X-Ray Single-Grating Interferometry for Wavefront Measurement and Correction of Hard X-Ray Nanofocusing Mirrors

Abstract

1. Introduction

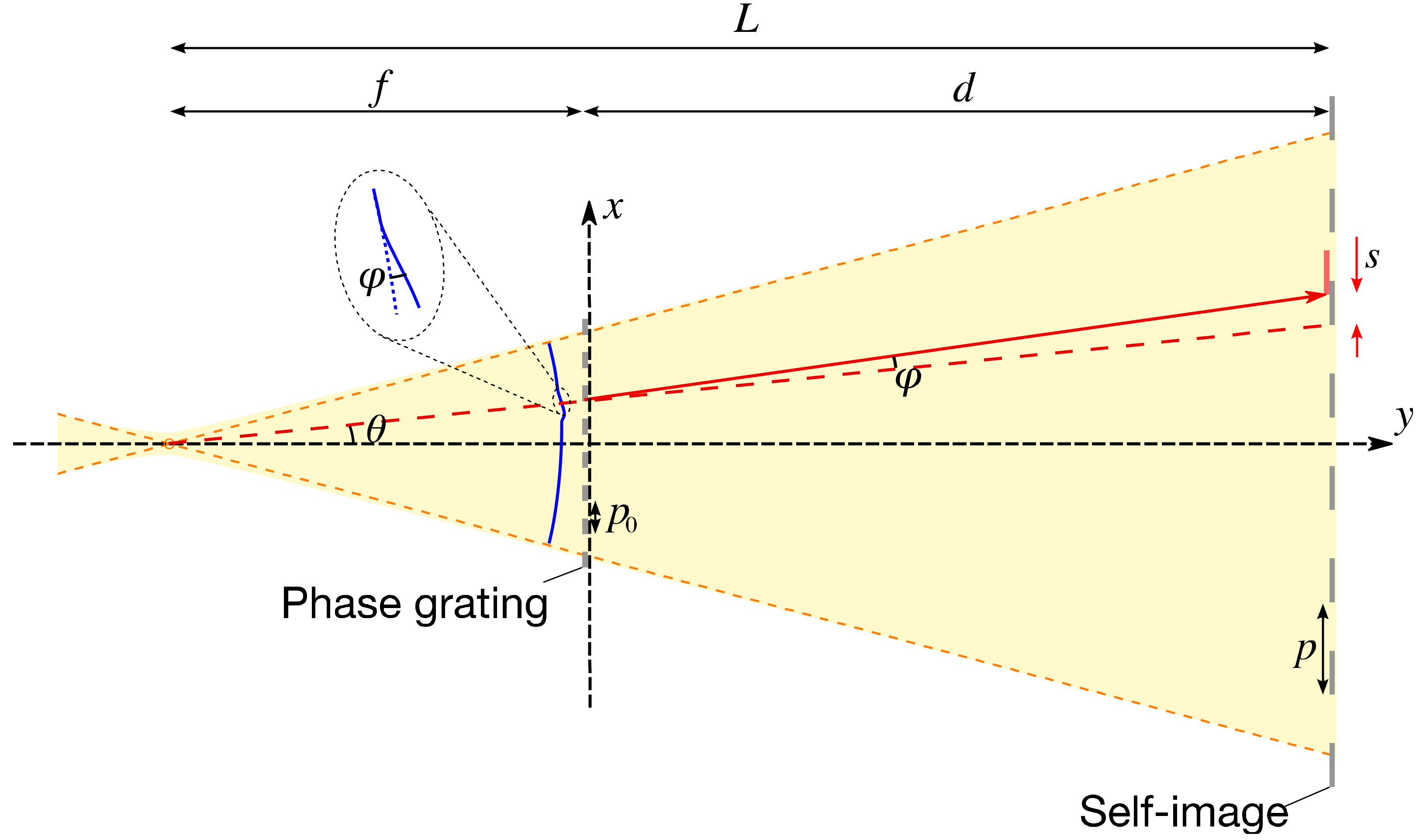

2. Materials and Methods

3. Results and Discussion

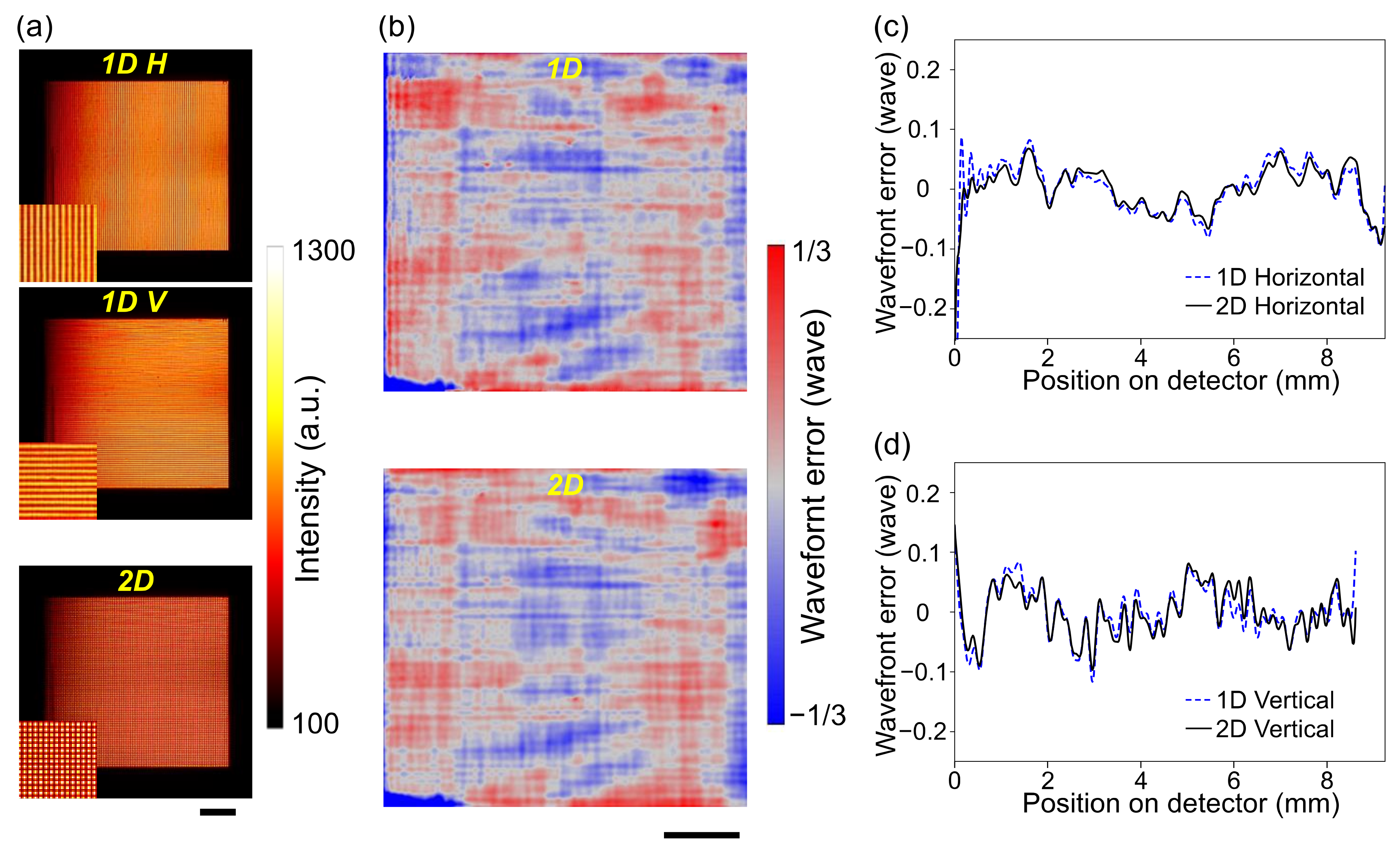

3.1. Fidelity of the Grating

3.2. Distortion of the X-Ray Detector

3.3. Alignments of the Grating and the Detector

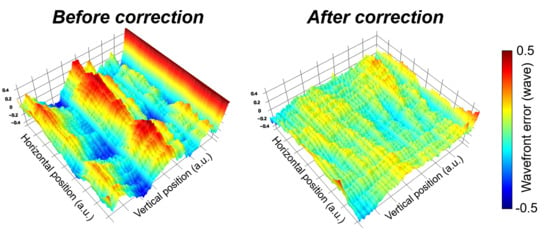

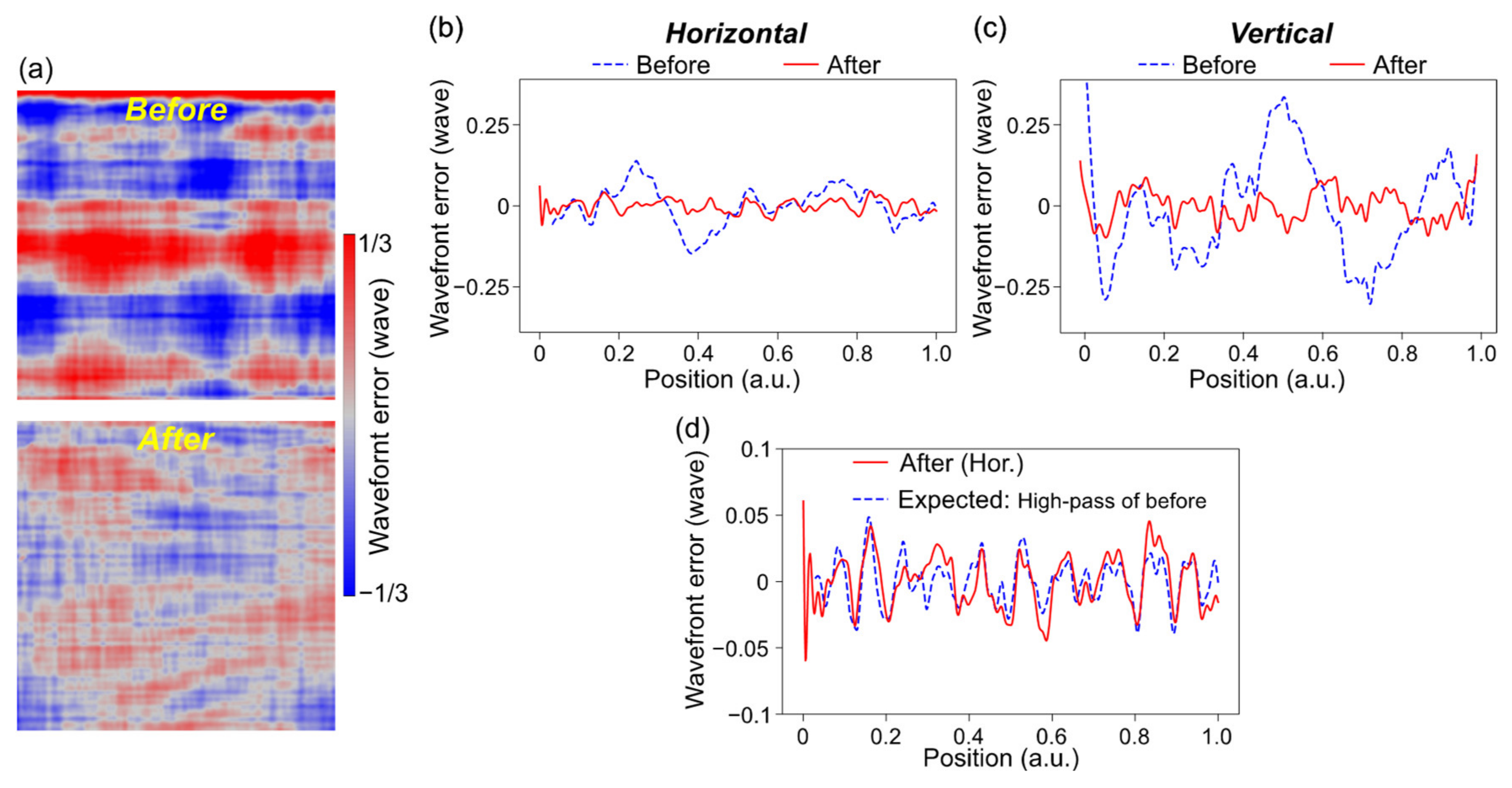

3.4. Wavefront Correction

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Yamauchi, K.; Mimura, H.; Kimura, T.; Yumoto, H.; Handa, S.; Matsuyama, S.; Arima, K.; Sano, Y.; Yamamura, K.; Inagaki, K.; et al. Single-nanometer focusing of hard x-rays