A Low-Cost Multi-Sensor Data Acquisition System for Fault Detection in Fused Deposition Modelling

Abstract

:1. Introduction

2. Related Work

2.1. Monitoring Models Used in AM Process

2.2. Low-Cost Data Acquisition Systems

- The authors proposed a low-cost multi-sensor data acquisition system for the 3D printer to detect various faults induced in the FDM 3D printed products during the printing process.

- In this work, the authors considered the different fault conditions for 3D printers during experimentation, such as disturbing bed leveling, changing nozzle temperature, changing belt tension, etc., and inducing severe defects in the finished product.

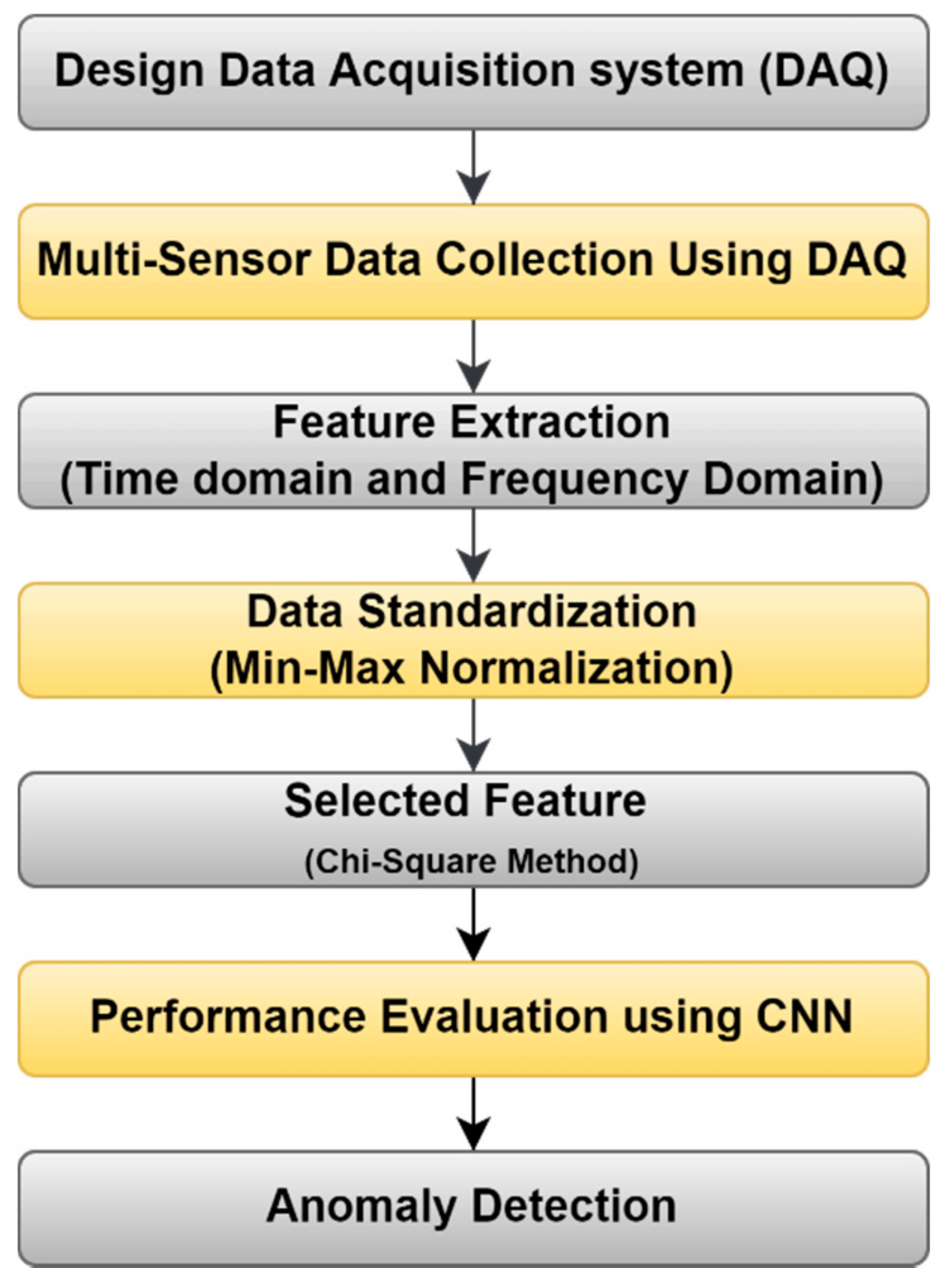

- The data acquired by the designed DAQ system refer to performing time and frequency domain analysis to extract various features from it and perform multiple fault diagnoses using the CNN model.

