Preliminary Investigation on Systems for the Preventive Diagnosis of Faults on Agricultural Operating Machines

Abstract

1. Introduction

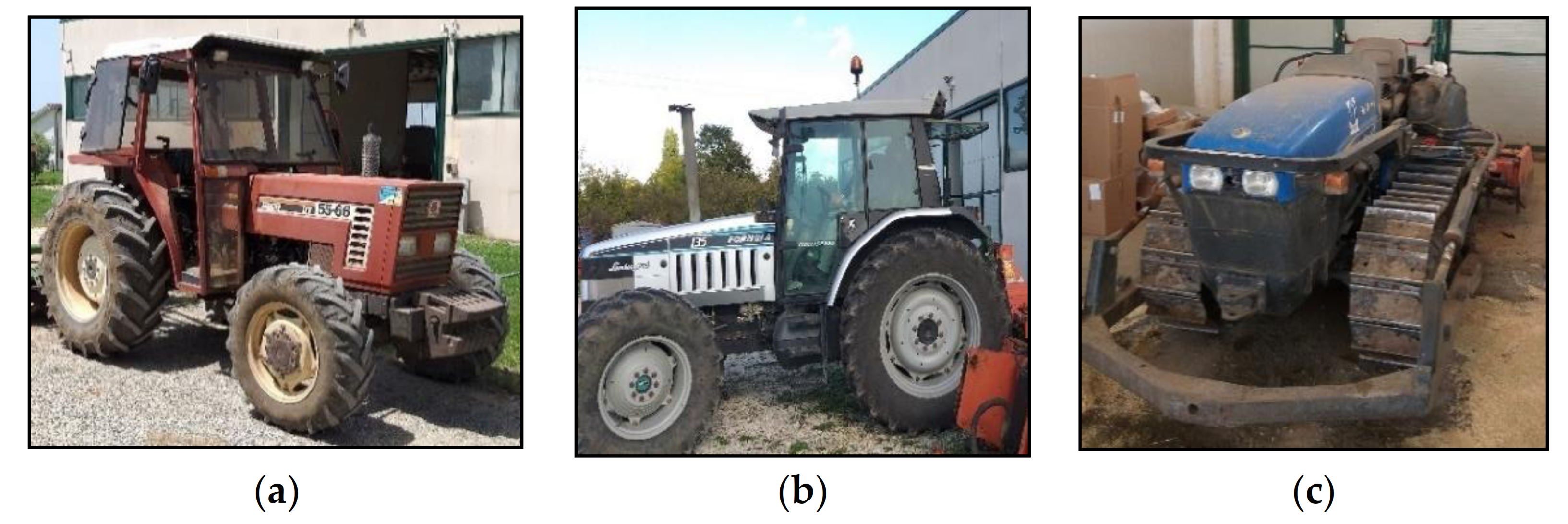

2. Materials and Methods

2.1. Investigation of Faults in Agricultural Machinery: The Rotary Harrow

- Can you indicate below the role that best represents you at the present time?

- What is the average frequency of failures in the power harrow?

- What is the most common type of fault?

- In the case of bearing failures, which are the most frequently affected?

- In the event of a failure, how much do you think the average down-time (time from failure to repair) is?

- In the most common cases of failure on a rotary harrow, how much do you think the repair costs will be? (Indicate an approximate cost or range of costs, from a minimum of... to a maximum of...).

