Proximity Gettering Design of Hydrocarbon–Molecular–Ion–Implanted Silicon Wafers Using Dark Current Spectroscopy for CMOS Image Sensors

Abstract

1. Introduction

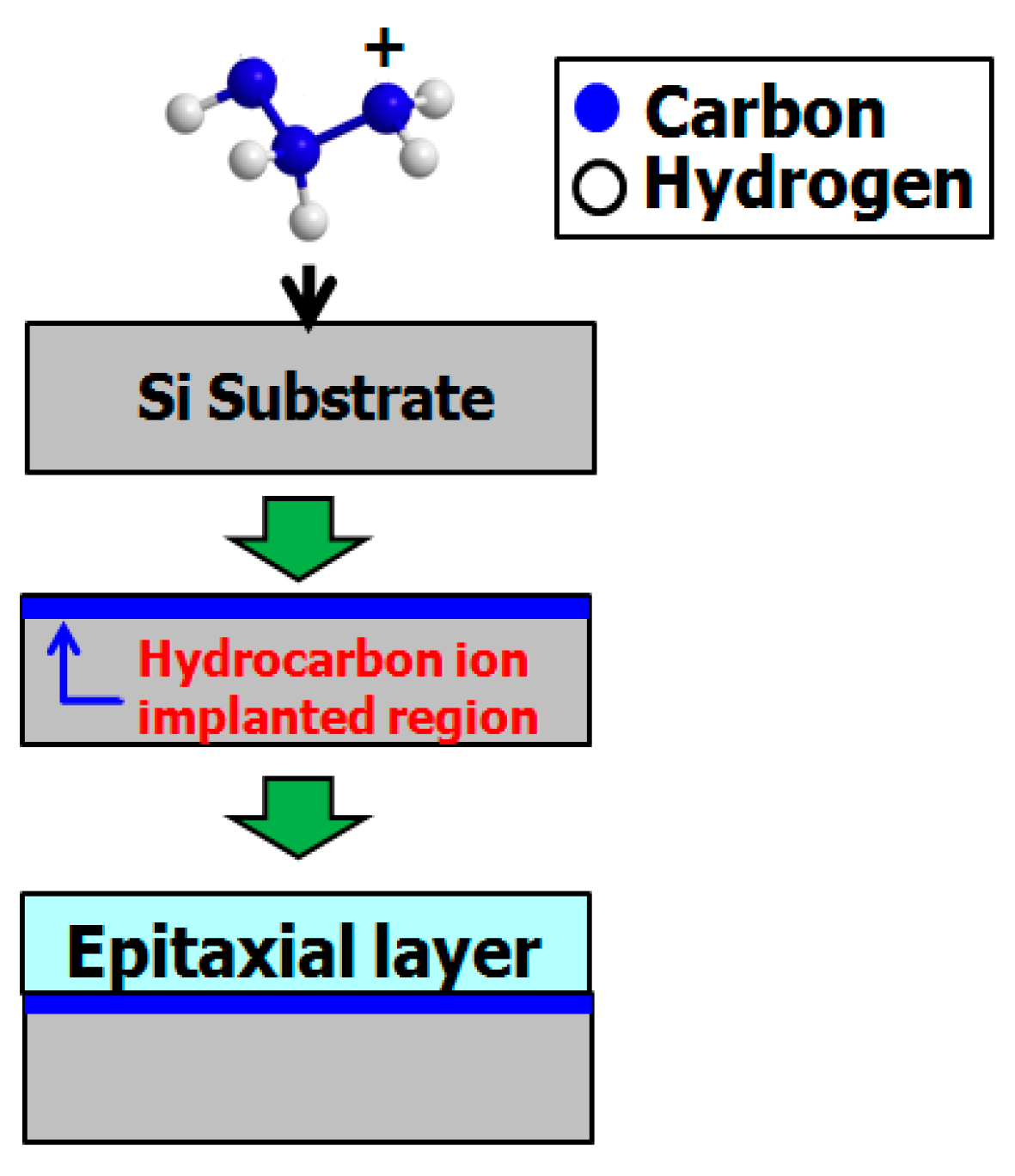

