Flexible Temperature Sensor Integration into E-Textiles Using Different Industrial Yarn Fabrication Processes

Abstract

1. Introduction

2. Materials and Methods

2.1. Fabrication of the Flexible Resistance Temperature Detectors

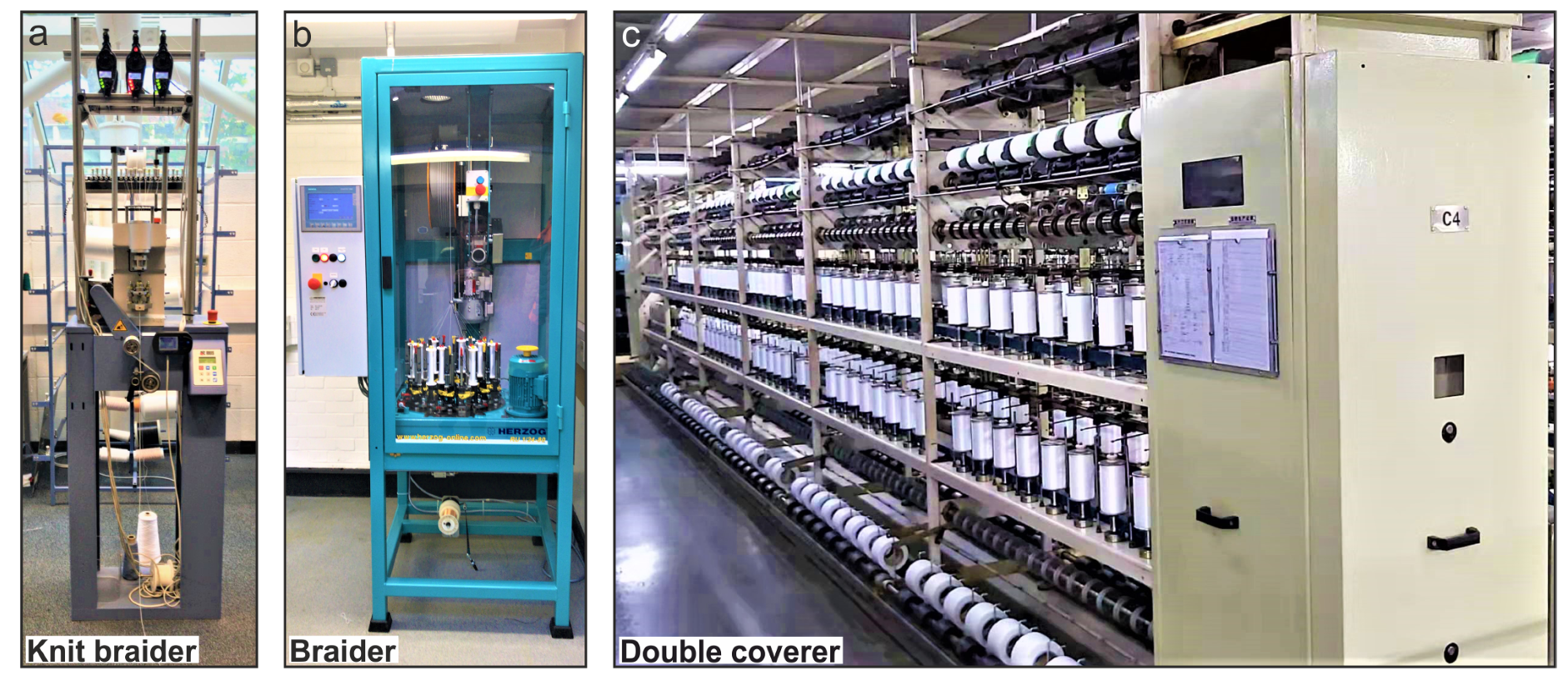

2.2. Construction of the Temperature-Sensing Yarn

2.3. Measuring the Temperature Coefficient of Resistance

2.4. Response Time Experiments

2.5. Temperature Cyclic Test

2.6. Bending Experiments Conducted on the Sensing Yarns

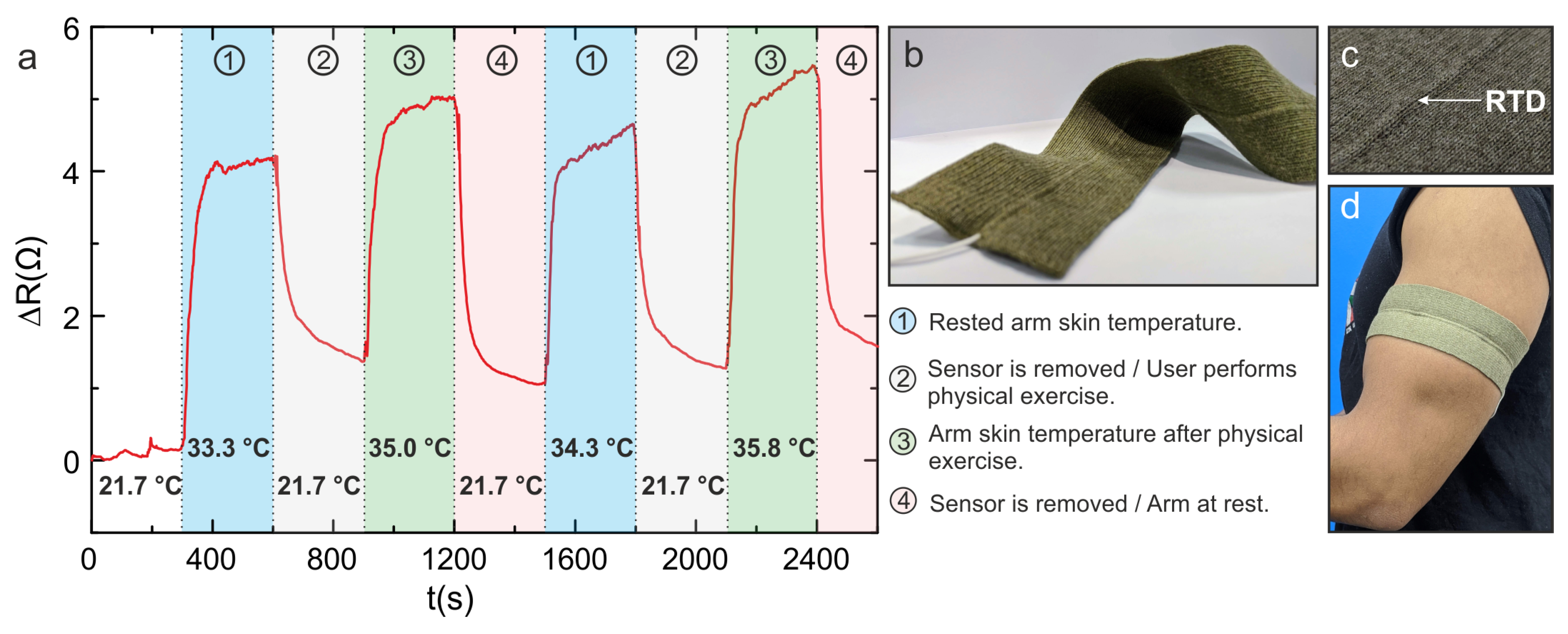

2.7. Manufacturing of a Prototype Armband to Measure Changes in Skin Temperature

3. Results

3.1. Temperature-Sensing Yarn

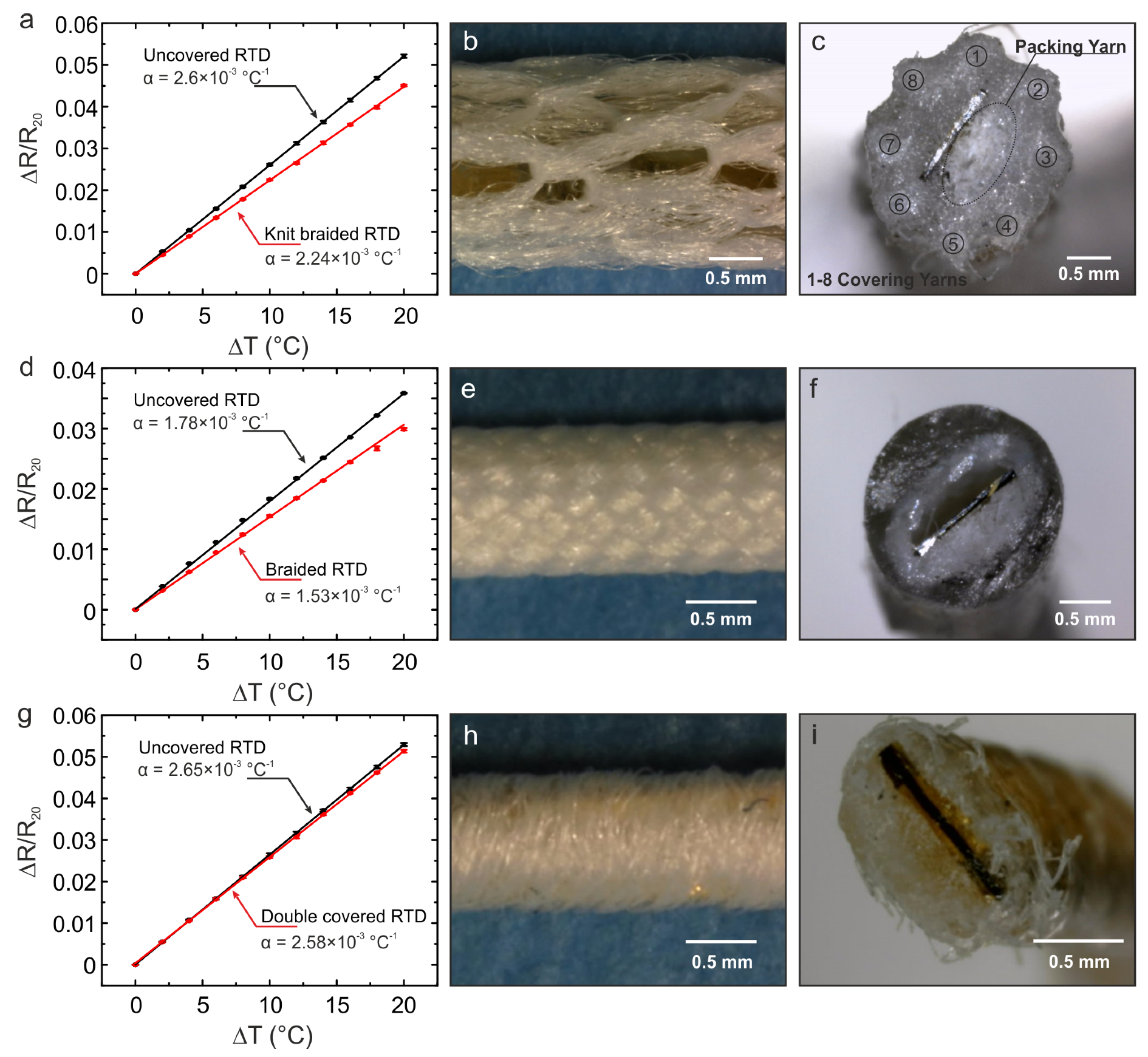

