Field Emission Current Stability and Noise Generation Mechanism of Large Aspect Ratio Diamond Nanowires

Abstract

1. Introduction

2. Sample Preparation and Characterization

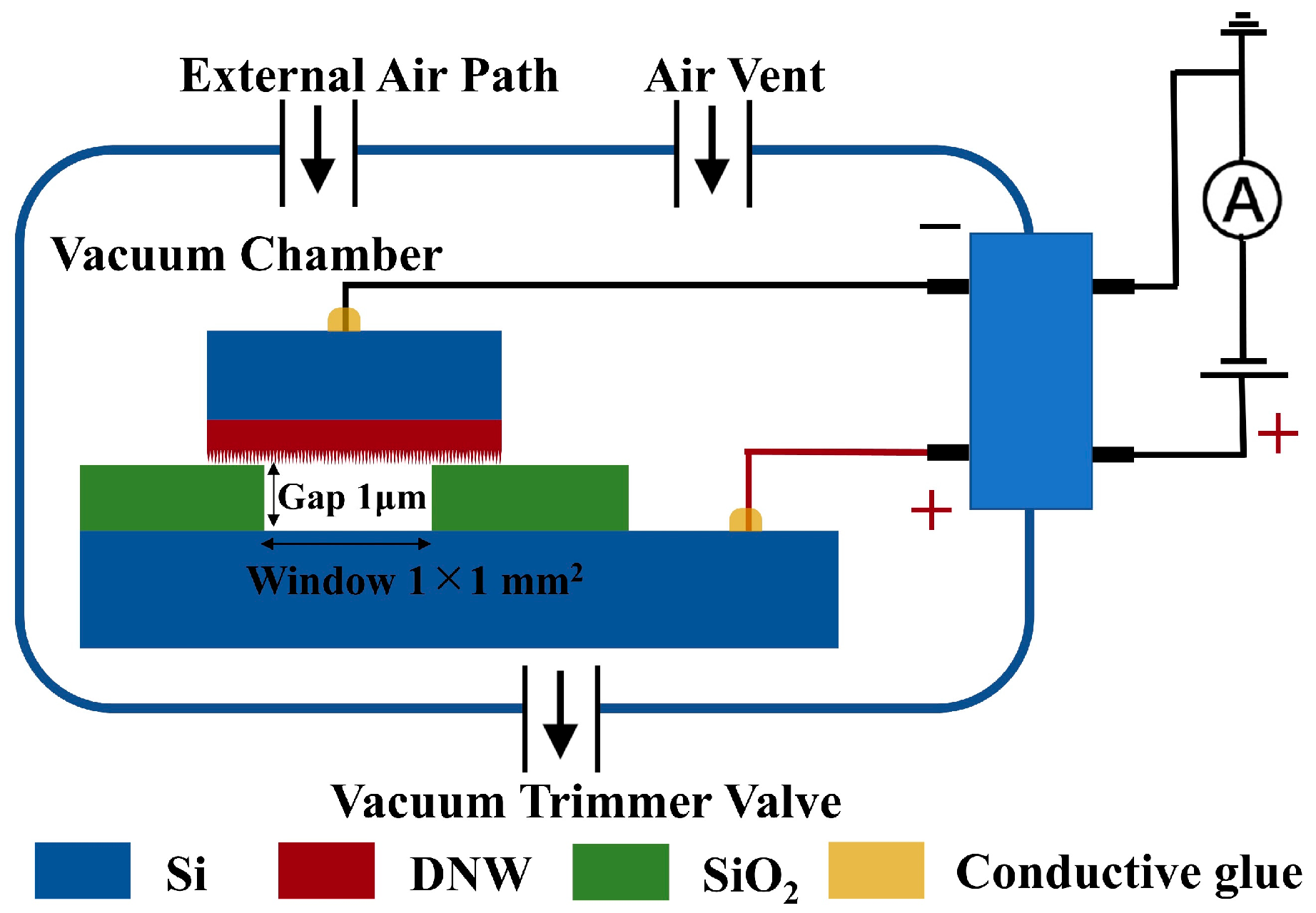

3. FE Properties and Current Stability Test System and Electrical Demonstration

4. Results and Discussion of FE Properties and Current Stability

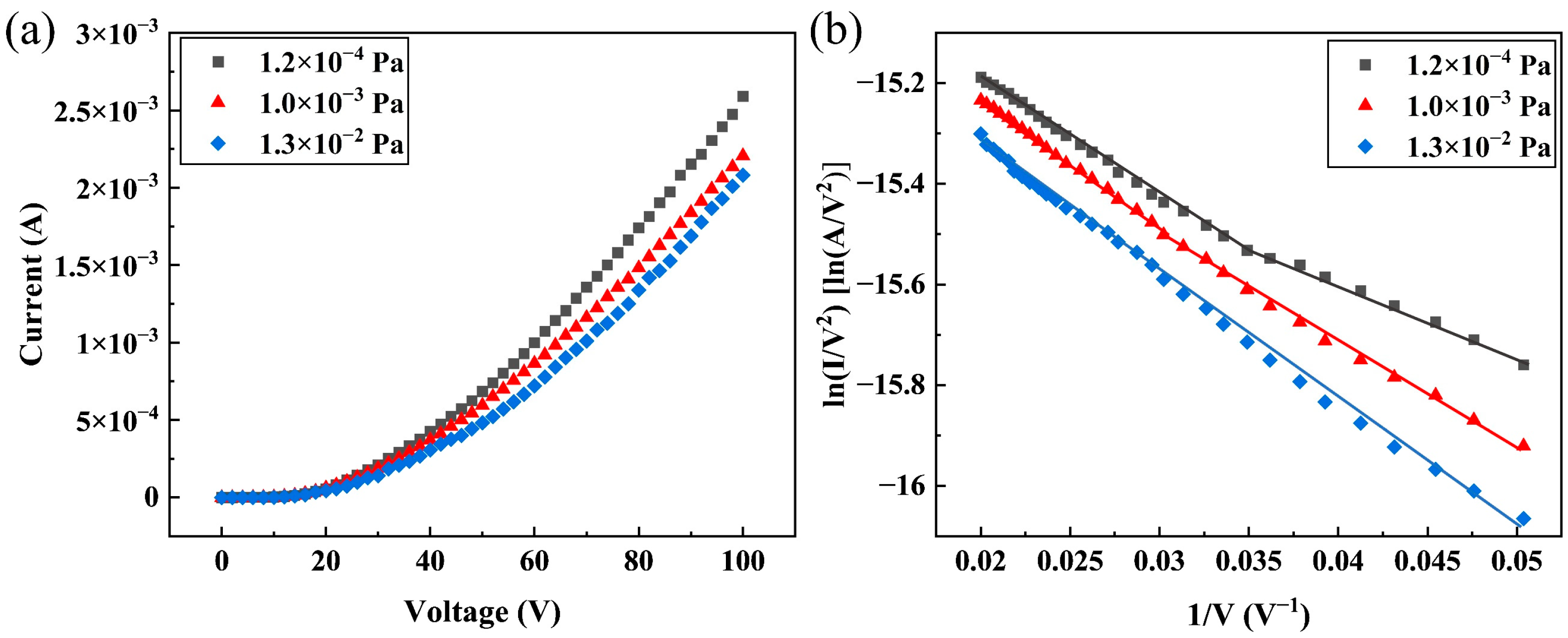

4.1. Effect of Vacuum Degree

4.1.1. FE Properties

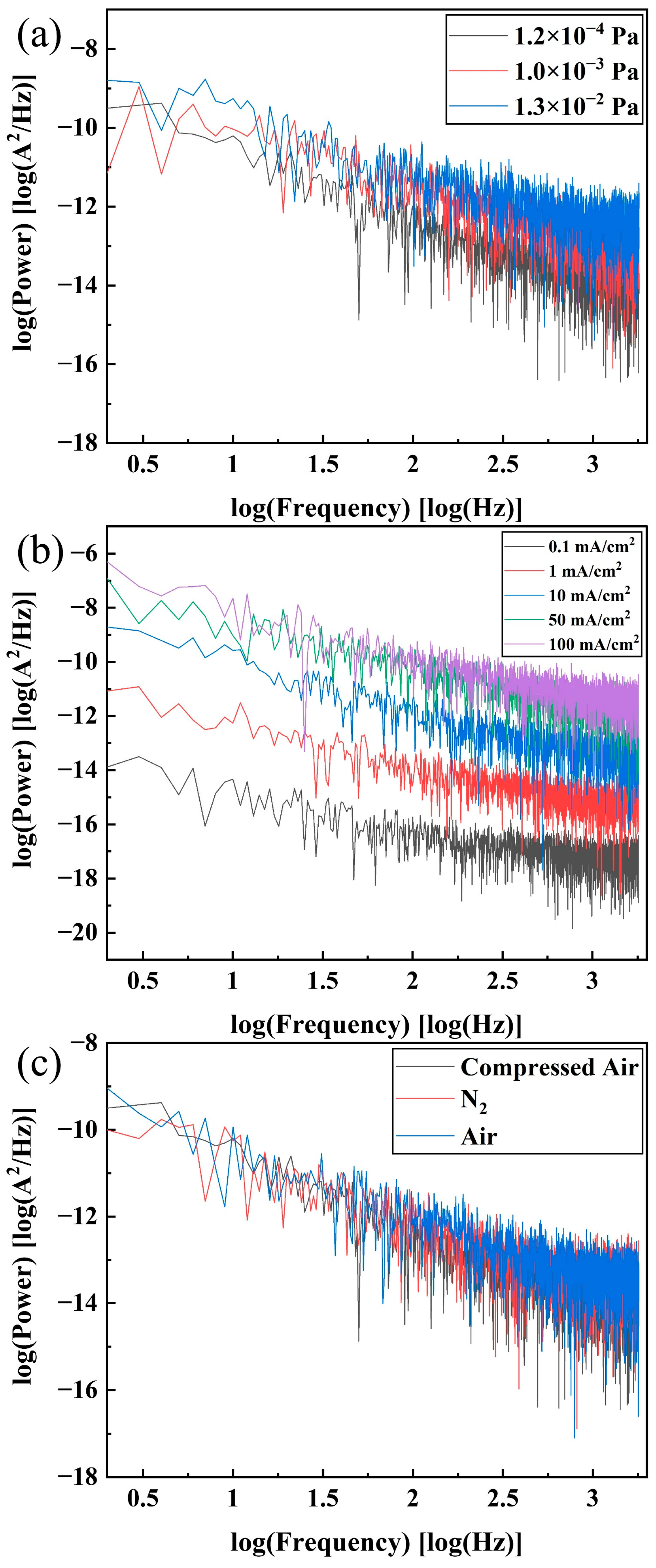

4.1.2. FE Current Stability

4.2. Effect of Current Density

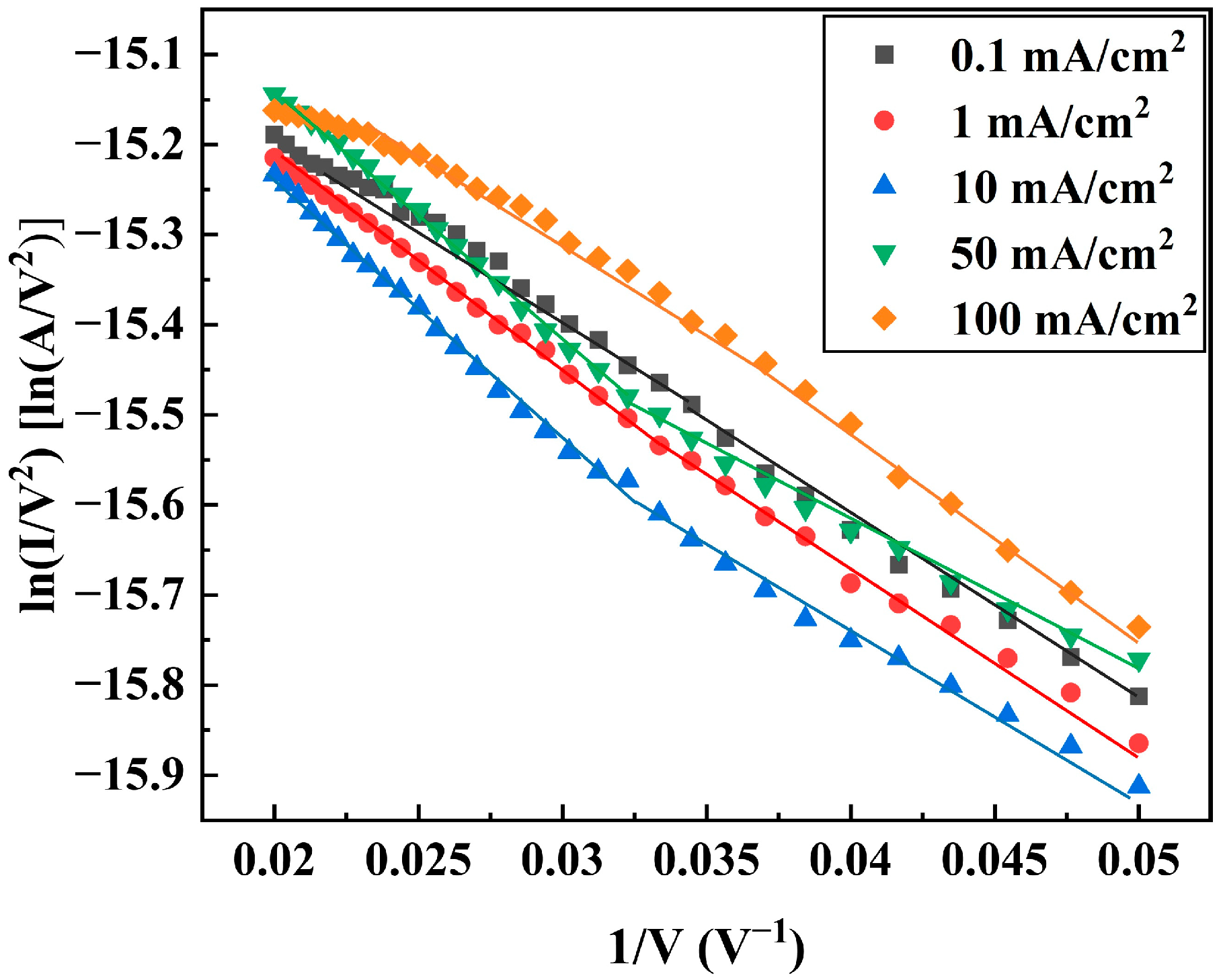

4.2.1. FE Properties

4.2.2. FE Current Stability

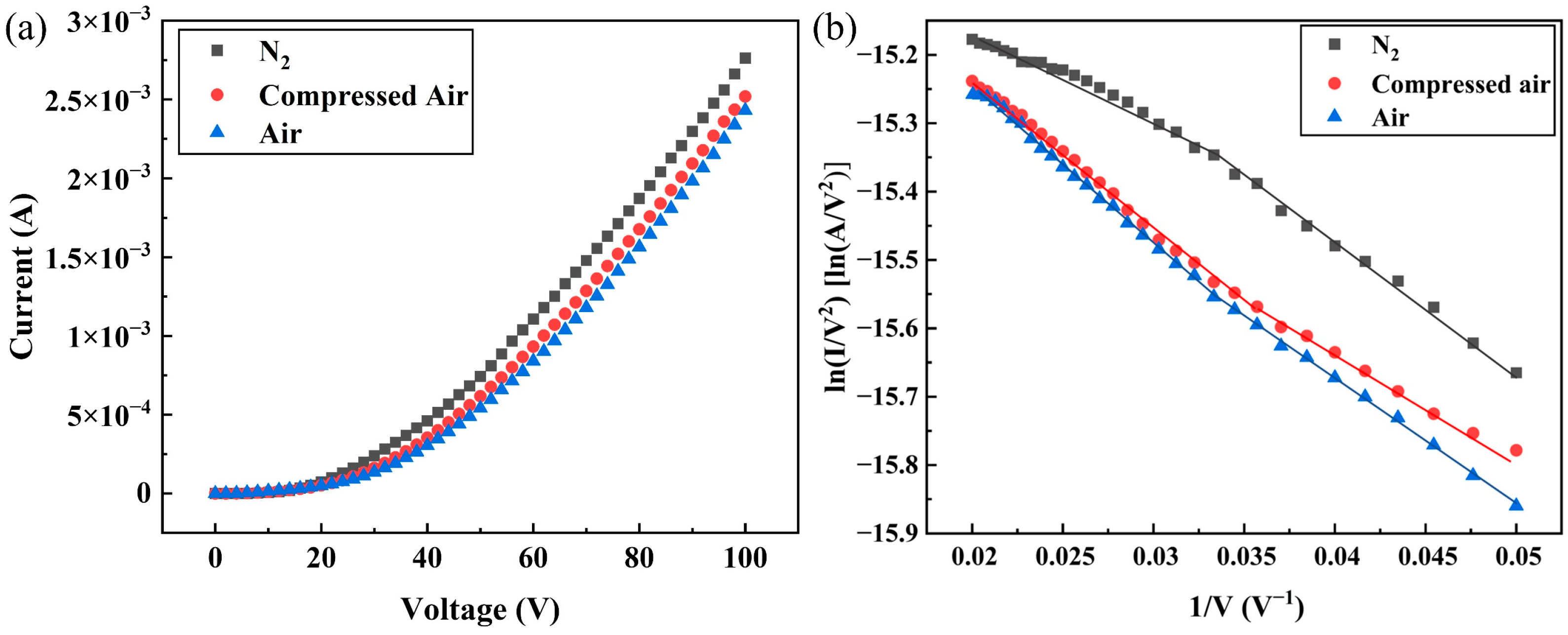

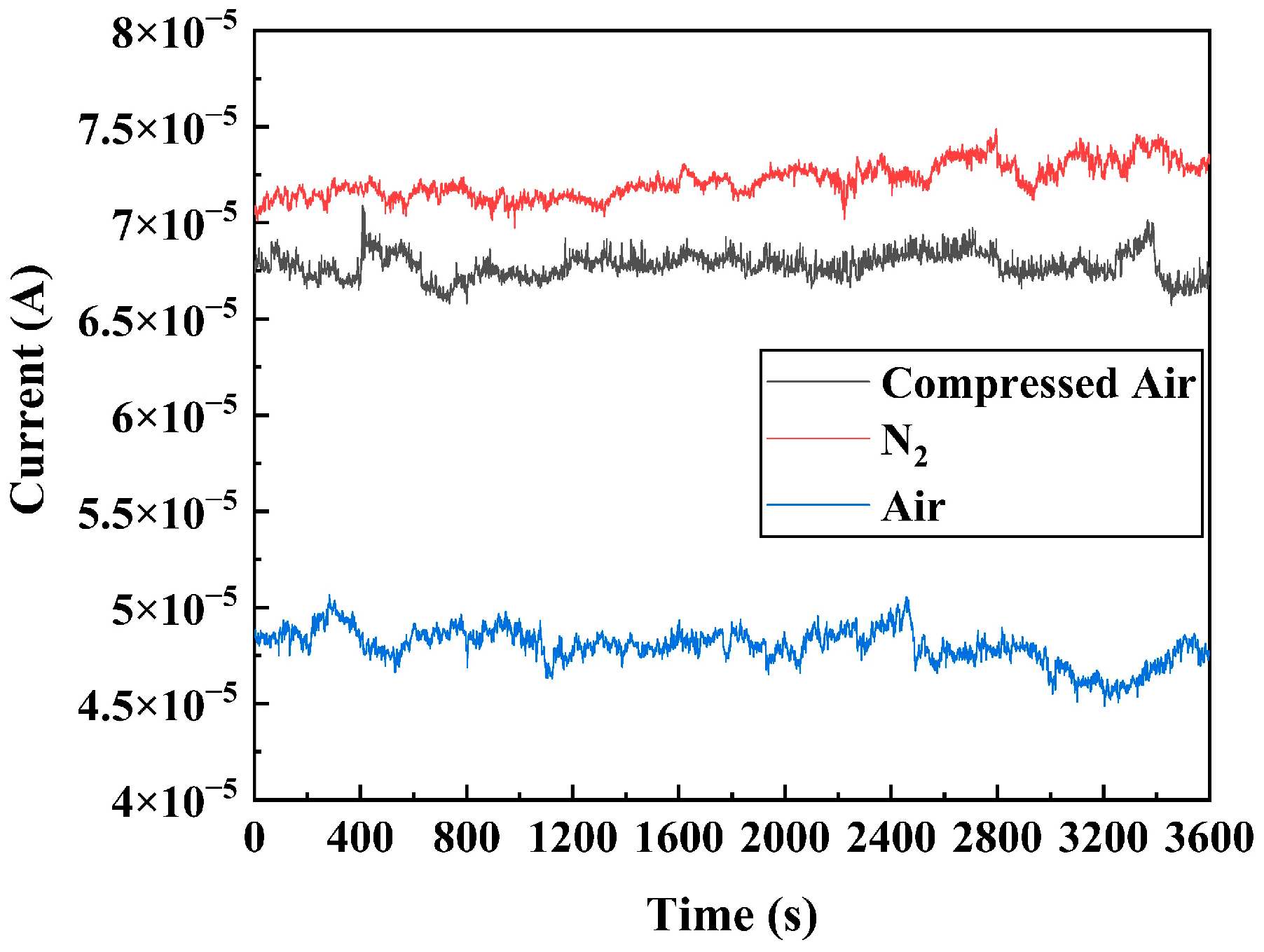