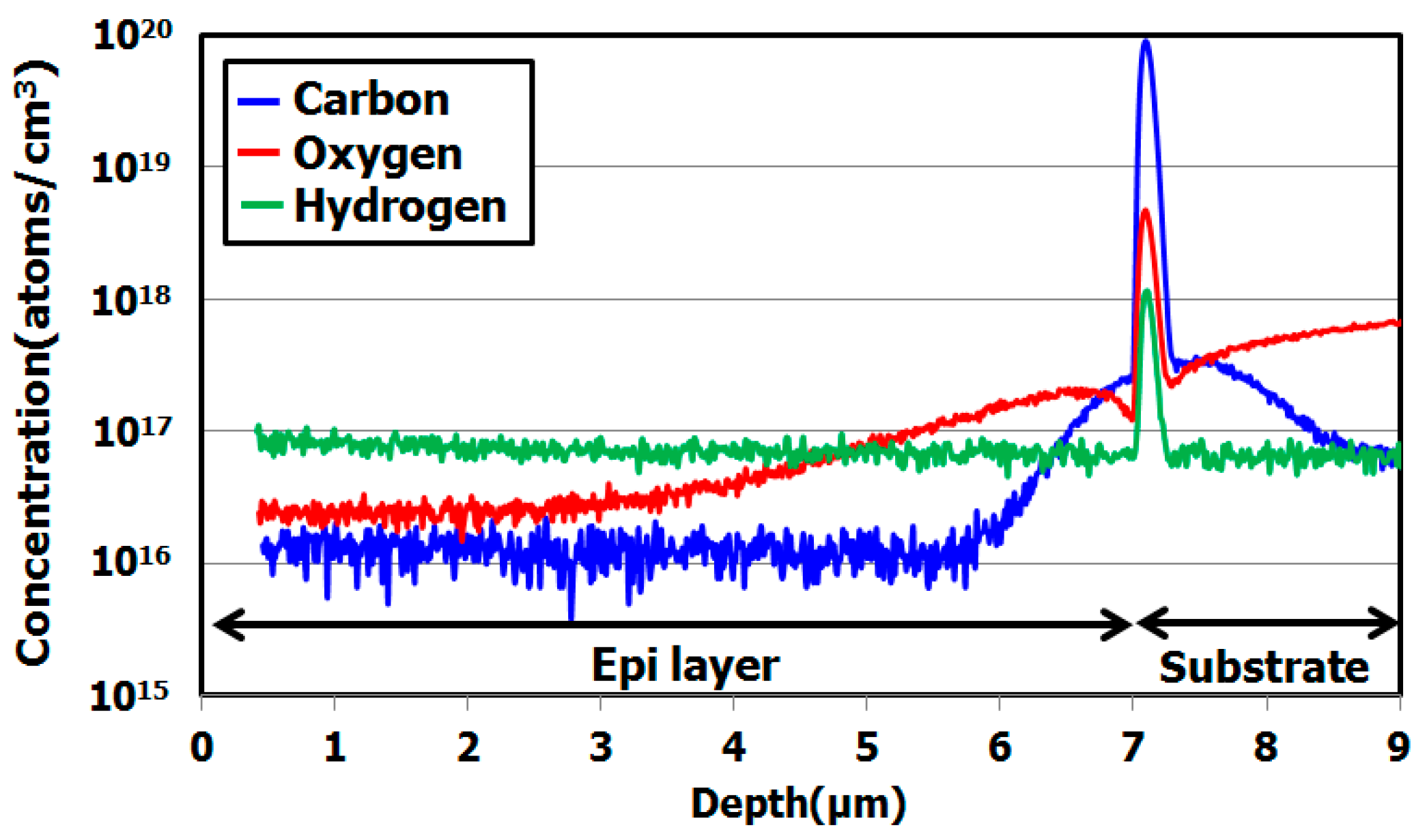

2. Production of Hydrocarbon–Molecular–Ion–Implanted Epitaxial Silicon Wafer

3. Materials and Methods

3.1. Sample Preparation

