Low-Cost Force Sensors Embedded in Physical Human–Machine Interfaces: Concept, Exemplary Realization on Upper-Body Exoskeleton, and Validation

Abstract

:1. Introduction

- Application in an isolated testing environment (experiment 1):

- ○

- Concerning the measurement accuracy: Does the sensor pad provide a linear, stable, and repeatable determination of applied normal forces with low hysteresis in an expanded load range up to 200 newtons with a maximal duration of 10 min? The applied threshold of maximum 200 newtons is derived from the fact that commercially available cobots or supportive exoskeletons do not typically feature load eases beyond.

- ○

- Concerning the ease of use: Is it necessary to fill the capsule with an incompressible medium such as water that influences the measured pressure in case of a spatial rotation of the sensor pad due to its varying hydrostatic head, and must be vented for preparing the sensor pad? Is the medium air a beneficial alternative?

- ○

- Concerning the operational safety: Does the sensor pad and in particular the flexible silicone capsule withstand a mechanical load test increasing to 500 newtons? The applied threshold of maximum 500 newtons is derived from a measurement range of 200 kilopascals [23] that equals a load of 564 newtons considering the surface area of the sensor pad with 28.2 square centimeters.

- Application in a realistic testing environment with embedded sensor pads in the interface of an active shoulder exoskeleton (experiment 2):

- ○

- Concerning the measurement accuracy: Does the sensor pad or its spatial array with three sensor pads provide reliable results for occurring interaction forces in human–machine interfaces?

- ○

- Concerning the interpretability: Might the spatial array of the sensor pads embedded in the interface of an exoskeleton be capable of detecting “poor” load conditions such as uneven pressure distributions?