3.2. Temperature Coefficient of Resistance of the Temperature Sensing Yarns

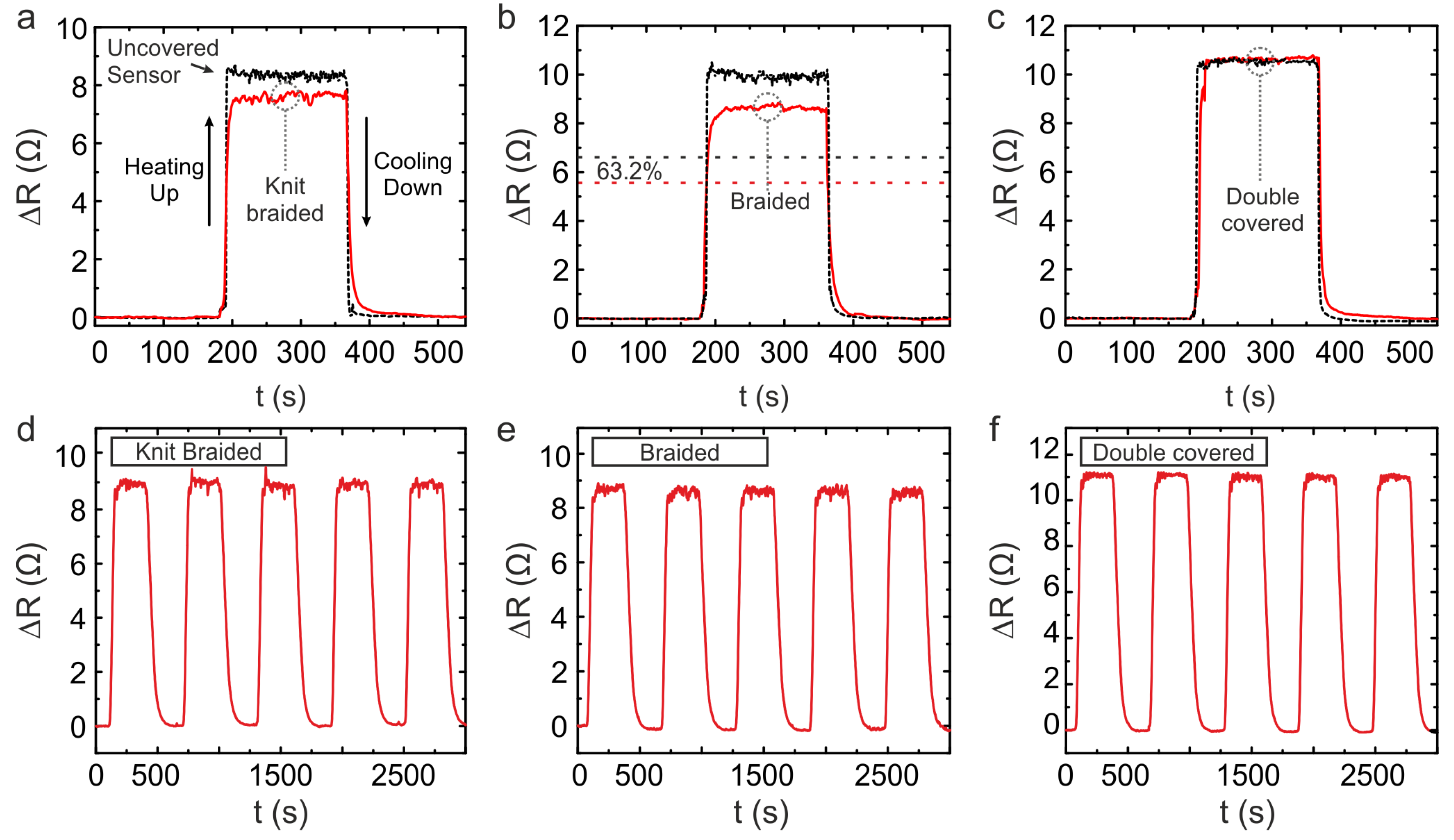

3.3. Response Time of the Temperature-Sensing Yarns

3.4. Temperature Cyclic Tests Results

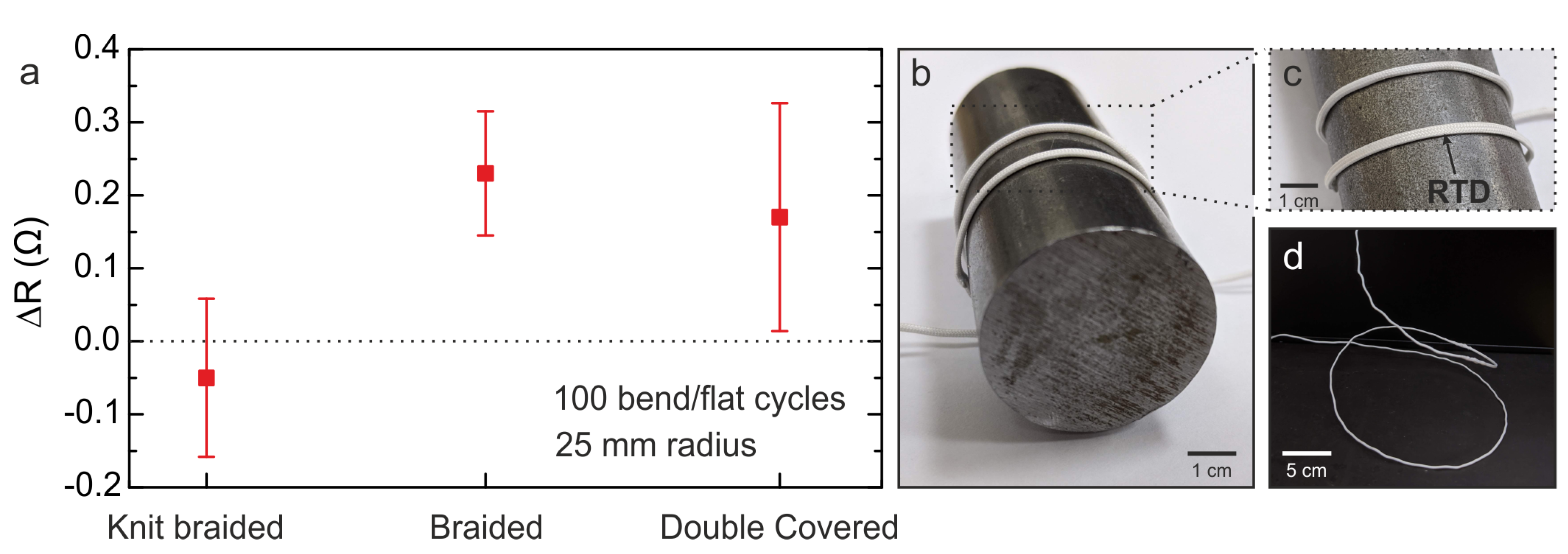

3.5. Results of Bending Experiments on the Temperature-Sensing Yarns

3.6. Temperature Measurements for the Armband Integrated with the Temperature-Sensing Yarn

4. Discussion

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Fuketa, H.; Hamamatsu, M.; Yokota, T.; Yukita, W.; Someya, T.; Sekitani, T.; Takamiya, M.; Someya, T.; Sakurai, T. 16.4 Energy-autonomous fever alarm armband integrating fully flexible solar cells, piezoelectric