3.2. Evaluation Technique for Hydrocarbon–Molecular–Ion–Implanted Silicon Wafers

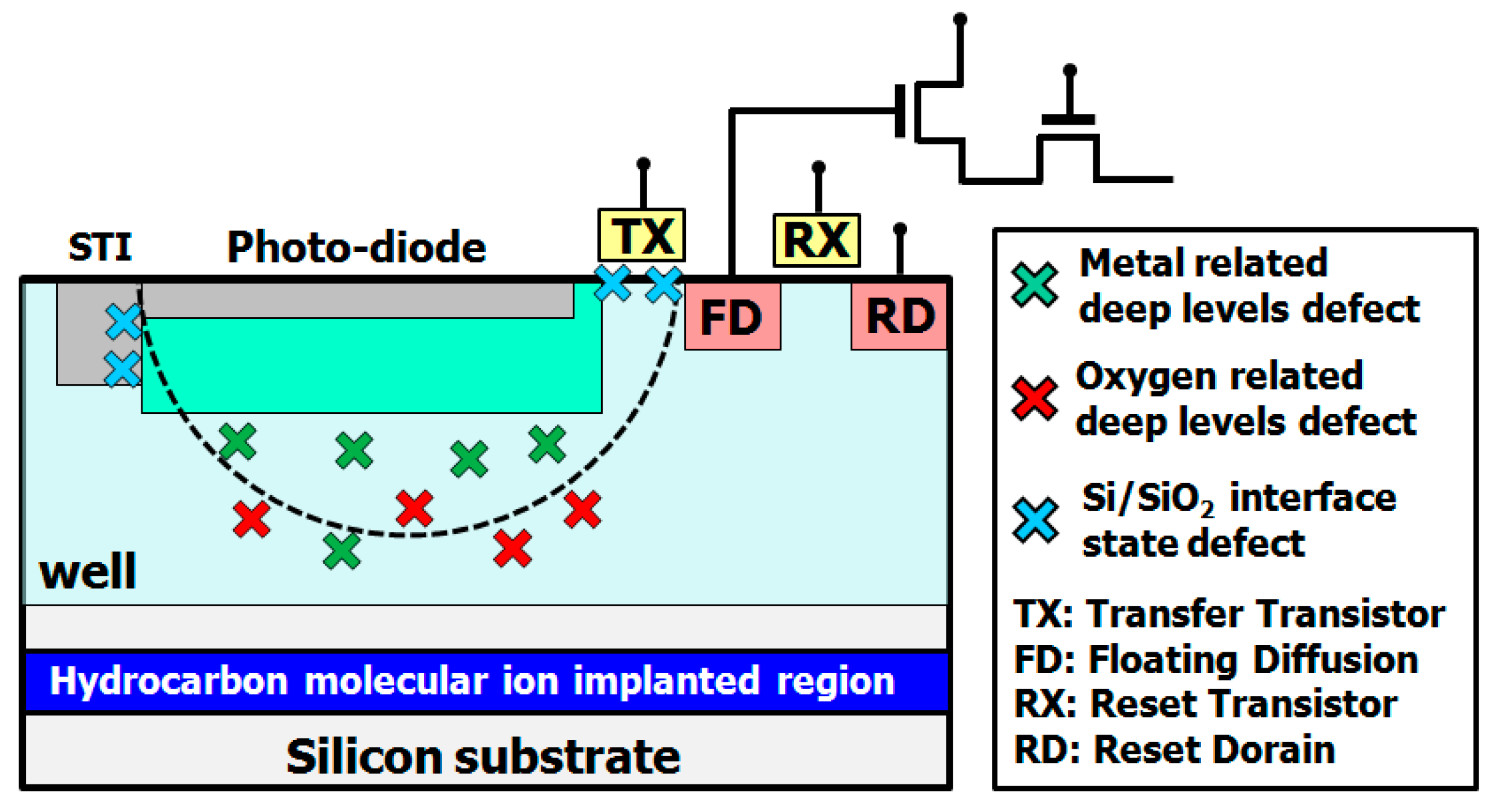

3.3. Gettering Capability Evaluation Using Dark Current Spectroscopy

4. Results and Discussion

