Severity Estimation for Interturn Short-Circuit and Demagnetization Faults through Self-Attention Network

Abstract

:1. Introduction

- The proposed SASEN can be used to evaluate the severity of ISCFs and DFs. By applying the self-attention mechanism, the SASEN provides superior model representation, feature extraction, and regression capabilities. The proposed strategy can be extended to the diagnosis of other faults.

- The proposed strategy can diagnose an HF, i.e., when the ISCF and DF occur simultaneously. To the best of our knowledge, this is the first study on diagnosing an HF by estimating its severity.

- Fault diagnosis is achieved for various load torques and fault conditions. In particular, the proposed strategy can diagnose faults even under untrained load torques. Therefore, it has an excellent generalization ability and is more effective, as it is not necessary to train all possible load torques.

- The proposed strategy can accurately diagnose faults without requiring the exact model and parameters necessary for severity estimation in the conventional method.

2. Analysis of Faults

2.1. Analysis of Interturn Short-Circuit Fault

2.2. Analysis of Demagnetization Fault and Hybrid Fault

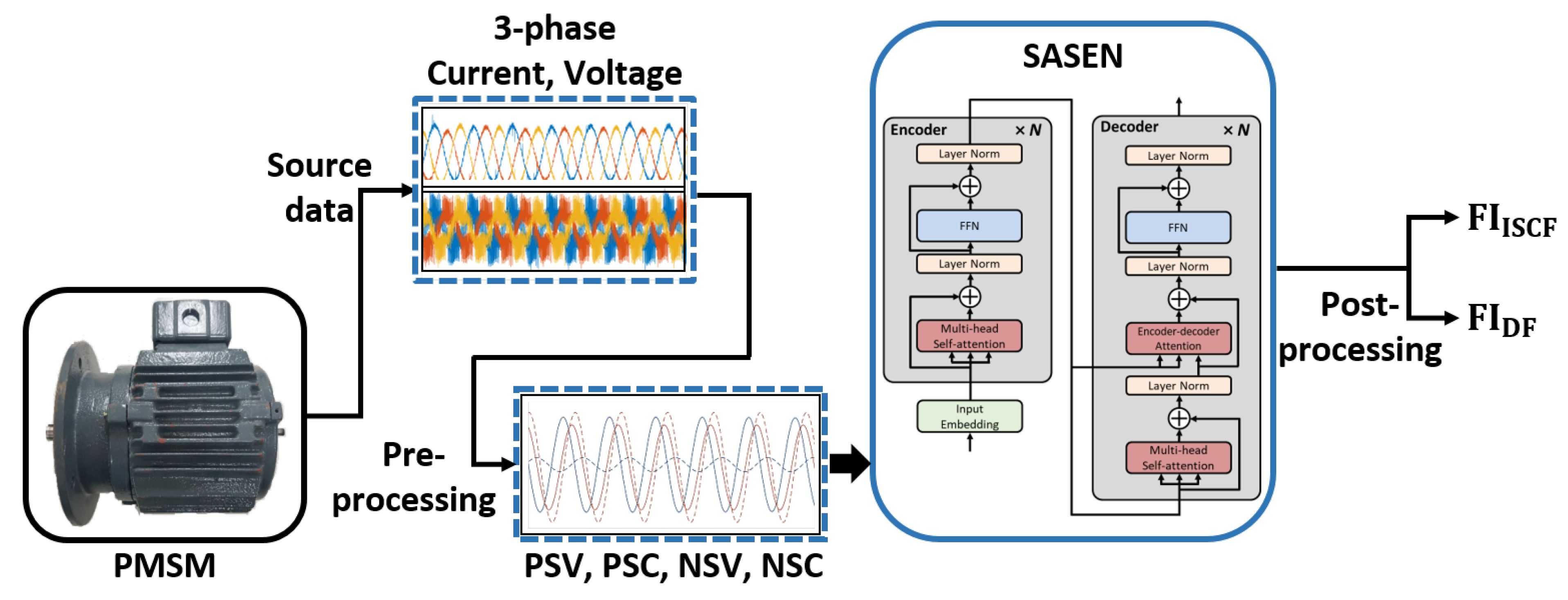

2.3. Input and Output Selection

3. Proposed Severity Estimation Method

3.1. Self-Attention Module

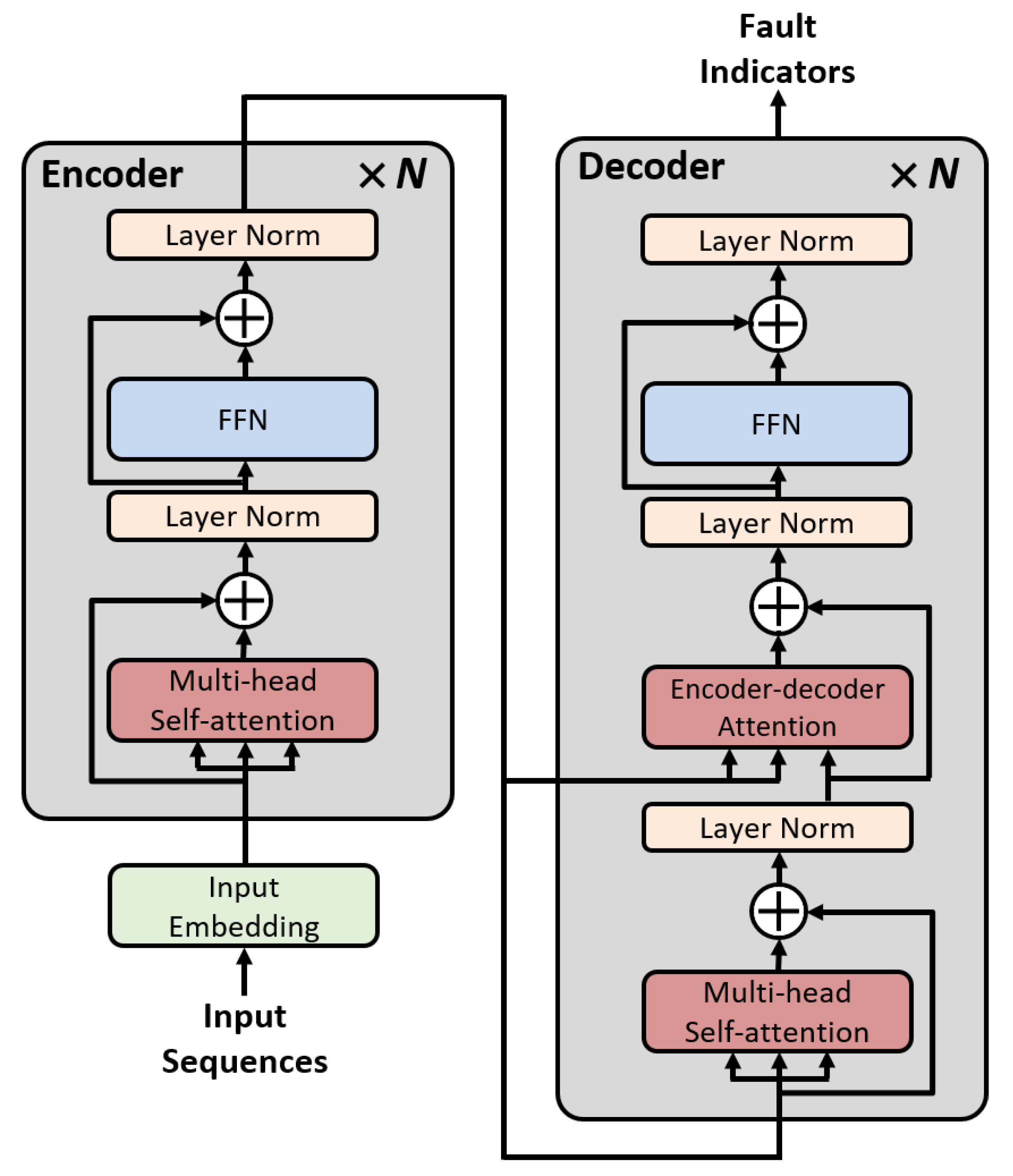

3.2. Self-Attention-Based Severity Estimation Network