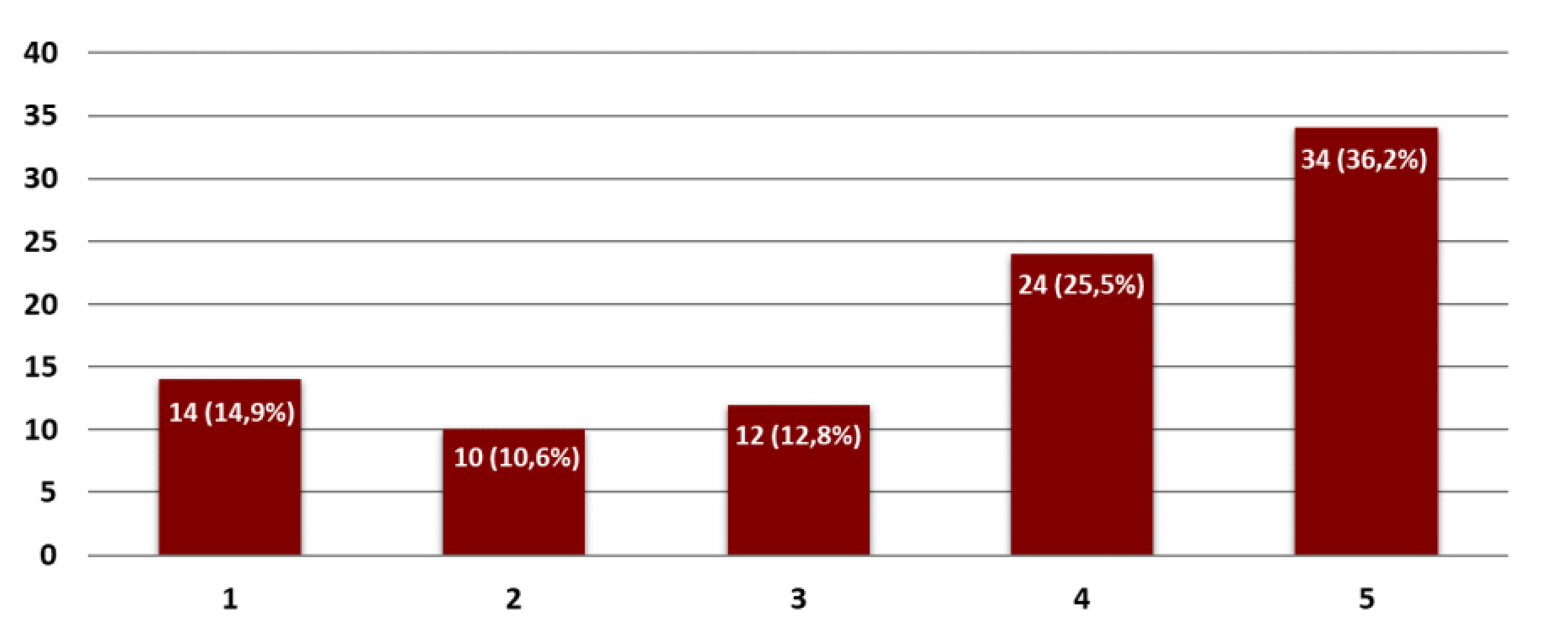

- On a scale of 1 (not at all useful) to 5 (fully useful), how important would it be for you to have on board a system that warns the driver in advance of a possible breakdown of the machine (detecting the first signs of deterioration of particular elements well in advance before actual breakdowns occur)?