2. Materials and Methods

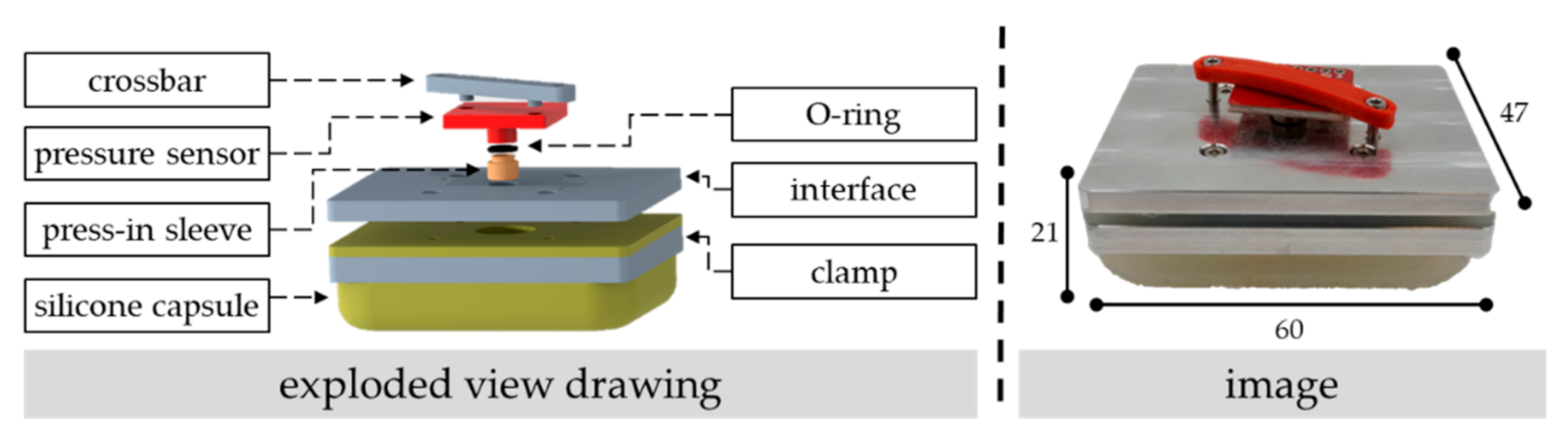

2.1. Basic Construction of the Sensor Pad and Its Embedding in an Exoskeletal Interface

2.2. Calibration of the Sensor Pad

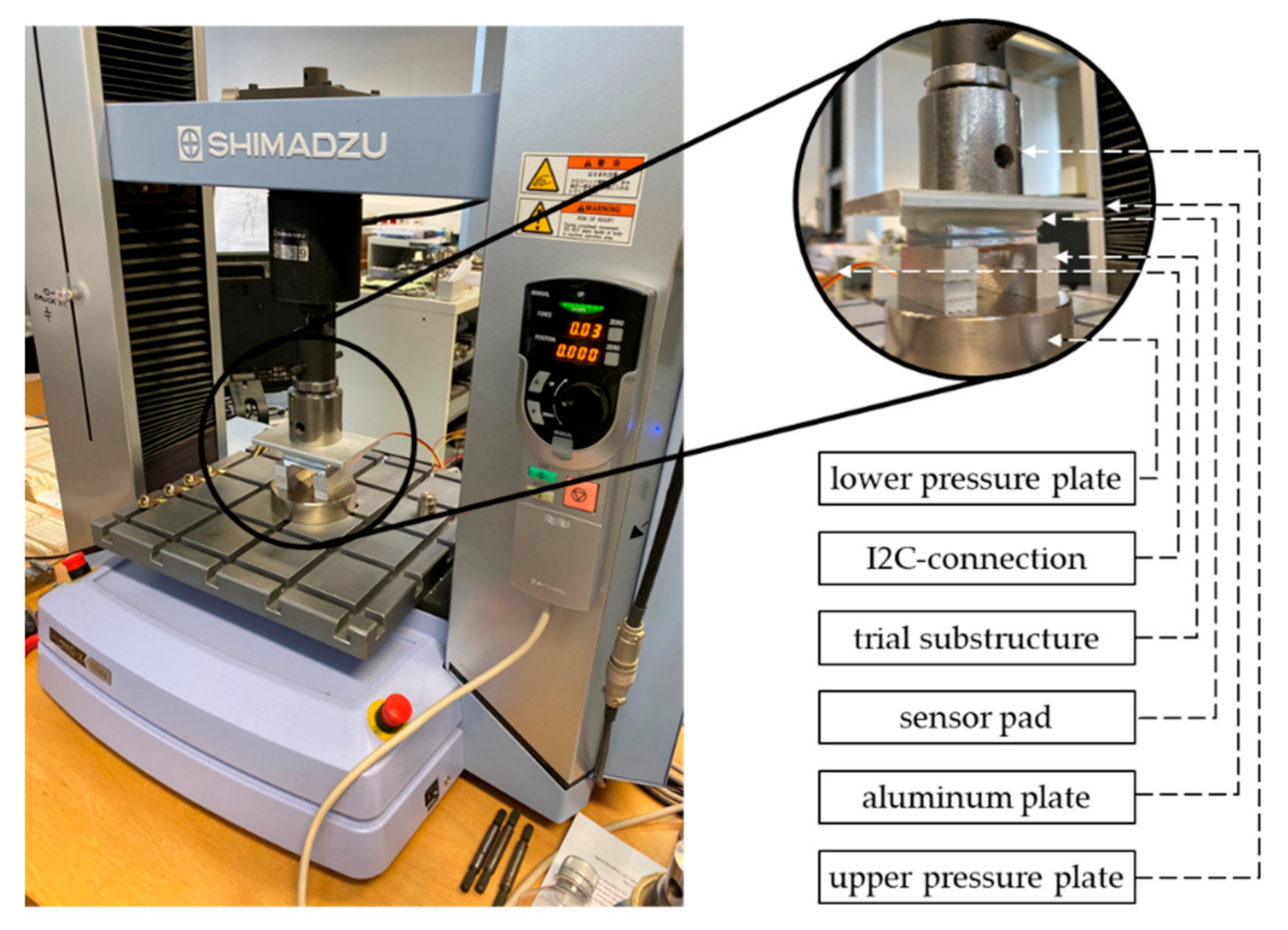

2.3. Test Setup—Material-Testing Machine (Experiment 1)

- Trial 1: force ascent from 0 newtons to 500 newtons with an increase rate of 5 newtons per second, and force decrease to 0 newtons with a decrease rate of 5 newtons per second, one cycle, sensor pad filled with either water or air;

- Trial 2: force ascent from 0 newtons to 200 newtons with an increase rate of 5 newtons per second, hold for 600 s, and force decrease to 0 newtons with a decrease rate of 5 newtons per second, one cycle, sensor pad filled with air;

- Trial 3: force ascent from 0 newtons to 100 newtons with an increase rate of 5 newtons per second, hold for one second, and force decrease to 0 newtons with a decrease rate of 5 newtons per second, five cycles, sensor pad filled with air.