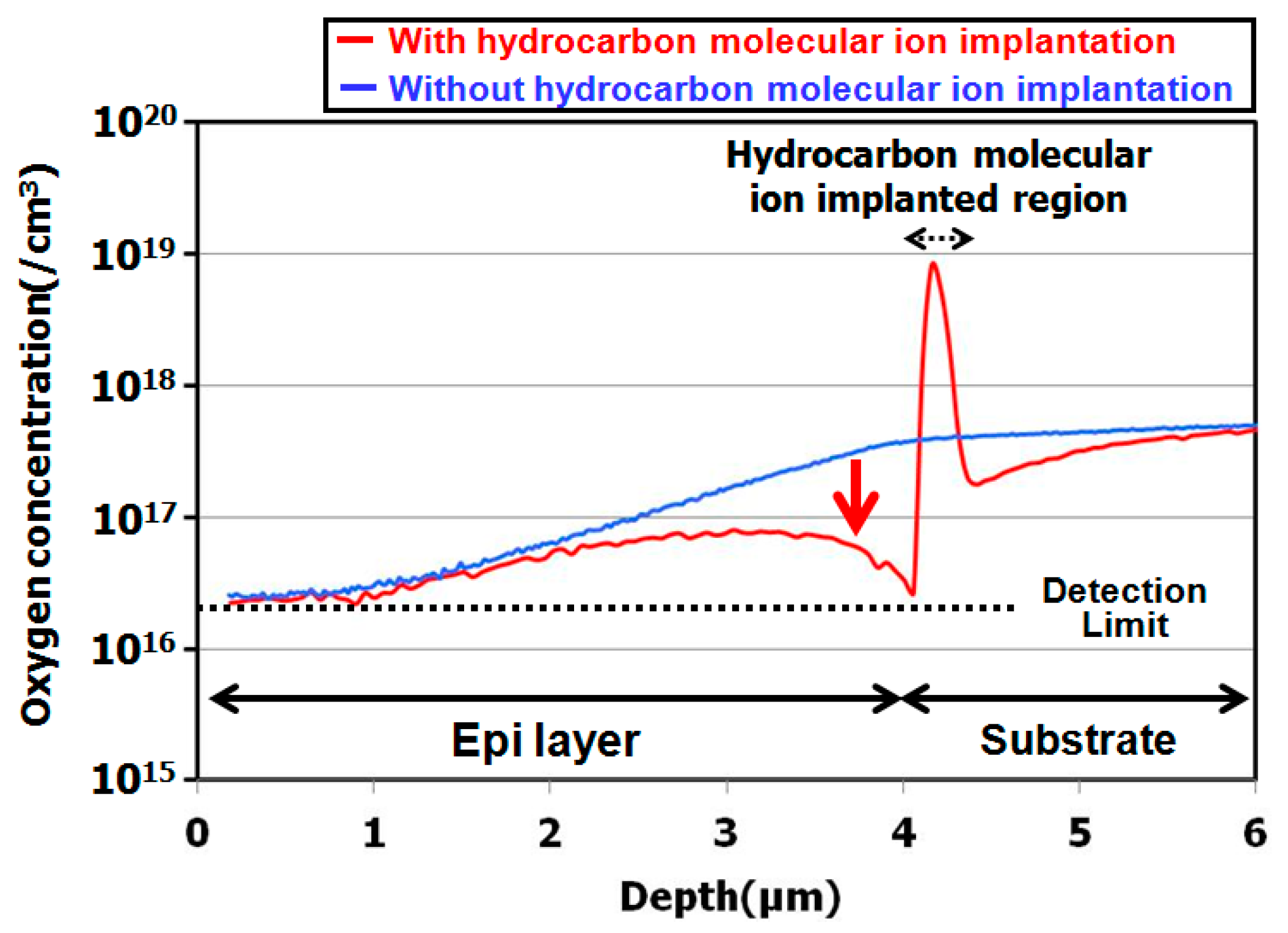

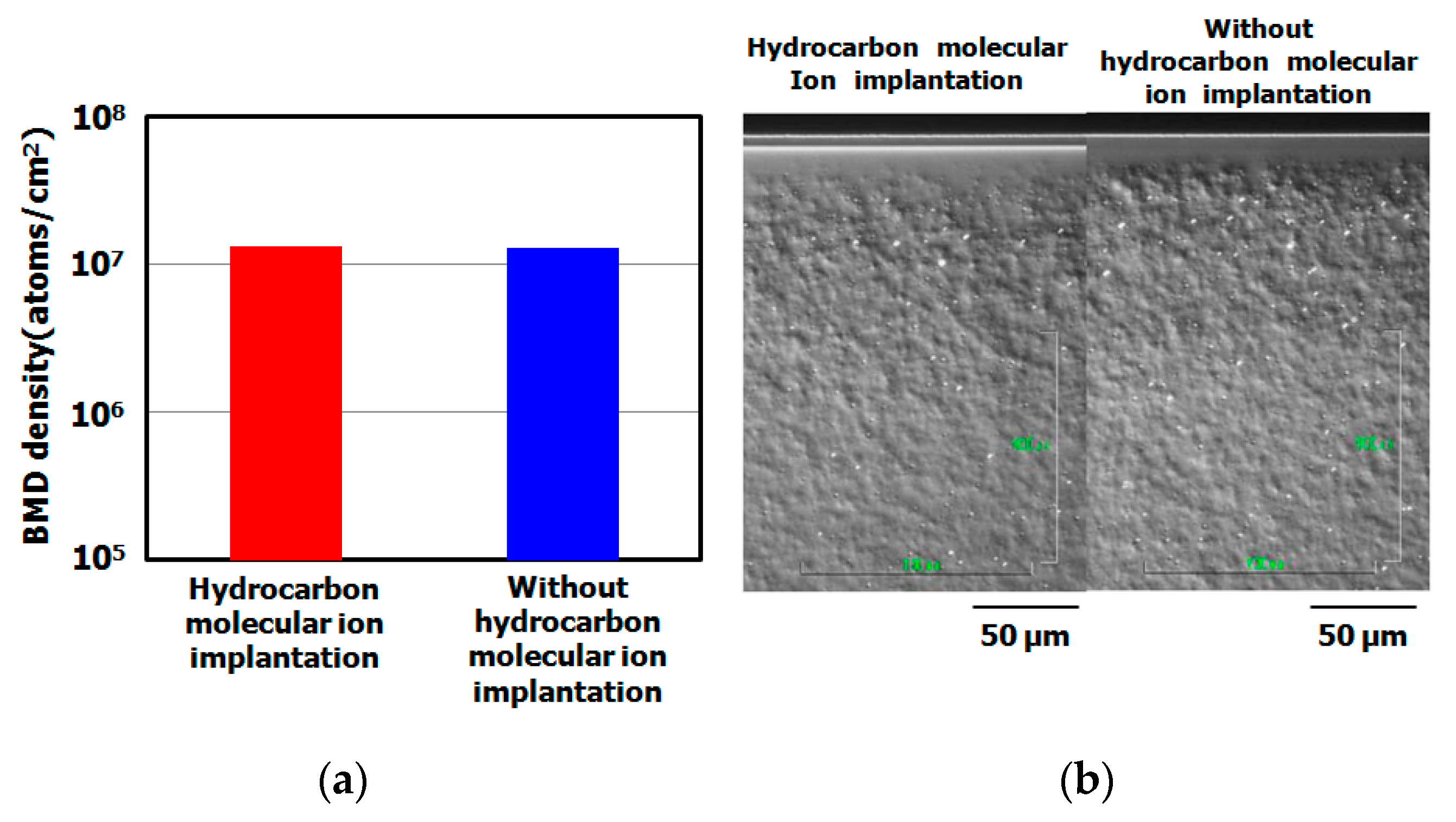

4.1. Metallic Impurity Gettering Capability of Hydrocarbon–Molecular–Ion–Implanted Epitaxial Silicon Wafer after Heat Treatment