speaker, temperature detector, and 12V organic complementary FET circuits. In Proceedings of the 2015 IEEE International Solid-State Circuits Conference—(ISSCC) Digest of Technical Papers, San Francisco, CA, USA, 22–26 February 2015. [Google Scholar] [CrossRef]

- McCallum, L.; Higgins, D. Measuring body temperature. Nurs. Times 2012, 108, 20–22. [Google Scholar] [PubMed]

- Nakagami, G.; Sanada, H.; Iizaka, S.; Kadono, T.; Higashino, T.; Koyanagi, H.; Haga, N. Predicting delayed pressure ulcer healing using thermography: A prospective cohort study. J. Wound Care 2010, 19, 465–472. [Google Scholar] [CrossRef] [PubMed]

- Fierheller, M.; Sibbald, R.G. A Clinical Investigation into the Relationship between Increased Periwound Skin Temperature and Local Wound Infection in Patients with Chronic Leg Ulcers. Adv. Skin Wound Care 2010, 23, 369–379. [Google Scholar] [CrossRef] [PubMed]

- Armstrong, D.G.; Holtz-Neiderer, K.; Wendel, C.; Mohler, M.J.; Kimbriel, H.R.; Lavery, L.A. Skin Temperature Monitoring Reduces the Risk for Diabetic Foot Ulceration in High-risk Patients. Am. J. Med. 2007, 120, 1042–1046. [Google Scholar] [CrossRef] [PubMed]

- Lavery, L.A.; Higgins, K.R.; Lanctot, D.R.; Constantinides, G.P.; Zamorano, R.G.; Armstrong, D.G.; Athanasiou, K.A.; Agrawal, C.M. Home Monitoring of Foot Skin Temperatures to Prevent Ulceration. Diabetes Care 2004, 27, 2642–2647. [Google Scholar] [CrossRef]

- Chen, W.; Dols, S.; Oetomo, S.B.; Feijs, L. Monitoring body temperature of newborn infants at neonatal intensive care units using wearable sensors. In Proceedings of the Fifth International Conference on Body Area Networks—BodyNets ’10, Corfu, Greece, 10–12 September 2010. [Google Scholar] [CrossRef]

- Mathur, N.; Glesk, I.; Buis, A. Skin Temperature Prediction in Lower Limb Prostheses. IEEE J. Biomed. Health Inform. 2016, 20, 158–165. [Google Scholar] [CrossRef]

- Hagberg, K.; Brånemark, R. Consequences of non-vascular trans-femoral amputation: A survey of quality of life, prosthetic use and problems. Prosthet. Orthot. Int. 2001, 25, 186–194. [Google Scholar] [CrossRef]