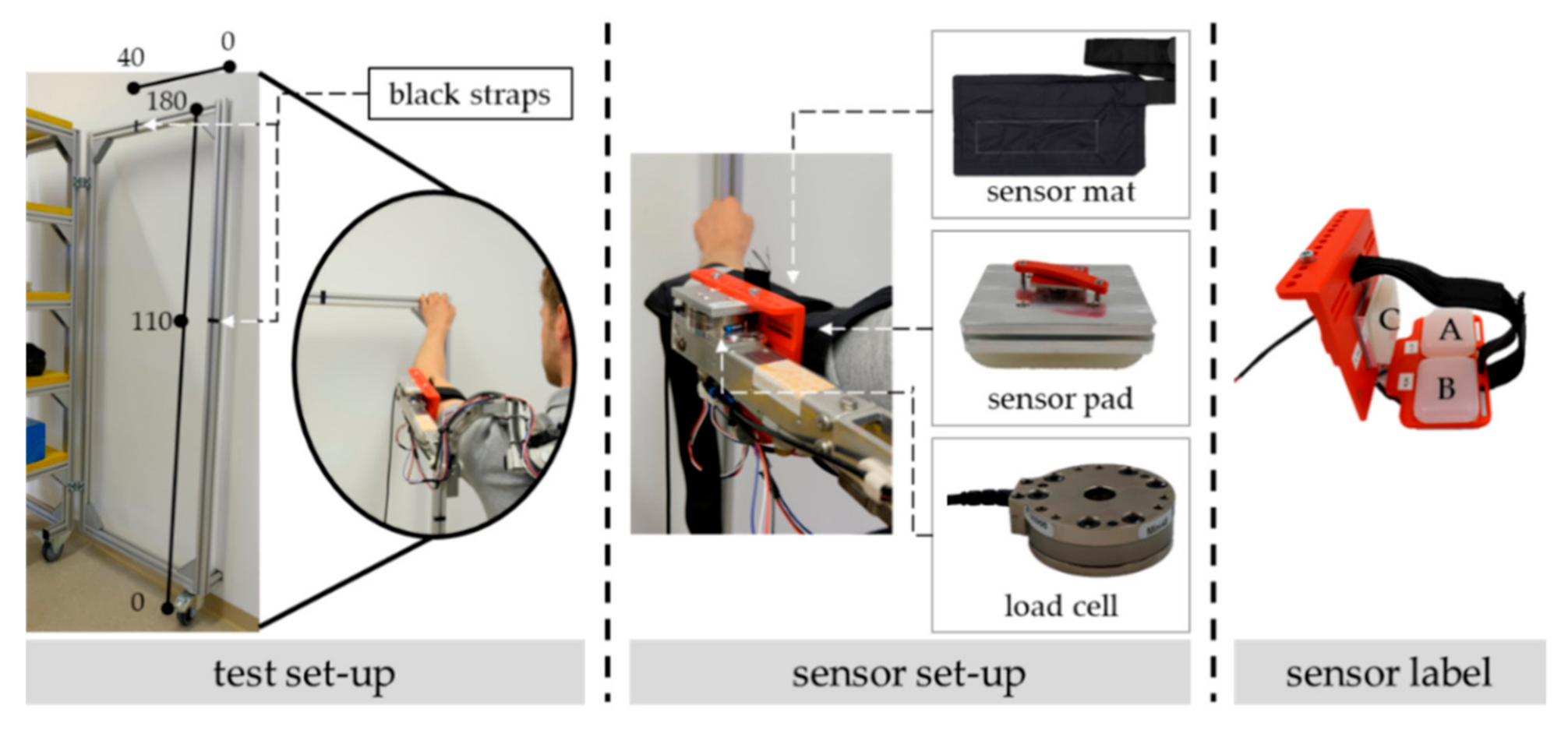

2.4. Test Setup—Exoskeleton Application (Experiment 2)

3. Results

3.1. Material-Testing Machine (Experiment 1)

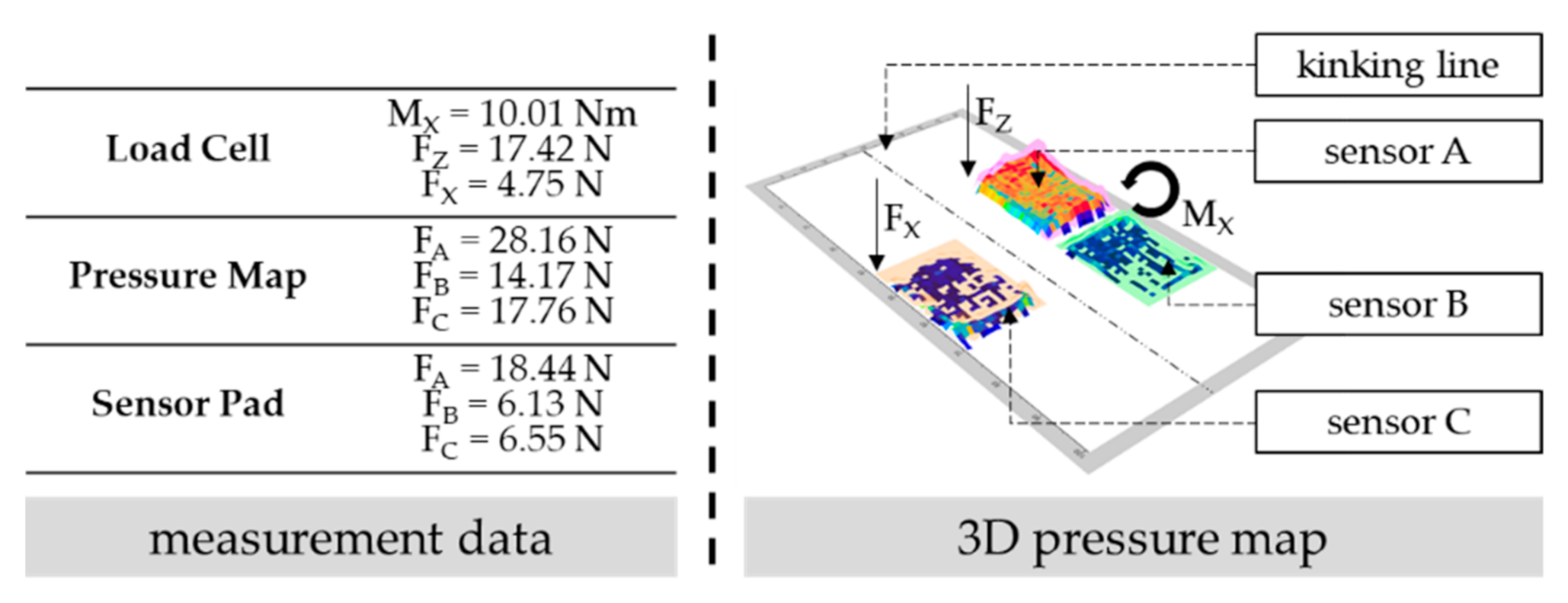

3.2. Application on Exoskeletal Interface (Experiment 2)

4. Discussion

4.1. Potential for Embedding in Exoskeletons

4.2. Ways for Improving the General Measurement Accuracy of the Sensor Pad

- Construction (hardware):One approach can be a redesign of the shape of the silicon capsule. This can imply the wall’s height or thickness, the form of the contact surface’s edge with an angular or chamfered edge, or the usage of a stiffer silicon with less material flexibility.

- Calibration (software):

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Weidner, R.; Kong, N.; Wulfsberg, J.P. Human Hybrid Robot: A New Concept for Supporting Manual Assembly Tasks. Prod. Eng. 2013, 7, 675–684. [Google Scholar] [CrossRef]

- Diebold, J. Automation: The Advent of the Automated Factory; van Nostrand Company: New York, NY, USA, 1952. [Google Scholar]

- Weidner, R.; Karafillidis, A. Distinguishing Support Technologies. A General Scheme and Its Application to Exoskeletons. In Developing Support Technologies. Biosystems and Biorobotic; Springer: Cham, Switzerland, 2018. [Google Scholar]