3. Methodology

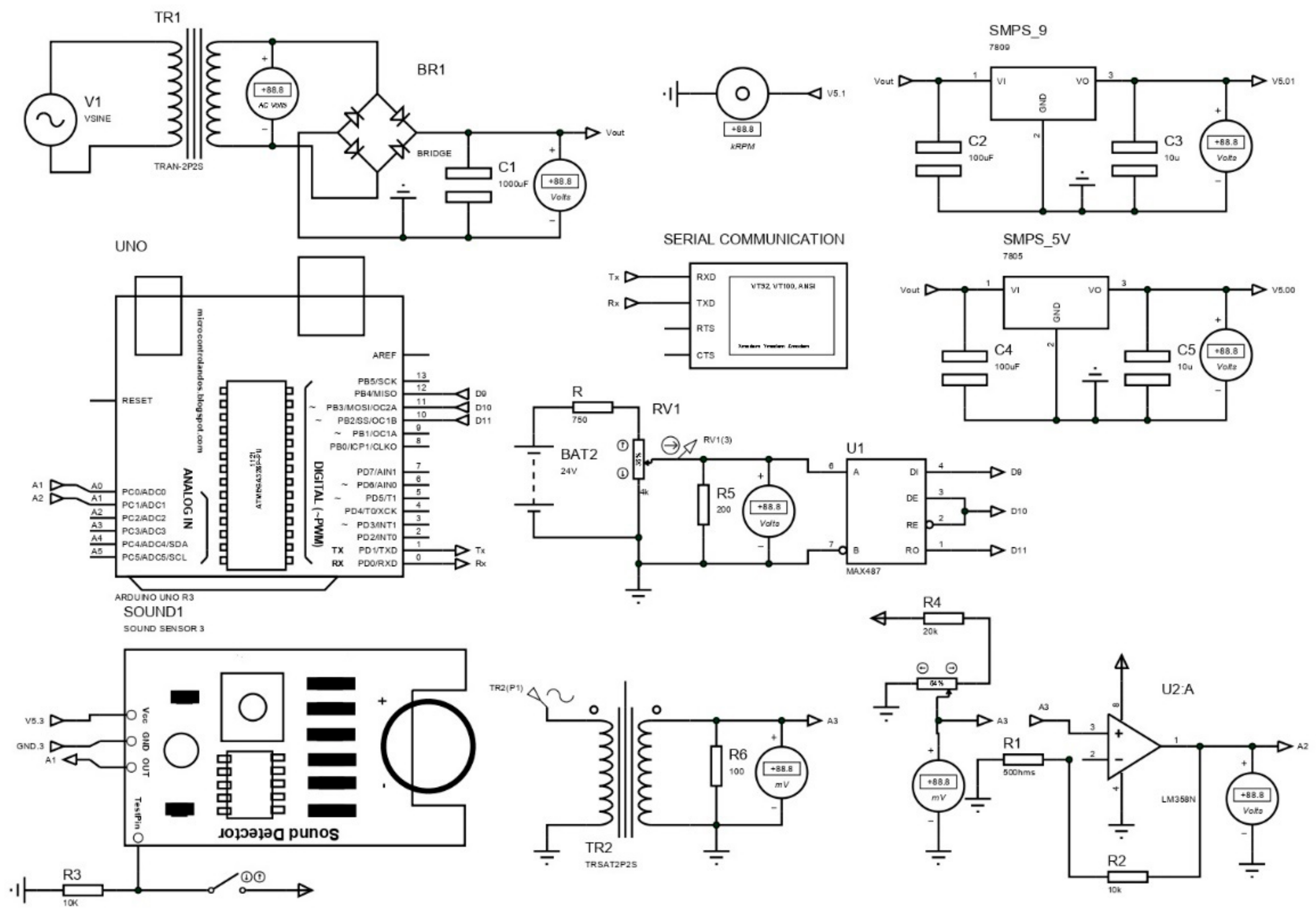

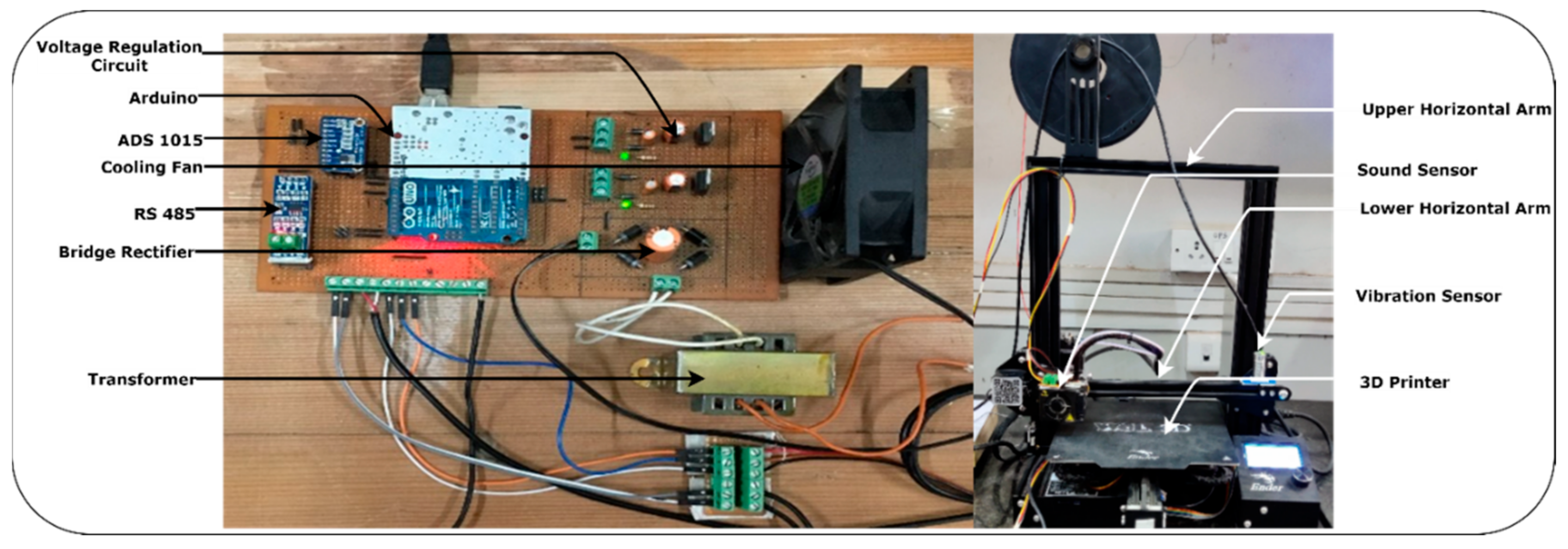

3.1. Data Acquisition and System Design

3.2. Location of Sensors

3.3. Experimental Conditions

| Normal and Induced Fault Condition | Description | FDM Product | Faults |

|---|---|---|---|

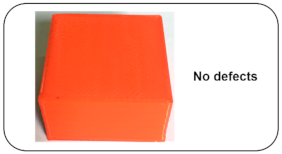

| Normal Condition | Bed and extrusion temperatures are kept at 50 °C and 200 °C throughout the printing process. The bed levelling is also uniform, using an adjustable screw connected to the levelling mechanism on which the 3D printer bed is mounted. The link connected to the horizontal beam and pully is tight enough to prevent the belt from slipping. |  | No fault |

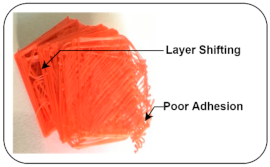

| Disturbed Bed Leveling (Level up) | Bed and extrusion temperatures are kept at 50 °C and 200 °C, respectively, throughout the printing process, and all links connected to horizontal columns are tight enough to prevent slippage. The bed leveling is disturbed using the adjustable screw that blocks the nozzle from the front side. |  |

|

| Disturbed Bed Leveling (Level down) | Bed and extrusion temperatures are kept at 50 °C and 200 °C, respectively, throughout the printing process, and all links connected to horizontal columns are tight enough to prevent slippage. The bed leveling is disturbed using the adjustable screw that keeps the distance between the nozzle and bed surface approximately 0.2 cm that prints the first few layers in the air. |  | |

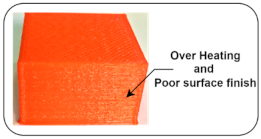

| Disturbed Extrusion Temperature: 260 °C | The bed level is uniform, and all links are tight enough to avoid slippage. The temperatures of the nozzle and bed are kept at 260 °C and 50 °C, respectively. Due to increasing nozzle temperature, the quality of the finished surface gets reduced. |  | |

| Disturbed Extrusion Temperature: 180 °C | The bed level is uniform, and all links are tight enough to avoid slippage. The nozzle and bed temperature are kept at 180 °C and 50 °C, respectively, due to decreasing nozzle temperature and causing weak layer deposition. This leads to cracking and edge warping defects in the final product. |  |

|

| Low Belt Tension | The bed and nozzle temperatures are kept at 50 °C and 200 °C, respectively, with uniform bed leveling. The link that connects the horizontal beams to the pully, which helps the stepper motor drive the nozzle assembly along a horizontal axis, becomes loosened. |  | |

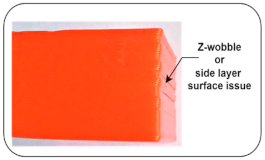

| High Belt Tension | The bed and nozzle temperature are kept at 50 °C and 200 °C, respectively, with uniform bed leveling. The link that connects horizontal beams to the pully, which helps the stepper motor drive the nozzle assembly along a horizontal axis, is tight enough. |  |