4.3. Effect of Atmosphere

4.3.1. FE Properties

4.3.2. FE Current Stability

4.4. FE Current Noise Power Spectrum of DNWs

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Terranova, M.L.; Orlanducci, S.; Rossi, M.; Tamburri, E. Nanodiamonds for field emission: State of the art. Nanoscale 2015, 7, 5094–5114. [Google Scholar] [CrossRef]

- Lahiri, I.; Verma, V.P.; Choi, W. An all-graphene based transparent and flexible field emission device. Carbon 2011, 49, 1614–1619. [Google Scholar] [CrossRef]

- Jacobs, L.; Barroo, C. Imaging chocolate at the nanoscale using field emission techniques. Appl. Surf. Sci. 2021, 535, 147747. [Google Scholar] [CrossRef]

- Shimoi, N.; Tohji, K. High-power switching device based on field emission mechanism fabricated using highly crystalline single-walled carbon nanotubes. Appl. Mater. Today 2022, 26, 101284. [Google Scholar] [CrossRef]

- Hugonnaud, V.; Mazouffre, S.; Krejci, D. Faraday cup sizing for electric propulsion ion beam study: Case of a field-emission-electric propulsion thruster. Rev. Sci. Instrum. 2021, 92, 084502. [Google Scholar] [CrossRef] [PubMed]

- Taniguchi, J.; Ohno, H.; Kawabata, Y.; Miyamoto, I. Ion-beam processing of single crystal diamond using SOG mask. Vacuum 2006, 80, 793–797. [Google Scholar] [CrossRef]

- Tsai, H.-Y.; Tseng, P.-T. Field emission characteristics of diamond nano-tip array fabricated by anodic aluminum oxide template with nano-conical holes. Appl. Surf. Sci. 2015, 351, 1004–1010. [Google Scholar] [CrossRef]

