Utility Tunnel Settlement Monitoring Using Distributed Fiber Optic and Ground Penetrating Radar Technologies

Abstract

1. Introduction

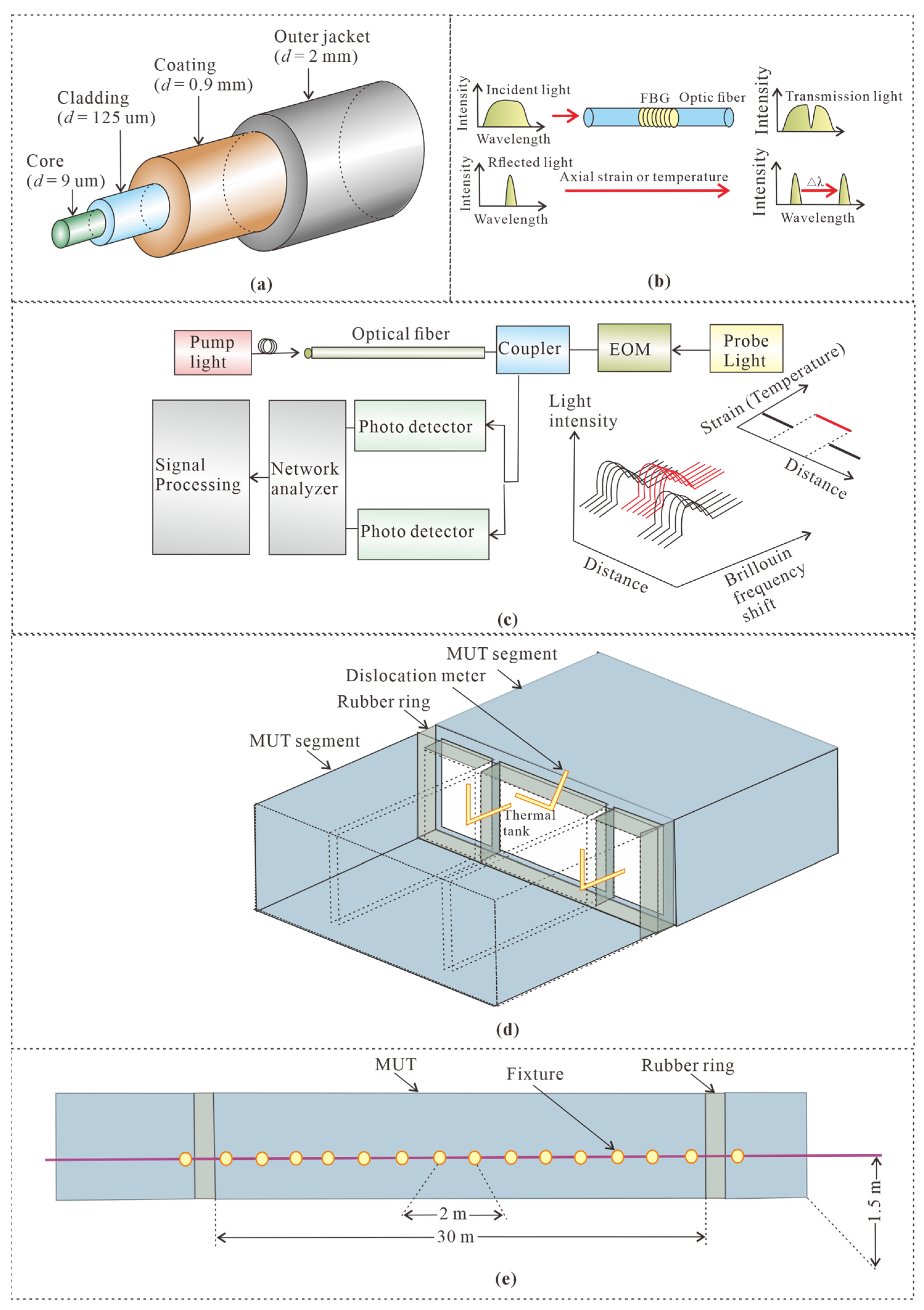

2. Materials and Methods

2.1. Field Site Description

2.2. On-Site Monitoring Scheme Using DFOS and GPR

3. Results and Discussion