- Wettenschwiler, P.D.; Stämpfli, R.; Lorenzetti, S.; Ferguson, S.J.; Rossi, R.M.; Annaheim, S. How Reliable Are Pressure Measurements with Tekscan Sensors on the Body Surface of Human Subjects Wearing Load Carriage Systems? Int. J. Ind. Ergon. 2015, 49, 60–67. [Google Scholar] [CrossRef]

- Scibilia, A.; Valori, M.; Pedrocchi, N.; Fassi, I.; Herbster, S.; Behrens, R.; Saenz, J.; Magisson, A.; Bidard, C.; Kuhnrich, M.; et al. Analysis of Interlaboratory Safety Related Tests in Power and Force Limited Collaborative Robots. IEEE Access 2021, 9, 80873–80882. [Google Scholar] [CrossRef]

- Matthiesen, S.; Schäfer, T.; Schmidt, S. Zielgerichtete und kundenorientierte Produktentwicklung—von der Anwendungsanalyse zur Validierung. Stuttg. Symp. Prod. 2015, 1–10. [Google Scholar] [CrossRef]

- Zhao, S.; Liu, R.; Fei, C.; Guan, D. Dynamic Interface Pressure Monitoring System for the Morphological Pressure Mapping of Intermittent Pneumatic Compression Therapy. Sensors 2019, 19, 2881. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Chaparro-Rico, B.D.M.; Cafolla, D.; Tortola, P.; Galardi, G. Assessing stiffness, joint torque and ROM for paretic and non-paretic lower limbs during the subacute phase of stroke using lokomat tools. Appl. Sci. 2020, 10, 6168. [Google Scholar] [CrossRef]

- Chaparro-Rico, B.; Cafolla, D.; Ceccarelli, M.; Castillo-Castaneda, E. Design and simulation of an assisting mechanism for arm exercises. Mech. Mach. Sci. 2017, 47, 115–123. [Google Scholar] [CrossRef]

- Mehrdad, S.; Liu, F.; Pham, M.T.; Leleve, A.; Atashzar, S.F. Review of Advanced Medical Telerobots. Appl. Sci. 2021, 11, 209. [Google Scholar] [CrossRef]

- Minervini, G.; Lucchese, A.; Perillo, L.; Serpico, R.; Minervini, G. Unilateral superior condylar neck fracture with dislocation in a child treated with an acrylic splint in the upper arch for functional repositioning of the mandible. Cranio 2017, 35, 337–341. [Google Scholar] [CrossRef]

- Fox, S.; Aranko, O.; Heilala, J.; Vahala, P. Exoskeletons: Comprehensive, Comparative and Critical Manufacturing Performance. J. Manuf. Technol. Manag. 2019, 31, 1261–1280. [Google Scholar] [CrossRef] [Green Version]

- Hoffmann, N.; Prokop, G.; Weidner, R. Methodologies for Evaluating Exoskeletons with Industrial Applications. Ergonomics 2021, 1–21. [Google Scholar] [CrossRef]

- Abdoli-Eramaki, M.; Stevenson, J.M.; Reid, S.A.; Bryant, T.J. Mathematical and Empirical Proof of Principle for an On-Body Personal Lift Augmentation Device (PLAD). J. Biomech. 2007, 40, 1694–1700. [Google Scholar] [CrossRef]

- Baser, O.; Kizilhan, H.; Kilic, E. Biomimetic Compliant Lower Limb Exoskeleton (BioComEx) and Its Experimental Evaluation. J. Braz. Soc. Mech. Sci. Eng. 2019, 41, 226. [Google Scholar] [CrossRef]

- Gabardi, M.; Solazzi, M.; Leonardis, D.; Frisoli, A. Design and Evaluation of a Novel 5 DoF Underactuated Thumb-Exoskeleton. IEEE Robot. Autom. Lett. 2018, 3, 2322–2329. [Google Scholar] [CrossRef]

- Galle, S.; Malcolm, P.; Derave, W.; De Clercq, D. Enhancing Performance during Inclined Loaded Walking with a Powered Ankle–Foot Exoskeleton. Eur. J. Appl. Physiol. 2014, 114, 2341–2351. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Huysamen, K.; de Looze, M.; Bosch, T.; Ortiz, J.; Toxiri, S.; O’Sullivan, L.W. Assessment of an Active Industrial Exoskeleton to Aid Dynamic Lifting and Lowering Manual Handling Tasks. Appl. Ergon. 2018, 68, 125–131. [Google Scholar] [CrossRef]