- Li, J.; Wang, Y.; Wei, Q.; Xie, Y.; Long, H.; Deng, Z.; Ma, L.; Yu, Z.; Jiang, Y.; Hu, N.; et al. Plasma-enhanced synthesis of carbon nanocone arrays by magnetic and electric fields coupling HFCVD. Surf. Coat. Tech. 2017, 324, 413–418. [Google Scholar] [CrossRef]

- Kunuku, S.; Sankaran, K.J.; Tsai, C.-Y.; Chang, W.-H.; Tai, N.-H.; Leou, K.-C.; Lin, I.-N. Investigations on Diamond Nanostructuring of Different Morphologies by the Reactive-Ion Etching Process and Their Potential Applications. ACS Appl. Mater. Inter. 2013, 5, 7439–7449. [Google Scholar] [CrossRef]

- Yu, Y.; Wu, L.; Zhi, J. Diamond Nanowires: Fabrication, Structure, Properties, and Applications. Angew. Chem. Int. Edit. 2014, 53, 14326–14351. [Google Scholar] [CrossRef]

- Uppireddi, K.; Rao, C.V.; Ishikawa, Y.; Weiner, B.R.; Morell, G. Temporal field emission current stability and fluctuations from graphene films. Appl. Phys. Lett. 2010, 97, 062106. [Google Scholar] [CrossRef]

- Chang, T.-H.; Kunuku, S.; Hong, Y.-J.; Leou, K.-C.; Yew, T.-R.; Tai, N.-H.; Lin, I.-N. Enhancement of the Stability of Electron Field Emission Behavior and the Related Microplasma Devices of Carbon Nanotubes by Coating Diamond Films. ACS Appl. Mater. Inter. 2014, 6, 11589–11597. [Google Scholar] [CrossRef]

- Uppireddi, K.; Weiner, B.R.; Morell, G. Study of the temporal current stability of field-emitted electrons from ultrananocrystalline diamond films. J. Appl. Phys. 2008, 103, 104315. [Google Scholar] [CrossRef]

