appl. Energy 2016, 172, 169–179. [Google Scholar] [CrossRef]

- Hu, C.; Youn, B.D.; Chung, J. A multiscale framework with extended kalman filter for lithium-ion battery soc and capacity estimation. Appl. Energy 2012, 92, 694–704. [Google Scholar] [CrossRef]

- Hua, Y.; Cordoba-Arenas, A.; Warner, N.; Rizzoni, G. A multi time-scale state-of-charge and state-of-health estimation framework using nonlinear predictive filter for lithium-ion battery pack with passive balance control. J. Power Sources 2015, 280, 293–312. [Google Scholar] [CrossRef]

- Kang, L.W.; Zhao, X.; Ma, J. A new neural network model for the state-of-charge estimation in the battery degradation process. Appl. Energy 2014, 121, 20–27. [Google Scholar] [CrossRef]

- Hu, X.S.; Li, S.B.; Peng, H. A comparative study of equivalent circuit models for li-ion batteries. J. Power Sources 2012, 198, 359–367. [Google Scholar] [CrossRef]

- Chen, M.; Rincon-Mora, G.A. Accurate electrical battery model capable of predicting runtime and iv performance. IEEE Trans. Energy Convers. 2006, 21, 504–511. [Google Scholar] [CrossRef]

- Samsung, S. Specification of Product for Lithium-ion Rechargeable Cell Model: Icr18650-26f. Available online: http://gamma.spb.ru/media/pdf/liion-lipolymer-lifepo4-akkumulyatory/ICR18650-26F.pdf (accessed on 14 June 2018).

- Abu-Sharkh, S.; Doerffel, D. Rapid test and non-linear model characterisation of solid-state lithium-ion batteries. J. Power Sources 2004, 130, 266–274. [Google Scholar] [CrossRef]

- Ogata, K. Discrete-Time Control Systems; Prentice Hall: Englewood Cliffs, NJ, USA, 1995; Volume 2. [Google Scholar]

- Haykin, S.S. Adaptive Filter Theory; Pearson Education: London, UK, 2008. [Google Scholar]

- Wei, Z.B.; Meng, S.J.; Xiong, B.Y.; Ji, D.X.; Tseng, K.J. Enhanced online model identification and state of charge estimation for lithium-ion battery with a fbcrls based observer. Appl. Energy 2016, 181, 332–341. [Google Scholar] [CrossRef]

- Wei, Z.B.; Zhao, J.Y.; Ji, D.X.; Tseng, K.J. A multi-timescale estimator for battery state of charge and capacity dual estimation based on an online identified model. Appl. Energy 2017, 204, 1264–1274. [Google Scholar] [CrossRef]

- Young, P.C. Recursive Estimation and Time-Series Analysis: An Introduction; Springer: Berlin, Germany, 2012. [Google Scholar]

- Yuan, S.; Wu, H.; Ma, X.; Yin, C. Stability analysis for li-ion battery model parameters and state of charge estimation by measurement uncertainty consideration. Energies 2015, 8, 7729–7751. [Google Scholar] [CrossRef]

| Polynomial Coefficients | Polynomial Coefficients Values |

|---|---|

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ali, M.U.; Kamran, M.A.; Kumar, P.S.; Himanshu; Nengroo, S.H.; Khan, M.A.; Hussain, A.; Kim, H.-J. An Online Data-Driven Model Identification and Adaptive State of Charge Estimation Approach for Lithium-ion-Batteries Using the Lagrange Multiplier Method. Energies 2018, 11, 2940. https://doi.org/10.3390/en11112940

Ali MU, Kamran MA, Kumar PS, Himanshu, Nengroo SH, Khan MA, Hussain A, Kim H-J. An Online Data-Driven Model Identification and Adaptive State of Charge Estimation Approach for Lithium-ion-Batteries Using the Lagrange Multiplier Method. Energies. 2018; 11(11):2940. https://doi.org/10.3390/en11112940

Chicago/Turabian StyleAli, Muhammad Umair, Muhammad Ahmad Kamran, Pandiyan Sathish Kumar, Himanshu, Sarvar Hussain Nengroo, Muhammad Adil Khan, Altaf Hussain, and Hee-Je Kim. 2018. "An Online Data-Driven Model Identification and Adaptive State of Charge Estimation Approach for Lithium-ion-Batteries Using the Lagrange Multiplier Method" Energies 11, no. 11: 2940. https://doi.org/10.3390/en11112940