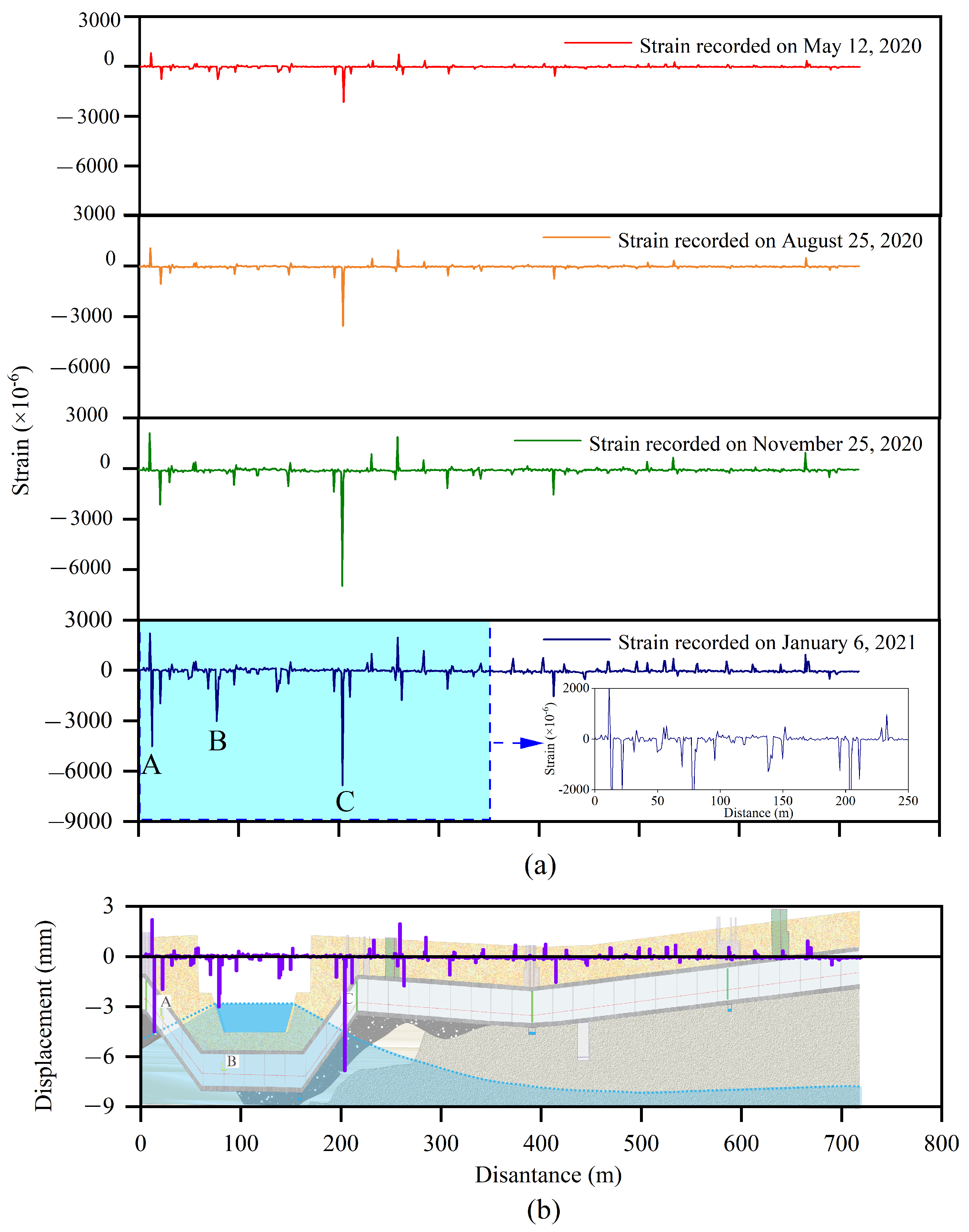

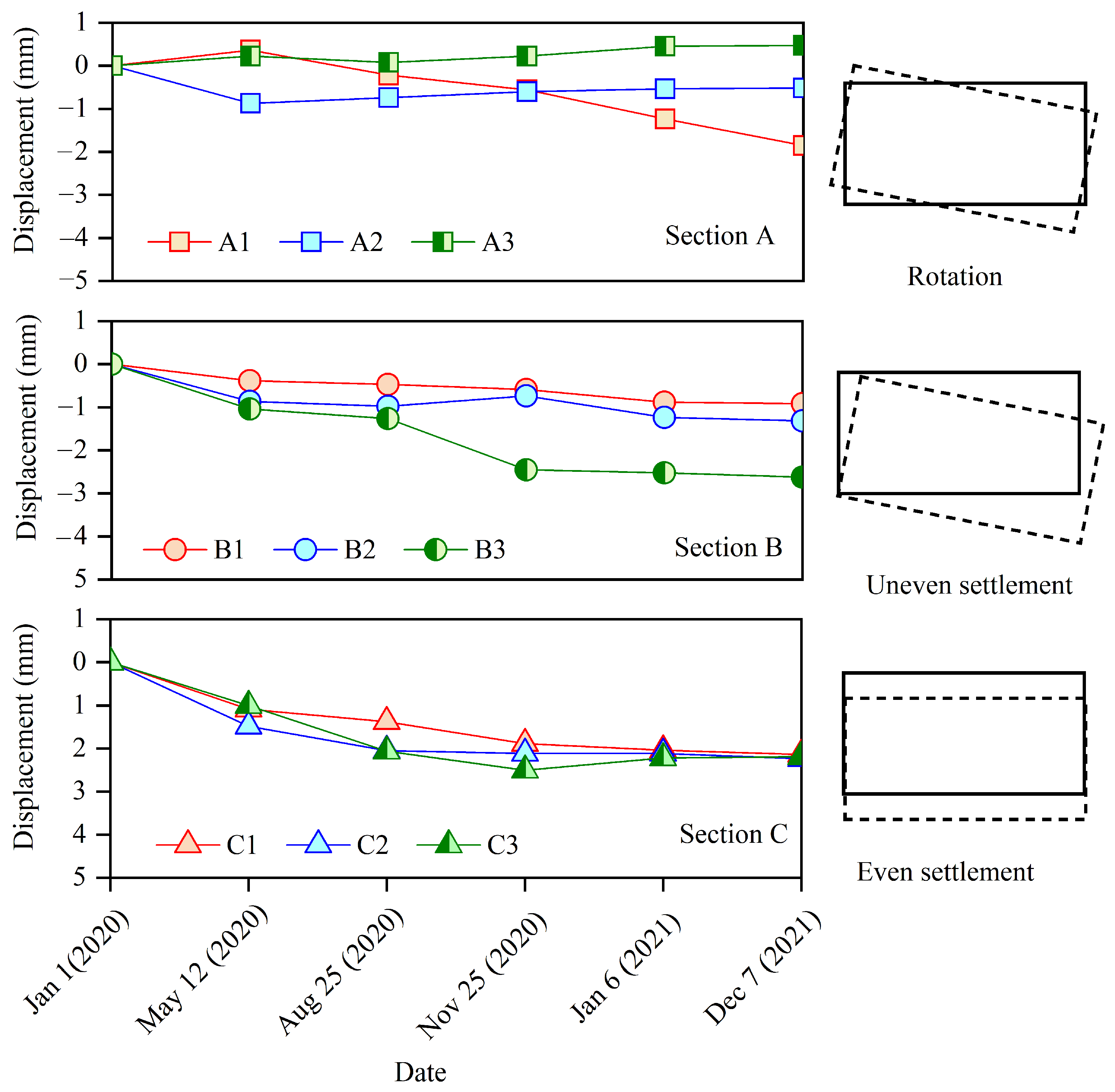

3.1. Settlement and Deformation Detection Base on the Fiber Optic Monitoring

3.2. MUT Settlement and Deformation Reasons Analysis Based on GPR Detection

4. Conclusions

- (i)

- The MUT deformation is mainly caused by joint dislocation. The adjacent MUT joint dislocation caused by foundation settlement can be accurately detected by BOFDA. The dislocation development is determined by intermittent river recharge and water infiltration into the foundation. The maximum strain is prone to appearing at the slopes near the riverbed edges.