- Mak, A.F.; Zhang, M.; Boone, D.A. State-of-the-art research in lower-limb prosthetic biomechanics-socket interface: A review. J. Rehabil. Res. Dev. 2001, 38, 161–174. [Google Scholar]

- Wade, A.J.; Broadhead, M.W.; Cady, E.B.; Llewelyn, M.E.; Tong, H.N.; Newham, D.J. Influence of muscle temperature during fatiguing work with the first dorsal interosseous muscle in man: A 31 P-NMR spectroscopy study. Eur. J. Appl. Physiol. 2000, 81, 203–209. [Google Scholar] [CrossRef]

- Smith, C.J.; Havenith, G. Body Mapping of Sweating Patterns in Athletes. Med. Sci. Sport. Exerc. 2012, 44, 2350–2361. [Google Scholar] [CrossRef]

- Chaen, Y.; Onitsuka, S.; Hasegawa, H. Wearing a Cooling Vest During Half-Time Improves Intermittent Exercise in the Heat. Front. Physiol. 2019, 10. [Google Scholar] [CrossRef] [PubMed]

- Giansanti, D.; Maccioni, G. Development and testing of a wearable Integrated Thermometer sensor for skin contact thermography. Med. Eng. Phys. 2007, 29, 556–565. [Google Scholar] [CrossRef] [PubMed]

- Yang, J.; Wei, D.; Tang, L.; Song, X.; Luo, W.; Chu, J.; Gao, T.; Shi, H.; Du, C. Wearable temperature sensor based on graphene nanowalls. RSC Adv. 2015, 5, 25609–25615. [Google Scholar] [CrossRef]

- Hong, S.Y.; Lee, Y.H.; Park, H.; Jin, S.W.; Jeong, Y.R.; Yun, J.; You, I.; Zi, G.; Ha, J.S. Stretchable Active Matrix Temperature Sensor Array of Polyaniline Nanofibers for Electronic Skin. Adv. Mater. 2015, 28, 930–935. [Google Scholar] [CrossRef] [PubMed]

- Huang, Y.; Zeng, X.; Wang, W.; Guo, X.; Hao, C.; Pan, W.; Liu, P.; Liu, C.; Ma, Y.; Zhang, Y.; et al. High-resolution flexible temperature sensor based graphite-filled polyethylene oxide and polyvinylidene fluoride composites for body temperature monitoring. Sens. Actuators A Phys. 2018, 278, 1–10. [Google Scholar] [CrossRef]

- Yang, Y.; Jung, J.H.; Yun, B.K.; Zhang, F.; Pradel, K.C.; Guo, W.; Wang, Z.L. Flexible Pyroelectric Nanogenerators using a Composite Structure of Lead-Free KNbO3Nanowires. Adv. Mater. 2012, 24, 5357–5362. [Google Scholar] [CrossRef]

- Costa, J.C.; Spina, F.; Lugoda, P.; Garcia-Garcia, L.; Roggen, D.; Münzenrieder, N. Flexible Sensors—From Materials to Applications. Technologies 2019, 7, 35. [Google Scholar] [CrossRef]

- Bauer, S.; Bauer-Gogonea, S.; Graz, I.; Kaltenbrunner, M.; Keplinger, C.; Schwödiauer, R. 25th Anniversary Article: A Soft Future: From Robots and Sensor Skin to Energy Harvesters. Adv. Mater. 2013, 26, 149–162. [Google Scholar] [CrossRef]

- Nathan, A.; Ahnood, A.; Cole, M.T.; Lee, S.; Suzuki, Y.; Hiralal, P.; Bonaccorso, F.; Hasan, T.; Garcia-Gancedo, L.; Dyadyusha, A.; et al. Flexible Electronics: The Next Ubiquitous Platform. Proc. IEEE 2012, 100, 1486–1517. [Google Scholar] [CrossRef]

- Cherenack, K.; Zysset, C.; Kinkeldei, T.; Münzenrieder, N.; Tröster, G. Woven Electronic Fibers with Sensing and Display Functions for Smart Textiles. Adv. Mater. 2010, 22, 5178–5182. [Google Scholar] [CrossRef]

