Advanced Signal Analysis Model for Internal Defect Mapping in Bridge Decks Using Impact-Echo Field Testing

Abstract

1. Introduction

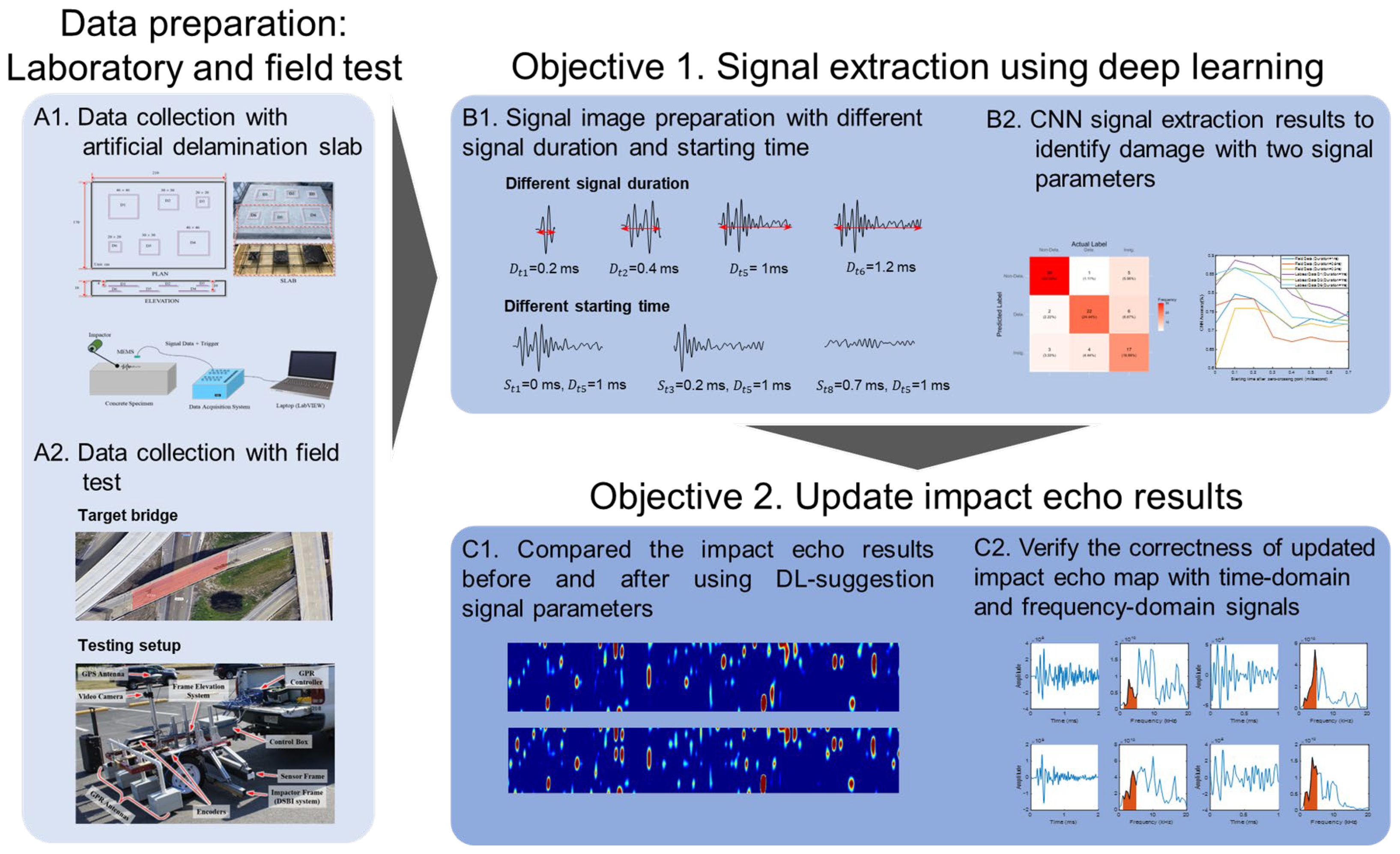

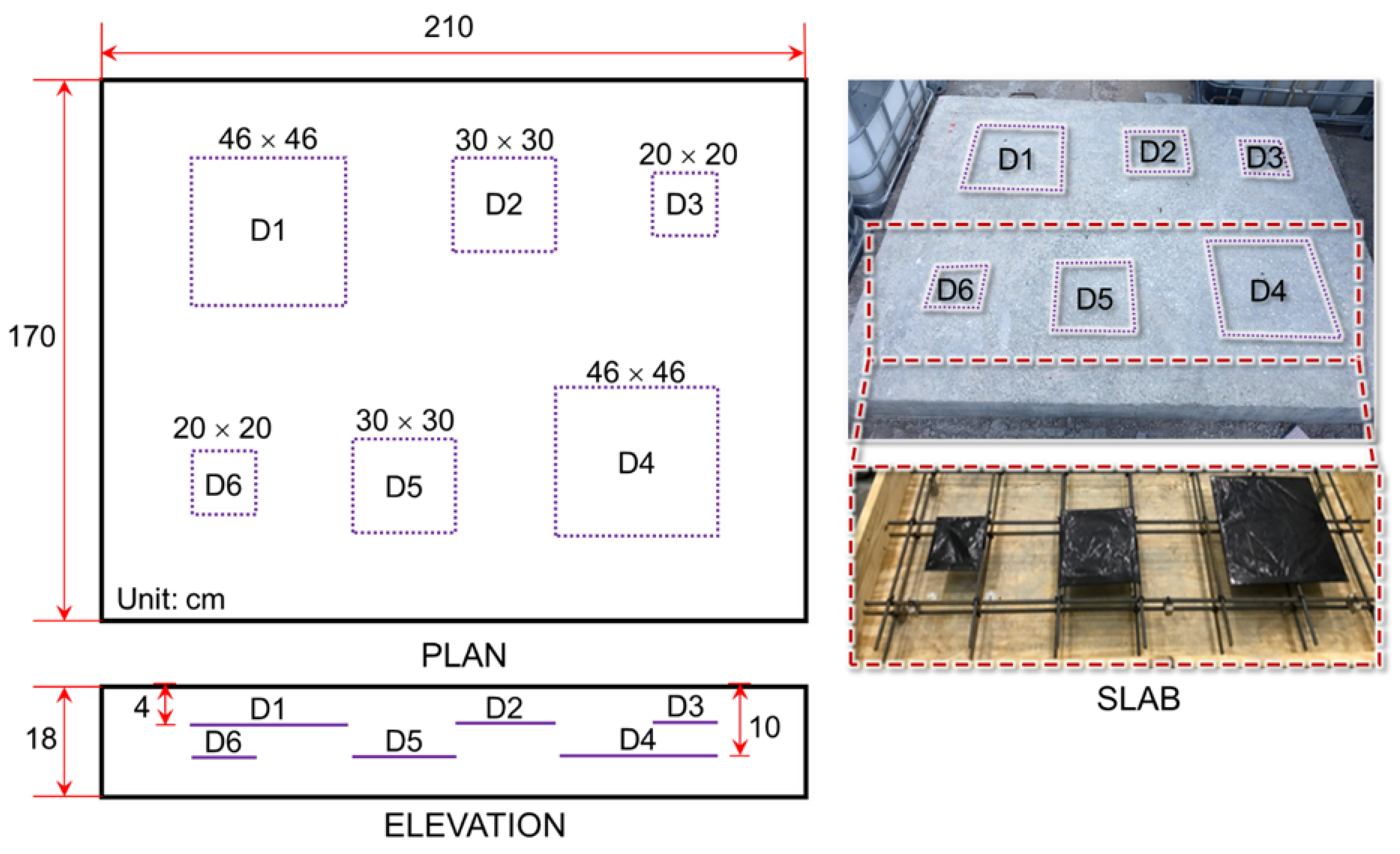

2. Experimental Program

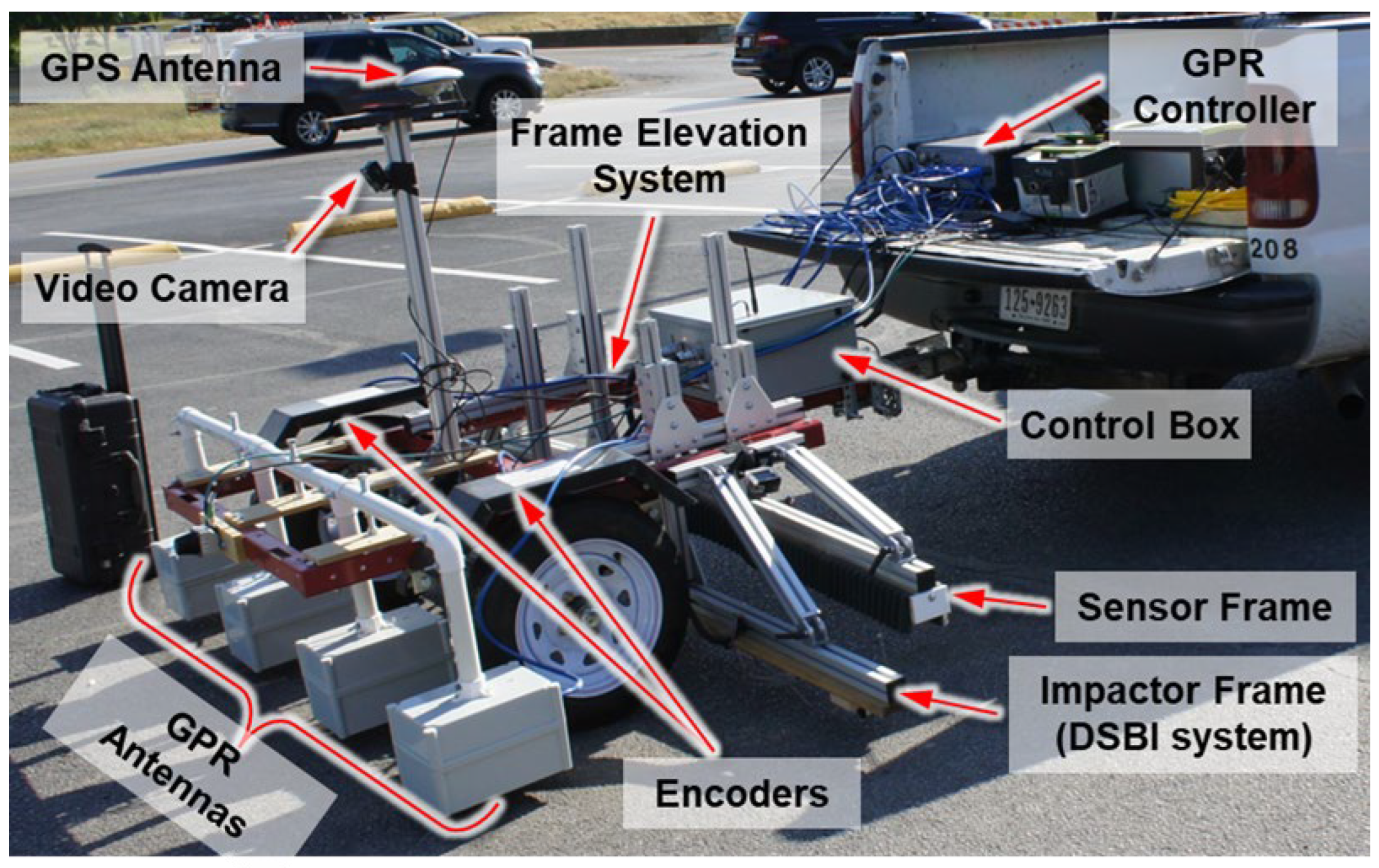

2.1. Experimental Details

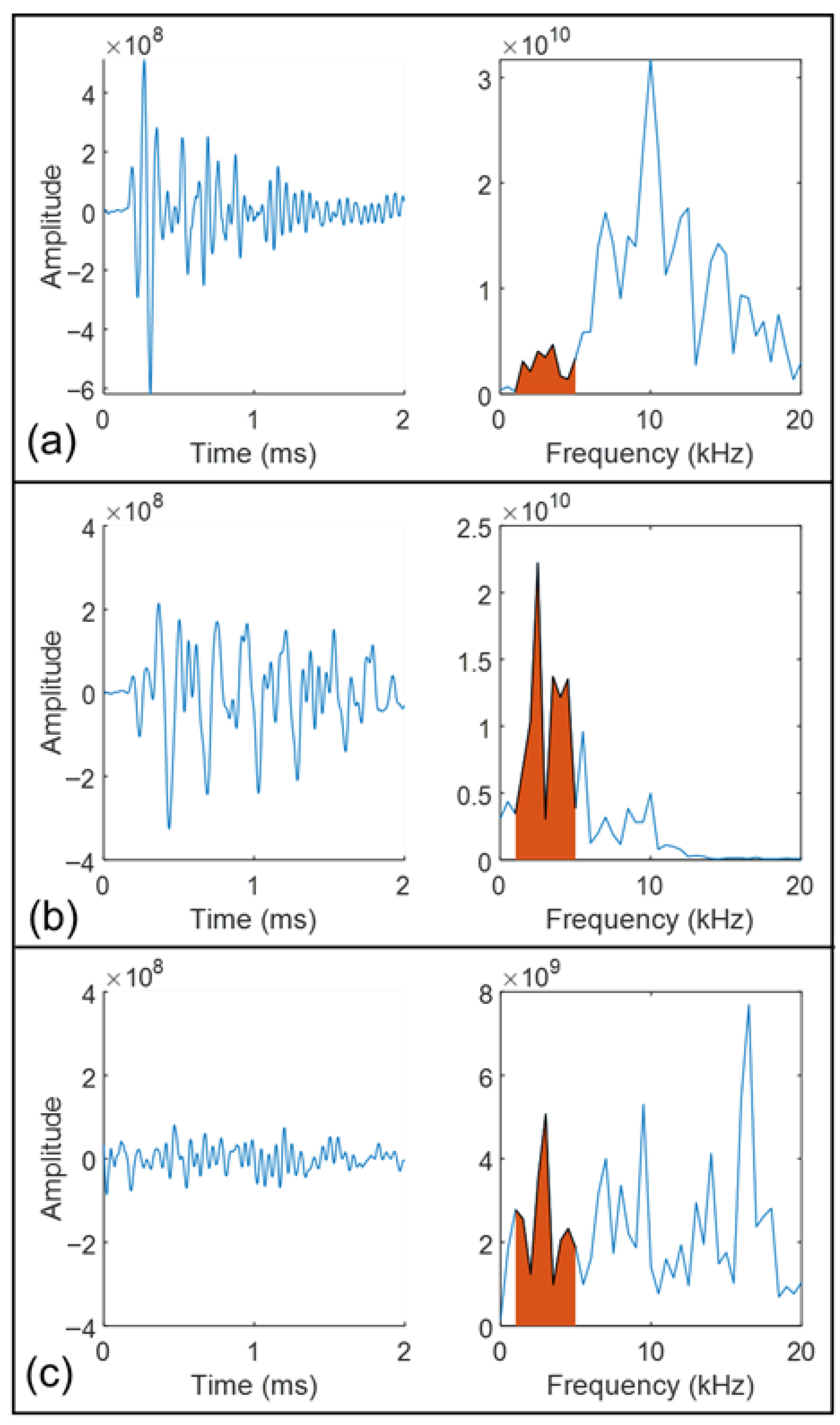

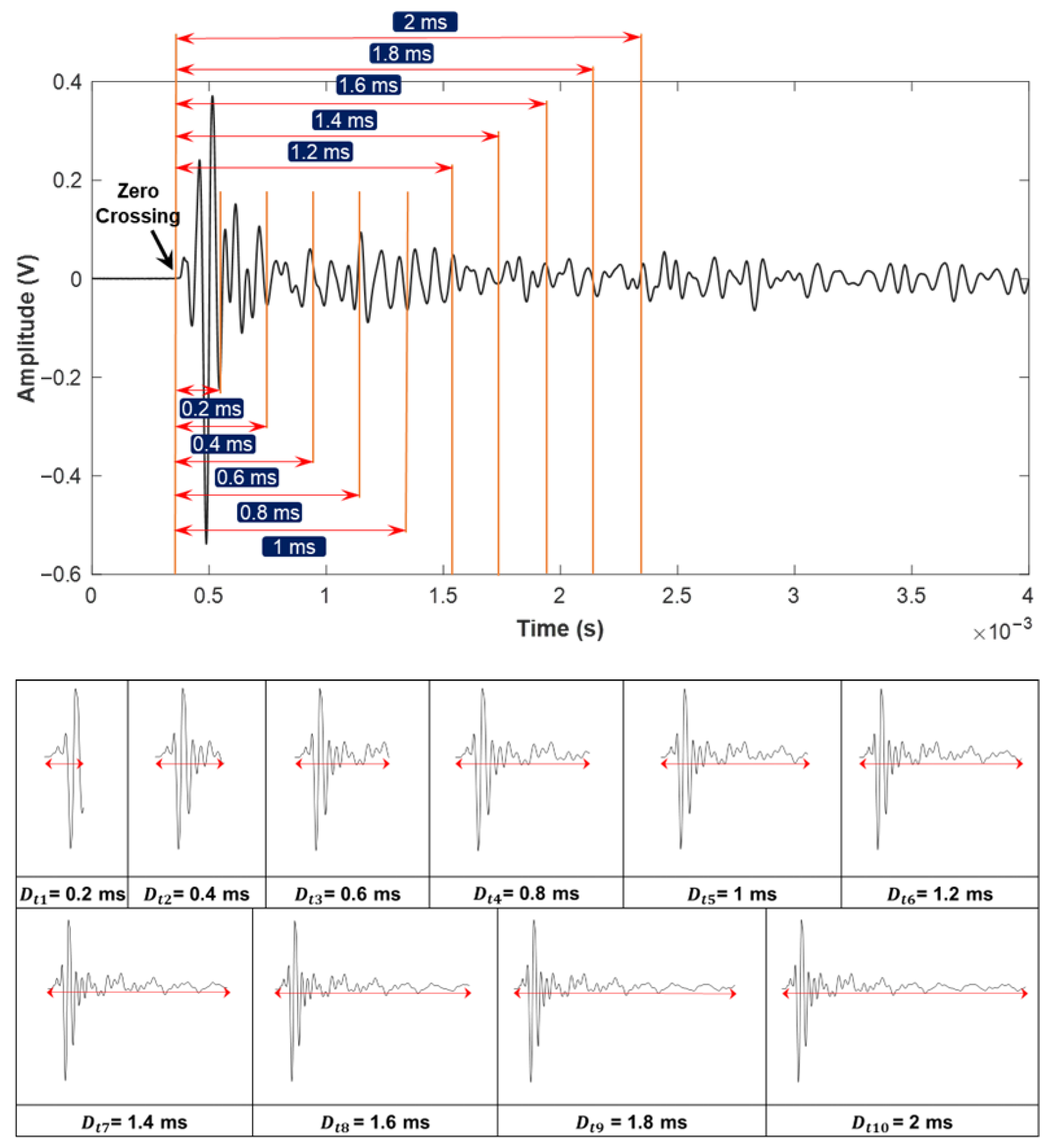

2.2. Deep Learning-Based Signal Extraction Algorithms

3. Results and Discussion

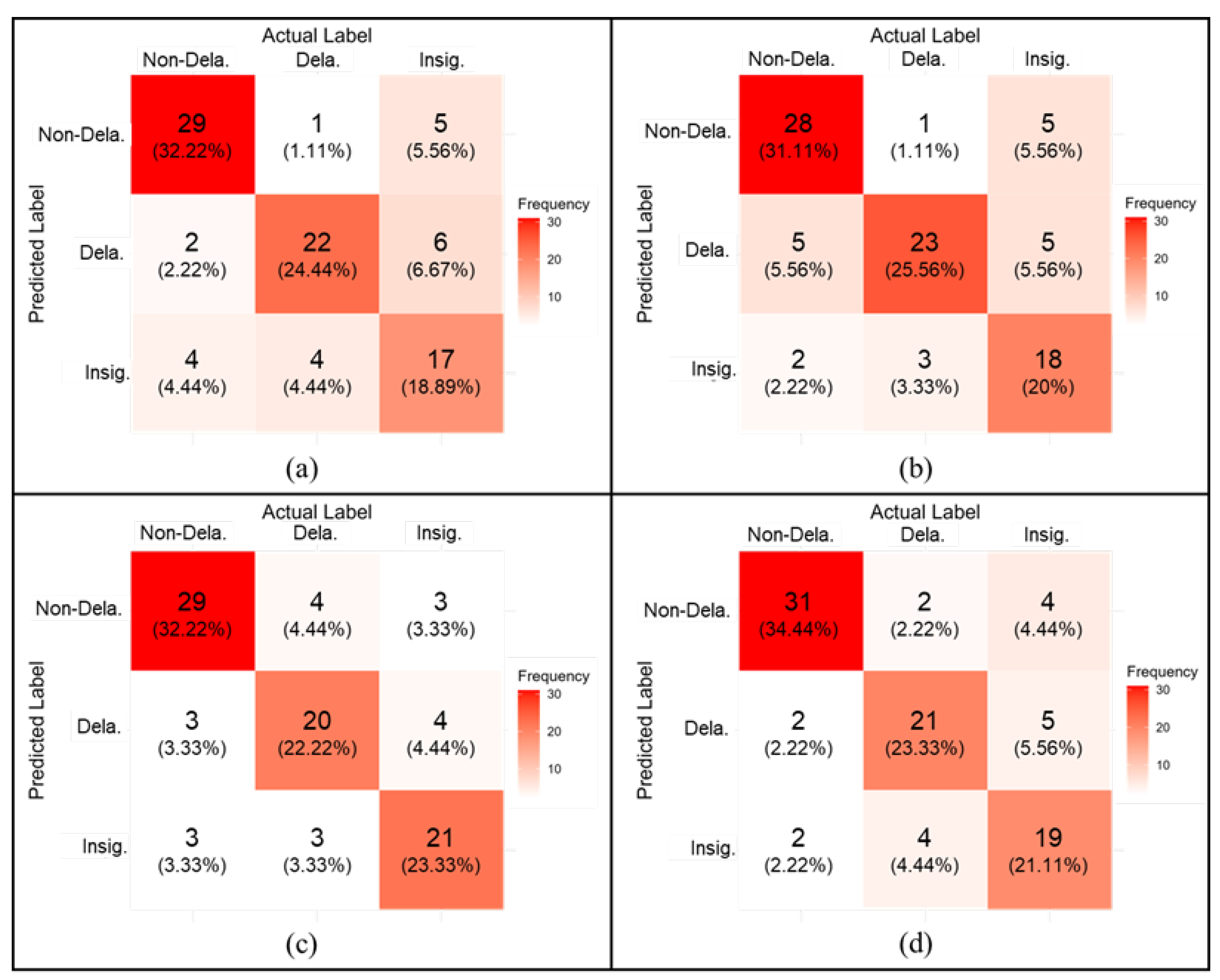

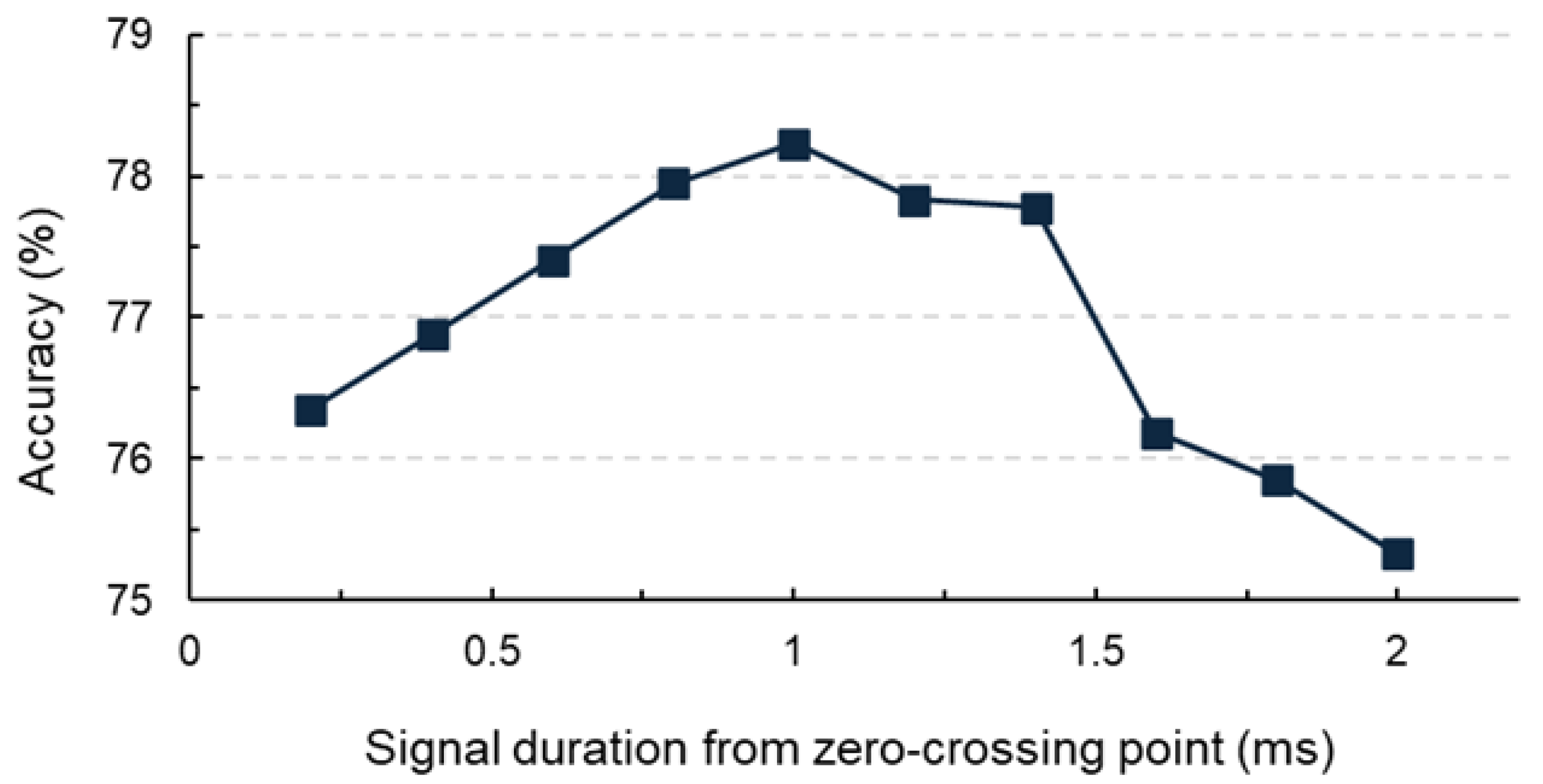

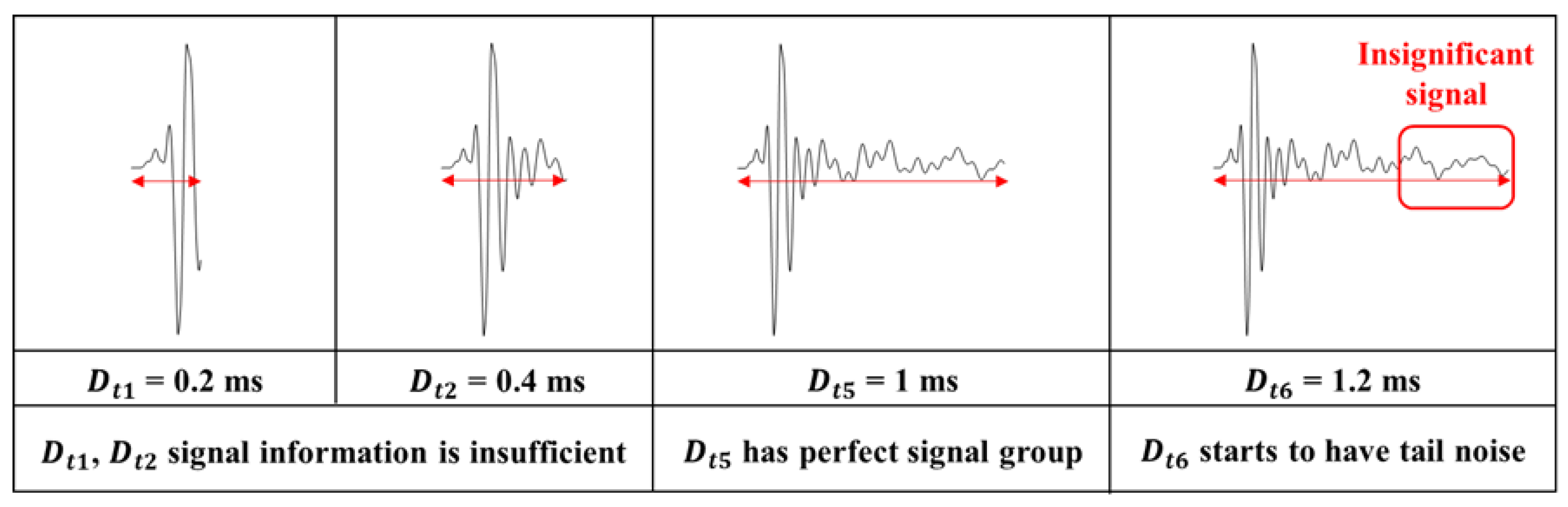

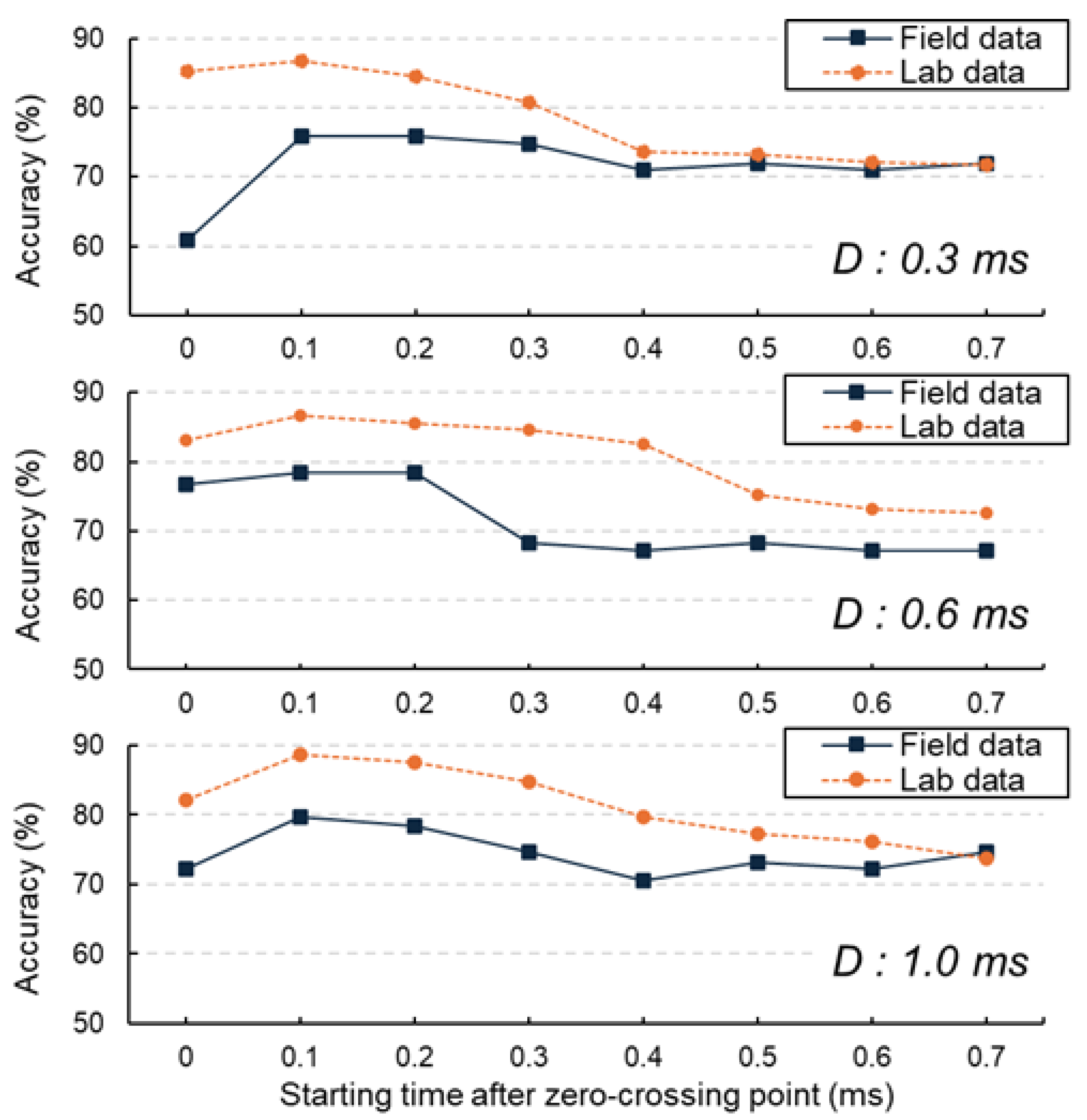

3.1. CNN-Based Signal Extraction Results

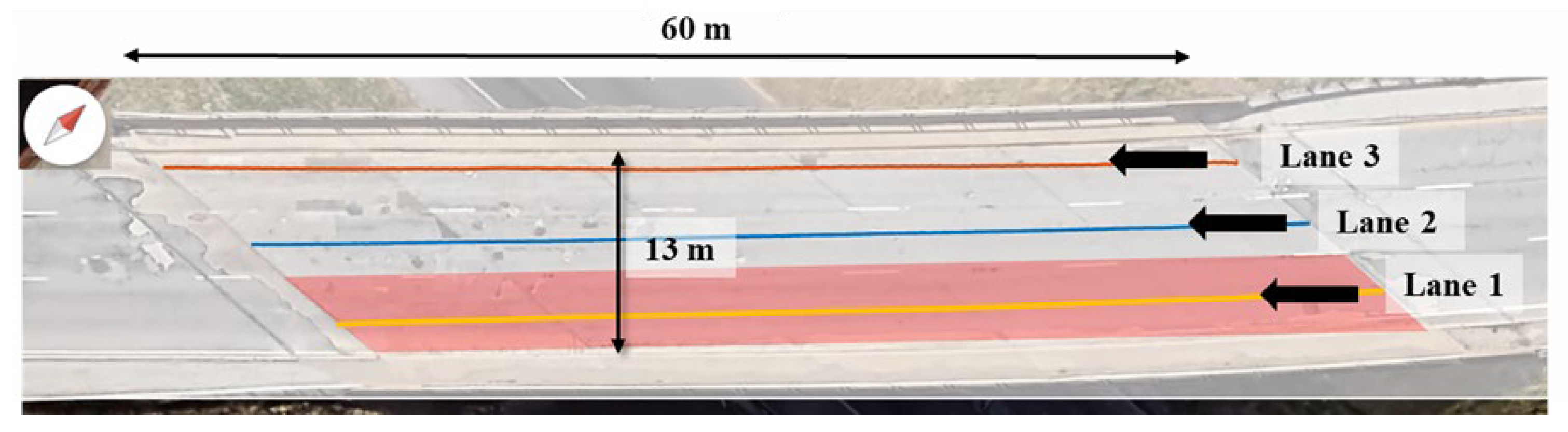

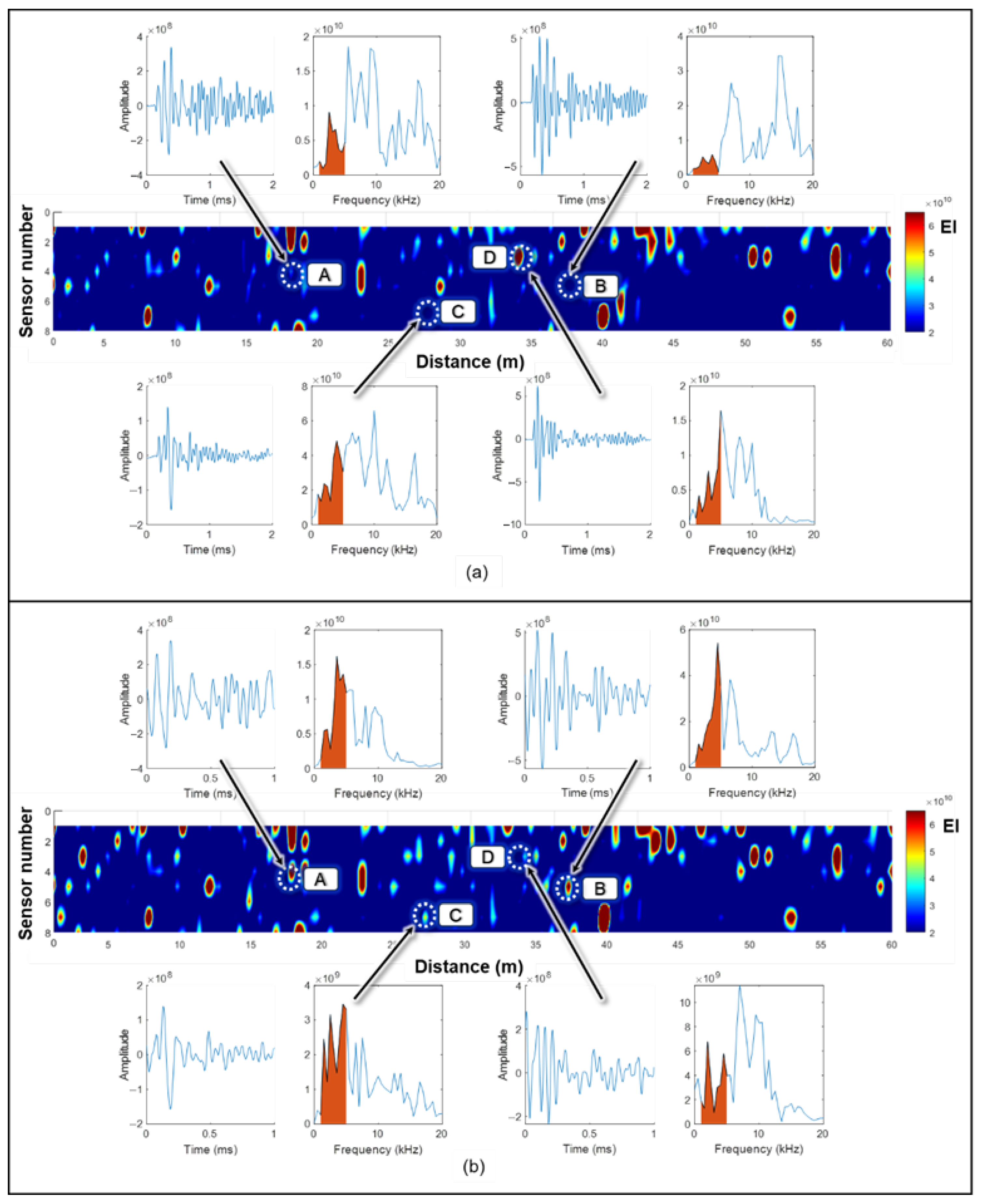

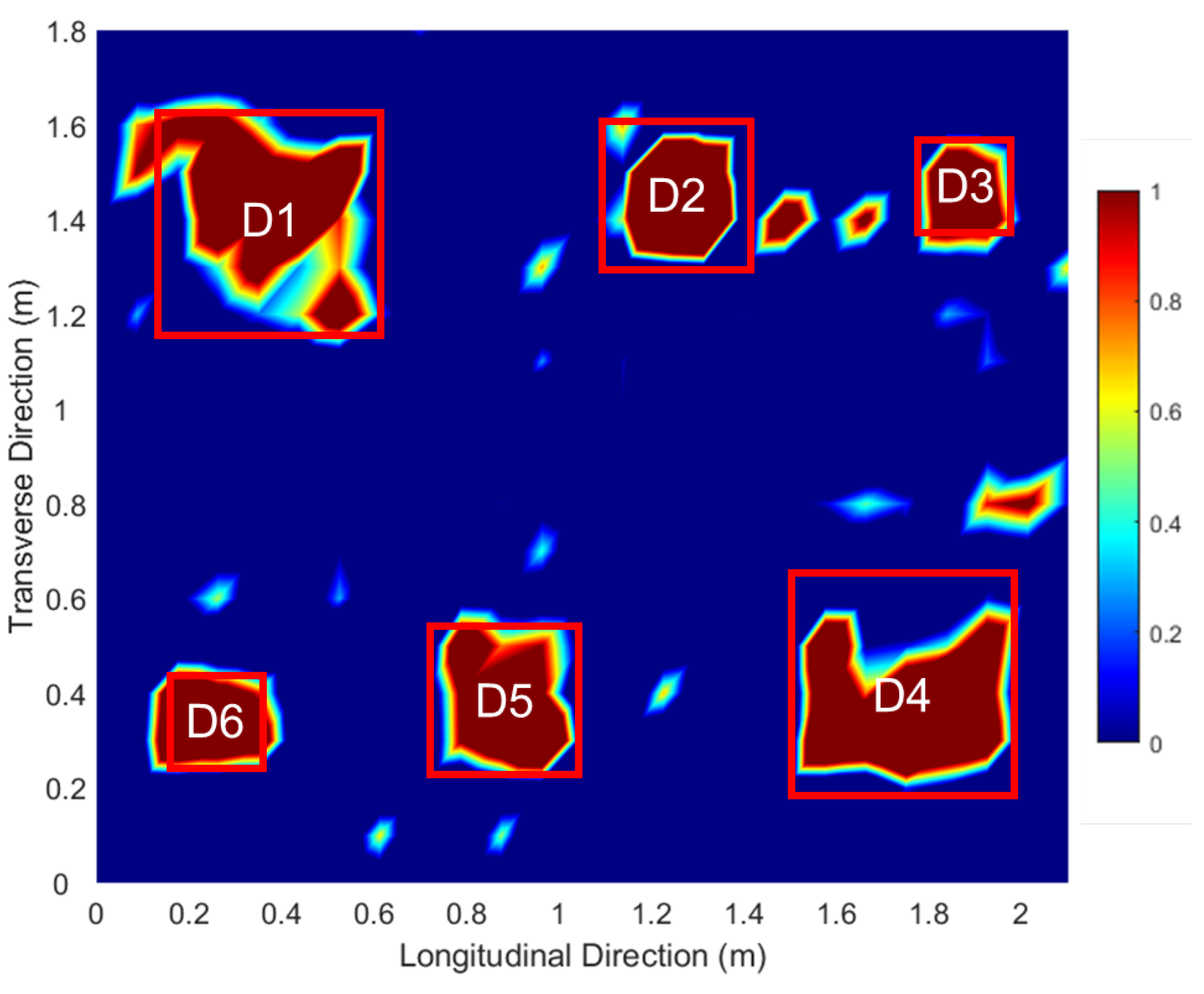

3.2. Delamination Results from Field Test