|

3.4. Data-Driven Model

4. Results and Discussion

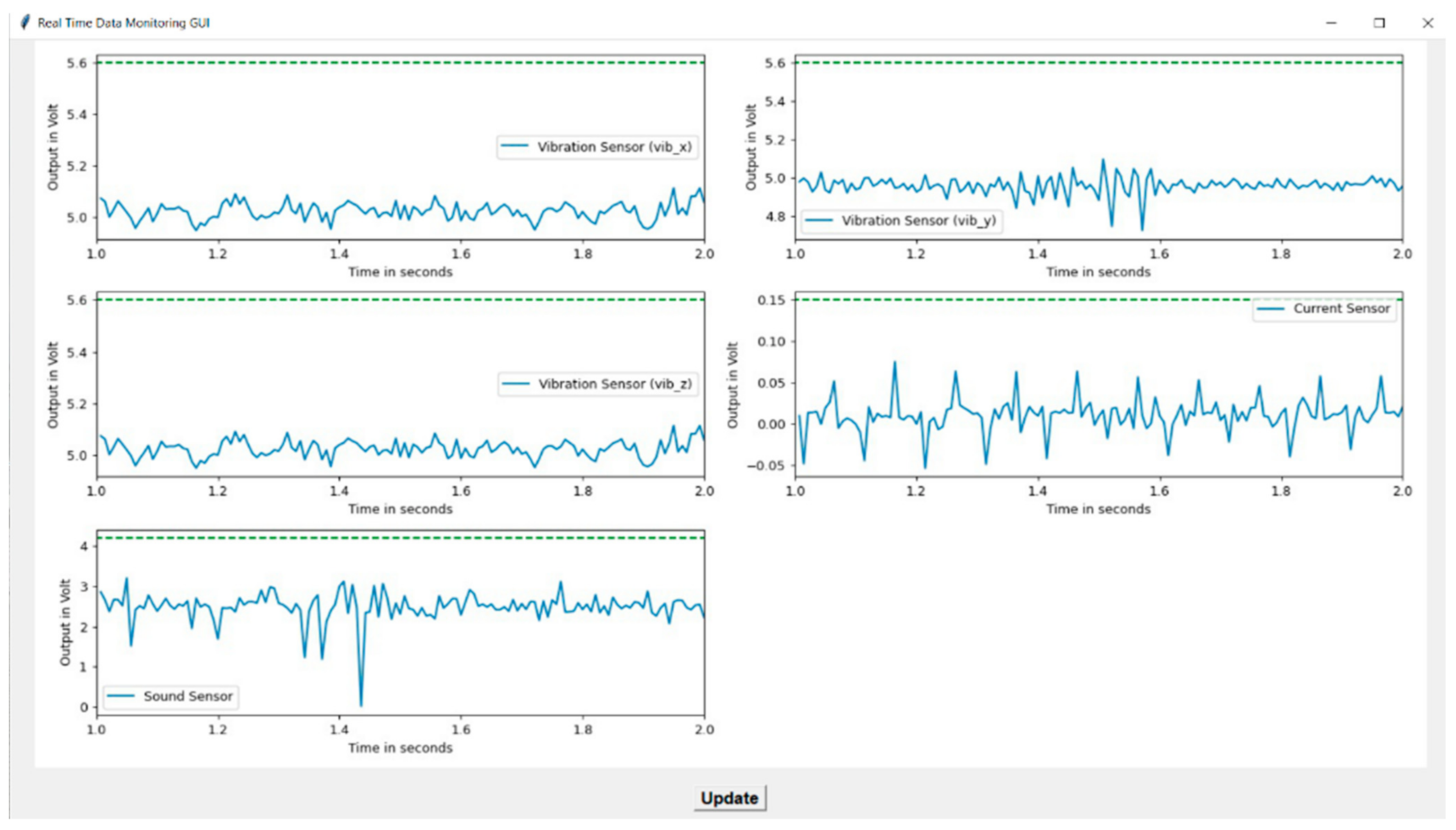

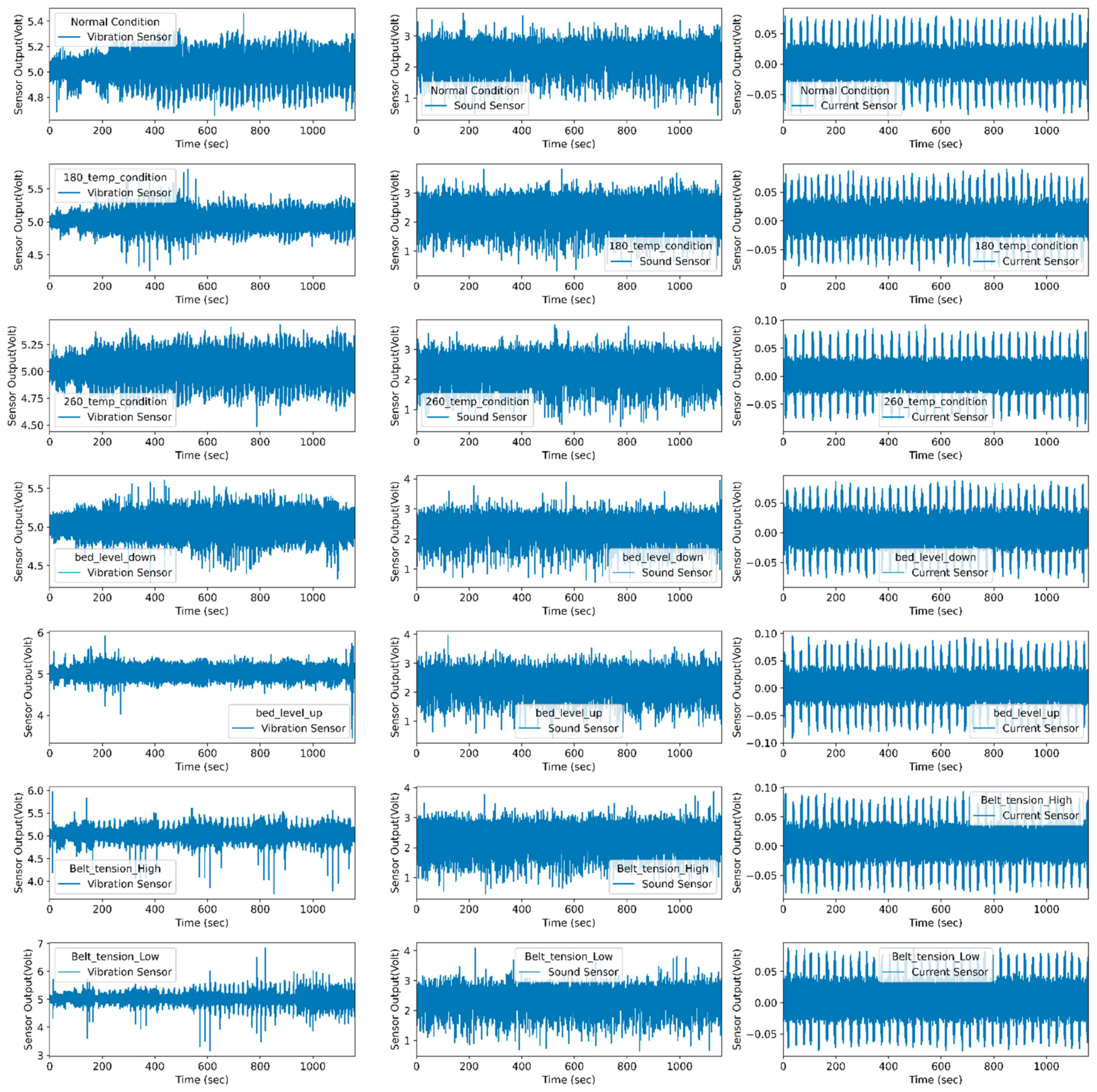

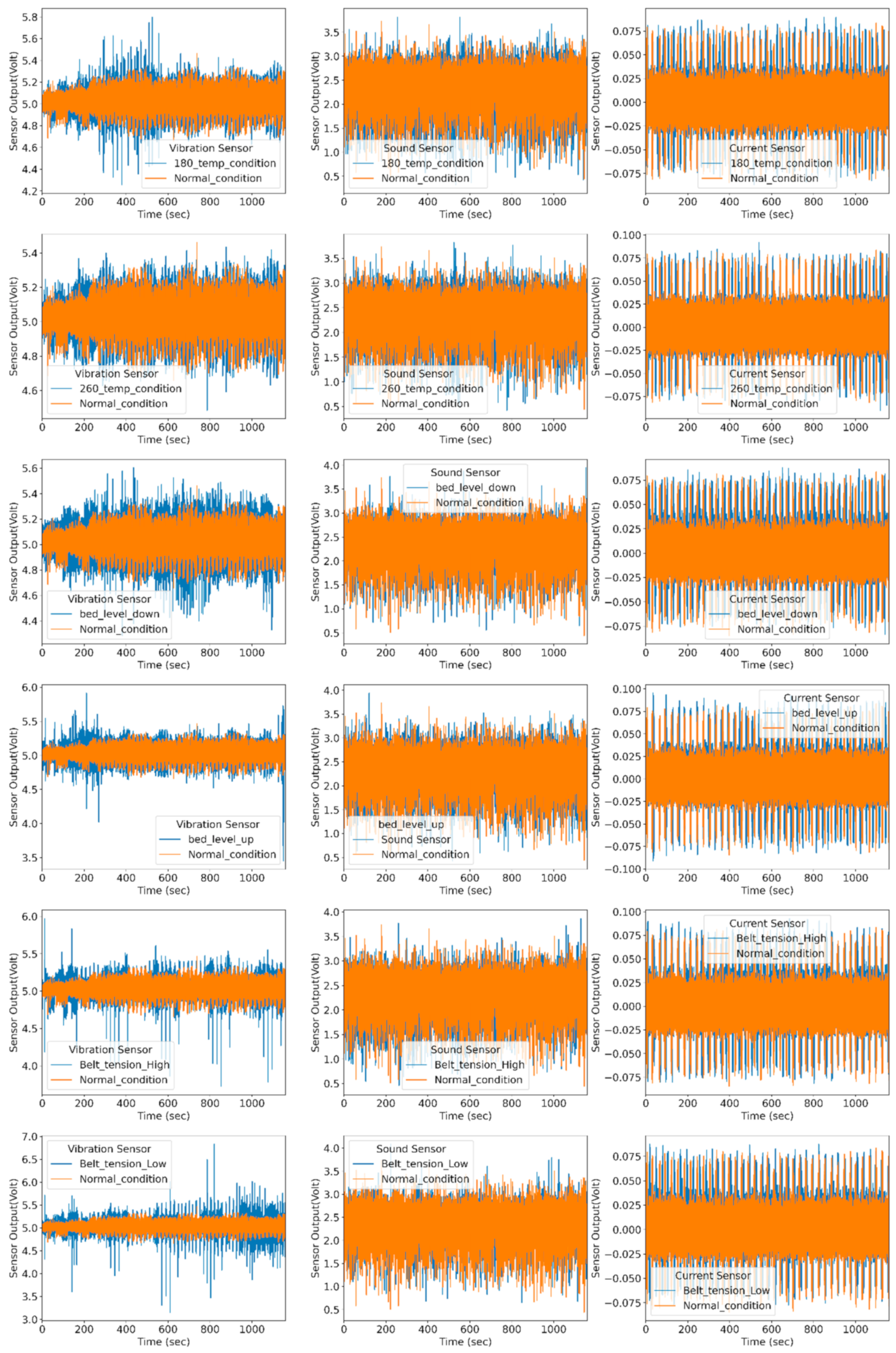

4.1. Multi-Sensor Data Analysis

4.2. Feature Extraction

4.3. Data Normalization/Standardization

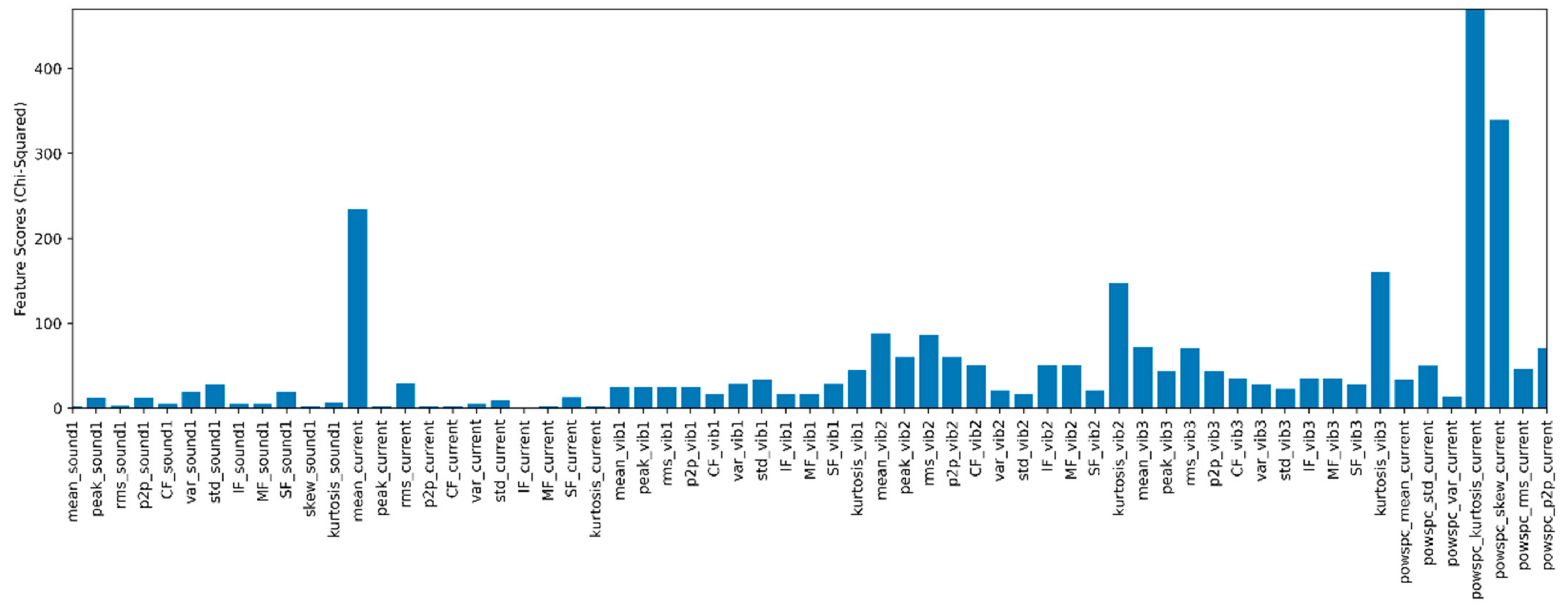

4.4. Feature Selection Using the Chi-Square Method

4.5. Model Performance Evaluation Using CNN

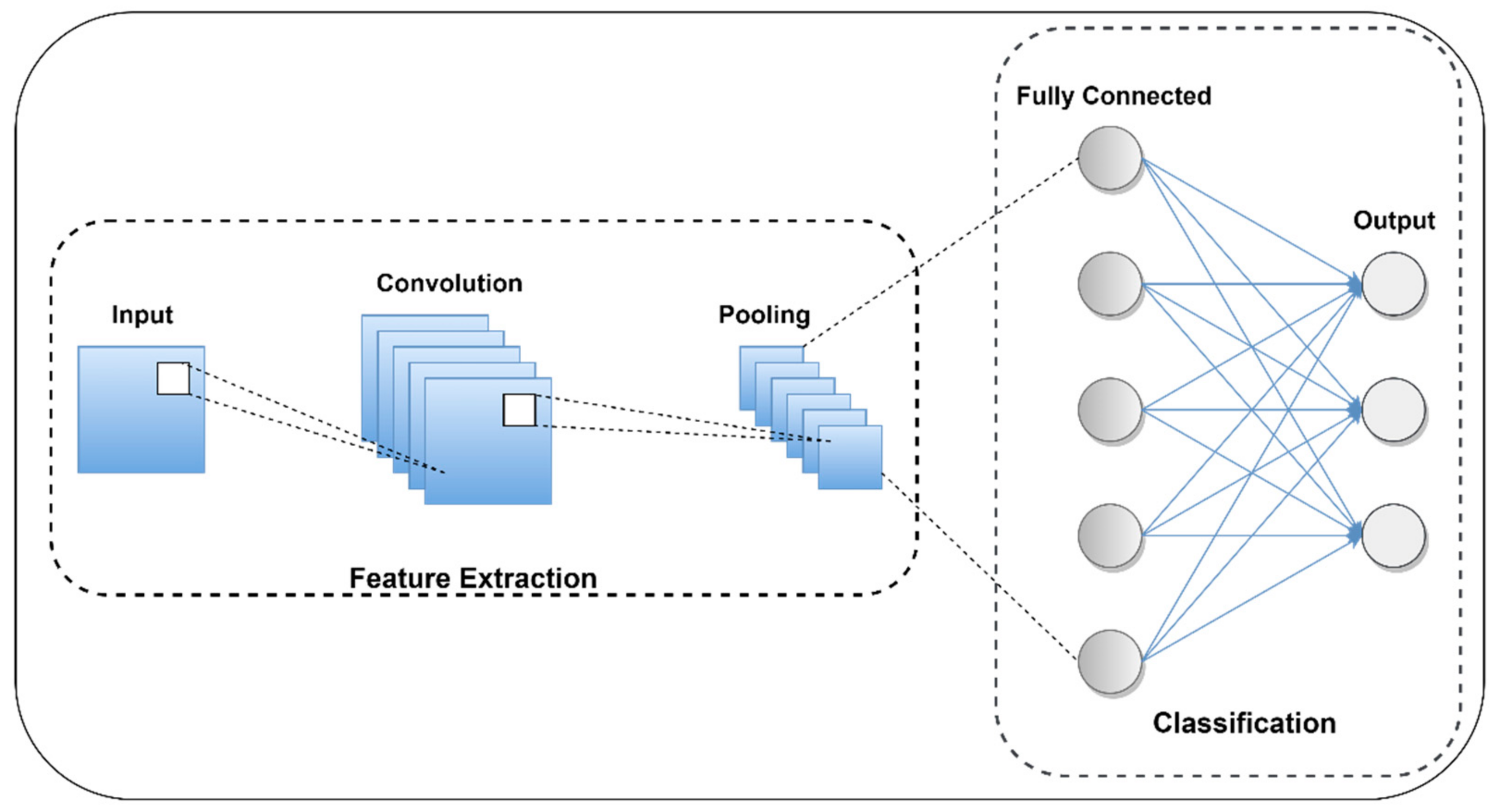

4.5.1. Working of CNN Model

Convolution Layer

Pooling Layer

Fully Connected Layer

4.5.2. Performance Evaluation Metrics

- tp is a true positive value, or actual and predicted value is true and positive.

- tn is a true negative value, or actual and predicted value is true and negative.

- fp is a false positive value, or the predicted output was a positive value, but the actual predicted output is negative.

- fn is a false-negative value, or the predicted output was a negative value, but the actual predicted output is positive.