- Golubkov, V.A.; Ivanov, A.S.; Ilyin, V.A.; Luchinin, V.V.; Bogdanov, S.A.; Chernov, V.V.; Vikharev, A.L. Stabilizing effect of diamond thin film on nanostructured silicon carbide field emission array. J. Vac. Sci. Technol. B 2016, 34, 062202. [Google Scholar] [CrossRef]

- Gao, J.; Zhao, L.; Hao, H. Field emission properties of the globe-like diamond microcrystalline aggregate films grown by MPCVD. Phys. B 2010, 405, 318–321. [Google Scholar] [CrossRef]

- Koinkar, P.M.; Kashid, R.V.; Patil, S.S.; Joag, D.S.; Murakami, R.; More, M.A. Noise Measurement and Analysis of Field Emission Current from Boron Doped Diamond. IEEE T. Nanotechnol. 2013, 12, 911–914. [Google Scholar] [CrossRef]

- Wang, Y.; Lin, C.; Zhang, J. Diamond Nanowires Array Prepared by Annealing Nano-Crystalline Diamond in Air and Its Application in Field Emission. In Proceedings of the 2023 IEEE 36th International Conference on Micro Electro Mechanical Systems (MEMS), Munich, Germany, 15–19 January 2023; pp. 921–924. [Google Scholar]

- Wang, Y.; Lin, C.; Zhang, J. High performance field emission cathode based on the diamond nanowires prepared by nanocrystalline diamond films annealed in air. J. Micromech. Microeng. 2024, 34, 025011. [Google Scholar] [CrossRef]

- Reuss, R.H.; Chalamala, B.R. Gas-induced current decay of molybdenum field emitter arrays. J. Vac. Sci. Technol. B 2003, 21, 1187–1202. [Google Scholar] [CrossRef]

- Miyata, K.; Kobashi, K. Air oxidation of undoped and B-doped polycrystalline diamond films at high temperature. J. Mater. Res. 1996, 11, 296–304. [Google Scholar] [CrossRef]

- Wu, J.Q.; Deng, S.Z.; Xu, N.S.; Chen, J. Field emission from α-Fe2O3 nanoflakes: Effect of vacuum pressure, gas adsorption and in-situ thermal treatment. Appl. Surf. Sci. 2014, 292, 454–461. [Google Scholar] [CrossRef]

- Márquez-Mijares, M.; Lepetit, B.; Lemoine, D. Carbon adsorption on tungsten and electronic field emission. Surf. Sci. 2016, 645, 56–62. [Google Scholar] [CrossRef]

- Rezek, B.; Nebel, C.E.; Stutzmann, M. Hydrogenated diamond surfaces studied by atomic and Kelvin force microscopy. Diam. Relat. Mater. 2004, 13, 740–745. [Google Scholar] [CrossRef]

- Ding, M.Q.; Auciello, O.; Carlisle, J.A.; Gruen, D.M. Effect of oxygen on field emission properties of ultrananocrystalline diamond-coated ungated Si tip arrays. J. Vac. Sci. Technol. B 2003, 21, 1644–1647. [Google Scholar] [CrossRef]

- Giubileo, F.; Bartolomeo, A.D.; Zhong, Y.; Zhao, S.; Passacantando, M. Field emission from AlGaN nanowires with low turn-on field. Nanotechnology 2020, 31, 475702. [Google Scholar] [CrossRef]

- Vasil’eva, E.A.; Kleshch, V.I.; Obraztsov, A.N. Effect of vacuum level on field emission from nanographite films. Tech. Phys. 2012, 57, 1003–1007. [Google Scholar] [CrossRef]

- Yamamoto, S. Fundamental physics of vacuum electron sources. Rep. Prog. Phys. 2006, 69, 181–232. [Google Scholar] [CrossRef]

- Zhao, X. Field Emission Study of Carbon Nanostructures. Ph.D. Thesis, William & Mary, Williamsburg, VA, USA, 2006. [Google Scholar]

- Bhattacharya, R.; Cannon, M.; Bhattacharjee, R.; Rughoobur, G.; Karaulac, N.; Chern, W.; Akinwande, A.I.; Browning, J. Effect of Room Air Exposure on the Field Emission Performance of UV Light Irradiated Si-Gated Field Emitter Arrays. J. Vac. Sci. Technol. B 2022, 40, 010601. [Google Scholar] [CrossRef]

- Derry, T.E.; Makau, N.W.; Stampfl, C. Oxygen adsorption on the (1 × 1) and (2 × 1) reconstructed C(111) surfaces: A density functional theory study. J. Phys.-Condens. Mat. 2010, 22, 265007. [Google Scholar] [CrossRef]

- Zheng, Y.; Kuntumalla, M.K.; Attrash, M.; Hoffman, A.; Huang, K. Effect of Surface Hydrogenation on the Adsorption and Thermal Evolution of Nitrogen Species on Diamond(001) by Microwave N 2 Plasma. J. Phys. Chem. C 2021, 125, 28157–28161. [Google Scholar] [CrossRef]

- Kuntumalla, M.K.; Zheng, Y.; Attrash, M.; Gani, G.; Michaelson, S.; Huang, K.; Hoffman, A. Microwave N2 plasma nitridation of H-diamond (111) surface studied by ex situ XPS, HREELS, UPS, TPD, LEED and DFT. Appl. Surf. Sci. 2022, 600, 154085. [Google Scholar] [CrossRef]

- Manelli, O.; Corni, S.; Righi, M.C. Water Adsorption on Native and Hydrogenated Diamond (001) Surfaces. J. Phys. Chem. C 2010, 114, 7045–7053. [Google Scholar] [CrossRef]

- Gao, X.; Liu, L.; Qi, D.; Chen, S.; Wee, A.T.S.; Ouyang, T.; Loh, K.P.; Yu, X.; Moser, H.O. Water-Induced Negative Electron Affinity on Diamond (100). J. Phys. Chem. C 2008, 112, 2487–2491. [Google Scholar] [CrossRef]

- Straub, H.C.; Renault, P.; Lindsay, B.G.; Smith, K.A.; Stebbings, R.F. Absolute partial cross sections for electron-impact ionization of H2, N2, and O2 from threshold to 1000 eV. Phys. Rev. A 1996, 54, 2146–2153. [Google Scholar] [CrossRef]

- Straub, H.C.; Lindsay, B.G.; Smith, K.A.; Stebbings, R.F. Absolute partial cross sections for electron-impact ionization of H2O and D2O from threshold to 1000 eV. J. Chem. Phys. 1998, 108, 109–116. [Google Scholar] [CrossRef]

- Kolekar, S.; Patole, S.P.; Patil, S.; Yoo, J.B.; Dharmadhikari, C.V. Study of thermal-field emission properties and investigation of temperature dependent noise in the field emission current from vertical carbon nanotube emitters. Surf. Sci. 2017, 664, 76–81. [Google Scholar] [CrossRef][Green Version]

- Kolekar, S.; Patole, S.P.; Yoo, J.-B.; Dharmadhikari, C.V. Investigation of Electron Transport Across Vertically Grown CNTs Using Combination of Proximity Field Emission Microscopy and Scanning Probe Image Processing Techniques. Electron. Mater. Lett. 2018, 14, 173–180. [Google Scholar] [CrossRef]

- Cho, B.; Itagaki, T.; Oshima, C. Record of the lowest frequency shot noise measurement below 10Hz. Appl. Phys. Lett. 2007, 91, 051916. [Google Scholar] [CrossRef]

- Suryawanshi, S.R.; Kolhe, P.S.; Rout, C.S.; Late, D.J.; More, M.A. Spectral analysis of the emission current noise exhibited by few layer WS2 nanosheets emitter. Ultramicroscopy 2015, 149, 51–57. [Google Scholar] [CrossRef]

- Chen, C.; Chen, S.; Shang, M.; Gao, F.; Yang, Z.; Liu, Q.; He, Z.; Yang, W. Fabrication of highly oriented 4H-SiC gourd-shaped nanowire arrays and their field emission properties. J. Mater. Chem. C 2016, 4, 5195–5201. [Google Scholar] [CrossRef]

- Chen, S.; Ying, P.; Wang, L.; Wei, G.; Gao, F.; Zheng, J.; Shang, M.; Yang, Z.; Yang, W.; Wu, T. Highly flexible and robust N-doped SiC nanoneedle field emitters. NPG Asia Mater. 2015, 7, e157. [Google Scholar] [CrossRef]

- Wang, L.; Li, C.; Yang, Y.; Chen, S.; Gao, F.; Wei, G.; Yang, W. Large-Scale Growth of Well-Aligned SiC Tower-Like Nanowire Arrays and Their Field Emission Properties. ACS Appl. Mater. Inter. 2015, 7, 526–533. [Google Scholar] [CrossRef] [PubMed]

- Wang, L.; Wei, G.; Gao, F.; Li, C.; Yang, W. High-temperature stable field emission of B-doped SiC nanoneedle arrays. Nanoscale 2015, 7, 7585–7592. [Google Scholar] [CrossRef] [PubMed]

- Tang, Y.B.; Cong, H.T.; Zhao, Z.G.; Cheng, H.M. Field emission from AlN nanorod array. Appl. Phys. Lett. 2005, 86, 153104. [Google Scholar] [CrossRef]

- Tang, Y.B.; Cong, H.T.; Wang, Z.M.; Cheng, H.-M. Catalyst-seeded synthesis and field emission properties of flowerlike Si-doped AlN nanoneedle array. Appl. Phys. Lett. 2006, 89, 253112. [Google Scholar] [CrossRef]

