Flexible Stretchable Strain Sensor Based on LIG/PDMS for Real-Time Health Monitoring of Test Pilots

Abstract

1. Introduction

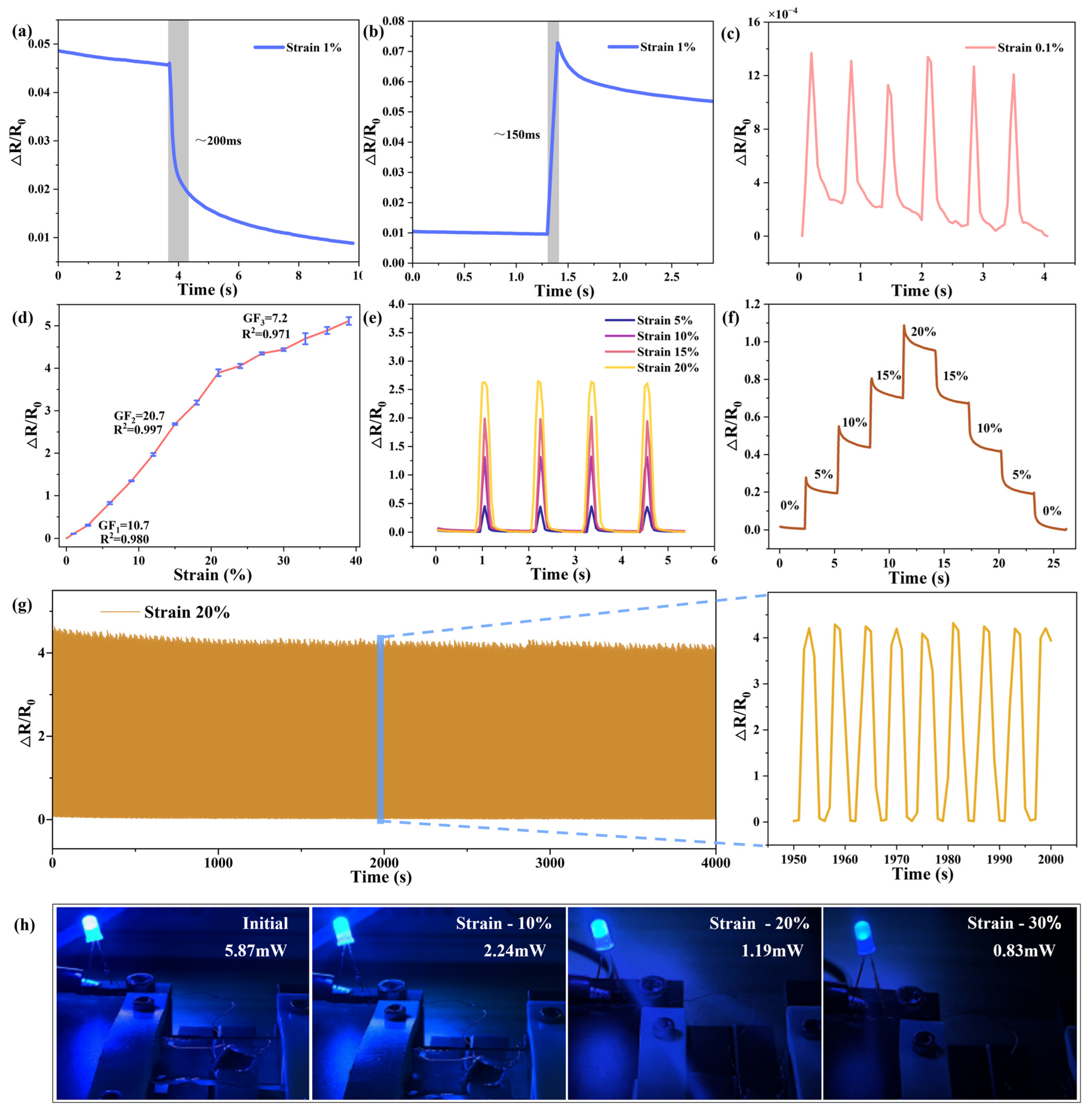

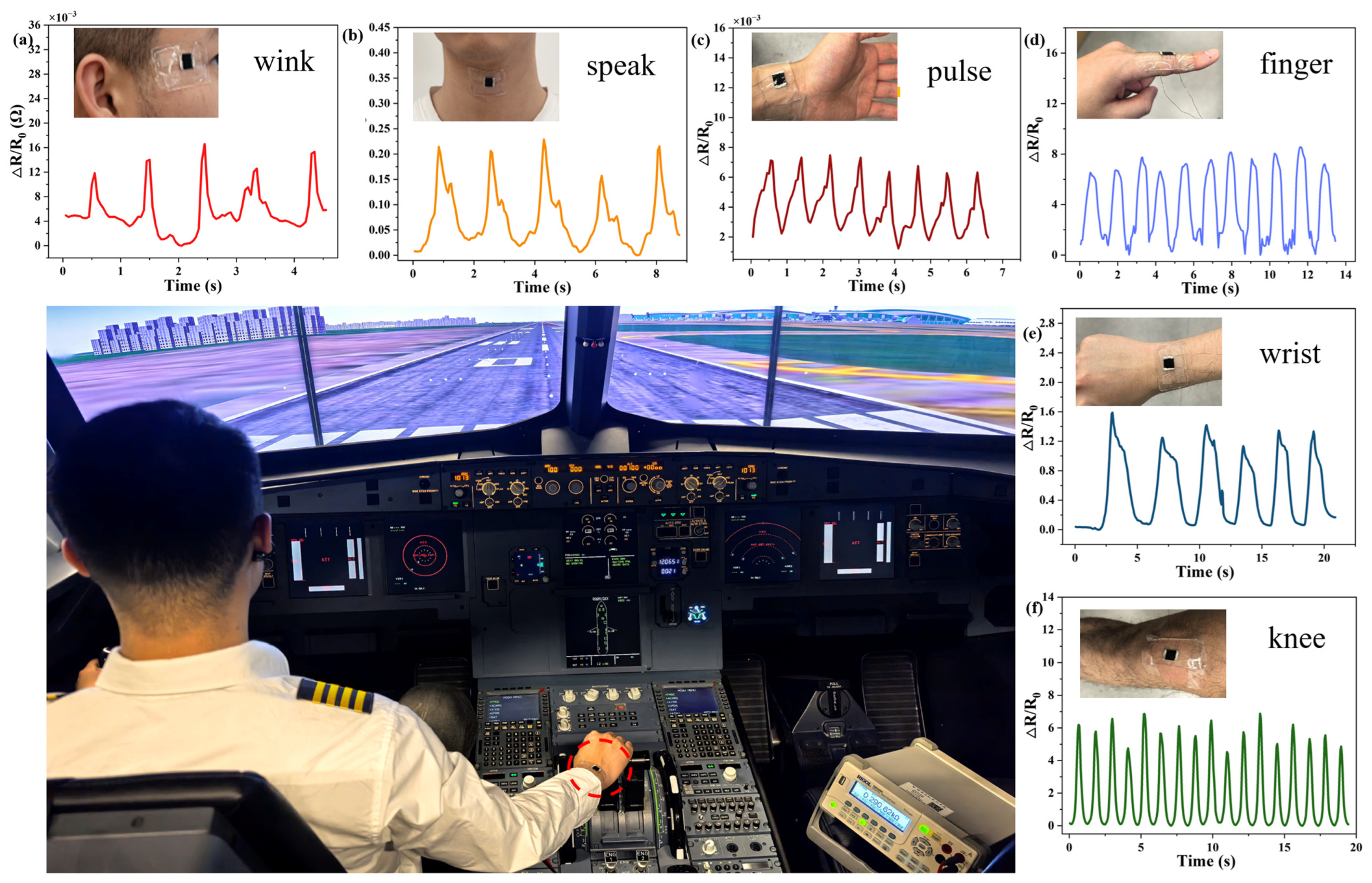

- By integrating laser direct writing technology and the transfer method, high-performance LIG was successfully fabricated on PI and subsequently transferred to a PDMS substrate, creating an LIG/PDMS flexible strain sensor with excellent tensile properties and sensitivity. This sensor demonstrates a maximum tensile strain of approximately 40% and a gauge factor of 20.7 within a 21% strain range.

- The LIG/PDMS-based flexible strain sensor exhibits outstanding sensing characteristics, including superior electrical conductivity (48 Ω), a low detection limit (0.1%), rapid response and recovery times (150 ms/200 ms), and excellent durability after undergoing more than 1000 stretching cycles.

- This LIG/PDMS-based flexible strain sensor was innovatively applied for the first time in the real-time monitoring of civil aviation test pilots, capturing physiological signals including blinking, pulse, finger bending, and wrist movement. This application provides a novel, efficient, and comfortable approach for real-time pilot monitoring.