4.2. Gettering Capability Dependence on Gettering Methods for Silicon Wafers

4.3. Gettering Capability Dependence on Hydrocarbon–Molecular–Ion Implantation Conditions

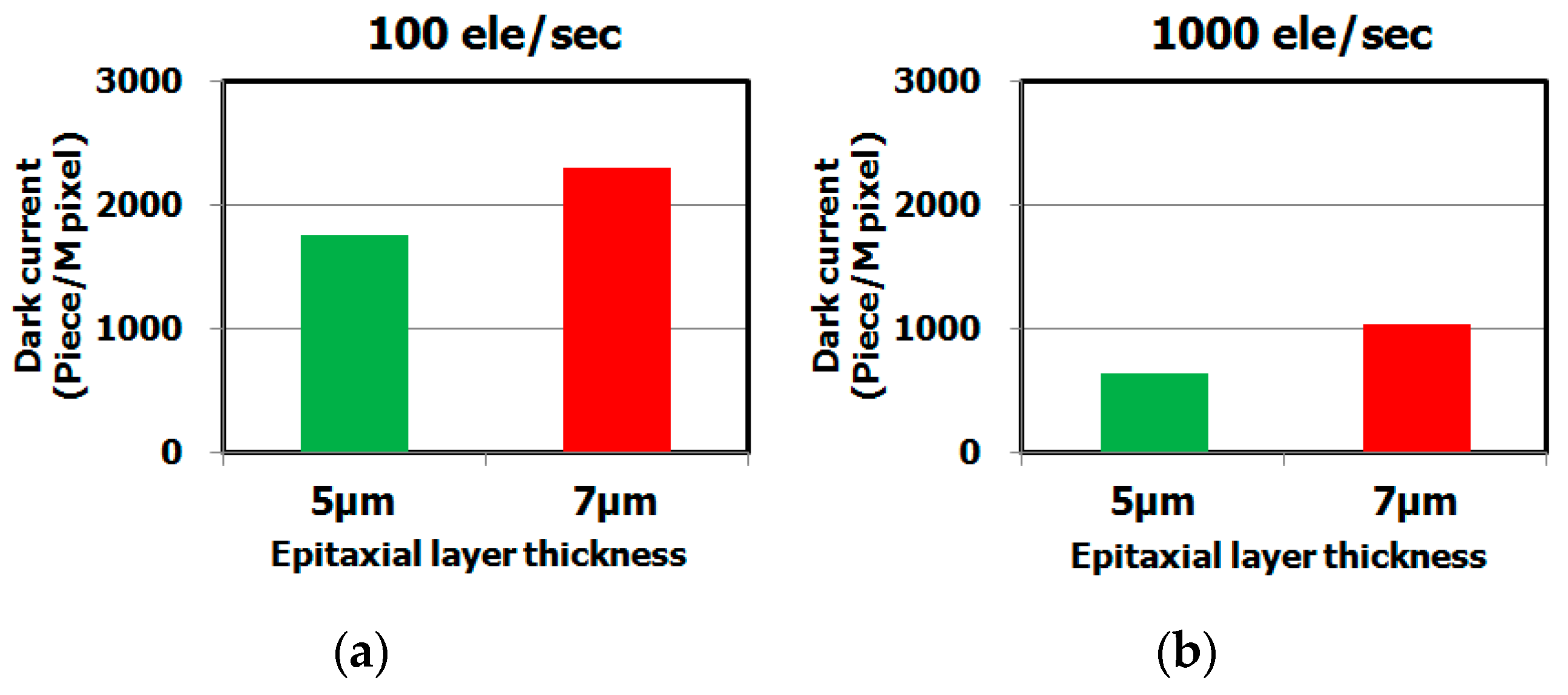

4.4. Gettering Capability Dependence on Epitaxial Growth Conditions (Epitaxial Layer Thickness)

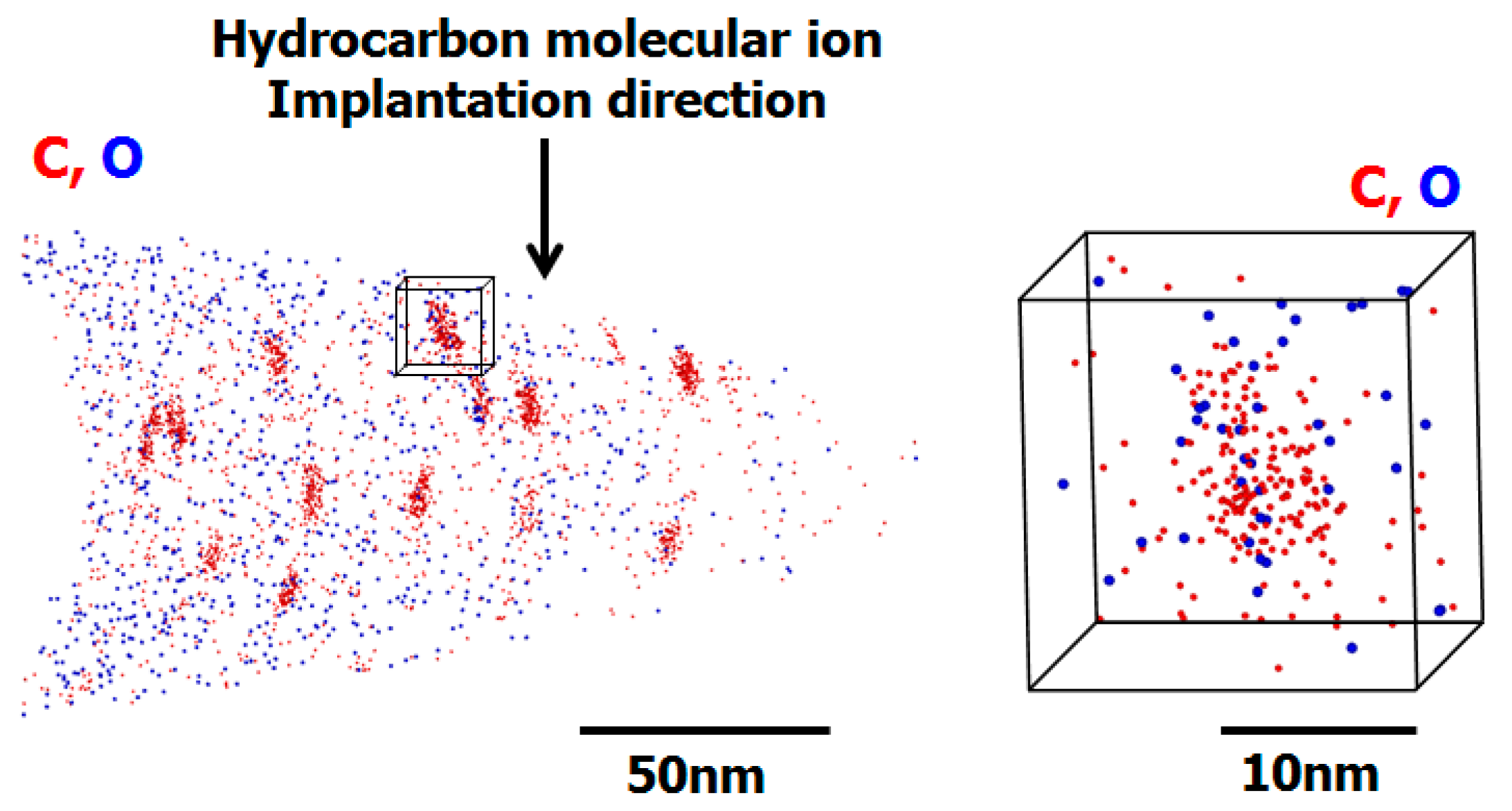

4.5. TEM and APT Observation Results of Hydrocarbon–Molecular–Ion–Implanted Epitaxial Silicon Wafer after CMOS Image Sensor Fabrication Process

4.6. Metallic Impurity Gettering Mechanism of Hydrocarbon–Molecular–Ion–Implanted Silicon Wafer

