A Review on Humidity, Temperature and Strain Printed Sensors—Current Trends and Future Perspectives

Abstract

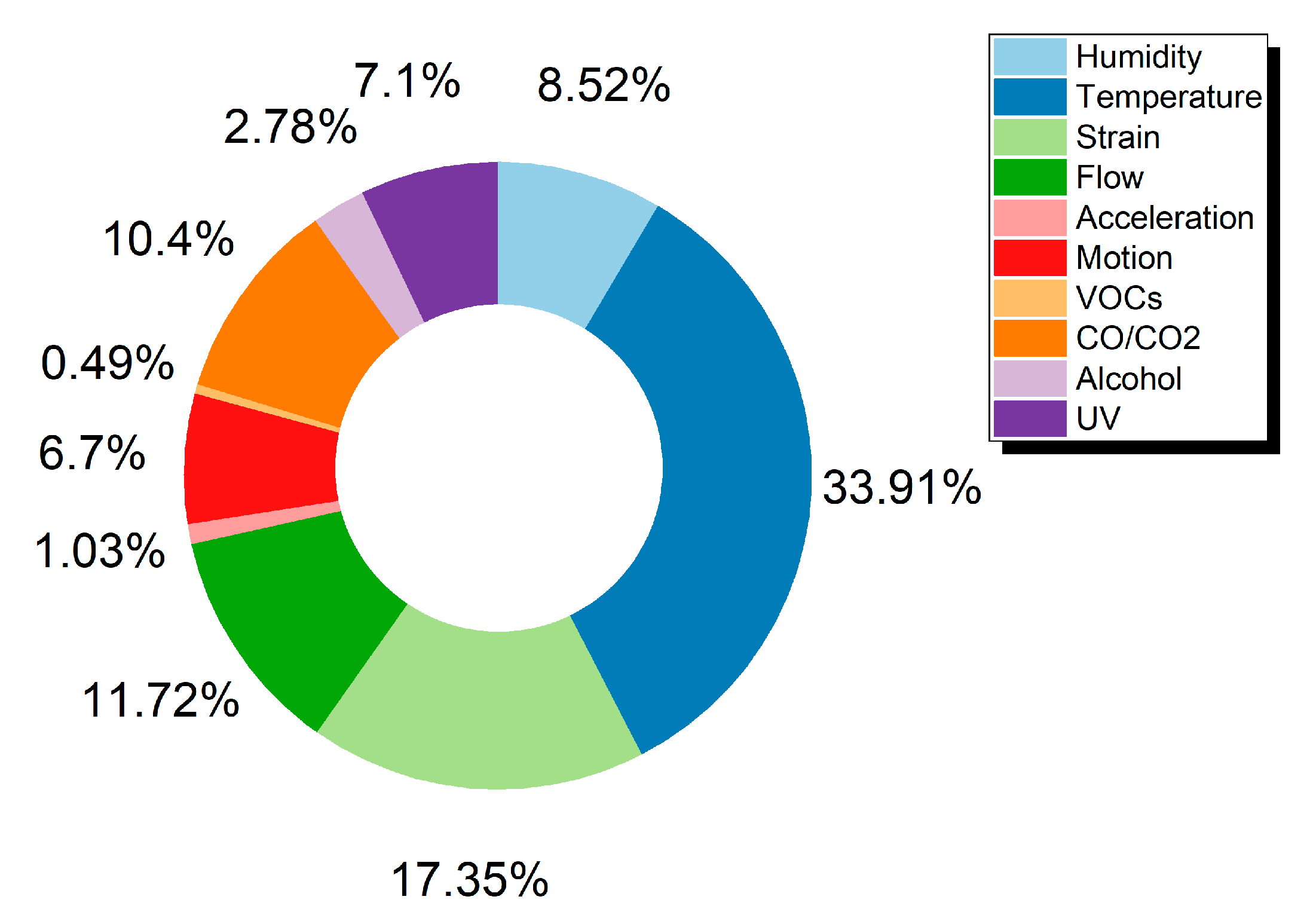

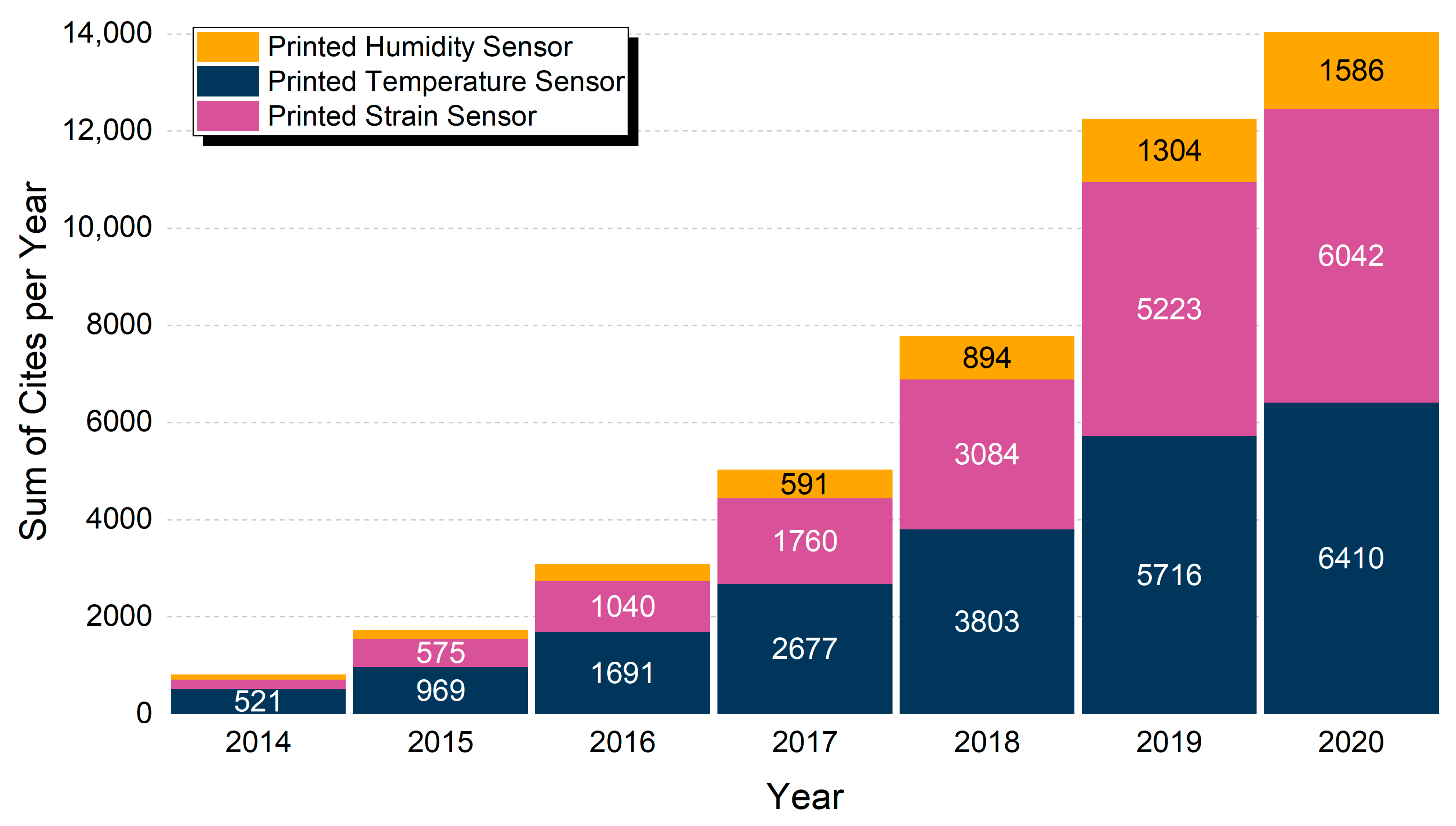

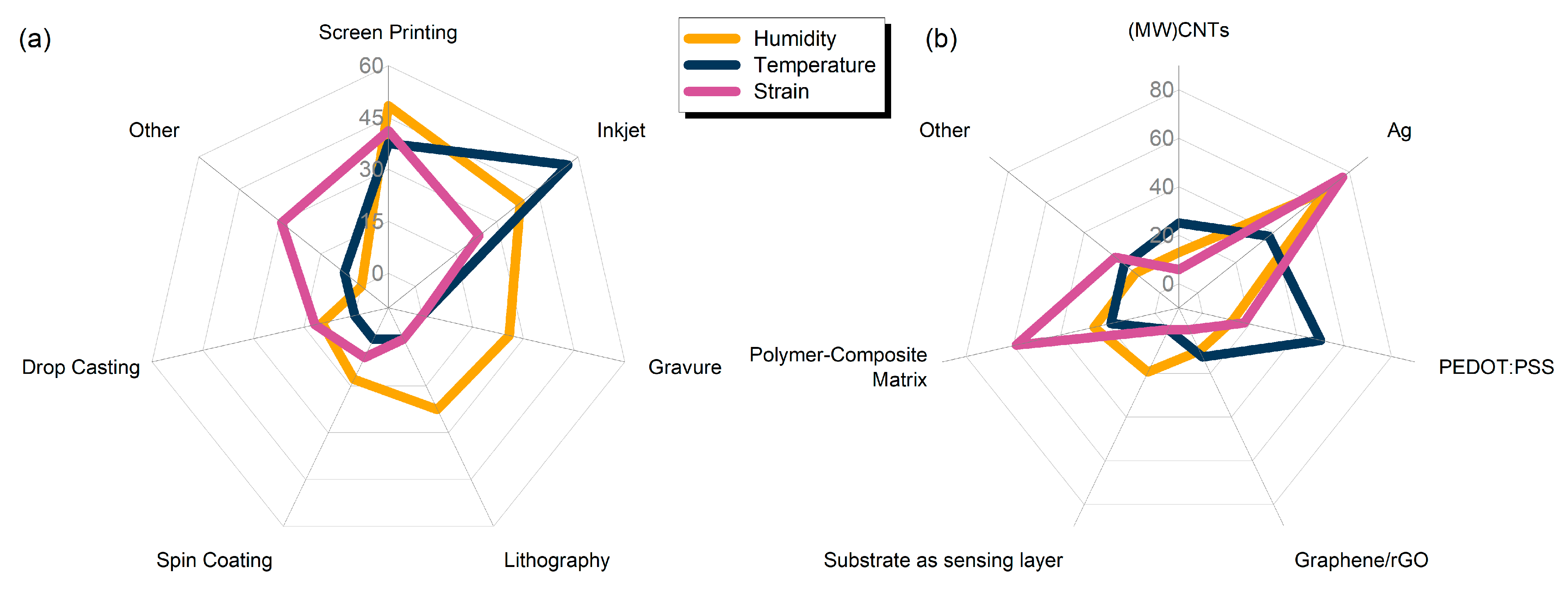

1. Introduction

- IoT: Optimized maintenance of buildings, smart labels for logistics, environmental monitoring, sensors for material monitoring, energy management, autonomous sensors, heating elements.

- Healthcare: Medical packages, patches for therapy and monitoring, biomarker diagnosis, OLEDs, smart wound treatment

- Automotive: OLED lighting, flexible and OLED displays for mirrors and HMI (Human-Machine Interface), sensors.