2. Materials and Methods

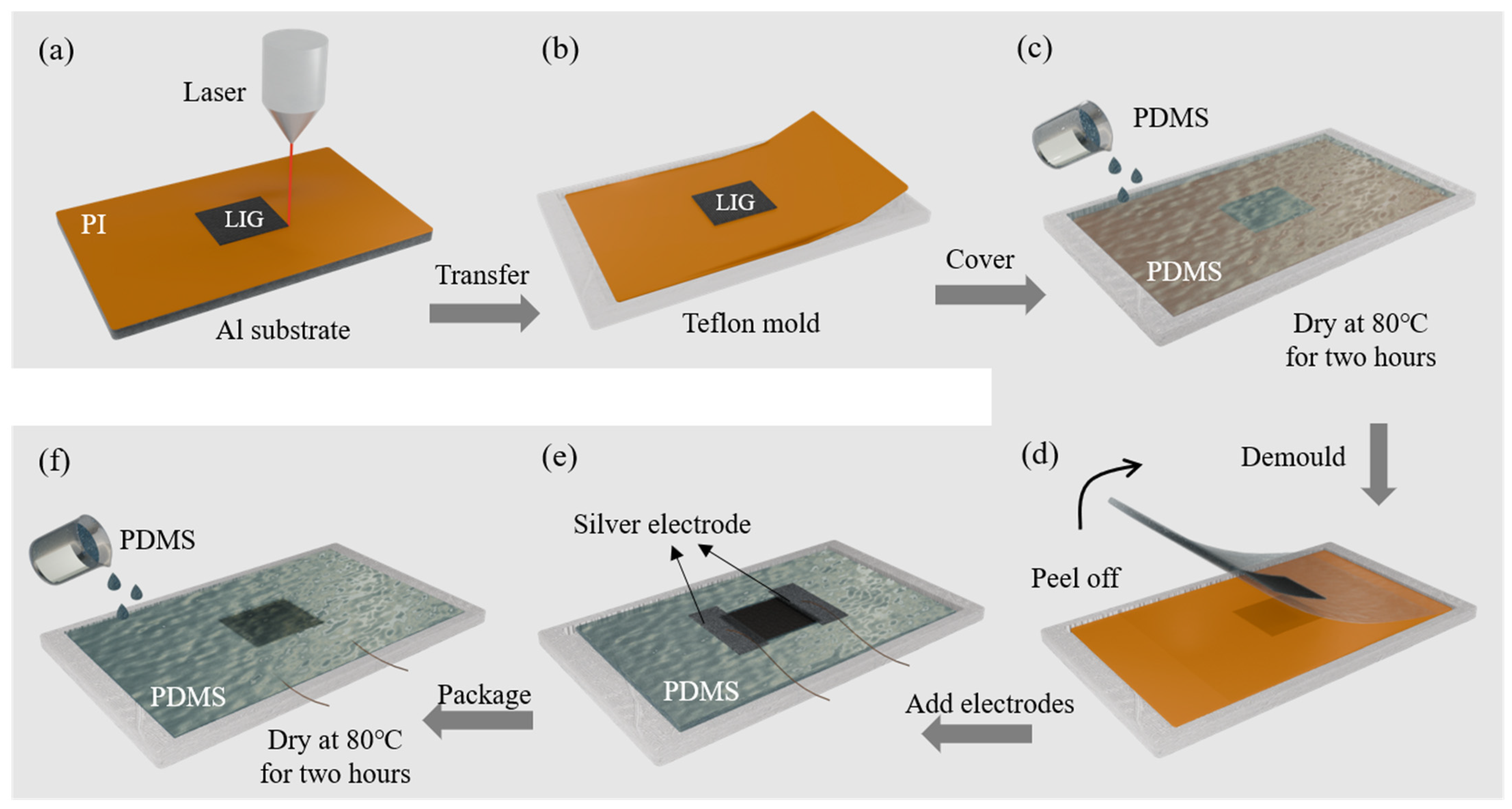

2.1. Preparation of LIG Strain Sensor

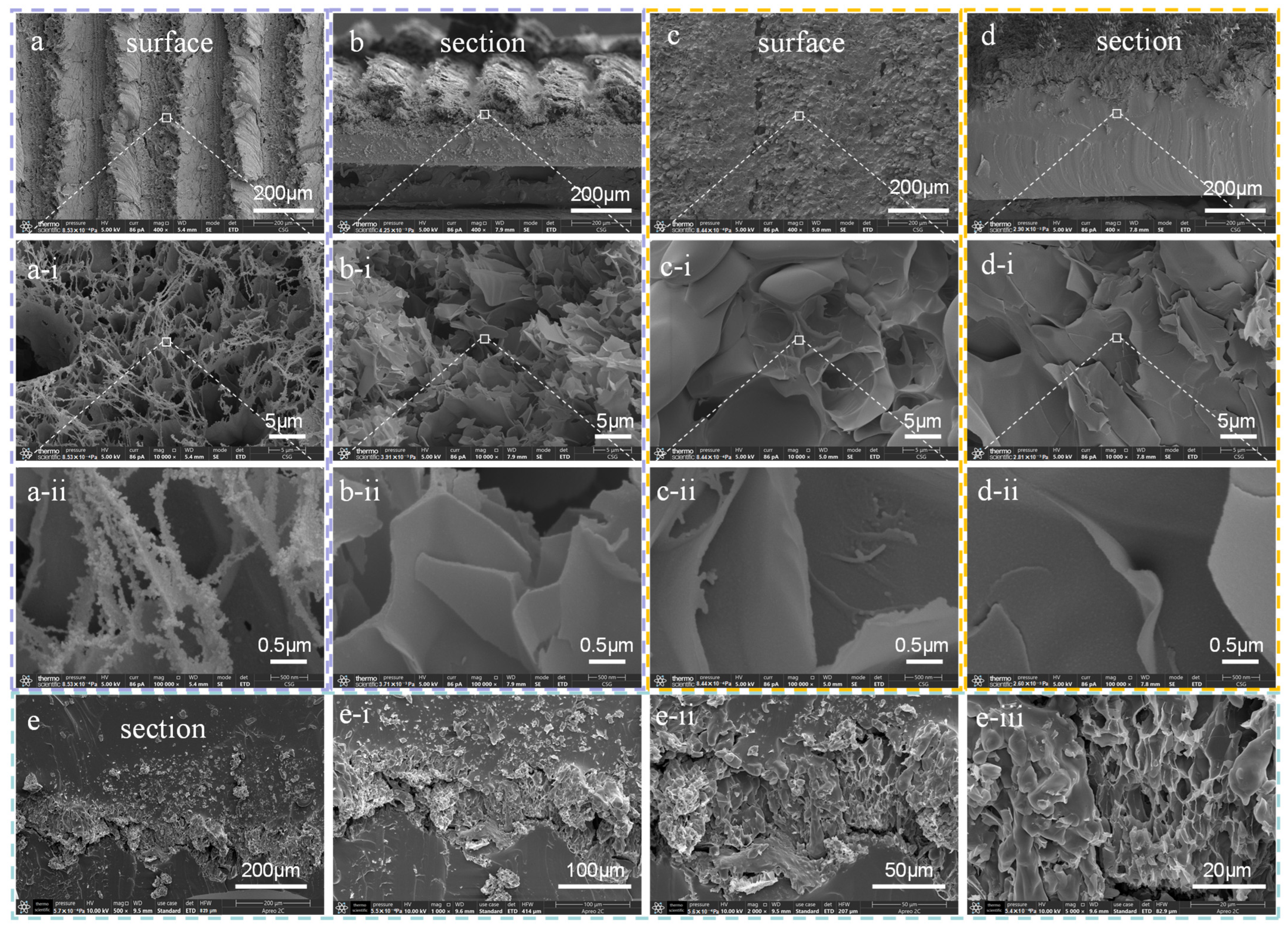

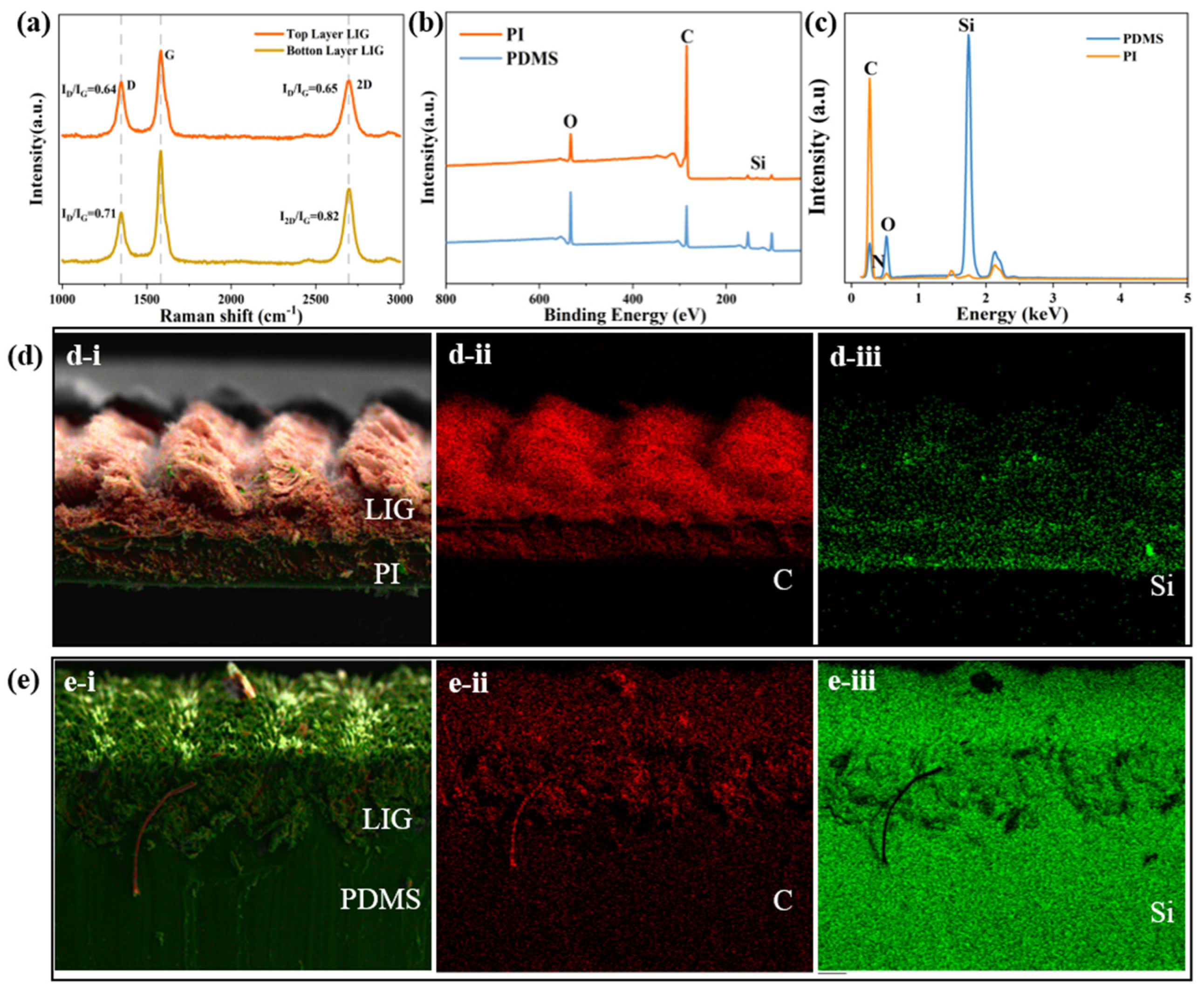

2.2. Materials Characterization

3. Results and Discussion

3.1. Performance Testing of Flexible Sensors

3.2. Application of LIG/PDMS-Based Flexible Wearable Sensors

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Shen, Z.; Liu, F.; Huang, S.; Wang, H.; Yang, C.; Huang, T.; Tao, J.; Xia, W.; Xie, X. Progress of flexible strain sensors for physiological signal monitoring. Biosens. Bioelectron. 2022, 211, 114298. [Google Scholar] [CrossRef] [PubMed]