- (ii)

- After the deformation position is accurately located by BOFDA, the MUT posture can be judged by the FBG monitored data. Rotation, even settlement, and uneven settlement can be observed through the three FBG-based dislocation meters installed on the top and side walls.

- (iii)

- The cause of MUT settlement is the compression of mudstone and collapse of loess. The interlayer delamination cracks caused by the uncoordinated settlement of the strata and the accumulated cracks at the bottom of the MUT can be accurately located by GPR.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| BOFDA | Brillouin frequency domain analysis |

| DFOS | Distributed fiber optic sensing |

| FBG | Fiber Bragg grating |

| GPR | Ground penetrating radar |

| MUT | Multi-purpose utility tunnel |

References

- Luo, Y.; Alaghbandrad, A.; Genger, T.K.; Hammad, A. History and recent development of multi-purpose utility tunnels. Tunn. Undergr. Space Technol. 2020, 103, 103511. [Google Scholar] [CrossRef]

- Liu, X.; Xu, Z.D.; Sun, B.; Liu, X.; Xu, D. Spatiotemporal state assessment for the underground pipe gallery: Physical model and experimental verification. Tunn. Undergr. Space Technol. 2024, 143, 105474. [Google Scholar] [CrossRef]

- Pan, Y.; Zong, Z.; Li, J.; Qian, H.; Wu, C. Investigating the dynamic response of a double-box utility tunnel buried in calcareous sand against ground surface explosion. Tunn. Undergr. Space Technol. 2024, 146, 105636. [Google Scholar] [CrossRef]

- Gao, Z.; Zhao, P.; Fan, Y.; Chen, Y. Influence of the closed end on the smoke propagation and temperature profile in urban utility tunnel fires. Tunn. Undergr. Space Technol. 2024, 150, 105852. [Google Scholar] [CrossRef]

- Zhou, Q.; He, H.; Liu, S.; Wang, P.; Zhou, Y.; Zhou, J.; Fan, H.; Jin, F. Evaluation of blast-resistant ability of shallow-buried reinforced concrete urban utility tunnel. Eng. Fail. Anal. 2021, 119, 105003. [Google Scholar] [CrossRef]

- Aleinikov, A.L.; Belikov, V.T.; Eppelbaum, L.V.; Nemzorov, N.I. Rock Destruction and Dangerous Geodynamic Processes in the Earth: A review. In Fundamental Research and Application of Physical Science; BP International: London, UK, 2023; pp. 141–183. [Google Scholar]

- Liu, Y.M.; Zhang, M.; Li, Y.X.; Chen, H. Research and application of small-diameter hydraulic fracturing in situ stress measurement system. Geosci. Instrum. Methods Data Syst. 2024, 13, 107–116. [Google Scholar] [CrossRef]

- Kang, J.T.; Li, M.; Mao, S.J.; Fan, Y.B.; Wu, Z.; Li, B. A coal mine tunnel deformation detection method using point cloud data. Sensors 2024, 24, 2299. [Google Scholar] [CrossRef]

- Wang, X.; Shi, B.; Wei, G.Q.; Chen, S.E.; Zhu, H.H.; Wang, T. Monitoring the behavior of segment joints in a shield tunnel using distributed fiber optic sensors. Struct. Control Heath Monit. 2018, 25, e2056. [Google Scholar] [CrossRef]

- Qian, H.; Li, J.; Zong, Z.; Wu, C.; Pan, Y. Behavior of precast segmental utility tunnel under ground surface Explosion: A numerical study. Tunn. Undergr. Space Technol. 2021, 115, 104071. [Google Scholar] [CrossRef]

- Islam, M.S.; Iskander, M. Ground settlement caused by perpendicularly crossing twin tunnels, a parametric study. Tunn. Undergr. Space Technol. 2024, 146, 105657. [Google Scholar] [CrossRef]

- Xu, Q.; Bai, C.; Peng, J.; Lu, Q.; Zhao, J. Model test of prefabricated underground utility tunnel crossing active ground fissures. Tunn. Undergr. Space Technol. 2023, 140, 105279. [Google Scholar] [CrossRef]

- Lin, Z.; Guo, C.; Ni, P.; Cao, D.; Huang, L.; Guo, Z.; Dong, P. Experimental and numerical investigations into leakage behaviour of a novel prefabricated utility tunnel. Tunn. Undergr. Space Technol. 2020, 104, 103529. [Google Scholar] [CrossRef]

- Zhang, X.; Broere, W. Design of a distributed optical fiber sensor system for measuring immersed tunnel joint deformations. Tunn. Undergr. Space Technol. 2023, 131, 104770. [Google Scholar] [CrossRef]

- Zhang, P.; Zhang, Y.; Ariaratnam, S.T.; Ma, B.; Zeng, C.; Liu, K. Field monitoring and analysis of soil deformation of curved steel pipe jacking in Gongbei tunnel. Tunn. Undergr. Space Technol. 2023, 138, 105153. [Google Scholar] [CrossRef]

- Mohamad, H.; Soga, K.; Bennett, P.J.; Mair, R.J.; Lim, C.S. Monitoring twin tunnel interaction using distributed optical fiber strain measurements. J. Geotech. Geoenviron. Eng. 2012, 138, 957–967. [Google Scholar] [CrossRef]

- Zhang, X.; Broere, W. Monitoring of Tidal Variation and Temperature Change-Induced Movements of an Immersed Tunnel Using Distributed Optical Fiber Sensors (DOFSs). Struct. Control Health Monit. 2023, 2023, 2419495. [Google Scholar] [CrossRef]

- Zhang, X.; Broere, W. Monitoring seasonal deformation behavior of an immersed tunnel with distributed optical fiber sensors. Measurement 2023, 219, 113268. [Google Scholar] [CrossRef]

- Song, H.; Pei, H.; Zhu, H. Monitoring of tunnel excavation based on the fiber Bragg grating sensing technology. Measurement 2021, 169, 108334. [Google Scholar] [CrossRef]

- Gómez, J.; Casas, J.R.; Villalba, S. Structural Health Monitoring with Distributed Optical Fiber Sensors of tunnel lining affected by nearby construction activity. Autom. Constr. 2020, 117, 103261. [Google Scholar] [CrossRef]

- Lai, J.; Qiu, J.; Fan, H.; Zhang, Q.; Hu, Z.; Wang, J.; Chen, J. Fiber Bragg Grating Sensors-Based In Situ Monitoring and Safety Assessment of Loess Tunnel. J. Sens. 2016, 2016, 8658290. [Google Scholar] [CrossRef]

- Lai, W.W.L.; Derobert, X.; Annan, P. A review of Ground Penetrating Radar application in civil engineering: A 30-year journey from Locating and Testing to Imaging and Diagnosis. NDT E Int. 2018, 96, 58–78. [Google Scholar] [CrossRef]

- Alani, A.M.; Tosti, F. GPR applications in structural detailing of a major tunnel using different frequency antenna systems. Constr. Build. Mater. 2018, 158, 1111–1122. [Google Scholar] [CrossRef]

- Zhang, F.; Xie, X.; Huang, H. Application of ground penetrating radar in grouting evaluation for shield tunnel construction. Tunn. Undergr. Space Technol. 2010, 25, 99–107. [Google Scholar] [CrossRef]

- Zhang, Q.; Xiong, Z. Crack detection of reinforced concrete structures based on BOFDA and FBG sensors. Shock. Vib. 2018, 2018, 6563537. [Google Scholar] [CrossRef]

- He, W.; Lai, W.W.L.; Sui, X.; Giannopoulos, A. Delamination characterization in thin asphalt pavement structure using dispersive GPR data. Constr. Build. Mater. 2023, 402, 132834. [Google Scholar] [CrossRef]