by Kirkpatrick–Baez mirrors. J. Phys. Condens. Matter 2011, 23, 394206. [Google Scholar] [CrossRef] [PubMed]

- Döring, F.; Robisch, A.L.; Eberl, C.; Osterhoff, M.; Ruhlandt, A.; Liese, T.; Schlenkrich, F.; Hoffmann, S.; Bartels, M.; Salditt, T.; et al. Sub-5 nm hard x-ray point focusing by a combined Kirkpatrick-Baez mirror and multilayer zone plate. Opt. Express 2013, 21, 19311–19323. [Google Scholar] [CrossRef] [PubMed]

- Mohacsi, I.; Vartiainen, I.; Rösner, B.; Guizar-Sicairos, M.; Guzenko, V.A.; McNulty, I.; Winarski, R.; Holt, M.V.; David, C. Interlaced zone plate optics for hard X-ray imaging in the 10 nm range. Sci. Rep. 2017, 7, 43624. [Google Scholar] [CrossRef]

- Bajt, S.; Prasciolu, M.; Fleckenstein, H.; Domaracký, M.; Chapman, H.N.; Morgan, A.J.; Yefanov, O.; Messerschmidt, M.; Du, Y.; Murray, K.T.; et al. X-ray focusing with efficient high-NA multilayer Laue lenses. Light Sci. Appl. 2018, 7, 17162. [Google Scholar] [CrossRef]

- Chapman, H.N.; Bajt, S. A ray-trace analysis of x-ray multilayer Laue lenses for nanometer focusing. J. Opt. 2020, 22, 115610. [Google Scholar] [CrossRef]

- Mimura, H.; Handa, S.; Kimura, T.; Yumoto, H.; Yamakawa, D.; Yokoyama, H.; Matsuyama, S.; Inagaki, K.; Yamamura, K.; Sano, Y.; et al. Breaking the 10 nm barrier in hard-X-ray focusing. Nat. Phys. 2010, 6, 122–125. [Google Scholar] [CrossRef]

- Matsuyama, S.; Inoue, T.; Yamada, J.; Kim, J.; Yumoto, H.; Inubushi, Y.; Osaka, T.; Inoue, I.; Koyama, T.; Tono, K.; et al. Nanofocusing of X-ray free-electron laser using wavefront-corrected multilayer focusing mirrors. Sci. Rep. 2018, 8, 18440. [Google Scholar] [CrossRef]

- Kimura, T.; Handa, S.; Mimura, H.; Yumoto, H.; Yamakawa, D.; Matsuyama, S.; Inagaki, K.; Sano, Y.; Tamasaku, K.; Nishino, Y.; et al. Wavefront control system for phase compensation in hard X-ray optics. Jpn. J. Appl. Phys. 2009, 48, 072503. [Google Scholar] [CrossRef]

- Seiboth, F.; Schropp, A.; Scholz, M.; Wittwer, F.; Rödel, C.; Wünsche, M.; Ullsperger, T.; Nolte, S.; Rahomäki, J.; Parfeniukas, K.; et al. Perfect X-ray focusing via fitting corrective glasses to aberrated optics. Nat. Commun. 2017, 8, 14623. [Google Scholar] [CrossRef]