4.5.3. Learning Curves for CNN

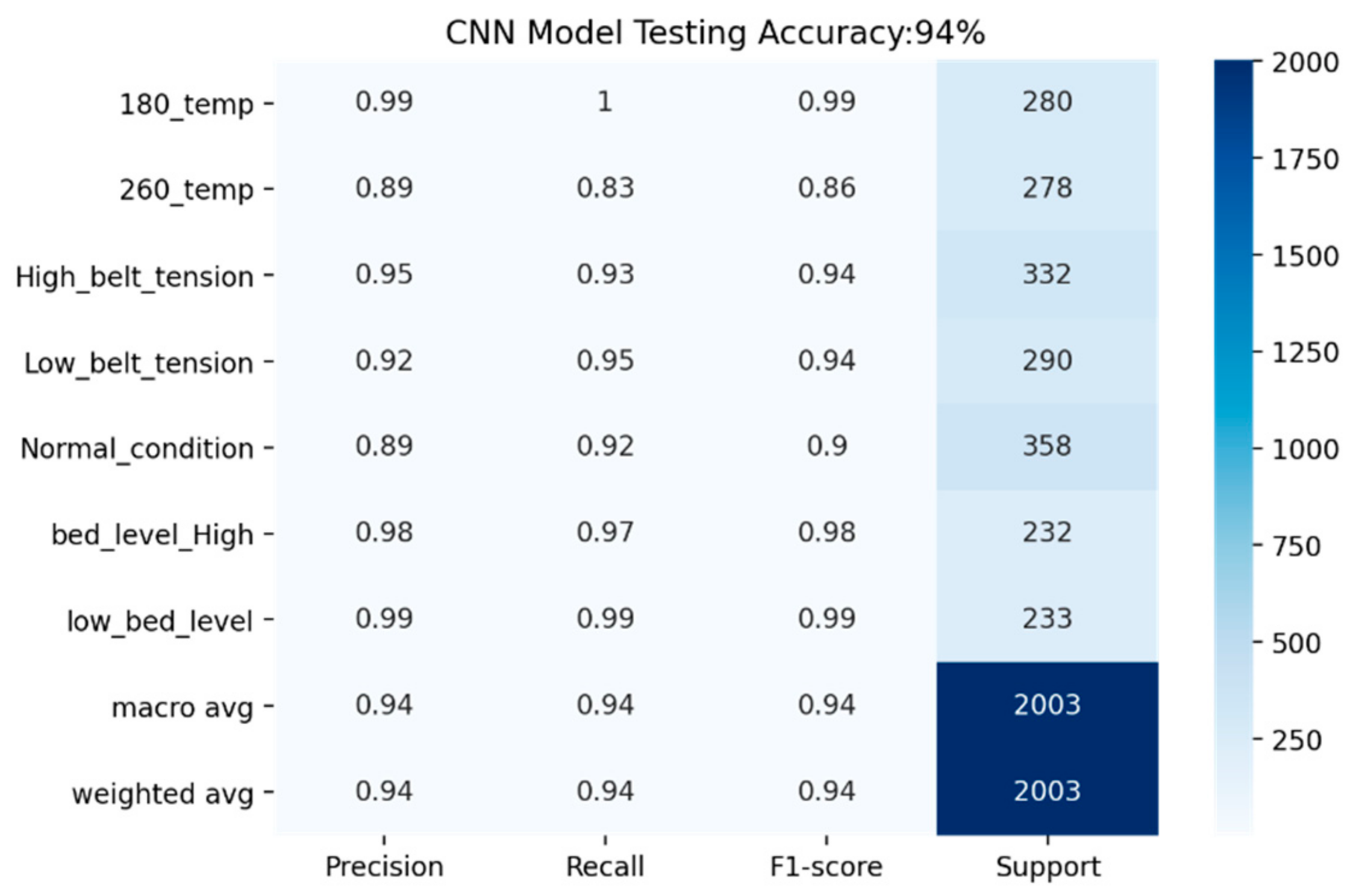

4.5.4. Multi-Fault Diagnosis Using CNN

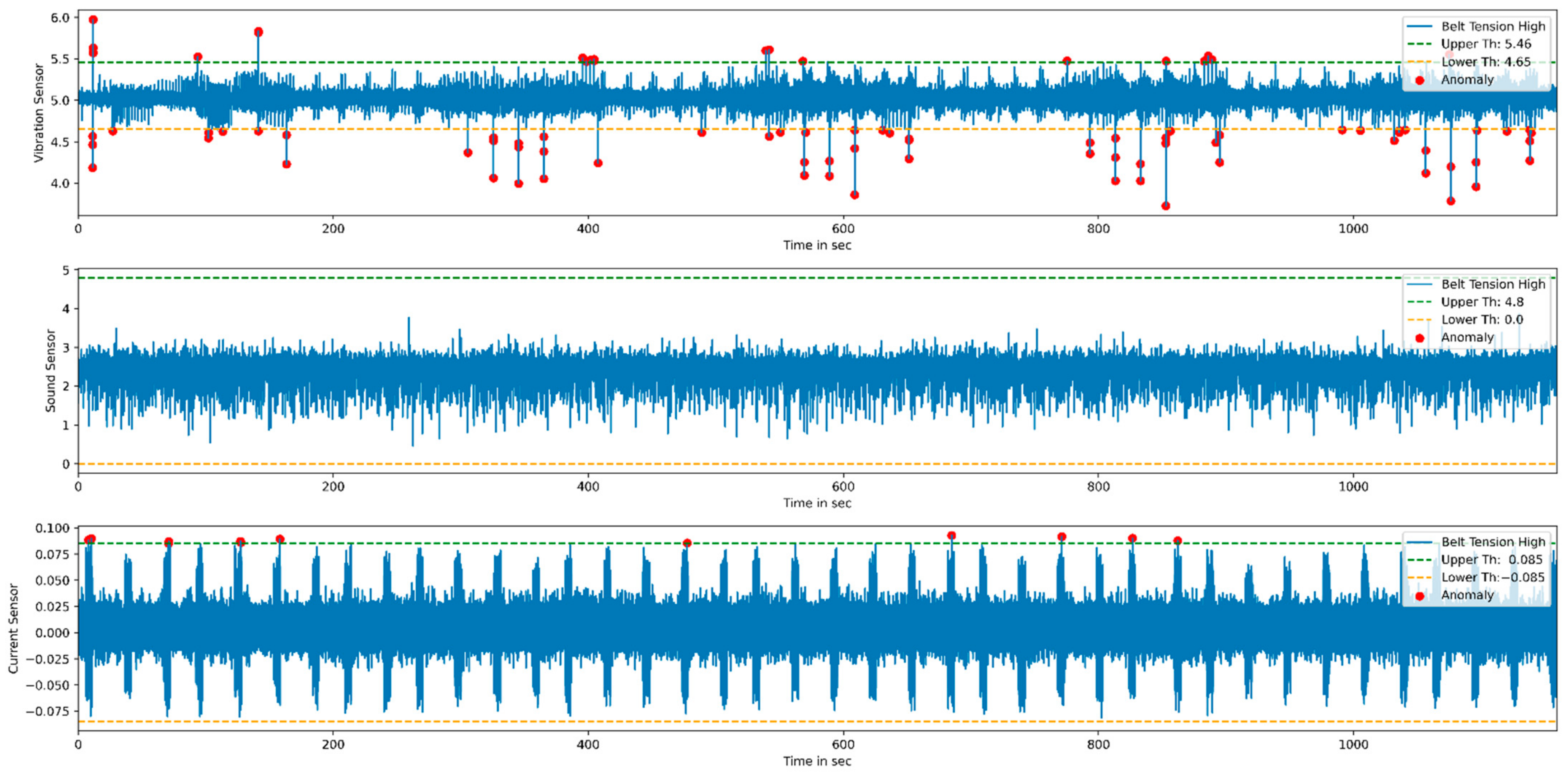

4.6. Anomaly Detection Using K-Means Clustering Algorithm

5. Conclusions

- The multiple sensor’s real-time data was captured through a developed low-cost DAQ system with a uniform sampling rate of 140 samples per second (Hz) using an Arduino microcontroller board.

- Multiple faults are induced in the 3D product, and the corresponding variations in the multiple sensor signals are recorded.

- Time and frequency domain analysis is performed, and features are selected using the chi-square method.

- The k-means cluster algorithm is used for data clustering purposes, and a bell curve or normal distribution curve is used for defining the individual sensor threshold values under normal conditions.

- The CNN model is used to classify the normal and faulty data to evaluate the model’s performance based on recall, precision, and F1 score. Around 94% classification accuracy is obtained by using the CNN model, and corresponding anomalies from individual sensors are also determined.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| ABS | Acrylonitrile Butadiene Styrene |