- Zysset, C.; Kinkeldei, T.W.; Munzenrieder, N.; Cherenack, K.; Troster, G. Integration Method for Electronics in Woven Textiles. IEEE Trans. Compon. Packag. Manuf. Technol. 2012, 2, 1107–1117. [Google Scholar] [CrossRef]

- Kinkeldei, T.; Denier, C.; Zysset, C.; Muenzenrieder, N.; Troester, G. 2D Thin Film Temperature Sensors Fabricated onto 3D Nylon Yarn Surface for Smart Textile Applications. Res. J. Text. Appar. 2013, 17, 16–20. [Google Scholar] [CrossRef]

- Soukup, R.; Hamacek, A.; Mracek, L.; Reboun, J. Textile based temperature and humidity sensor elements for healthcare applications. In Proceedings of the 2014 37th International Spring Seminar on Electronics Technology, Dresden, Germany, 7–11 May 2014. [Google Scholar] [CrossRef]

- Roh, J.S.; Kim, S. All-fabric intelligent temperature regulation system for smart clothing applications. J. Intell. Mater. Syst. Struct. 2015, 27, 1165–1175. [Google Scholar] [CrossRef]

- Husain, M.D.; Kennon, R.; Dias, T. Design and fabrication of Temperature Sensing Fabric. J. Ind. Text. 2013, 44, 398–417. [Google Scholar] [CrossRef]

- Lugoda, P.; Dias, T.; Morris, R. Electronic temperature sensing yarn. J. Multidiscip. Eng. Sci. Stud. 2015, 1, 100–103. [Google Scholar]

- Lugoda, P.; Hughes-Riley, T.; Morris, R.; Dias, T. A Wearable Textile Thermograph. Sensors 2018, 18, 2369. [Google Scholar] [CrossRef]

- Lugoda, P.; Dias, T.; Hughes-Riley, T.; Morris, R. Refinement of Temperature Sensing Yarns. Proceedings 2017, 2, 123. [Google Scholar] [CrossRef]

- Ojuroye, O.O.; Torah, R.N.; Komolafe, A.O.; Beeby, S.P. Embedded Capacitive Proximity and Touch Sensing Flexible Circuit System for Electronic Textile and Wearable Systems. IEEE Sens. J. 2019, 19, 6975–6985. [Google Scholar] [CrossRef]

- Komolafe, A.; Torah, R.; Wei, Y.; Nunes-Matos, H.; Li, M.; Hardy, D.; Dias, T.; Tudor, M.; Beeby, S. Integrating Flexible Filament Circuits for E-Textile Applications. Adv. Mater. Technol. 2019, 4, 1900176. [Google Scholar] [CrossRef]

- Jones, L.A.; Berris, M. The psychophysics of temperature perception and thermal-interface design. In Proceedings of the 10th Symposium on Haptic Interfaces for Virtual Environment and Teleoperator Systems, Orlando, FL, USA, 24–25 March 2002; pp. 137–142. [Google Scholar] [CrossRef]

- Salvatore, G.A.; Sülzle, J.; Valle, F.D.; Cantarella, G.; Robotti, F.; Jokic, P.; Knobelspies, S.; Daus, A.; Büthe, L.; Petti, L.; et al. Biodegradable and Highly Deformable Temperature Sensors for the Internet of Things. Adv. Funct. Mater. 2017, 27, 1702390. [Google Scholar] [CrossRef]

- Wu, J.; Han, S.; Yang, T.; Li, Z.; Wu, Z.; Gui, X.; Tao, K.; Miao, J.; Norford, L.K.; Liu, C.; et al. Highly Stretchable and Transparent Thermistor Based on Self-Healing Double Network Hydrogel. ACS Appl. Mater. Interfaces 2018, 10, 19097–19105. [Google Scholar] [CrossRef] [PubMed]

- Hughes-Riley, T.; Lugoda, P.; Dias, T.; Trabi, C.; Morris, R. A Study of Thermistor Performance within a Textile Structure. Sensors 2017, 17, 1804. [Google Scholar] [CrossRef] [PubMed]

- Lindeque, B.G.; Shuler, F.D.; Bates, C.M. Skin Temperatures Generated Following Plaster Splint Application. Orthopedics 2013, 36, 364–367. [Google Scholar] [CrossRef]