- Laundy, D.; Dhamgaye, V.; Moxham, T.; Sawhney, K. Adaptable refractive correctors for x-ray optics. Optica 2019, 12, 1484–1490. [Google Scholar] [CrossRef]

- Weitkamp, T.; Nöhammer, B.; Diaz, A.; David, C. X-ray wavefront analysis and optics characterization with a grating interferometer. Appl. Phys. Lett. 2005, 86, 054101. [Google Scholar] [CrossRef]

- Idir, M.; Mercere, P.; Modi, M.H.; Dovillaire, G.; Levecq, X.; Bucourt, S.; Escolano, L.; Sauvageot, P. X-ray active mirror coupled with a Hartmann wavefront sensor. Nucl. Instrum. Methods Phys. Res. A 2006, 616, 161–171. [Google Scholar] [CrossRef]

- Bérujon, S.; Ziegler, E.; Cerbino, R.; Peverini, R. Two-Dimensional X-Ray beam phase sensing. Phys. Rev. Lett. 2012, 108, 158102. [Google Scholar] [CrossRef] [PubMed]

- Berujon, S.; Ziegler, E.; Clotens, P. X-ray pulse wavefront metrology using speckle tracking. J. Synchrotron Rad. 2015, 22, 886–894. [Google Scholar] [CrossRef]

- Uhlén, F.; Rahomäki, J.; Nilsson, D.; Seiboth, F.; Sanz, C.; Wagner, U.; Rau, C.; Schroer, C.G.; Vogt, U. Ronchi test for characterization of X-ray nanofocusing optics and beamlines. J. Synchrotron Rad. 2014, 21, 1105–1109. [Google Scholar] [CrossRef]

- Maiden, A.M.; Rodenburg, J.M. An improved ptychographical phase retrieval algorithm for diffractive imaging. Ultramicroscopy 2009, 109, 1256–1262. [Google Scholar] [CrossRef]

- Kewish, C.M.; Thibault, P.; Dierolf, M.; Bunk, O.; Menzel, A.; Vila-Comamala, J.; Jefimovs, K.; Pfeiffer, F. Ptychographic characterization of the wavefield in the focus of reflective hard X-ray optics. Ultramicroscopy 2010, 110, 325–329. [Google Scholar] [CrossRef]

- Hagemann, J.; Robisch, A.-L.; Luke, D.R.; Homann, C.; Hohage, T.; Clotens, P.; Suhonen, H.; Salditt, T. Reconstruction of wave front and object for inline holography from a set of detection planes. Opt. Express 2014, 22, 11552–11569. [Google Scholar] [CrossRef]

- Hagemann, J.; Robisch, A.-L.; Osterhoff, M.; Salditt, T. Probe reconstruction for holographic X-ray imaging. J. Synchrotron Rad. 2017, 24, 498–505. [Google Scholar] [CrossRef]

- Ray-Chaudhuri, A.K.; Ng, W.; Cerrina, F.; Tan, Z.; Bjorkholm, J.; Tennant, D.; Spector, S.J. Alignment of a multilayer-coated imaging system using extreme ultraviolet Foucault and Ronchi interferometric testing. J. Vac. Sci. Technol. B 1995, 13, 3089. [Google Scholar] [CrossRef]

- Naulleau, P.P.; Goldberg, K.A.; Bokor, J. Extreme ultraviolet carrier-frequency shearing interferometry of a lithographic four-mirror optical system. J. Vac. Sci. Technol. B 2000, 18, 2939. [Google Scholar] [CrossRef]

- Matsuyama, S.; Yokoyama, H.; Fukui, R.; Kohmura, Y.; Tamasaku, K.; Yabashi, M.; Yashiro, W.; Momose, A.; Ishikawa, T.; Yamauchi, K. Wavefront measurement for a hard-X-ray nanobeam using single-grating interferometry. Opt. Express 2012, 20, 24977–24986. [Google Scholar] [CrossRef] [PubMed]