| AM | Additive Manufacturing |

| ADC | Analog to digital converter |

| CSV | Comma-Separated Values |

| CNN | Convolutional Neural Network |

| CFM | Cubic Feet per Minute |

| CT | Current transformer |

| DAQ | Data Acquisition System |

| DLP | Digital Light Processing |

| DC | Direct Current |

| FFT | Fast Fourier Transform |

| FBG | Fiber Bragg Grating |

| FOS | Factor of Safety |

| FDM | Fused Deposition Modelling |

| GUI | Graphical User Interface |

| IC | Integrated Circuit |

| I2C | Inter-Integrated Circuit, eye-squared-Communication |

| MEMS | Micro-Electro-Mechanical System |

| PLA | Polylactic Acid |

| PSD | Power Spectrum Density |

| PCB | Printed Circuit Board |

| SLS | Selective Laser Sintering |

| SPI | Serial Peripheral Interface |

| SRAM | Static random-access memory |

| SLA | Stereolithography |

| SCADA | Supervisory Control and Data Acquisition |

| SMPS | Switch Mode Power Supply |

| USB | Universal Serial Bus |

Appendix A

Appendix A.1. Arduino Uno Specification

| Parameter | Specification |

|---|---|

| Clock speed | 16 MHz |

| Operating voltage | 5 V |

| Analog Pins | 6 |

| Digital Pins | 14 |

| SRAM | 2 kb |

| Flash Memory | 32 kb |

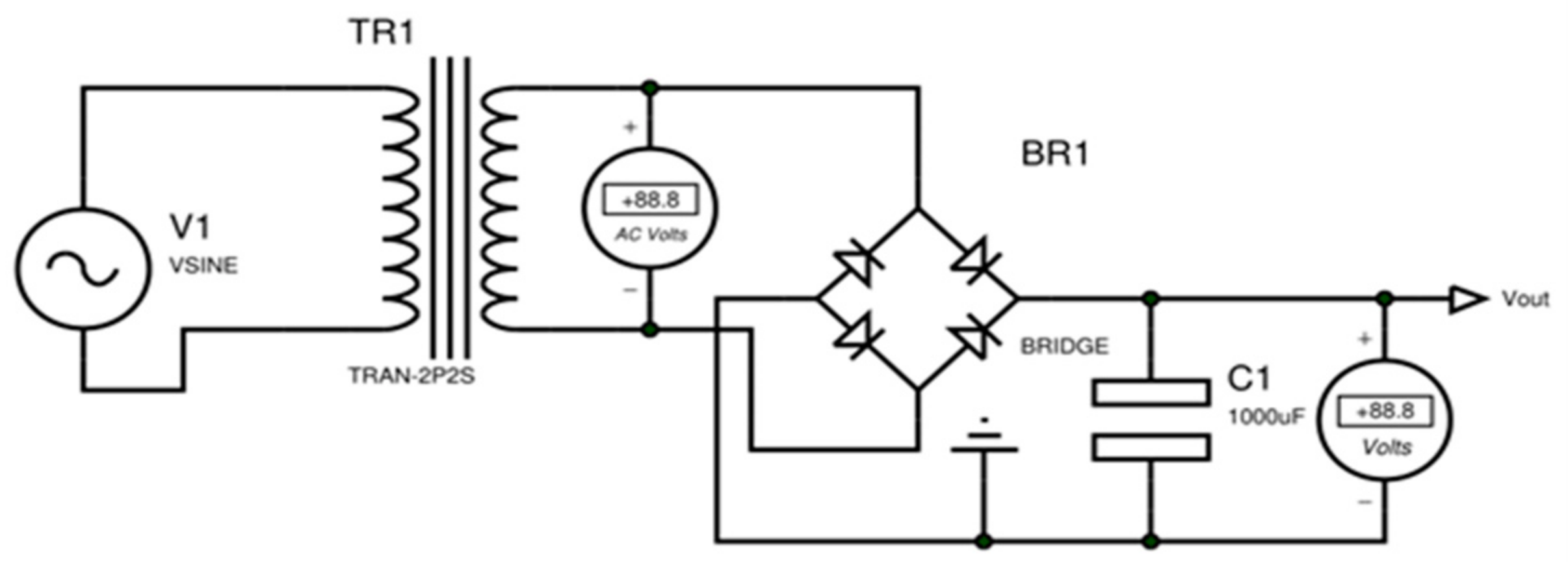

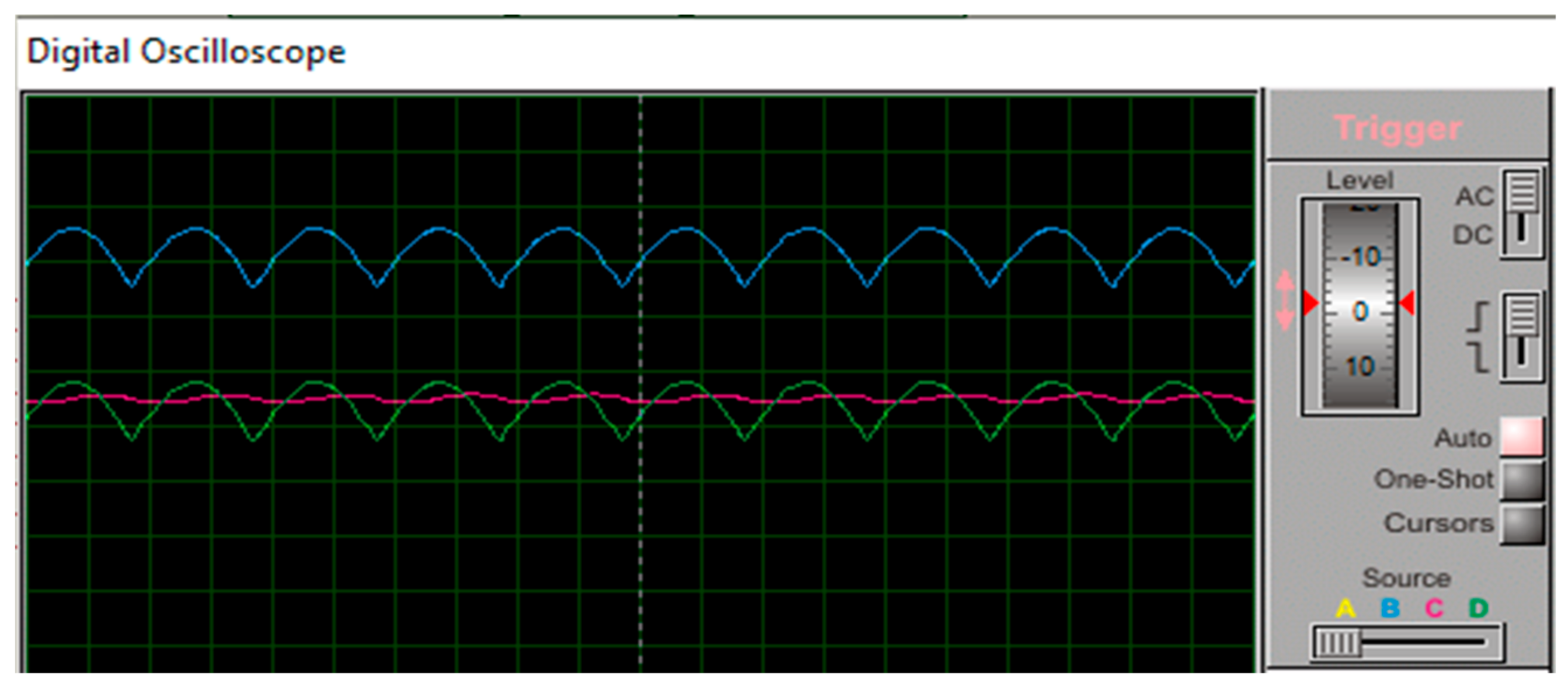

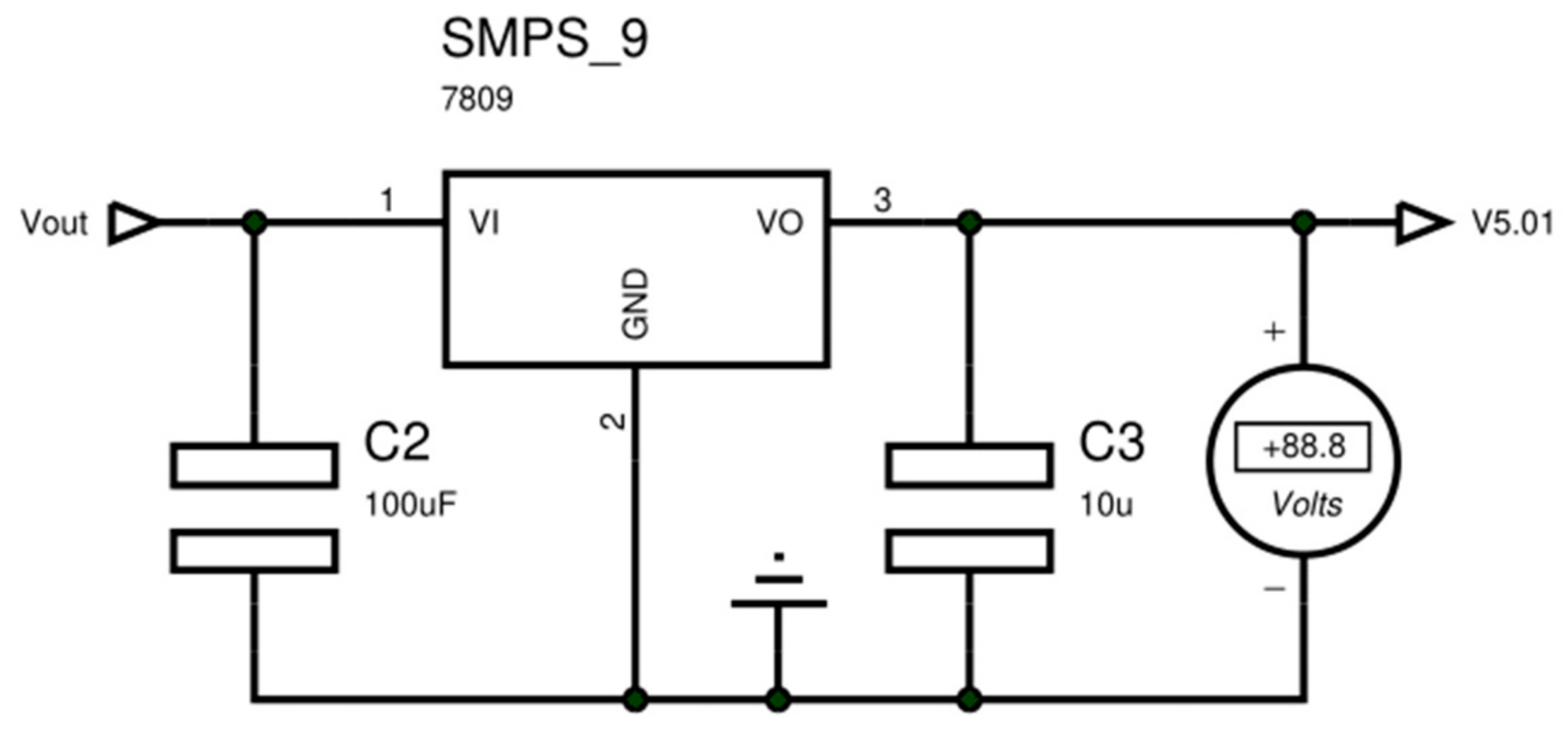

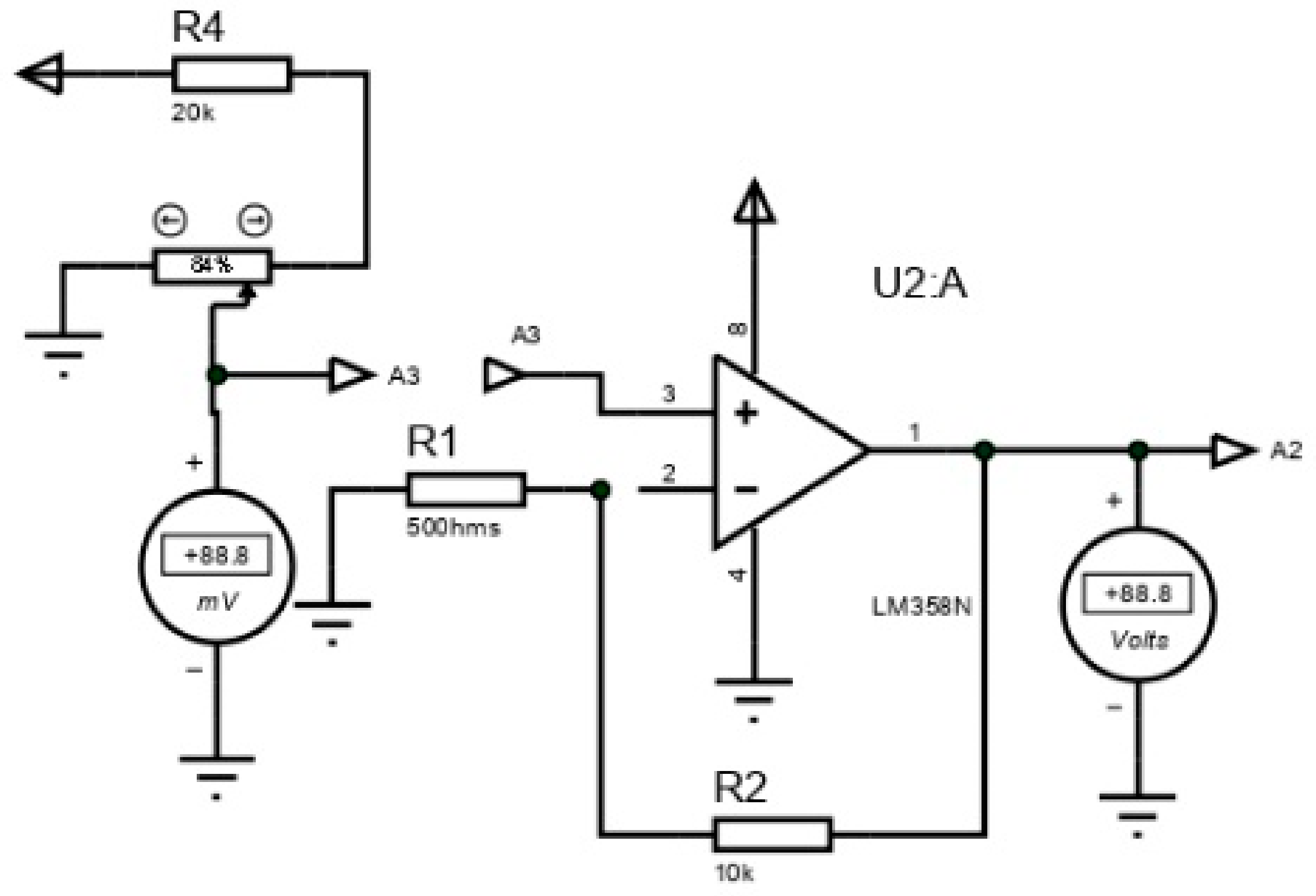

Appendix A.2. Power Supply

Appendix A.3. Sound Sensor

| Parameter | Specification |

|---|---|

| Model | MAX4466 Electret Microphone Amplifier |

| Supply Voltage | 2.41 to 5.5 V |

| Power-Supply Rejection Ratio | 112 dB |

| Common-Mode Rejection Ratio | 126 dB |

| Gain Bandwidth Product (kHz) | 600 |

Appendix A.4. Current Sensor

| Parameters | Specification |

|---|---|

| Model | SCT-013-030 |

| Input Current | 0 to 30 A |

| Output | 0 to 1 V |

| Frequency range | 50 Hz to 1 kHz |

| Temperature range | −25 °C to 70 °C |

Appendix A.5. Vibration Sensor

| Parameters | Specification |

|---|---|

| Model | VBR1/D0-3 |

| Supply Voltage | 24 V |

| Number of Axis | 3 |

| Frequency Range | 400 Hz |

| Weight | 100 g |

| Operating Range | 16 g |

Appendix A.6. ADS1015

Appendix A.7. RS485 Module

Appendix B

Appendix B.1. Power Supply Unit

The Full-Wave Bridge Rectifier Circuit

- Selecting the appropriate size of the heatsink,

- Keeping the low voltage difference across IC,

- Using multiples voltage regulating IC that can convert high voltage supply into a lower supply voltage due to performing step by step reduction and cause a minimum voltage to drop across IC,

- Selecting the appropriate cooling fan size, etc.

- = amount of heat generated by 7805 IC

- = amount of heat generated by 7809 IC

- QT = Total amount of heat generated

- = Input voltage given to voltage regulating IC

- = output current given by output terminal of IC

- FOS = factor of safety.

- = Amount of Heat Generated by Fan

- M = Mass flow rate in Kg/s

- = Specific Heat of air

- = Change in temperature.

| Part Name | Rated Voltage | Input Power | Rated Current | Rated Speed | Airflow (CFM) | Noise Level (dB) | Static Pressure |

|---|---|---|---|---|---|---|---|

| OD9225-12HHBIP68 | 12 VDC | 3.0 W | 0.29 A | 3300 RPM | 60 | 38 | 0.25″ H2O |

Appendix B.2. Sensor Configuration with DAQ System

Appendix B.2.1. Current Transformer (CT)

Appendix B.2.2. Sound Sensor

- = Measured Intensity of sound in dB

- = The analog value generated by applying a differential voltage to the sound sensor as output

- = The analog value generated by applying reference voltage (VCC/2).

Appendix B.2.3. Vibration Sensor

| Full Scale in g | Correction Factor |

|---|---|

| 2 | 6.1037 × 10−5 |

| 4 | 1.2207 × 10−4 |

| 8 | 2.4415 × 10−4 |

| 16 | 4.88305 × 10−4 |

References

- Abdulhameed, O.; Al-Ahmari, A.; Ameen, W.; Mian, S.H. Additive manufacturing: Challenges, trends, and applications. Adv. Mech. Eng. 2019, 11, 1687814018822880. [Google Scholar] [CrossRef] [Green Version]

- Haidiezul, A.; Aiman, A.; Bakar, B. Surface Finish Effects Using Coating Method on 3D Printing (FDM) Parts. IOP Conf. Ser. Mater. Sci. Eng. 2018, 318, 012065. [Google Scholar] [CrossRef]

- Tang, Q.; Yin, S.; Zhang, Y.; Wu, J. A tool vector control for laser additive manufacturing in five-axis configuration. Int. J. Adv. Manuf. Technol. 2018, 98, 1671–1684. [Google Scholar] [CrossRef]

- Kousiatza, C.; Karalekas, D. In-situ monitoring of strain and temperature distributions during fused deposition modeling process. Mater. Des. 2016, 97, 400–406. [Google Scholar] [CrossRef]

- Syrlybayev, D.; Zharylkassyn, B.; Seisekulova, A.; Akhmetov, M.; Perveen, A.; Talamona, D. Optimisation of Strength Properties of FDM Printed Parts—A Critical Review. Polymers 2021, 13, 1587. [Google Scholar] [CrossRef] [PubMed]

- Wong, K.V.; Hernandez, A. A Review of Additive Manufacturing. ISRN Mech. Eng. 2012, 2012, 208760. [Google Scholar] [CrossRef] [Green Version]

- Agron, D.J.S.; Nwakanma, C.I.; Lee, J.-M.; Kim, D.-S. Smart Monitoring for SLA-type 3D Printer using Artificial Neural Network. KICS 2020, 72, 1203–1204. [Google Scholar]

- Kadam, V.; Kumar, S.; Bongale, A.; Wazarkar, S.; Kamat, P.; Patil, S. Enhancing Surface Fault Detection Using Machine Learning for 3D Printed Products. Appl. Syst. Innov. 2021, 4, 34. [Google Scholar] [CrossRef]

- Gunaydin, K.; Türkmen, H. Common FDM 3D Printing Defects. In Proceedings of the International Congress on 3D Printing (Additive Manufacturing) Technologies and Digital Industry, Antalya, Turkey, 19–21 April 2018. [Google Scholar]

- Saâdaoui, M.; Khaldoun, F.; Adrien, J.; Reveron, H.; Chevalier, J. X-ray tomography of additive-manufactured zirconia: Processing defects–Strength relations. J. Eur. Ceram. Soc. 2019, 40, 3200–3207. [Google Scholar] [CrossRef]

- Szymanik, B.; Psuj, G.; Hashemi, M.; Lopato, P. Detection and Identification of Defects in 3D-Printed Dielectric Structures via Thermographic Inspection and Deep Neural Networks. Materials 2021, 14, 4168. [Google Scholar] [CrossRef]

- Yuan, L. Solidification Defects in Additive Manufactured Materials. JOM 2019, 71, 3221–3222. [Google Scholar] [CrossRef] [Green Version]

- Sayyad, S.; Kumar, S.; Bongale, A.; Kamat, P.; Patil, S.; Kotecha, K. Data-Driven Remaining Useful Life Estimation for Milling Process: Sensors, Algorithms, Datasets, and Future Directions. IEEE Access 2021, 9, 110255–110286. [Google Scholar] [CrossRef]

- Lee, J.; Bagheri, B.; Kao, H.-A. A Cyber-Physical Systems architecture for Industry 4.0-based manufacturing systems. Manuf. Lett. 2015, 3, 18–23. [Google Scholar] [CrossRef]

- Wan, J.; Canedo, A.; Al Faruque, M.A. Cyber–Physical Codesign at the Functional Level for Multidomain Automotive Systems. IEEE Syst. J. 2015, 11, 1–11. [Google Scholar] [CrossRef]

- Lee, J.; Bagheri, B.; Jin, C. Introduction to cyber manufacturing. Manuf. Lett. 2016, 8, 11–15. [Google Scholar] [CrossRef] [Green Version]

- Glaessgen, E.; Stargel, D. The digital twin paradigm for future NASA and U.S. Air Force Vehicles. In Proceedings of the 53rd AIAA/ASME/ASCE/AHS/ASC Structures, Structural Dynamics and Materials Conference 20th AIAA/ASME/AHS Adaptive Structures Conference 14th AIAA, Honolulu, HI, USA, 23–26 April 2012. [Google Scholar] [CrossRef] [Green Version]

- Sayyad, S.; Kumar, S.; Bongale, A.; Bongale, A.M.; Patil, S. Estimating Remaining Useful Life in Machines Using Artificial Intelligence: A Scoping Review. Libr. Philos. Pract. 2021, 2021, 1–26. [Google Scholar]

- Li, Z.; Zhang, Z.; Shi, J.; Wu, D. Prediction of surface roughness in extrusion-based additive manufacturing with machine learning. Robot. Comput. Manuf. 2019, 57, 488–495. [Google Scholar] [CrossRef]

- Zhao, R.; Yan, R.; Chen, Z.; Mao, K.; Wang, P.; Gao, R.X. Deep learning and its applications to machine health monitoring. Mech. Syst. Signal Process. 2019, 115, 213–237. [Google Scholar] [CrossRef]

- Banadaki, Y.; Razaviarab, N.; Fekrmandi, H.; Sharifi, S. Toward Enabling a Reliable Quality Monitoring System for Additive Manufacturing Process using Deep Convolutional Neural Networks. arXiv 2020, arXiv:2003.08749. [Google Scholar]

- Langeland, S.A. Automatic Error Detection in 3D Pritning Using Computer Vision. Master’s Thesis, The University of Bergen, Bergen, Norway, 2020. [Google Scholar]

- Delli, U.; Chang, S. Automated Process Monitoring in 3D Printing Using Supervised Machine Learning. Procedia Manuf. 2018, 26, 865–870. [Google Scholar] [CrossRef]

- Stoyanov, S.; Bailey, C. Machine learning for additive manufacturing of electronics. In Proceedings of the 2017 40th International Spring Seminar on Electronics Technology (ISSE), Sofia, Bulgaria, 10–14 May 2017. [Google Scholar] [CrossRef]

- González, A.; Olazagoitia, J.L.; Vinolas, J. A Low-Cost Data Acquisition System for Automobile Dynamics Applications. Sensors 2018, 18, 366. [Google Scholar] [CrossRef] [Green Version]

- Gopalakrishna, G.K.; Padubidre, S.P. Development of low cost system for condition monitoring of rolling element bearing using MEMS based accelerometer. AIP Conf. Proc. 2019, 2080, 50003. [Google Scholar] [CrossRef]

- Shen, H.; Nugegoda, D. Real-time automated behavioural monitoring of mussels during contaminant exposures using an improved microcontroller-based device. Sci. Total Environ. 2022, 806, 150567. [Google Scholar] [CrossRef]

- Barile, G.; Leoni, A.; Pantoli, L.; Stornelli, V. Real-Time Autonomous System for Structural and Environmental Monitoring of Dynamic Events. Electronics 2018, 7, 420. [Google Scholar] [CrossRef] [Green Version]

- Titov, A.; Ceccarelli, M. Prototype and Testing of L-CaPaMan. In Advances in Mechanism Design III, Mechanisms and Machine Science; Springer: Cham, Switzerland, 2020; pp. 249–258. [Google Scholar]

- Damcı, E.; Sekerci, Ç. Development of a Low-Cost Single-Axis Shake Table Based on Arduino. Exp. Tech. 2018, 43, 179–198. [Google Scholar] [CrossRef]

- Paladino, O.; Fissore, F.; Neviani, M. A Low-Cost Monitoring System and Operating Database for Quality Control in Small Food Processing Industry. J. Sens. Actuator Netw. 2019, 8, 52. [Google Scholar] [CrossRef] [Green Version]