- Consumer electronics: Flexible displays and sensors, curved touch surfaces with sensors, smart wearables, memories, batteries, RFID tags.

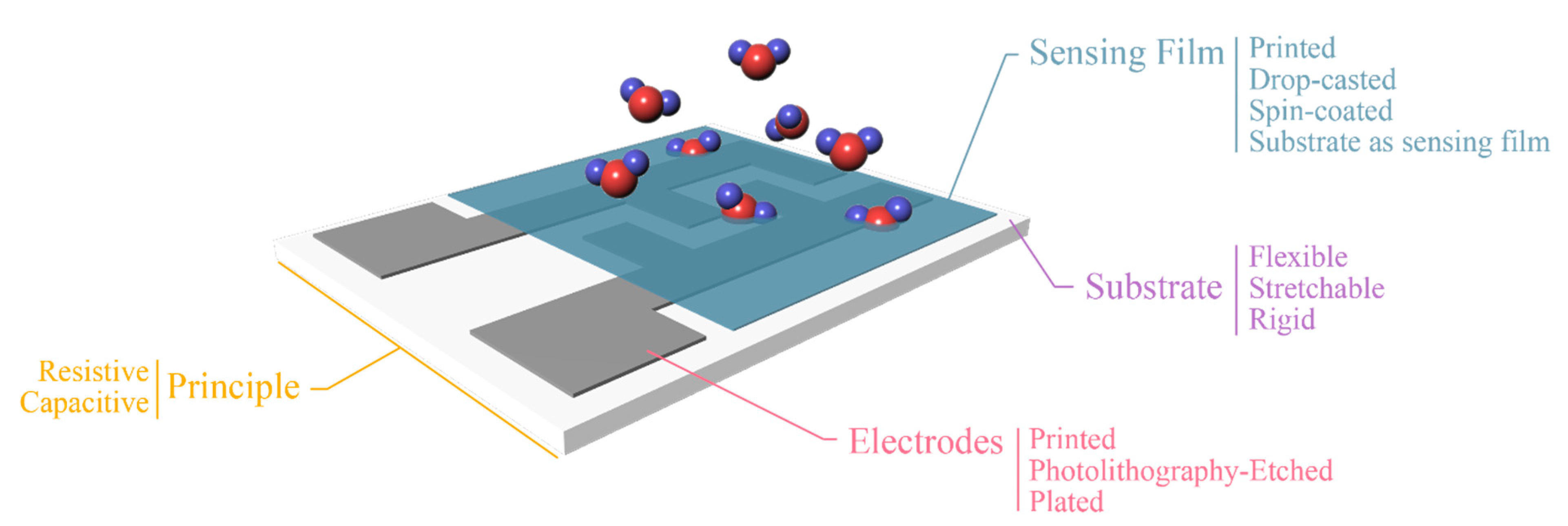

2. Printed Humidity Sensors

2.1. Resistive Printed Humidity Sensors

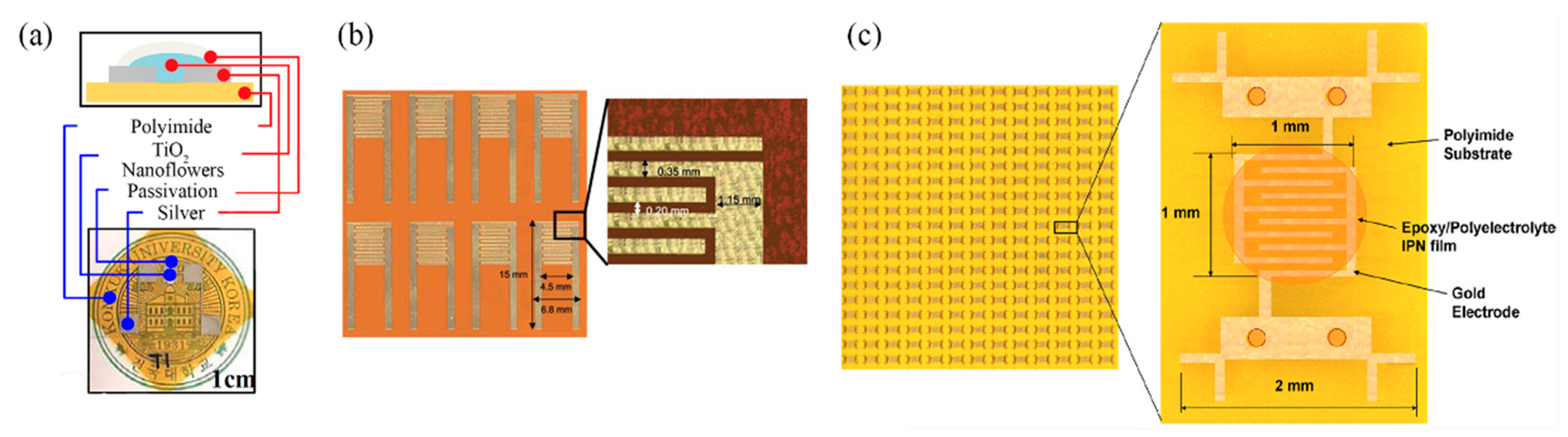

2.1.1. Kapton—Based Resistive Humidity Sensors

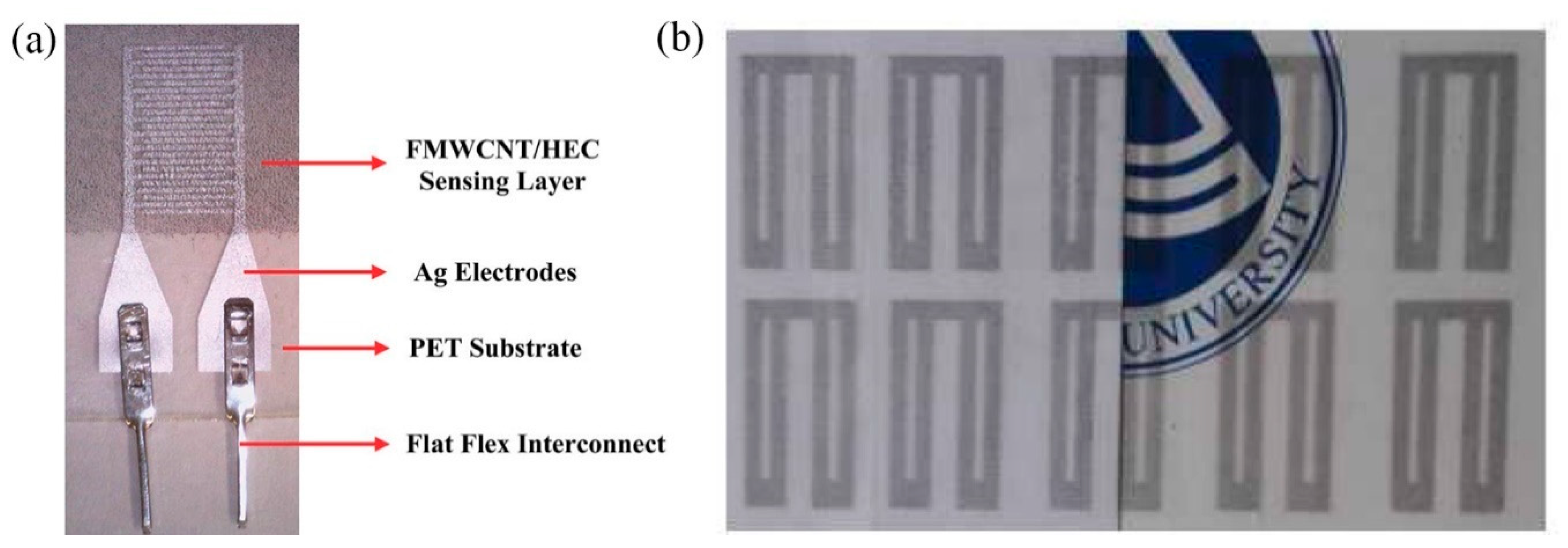

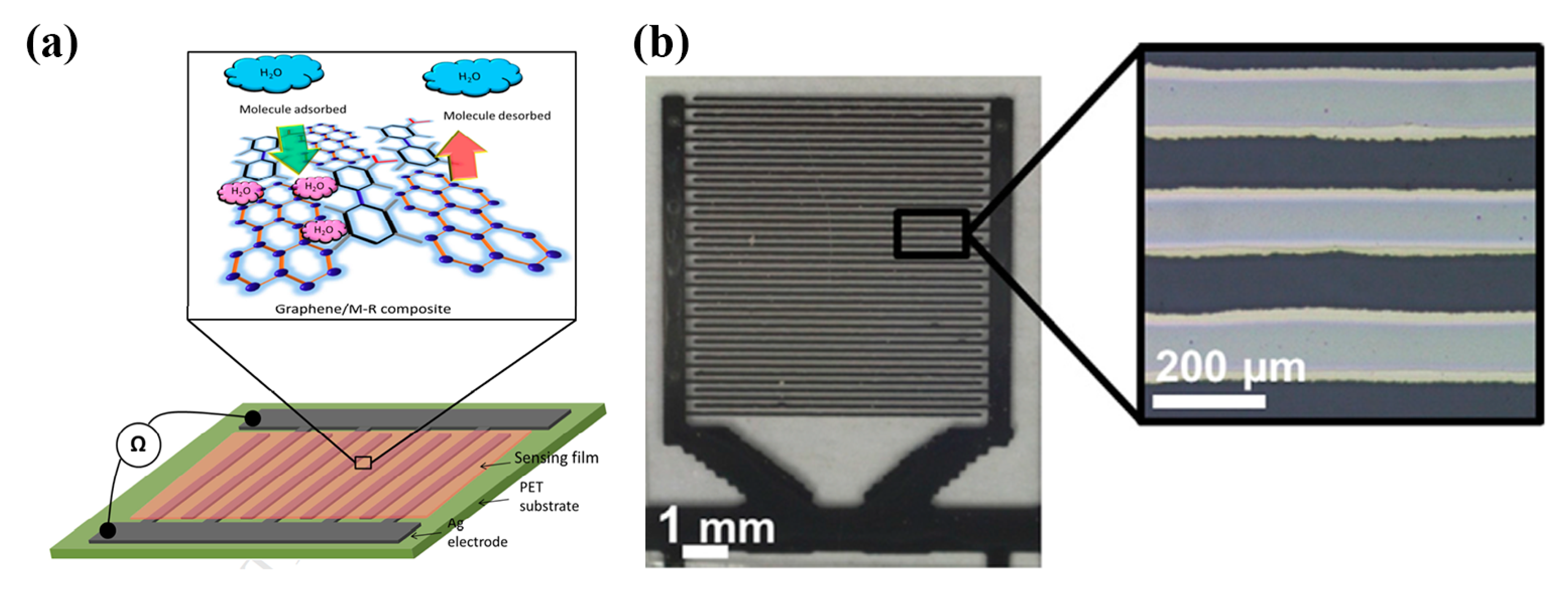

2.1.2. PET—Based Resistive Humidity Sensors

2.1.3. Resistive Humidity Sensors on Other Substrates

2.1.4. Resistive Humidity Sensors Comparison

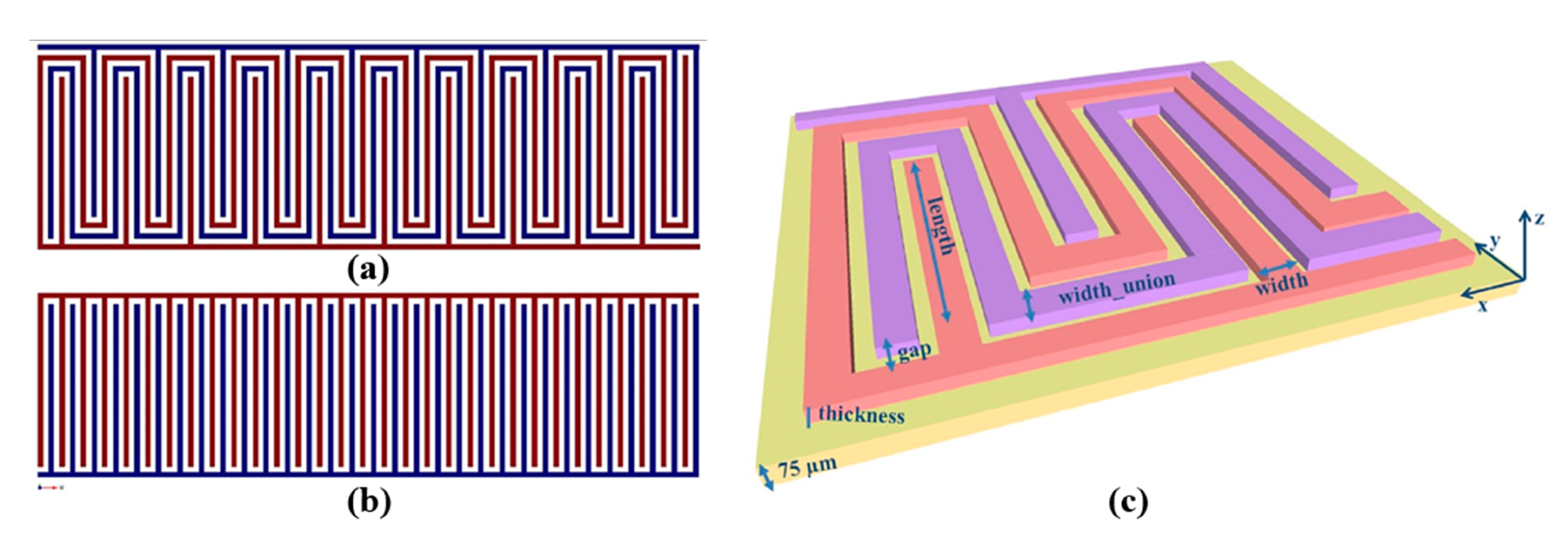

2.2. Capacitive Printed Humidity Sensors

2.2.1. Kapton—Based Capacitive Printed Humidity Sensors

2.2.2. PET—Based Capacitive Printed Humidity Sensors

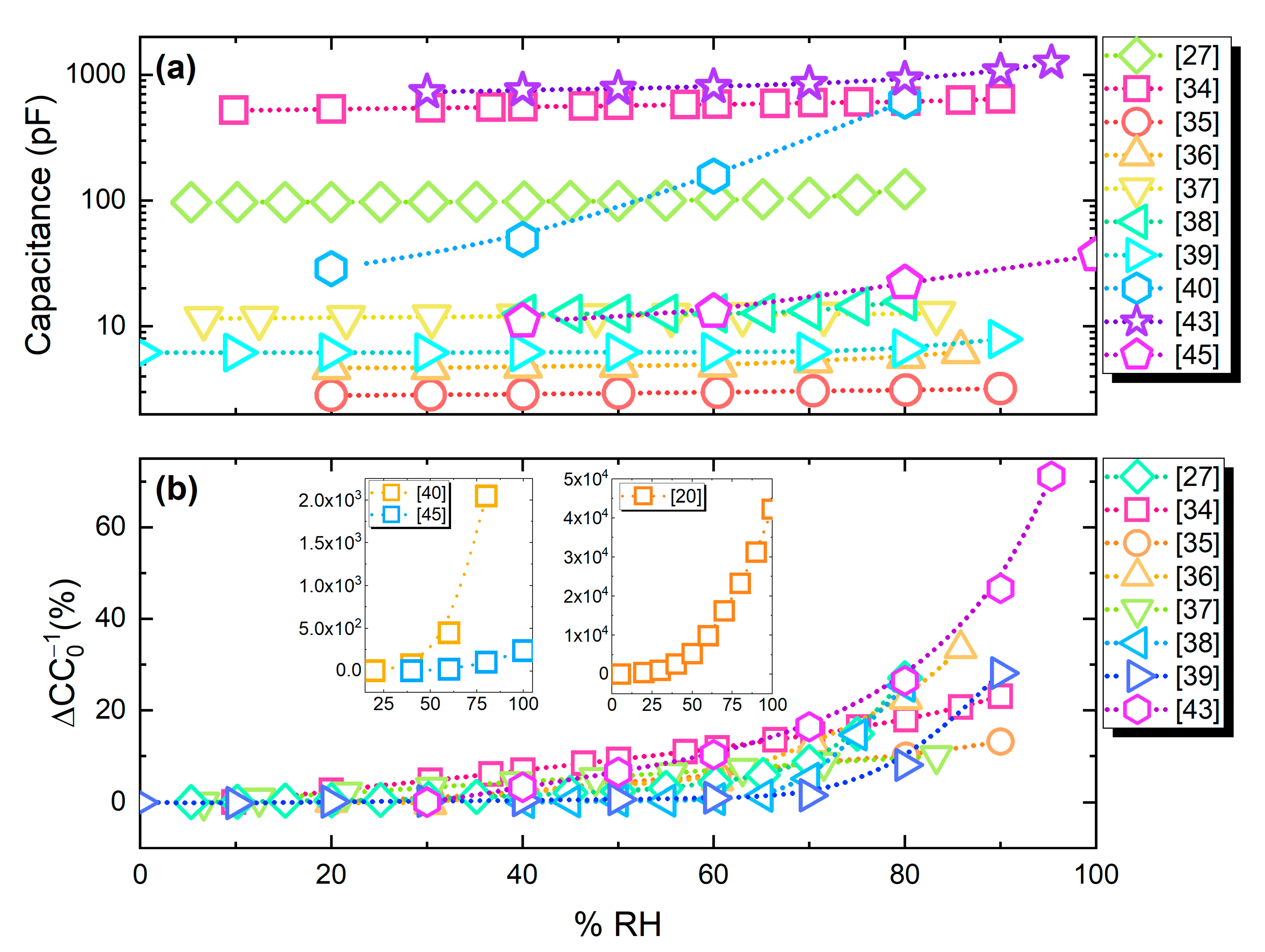

2.2.3. Capacitive Humidity Sensors Comparison

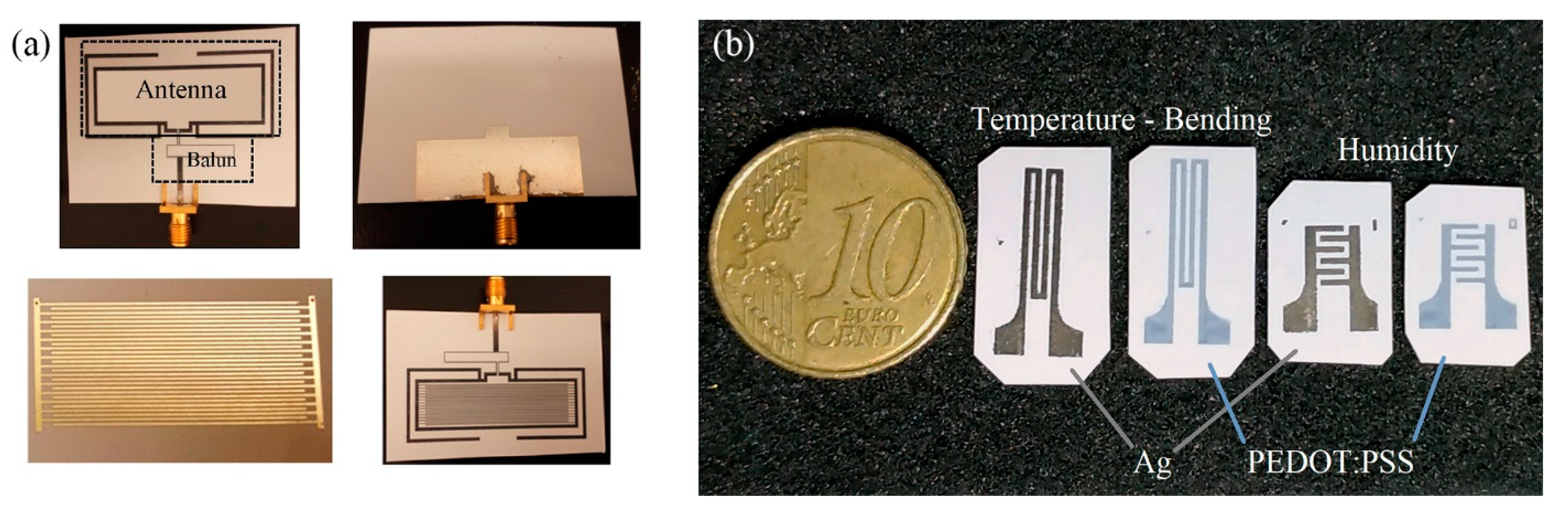

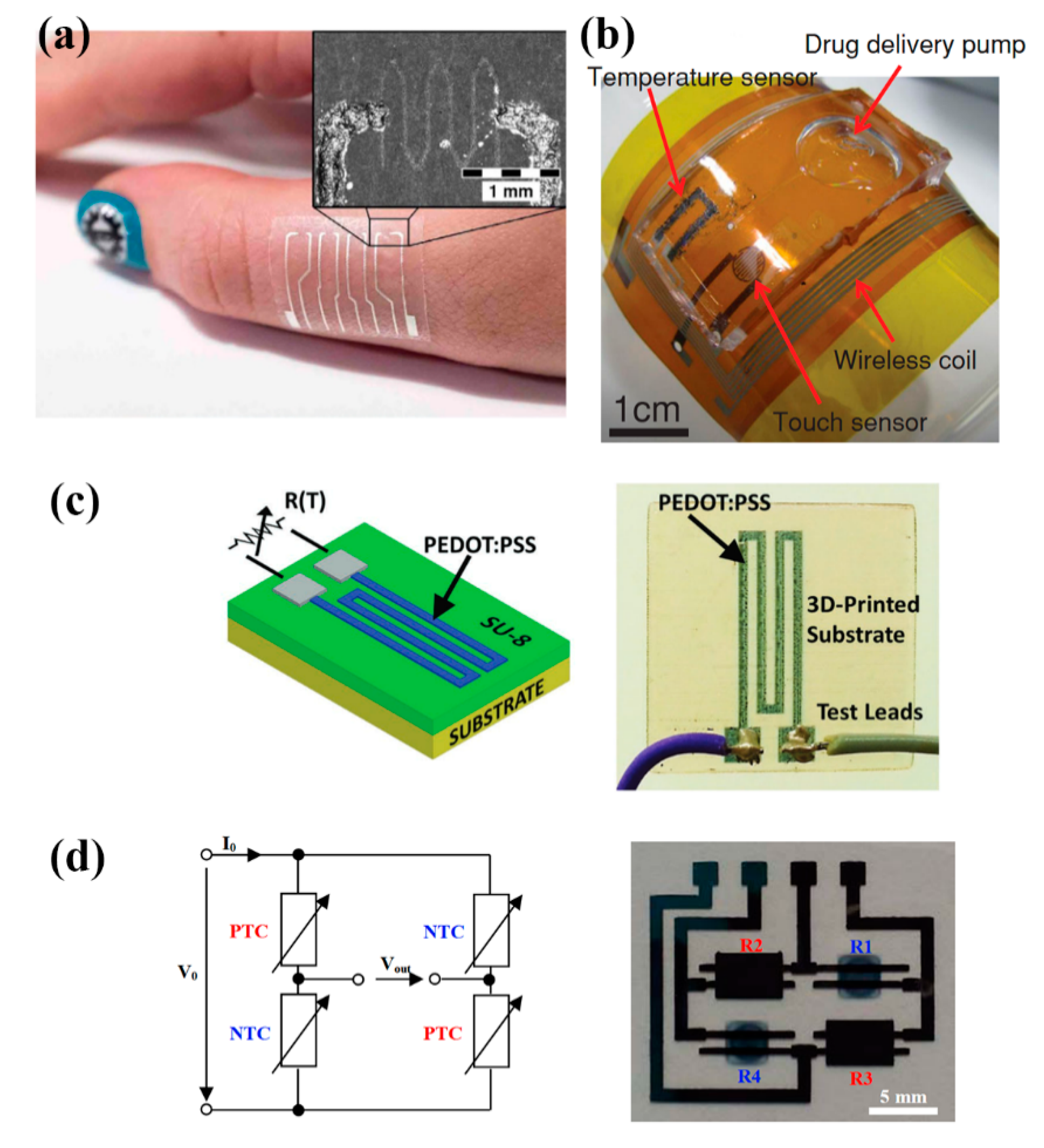

3. Printed Temperature Sensors

3.1. Printed Temperature Sensors Based on PEDOT:PSS

3.2. Printed Temperature Sensors Based on Ag

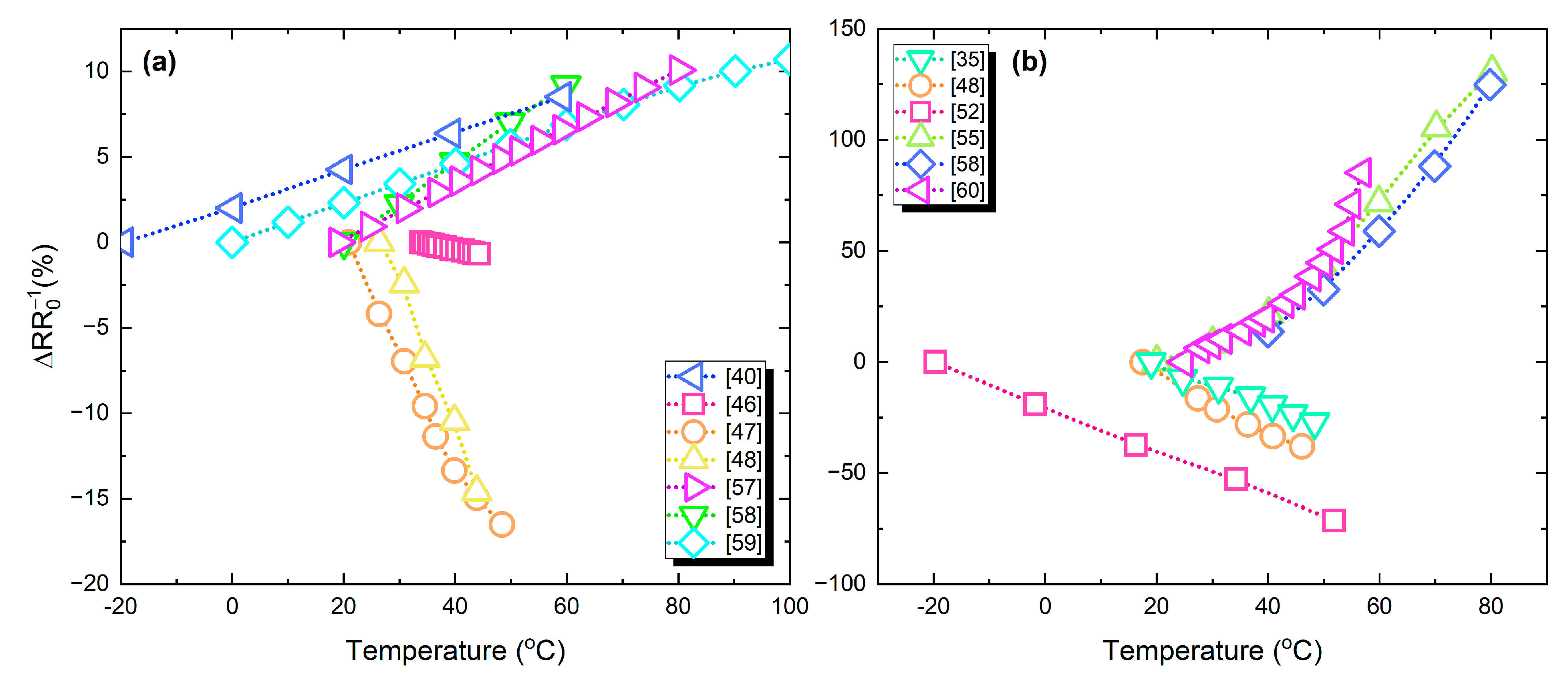

3.3. Printed Temperature Sensors Comparison

4. Printed Strain—Bending Sensors

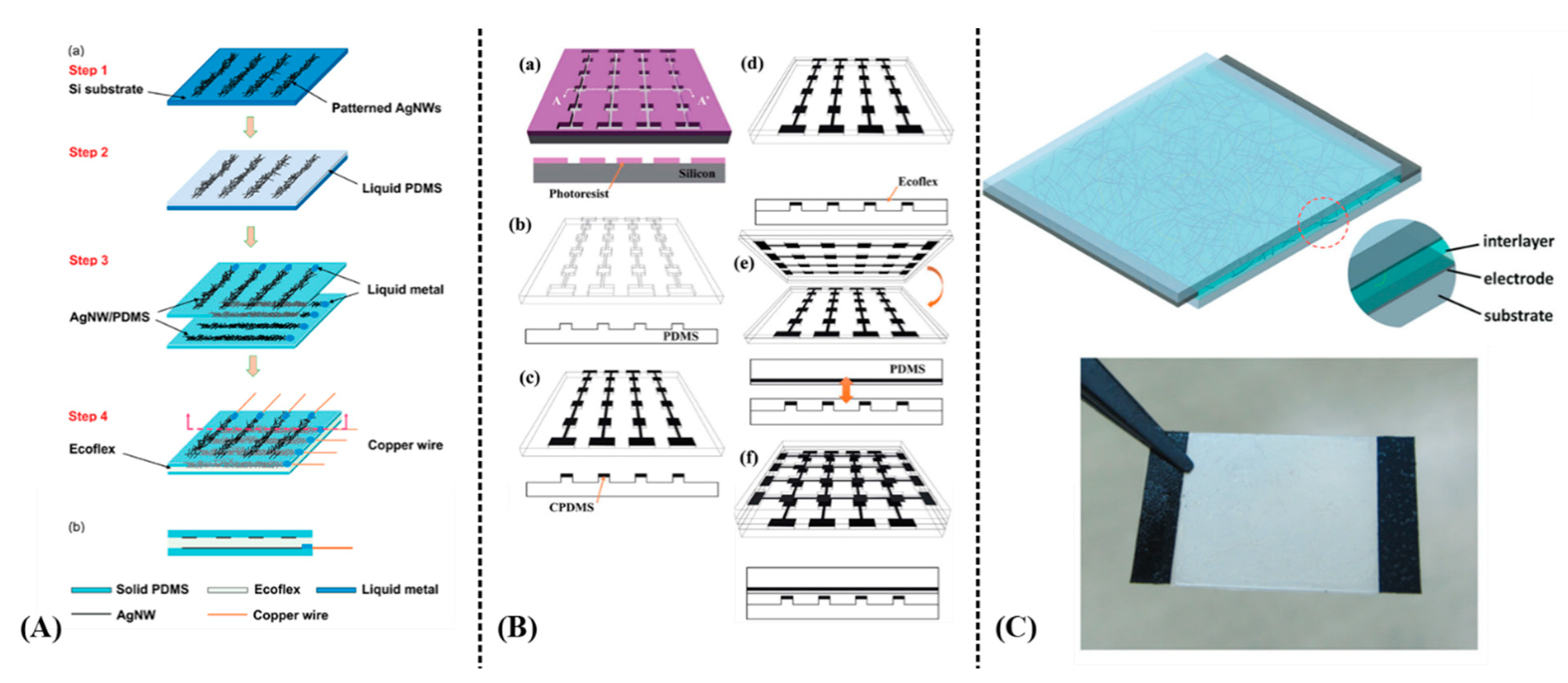

4.1. Capacitive Printed Strain—Bending Sensors

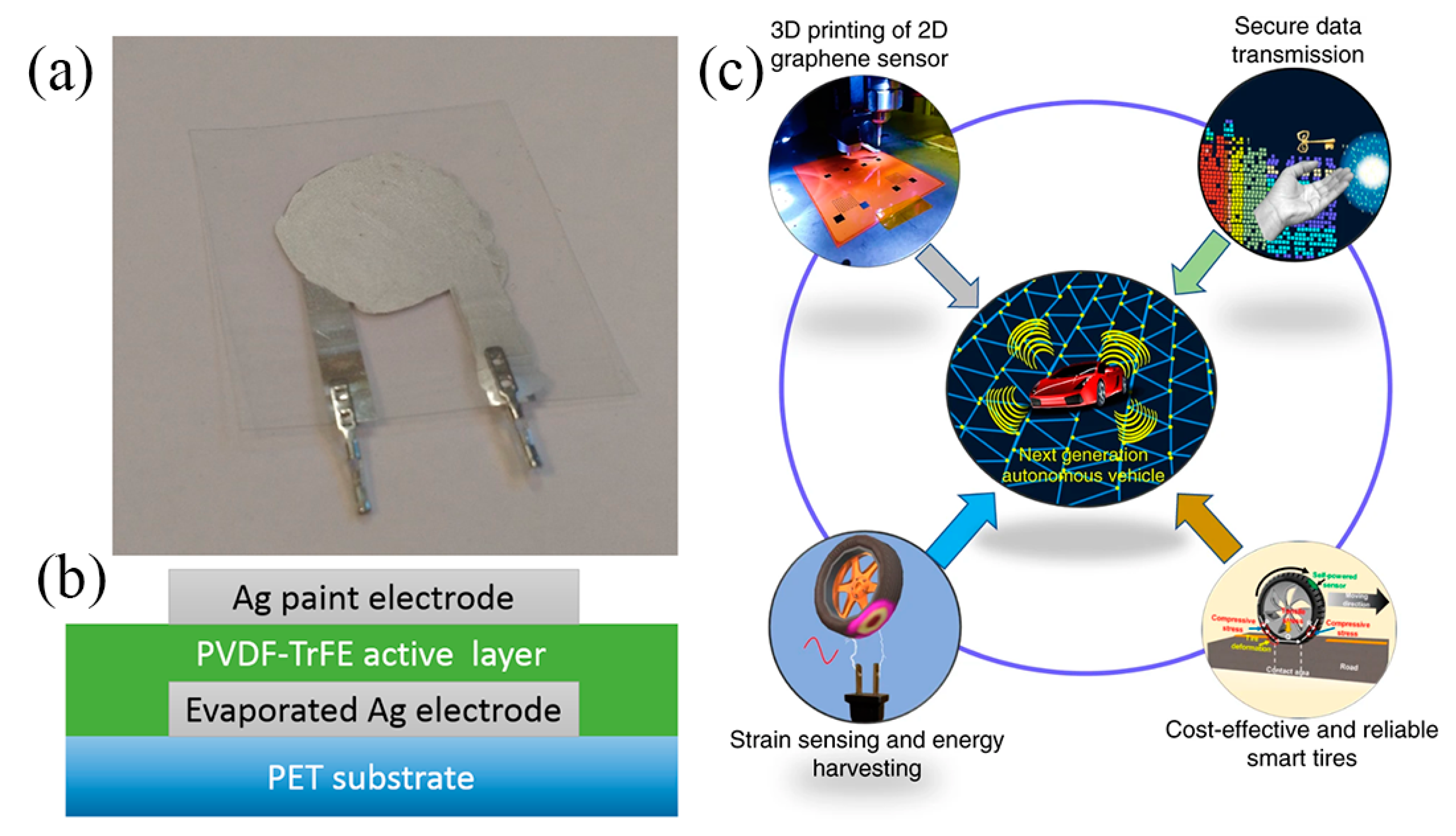

4.2. Piezoelectric Printed Strain—Bending Sensors

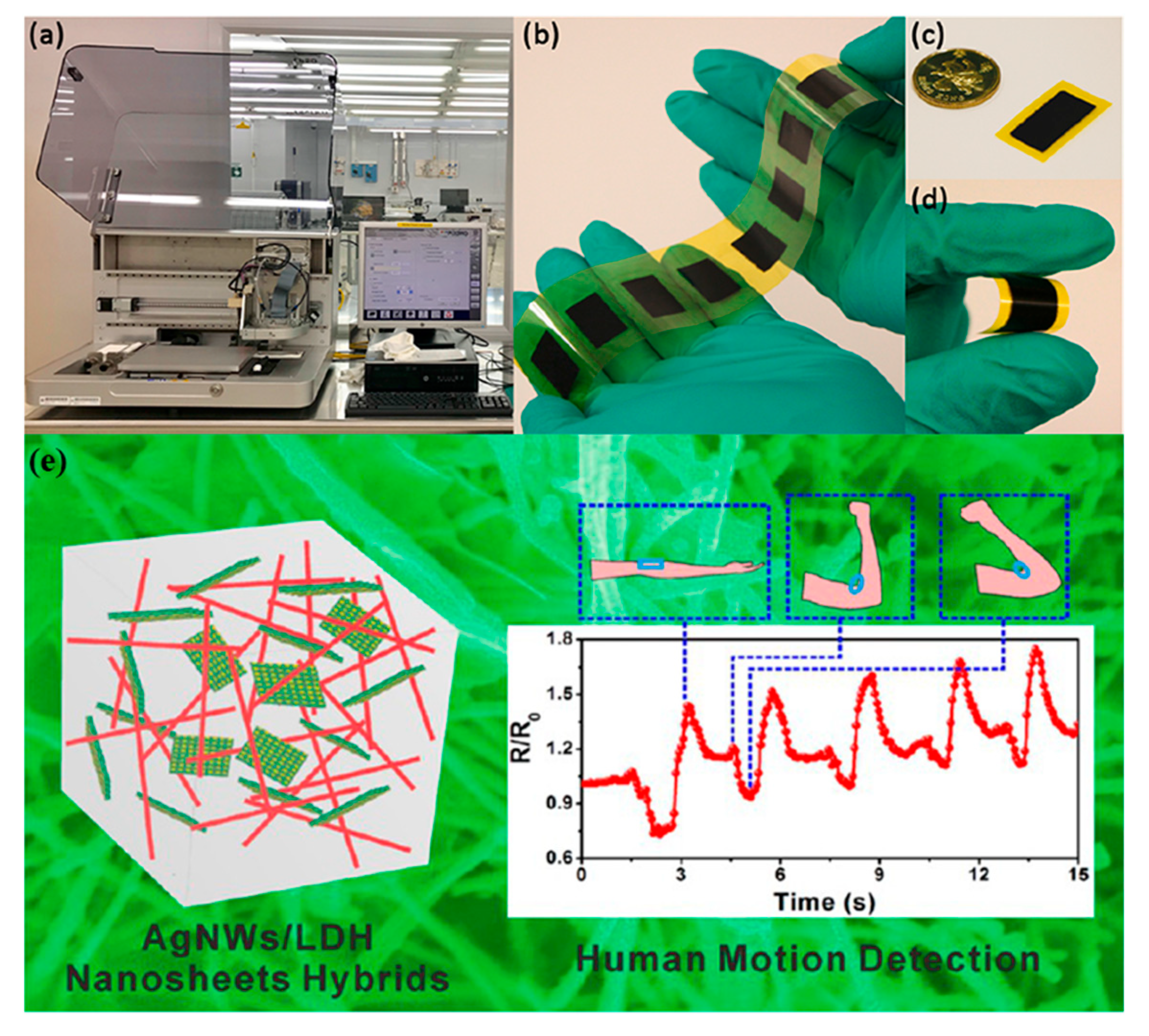