- Merthe, D.J.; Yashchuk, V.V.; Goldberg, K.A.; Kunz, M.; Tamura, N.; McKinney, W.R.; Artemiev, N.A.; Celestre, R.S.; Morrison, G.Y.; Anderson, E.H.; et al. Methodology for optimal in situ alignment and setting of bendable optics for nearly diffraction-limited focusing of soft x-rays. Opt. Eng. 2013, 52, 033603. [Google Scholar] [CrossRef][Green Version]

- Niibe, M.; Sugisaki, K.; Okada, M.; Kato, S.; Ouchi, C.; Hasegawa, T. Wavefront metrology for EUV projection optics by soft X-ray interferometry in the NewSUBARU. AIP Conf. Proc. 2007, 879, 1520–1523. [Google Scholar]

- Liu, Y.; Seaberg, M.; Zhu, D.; Krzywinski, J.; Seiboth, F.; Hardin, C.; Cocco, D.; Aquila, A.; Nagler, B.; Lee, H.J.; et al. High-accuracy wavefront sensing for x-ray free electron lasers. Optica 2018, 5, 967–975. [Google Scholar] [CrossRef]

- Inoue, T.; Matsuyama, S.; Kawai, S.; Yumoto, H.; Inubushi, Y.; Osaka, T.; Inoue, I.; Koyama, T.; Tono, K.; Ohashi, H.; et al. Systematic-error-free wavefront measurement using an X-ray single-grating interferometer. Rev. Sci. Instrum. 2018, 89, 043106. [Google Scholar] [CrossRef] [PubMed]

- Liu, Y.; Seaberg, M.; Feng, Y.; Li, K.; Ding, Y.; Marcus, G.; Fritz, D.; Shi, X.; Grizolli, W.; Assoufid, L.; et al. X-ray free-electron laser wavefront sensing using the fractional Talbot effect. J. Synchrotron Rad. 2020, 27, 254–261. [Google Scholar] [CrossRef]

- Yamada, J.; Matsuyama, S.; Inoue, T.; Nakamura, N.; Osaka, T.; Inoue, I.; Inubushi, Y.; Tono, K.; Yumoto, H.; Koyama, T.; et al. Development of XFEL sub-10 nm focusing mirrors at SACLA: Wavefront-corrected multilayer KB system and upgrade to advanced KB system. In Proceedings of the RIAO-OPTILAS-MOPM 2019, Cancun, Mexico, 23–27 September 2019; 2019. [Google Scholar]

- Handa, S.; Mimura, H.; Yumoto, H.; Kimura, T.; Matsuyama, S.; Sano, Y.; Yamauchi, K. Highly accurate differential deposition for X-ray reflective optics. Surf. Interface Anal. 2008, 40, 1019–1022. [Google Scholar] [CrossRef]

- Yashiro, W.; Takeda, Y.; Takeuchi, A.; Suzuki, Y.; Momose, A. Hard-X-ray phase-difference microscopy using a Fresnel zone plate and a transmission grating. Phys. Rev. Lett. 2009, 103, 180801. [Google Scholar] [CrossRef]

- Takeda, M.; Ina, H.; Kobayashi, S. Fourier-transform method of fringe-pattern analysis for computer-based topography and interferometry. J. Opt. Soc. Am. 1982, 72, 156–160. [Google Scholar] [CrossRef]

- Bruning, J.H.; Herriott, D.R.; Gallagher, J.E.; Rosenfeld, D.P.; White, A.D.; Brangaccio, D.J. Digital wavefront measuring interferometer for testing optical surfaces and lenses. Appl. Opt. 1974, 13, 2693–2703. [Google Scholar] [CrossRef] [PubMed]

- Setson, K.A.; Brohinsky, R. Electrooptic holography and its application to hologram interferometry. Appl. Opt. 1985, 24, 3631–3637. [Google Scholar] [CrossRef] [PubMed]