4. Concluding Remarks

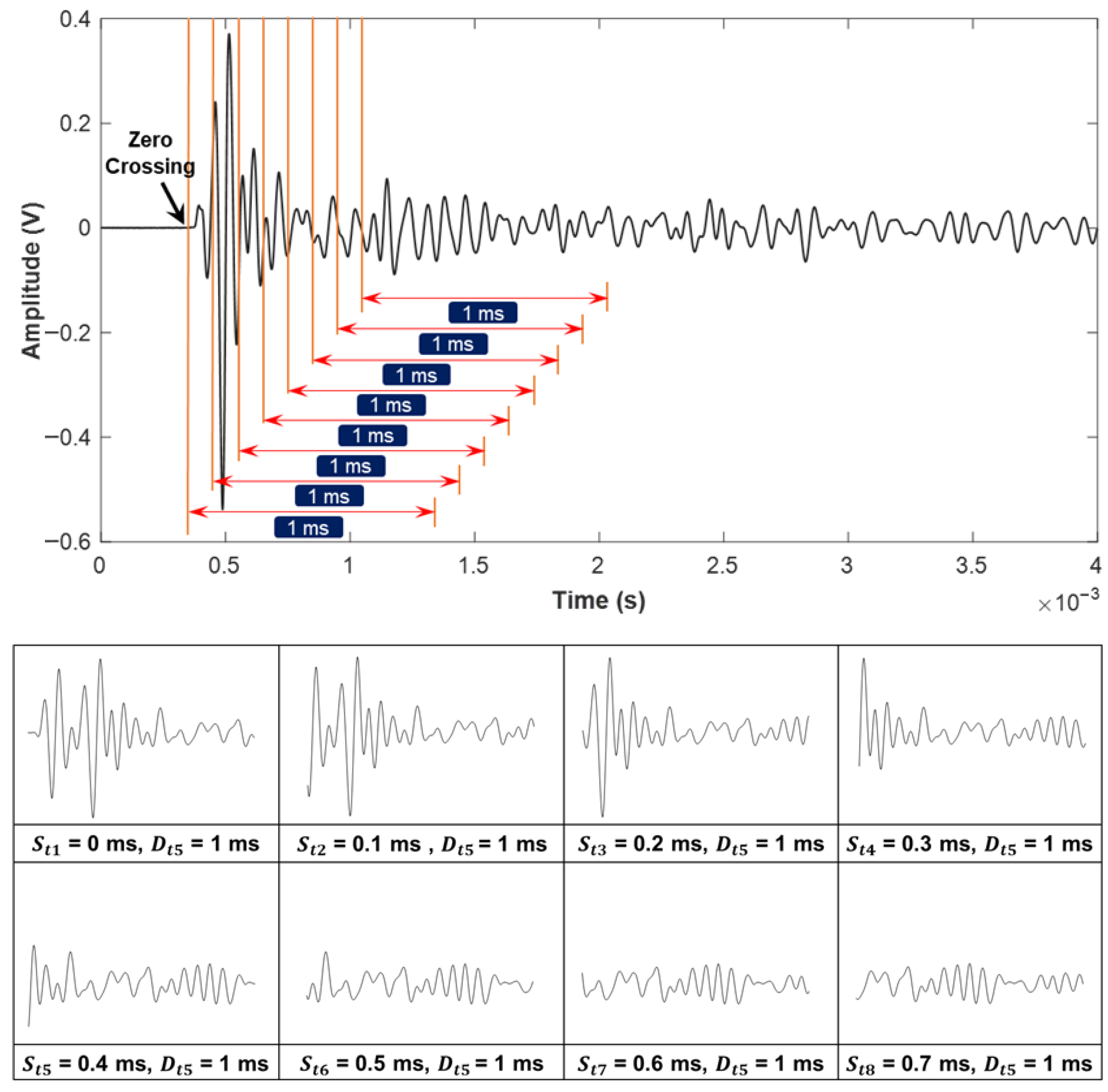

- Deep learning analysis determined that a 1 ms signal duration combined with a 0.1 ms starting point after the zero-crossing delivers optimal damage detection performance, reaching an accuracy of approximately 88.8%.

- The CNN-based signal extraction method effectively reduces the misinterpretation of signals—both omissions and exaggerations—caused by environmental noise and field-testing variability.

- Implementing CNN-optimized signal parameters allows for more consistent and reliable interpretation of impact-echo results, particularly under challenging field conditions.

- Incorporating the optimized parameters into both time- and frequency-domain analyses significantly enhances the precision and reliability of damage detection.