4.3. Piezoresistive Printed Strain—Bending Sensors

4.4. Comparison of Printed Strain—Bending Sensors

5. Conclusions—Future Outlook

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Farahani, H.; Wagiran, R.; Hamidon, M.N. Humidity Sensors Principle, Mechanism, and Fabrication Technologies: A Comprehensive Review. Sensors 2014, 14, 7881–7939. [Google Scholar] [CrossRef] [PubMed]

- Kuzubasoglu, B.A.; Bahadir, S.K. Flexible temperature sensors: A review. Sens. Actuators A Phys. 2020, 315, 112282. [Google Scholar] [CrossRef]

- Amjadi, M.; Kyung, K.-U.; Park, I.; Sitti, M. Stretchable, Skin-Mountable, and Wearable Strain Sensors and Their Potential Applications: A Review. Adv. Funct. Mater. 2016, 26, 1678–1698. [Google Scholar] [CrossRef]

- Cui, Z. Printed Electronics: Materials, Technologies and Applications; John Wiley & Sons Singapore Pte. Ltd.: Singapore, 2016; ISBN 978-1-118-92095-4. [Google Scholar]

- Suganuma, K. Introduction to Printed Electronics. In Springer Briefs in Electrical and Computer Engineering; Springer: New York, NY, USA, 2014; Volume 74, ISBN 978-1-4614-9624-3. [Google Scholar]

- Lupo, D.; Ranfeld, C. OE-A Roadmap for Organic and Printed Electronics Applications. In Applications of Organic and Printed Electronics; Springer: Boston, MA, USA, 2017. [Google Scholar]