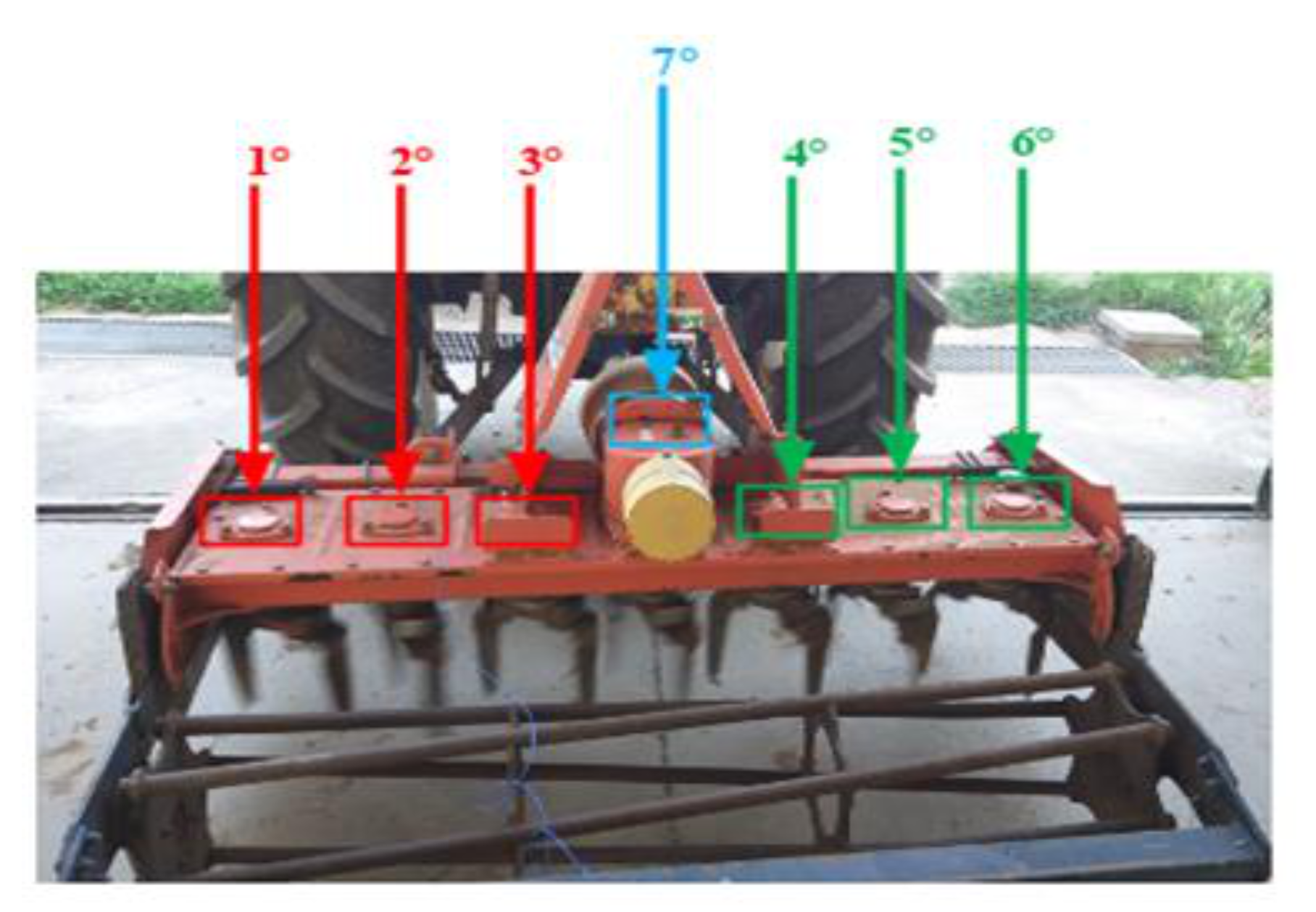

2.2. Description of Investigation Method for Bearing Failures in the Rotary Harrow

- Start-up of the instrument to measure the signal for the bearing being evaluated;

- Interruption of the measurement by the “pause” command;

- The shift of the accelerometer to the next bearing;

- Restart the measurement.