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- 23 CFR § 650; National Bridge Inspection Standards. Federal Highway Administration U.S. Department of Transportation, Federal Highway Administration: Washington, DC, USA, 2019.

- Locke, W.; Sybrandt, J.; Redmond, L.; Safro, I.; Atamturktur, S. Using Drive-by Health Monitoring to Detect Bridge Damage Considering Environmental and Operational Effects. J. Sound Vib. 2020, 468, 115088. [Google Scholar] [CrossRef]

- Abu Dabous, S.; Feroz, S. Condition Monitoring of Bridges with Non-Contact Testing Technologies. Autom. Constr. 2020, 116, 103224. [Google Scholar] [CrossRef]

- Sohn, H.; Dzwonczyk, M.; Straser, E.G.; Kiremidjian, A.S.; Law, K.H.; Meng, T. An Experimental Study of Temperature Effect on Modal Parameters of the Alamosa Canyon Bridge. Earthq. Eng. Struct. Dyn. 1999, 28, 879–897. [Google Scholar] [CrossRef]

- Xue, J.; Briseghella, B.; Huang, F.; Nuti, C.; Tabatabai, H.; Chen, B. Review of Ultra-High Performance Concrete and Its Application in Bridge Engineering. Constr. Build. Mater. 2020, 260, 119844. [Google Scholar] [CrossRef]

- Srikanth, I.; Arockiasamy, M. Deterioration Models for Prediction of Remaining Useful Life of Timber and Concrete Bridges: A Review. J. Traffic Transp. Eng. Engl. Ed. 2020, 7, 152–173. [Google Scholar] [CrossRef]

- Ham, S.; Popovics, J.S. Application of Contactless Ultrasound toward Automated Inspection of Concrete Structures. Autom. Constr. 2015, 58, 155–164. [Google Scholar] [CrossRef]

- Jang, D.; Park, J.; Choi, S.; Bang, J.; Choi, J.; Kim, J.; Yang, B.; Jeon, H. Novel Approach for Crack Detections and Rapid Repairment Methods in Cement-Based Self-Heating Composites for Smart Infrastructures. Compos. Part B Eng. 2025, 293, 112126. [Google Scholar] [CrossRef]