- Martín-Martín, A.; Orduna-Malea, E.; Thelwall, M.; López-Cózar, E.D. Google Scholar, Web of Science, and Scopus: A systematic comparison of citations in 252 subject categories. J. Inf. 2018, 12, 1160–1177. [Google Scholar] [CrossRef]

- Chansin, G. Printed and Flexible Sensors 2015–2025: Technologies, Players, Forecasts. Technologies Repoter. 2015. Available online: https://www.idtechex.com/en/research-report/printed-and-flexible-sensors-2015-2025-technologies-players-forecasts/428 (accessed on 26 December 2020).

- Dubourg, G.; Segkos, A.; Katona, J.; Radović, M.; Savić, S.; Niarchos, G.; Tsamis, C.; Crnojevic-Bengin, V. Fabrication and Characterization of Flexible and Miniaturized Humidity Sensors Using Screen-Printed TiO2 Nanoparticles as Sensitive Layer. Sensors 2017, 17, 1854. [Google Scholar] [CrossRef]

- Zhang, X.; Turkani, V.S.; Hajian, S.; Bose, A.K.; Maddipatla, D.; Hanson, A.J.; Narakathu, B.B.; Atashbar, M.Z. Novel Printed Carbon Nanotubes Based Resistive Humidity Sensors. In Proceedings of the 2019 IEEE International Conference on Flexible and Printable Sensors and Systems (FLEPS), Glasgow, Scotland, 8 July 2019; pp. 1–3. [Google Scholar]

- Virtanen, J.; Ukkonen, L.; Bjorninen, T.; Sydanheimo, L. Printed humidity sensor for UHF RFID systems. In Proceedings of the 2010 IEEE Sensors Applications Symposium (SAS), Limerick, Ireland, 23–25 February 2010; pp. 269–272. [Google Scholar]

- Quddious, A.; Yang, S.; Khan, M.M.; Tahir, F.A.; Shamim, A.; Salama, K.N.; Cheema, H.M. Disposable, Paper-Based, Inkjet-Printed Humidity and H2S Gas Sensor for Passive Sensing Applications. Sensors 2016, 16, 2073. [Google Scholar] [CrossRef]