4.6.1. Relaxation-Induced Gettering Mechanism

4.6.2. Segregate-Induced Gettering Mechanism

4.6.3. Origin of Gettering Sinks in Hydrocarbon–Molecular–Ion Implanted Projection Range

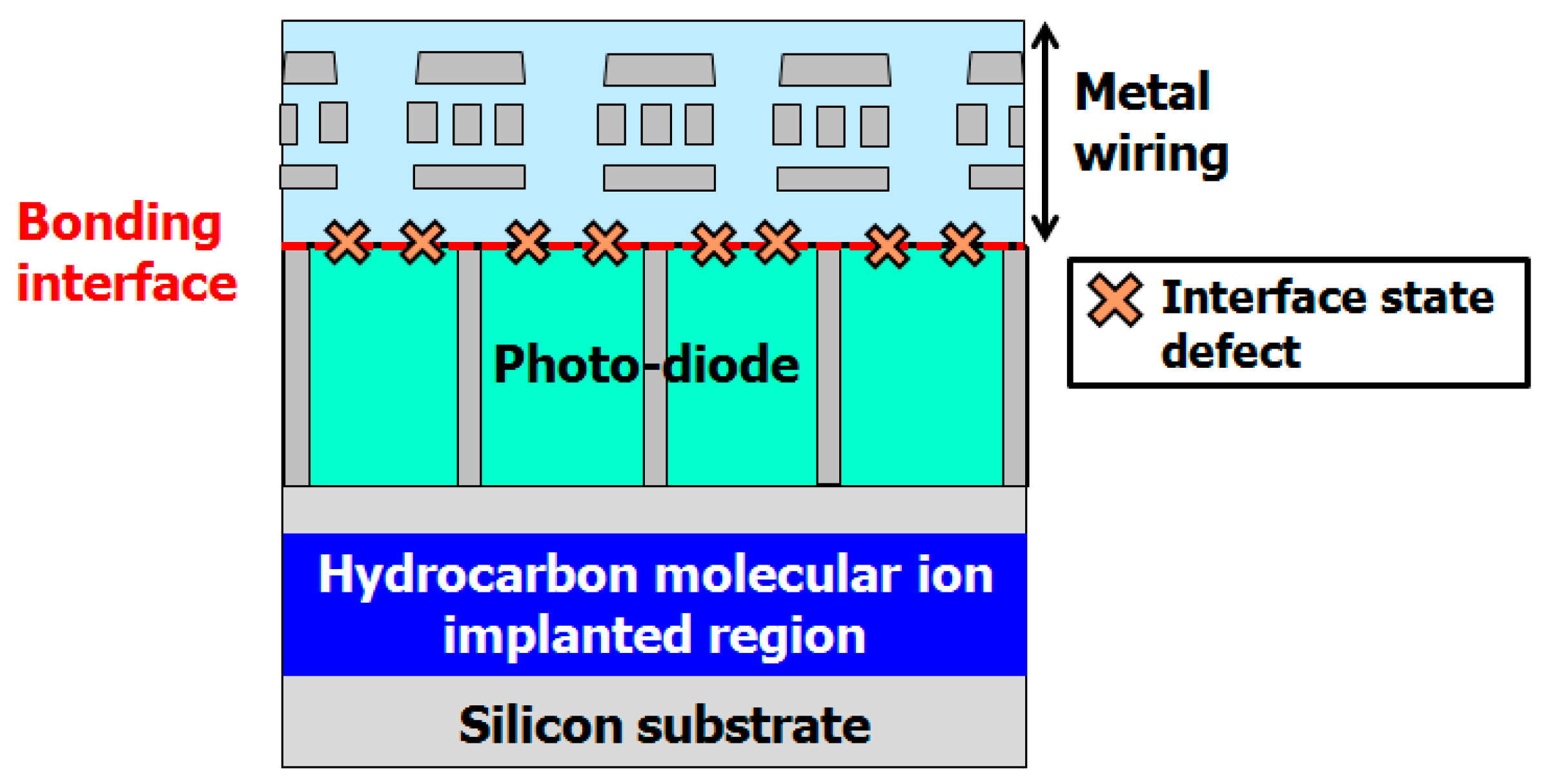

5. Gettering Technology Design for Back-Side-Illuminated CMOS Image Sensors

6. Conclusions

7. Patents

- Kadono, T.; Kurita, K. Method of producing semiconductor epitaxial wafer, semiconductor epitaxial wafer, and method of producing solid-state image sensing device. Japan Patent 5,673,811, 9 January 2015.