- Jang, D.; Bang, J.; Yoon, H.N.; Seo, J.; Jung, J.; Jang, J.G.; Yang, B. Deep Learning-Based LSTM Model for Prediction of Long-Term Piezoresistive Sensing Performance of Cement-Based Sensors Incorporating Multi-Walled Carbon Nanotube. Comput. Concr. 2022, 30, 301–310. [Google Scholar]

- Ham, S.; Popovics, J.S. Application of Micro-Electro-Mechanical Sensors Contactless NDT of Concrete Structures. Sensors 2015, 15, 9078–9096. [Google Scholar] [CrossRef] [PubMed]

- Ham, S.; Song, H.; Oelze, M.L.; Popovics, J.S. A Contactless Ultrasonic Surface Wave Approach to Characterize Distributed Cracking Damage in Concrete. Ultrasonics 2017, 75, 46–57. [Google Scholar] [CrossRef] [PubMed]

- Azari, H.; Lin, S. Evaluation of the Impact Echo Method for Concrete Bridge Decks with Asphalt Overlays. Transp. Res. Rec. 2019, 2673, 436–444. [Google Scholar] [CrossRef]

- Coleman, Z.W.; Schindler, A.K.; Jetzel, C.M. Impact-Echo Defect Detection in Reinforced Concrete Bridge Decks without Overlays. J. Perform. Constr. Facil. 2021, 35, 04021058. [Google Scholar] [CrossRef]

- Lin, S.; Meng, L.; Zhao, G.; Zhang, J.; Xin, J.; Cheng, Y.; Cheng, S.; Zhai, C. Automatic Elimination of Invalid Impact-Echo Signals for Detecting Delamination in Concrete Bridge Decks Based on Deep Learning. Dev. Built Environ. 2024, 19, 100521. [Google Scholar] [CrossRef]

- Jiang, W.; Xie, Y.; Wu, J.; Guo, J.; Long, G. Identifying Bonding Interface Flaws in CRTS III Type Ballastless Track Structure Using the Impact-Echo Method. Eng. Struct. 2021, 227, 111429. [Google Scholar] [CrossRef]

- Dawood, N.; Marzouk, H.; Hussein, A.; Gillis, N. Nondestructive Assessment of a Jetty Bridge Structure Using Impact-Echo and Shear-Wave Techniques. J. Bridge Eng. 2013, 18, 801–809. [Google Scholar] [CrossRef]

- Sawicki, B.; Piotrowski, T.; Garbacz, A. Development of Impact-Echo Multitransducer Device for Automated Concrete Homogeneity Assessment. Materials 2021, 14, 2144. [Google Scholar] [CrossRef]

- Hoxha, E.; Feng, J.; Sanakov, D.; Gjinofci, A.; Xiao, J. Robotic Inspection and Characterization of Subsurface Defects on Concrete Structures Using Impact Sounding. In Proceedings of the 13th International Workshop on Structural Health Monitoring, Stanford, CA, USA, 15–17 March 2022. [Google Scholar]

- Yang, S.; Jang, D.; Kim, J.; Jeon, H. Autonomous Concrete Crack Monitoring Using a Mobile Robot with a 2-DoF Manipulator and Stereo Vision Sensors. Sensors 2025, 25, 6121. [Google Scholar] [CrossRef]