- Zhang, X.; Maddipatla, D.; Bose, A.K.; Hajian, S.; Narakathu, B.B.; Williams, J.D.; Mitchell, M.F.; Atashbar, M. Printed Carbon Nanotubes-Based Flexible Resistive Humidity Sensor. IEEE Sens. J. 2020, 20, 12592–12601. [Google Scholar] [CrossRef]

- Jeong, H.; Noh, Y.; Lee, D. Highly stable and sensitive resistive flexible humidity sensors by means of roll-to-roll printed electrodes and flower-like TiO2 nanostructures. Ceram. Int. 2019, 45, 985–992. [Google Scholar] [CrossRef]

- Kim, M.-J.; Gong, M.-S. Water-resistive humidity sensor prepared by printing process using polyelectrolyte ink derived from new monomer. Analyst 2012, 137, 1487–1494. [Google Scholar] [CrossRef]

- Turkani, V.S.; Narakathu, B.B.; Maddipatla, D.; Bazuin, B.J.; Atashbar, M.Z. P1FW.5—A Fully Printed CNT Based Humidity Sensor on Flexible PET Substrate. Proceedings IMCS 2018, 2018, 519–520. [Google Scholar]

- Barmpakos, D.; Tsamis, C.; Kaltsas, G. Multi-parameter paper sensor fabricated by inkjet-printed silver nanoparticle ink and PEDOT:PSS. Microelectron. Eng. 2020, 225, 111266. [Google Scholar] [CrossRef]

- Lim, D.-I.; Cha, J.-R.; Gong, M.-S. Preparation of flexible resistive micro-humidity sensors and their humidity-sensing properties. Sen. Actuators B Chem. 2013, 183, 574–582. [Google Scholar] [CrossRef]