3.3. Training Procedure

3.4. Overall Structure of Diagnosis System

4. Experimental Results

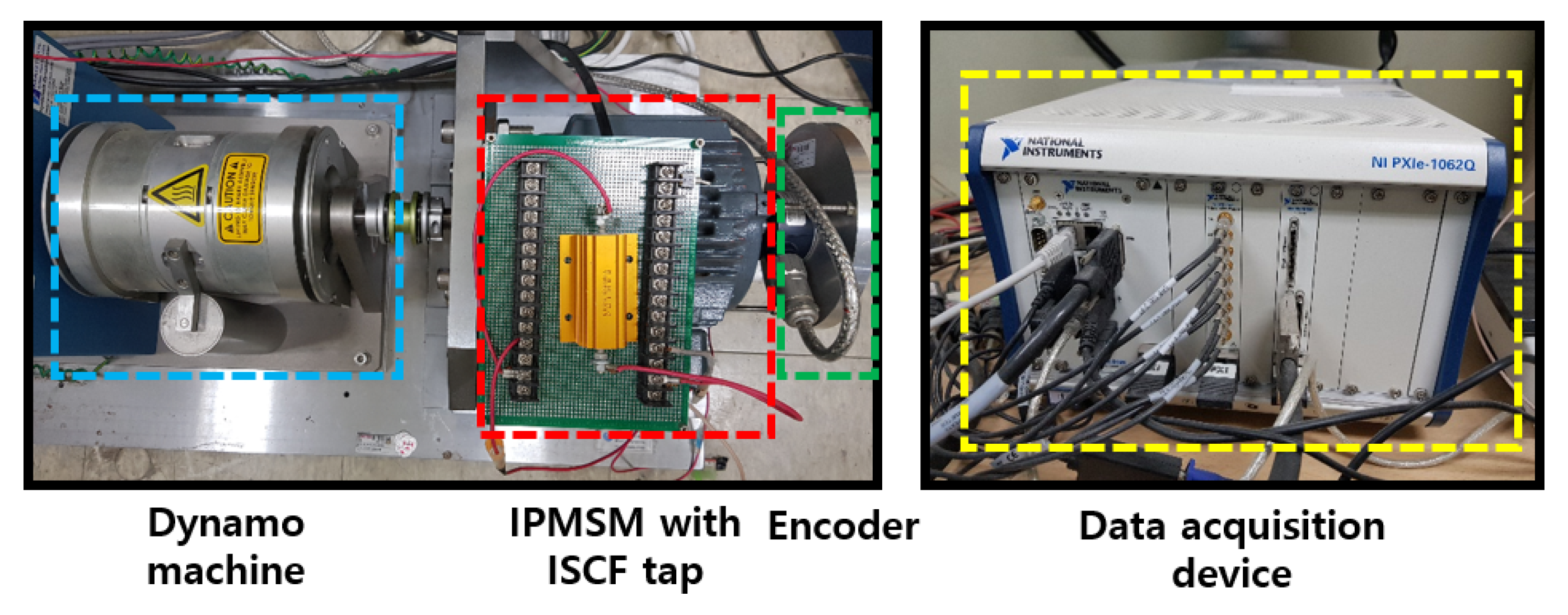

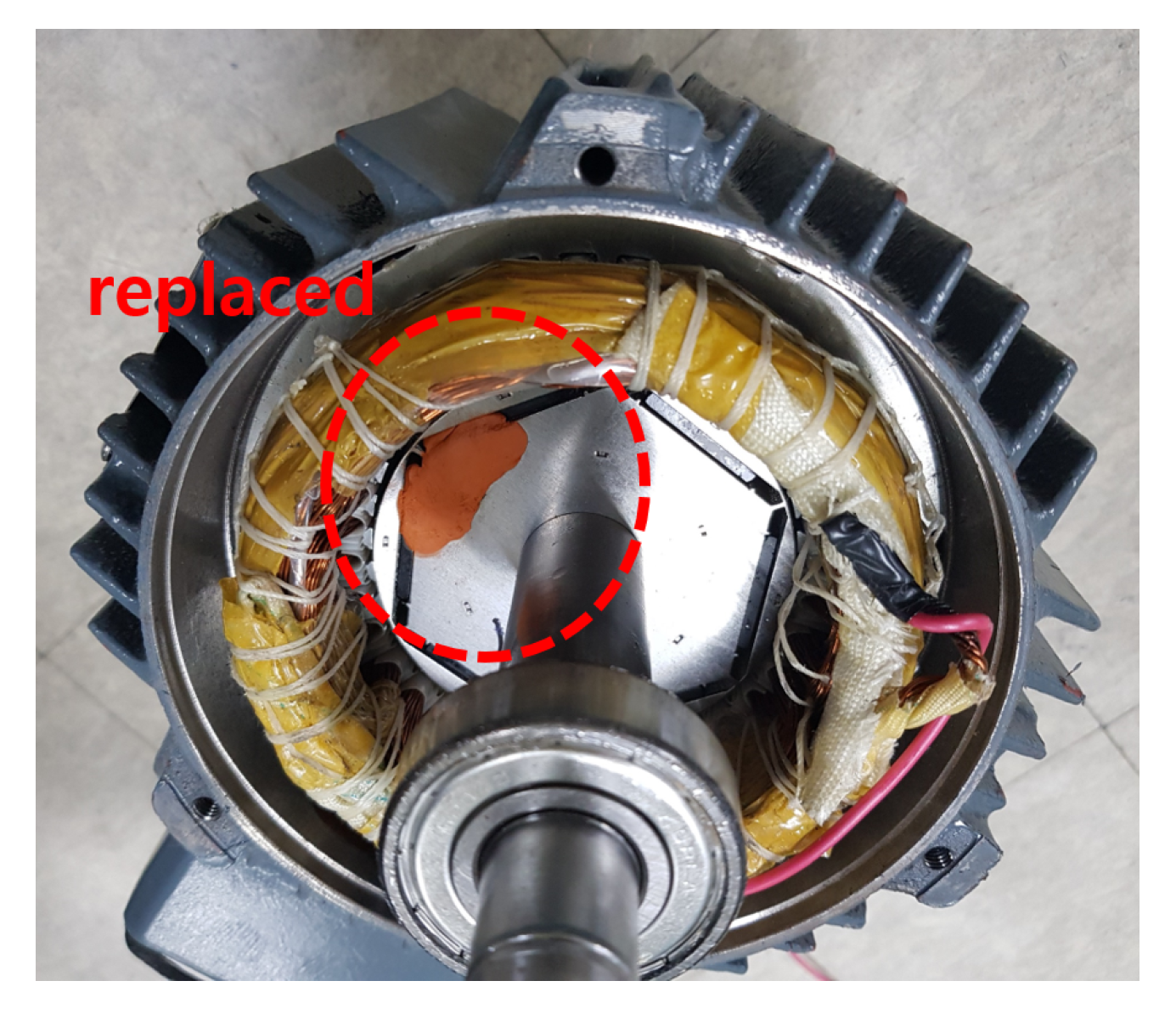

4.1. Experimental Setup

4.2. Training and Test

4.3. Results and Discussion

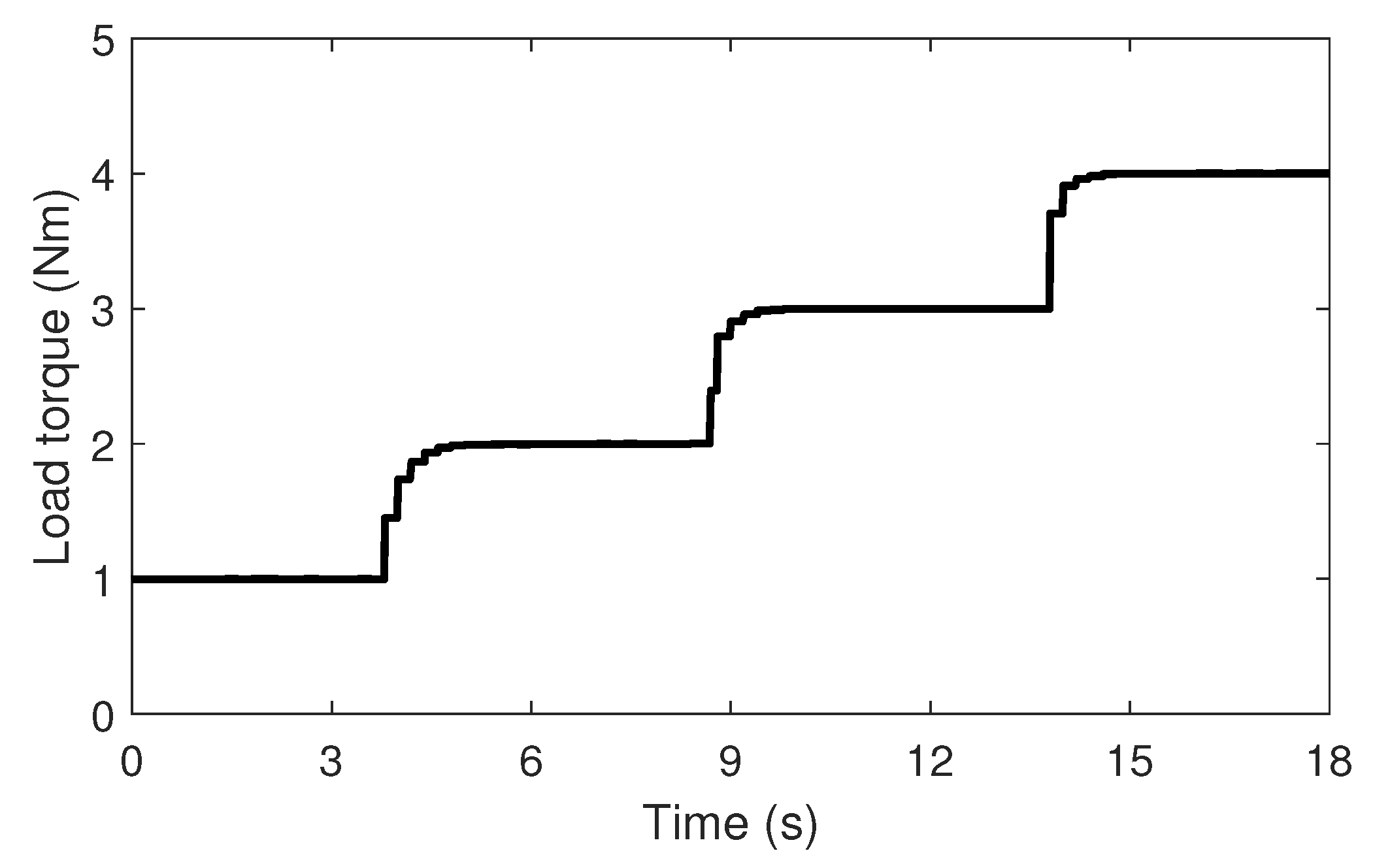

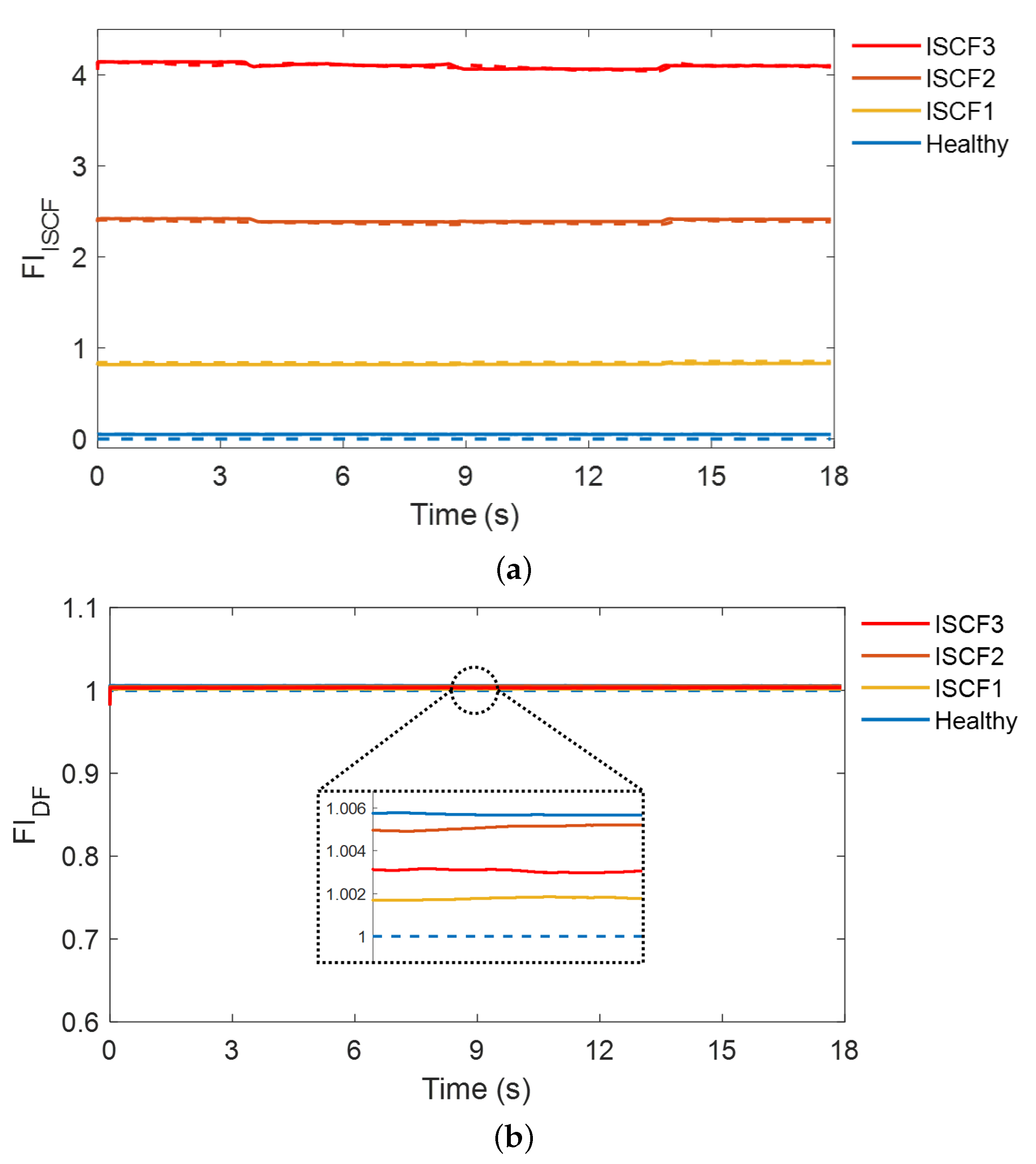

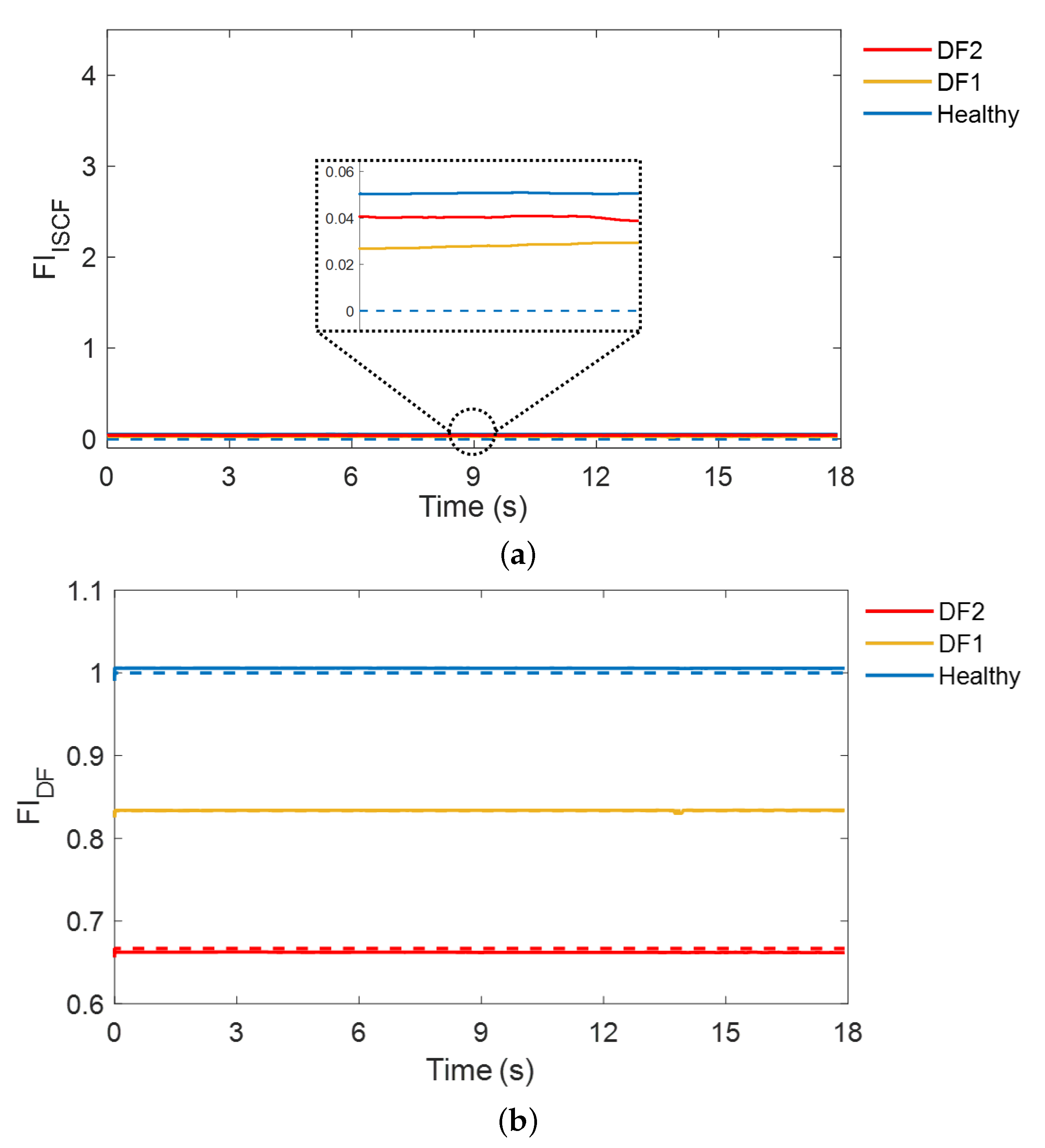