3. Results

3.1. Questionnaire Preliminary Investigation

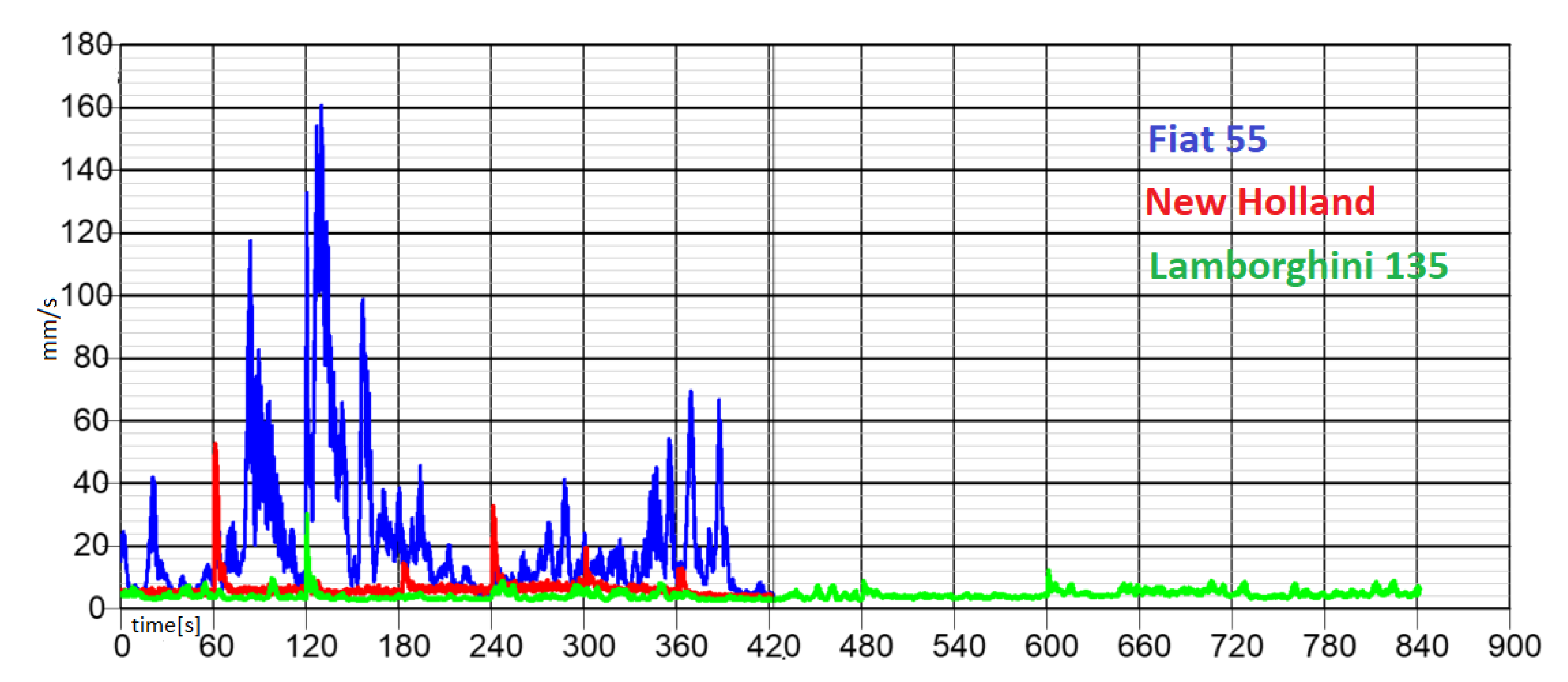

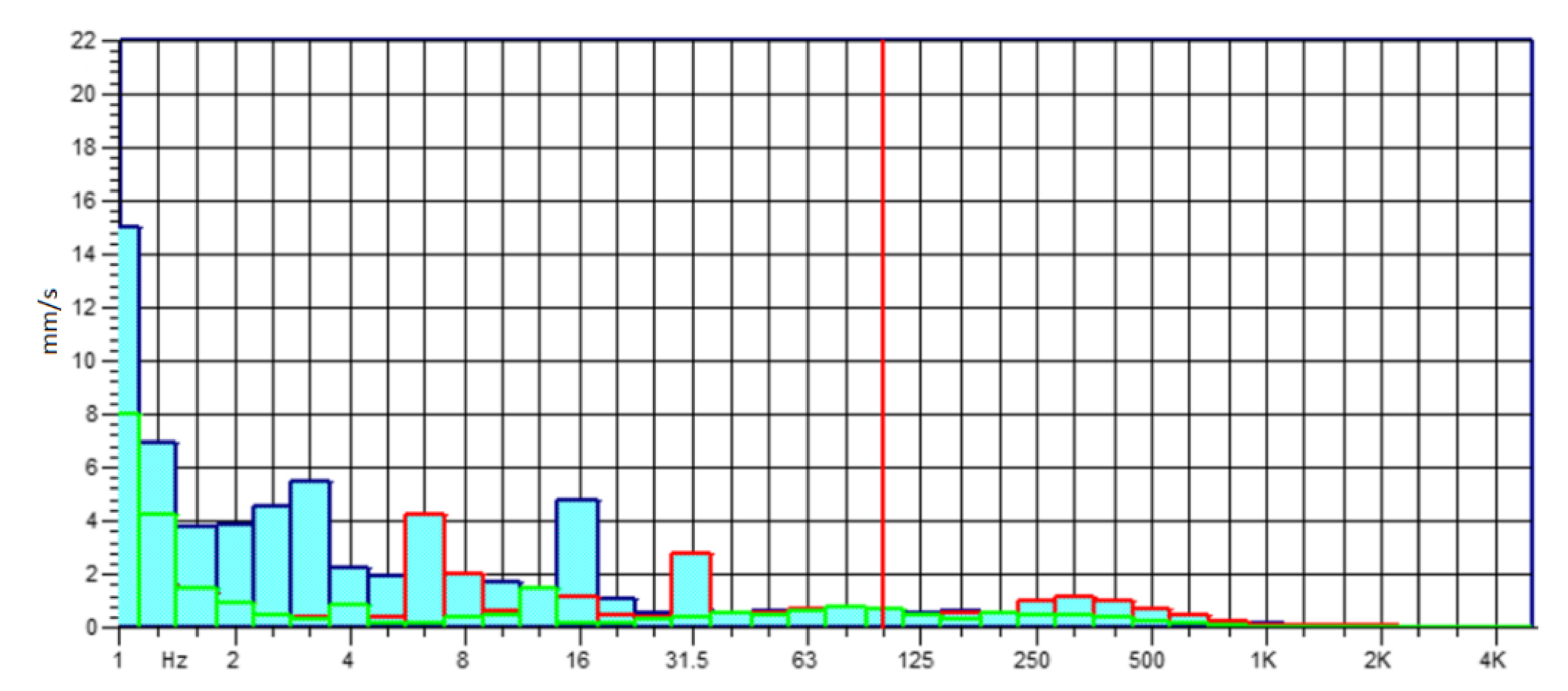

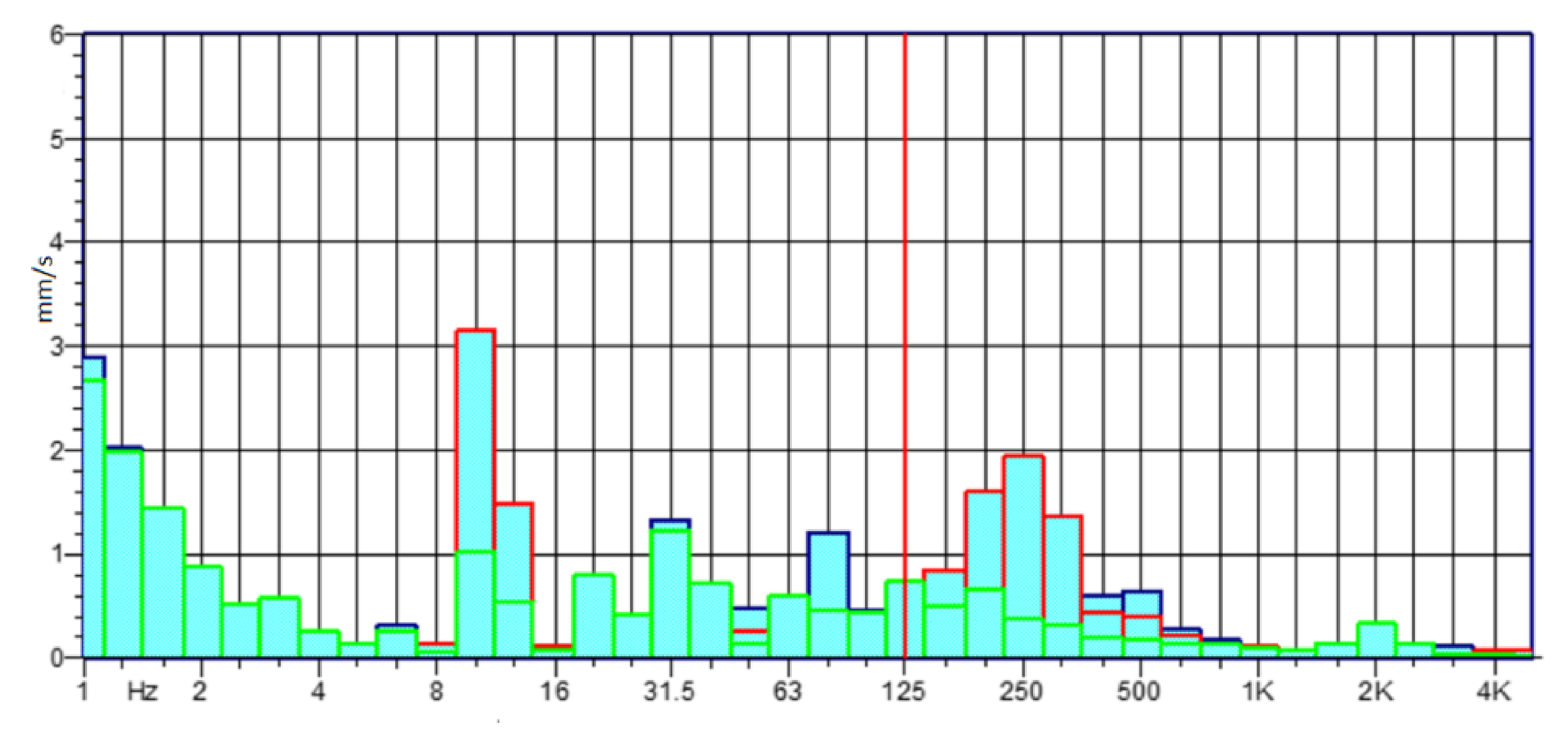

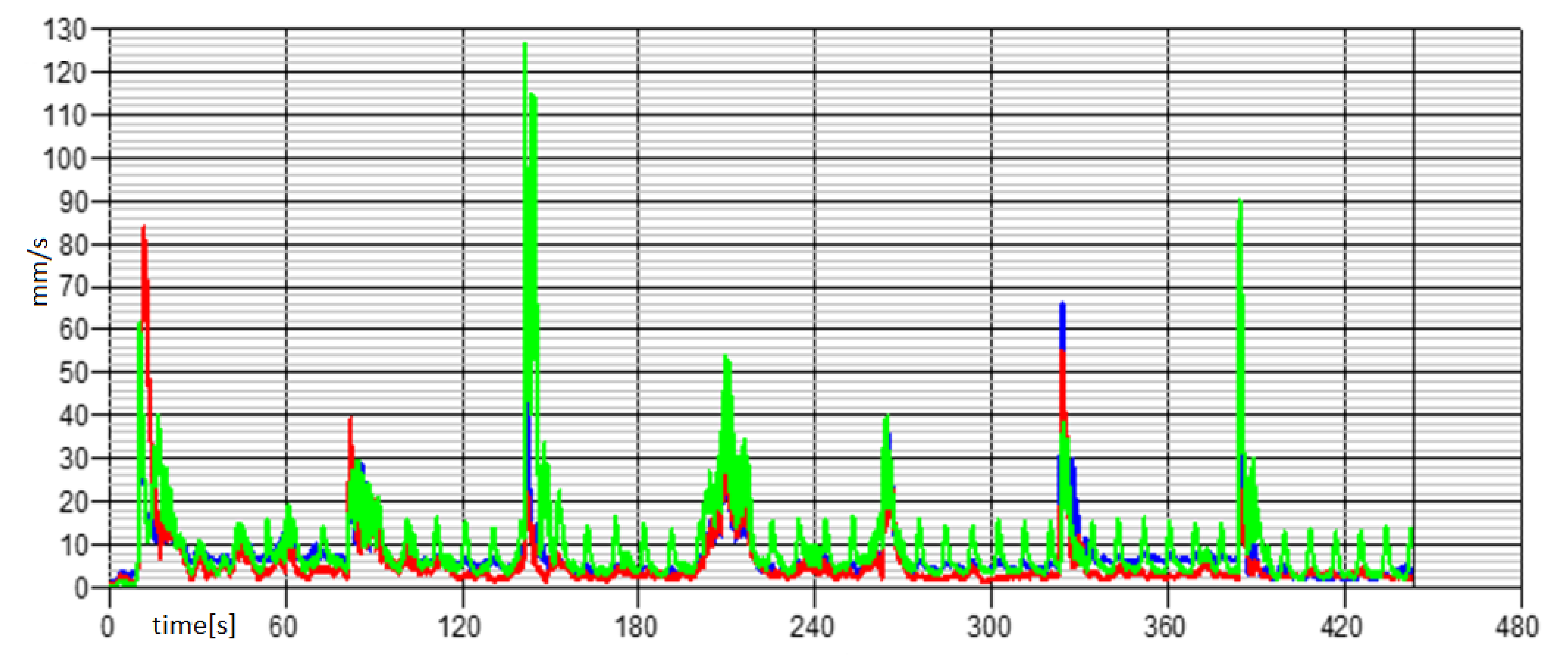

3.2. Experimental Investigation

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Mishra, C.; Samantaray, A.K.; Chakraborty, G. Rolling Element Bearing Defect Diagnosis under Variable Speed Operation through Angle Synchronous Averaging of Wavelet De-Noised Estimate. Mech. Syst. Signal. Process. 2016, 72, 206–222. [Google Scholar] [CrossRef]

- Sakai, T. Review and Prospects for Current Studies on Very High Cycle Fatigue of Metallic Materials for Machine Structural Use. J. Solid Mech. Mater. Eng. 2009, 3, 425–439. [Google Scholar] [CrossRef]

- Alfaro Degan, G.; Coltrinari, G.; Lippiello, D.; Pinzari, M. A comparison between methods for assessment of whole-body vibration exposure: A case study in a limestone quarry. Int. J. Saf. Secur. Eng. 2018, 8, 90–97. [Google Scholar] [CrossRef]