- Momose, A.; Yashiro, W.; Takeda, Y.; Suzuki, Y.; Hattori, T. Phase tomography by X-ray talbot interferometry for biological imaging. Jpn. J. Appl. Phys. 2006, 45, 5254–5262. [Google Scholar] [CrossRef]

- Takeda, Y.; Yashiro, W.; Suzuki, Y.; Aoki, S.; Hattori, T.; Momose, A. X-ray phase imaging with single phase grating. Jpn. J. Appl. Phys. 2007, 3, L89–L91. [Google Scholar] [CrossRef]

- Yashiro, W.; Takeda, Y.; Momose, A. Efficiency of capturing a phase image using cone-beam x-ray Talbot interferometry. J. Opt. Soc. Am. A. 2008, 8, 2025–2039. [Google Scholar] [CrossRef]

- Huang, L.; Idir, M.; Zuo, C.; Kaznatcheev, K.; Zhou, L.; Asundi, A. Comparison of two-dimensional integration methods for shape reconstruction from gradient data. Opt. Laser. Eng. 2015, 64, 1–11. [Google Scholar] [CrossRef]

- Ishikawa, T.; Tamasaku, K.; Yabashi, M.; Goto, S.; Tanaka, Y.; Yamazaki, H.; Takeshita, K.T.; Kimura, H.; Ohashi, H.; Matsushita, T.; et al. 1-km beamline at SPring-8. Proc. SPIE 2001, 4145, 1–10. [Google Scholar]

- Bon, P.; Monneret, S.; Wattellier, B. Noniterative boundary-artifact-free wavefront reconstruction from its derivatives. Appl. Opt. 2012, 23, 5698–5704. [Google Scholar] [CrossRef]

- Yamada, J.; Matsuyama, S.; Sano, Y.; Yamauchi, K. Simulation of concave–convex imaging mirror system for development of a compact and achromatic full-field x-ray microscope. Appl. Opt. 2017, 56, 967–974. [Google Scholar] [CrossRef]

- Yamada, J.; Matsuyama, S.; Sano, Y.; Kohmura, Y.; Yabashi, M.; Ishikawa, T.; Yamauchi, K. Compact reflective imaging optics in hard X-ray region based on concave and convex mirrors. Opt. Express 2019, 27, 3429–3438. [Google Scholar] [CrossRef]

- Born, M.; Wolf, E. Principles of Optics, 7th ed.; Cambridge University Press: Cambridge, UK, 2001. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yamada, J.; Inoue, T.; Nakamura, N.; Kameshima, T.; Yamauchi, K.; Matsuyama, S.; Yabashi, M. X-Ray Single-Grating Interferometry for Wavefront Measurement and Correction of Hard X-Ray Nanofocusing Mirrors. Sensors 2020, 20, 7356. https://doi.org/10.3390/s20247356

Yamada J, Inoue T, Nakamura N, Kameshima T, Yamauchi K, Matsuyama S, Yabashi M. X-Ray Single-Grating Interferometry for Wavefront Measurement and Correction of Hard X-Ray Nanofocusing Mirrors. Sensors. 2020; 20(24):7356. https://doi.org/10.3390/s20247356

Chicago/Turabian StyleYamada, Jumpei, Takato Inoue, Nami Nakamura, Takashi Kameshima, Kazuto Yamauchi, Satoshi Matsuyama, and Makina Yabashi. 2020. "X-Ray Single-Grating Interferometry for Wavefront Measurement and Correction of Hard X-Ray Nanofocusing Mirrors" Sensors 20, no. 24: 7356. https://doi.org/10.3390/s20247356

APA StyleYamada, J., Inoue, T., Nakamura, N., Kameshima, T., Yamauchi, K., Matsuyama, S., & Yabashi, M. (2020). X-Ray Single-Grating Interferometry for Wavefront Measurement and Correction of Hard X-Ray Nanofocusing Mirrors. Sensors, 20(24), 7356. https://doi.org/10.3390/s20247356