- Zhang, D.; Chang, H.; Liu, R. Humidity-Sensing Properties of One-Step Hydrothermally Synthesized Tin Dioxide-Decorated Graphene Nanocomposite on Polyimide Substrate. J. Electron. Mater. 2016, 45, 4275–4281. [Google Scholar] [CrossRef]

- Ali, S.; Hassan, A.; Hassan, G.; Bae, J.; Lee, C.H. All-printed humidity sensor based on graphene/methyl-red composite with high sensitivity. Carbon 2016, 105, 23–32. [Google Scholar] [CrossRef]

- Turkani, V.S.; Maddipatla, D.; Narakathu, B.B.; Saeed, T.S.; Obare, S.O.; Bazuin, B.J.; Atashbar, M.Z. A highly sensitive printed humidity sensor based on a functionalized MWCNT/HEC composite for flexible electronics application. Nanoscale Adv. 2019, 1, 2311–2322. [Google Scholar] [CrossRef]

- Zhang, R.; Peng, B.; Yuan, Y. Flexible printed humidity sensor based on poly(3,4-ethylenedioxythiophene)/reduced graphene oxide/Au nanoparticles with high performance. Compos. Sci. Technol. 2018, 168, 118–125. [Google Scholar] [CrossRef]

- Kulkarni, M.; Apte, S.K.; Naik, S.D.; Ambekar, J.D.; Kale, B.B. Ink-jet printed conducting polyaniline based flexible humidity sensor. Sens. Actuators B Chem. 2013, 178, 140–143. [Google Scholar] [CrossRef]

- Kutzner, C.; Lucklum, R.; Torah, R.; Beeby, S.; Tudor, J. Novel screen printed humidity sensor on textiles for smart textile applications. In Proceedings of the 2013 Transducers & Eurosensors XXVII: The 17th International Conference on Solid-State Sensors, Actuators and Microsystems (TRANSDUCERS & EUROSENSORS XXVII, Barcelona, Spain, 16–20 June 2013; pp. 282–285. [Google Scholar]

- Ahn, H.Y.; Kim, J.-G.; Gong, M.-S. Preparation of flexible resistive humidity sensors with different electrode gaps by screen printing and their humidity-sensing properties. Macromol. Res. 2012, 20, 174–180. [Google Scholar] [CrossRef]

- Burman, D.; Santra, S.; Pramanik, P.; Guha, P.K. Pt decorated MoS2 nanoflakes for ultrasensitive resistive humidity sensor. Nanotechnology 2018, 29, 115504. [Google Scholar] [CrossRef]

- Choi, K.H.; Sajid, M.; Aziz, S.; Yang, B.-S. Wide range high speed relative humidity sensor based on PEDOT:PSS–PVA composite on an IDT printed on piezoelectric substrate. Sens. Actuators A. Phys. 2015, 228, 40–49. [Google Scholar] [CrossRef]

- Aziz, S.; Chang, D.E.; Doh, Y.H.; Kang, C.U.; Choi, K.H. Humidity Sensor Based on PEDOT:PSS and Zinc Stannate Nano-composite. J. Electron. Mater. 2015, 44, 3992–3999. [Google Scholar] [CrossRef]

- Kapton HN Polyimide Film Datasheet. Available online: https://docs.rs-online.com/c6e2/0900766b80659d8c.pdf (accessed on 20 December 2020).

- Rohatgi, A. WebPlotDigitizer 4.4. Available online: https://automeris.io/WebPlotDigitizer/ (accessed on 20 December 2020).

- Ding, H.; He, P.; Yang, J.; Liu, C.; Zhao, H.; Derby, B. Water-based highly conductive graphene inks for fully printed humidity sensors. J. Phys. D Appl. Phys. 2020, 53, 455304. [Google Scholar] [CrossRef]

- Kim, D.-U.; Gong, M.-S. Thick films of copper-titanate resistive humidity sensor. Sens. Actuators B Chem. 2005, 110, 321–326. [Google Scholar] [CrossRef]

- Khan, M.U.; Hassan, G.; Awais, M.; Bae, J. All printed full range humidity sensor based on Fe2O3. Sens. Actuators A Phys. 2020, 311, 112072. [Google Scholar] [CrossRef]

- Harrey, P.; Ramsey, B.; Evans, P.; Harrison, D. Capacitive-type humidity sensors fabricated using the offset lithographic printing process. Sens. Actuators B. Chem. 2002, 87, 226–232. [Google Scholar] [CrossRef]

- Rivadeneyra, A.; Fernández-Salmerón, J.; Banqueri, J.; López-Villanueva, J.A.; Capitán-Vallvey, L.F.; Palma, A.J. A novel electrode structure compared with interdigitated electrodes as capacitive sensor. Sens. Actuators B Chem. 2014, 204, 552–560. [Google Scholar] [CrossRef]

- Romero, F.J.; Rivadeneyra, A.; Salinas-Castillo, A.; Ohata, A.; Morales, D.P.; Becherer, M.; Rodríguez, N. Design, fabrication and characterization of capacitive humidity sensors based on emerging flexible technologies. Sens. Actuators B Chem. 2019, 287, 459–467. [Google Scholar] [CrossRef]

- Boudaden, J.; Steinmaßl, M.; Endres, H.-E.; Drost, A.; Eisele, I.; Kutter, C.; Müller-Buschbaum, P. Polyimide-Based Capacitive Humidity Sensor. Sensors 2018, 18, 1516. [Google Scholar] [CrossRef]

- Reddy, A.S.G.; Narakathu, B.B.; Atashbar, M.Z.; Rebros, M.; Rebrosova, E.; Bazuin, B.J.; Joyce, M.K.; Fleming, P.D.; Pekarovicova, A. Printed Capacitive Based Humidity Sensors on Flexible Substrates. Sens. Lett. 2011, 9, 869–871. [Google Scholar] [CrossRef]

- Altenberend, U.; Molina-Lopez, F.; Oprea, A.; Briand, D.; Barsan, N.; De Rooij, N.F.; Weimar, U. Towards fully printed capacitive gas sensors on flexible PET substrates based on Ag interdigitated transducers with increased stability. Sens. Actuators B Chem. 2013, 187, 280–287. [Google Scholar] [CrossRef]

- Courbat, J.; Kim, Y.; Briand, D.; De Rooij, N. Inkjet printing on paper for the realization of humidity and temperature sensors. In Proceedings of the 2011 16th International Solid-State Sensors, Actuators and Microsystems Conference, Beijing, China, 5–9 June 2011; pp. 1356–1359. [Google Scholar]

- McGhee, J.; Sagu, J.S.; Southee, D.J.; Evans, P.S.A.; Wijayantha, K.G.U. Printed, Fully Metal Oxide, Capacitive Humidity Sensors Using Conductive Indium Tin Oxide Inks. ACS Appl. Electron. Mater. 2020, 2, 3593–3600. [Google Scholar] [CrossRef]

- Rivadeneyra, A.; Salmeron, J.F.; Murru, F.; Lapresta-Fernández, A.; Rodríguez, N.; Capitan-Vallvey, L.F.; Morales, D.P.; Salinas-Castillo, A. Carbon Dots as Sensing Layer for Printed Humidity and Temperature Sensors. Nanomaterials 2020, 10, 2446. [Google Scholar] [CrossRef] [PubMed]

- Komazaki, Y.; Uemura, S. Stretchable, printable, and tunable PDMS-CaCl2 microcomposite for capacitive humidity sensors on textiles. Sens. Actuators B Chem. 2019, 297, 126711. [Google Scholar] [CrossRef]

- Reddy, A.; Narakathu, B.B.; Atashbar, M.Z.; Rebros, M.; Rebrosova, E.; Joyce, M. Fully Printed Flexible Humidity Sensor. Procedia Eng. 2011, 25, 120–123. [Google Scholar] [CrossRef]

- Gaspar, C.; Olkkonen, J.; Passoja, S.; Smolander, M. Paper as Active Layer in Inkjet-Printed Capacitive Humidity Sensors. Sensors 2017, 17, 1464. [Google Scholar] [CrossRef]

- Vuorinen, T.; Niittynen, J.; Kankkunen, T.; Kraft, T.M.; Mäntysalo, M. Inkjet-Printed Graphene/PEDOT:PSS Temperature Sensors on a Skin-Conformable Polyurethane Substrate. Sci. Rep. 2016, 6, 35289. [Google Scholar] [CrossRef]

- Honda, W.; Harada, S.; Arie, T.; Akita, S.; Takei, K. Wearable, Human-Interactive, Health-Monitoring, Wireless Devices Fabricated by Macroscale Printing Techniques. Adv. Funct. Mater. 2014, 24, 3299–3304. [Google Scholar] [CrossRef]

- Yamamoto, Y.; Harada, S.; Yamamoto, D.; Honda, W.; Arie, T.; Akita, S.; Takei, K. Printed multifunctional flexible device with an integrated motion sensor for health care monitoring. Sci. Adv. 2016, 2, e1601473. [Google Scholar] [CrossRef]

- Harada, S.; Kanao, K.; Yamamoto, Y.; Arie, T.; Akita, S.; Takei, K.; Shingo, H. Flexible, printed tactle, friction, and temperature sensor array for artificial skin. In Proceedings of the 2015 Transducers—2015 18th International Conference on Solid-State Sensors, Actuators and Microsystems (TRANSDUCERS), Anchorage, Alaska, 21–25 June 2015; pp. 164–167. [Google Scholar]

- Ren, X.; Pei, K.; Peng, B.; Zhang, Z.; Wang, Z.; Wang, X.; Chan, P.K.L. A Low-Operating-Power and Flexible Active-Matrix Organic-Transistor Temperature-Sensor Array. Adv. Mater. 2016, 28, 4832–4838. [Google Scholar] [CrossRef]

- Nakata, S.; Arie, T.; Akita, S.; Takei, K. Wearable, Flexible, and Multifunctional Healthcare Device with an ISFET Chemical Sensor for Simultaneous Sweat pH and Skin Temperature Monitoring. ACS Sens. 2017, 2, 443–448. [Google Scholar] [CrossRef]

- Yamamoto, D.; Nakata, S.; Kanao, K.; Arie, T.; Akita, S.; Takei, K. All-printed, planar-type multi-functional wearable flexible patch integrated with acceleration, temperature, and ECG sensors. In Proceedings of the 2017 IEEE 30th International Conference on Micro Electro Mechanical Systems (MEMS), Las Vegas, NV, USA, 22–26 January 2017; pp. 239–242. [Google Scholar]

- Yokota, T.; Inoue, Y.; Terakawa, Y.; Reeder, J.; Kaltenbrunner, M.; Ware, T.; Yang, K.; Mabuchi, K.; Murakawa, T.; Sekino, M.; et al. Ultraflexible, large-area, physiological temperature sensors for multipoint measurements. Proc. Natl. Acad. Sci. USA 2015, 112, 14533–14538. [Google Scholar] [CrossRef] [PubMed]

- Yamamoto, Y.; Yamamoto, D.; Takada, M.; Naito, H.; Arie, T.; Akita, S.; Takei, K. Efficient Skin Temperature Sensor and Stable Gel-Less Sticky ECG Sensor for a Wearable Flexible Healthcare Patch. Adv. Heal. Mater. 2017, 6, 1700495. [Google Scholar] [CrossRef] [PubMed]