- Kadono, T.; Kurita, K. Method of producing semiconductor epitaxial wafer, semiconductor epitaxial wafer, and method of producing solid-state image sensing device. Japan Patent 5,799,935, 4 September 2015.

- Kadono, T.; Kurita, K. Method of producing semiconductor epitaxial wafer, semiconductor epitaxial wafer, and method of producing solid-state image sensing device. Japan Patent 5,799,936, 4 September 2015.

- Kadono, T. Method of producing epitaxial silicon wafer, epitaxial silicon wafer, and method of producing solid-state image sensing device. Japan Patent 5,776,669, 9 September 2015.

- Kadono, T. Method of producing epitaxial silicon wafer, epitaxial silicon wafer, and method of producing solid-state image sensing device. Japan Patent 5,776,670, 17 July 2015.

- Kadono, T. Method of producing semiconductor epitaxial wafer, semiconductor epitaxial wafer, and method of producing solid-state image sensing device. U.S. Patent 9,224,601,29 December 2015.

- Kadono, T. Semiconductor epitaxial wafer. U.S. Patent 9,397,172, 19 July 2016.

- Kadono, T.; Kurita, K. Method of producing semiconductor epitaxial wafer, semiconductor epitaxial wafer, and method of producing solid-state image sensing device. U.S. Patent 9,496,139, 15 November 2016.

- Iwanaga, T.; Kurita, K.; Kadono, T. Method of producing epitaxial silicon wafer and epitaxial silicon wafer. Japan Patent 6,056,772, 16 December 2016.

- Kadono, T.; Kurita, K. Method of producing epitaxial silicon wafer, epitaxial silicon wafer, and method of producing solid-state image sensing device. Japan Patent 6,107,068, 17 March 2017.

- Kadono, T.; Kurita, K. Method of producing semiconductor epitaxial wafer, semiconductor epitaxial wafer, and method of producing solid-state image sensing device. Japan Patent 6,221,928, 13 October 2017.

- Kadono, T.; Kurita, K. Method of producing bonded silicon wafer and bonded silicon wafer. Japan Patent 6,229,258, 27 October 2017.

- Shigematsu, S.; Okuyama, R.; Kurita, K. Gettering capability evaluation mehod and epitaxial silicon wafer. Japan Patent 6,327,393, 27 April 2017.

- Kadono, T.; Kurita, K. Method of producing semiconductor epitaxial wafer, semiconductor epitaxial wafer, and method of producing solid-state image sensing device. Japan Patent 6,278,592, 26 January 2018.

- Kadono, T.; Kurita, K. Method of producing semiconductor epitaxial wafer, semiconductor epitaxial wafer, and method of producing solid-state image sensing device. Japan Patent 6,289,805, 16 February 2018.

- Kadono, T.; Kurita, K. Method of producing bonded silicon wafer and bonded silicon wafer. Japan Patent 6,265,291, 15 January 2018.

- Kadono, T.; Kurita, K. Method of producing semiconductor epitaxial wafer, semiconductor epitaxial wafer, and method of producing solid-state image sensing device. Japan Patent 6,278,591, 26 January 2018.

- Kadono, T.; Kurita, K. Method of producing epitaxial silicon wafer, epitaxial silicon wafer, and method of producing solid-state image sensing device. Japan Patent 6,280,301, 26 January 2018.

- Kadono, T.; Kurita, K. Method of producing epitaxial silicon wafer, epitaxial silicon wafer, and method of producing solid-state image sensing device. Japan Patent 6,361,779, 6 July 2018.

- Iwanaga, T.; Kurita, K.; Kadono, T. Epitaxial wafer manufacturing method and epitaxial wafer. U.S. Patent 10,062,569, 28 August 2018.

- Iwanaga, T.; Kurita, K. Method of producing epitaxial silicon wafer. Japan Patent 6,413,238, 12 October 2018.

- Kadono, T.; Kurita, K. Method of producing semiconductor epitaxial wafer and method of producing solid-state image sensing device. Japan Patent 6,459,948, 11 January 2019.

- Kadono, T.; Kurita, K. Method of producing semiconductor epitaxial wafer and method of producing solid-state image sensing device. Japan Patent 6,485,315, 1 March 2019.

Author Contributions

Acknowledgments

Conflicts of Interest

References

- Kuroda, T. Essential Principles of Image Sensors; CRC Press: Tokyo, Japan, 2014; Chapter 5; p. 55. [Google Scholar]

- Takahashi, H. CMOS Image Sensor; Corona: Tokyo, Japan, 2012; Chapter 3; pp. 123–124. (In Japanese) [Google Scholar]

- Graff, K. Metal Impurities in Silicon-Devices Fabrication, 2nd ed.; Springer: Berlin/Heidelberg, Germany, 2000; Chapter 7; pp. 190–200. [Google Scholar]

- Claeys, C.; Simoen, E. Metal Impurities in Silicon- and Germanium-Based Technologies; Springer: Cham, Switzerland, 2018; Chapter 7; pp. 332–336. [Google Scholar]

- Weber, E.R. Transition metals in silicon. Appl. Phys. 1983, 30, 1–22. [Google Scholar] [CrossRef]

- Istratov, A.A.; Weber, E.R. Electrical properties and recombination activity of copper, nickel and cobalt in silicon. Appl. Phys. 1998, 66, 123–136. [Google Scholar] [CrossRef]