- Wang, F.; Yu, H.; Lv, X.; Ma, X.; Qu, Q.; Wang, H.; Chen, D.; Liu, Y. MXene–MWCNT conductive network for long-lasting wearable strain sensors with gesture recognition capabilities. Micromachines 2025, 16, 123. [Google Scholar] [CrossRef]

- Kong, W.; Zhou, C.; Dai, K.; Jia, L.; Yan, D.; Li, Z. Highly stretchable and durable fibrous strain sensor with growth ring-like spiral structure for wearable electronics. Compos. Part B 2021, 225, 109275. [Google Scholar] [CrossRef]

- Zhao, X.; Li, J.; Jiang, M.; Zhai, W.; Dai, K.; Liu, C.; Shen, C. Flexible strain sensor based on CNTs/CB/TPU conductive fibrous film with wide sensing range and high sensitivity for human biological signal acquisition. Polymer 2024, 302, 127049. [Google Scholar] [CrossRef]

- Minjeong, H.; Seongdong, L.; Hyunhyub, K. Wearable and flexible sensors for user-interactive health-monitoring devices. J. Mater. Chem. B 2018, 6, 4043–4064. [Google Scholar] [CrossRef]

- Joohyung, B.; Byungkwon, C.; Jaeyoung, L.; Yongha, H.; Hongyun, S. Ultra-broad linear range and sensitive flexible piezoresistive sensor using reversed lattice structure for wearable electronics. ACS Appl. Mater. Interfaces 2023, 15, 34120–34131. [Google Scholar] [CrossRef]

- Fu, N.; Liu, H.; Zhang, J.; Wang, S.; Yang, Y.; Chen, K.; Deng, Z. Bioinspired multifunctional MXene-decorated textile for thermal management, durable self-cleaning, bio-protection and wearable strain sensor. Appl. Surf. Sci. 2024, 669, 160607. [Google Scholar] [CrossRef]