- Levesque, L.; Pardoel, S.; Lovrenovic, Z.; Doumit, M. Experimental Comfort Assessment of an Active Exoskeleton Interface. In Proceedings of the IEEE 5th International Symposium on Robotics and Intelligent Sensors, Ottawa, ON, Canada, 5–7 October 2017; pp. 38–43. [Google Scholar] [CrossRef]

- Cha, D.; Oh, S.N.; Lee, H.H.; Kim, K.S.; Kim, K.; Kim, S. Design and Evaluation of the Unmanned Technology Research Center Exoskeleton Implementing the Precedence Walking Assistance Mechanism. J. Electr. Eng. Technol. 2015, 10, 2376–2383. [Google Scholar] [CrossRef] [Green Version]

- Jung, Y.; Bae, J. Kinematic Analysis of a 5-DOF Upper-Limb Exoskeleton with a Tilted and Vertically Translating Shoulder Joint. IEEE/ASME Trans. Mechatron. 2015, 20, 1428–1439. [Google Scholar] [CrossRef]

- Otten, B.; Hoffmann, N.; Weidner, R. Towards Adaptive System Behavior and Learning Processes for Active Exoskeletons. In Production at the Leading Edge of Technology; Behrens, B.A., Brosius, A., Hintze, W., Ihlenfeldt, S., Wulfsberg, J.P., Eds.; Springer: Berlin/Heidelberg, Germany, 2020; pp. 476–484. [Google Scholar] [CrossRef]

- Ferguson-Pell, M.; Cardi, M. Pressure Mapping Systems. TeamRehab Rep. 1992, 3, 26–32. [Google Scholar]

- Lee, N.K.S.; Goonetilleke, R.S.; Cheung, Y.S.; So, G.M.Y. A Flexible Encapsulated MEMS Pressure Sensor System for Biomechanical Applications. Microsyst. Technol. 2001, 7, 55–62. [Google Scholar] [CrossRef]

- Giovanelli, D.; Farella, E. Force Sensing Resistor and Evaluation of Technology for Wearable Body Pressure Sensing. J. Sens. 2016, 2016, 9391850. [Google Scholar] [CrossRef] [Green Version]

- Lebossé, C.; Renaud, P.; Bayle, B.; de Mathelin, M. Modeling and Evaluation of Low-Cost Force Sensors. IEEE Trans. Robot. 2011, 27, 815–822. [Google Scholar] [CrossRef]

- Hollinger, A.; Wanderley, M.M. Evaluation of Commercial Force-Sensing Resistors. In Proceedings of the International Conference on New Interfaces for Musical Expression, Paris, France, 4–8 June 2006. [Google Scholar]

- Almassri, A.M.; Wan Hasan, W.Z.; Ahmad, S.A.; Ishak, A.J.; Ghazali, A.M.; Talib, D.N.; Wada, C. Pressure Sensor: State of the Art, Design, and Application for Robotic Hand. J. Sens. 2015, 2015, 846487. [Google Scholar] [CrossRef] [Green Version]

- Hoffmann, N.; Ersoysal, S.; Weidner, R. Towards Embedded Force Sensors in Exoskeletons for Evaluating Interaction Forces in Interfaces. In Annals of Scientific Society for Assembly, Handling and Industrial Robotics; Schüppstuhl, T., Tracht, K., Henrich, D., Eds.; Springer: Berlin/Heidelberg, Germany, 2020; pp. 69–79. [Google Scholar] [CrossRef]

- Smooth-On. Dragon Skin Series Technical Bulletin. 2018. Available online: www.smooth-on.com/tb/files/DRAGON_SKIN_SERIES_TB.pdf (accessed on 10 January 2021).