- Suo, Z.; Ma, E.Y.; Gleskova, H.; Wagner, S. Mechanics of rollable and foldable film-on-foil electronics. Appl. Phys. Lett. 1999, 74, 1177–1179. [Google Scholar] [CrossRef]

- Cherenack, K.H.; Kinkeldei, T.; Zysset, C.; Tröster, G. Woven Thin-Film Metal Interconnects. IEEE Electron. Device Lett. 2010, 31, 740–742. [Google Scholar] [CrossRef]

- Lugoda, P.; Hughes-Riley, T.; Oliveira, C.; Morris, R.; Dias, T. Developing Novel Temperature Sensing Garments for Health Monitoring Applications. Fibers 2018, 6, 46. [Google Scholar] [CrossRef]

- Dellinger, J.H. The temperature coefficient of resistance of copper. Bull. Bur. Stand. 1911, 7, 71–101. [Google Scholar] [CrossRef]

- Bolton, W. Instrumentation System Elements. In Instrumentation and Control Systems; Elsevier: Amsterdam, The Netherlands, 2015; pp. 15–65. [Google Scholar] [CrossRef]

- Wang, Q.; Kong, W.; Yao, J.; Chang, A. Fabrication and electrical properties of the fast response Mn1.2Co1.5Ni0.3O4 miniature NTC chip thermistors. Ceram. Int. 2019, 45, 378–383. [Google Scholar] [CrossRef]

| Method of | Uncovered | Covered | Decrease | Percentage | Room |

|---|---|---|---|---|---|

| Embedding | RTD | RTD | in | Decrease in | Temperature |

| (°C−1) | (°C−1) | (°C−1) | (%) | (°C−1) | |

| Knit braid | 2.60 × 10−3 | 2.24 × 10−3 | 3.6 × 10−4 | 13.8 | 24.3 |

| Braid | 1.78 × 10−3 | 1.53 × 10−3 | 2.5 × 10−4 | 14.0 | 24.0 |

| Double cover | 2.65 × 10−3 | 2.58 × 10−3 | 7 × 10−5 | 2.6 | 20.9 |

| Method of Embedding | for Heating | for Cooling | Increase in for Heating | Increase in for Cooling |

|---|---|---|---|---|

| (s) | (s) | (s) | (s) | |

| Knit braid | 4.7 ± 0.5 | 6.2 ± 1.0 | 3.3 ± 0.5 | 4.5 ± 1.0 |

| Braid | 3.4 ± 0.9 | 5 ± 0.6 | 1.9 ± 1.0 | 3.1 ± 0.9 |

| Double cover | 2.4 ± 0.5 | 3.3 ± 0.6 | 1.1 ± 0.7 | 1.8 ± 0.6 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lugoda, P.; Costa, J.C.; Oliveira, C.; Garcia-Garcia, L.A.; Wickramasinghe, S.D.; Pouryazdan, A.; Roggen, D.; Dias, T.; Münzenrieder, N. Flexible Temperature Sensor Integration into E-Textiles Using Different Industrial Yarn Fabrication Processes. Sensors 2020, 20, 73. https://doi.org/10.3390/s20010073

Lugoda P, Costa JC, Oliveira C, Garcia-Garcia LA, Wickramasinghe SD, Pouryazdan A, Roggen D, Dias T, Münzenrieder N. Flexible Temperature Sensor Integration into E-Textiles Using Different Industrial Yarn Fabrication Processes. Sensors. 2020; 20(1):73. https://doi.org/10.3390/s20010073

Chicago/Turabian StyleLugoda, Pasindu, Julio C. Costa, Carlos Oliveira, Leonardo A. Garcia-Garcia, Sanjula D. Wickramasinghe, Arash Pouryazdan, Daniel Roggen, Tilak Dias, and Niko Münzenrieder. 2020. "Flexible Temperature Sensor Integration into E-Textiles Using Different Industrial Yarn Fabrication Processes" Sensors 20, no. 1: 73. https://doi.org/10.3390/s20010073

APA StyleLugoda, P., Costa, J. C., Oliveira, C., Garcia-Garcia, L. A., Wickramasinghe, S. D., Pouryazdan, A., Roggen, D., Dias, T., & Münzenrieder, N. (2020). Flexible Temperature Sensor Integration into E-Textiles Using Different Industrial Yarn Fabrication Processes. Sensors, 20(1), 73. https://doi.org/10.3390/s20010073