- Tang, K.; Liu, D.; Xie, S.; Qiu, J.; Lai, J.; Liu, T.; Fang, Y. Analysis of loess water migration regularity and failure response of tunnel structure under rainfall environment. Bull. Eng. Geol. Environ. 2024, 83, 251. [Google Scholar] [CrossRef]

- Wang, Y.C.; Zheng, S.H.; Li, Y.L.; Wang, Y.M.; Huang, Y.H. The failure characteristics around shallow buried tunnels under rainfall conditions. Geomat. Nat. Hazards Risk 2021, 12, 363–380. [Google Scholar] [CrossRef]

- Ming, H.F.; Wang, M.S.; Tan, Z.S.; Wang, X.Y. Analytical solutions for stead seepage into an underwater circular tunnel. Tunn. Undergr. Space Technol. 2010, 25, 391–396. [Google Scholar]

- Hong, W.T.; and Lee, J.S. Estimation of ground cavity configurations using ground penetrating radar and time domain reflectometry. Nat. Hazards 2018, 92, 1789–1807. [Google Scholar] [CrossRef]

- Dinh, K.; Gucunski, N. Factors affecting the detectability of concrete delamination in GPR images. Constr. Build. Mater. 2021, 274, 121837. [Google Scholar] [CrossRef]

- Lekkala, M.R.; Latheef, M.; Jung, J.H.; Coraddu, A.; Zhu, H.; Srinil, N.; Lee, B.H.; Kim, D.K. Recent advances in understanding the flow over bluff bodies with different geometries at moderate Reynolds numbers. Ocean Eng. 2022, 261, 111611. [Google Scholar] [CrossRef]

- Carvalho, I.A.; Assi, G.R.S. Enhanced control of the turbulent flow past a circular cylinder with rotating rods inspired by an inviscid solution. J. Fluids Struct. 2022, 113, 103652. [Google Scholar] [CrossRef]

- Zhang, T.; Cao, D.; Guo, C.; Wang, F. Mechanical properties and reinforcement mechanism study of sulfate saline soil solidified by polyurethane and water glass. Case Stud. Constr. Mater. 2025, 22, e04328. [Google Scholar] [CrossRef]

- Cao, D.; Fan, L.; Huang, R.; Guo, C. Investigation of the Mechanical Properties of Reinforced Calcareous Sand Using a Permeable Polyurethane Polymer Adhesive. Materials 2024, 17, 5277. [Google Scholar] [CrossRef] [PubMed]

| Sections | Strain (×10−6) | |||

|---|---|---|---|---|

| 16 May 2020 | 25 August 2020 | 25 November 2020 | 6 January 2021 | |

| Section A | −749 | −1048 | −2120 | −4478 |

| Section B | −722 | −85 | −320 | −3179 |

| Section C | −2178 | −3659 | −7147 | −6838 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, J.; Cao, D.; Xiao, T.; Wang, C. Utility Tunnel Settlement Monitoring Using Distributed Fiber Optic and Ground Penetrating Radar Technologies. Sensors 2025, 25, 6964. https://doi.org/10.3390/s25226964

Li J, Cao D, Xiao T, Wang C. Utility Tunnel Settlement Monitoring Using Distributed Fiber Optic and Ground Penetrating Radar Technologies. Sensors. 2025; 25(22):6964. https://doi.org/10.3390/s25226964

Chicago/Turabian StyleLi, Jinyong, Dingfeng Cao, Tao Xiao, and Chunyan Wang. 2025. "Utility Tunnel Settlement Monitoring Using Distributed Fiber Optic and Ground Penetrating Radar Technologies" Sensors 25, no. 22: 6964. https://doi.org/10.3390/s25226964

APA StyleLi, J., Cao, D., Xiao, T., & Wang, C. (2025). Utility Tunnel Settlement Monitoring Using Distributed Fiber Optic and Ground Penetrating Radar Technologies. Sensors, 25(22), 6964. https://doi.org/10.3390/s25226964