- Dorafshan, S.; Azari, H. Evaluation of Bridge Decks with Overlays Using Impact Echo, a Deep Learning Approach. Autom. Constr. 2020, 113, 103133. [Google Scholar] [CrossRef]

- Sengupta, A.; Ilgin Guler, S.; Shokouhi, P. Interpreting Impact Echo Data to Predict Condition Rating of Concrete Bridge Decks: A Machine-Learning Approach. J. Bridge Eng. 2021, 26, 04021044. [Google Scholar] [CrossRef]

- Wu, Y.; Wang, Y.; Li, D.; Zhang, J. Two-Step Detection of Concrete Internal Condition Using Array Ultrasound and Deep Learning. NDT E Int. 2023, 139, 102945. [Google Scholar] [CrossRef]

- Cygert, S.; Czyżewski, A. Robust Object Detection with Multi-Input Multi-Output Faster R-CNN. In Proceedings of the Image Analysis and Processing—ICIAP 2022, Lecce, Italy, 23–27 May 2022; Sclaroff, S., Distante, C., Leo, M., Farinella, G.M., Tombari, F., Eds.; Springer International Publishing: Cham, Switzerland, 2022; pp. 572–583. [Google Scholar]

- Dorafshan, S.; Azari, H. Deep Learning Models for Bridge Deck Evaluation Using Impact Echo. Constr. Build. Mater. 2020, 263, 120109. [Google Scholar] [CrossRef]

- Abdeljaber, O.; Avci, O.; Kiranyaz, M.S.; Boashash, B.; Sodano, H.; Inman, D.J. 1-D CNNs for Structural Damage Detection: Verification on a Structural Health Monitoring Benchmark Data. Neurocomputing 2018, 275, 1308–1317. [Google Scholar] [CrossRef]

- Torlapati, R.; Azari, H.; Shokouhi, P. Classification of Impact Echo Signals Using Explainable Deep Learning and Transfer Learning Approaches. Transp. Res. Rec. 2023, 2677, 464–477. [Google Scholar] [CrossRef]

- Yoon, Y.-G.; Kim, C.-M.; Oh, T.-K. A Study on the Applicability of the Impact-Echo Test Using Semi-Supervised Learning Based on Dynamic Preconditions. Sensors 2022, 22, 5484. [Google Scholar] [CrossRef] [PubMed]

- Zhang, J.-K.; Yan, W.; Cui, D.-M. Concrete Condition Assessment Using Impact-Echo Method and Extreme Learning Machines. Sensors 2016, 16, 447. [Google Scholar] [CrossRef]

- Wu, Y.C.; Lamsal, A.; Ham, S.P. Delamination Damage Identification through Multi-Input Data Using Impact Echo and Study of Model Efficiency. Nondestruct. Test. Eval. 2024, 1–28. [Google Scholar] [CrossRef]

- Xu, J.; Yu, X. Detection of Concrete Structural Defects Using Impact Echo Based on Deep Networks. J. Test. Eval. 2021, 49, 109–120. [Google Scholar] [CrossRef]

- Xiao, Z.; Song, K.-Y.; Gupta, M.M. Development of a CNN Edge Detection Model of Noised X-Ray Images for Enhanced Performance of Non-Destructive Testing. Measurement 2021, 174, 109012. [Google Scholar] [CrossRef]

- Virupakshappa, K.; Oruklu, E. Multi-Class Classification of Defect Types in Ultrasonic NDT Signals with Convolutional Neural Networks. In Proceedings of the 2019 IEEE International Ultrasonics Symposium (IUS), Glasgow, UK, 6–9 October 2019; pp. 1647–1650. [Google Scholar]

- Wu, Y.; Zhang, J.; Gao, C.; Xu, J. Internal Defect Detection Quantification and Three-Dimensional Localization Based on Impact Echo and Classification Learning Model. Measurement 2023, 218, 113153. [Google Scholar] [CrossRef]

- Kang, S.; Wu, Y.C.; David, D.S.; Ham, S. Rapid Damage Assessment of Concrete Bridge Deck Leveraging an Automated Double-Sided Bounce System. Autom. Constr. 2022, 138, 104244. [Google Scholar] [CrossRef]

- Leissa, A.W. The Free Vibration of Rectangular Plates. J. Sound Vib. 1973, 31, 257–293. [Google Scholar] [CrossRef]

- Kang, S.; Ham, S.; Kim, K.-J. An Analytical, Numerical, and Experimental Study of Rayleigh Wave Scattering for Internal Vertical Crack Evaluation. Constr. Build. Mater. 2021, 306, 124838. [Google Scholar] [CrossRef]

- Kee, S.-H.; Oh, T.; Popovics, J.S.; Arndt, R.W.; Zhu, J. Nondestructive Bridge Deck Testing with Air-Coupled Impact-Echo and Infrared Thermography. J. Bridge Eng. 2012, 17, 928–939. [Google Scholar] [CrossRef]

- Chaudhary, M.T.A. Effectiveness of Impact Echo Testing in Detecting Flaws in Prestressed Concrete Slabs. Constr. Build. Mater. 2013, 47, 753–759. [Google Scholar] [CrossRef]

- Guthrie, W.S.; Larsen, J.L.; Baxter, J.S.; Mazzeo, B.A. Automated Air-Coupled Impact-Echo Testing of a Concrete Bridge Deck from a Continuously Moving Platform. J. Nondestruct. Eval. 2019, 38, 32. [Google Scholar] [CrossRef]

| No | Layer | Output Dimension | Filters | Kernel Size | Activation Function | Total Parameters |

|---|---|---|---|---|---|---|

| 1 | Input | 200 × 200 × 200 | – | – | – | – |

| 2 | Conv-1 | 196 × 196 × 32 | 32 | 5 × 5 | ReLU | 2432 |

| 3 | Pool-1 | 65 × 65 × 32 | – | 3 × 3 | – | 0 |

| 4 | Conv-2 | 61 × 61 × 64 | 64 | 5 × 5 | ReLU | 51,264 |

| 5 | Pool-2 | 20 × 20 × 64 | – | 3 × 3 | – | 0 |

| 6 | Conv-3 | 18 × 18 × 128 | 128 | 3 × 3 | ReLU | 73,856 |

| 7 | Pool-3 | 6 × 6 × 128 | – | 3 × 3 | – | 0 |

| 8 | Dense-1 | 512 | – | – | ReLU | 3,211,776 |

| 9 | Dense-2 | 128 | – | – | ReLU | 65,664 |

| 10 | Output | 3 | – | – | Softmax | 387 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lamsal, A.; Lamsal, B.; Kim, B.-J.; Ham, S.P.; Jang, D. Advanced Signal Analysis Model for Internal Defect Mapping in Bridge Decks Using Impact-Echo Field Testing. Sensors 2025, 25, 6623. https://doi.org/10.3390/s25216623

Lamsal A, Lamsal B, Kim B-J, Ham SP, Jang D. Advanced Signal Analysis Model for Internal Defect Mapping in Bridge Decks Using Impact-Echo Field Testing. Sensors. 2025; 25(21):6623. https://doi.org/10.3390/s25216623

Chicago/Turabian StyleLamsal, Avishkar, Biggyan Lamsal, Bum-Jun Kim, Suyun Paul Ham, and Daeik Jang. 2025. "Advanced Signal Analysis Model for Internal Defect Mapping in Bridge Decks Using Impact-Echo Field Testing" Sensors 25, no. 21: 6623. https://doi.org/10.3390/s25216623

APA StyleLamsal, A., Lamsal, B., Kim, B.-J., Ham, S. P., & Jang, D. (2025). Advanced Signal Analysis Model for Internal Defect Mapping in Bridge Decks Using Impact-Echo Field Testing. Sensors, 25(21), 6623. https://doi.org/10.3390/s25216623