- Bali, C.; Brandlmaier, A.; Ganster, A.; Raab, O.; Zapf, J.; Hübler, A. Fully Inkjet-Printed Flexible Temperature Sensors Based on Carbon and PEDOT:PSS1. Mater. Today Proc. 2016, 3, 739–745. [Google Scholar] [CrossRef]

- Farooqui, M.F.; Karimi, M.A.; Salama, K.N.; Shamim, A. 3D-Printed Disposable Wireless Sensors with Integrated Microelectronics for Large Area Environmental Monitoring. Adv. Mater. Technol. 2017, 2, 1700051. [Google Scholar] [CrossRef]

- Zikulnig, J.; Hirschl, C.; Rauter, L.; Krivec, M.; Lammer, H.; Riemelmoser, F.; Roshanghias, A. Inkjet printing and characterisation of a resistive temperature sensor on paper substrate. Flex. Print. Electron. 2019, 4, 015008. [Google Scholar] [CrossRef]

- Dankoco, M.D.; Tesfay, G.Y.; Benevent, E.; Bendahan, M. Temperature sensor realized by inkjet printing process on flexible substrate. Mater. Sci. Eng. B 2016, 205, 1–5. [Google Scholar] [CrossRef]

- Ali, S.; Hassan, A.; Bae, J.; Lee, C.H.; Kim, J. All-Printed Differential Temperature Sensor for the Compensation of Bending Effects. Langmuir 2016, 32, 11432–11439. [Google Scholar] [CrossRef] [PubMed]

- Molina-Lopez, F.; Quintero, A.V.; Mattana, G.; Briand, D.; De Rooij, N.F. Large-area compatible fabrication and encapsulation of inkjet-printed humidity sensors on flexible foils with integrated thermal compensation. J. Micromech. Microeng. 2013, 23, 025012. [Google Scholar] [CrossRef]

- Liew, Q.J.; Aziz, A.S.A.; Lee, H.W.; Lee, M.W.; Hawari, H.F.; Khir, M.H.M. Inkjet-Printed Flexible Temperature Sensor Based on Silver Nanoparticles Ink. Eng. Proc. 2020, 2, 3. [Google Scholar] [CrossRef]

- Aliane, A.; Fischer, V.; Galliari, M.; Tournon, L.; Gwoziecki, R.; Serbutoviez, C.; Chartier, I.; Coppard, R. Enhanced printed temperature sensors on flexible substrate. Microelectron. J. 2014, 45, 1621–1626. [Google Scholar] [CrossRef]

- Wu, L.; Qian, J.; Peng, J.; Wang, K.; Liu, Z.; Ma, T.; Zhou, Y.; Wang, G.; Ye, S. Screen-printed flexible temperature sensor based on FG/CNT/PDMS composite with constant TCR. J. Mater. Sci. Mater. Electron. 2019, 30, 9593–9601. [Google Scholar] [CrossRef]

- Katerinopoulou, D.; Zalar, P.; Sweelssen, J.; Kiriakidis, G.; Rentrop, C.; Groen, P.; Gelinck, G.H.; Brand, J.V.D.; Smits, E.C. Large-Area All-Printed Temperature Sensing Surfaces Using Novel Composite Thermistor Materials. Adv. Electron. Mater. 2019, 5, 1800605. [Google Scholar] [CrossRef]

- Moschos, A.; Syrový, T.; Syrová, L.; Kaltsas, G. A screen-printed flexible flow sensor. Meas. Sci. Technol. 2017, 28, 055105. [Google Scholar] [CrossRef]

- Awasthi, C.; Sehrawat, P.; Meena, R.C.; Asokan, K.; Islam, S.S. Temperature sensing performance of 2D-MoSe2 based thermistor. In Proceedings of the International Conference on Recent Trends in Mechanical and Materials Engineering, Chennai, India, 12–13 December 2019; AIP Publishing: Melville, NY, USA, 2020; Volume 2276, p. 20028. [Google Scholar]

- Munasinghe, N.; Paul, G. Integrated 3-D Printable Temperature Sensor for Advanced Manufacturing. In Proceedings of the Australasian Conference on Robotics and Automation, Brisbane, QCL, Australia, 8–10 December 2020. [Google Scholar]

- Xiao, Y.; Jiang, S.W.; Li, Y.; Zhang, W. Screen-printed flexible negative temperature coefficient temperature sensor based on polyvinyl chloride/carbon black composites. Smart Mater. Struct. 2021. [Google Scholar] [CrossRef]

- Yao, S.; Zhu, Y. Wearable multifunctional sensors using printed stretchable conductors made of silver nanowires. Nanoscale 2014, 6, 2345–2352. [Google Scholar] [CrossRef]

- Woo, S.-J.; Kong, J.-H.; Kim, D.-G.; Kim, J.-M. A thin all-elastomeric capacitive pressure sensor array based on micro-contact printed elastic conductors. J. Mater. Chem. C 2014, 2, 4415–4422. [Google Scholar] [CrossRef]

- He, P.; Jiu, J.; Nogi, M.; Sugahara, T.; Nagao, S.; Koga, H.; He, P.; Suganuma, K. A highly sensitive and flexible pressure sensor with electrodes and elastomeric interlayer containing silver nanowires. Nanoscale 2015, 7, 2926–2932. [Google Scholar] [CrossRef]

- Rajala, S.; Schouten, M.; Krijnen, G.; Tuukkanen, S. High Bending-Mode Sensitivity of Printed Piezoelectric Poly(vinylidenefluoride-co-trifluoroethylene) Sensors. ACS Omega 2018, 3, 8067–8073. [Google Scholar] [CrossRef]

- Kärki, S.; Mäntysalo, M.; Lekkala, J. A PVDF Sensor with Printed Electrodes for Normal and Shear Stress Measurements on Sole. In Proceedings of the XIX IMEKO World Congress Fundamental and Applied Metrology, Lisbon, Portugal, 6–11 September 2009. [Google Scholar]

- Khan, S.; Dahiya, R.; Tinku, S.; Lorenzelli, L. Conformable Tactile Sensing Using Screen Printed P(VDF-TrFE) and MWCNT-PDMS Composites. In Proceedings of the IEEE SENSORS 2014 Proceedings, Valencia, Spain, 2–5 November 2014; pp. 862–865. [Google Scholar]

- Maurya, D.; Khaleghian, S.; Sriramdas, R.; Kumar, P.; Kishore, R.A.; Kang, M.G.; Kumar, V.; Song, H.-C.; Lee, S.-Y.; Yan, Y.; et al. 3D printed graphene-based self-powered strain sensors for smart tires in autonomous vehicles. Nat. Commun. 2020, 11, 1–10. [Google Scholar] [CrossRef]

- Xiao, Y.; Jiang, S.; Li, Y.; Zhang, W. Highly sensitive printed crack-enhanced strain sensor as dual-directional bending detector. Smart Mater. Struct. 2020, 29, 045023. [Google Scholar] [CrossRef]

- Zhou, P.; Liao, Y.; Li, Y.; Pan, D.; Cao, W.; Yang, X.; Zou, F.; Zhou, L.-M.; Zhang, Z.; Su, Z. An inkjet-printed, flexible, ultra-broadband nanocomposite film sensor for in-situ acquisition of high-frequency dynamic strains. Compos. Part A Appl. Sci. Manuf. 2019, 125, 105554. [Google Scholar] [CrossRef]

- Wei, Y.; Chen, S.; Li, F.; Lin, Y.; Zhang, Y.; Liu, L. Highly Stable and Sensitive Paper-Based Bending Sensor Using Silver Nanowires/Layered Double Hydroxides Hybrids. ACS Appl. Mater. Interfaces 2015, 7, 14182–14191. [Google Scholar] [CrossRef] [PubMed]

- Correia, V.; Caparrós, C.; Casellas, C.; Francesch, L.; Rocha, J.G.; Lanceros-Mendez, S. Development of inkjet printed strain sensors. Smart Mater. Struct. 2013, 22, 105028. [Google Scholar] [CrossRef]

- Wang, X.; Wu, D.; Cao, W.; Li, F.; Wang, X.; Liu, S. N-layer screen printed ceramic on stainless steel based pressure sensor. In Proceedings of the 2016 17th International Conference on Electronic Packaging Technology (ICEPT), Wuhan, China, 16–19 August 2016; pp. 1311–1314. [Google Scholar]

- Emon, O.F.; Choi, J.-W. Flexible Piezoresistive Sensors Embedded in 3D Printed Tires. Sensors 2017, 17, 656. [Google Scholar] [CrossRef] [PubMed]

- Alaferdov, A.V.; Savu, R.; Rackauskas, A.T.; Rackauskas, S.; Canesqui, M.A.; De Lara, D.S.; Setti, G.O.; Joanni, E.; De Trindade, G.M.; Lima, U.B.; et al. A wearable, highly stable, strain and bending sensor based on high aspect ratio graphite nanobelts. Nanotechnology 2016, 27, 375501. [Google Scholar] [CrossRef] [PubMed]

- Charara, M.; Abshirini, M.; Saha, M.C.; Altan, M.C.; Liu, Y. Highly sensitive compression sensors using three-dimensional printed polydimethylsiloxane/carbon nanotube nanocomposites. J. Intell. Mater. Syst. Struct. 2019, 30, 1216–1224. [Google Scholar] [CrossRef]

- Gerlach, C.; Krumm, D.; Illing, M.; Lange, J.; Kanoun, O.; Odenwald, S.; Hubler, A. Printed MWCNT-PDMS-Composite Pressure Sensor System for Plantar Pressure Monitoring in Ulcer Prevention. IEEE Sens. J. 2015, 15, 3647–3656. [Google Scholar] [CrossRef]

- Kim, K.; Jung, M.; Kim, B.; Kim, J.; Shin, K.; Kwon, O.-S.; Jeon, S. Low-voltage, high-sensitivity and high-reliability bimodal sensor array with fully inkjet-printed flexible conducting electrode for low power consumption electronic skin. Nano Energy 2017, 41, 301–307. [Google Scholar] [CrossRef]

- Kang, T.-K. Inkjet Printing of Highly Sensitive, Transparent, Flexible Linear Piezoresistive Strain Sensors. Coatings 2021, 11, 51. [Google Scholar] [CrossRef]

- Mraović, M.; Muck, T.; Pivar, M.; Trontelj, J.; Pleteršek, A. Humidity Sensors Printed on Recycled Paper and Cardboard. Sensors 2014, 14, 13628–13643. [Google Scholar] [CrossRef]