- Chi, J.L.; Panos, L.; Paschalis, A. Flexible and stretchable electrically conductive polymer materials for physical sensing applications. Polym. Rev. 2023, 63, 67–126. [Google Scholar] [CrossRef]

- Wang, J.; Liu, S.; Chen, Z.; Shen, T.; Wang, Y.; Yin, R.; Liu, H.; Liu, C.; Shen, C. Ultrasensitive electrospinning fibrous strain sensor with synergistic conductive network for human motion monitoring and human-computer interaction. J. Mater. Sci. Technol. 2025, 213, 213–222. [Google Scholar] [CrossRef]

- Li, M.; Lu, J.; Wan, P.; Jiang, M.; Mo, Y.; Pan, C. An Ultrasensitive perovskite single-model plasmonic strain sensor based on piezoelectric effect. Adv. Funct. Mater. 2024, 34, 2403840. [Google Scholar] [CrossRef]

- Zhang, C.; Ouyang, W.; Zhang, L.; Li, D. A dual-mode fiber-shaped flexible capacitive strain sensor fabricated by direct ink writing technology for wearable and implantable health monitoring applications. Microsyst. Nanoeng. 2023, 9, 158. [Google Scholar] [CrossRef]

- Sheraz, A.; Saad, N.; Muhammad, Z.K. Electrospun nanofibrous yarn based piezoresistive flexible strain sensor for human motion detection and speech recognition. J. Thermoplast. Compos. Mater. 2023, 36, 2459–2481. [Google Scholar] [CrossRef]

- Fu, Q.; Tang, J.; Wang, W.; Wang, R. Biocomposite polyvinyl alcohol/ferritin hydrogels with enhanced stretchability and conductivity for flexible strain sensors. Gels 2025, 11, 59. [Google Scholar] [CrossRef] [PubMed]

- Shen, Z.; Zhang, Z.; Zhang, N.; Li, J.; Zhou, P.; Hu, F.; Rong, Y.; Lu, B.; Gu, G. High-stretchability, ultralow-hysteresis conducting polymer hydrogel strain sensors for soft machines. Adv. Mater. 2022, 34, e2203650. [Google Scholar] [CrossRef] [PubMed]

- Zhao, Y.; Li, B.; Zhong, M.; Fan, H.; Li, Z.; Lyu, S.; Xing, X.; Qin, W. Highly sensitive, wearable piezoresistive methylcellulose/chitosan@ MXene aerogel sensor array for real-time monitoring of physiological signals of pilots. Sci. China Mater. 2025, 68, 542–551. [Google Scholar] [CrossRef]

- Guo, Q.; Pang, W.; Xie, X.; Xu, Y.; Yuan, W. Stretchable, conductive and porous MXene-based multilevel structured fibers for sensitive strain sensing and gas sensing. J. Mater. Chem. A 2022, 10, 15634–15646. [Google Scholar] [CrossRef]

- Deng, B.; Wang, Z.; Liu, W.; Hu, B. Multifunctional motion sensing enabled by laser-induced graphene. Materials 2023, 16, 6363. [Google Scholar] [CrossRef]

- Xu, K.; Cai, Z.; Luo, H.; Lu, Y.; Ding, C.; Yang, G.; Wang, L.; Kuang, C.; Liu, J.; Yang, H. Toward integrated multifunctional laser-induced graphene-based skin-like flexible sensor systems. ACS Nano 2024, 18, 26435–26476. [Google Scholar] [CrossRef]

- Li, Z.; Zhang, W.; Xing, F. Graphene optical biosensors. Int. J. Mol. Sci. 2019, 20, 2461. [Google Scholar] [CrossRef]

- Lv, H.; Yao, Y.; Li, S.; Wu, G.; Zhao, B.; Zhou, X.; Dupont, R.L.; Kara, U.I.; Zhou, Y.; Xi, X.; et al. Staggered circular nanoporous graphene converts electromagnetic waves into electricity. Nat. Commun. 2023, 14, 1982. [Google Scholar] [CrossRef]

- Wu, Q.; Qiao, Y.; Guo, R.; Naveed, S.; Hirtz, T.; Li, X.; Fu, Y.; Wei, Y.; Deng, G.; Yang, Y.; et al. Triode-mimicking graphene pressure sensor with positive resistance variation for physiology and motion monitoring. ACS Nano 2020, 14, 10104. [Google Scholar] [CrossRef]