- TE Connectivity. MS5803-01BA; TE Connectivity: Schaffhausen, Switzerland, 2017. [Google Scholar]

- Sposito, M.; Toxiri, S.; Caldwell, D.G.; Ortiz, J.; De Momi, E. Towards Design Guidelines for Physical Interfaces on Industrial Exoskeletons : Overview on Evaluation Metrics. In International Symposium on Wearable Robotics; Springer: Berlin/Heidelberg, Germany, 2018. [Google Scholar]

- Otten, B.; Weidner, R.; Argubi-Wollesen, A. Evaluation of a Novel Active Exoskeleton for Tasks at or Above Head Level. IEEE Robot. Autom. Lett. 2018, 3, 2408–2415. [Google Scholar] [CrossRef]

- Aijse, D.V.; Molly, M.; Reinier, K.; Idsart, K.; Michiel, D.L. The Amount of Support Provided by a Passive Arm Support Exoskeleton in a Range of Elevated Arm Postures. IISE Trans. Occup. Ergon. Hum. Factors 2019, 7, 311–321. [Google Scholar] [CrossRef]

- Hackbart, R.; Kostelnik, J.; Kuschan, J.; Schmidt, H.; Krüger, J.; Vieroth, R.; Lang, K.-D. SmartSensX: Ein Konzept Für Vernetzte Tragbare Sensoren Zur Anwendung in Der Softrobotik Und Mensch Maschine Interaktion. In Technische Unterstützungssysteme, die die Menschen Wirklich Wollen; Weidner, R., Karafillidis, A., Eds.; Helmut-Schmidt-Universität: Hamburg, Germany, 2018; pp. 289–296. [Google Scholar]

- Hoffmann, N.; Schubert, T.; Ralfs, L.; Weidner, R. Gestaltung und Multidimensionale Bewertung von Physischen Schnittstellen Exoskelettaler Systeme; GFA-Press: Bochum, Germany, 2021. [Google Scholar]

| Normal Forces | Shear Forces | ||

|---|---|---|---|

| Test Subject 1 | Force–Torque Sensor | Force–Torque Sensor | |

| Force–Torque Sensor | 1 | 1 | |

| Sensor Pad | 0.68 | −0.34 | |

| Pressure Map | 0.69 | −0.01 | |

| Test Subject 2 | Force–Torque Sensor | Force–Torque Sensor | |

| Force–Torque Sensor | 1 | 1 | |

| Sensor Pad | 0.84 | 0.19 | |

| Pressure Map | 0.68 | 0.21 | |

| Test Subject 3 | Force–Torque Sensor | Force–Torque Sensor | |

| Force–Torque Sensor | 1 | 1 | |

| Sensor Pad | 0.99 | 0.56 | |

| Pressure Map | 0.98 | 0.48 | |

| Load (Newton) | Contact Surface (Square Centimeters) |

|---|---|

| 25.01 | 5.44 × 4.15 |

| 49.52 | 5.67 × 4.36 |

| 102.97 | 5.96 × 4.63 |

| 171.61 | 6.20 × 4.85 |

| 494.26 | 6.63 × 5.27 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hoffmann, N.; Ersoysal, S.; Prokop, G.; Hoefer, M.; Weidner, R. Low-Cost Force Sensors Embedded in Physical Human–Machine Interfaces: Concept, Exemplary Realization on Upper-Body Exoskeleton, and Validation. Sensors 2022, 22, 505. https://doi.org/10.3390/s22020505

Hoffmann N, Ersoysal S, Prokop G, Hoefer M, Weidner R. Low-Cost Force Sensors Embedded in Physical Human–Machine Interfaces: Concept, Exemplary Realization on Upper-Body Exoskeleton, and Validation. Sensors. 2022; 22(2):505. https://doi.org/10.3390/s22020505

Chicago/Turabian StyleHoffmann, Niclas, Samet Ersoysal, Gilbert Prokop, Matthias Hoefer, and Robert Weidner. 2022. "Low-Cost Force Sensors Embedded in Physical Human–Machine Interfaces: Concept, Exemplary Realization on Upper-Body Exoskeleton, and Validation" Sensors 22, no. 2: 505. https://doi.org/10.3390/s22020505

APA StyleHoffmann, N., Ersoysal, S., Prokop, G., Hoefer, M., & Weidner, R. (2022). Low-Cost Force Sensors Embedded in Physical Human–Machine Interfaces: Concept, Exemplary Realization on Upper-Body Exoskeleton, and Validation. Sensors, 22(2), 505. https://doi.org/10.3390/s22020505