- Chen, S.; Shang, M.; Gao, F.; Wang, L.; Ying, P.; Yang, W.; Fang, X. Extremely Stable Current Emission of P-Doped SiC Flexible Field Emitters. Adv. Sci. 2016, 3, 1500256. [Google Scholar] [CrossRef]

| Vacuum Degree (Pa) | 1.2 × 10−4 | 1.0 × 10−3 | 1.3 × 10−2 | |||

|---|---|---|---|---|---|---|

| (V/μm) | 1.84 | 2.23 | 3.50 | |||

| (mA/cm2)@100 V | 249.04 | 212.50 | 200.08 | |||

| Slope of F-N curve | −16.70 | −20.95 | −20.84 | −26.09 | −23.38 | −28.11 |

| Rate of (%) | 0 | 15.75 | 21.66 | |||

| Vacuum Degree (Pa) | 1.2 × 10−4 | 1.0 × 10−3 | 1.3 × 10−2 |

|---|---|---|---|

| (A) | 6.79 × 10−5 | 6.03 × 10−5 | 4.43 × 10−5 |

| (A) | 9.34 × 10−7 | 1.50 × 10−6 | 2.11 × 10−6 |

| (%) | 1.37 | 2.48 | 4.76 |

| 0.95 | 1.24 | 1.09 |

| Test Current Density (mA/cm2) | 0.1 | 1 | 10 | 50 | 100 | |||||

|---|---|---|---|---|---|---|---|---|---|---|

| (V/μm) | 1.75 | 1.94 | 2.14 | 2.04 | 1.84 | |||||

| (mA/cm2)@100 V | 242.31 | 241.35 | 232.69 | 236.54 | 239.42 | |||||

| Slope of F-N curve | −18.28 | −19.69 | −18.91 | −21.82 | −18.15 | −24.08 | −17.42 | −23.84 | −21.88 | −20.08 |

| Rate of (%) | 0 | 7.08 | 14.37 | 13.59 | 1.32 | |||||

| Test Current Density (mA/cm2) | 0.1 | 1 | 10 | 50 | 100 |

|---|---|---|---|---|---|

| Applied voltage (V) | 3.3 | 9.8 | 27.0 | 44.6 | 61.3 |

| (A) | 1.01 × 10−6 | 9.99 × 10−6 | 1.00 × 10−4 | 5.00 × 10−4 | 1.00 × 10−3 |

| (A) | 7.04 × 10−9 | 1.07 × 10−7 | 1.48 × 10−6 | 8.04 × 10−6 | 1.30 × 10−5 |

| (%) | 0.70 | 1.07 | 1.48 | 1.61 | 1.30 |

| 0.92 | 1.12 | 1.30 | 1.28 | 1.30 |

| Atmosphere | N2 | Compressed Air | Air | |||

|---|---|---|---|---|---|---|

| (V/μm) | 1.65 | 1.86 | 2.13 | |||

| (mA/cm2)@100 V | 265.38 | 248.08 | 233.65 | |||

| Slope of F-N curve | −19.51 | −17.14 | −17.59 | −20.17 | −18.98 | −21.69 |

| Rate of (%) | 0 | 11.45 | 16.99 | |||

| Gas | (eV) | (eV) | σ (10−16 cm2)@20 eV |

|---|---|---|---|

| O2 | −5.01 | 6.5 | 0.293 |

| N2 | +2.45 | 5.5 | 0.218 |

| H2O | −0.26 | 4.9 | 0.457 |

| Atmosphere | N2 | Compressed Air | Air |

|---|---|---|---|

| (A) | 7.23 × 10−5 | 6.79 × 10−5 | 4.80 × 10−5 |

| (A) | 9.01 × 10−7 | 9.34 × 10−7 | 9.22 × 10−7 |

| (%) | 1.25 | 1.37 | 1.92 |

| 1.05 | 1.32 | 1.20 |

| Field Emission Structure | (V/μm) | Test Current Density (mA/cm2) | Current Fluctuation Rate (%) |

|---|---|---|---|

| 4H-SiC nanowires [41] | 0.95 | 0.7 | 2.1 |

| N-SiC nanoneedles [42] | 1.22 | 1.1 | 6.5 |

| SiC nanowires [43] | 1.50 | 0.7 | 3.8 |

| B-SiC nanoneedles [44] | 1.92 | 0.5 | 6.5 |

| AlN nanorods [45] | 8.8 | 10.3 | 2 |

| Si-AlN nanoneedles [46] | 1.8 | 10 | 5 |

| P-SiC nanoparticles [47] | 1.03 | 2.65 | 3.0 |

| DNWs | 1.36 | 0.1 | 0.70 |

| 1.94 | 1 | 1.07 | |

| 2.14 | 10 | 1.48 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Y.; Zhang, J. Field Emission Current Stability and Noise Generation Mechanism of Large Aspect Ratio Diamond Nanowires. Sensors 2025, 25, 2925. https://doi.org/10.3390/s25092925

Wang Y, Zhang J. Field Emission Current Stability and Noise Generation Mechanism of Large Aspect Ratio Diamond Nanowires. Sensors. 2025; 25(9):2925. https://doi.org/10.3390/s25092925

Chicago/Turabian StyleWang, Yang, and Jinwen Zhang. 2025. "Field Emission Current Stability and Noise Generation Mechanism of Large Aspect Ratio Diamond Nanowires" Sensors 25, no. 9: 2925. https://doi.org/10.3390/s25092925

APA StyleWang, Y., & Zhang, J. (2025). Field Emission Current Stability and Noise Generation Mechanism of Large Aspect Ratio Diamond Nanowires. Sensors, 25(9), 2925. https://doi.org/10.3390/s25092925