- Zhang, W.H.; Yin, M.J.; Zhao, Q.; Jin, C.; Wang, N.; Ji, S.; Ritt, C.L.; Elimelech, M.; An, Q.F. Graphene oxide membranes with stable porous structure for ultrafast water transport. Nat. Nanotechnol. 2021, 16, 337–343. [Google Scholar] [CrossRef]

- Novoselov, K.S.; Geim, A.K.; Morozov, S.V.; Jiang, D.; Zhang, Y.; Dubonos, S.V.; Grigorieva, I.V.; Firsov, A.A. Electric Field Effect in Atomically Thin Carbon Films. Science 2004, 306, 666–669. [Google Scholar] [CrossRef] [PubMed]

- Hao, Y.; Bharathi, M.S.; Wang, L.; Liu, Y.; Chen, H.; Nie, S.; Wang, X.; Chou, H.; Tan, C.; Fallahazad, B.; et al. The role of surface oxygen in the growth of large single-crystal graphene on copper. Science 2013, 342, 720–723. [Google Scholar] [CrossRef] [PubMed]

- Qi, S.; Huang, G. Progress of graphene preparation by liquid-phase exfoliation. Mater. Rep. 2017, 31, 34–40. [Google Scholar] [CrossRef]

- Bhuyan, M.S.A.; Uddin, M.N.; Islam, M.M.; Bipasha, F.A.; Hossain, S.S. Synthesis of graphene. Int. Nano Lett. 2016, 6, 65–83. [Google Scholar] [CrossRef]

- Brownson, D.A.C.; Banks, C.E. The electrochemistry of CVD graphene: Progress and prospects. Phys. Chem. Chem. Phys. 2012, 14, 8264–8281. [Google Scholar] [CrossRef]

- Lin, J.; Peng, Z.; Liu, Y.; Ruiz-Zepeda, F.; Ye, R.; Samuel, E.L.G.; Yacaman, M.J.; Yakobson, B.I.; Tour, J.M. Laser-induced porous graphene films from commercial polymers. Nat. Commun. 2014, 5, 5714. [Google Scholar] [CrossRef]

- Ye, R.; James, D.K.; Tour, J.M. Laser-induced graphene: From discovery to translation. Adv. Mater. 2019, 31, 1803621. [Google Scholar] [CrossRef]

- Huang, L.; Su, J.; Song, Y.; Ye, R. Laser-induced graphene: En route to smart sensing. Nano-Micro Lett. 2020, 12, 157. [Google Scholar] [CrossRef]

- Vivaldi, F.M.; Dallinger, A.; Bonini, A.; Poma, N.; Sembranti, L.; Biagini, D.; Salvo, P.; Greco, F.; Francesco, F.D. Three-dimensional (3D) laser-induced graphene: Structure, properties, and application to chemical sensing. ACS Appl. Mater. Interfaces 2021, 13, 30245–30260. [Google Scholar] [CrossRef] [PubMed]

- Barja, M.A.; Ryu, K.Y.; Tarancón, S.; Tejado, E.; Hamada, A.; Martinez, J. Laser-induced graphene strain sensors for body movement monitoring. ACS Omega 2024, 9, 38359–38370. [Google Scholar] [CrossRef] [PubMed]

- Wang, H.; Zhao, Z.; Liu, P.; Guo, X. A soft and stretchable electronics using laser-induced graphene on polyimide/PDMS composite substrate. NPJ Flex. Electron. 2022, 6, 26. [Google Scholar] [CrossRef]

- Tahir, R.; Khurram, M.T.; Afzal, A.; Andrews, B.; Qi, X.J.; Ma, Y.L.; Amjad, A.; Qu, L.J.; Tian, M.W. Wearable and flexible multifunctional sensor based on laser-induced graphene for the sports monitoring system. ACS Appl. Mater. Interfaces 2022, 14, 54170–54181. [Google Scholar] [CrossRef]

- Yen, Y.H.; Hsu, C.S.; Lei, Z.Y.; Wang, H.J.; Su, C.Y.; Dai, C.L.; Tsai, Y.C. Laser-induced graphene stretchable strain sensor with vertical and parallel patterns. Micromachines 2022, 13, 1220. [Google Scholar] [CrossRef]

- Han, S.; Tan, H.; Wei, J.; Yuan, H.; Li, S.; Yang, P.; Mi, H.; Liu, C.; Shen, C. Surface modification of super arborized silica for flexible and wearable ultrafast-response strain sensors with low hysteresis. Adv. Sci. 2023, 10, 2301713. [Google Scholar] [CrossRef]

- Weng, S.; Zhang, Z.; Gao, K.; Zhu, H.; Hu, B.; He, D.; Wang, F. Performance and mechanism of a graphene assembled film-based flexible sensor for strain monitoring of civil infrastructures. Sens. Actuators A 2025, 387, 116430. [Google Scholar] [CrossRef]

- Hou, Y.; Zhang, H.; Zhou, K. Ultraflexible sensor development via 4D printing: Enhanced sensitivity to strain, temperature, and magnetic fields. Adv. Sci. 2024, 12, 2411584. [Google Scholar] [CrossRef]

- Tsogbayar, D.; Seo, J.; Hwang, T.; Park, J.; Ko, E.; Kim, Y.; Yoon, C.M.; Lee, H.S. Advanced flexible physical sensors with independent detection mechanisms of pressure and strain stimuli for overcoming signal interference. ACS Appl. Mater. Interfaces 2024, 16, 49574–49583. [Google Scholar] [CrossRef]

- Xing, X.; Zou, Y.; Zhong, M.; Li, S.; Fan, H.; Lei, X.; Yin, J.; Shen, J.; Liu, X.; Xu, M.; et al. A flexible wearable sensor based on laser-induced graphene for high-precision fine motion capture for pilots. Sensors 2024, 24, 1349. [Google Scholar] [CrossRef]

- Shang, Y.; Zhang, B.; Liu, J.; Xia, C.; Yang, X.; Yan, D.; Sun, J. Facile and economical fabrication of superhydrophobic flexible resistive strain sensors for human motion detection. Nanomanuf. Metrol. 2023, 6, 2. [Google Scholar] [CrossRef]

- Wei, Y.; Zhang, W.; Pan, T.; Xiao, H. Spindle-knot reinforced liquid metal-based strain sensor with excellent stretchability and stability. Chem. Eng. J. 2025, 503, 158365. [Google Scholar] [CrossRef]

- Yu, T.; Chen, R.; Chang, G.; Xu, B.; Ye, F.; Xu, Y.; Liu, X.; Li, R. Development of a flexible strain sensor for monitoring human activities based on 3D MXene microspheres and 1D CNTs. Mater. Lett. 2024, 377, 137460. [Google Scholar] [CrossRef]

| Materials | Processing | Response Time (ms) | Gauge Factor (GF) | References |

|---|---|---|---|---|

| LIG-PDMS | Laser direct writing | 150 | 15.79 | [35] |

| PAM-3-TSASN-LiCl hydrogel | Surface modification | 210 | 4.5 | [36] |

| GAF | Graphite oxide reduction | 208 | 0.84 | [37] |

| LM@CNTs-5/Fe/Ecoflex | 4D Printing | 83 | 19.8 | [38] |

| B-TMN-SHFSS | \ | 230 | 0.146 | [39] |

| LIG | Laser direct writing | 150 | 41.4 | [40] |

| PDMS-SEBS(CB) | Spraying carbon black | 168 | 7.35 | [41] |

| Gallium-based liquid metals | Extrusion thermal pressing method | 180 | 4.59 | [42] |

| PDMS/CNT/FM@MX | Ultrasonically dispersed | 330 | 5.59 | [43] |

| LIG-PDMS | Laser direct writing | 150 | 20.7 | This work |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, S.; Wu, Z.; Fan, H.; Zhong, M.; Xing, X.; Wang, Y.; Yang, H.; Liu, Q.; Zhang, D. Flexible Stretchable Strain Sensor Based on LIG/PDMS for Real-Time Health Monitoring of Test Pilots. Sensors 2025, 25, 2884. https://doi.org/10.3390/s25092884

Li S, Wu Z, Fan H, Zhong M, Xing X, Wang Y, Yang H, Liu Q, Zhang D. Flexible Stretchable Strain Sensor Based on LIG/PDMS for Real-Time Health Monitoring of Test Pilots. Sensors. 2025; 25(9):2884. https://doi.org/10.3390/s25092884

Chicago/Turabian StyleLi, Shouqing, Zhanghui Wu, Hongyun Fan, Mian Zhong, Xiaoqing Xing, Yongzheng Wang, Huaxiao Yang, Qijian Liu, and Deyin Zhang. 2025. "Flexible Stretchable Strain Sensor Based on LIG/PDMS for Real-Time Health Monitoring of Test Pilots" Sensors 25, no. 9: 2884. https://doi.org/10.3390/s25092884

APA StyleLi, S., Wu, Z., Fan, H., Zhong, M., Xing, X., Wang, Y., Yang, H., Liu, Q., & Zhang, D. (2025). Flexible Stretchable Strain Sensor Based on LIG/PDMS for Real-Time Health Monitoring of Test Pilots. Sensors, 25(9), 2884. https://doi.org/10.3390/s25092884