- Alfaro Degan, G.; Coltrinari, G.; Lippiello, D.; Pinzari, M. Risk assessment of the whole-body vibration exposure for drivers of armored vehicles: A case study. Int. J. Saf. Secur. Eng. 2016, 6, 53–62. [Google Scholar] [CrossRef]

- Thorsen, O.V.; Dalva, M. Failure Identification and Analysis for High-Voltage Induction Motors in the Petrochemical Industry. IEEE Trans. Ind. Appl. 1999, 35, 810–818. [Google Scholar] [CrossRef]

- Meyer, L.D.; Ahlgren, F.F.; Weichbrodt, B. An Analytic Model for Ball Bearing Vibrations to Predict Vibration Response to Distributed Defects. J. Mech. Des. 1980, 102, 205. [Google Scholar] [CrossRef]

- Marcantonio, V.; Monarca, D.; Colantoni, A.; Cecchini, M. Ultrasonic Waves for Materials Evaluation in Fatigue, Thermal and Corrosion Damage: A Review. Mech. Syst. Signal. Process. 2019, 120, 32–42. [Google Scholar] [CrossRef]

- Washo, M.W. A Quick Method of Determining Root Causes and Corrective Actions of Failed Ball Bearings. Lubric. Eng. 1996, 52, 206–213. [Google Scholar]

- Alfaro Degan, G.; Coltrinari, G.; Lippiello, D.; Pinzari, M. Effects of ground conditions on whole-body vibration exposure on cars: A case study of drivers of armored vehicles. WIT Trans. Built Environ. 2017, 176, 431–438. [Google Scholar]

- Alfaro Degan, G.; Antonucci, A.; Coltrinari, G.; Lippiello, D. Safety-oriented multi-task approach to manage whole-body vibration exposure among quarry operators. WIT Trans. Built Environ. 2019, 189, 43–53. [Google Scholar]

- Papa, M. Analysis of Agricultural Machinery to Reduce the Vibration to the Operator Seat. In Proceedings of the XXIV AIMETA Conference 2019, Rome, Italy, 15–19 September 2019; Springer Nature: New York, NY, USA, 2020; pp. 322–335. [Google Scholar]

- Cutini, M.; Brambilla, M.; Bisaglia, C. Whole-body vibration in farming: Background document for creating a simplified procedure to determine agricultural tractor vibration comfort. Agriculture 2017, 7, 84. [Google Scholar] [CrossRef]