- Khan, Y.; Garg, M.; Gui, Q.; Schadt, M.; Gaikwad, A.; Han, D.; Yamamoto, N.A.D.; Hart, P.; Welte, R.; Wilson, W.; et al. Flexible Hybrid Electronics: Direct Interfacing of Soft and Hard Electronics for Wearable Health Monitoring. Adv. Funct. Mater. 2016, 26, 8764–8775. [Google Scholar] [CrossRef]

| Query | Results Found | Sum of the Times Cited | Avg. Citations Per Item | H-Index |

|---|---|---|---|---|

| Printed Humidity Sensor | 381 | 5055 | 13.27 | 37 |

| Printed Temperature Sensor | 1513 | 21,968 | 14.52 | 60 |

| Printed Strain Sensor | 774 | 17,970 | 23.22 | 62 |

| Active Material | Electrodes | Substrate | Range (%RH) | Sensitivity 1 | Ref. |

|---|---|---|---|---|---|

| Gravure printed MWCNTs | Screen-printed, Ag | PI | 30–60 | 0.96%/% RH | [10] |

| Gravure printed MWCNTs | Screen-printed, Ag | PI | 10–90 | – | [13] |

| Drop-cast TiO2 nanoflowers | Gravure, Ag | PI | 20–95 | 485.7/RH% | [14] |

| Screen-printed MEPAB/CMDAB/MMA copolymer | Screen-printed, Ag/Au | PI | 20–95 | 0.0586 logΩ/% RH | [15] |

| Screen-printed epoxy/IPN polyelectrolyte | Chemical Etching–Plating (Ni/Au) | PI | 20–95 | 0.046 logΩ/% RH | [18] |

| Drop-cast SnO2/rGO | Chemical Etching–Plating (Cu/Ni) | PI | 11–97 | 15.19–45.02% | [19] |

| Spin-coat PEDOT:PSS (15%) + PVA (SAW) | Photolithography | LiNbO3 | 0–80 | 350 Ω/% RH | [27] |

| Spin-coat PEDOT:PSS (5 wt%) + ZnSnO3 (5 wt%) | Photolithography, Au | LiNbO3 | 0–90 | – | [28] |

| Screen-printed MDBBAC/MMA (70/30) Polyelectrolyte | Screen-printed, Ag–Plating (Cu/Ni/Au) | Glass Epoxy | 20–95 | 0.0349 logΩ/% RH | [25] |

| EHD Graphene/methyl-red | Inkjet-printed, Ag | PET | 5–95 | 96.36% | [20] |

| Drop-cast Pt/MoS2 (0.25:1) | Photolithography, Au | Ceramic | 35–85 | ~4000 times (85 % RH) | [26] |

| Gravure printed CNT | Screen-printed, Ag | PET | 20–80 | 0.1%/% RH | [16] |

| Screen-printed TiO2-Cu2O-Na2O | Screen-printed, Pt | Al2O3 | 20–95 | – | [32] |

| Inkjet-printed PANI | – | Polyester | 20–95 | – | [23] |

| Micro-pipette deposited Nafion | Screen-printed Ag on screen-printed PU | Polyester Cotton Fabric | 30–90 | – | [24] |

| Gravure printed FMWCNT/HEC (1:6 w/w) | Screen-printed, Ag | PET | 20–80 | 0.048/% RH | [21] |

| Inkjet-printed PEDOT:rGO-PEI/Au NPs | – | PET | 11–98 | 7.41–51.60% | [22] |

| Spin-coated Fe2O3 | Inkjet-printed, Ag | PET | 0–100 | ~88.89% | [33] |

| Substrate | Inkjet-printed, Ag | Paper | 18–88 | – | [12] |

| Substrate | Inkjet-printed Ag & PEDOT: PSS | Paper | 0–85 | 0.0492 & 0.0551 logΩ/% RH | [17] |

| Active Material | Electrodes | Substrate | Range | Sensitivity 1 | Reference |

|---|---|---|---|---|---|

| 7.6 μm polyimide (HN30) (Substrate) | Offset, Ag | PI | 10–90 | 1.025 pF/% RH | [34] |

| 75 μm polyimide (Substrate) | Inkjet, Ag | PI | 20–90 | 5.2 ± 0.2 fF/% RH | [35] |

| 125 μm polyimide (Substrate) | Inkjet, Ag | PI | 20–85 | 24.71 fF/% RH | [36] |

| 4.6 μm spin-coated polyimide | Lithography, Au | Glass | 6–85 | 15.2 fF/% RH | [37] |

| PEDOT:PSS (5%) + PVA (SAW) | Photolithography | LiNbO3 | 0–80 | 0.33 pF/% RH | [27] |

| Spin-coated PMMA | Gravure, Ag | PET | 40–80 | 11.9% | [38] |

| EHD Graphene/methyl-red | Inkjet, Ag | PET | 5–95 | 2869500% | [20] |

| Ni/Parylene-C/Poly(etherurethane) | Inkjet, Ag | PET | 10–90 | 3.15 fF/% RH | [39] |

| Inkjet, cellulose acetate butyrate | Inkjet, Ag | Paper | 20–80 | – | [40] |

| Screen-printed PDMS-CaCl2 | Screen-printed Ag/Au | Textile | 30–95 | 10.2% (30 to 60% RH) | [43] |

| Gravure, pHEMA | Gravure, Ag | PET | 30–80 | 172% | [44] |

| Screen-printed Indium Tin Oxide/Aluminum Oxide | Screen-printed Ag | PET | 5–95 | 0.85–7.76 pF/% RH | [41] |

| Drop-cast, Carbon dots | Screen-printed Ag | PET | 20–90 | 70 fF/% RH | [42] |

| Substrate | Inkjet, Ag | Paper | 40–100 | 2 pF/% RH | [45] |

| Materials | Substrate | Process | Range (°C) | Sensitivity (%/°C) | Ref. |

|---|---|---|---|---|---|

| PEDOT: PSS/graphene/EGC | PU | Inkjet | 35–45 | 0.064/0.034 | [46] |

| PEDOT: PSS/CNT | PI | Shadow Mask | 22–50 | 0.61 | [47] |

| PEDOT: PSS/DMSO | PEN | Inkjet | 20–70 | 2.5 × 10−3 | [55] |

| PEDOT: PSS/CNT (3:1) | PET | Screen printing | 26–45 | 0.89 | [48] |

| PEDOT: PSS | SU-8 | Inkjet | −20–50 | 0.018 | [56] |

| PEDOT: PSS/CNT | PET | Screen printing | 20–45 | 1.3 | [52] |

| Ag | PI | Inkjet | 20–60 | 2.19 × 10−3 | [58] |

| Ag | PET | Inkjet | 0–100 | 1.076 × 10−3 | [59] |

| Ag | PET | Inkjet | 30–100 | 0.1086 Ω/°C | [61] |

| Au, PTC & NTC pastes | PEN/PET | Screen printing | 20–80 | 0.06 V/°C | [62] |

| Ag, Ni | PET | Inkjet, Electrodeposition | −10–60 | 1.82 × 10−3 | [60] |

| Flake graphite/CNT/PDMS | PET | Screen printing | 40–80 | 0.028 | [63] |

| Mn2O3/NiO/Co3O4/CuO/ZnOPVDF, PDMS, CYTOP | PI | Screen printing | 40–140 | 91.76% (full range change) | [64] |

| BaTiO3, activated carbon, thermoset polymeric | PET | Screen printing | 25–55 | 0.022 | [65] |

| MoSe2, Ag | Glass | Drop-cast | −0.15–99.8 | ~−0.51 | [66] |

| Polylactic Acid—Carbon black | Free standing | 3D Printing | 25–36 | – | [67] |

| Polyvinyl chloride/carbon black | PET | Screen printing | 18–44 | −0.148 | [68] |

| Ag | Paper | Inkjet | −20–60 | 1.1 × 10−3 | [40] |

| Ag | Paper | Inkjet | 20–80 | 1.63 × 10−3 | [57] |

| Ag & PEDOT: PSS | Paper | Inkjet | 25–45 | 0.938 × 10−3 & −13.9 × 10−3 | [17] |

| Materials | Substrate | Process | Principle | Range | Sensitivity/Gauge Factor | Ref. |

|---|---|---|---|---|---|---|

| AgNWs, Ecoflex, PDMS | Embedded | Screen printing, drop-casting | Capacitive | 50% tensile | GF: 0.7 | [69] |

| CNTs, Ecoflex, PDMS | Embedded | μcontact printing | Capacitive | 50% tensile | GF: 0.5 | [70] |

| AgNW-PU | PET, Adhesive Bandage | Drop-cast, spin-coating | Capacitive | 2 mm tensile | 5.54 kPa−1–0.88 kPa−1 | [71] |

| PVDF, AgNPs | Embedded | Inkjet | Piezoelectric | 3 N | 2.8 ± 0.9 mV/N | [73] |

| P(VDF-TrFE), Ag | PET | Vacuum evaporation | Piezoelectric | – | 140 ± 50 nC/N | [72] |

| Ceramic dielectric, Pt/Ag | Steel | Screen printing | Piezoelectric | 0–18 MPa | – | [80] |

| P(VDF-TrFE), Ag | PI | Screen printing | Piezoelectric | 0.5–4N | 0.05 V/N | [74] |

| Ionic liquid/polymer, MWCNT | TangoPlus | 3D printing, molding | Piezoresistive | – | – | [81] |

| MWCNT, PDMS, Ag | Embedded | Screen printing | Piezoresistive | 0–11 N Compressive | 20 kΩ/N | [74] |

| Polyvinyl chloride/carbon black, Ag | PI | Screen printing | Piezoresistive | 0.14% | GFtensile: 741 GFcompr: 1563 | [76] |

| Thin graphite nanobelt, Ti/Au | PDMS | Modified Langmuir-Blodge | Piezoresistive | 40% Strain | GF: 1–24 | [82] |

| PDMS, MWCNT | Embedded | 3D printing | Piezoresistive | 15% Strain | GF: 1–16 | [83] |

| PDMS, MWCNT, Ag | PET | Screen printing | Piezoresistive | 1.5 kPa–15.5 kPa | – | [84] |

| PEDOT: PSS/PUD, Ag | PDMS | Mold cast, inkjet | Piezoresistive | 3 Pa–5 kPa | – | [85] |

| AgNW, Layered double hydroxides | Paper | Screen printing | Piezoresistive | 180° Compressive | 0.16 rad−1 | [78] |

| PeDOT, TIPS-pentacene, Ag, PVPh | PI | Inkjet | Piezoresistive | 4000 N | GF: 0.35 | [79] |

| PEDOT: PSS & Ag | Paper | Inkjet | Piezoresistive | 10% | GFtensile: 0.42 GFcompress: 0.15 | [17] |

| PEDOT: PSS | PET | Inkjet | Piezoresistive | 0.33% | 165 | [86] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Barmpakos, D.; Kaltsas, G. A Review on Humidity, Temperature and Strain Printed Sensors—Current Trends and Future Perspectives. Sensors 2021, 21, 739. https://doi.org/10.3390/s21030739

Barmpakos D, Kaltsas G. A Review on Humidity, Temperature and Strain Printed Sensors—Current Trends and Future Perspectives. Sensors. 2021; 21(3):739. https://doi.org/10.3390/s21030739

Chicago/Turabian StyleBarmpakos, Dimitris, and Grigoris Kaltsas. 2021. "A Review on Humidity, Temperature and Strain Printed Sensors—Current Trends and Future Perspectives" Sensors 21, no. 3: 739. https://doi.org/10.3390/s21030739

APA StyleBarmpakos, D., & Kaltsas, G. (2021). A Review on Humidity, Temperature and Strain Printed Sensors—Current Trends and Future Perspectives. Sensors, 21(3), 739. https://doi.org/10.3390/s21030739