- Soto-Ocampo, C.R.; Mera, J.M.; Cano-Moreno, J.D.; Garcia-Bernardo, J.L. Low-Cost, High-Frequency, Data Acquisition System for Condition Monitoring of Rotating Machinery through Vibration Analysis-Case Study. Sensors 2020, 20, 3493. [Google Scholar] [CrossRef]

- Vidal-Pardo, A.; Pindado, S. Design and Development of a 5-Channel Arduino-Based Data Acquisition System (ABDAS) for Experimental Aerodynamics Research. Sensors 2018, 18, 2382. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- D’Ausilio, A. Arduino: A low-cost multipurpose lab equipment. Behav. Res. Methods 2011, 44, 305–313. [Google Scholar] [CrossRef]

- Ferencz, K.; Domokos, J. IoT Sensor Data Acquisition and Storage System Using Raspberry Pi and Apache Cassandra. In Proceedings of the 2018 International IEEE Conference and Workshop in Óbuda on Electrical and Power Engineering (CANDO-EPE), Budapest, Hungary, 20–21 November 2018; pp. 000143–000146. [Google Scholar] [CrossRef]

- Moreno, C.; González, A.; Olazagoitia, J.L.; Vinolas, J. The Acquisition Rate and Soundness of a Low-Cost Data Acquisition System (LC-DAQ) for High Frequency Applications. Sensors 2020, 20, 524. [Google Scholar] [CrossRef] [Green Version]

- Chand, T.; Sharma, B. HRCCTP: A hybrid reliable and congestion control transport protocol for wireless sensor networks. In Proceedings of the 2015 IEEE Sensors, Busan, Korea, 1–4 November 2015; pp. 1–4. [Google Scholar] [CrossRef]

- Trapero, D. FDM 3D Printing: Common Problems and How to Solve Them. BitFab. 2020. Available online: https://wikifactory.com/+bitfab/stories/fdm-3d-printing-common-problems-and-how-to-solve-them (accessed on 8 October 2021).

- Carolo, L. Gaps in 3D Prints: How to Fix & Avoid Them. All3DP, 7 February 2021. [Google Scholar]

- Galati, M.; Minetola, P. On the measure of the aesthetic quality of 3D printed plastic parts. Int. J. Interact. Des. Manuf. 2019, 14, 381–392. [Google Scholar] [CrossRef]

- Manufactur3D. Common Problems in 3D Printing & How to Resolve Them–Part I. Manufactur3D, 4 December 2018. [Google Scholar]

- Marani, M.; Zeinali, M.; Songmene, V.; Mechefske, C.K. Tool wear prediction in high-speed turning of a steel alloy using long short-term memory modelling. Meas. J. Int. Meas. Confed. 2021, 177, 109329. [Google Scholar] [CrossRef]

- Singhal, R.; Rana, R. Chi-square test and its application in hypothesis testing. J. Pract. Cardiovasc. Sci. 2015, 1, 69–71. [Google Scholar] [CrossRef]

- Huang, Z.; Zhu, J.; Lei, J.; Li, X.; Tian, F. Tool wear predicting based on multi-domain feature fusion by deep convolutional neural network in milling operations. J. Intell. Manuf. 2020, 31, 953–966. [Google Scholar] [CrossRef]

- Phung, V.H.; Rhee, E.J. A High-Accuracy Model Average Ensemble of Convolutional Neural Networks for Classification of Cloud Image Patches on Small Datasets. Appl. Sci. 2019, 9, 4500. [Google Scholar] [CrossRef] [Green Version]

- Maeda-Gutiérrez, V.; Galván-Tejada, C.E.; Zanella-Calzada, L.A.; Celaya-Padilla, J.M.; Galván-Tejada, J.I.; Gamboa-Rosales, H.; Luna-García, H.; Magallanes-Quintanar, R.; Guerrero Méndez, C.A.; Olvera-Olvera, C.A. Comparison of Convolutional Neural Network Architectures for Classification of Tomato Plant Diseases. Appl. Sci. 2020, 10, 1245. [Google Scholar] [CrossRef] [Green Version]

- Lecun, Y.; Bottou, L.; Bengio, Y.; Haffner, P. Gradient-based learning applied to document recognition. Proc. IEEE 1998, 86, 2278–2324. [Google Scholar] [CrossRef] [Green Version]

- Guzmán-Fernández, M.; de la Torre, M.Z.; Ortega-Sigala, J.; Guzmán-Valdivia, C.; Galvan-Tejeda, J.I.; Crúz-Domínguez, O.; Ortiz-Hernández, A.; Fraire-Hernández, M.; Sifuentes-Gallardo, C.; Durán-Muñoz, H. Arduino: A Novel Solution to the Problem of High-Cost Experimental Equipment in Higher Education. Exp. Tech. 2021, 45, 613–625. [Google Scholar] [CrossRef]

- Kharb, K.; Sharma, B.; Aseri, T.C. Reliable and congestion control protocols for wireless sensor networks. Int. J. Eng. Technol. Innov. 2016, 6, 68–78. [Google Scholar]

- Bajaj, K.; Sharma, B.; Singh, R. Integration of WSN with IoT Applications: A Vision, Architecture, and Future Challenges; Springer: Cham, Switzerland, 2020; pp. 79–102. [Google Scholar] [CrossRef]

- Sharma, B.; Aseri, T.C. A hybrid and dynamic reliable transport protocol for wireless sensor networks. Comput. Electr. Eng. 2015, 48, 298–311. [Google Scholar] [CrossRef]

| Sensors | Sampling Frequency (Hz) |

|---|---|

| Sound | 1537–1540 |

| Current | 365–370 |

| Vibration (along X, Y, Z direction) | 206–210 |

| Sound + Current | 328–300 |

| Current + Vibration | 150–155 |

| Sound + Vibration | 195–200 |

| Current + Vibration + Sound | 140 |

| Feature | Feature Name | Formula |

|---|---|---|

| Time domain | Root Mean Square | |

| Mean | ||

| Variance | ||

| Skewness | ||

| Kurtosis | ||

| Standard Deviation | ||

| Shape Factor | ||

| Clearance Factor | ||

| Peak to Peak | ||

| Crest Factor | ||

| Impulse factor | ||

| Frequency domain | Spectral Mean | |

| Spectral Variance | ||

| Spectral Standard Deviation | ||

| Spectral Skewness | ||

| Spectrum Kurtosis |

| Sr. No | Feature | Chi-Square Score | Sr. No | Feature | Chi-Square Score |

|---|---|---|---|---|---|

| 1 | powspc_kurtosis_current | 749.0191 | 21 | IF_vib3 | 54.45829 |

| 2 | powspc_skew_current | 541.3756 | 22 | MF_vib3 | 54.41491 |

| 3 | mean_current | 376.5628 | 23 | CF_vib3 | 54.41491 |

| 4 | kurtosis_vib3 | 255.8377 | 24 | powspc_mean_current | 54.4077 |

| 5 | kurtosis_vib2 | 230.5496 | 25 | std_vib1 | 53.96427 |

| 6 | mean_vib2 | 139.974 | 26 | rms_current | 46.5927 |

| 7 | rms_vib2 | 136.3834 | 27 | var_vib1 | 44.64349 |

| 8 | mean_vib3 | 114.8013 | 28 | SF_vib1 | 44.49147 |

| 9 | powspc_p2p_current | 114.0053 | 29 | std_sound1 | 43.93499 |

| 10 | rms_vib3 | 113.5372 | 30 | mean_vib1 | 43.30074 |

| 11 | p2p_vib2 | 92.40597 | 31 | rms_vib1 | 42.90891 |

| 12 | peak_vib2 | 92.40597 | 32 | var_vib3 | 41.39019 |

| 13 | powspc_std_current | 81.00898 | 33 | SF_vib3 | 41.35895 |

| 14 | IF_vib2 | 77.83489 | 34 | p2p_vib1 | 38.15497 |

| 15 | CF_vib2 | 77.71817 | 35 | peak_vib1 | 38.15497 |

| 16 | MF_vib2 | 77.71817 | 36 | std_vib3 | 34.05571 |

| 17 | powspc_rms_current | 75.84044 | 37 | SF_vib2 | 31.32263 |

| 18 | kurtosis_vib1 | 69.38061 | 38 | var_vib2 | 31.23275 |

| 19 | p2p_vib3 | 65.75025 | 39 | SF_sound1 | 30.55542 |

| 20 | peak_vib3 | 65.75025 | 40 | var_sound1 | 30.53649 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kumar, S.; Kolekar, T.; Patil, S.; Bongale, A.; Kotecha, K.; Zaguia, A.; Prakash, C. A Low-Cost Multi-Sensor Data Acquisition System for Fault Detection in Fused Deposition Modelling. Sensors 2022, 22, 517. https://doi.org/10.3390/s22020517

Kumar S, Kolekar T, Patil S, Bongale A, Kotecha K, Zaguia A, Prakash C. A Low-Cost Multi-Sensor Data Acquisition System for Fault Detection in Fused Deposition Modelling. Sensors. 2022; 22(2):517. https://doi.org/10.3390/s22020517

Chicago/Turabian StyleKumar, Satish, Tushar Kolekar, Shruti Patil, Arunkumar Bongale, Ketan Kotecha, Atef Zaguia, and Chander Prakash. 2022. "A Low-Cost Multi-Sensor Data Acquisition System for Fault Detection in Fused Deposition Modelling" Sensors 22, no. 2: 517. https://doi.org/10.3390/s22020517

APA StyleKumar, S., Kolekar, T., Patil, S., Bongale, A., Kotecha, K., Zaguia, A., & Prakash, C. (2022). A Low-Cost Multi-Sensor Data Acquisition System for Fault Detection in Fused Deposition Modelling. Sensors, 22(2), 517. https://doi.org/10.3390/s22020517