- Nishio, K.; Hoshiya, S.; Miyachi, T.; Matsuki, M. An Investigation of the Early Detection of Defects in Ball Bearings by the Vibration Monitoring. ASME Press: New York, NY, USA, 1979; pp. 1–12. [Google Scholar]

- Tandon, N. A Comparison of Some Vibration Parameters for the Condition Monitoring of Rolling Element Bearings. Measurement 1994, 12, 285–289. [Google Scholar] [CrossRef]

- Tandon, N.; Nakra, B.C. Comparison of Vibration and Acoustic Measurement Techniques for the Condition Monitoring of Rolling Element Bearings. Tribol. Int. 1992, 25, 205–212. [Google Scholar] [CrossRef]

- Sun, L.; Luo, F.; Shang, T.; Chen, H.; Moro, A. Research on torsional vibration reduction of crankshaft in off-road diesel engine by simulation and experiment. J. Vibroeng. 2018, 20, 345–357. [Google Scholar]

- Heng, A.; Zhang, S.; Tan, A.C.C.; Mathew, J. Rotating Machinery Prognostics: State of the Art, Challenges and Opportunities. Mech. Syst. Signal. Process. 2009, 23, 724–739. [Google Scholar] [CrossRef]

- Yang, Y.; Wang, H.; Cheng, J.; Zhang, K. A Fault Diagnosis Approach for Roller Bearing Based on VPMCD under Variable Speed Condition. Measurement 2013, 46, 2306–2312. [Google Scholar] [CrossRef]

- Cantwell, W.J.; Morton, J. The Significance of Damage and Defects and Their Detection in Composite Materials: A Review. J. Strain Anal. Eng. Des. 1992, 27, 29–42. [Google Scholar] [CrossRef]

- Tandon, N.; Choudhury, A. A Review of Vibration and Acoustic Measurement Methods for the Detection of Defects in Rolling Element Bearings. Tribol. Int. 1999, 32, 469–480. [Google Scholar] [CrossRef]

- Boubezoul, A.; Koita, A.; Daucher, D. Vehicle Trajectories Classification Using Support Vectors Machines for Failure Trajectory Prediction. In Proceedings of the 2009 International Conference on Advances in Computational Tools for Engineering Applications, Beirut, Lebanon, 15–17 September 2009; IEEE: New York, NY, USA, 2009; pp. 486–491. [Google Scholar]

- Farrar, C.R.; Doebling, S.W.; Nix, D.A. Vibration–Based Structural Damage Identification. Philos. Trans. R. Soc. Lond. Ser. A Math. Phys. Eng. Sci. 2001, 359, 131–149. [Google Scholar] [CrossRef]

- Zoltewicz, J.S.; Mondello, S.; Yang, B.; Newsom, K.J.; Kobeissy, F.; Yao, C.; Lu, X.-C.M.; Dave, J.R.; Shear, D.A.; Schmid, K.; et al. Biomarkers Track Damage after Graded Injury Severity in a Rat Model of Penetrating Brain Injury. J. Neurotrauma 2013, 30, 1161–1169. [Google Scholar] [CrossRef] [PubMed]

- Basseville, M.; Benveniste, A.; Gach-Devauchelle, B.; Goursat, M.; Bonnecase, D.; Dorey, P.; Prevosto, M.; Olagnon, M. In Situ Damage Monitoring in Vibration Mechanics: Diagnostics and Predictive Maintenance. Mech. Syst. Signal Process. 1993, 7, 401–423. [Google Scholar] [CrossRef]

- Jin, X.; Chen, K.; Ji, J.; Zhao, K.; Du, X.; Ma, H. Intelligent vibration detection and control system of agricultural machinery engine. Measurement 2019, 145, 503–510. [Google Scholar] [CrossRef]

- Zeng, X.; Kociolek, A.M.; Khan, M.I.; Milosavljevic, S.; Bath, B.; Trask, C. Whole body vibration exposure patterns in Canadian prairie farmers. Ergonomics 2017, 60, 1064–1073. [Google Scholar] [CrossRef] [PubMed]