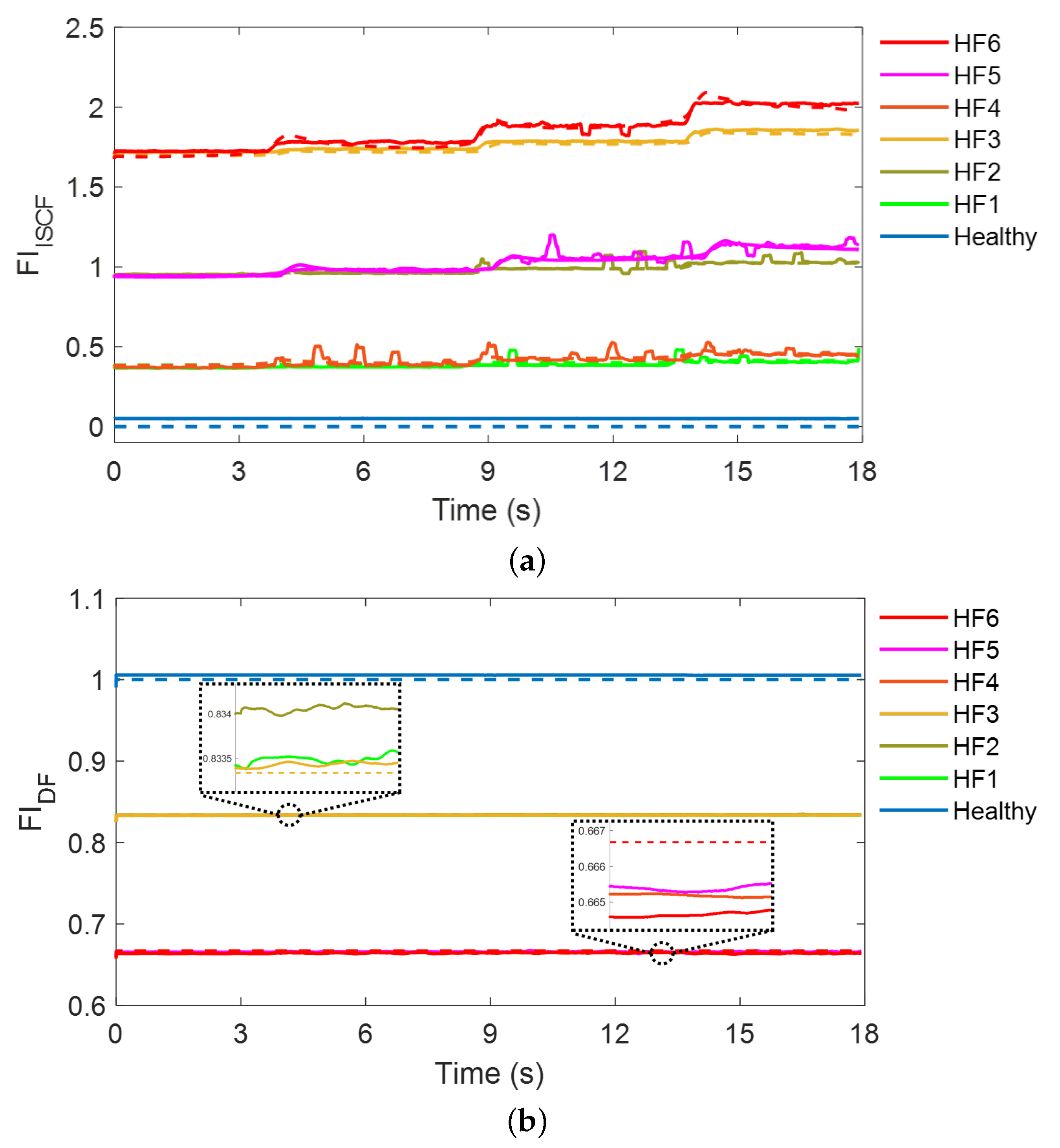

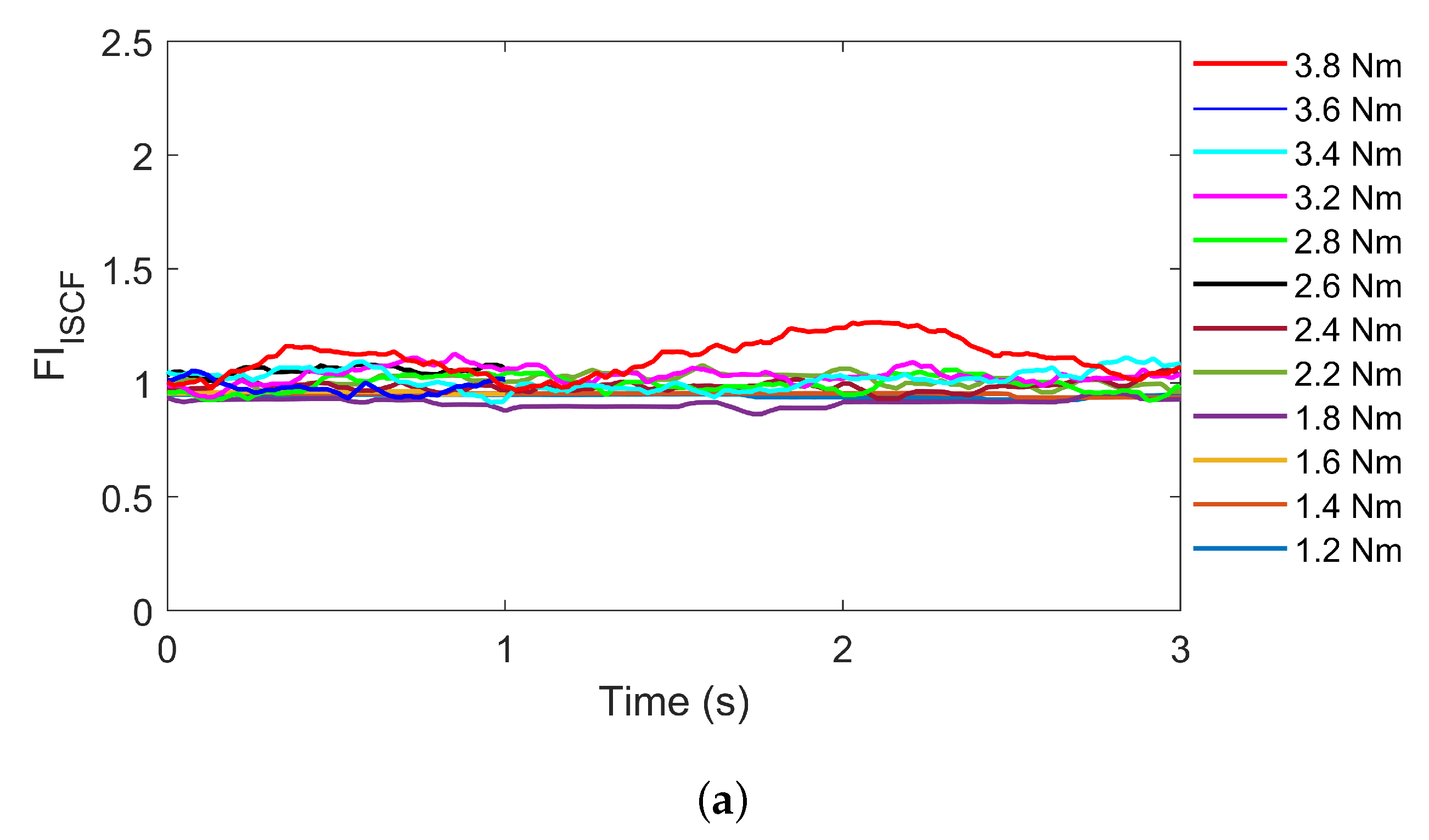

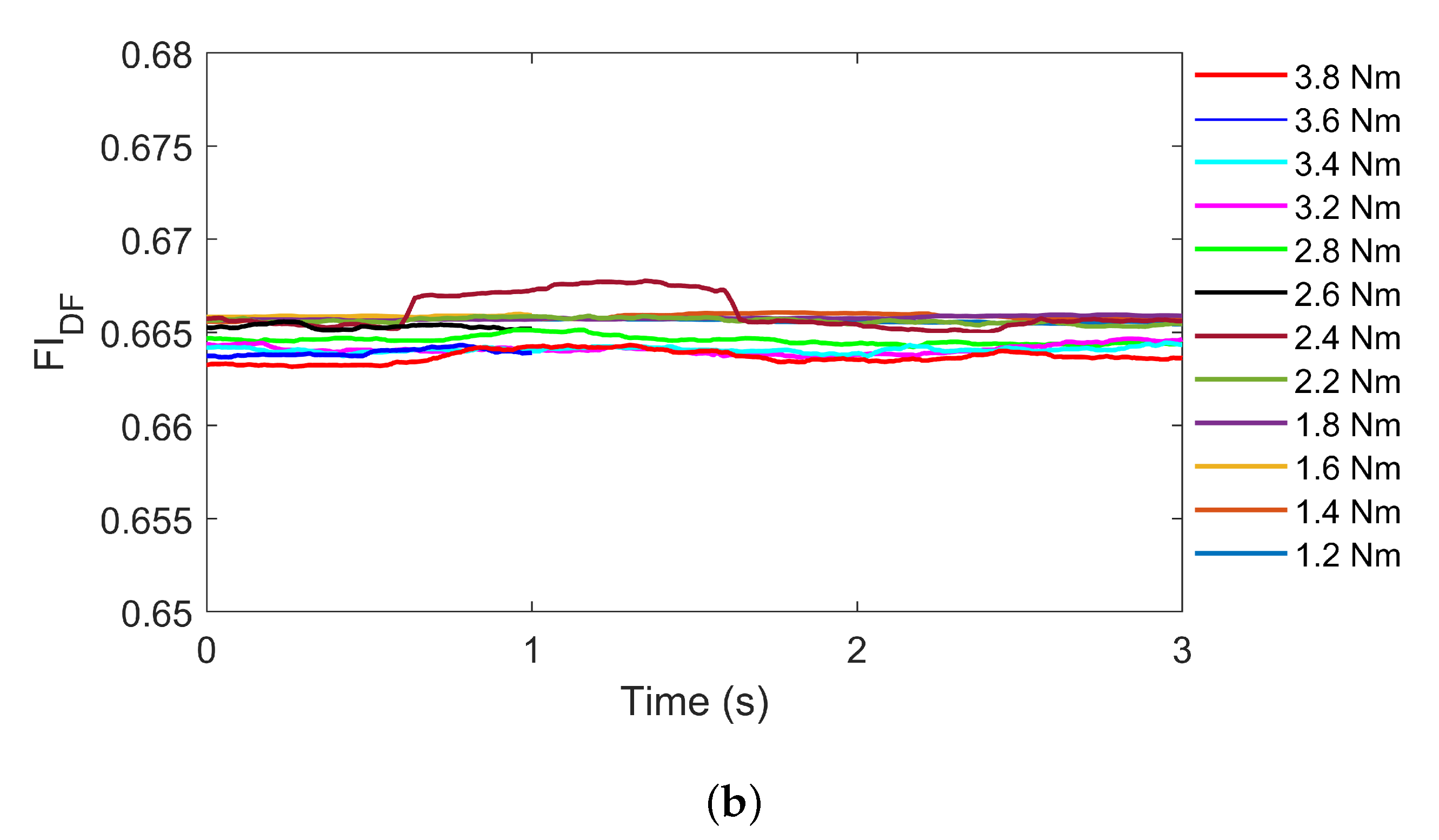

4.3.1. Test Results for Transient Load Torque

4.3.2. Test Results for Untrained Load Torque

4.4. Comparison with Other Methods

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| PMSM | Permanent-magnet synchronous machine |

| ISCF | Interturn short-circuit fault |

| DF | Demagnetization fault |

| BF | Bearing fault |

| PM | Permanent magnet |

| TCN | Transformer convolution network |

| RNN | Recurrent neural network |

| SASEN | Self-attention-based severity estimation network |

| MSA | Multi-head self-attention |

| PSV | Positive-sequence voltage |

| PSC | Positive-sequence current |

| NSV | Negative-sequence voltage |

| NSC | Negative-sequence current |

| HF | Hybrid fault |

| FFN | Fully connected feed-forward network |

References

- Choudhary, A.; Goyal, D.; Shimi, S.L.; Akula, A. Condition monitoring and fault diagnosis of induction motors: A review. Arch. Comput. Methods Eng. 2019, 26, 1221–1238. [Google Scholar] [CrossRef]

- Choi, S.; Haque, M.S.; Tarek, M.T.B.; Mulpuri, V.; Duan, Y.; Das, S.; Garg, V.; Ionel, D.M.; Masrur, M.A.; Mirafzal, B.; et al. Fault diagnosis techniques for permanent magnet AC machine and drives—A review of current state of the art. IEEE Trans. Transp. Electrif. 2018, 4, 444–463. [Google Scholar] [CrossRef]

- Moon, S.; Jeong, H.; Lee, H.; Kim, S.W. Detection and classification of demagnetization and interturn short faults of IPMSMs. IEEE Trans. Ind. Electron. 2017, 64, 9433–9441. [Google Scholar] [CrossRef]

- Boileau, T.; Leboeuf, N.; Nahid-Mobarakeh, B.; Meibody-Tabar, F. Synchronous demodulation of control voltages for stator interturn fault detection in PMSM. IEEE Trans. Power Electron. 2013, 28, 5647–5654. [Google Scholar] [CrossRef]

- Bouzid, M.B.K.; Champenois, G.; Bellaaj, N.M.; Signac, L.; Jelassi, K. An effective neural approach for the automatic location of stator interturn faults in induction motor. IEEE Trans. Ind. Electron. 2008, 55, 4277–4289. [Google Scholar] [CrossRef]

- Hang, J.; Ding, S.; Ren, X.; Hu, Q.; Huang, Y.; Hua, W.; Wang, Q. Integration of interturn fault diagnosis and torque ripple minimization control for direct-torque-controlled SPMSM drive system. IEEE Trans. Power Electron. 2021, 36, 11124–11134. [Google Scholar] [CrossRef]

- Cruz, S.M.; Cardoso, A.M. Multiple reference frames theory: A new method for the diagnosis of stator faults in three-phase induction motors. IEEE Trans. Energy Convers. 2005, 20, 611–619. [Google Scholar] [CrossRef]

- Park, J.K.; Hur, J. Detection of inter-turn and dynamic eccentricity faults using stator current frequency pattern in IPM-type BLDC motors. IEEE Trans. Ind. Electron. 2015, 63, 1771–1780. [Google Scholar] [CrossRef]

- Ebrahimi, B.M.; Faiz, J. Demagnetization fault diagnosis in surface mounted permanent magnet synchronous motors. IEEE Trans. Magn. 2012, 49, 1185–1192. [Google Scholar] [CrossRef]

- Prieto, M.D.; Espinosa, A.G.; Ruiz, J.R.R.; Urresty, J.C.; Ortega, J.A. Feature extraction of demagnetization faults in permanent-magnet synchronous motors based on box-counting fractal dimension. IEEE Trans. Ind. Electron. 2010, 58, 1594–1605. [Google Scholar] [CrossRef]

- Saavedra, H.; Urresty, J.C.; Riba, J.R.; Romeral, L. Detection of interturn faults in PMSMs with different winding configurations. Energy Convers. Manag. 2014, 79, 534–542. [Google Scholar] [CrossRef]

- Ruiz, J.R.R.; Rosero, J.A.; Espinosa, A.G.; Romeral, L. Detection of demagnetization faults in permanent-magnet synchronous motors under nonstationary conditions. IEEE Trans. Magn. 2009, 45, 2961–2969. [Google Scholar] [CrossRef]

- Espinosa, A.G.; Rosero, J.A.; Cusido, J.; Romeral, L.; Ortega, J.A. Fault detection by means of Hilbert–Huang transform of the stator current in a PMSM with demagnetization. IEEE Trans. Energy Convers. 2010, 25, 312–318. [Google Scholar] [CrossRef] [Green Version]

- Rajagopalan, S.; Aller, J.M.; Restrepo, J.A.; Habetler, T.G.; Harley, R.G. Detection of rotor faults in brushless DC motors operating under nonstationary conditions. IEEE Trans. Ind. Appl. 2006, 42, 1464–1477. [Google Scholar] [CrossRef] [Green Version]

- Hang, J.; Zhang, J.; Cheng, M.; Huang, J. Online interturn fault diagnosis of permanent magnet synchronous machine using zero-sequence components. IEEE Trans. Power Electron. 2015, 30, 6731–6741. [Google Scholar] [CrossRef]

- Jeong, H.; Moon, S.; Kim, S.W. An early stage interturn fault diagnosis of PMSMs by using negative-sequence components. IEEE Trans. Ind. Electron. 2017, 64, 5701–5708. [Google Scholar] [CrossRef]

- Mazzoletti, M.A.; Bossio, G.R.; De Angelo, C.H.; Espinoza-Trejo, D.R. A model-based strategy for interturn short-circuit fault diagnosis in PMSM. IEEE Trans. Ind. Electron. 2017, 64, 7218–7228. [Google Scholar] [CrossRef]