- Jastrzebski, L.; Soydan, R.; Cullen, G.W.; Henry, W.N.; Vecrumba, S. Silicon Wafers for CCD Imagers. Electrochem. Soc. 1987, 134, 212–221. [Google Scholar] [CrossRef]

- Rotondara, A.L.; Hurd, T.Q.; Kaniava, A.; Vanhellemont, J.; Simoen, E.; Heyns, M.M.; Claeys, C.; Brown, G. Impact of Fe and Cu Contamination on the Minority Carrier Lifetime of Silicon Substrates. J. Electrochem. Soc. 1996, 143, 3014–3019. [Google Scholar] [CrossRef]

- Lee, K.-W.; Bea, J.-C.; Fukushima, T.; Tanak, A.T.; Koyanagi, M. Cu Retardation Performance of Extrinsic Gettering Layers in Thinned Wafers Evaluated by Transient Capacitance Measurement. J. Electrochem. Soc. 2011, 158, H795–H799. [Google Scholar] [CrossRef]

- Shoyama, T. Influence of various impurities on performance of CMOS image sensor. In Proceedings of the 2018 8th Forum on the Science and Technology of Silicon Materials, Okayama, Japan, 21 November 2018; pp. 184–186. [Google Scholar]

- Leyris, C.; Martinez, F.; Valenza, M.; Hoffmann, A.; Vildeuil, J.C.; Roy, F. Impact of Random Telegraph Signal in CMOS Image Sensors for Low-Light Levels. In Proceedings of the 32nd European IEEE Solid-State Circuits Conference, Montreux, Switzerland, 19–21 September 2006; pp. 376–379. [Google Scholar]

- Virmontois, C.; Goiffon, V.; Magnan, P.; Saint-Pe, O.; Girard, S.; Petit, S.; Rolland, G.; Bardoux, A. Total Ionizing Dose Versus Displacement Damage Dose Induced Dark Current Random Telegraph Signals in CMOS Image Sensors. IEEE Trans. Nucl. Sci. 2011, 58, 3085–3094. [Google Scholar] [CrossRef]

- Regolini, J.L.; Benoit, D.; Morin, P. Passivation issues in active pixel CMOS image sensors. Microelectron. Reliab. 2007, 47, 739–742. [Google Scholar] [CrossRef]

- Gilles, D.; Weber, E.R.; SooKap, H. Mechanism of internal gettering of interstitial impurities in Czochralski-grown silicon. Phys. Rev. Lett. 1990, 64, 196. [Google Scholar] [CrossRef] [PubMed]

- Aoki, M.; Hara, A.; Ohsawa, A. Fundamental properties of intrinsic gettering of iron in a silicon wafer. J. Appl. Phys. 1992, 72, 895–898. [Google Scholar] [CrossRef]

- Shimura, F. Semiconductor Silicon Crystal Technology; Academic Press: Cambridge, MA, USA, 1989. [Google Scholar]

- Wong, H.; Cheung, N.W.; Chu, P.K. Gettering of gold and copper with implanted carbon in silicon. Appl. Phys. Lett. 1988, 52, 889–891. [Google Scholar] [CrossRef]

- Wong, H.; Cheung, N. Proximity gettering with mega-electron-volt carbon and oxygen implantations. Appl. Phys. Lett. 1988, 52, 1023–1025. [Google Scholar] [CrossRef]

- Kuroi, T.; Kawasaki, Y.; Komori, S.; Fukumoto, K.; Inoshi, M.; Tsukamoto, K.; Shinyashiki, H.; Shingyouji, T. Proximity Gettering of Heavy Metals by High-Energy Ion Implantation. Jpn. J. Appl. Phys. 1993, 32, 303–307. [Google Scholar] [CrossRef]

- Agarwal, A.; Christensen, K.; Venable, D.; Maher, D.M.; Rozgonyi, G.A. Oxygen gettering and precipitation at MeV Si+ ion implantation induced damage in silicon. Appl. Phys. Lett. 1996, 69, 3899. [Google Scholar] [CrossRef]

- Kononchuk, O.; Brown, R.A.; Radzimiski, Z.; Rozgonyi, G.A. Gettering of Fe to below 1010 cm−3 in MeV self-implanted Czochralski and float zone silicon. Appl. Phys. Lett. 1996, 69, 4203. [Google Scholar] [CrossRef]

- Brown, R.A.; Kononchuk, O.; Bondarenko, I.; Romanowski, A.; Radzzimski, Z.; Rozgonyi, G.A. Metallic Impurity Gettering and Secondary Defect Formation in Megaelectron Volt Self-Implanted Czochralski and Float-Zone Silicon. J. Electrochem. Soc. 1997, 144, 2872–2881. [Google Scholar] [CrossRef]

- Koveshikov, S.; Rozgonyi, G.A. Mechanism of iron gettering in MeV Si ion implanted epitaxial silicon. J. Appl. Phys. 1998, 84, 3078–3084. [Google Scholar] [CrossRef]

- Li, F.; Nathan, A. CCD Image Sensors in Deep-Ultraviolet. Degradation Behavior and Damage Mechanisms; Springer: Berlin/Heidelberg, Germany, 2005. [Google Scholar]

- Takahashi, S. A 45 nm Stacked CMOS Image Sensor Process Technology for Submicron Pixel. Sensors 2017, 17, 2816. [Google Scholar] [CrossRef]

- Venezia, V.C. Second Generation Small Pixel Technology Using Hybrid Bond Stacking. Sensors 2018, 18, 667. [Google Scholar] [CrossRef] [PubMed]

- