Optimisation of an nIR-Emitting Benzoporphyrin Pressure-Sensitive Paint Formulation

Abstract

1. Introduction

2. Materials and Methods

2.1. Synthesis and Characterisation

2.2. PSP Formulations

2.3. Luminescence Spectra and Lifetimes

2.4. PSP Performance Studies (A Priori Calibrations)

3. Results

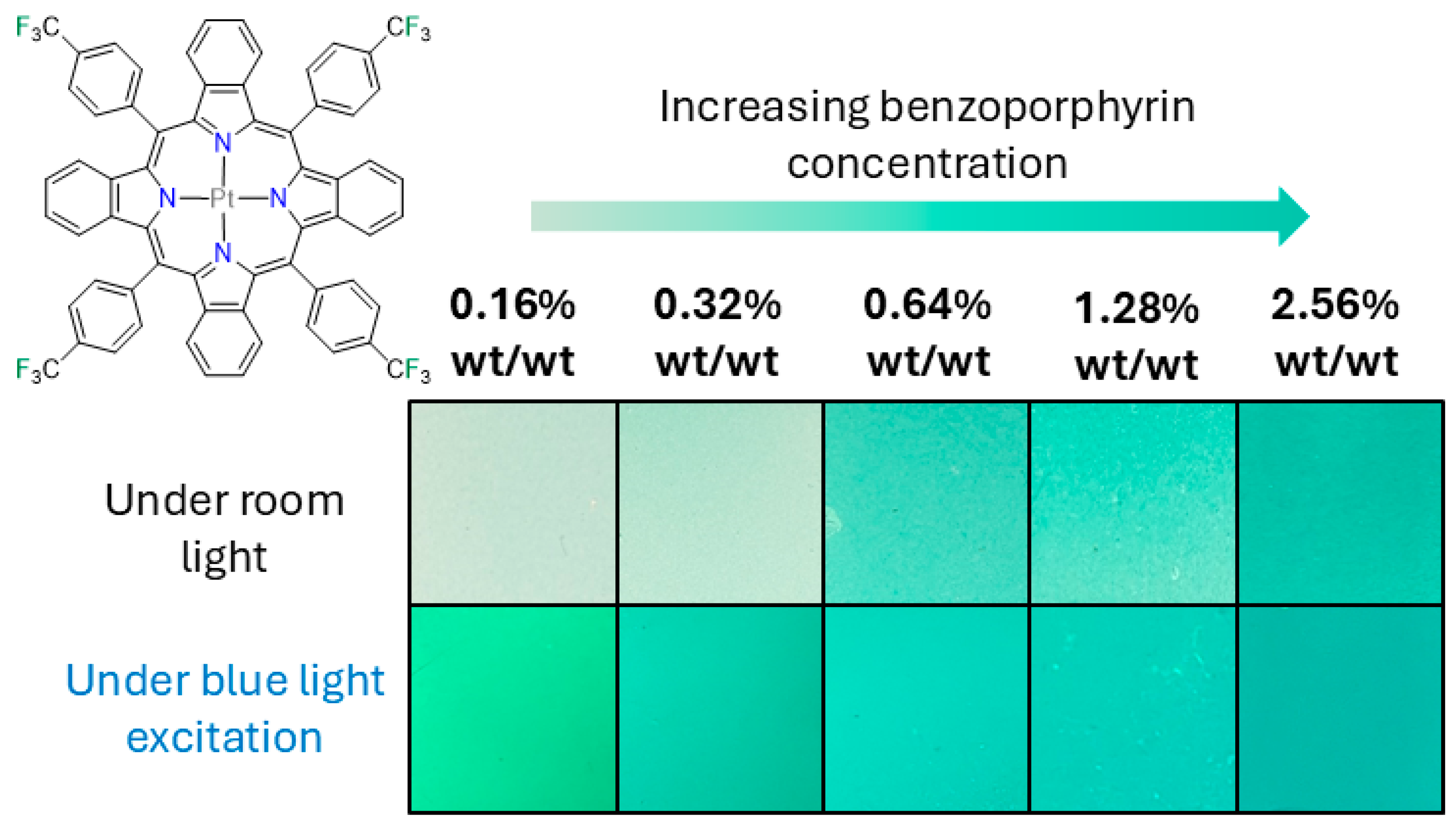

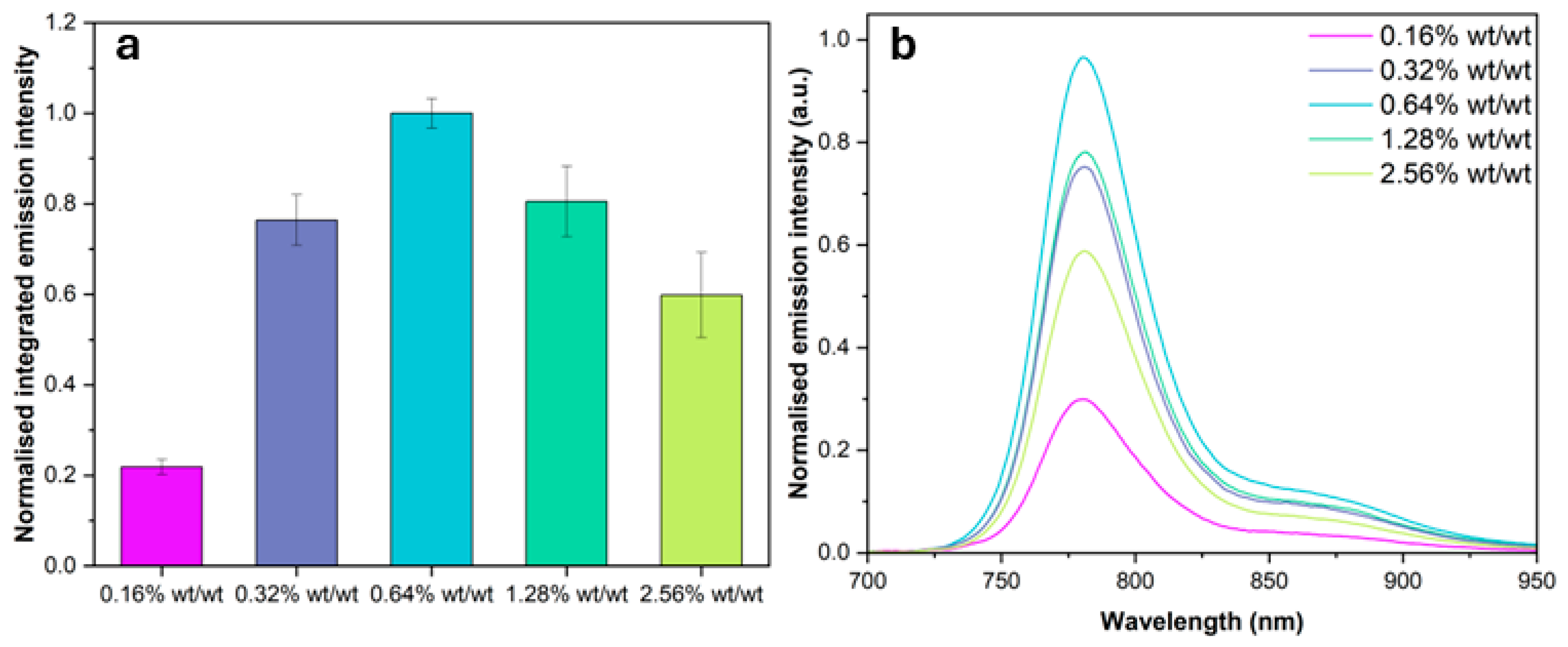

3.1. Luminescene Intensity

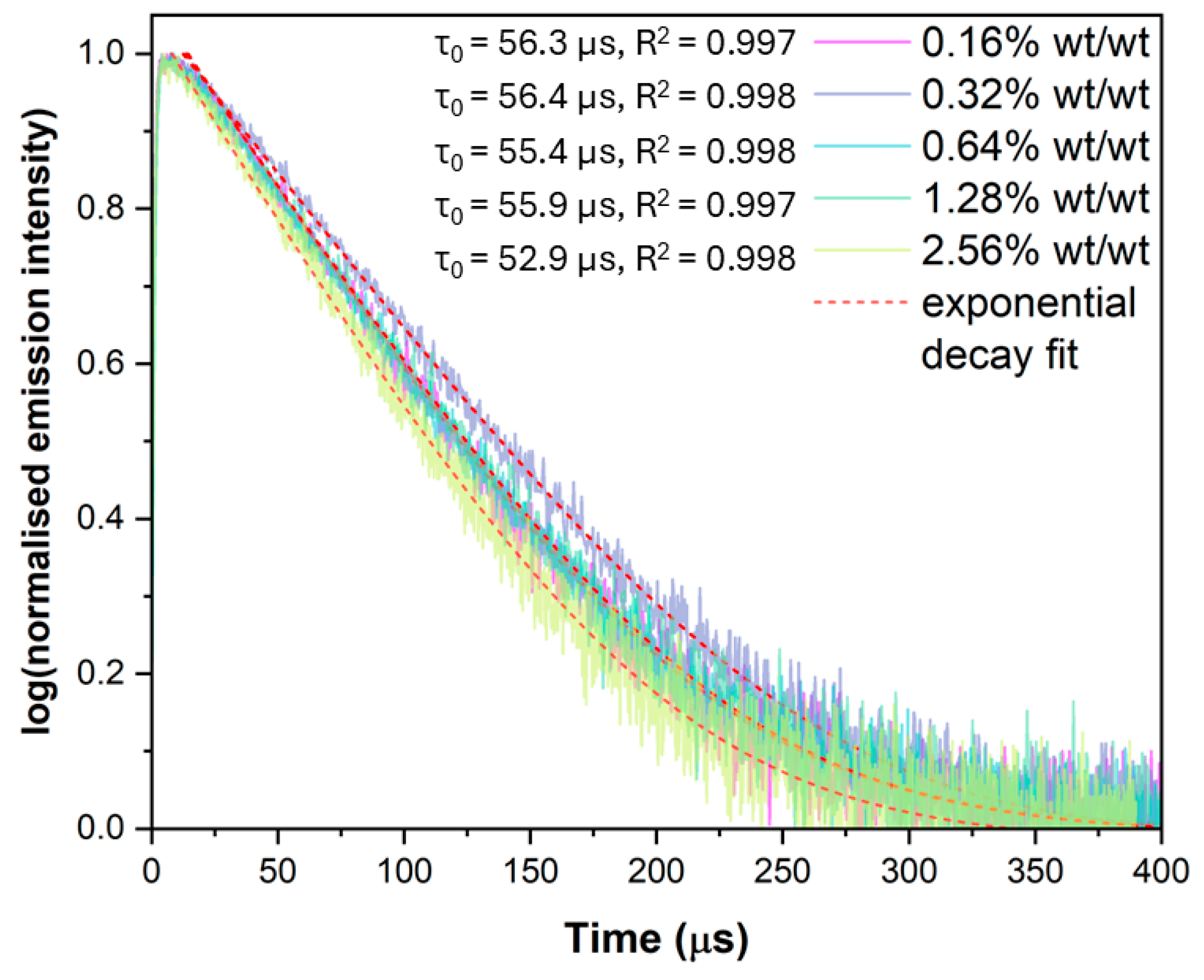

3.2. Luminescene Lifetime, τ

3.3. Pressure Sensitivity, Sp(T)

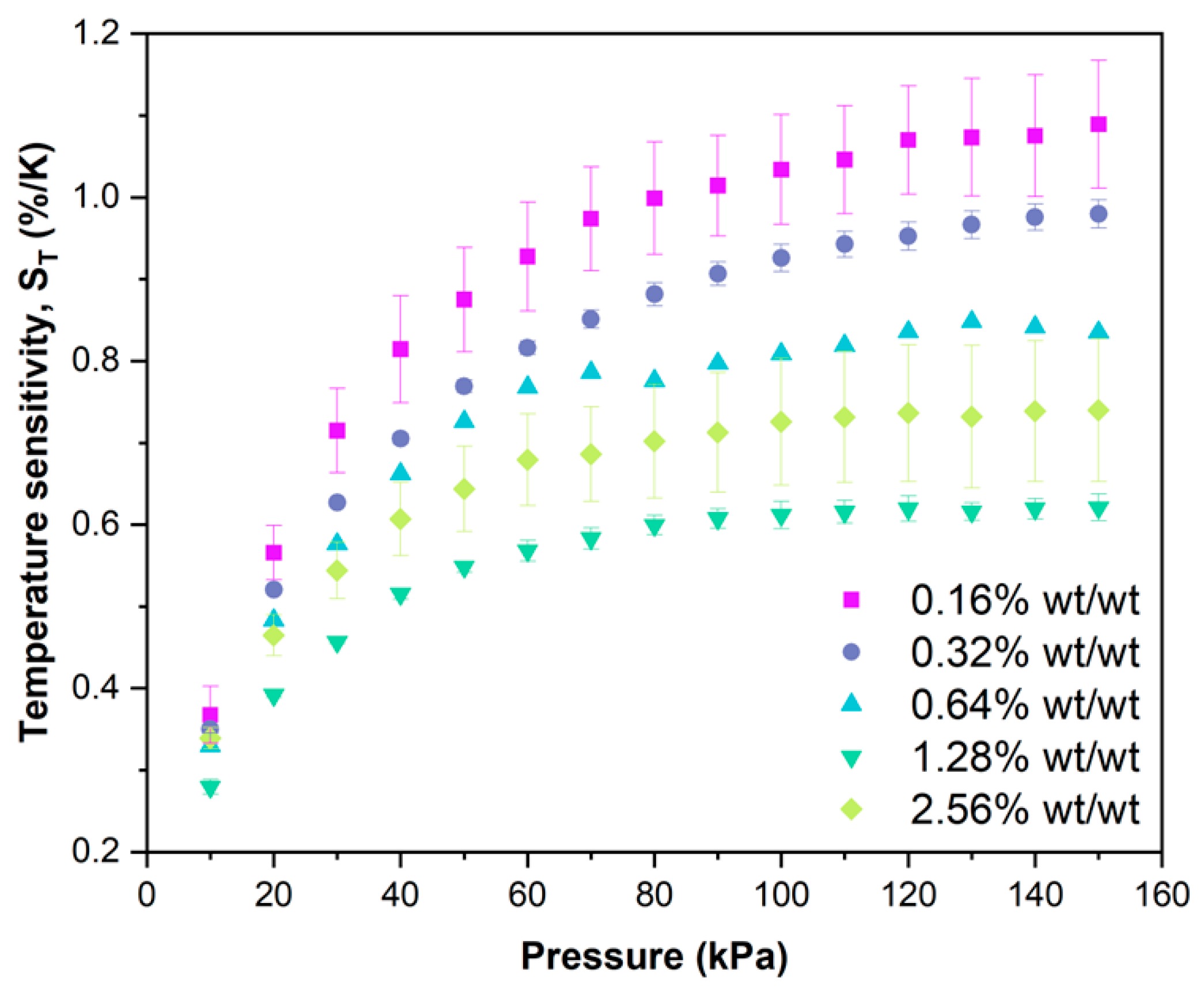

3.4. Temperature Sensitivity, ST

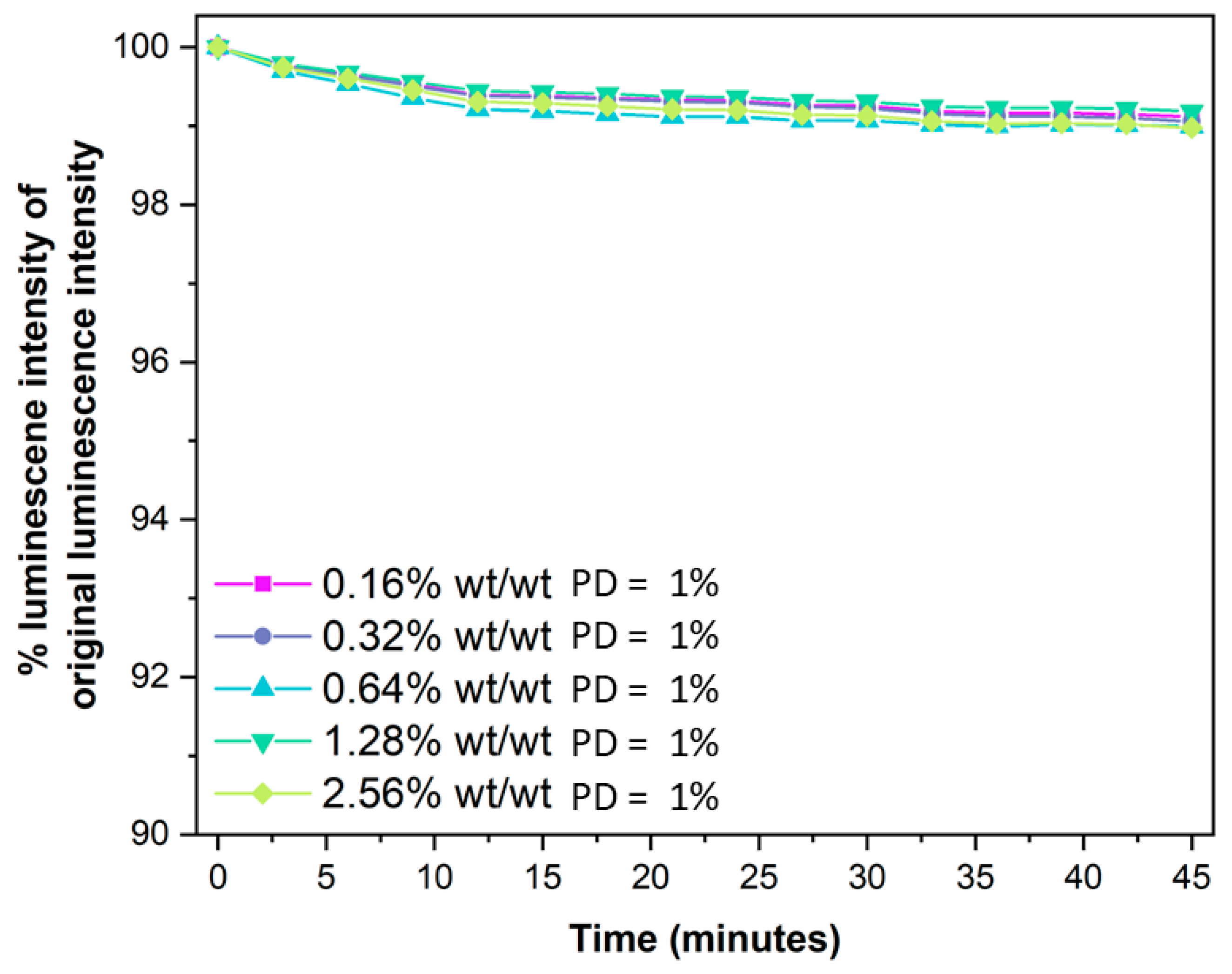

3.5. Photodegradation, PD

4. Discussion

4.1. The Effect of Benzoporphyrin Loading on Luminescence Intensity

4.2. The Effect of Benzoporphyrin Loading on the Luminescence Lifetime, τ0

4.3. The Effect of Benzoporphyrin Loading on the Pressure Sensitivity, Sp(T)

4.4. The Effect of Benzoporphyrin Loading on the Temperature Sensitivity, ST(P)

4.5. The Effect of Benzoporphyrin Loading on PD

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| PSPs | Pressure-sensitive paints |

| PtTFPP | (2,3,4,5,6-pentafluorphenyl)-porphyrin |

| PtTFPL | Platinum(II)-meso-tetra(pentafluouorophenyl)porpholactone |

| BP-PSP | Benzoporphyrin pressure-sensitive paint |

| PD | Photodegradation |

| FIB | Fluoro/Iso/Butyl |

References

- Liu, T.; Sullivan, J.P.; Asai, K.; Klein, C.; Egami, Y. Pressure and Temperature Sensitive Paints; Experimental Fluid Mechanics; Springer International Publishing: Cham, Switzerland, 2021; ISBN 978-3-030-68055-8. [Google Scholar]

- Vardaki, E.; Stokes, N.; Patel, S.; Gustafsson, P. Pressure Sensitive Paint Measurements on the Gripen Model at the ARA Transonic Wind Tunnel. In Proceedings of the 50th AIAA Aerospace Sciences Meeting including the New Horizons Forum and Aerospace Exposition, Nashville, TN, USA, 9–12 January 2012. [Google Scholar]

- McLachlan, B.G.; Bell, J.H. Pressure-Sensitive Paint in Aerodynamic Testing. Exp. Therm. Fluid Sci. 1995, 10, 470–485. [Google Scholar] [CrossRef]

- Mébarki, Y.; Cooper, K.R.; Reichert, T.M. Automotive Testing Using Pressure-Sensitive Paint. J. Vis. 2003, 6, 381–393. [Google Scholar] [CrossRef]

- Yamashita, T.; Sugiura, H.; Nagai, H.; Asai, K.; Ishida, K. Pressure-Sensitive Paint Measurement of the Flow around a Simplified Car Model. J. Vis. 2007, 10, 289–298. [Google Scholar] [CrossRef]

- Nakakita, K.; Takama, Y.; Imagawa, K.; Kato, H. Unsteady PSP Measurement of Transonic Unsteady Flow Field around a Rocket Fairing Model. In Proceedings of the 28th Aerodynamic Measurement Technology, Ground Testing, and Flight Testing Conference,, New Orleans, LA, USA, 25–28 June 2012. [Google Scholar]

- Sugioka, Y.; Numata, D.; Asai, K.; Koike, S.; Nakakita, K.; Koga, S. Unsteady PSP Measurement of Transonic Buffet on a Wing. In Proceedings of the 53rd AIAA Aerospace Sciences Meeting; American Institute of Aeronautics and Astronautics, Kissimmee, FL, USA, 5–9 January 2015. [Google Scholar]

- Juliano, T.J.; Kumar, P.; Peng, D.; Gregory, J.W.; Crafton, J.; Fonov, S. Single-Shot, Lifetime-Based Pressure-Sensitive Paint for Rotating Blades. Meas. Sci. Technol. 2011, 22, 085403. [Google Scholar] [CrossRef]

- Weiss, A.; Geisler, R.; Schwermer, T.; Yorita, D.; Henne, U.; Klein, C.; Raffel, M. Single-Shot Pressure-Sensitive Paint Lifetime Measurements on Fast Rotating Blades Using an Optimized Double-Shutter Technique. Exp. Fluids 2017, 58, 120. [Google Scholar] [CrossRef]

- Matsuyama, T.; Nagata, T.; Kasai, M.; Nonomura, T. Improvement of Pressure-Sensitive-Paint Measurement of Rotating Blades by Adjusting Oxygen Concentration under Low-Pressure Conditions. In Proceedings of the AIAA SCITECH 2023 Forum, Gaylord National Harbor, MD, USA, 23–27 January 2023. [Google Scholar]

- Egami, Y.; Iigima, Y.; Asai, K. Optimization of Polymer-Based PSP for Cryogenic Wind Tunnels. In Proceedings of the ICIASF 2001 Record, 19th International Congress on Instrumentation in Aerospace Simulation Facilities (Cat. No. 01CH37215), Cleveland, OH, USA, 27–30 August 2001; pp. 177–185. [Google Scholar]

- Qiao, P.; Wu, J.; Huang, H.; Li, G.; Li, D.; Du, H. Experimental Investigation on Temperature Effects of Cryogenic Pressure-Sensitive Paint. Aerospace 2025, 12, 329. [Google Scholar] [CrossRef]

- Asai, K.; Amao, Y.; Iijima, Y.; Okura, I.; Nishide, H. Novel Pressure-Sensitive Paint for Cryogenic and Unsteady Wind-Tunnel Testing. J. Thermophys. Heat Transf. 2002, 16, 109–115. [Google Scholar] [CrossRef]

- Quinn, M.K.; Nunn, E.; Adams, J.; Tanner, M.; Goulding, S.; Cardy, A.; Garrard, M.; Stokes, N.; Roberts, D.A.; Jewson, T. Application of Pressure-Sensitive Paint for Explosive Blast Measurements. Meas. Sci. Technol. 2023, 35, 035201. [Google Scholar] [CrossRef]

- Quinn, M.; Nunn, E.; Adams, J.; Tanner, M.; Goulding, S.; Cardy, A.; Gerrard, M.; Stokes, N.P.; Roberts, D.; Jewson, T. Post Processing of Fast Response PSP for Blast Wave Testing. In Proceedings of the 20th International Symposium on Flow Visualization, Delft, The Netherlands, 10–13 July 2023. [Google Scholar]

- Mizukaki, T.; Iwasaki, F.; Mori, M.; Kato, A.; Numata, D. Four-Dimensional Visualization of Blast Loading inside a Detonation-Driven Shock Tube Using Improved Pressure-Sensitive Paint and Digital Image Correlation. Sci. Technol. Energ. Mater. 2021, 82, 95–102. [Google Scholar] [CrossRef]

- Wei, C.; Zhang, H.; Fan, H.; Wang, P.; Peng, D.; Liu, Y. Resolving High-Frequency Aeroacoustic Noises of High-Speed Dual-Impinging Jets Using Fast Pressure-Sensitive Paint. Exp. Fluids 2024, 65, 131. [Google Scholar] [CrossRef]

- Liu, X.; Qin, C.; Zhao, K.; Wang, P.; Liu, Y.; Peng, D. Identification of Discrete Tonal Noise in Inclined Jet Impingement Using Pressure-Sensitive Paint. AIAA J. 2023, 61, 626–639. [Google Scholar] [CrossRef]

- Goessling, J.; Fischer, F.; Seume, J.R.; Hilfer, M. Uncertainty and Validation of Unsteady Pressure-Sensitive Paint Measurements of Acoustic Fields under Aero Engine-like Conditions. Exp. Fluids 2023, 64, 22. [Google Scholar] [CrossRef]

- Basu, B.J.; Vasantharajan, N.; Raju, C. A Novel Pyrene-Based Binary Pressure Sensitive Paint with Low Temperature Coefficient and Improved Stability. Sens. Actuators B Chem. 2009, 138, 283–288. [Google Scholar] [CrossRef]

- Khalil, G.E.; Costin, C.; Crafton, J.; Jones, G.; Grenoble, S.; Gouterman, M.; Callis, J.B.; Dalton, L.R. Dual-Luminophor Pressure-Sensitive Paint: I. Ratio of Reference to Sensor Giving a Small Temperature Dependency. Sens. Actuators B Chem. 2004, 97, 13–21. [Google Scholar] [CrossRef]

- Gu, F.; Wei, C.; Liu, Y.; Peng, D.; Liang, L. Temperature Sensitivity Elimination in Sprayable Fast-Responding Pressure-Sensitive Paint. Sens. Actuators Phys. 2022, 345, 113797. [Google Scholar] [CrossRef]

- Mitsuo, K.; Asai, K.; Hayasaka, M.; Kameda, M. Temperature Correction of PSP Measurement Using Dual-Luminophor Coating. J. Vis. 2003, 6, 213–223. [Google Scholar] [CrossRef]

- Lee, S.-K.; Okura, I. Photostable Optical Oxygen Sensing Material: PlatinumTetrakis(Pentafluorophenyl)Porphyrin Immobilized in Polystyrene. Anal. Commun. 1997, 34, 185–188. [Google Scholar] [CrossRef]

- Nunn, E.J.; Tsioumanis, D.; Whitehead, G.F.S.; Fisher, T.B.; Roberts, D.A.; Quinn, M.K.; Natrajan, L.S. Tuning the Performance of Metalloporphyrin-Based Pressure-Sensitive Paints through the Nature of the Central Metal Ion. ACS Omega 2024, 9, 51580–51590. [Google Scholar] [CrossRef] [PubMed]

- Khalil, G.; Gouterman, M.; Ching, S.; Costin, C.; Coyle, L.; Gouin, S.; Green, E.; Sadilek, M.; Wan, R.; Yearyean, J.; et al. Synthesis and Spectroscopic Characterization of Ni, Zn, Pd and Pt Tetra(Pentafluorophenyl)Porpholactone with Comparisons to Mg, Zn, Y, Pd and Pt Metal Complexes of Tetra(Pentafluorophenyl)Porphine. J. Porphyr. Phthalocyanines 2002, 6, 135–145. [Google Scholar] [CrossRef]

- Nunn, E.J.; Tsioumanis, D.; Fisher, T.B.; Roberts, D.A.; Quinn, M.K.; Natrajan, L.S. Development of Bright NIR-Emitting Pressure-Sensitive Paints Using Benzoporphyrin Luminophores. Chem. Sci. 2025, 16, 7018–7025. [Google Scholar] [CrossRef] [PubMed]

- Grenoble, S.; Gouterman, M.; Khalil, G.; Callis, J.; Dalton, L. Pressure-Sensitive Paint (PSP): Concentration Quenching of Platinum and Magnesium Porphyrin Dyes in Polymeric Films. J. Lumin. 2005, 113, 33–44. [Google Scholar] [CrossRef]

- Nunn, E.J.; Tsioumanis, D.; Whitehead, G.F.S.; Fisher, T.B.; Roberts, D.A.; Quinn, M.K.; Natrajan, L.S. Exploring the Effect of Porphyrin Chemical Structure on the Performance of Polymer-Based Pressure-Sensitive Paints. Sens. Actuators B Chem. 2024, 409, 135577. [Google Scholar] [CrossRef]

- Sakaue, H.; Ishii, K. Optimization of Anodized-Aluminum Pressure-Sensitive Paint by Controlling Luminophore Concentration. Sensors 2010, 10, 6836–6847. [Google Scholar] [CrossRef] [PubMed]

- Determining Fluorescence Lifetimes—Edinburgh Instruments. Available online: https://www.edinst.com/resource/determining-fluorescence-lifetimes/ (accessed on 17 July 2025).

- Borisov, S.M. Fundamentals of Quenched Phosphorescence O2 Sensing and Rational Design of Sensor Materials. In Quenched-Phosphorescence Detection of Molecular Oxygen: Applications in Life Sciences; Papkovsky, D.B., Dmitriev, R.I., Eds.; The Royal Society of Chemistry: London, UK, 2018; pp. 1–18. [Google Scholar]

- Hutter, L.H.; Müller, B.J.; Koren, K.; Borisov, S.M.; Klimant, I. Robust Optical Oxygen Sensors Based on Polymer-Bound NIR-Emitting Platinum(II)–Benzoporphyrins. J. Mater. Chem. C 2014, 2, 7589–7598. [Google Scholar] [CrossRef]

- Carraway, E.R.; Demas, J.N.; DeGraff, B.A. Luminescence Quenching Mechanism for Microheterogeneous Systems. Anal. Chem. 1991, 63, 332–336. [Google Scholar] [CrossRef]

- Single-Component Pressure Sensitive Paints–ISSI. Available online: https://innssi.com/single-component-pressure-sensitive-paints/ (accessed on 18 July 2025).

- Puklin, E.; Carlson, B.; Gouin, S.; Costin, C.; Green, E.; Ponomarev, S.; Tanji, H.; Gouterman, M. Ideality of Pressure-Sensitive Paint. I. Platinum Tetra(Pentafluorophenyl)Porphine in Fluoroacrylic Polymer. J. Appl. Polym. Sci. 2000, 77, 2795–2804. [Google Scholar] [CrossRef]

- Strasser, N.S.; Murakami, D.D.; Lash, E.L.; Hand, L.A.; Combs, C.S. Characterization of Photodegradation in Unsteady Pressure-Sensitive Paint Under Varying Pressures. In Proceedings of the AIAA Aviation Forum and Ascend 2024, Las Vegas, NV, USA, 29 July–2 August 2024. [Google Scholar]

| Benzoporphyrin Loading | τ0 (μs) | τair * (μs) |

|---|---|---|

| 0.16% wt/wt | 56.3 | 14.9 |

| 0.32% wt/wt | 56.4 | 14.9 |

| 0.64% wt/wt | 55.4 | 14.5 |

| 1.28% wt/wt | 55.9 | 14.1 |

| 2.56% wt/wt | 52.9 | 13.0 |

| Benzoporphyrin Loading | Sp(T) (%/kPa) | ||

|---|---|---|---|

| T = 273 K | T = 293 K | T = 313 K | |

| 0.16% wt/wt | 0.635 ± 0.006 | 0.685 ± 0.006 | 0.716 ± 0.003 |

| 0.32% wt/wt | 0.647 ± 0.003 | 0.693 ± 0.004 | 0.724 ± 0.001 |

| 0.64% wt/wt a | 0.699 | 0.737 | 0.751 |

| 1.28% wt/wt | 0.717 ± 0.001 | 0.740 ± 0.004 | 0.748 ± 0.002 |

| 2.56% wt/wt | 0.694 ± 0.018 | 0.713 ± 0.007 | 0.743 ± 0.006 |

| Benzoporphyrin Loading | Temperature Sensitivity at 100 kPa ST(100 kPa) (%/K) |

|---|---|

| 0.16% wt/wt | 1.03 ± 0.07 |

| 0.32% wt/wt | 0.93 ± 0.02 |

| 0.64% wt/wta | 0.81 |

| 1.28% wt/wt | 0.61 ± 0.02 |

| 2.56% wt/wt | 0.73 ± 0.08 |

| Benzoporphyrin Loading | Photodegradation PD (%) |

|---|---|

| 0.16% wt/wt | 1 |

| 0.32% wt/wt | 1 |

| 0.64% wt/wt | 1 |

| 1.28% wt/wt | 1 |

| 2.56% wt/wt | 1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nunn, E.J.; Natrajan, L.S.; Quinn, M.K. Optimisation of an nIR-Emitting Benzoporphyrin Pressure-Sensitive Paint Formulation. Sensors 2025, 25, 4560. https://doi.org/10.3390/s25154560

Nunn EJ, Natrajan LS, Quinn MK. Optimisation of an nIR-Emitting Benzoporphyrin Pressure-Sensitive Paint Formulation. Sensors. 2025; 25(15):4560. https://doi.org/10.3390/s25154560

Chicago/Turabian StyleNunn, Elliott J., Louise S. Natrajan, and Mark K. Quinn. 2025. "Optimisation of an nIR-Emitting Benzoporphyrin Pressure-Sensitive Paint Formulation" Sensors 25, no. 15: 4560. https://doi.org/10.3390/s25154560

APA StyleNunn, E. J., Natrajan, L. S., & Quinn, M. K. (2025). Optimisation of an nIR-Emitting Benzoporphyrin Pressure-Sensitive Paint Formulation. Sensors, 25(15), 4560. https://doi.org/10.3390/s25154560