- Yu, Y.; Huang, X.; Li, Z.; Wu, M.; Shi, T.; Cao, Y.; Yang, G.; Niu, F. Full Parameter Estimation for Permanent Magnet Synchronous Motors. IEEE Trans. Ind. Electron. 2021, 69, 4376–4386. [Google Scholar] [CrossRef]

- Ullah, Z.; Lodhi, B.A.; Hur, J. Detection and identification of demagnetization and bearing faults in PMSM using transfer learning-based VGG. Energies 2020, 13, 3834. [Google Scholar] [CrossRef]

- Wang, C.S.; Kao, I.H.; Perng, J.W. Fault Diagnosis and Fault Frequency Determination of Permanent Magnet Synchronous Motor Based on Deep Learning. Sensors 2021, 21, 3608. [Google Scholar] [CrossRef]

- Skowron, M.; Orlowska-Kowalska, T.; Kowalski, C.T. Detection of permanent magnet damage of PMSM drive based on direct analysis of the stator phase currents using convolutional neural network. IEEE Trans. Ind. Electron. 2022. [Google Scholar] [CrossRef]

- Skowron, M.; Orlowska-Kowalska, T.; Wolkiewicz, M.; Kowalski, C.T. Convolutional neural network-based stator current data-driven incipient stator fault diagnosis of inverter-fed induction motor. Energies 2020, 13, 1475. [Google Scholar] [CrossRef] [Green Version]

- Li, Y.; Wang, Y.; Zhang, Y.; Zhang, J. Diagnosis of Inter-turn Short Circuit of Permanent Magnet Synchronous Motor Based on Deep learning and Small Fault Samples. Neurocomputing 2021, 442, 348–358. [Google Scholar] [CrossRef]

- Pei, X.; Zheng, X.; Wu, J. Rotating Machinery Fault Diagnosis Through a Transformer Convolution Network Subjected to Transfer Learning. IEEE Trans. Instrum. Meas. 2021, 70, 1–11. [Google Scholar] [CrossRef]

- Lee, H.; Jeong, H.; Koo, G.; Ban, J.; Kim, S.W. Attention recurrent neural network-based severity estimation method for interturn short-circuit fault in permanent magnet synchronous machines. IEEE Trans. Ind. Electron. 2020, 68, 3445–3453. [Google Scholar] [CrossRef]

- Vaswani, A.; Shazeer, N.; Parmar, N.; Uszkoreit, J.; Jones, L.; Gomez, A.N.; Kaiser, Ł.; Polosukhin, I. Attention is all you need. In Proceedings of the Advances in Neural Information Processing Systems 30 (NIPS 2017), Long Beach, CA, USA, 4–9 December 2017; Volume 30. [Google Scholar]

- He, K.; Zhang, X.; Ren, S.; Sun, J. Deep residual learning for image recognition. In Proceedings of the 2016 IEEE Conference on Computer Vision and Pattern Recognition (CVPR), Las Vegas, NV, USA, 27–30 June 2016; pp. 770–778. [Google Scholar]

- Ba, J.L.; Kiros, J.R.; Hinton, G.E. Layer normalization. arXiv 2016, arXiv:1607.06450. [Google Scholar]

| Parameters | Values |

|---|---|

| Power | kW |

| Rated torque | Nm |

| Rated speed | 4500 rpm |

| Rated current | A |

| d-axis inductance | mH |

| q-axis inductance | mH |

| Stator resistance | 0.43 |

| Back EMF constant | 36 V/kr/min |

| Case | Healthy | ISCF1 | ISCF2 | ISCF3 | DF1 | DF2 |

|---|---|---|---|---|---|---|

| () | inf | 0.218 | 0.218 | 0.218 | inf | inf |

| 0 | 0.042 | 0.083 | 0.125 | 0 | 0 | |

| 1 | 1 | 1 | 1 | 0.833 | 0.667 | |

| Case | HF1 | HF2 | HF3 | HF4 | HF5 | HF6 |

| () | 0.217 | 0.217 | 0.217 | 0.217 | 0.217 | 0.217 |

| 0.042 | 0.083 | 0.125 | 0.042 | 0.083 | 0.125 | |

| 0.833 | 0.833 | 0.833 | 0.667 | 0.667 | 0.667 | |

| Speed (rpm) | 4500 | |||||

| Torque (Nm) | 1, 2, 3, 4 | |||||

| RMSE of | RMSE of | Test Time (ms) | |

|---|---|---|---|

| TCN [24] | 0.225 | 0.0126 | 28.8 |

| Attention RNN [25] | 0.0879 | 0.0006 | 516.4 |

| Proposed | 0.0566 | 0.0019 | 40.6 |

| Proposed Method | [17] | [18] | [20] | [21] | [23] | [25] | |

|---|---|---|---|---|---|---|---|

| Fault diagnosis for ISCF | O | O | X | X | X | O | O |

| Fault diagnosis for DF | O | X | O | O | O | X | X |

| Fault diagnosis for HF | O | X | X | X | O | X | X |

| Estimation of fault severity | O | O | O | X | X | X | O |

| No need for accurate model | O | X | X | O | O | O | O |

| Fault diagnosis under varying torque | O | O | O | O | O | X | O |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lee, H.; Jeong, H.; Kim, S.; Kim, S.W. Severity Estimation for Interturn Short-Circuit and Demagnetization Faults through Self-Attention Network. Sensors 2022, 22, 4639. https://doi.org/10.3390/s22124639

Lee H, Jeong H, Kim S, Kim SW. Severity Estimation for Interturn Short-Circuit and Demagnetization Faults through Self-Attention Network. Sensors. 2022; 22(12):4639. https://doi.org/10.3390/s22124639

Chicago/Turabian StyleLee, Hojin, Hyeyun Jeong, Seongyun Kim, and Sang Woo Kim. 2022. "Severity Estimation for Interturn Short-Circuit and Demagnetization Faults through Self-Attention Network" Sensors 22, no. 12: 4639. https://doi.org/10.3390/s22124639

APA StyleLee, H., Jeong, H., Kim, S., & Kim, S. W. (2022). Severity Estimation for Interturn Short-Circuit and Demagnetization Faults through Self-Attention Network. Sensors, 22(12), 4639. https://doi.org/10.3390/s22124639