| Tractor | Mass (kg) | Motor Torque (Nm) | Engine Power (kW) |

|---|---|---|---|

| Fiat 55l | 2925 | 176.0 | 41 |

| New Holland TLK75FA 2005 | 4150 | 322.0 | 63 |

| Lamborghini 135 | 6100 | 597.1 | 100 |

| Tractor | Engine Speed | Bearing | ||||||

|---|---|---|---|---|---|---|---|---|

| 1° | 2° | 3° | 4° | 5° | 6° | 7° | ||

| Fiat 55l | 600 rpm | 8.55 | 11.52 | 24.09 | 15.92 | 10.61 | 9.95 | 13.02 |

| Fiat 55l | 600 rpm | 16 | 16 | 16 | 16 | 16 | 16 | 16 |

| Fiat 55l | 1000 rpm | 10.78 | 23.44 | 40.48 | 10.24 | 10.17 | 12.74 | 14.08 |

| Fiat 55l | 1000 rpm | 25 | 16 | 12.5 | 12.5 | 12.5 | 12.5 | 12.5 |

| Fiat 55l | 1500 rpm | 3.38 | 3.62 | 3.55 | 2.49 | 2.83 | 2.89 | 2.04 |

| Fiat 55l | 1500 rpm | 6.3 | 25 | 25 | 315 | 250 | 6.3 | 160 |

| Fiat 55l | 2000 rpm | 9.7 | 5.86 | 5.40 | 3.31 | 3.57 | 3.88 | 4.43 |

| Fiat 55l | 2000 rpm | 31.5 | 31.5 | 31.5 | 31.5 | 31.5 | 31.5 | 31.5 |

| New Holland TLK75FA 2005 | 600 rpm | 6.11 | 5.02 | 4.48 | 4.46 | 5.96 | 7.27 | 4.89 |

| New Holland TLK75FA 2005 | 600 rpm | 6.3 | 6.3 | 6.3 | 31.5 | 6.3 | 6.3 | 6.3 |

| New Holland TLK75FA 2005 | 1000 rpm | 4.40 | 5.035 | 3.173 | 4.30 | 4.687 | 4.816 | 3.74 |

| New Holland TLK75FA 2005 | 1000 rpm | 2.5 | 2.5 | 2.5 | 2.5 | 2.5 | 2.5 | 2.5 |

| New Holland TLK75FA 2005 | 1500 rpm | 5.59 | 5.48 | 4.19 | 4.65 | 5.29 | 5.44 | 5.46 |

| New Holland TLK75FA 2005 | 1500 rpm | 25 | 25 | 63 | 25 | 25 | 25 | 25 |

| New Holland TLK75FA 2005 | 2000 rpm | 6.00 | 4.98 | 8.63 | 9.67 | 9.98 | 8.85 | 10.12 |

| New Holland TLK75FA 2005 | 2000 rpm | 31.5 | 31.5 | 31.5 | 31.5 | 31.5 | 31.5 | 31.5 |

| Lamborghini 135 | 600 rpm | 3.45 | 2.93 | 6.12 | 2.79 | 8.47 | 3.32 | 4.45 |

| Lamborghini 135 | 600 rpm | 12.5 | 12.5 | 80 | 100 | 125 | 12.5 | 4 |

| Lamborghini 135 | 1000 rpm | 3.12 | 3.11 | 3.46 | 2.90 | 3.25 | 4.03 | 3.21 |

| Lamborghini 135 | 1000 rpm | 10 | 100 | 80 | 100 | 12.5 | 12.5 | 250 |

| Lamborghini 135 | 1500 rpm | 415.98 | 5.30 | 8.27 | 3.53 | 3.79 | 5.06 | 3.84 |

| Lamborghini 135 | 1500 rpm | 25 | 25 | 25 | 100 | 125 | 315 | 250 |

| Lamborghini 135 | 2000 rpm | 5.68 | 6.58 | 5.87 | 4.20 | 5.34 | 5.10 | 5.81 |

| Lamborghini 135 | 2000 rpm | 10 | 10 | 10 | 10 | 125 | 10 | 10 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cecchini, M.; Piccioni, F.; Ferri, S.; Coltrinari, G.; Bianchini, L.; Colantoni, A. Preliminary Investigation on Systems for the Preventive Diagnosis of Faults on Agricultural Operating Machines. Sensors 2021, 21, 1547. https://doi.org/10.3390/s21041547

Cecchini M, Piccioni F, Ferri S, Coltrinari G, Bianchini L, Colantoni A. Preliminary Investigation on Systems for the Preventive Diagnosis of Faults on Agricultural Operating Machines. Sensors. 2021; 21(4):1547. https://doi.org/10.3390/s21041547

Chicago/Turabian StyleCecchini, Massimo, Francesca Piccioni, Serena Ferri, Gianluca Coltrinari, Leonardo Bianchini, and Andrea Colantoni. 2021. "Preliminary Investigation on Systems for the Preventive Diagnosis of Faults on Agricultural Operating Machines" Sensors 21, no. 4: 1547. https://doi.org/10.3390/s21041547

APA StyleCecchini, M., Piccioni, F., Ferri, S., Coltrinari, G., Bianchini, L., & Colantoni, A. (2021). Preliminary Investigation on Systems for the Preventive Diagnosis of Faults on Agricultural Operating Machines. Sensors, 21(4), 1547. https://doi.org/10.3390/s21041547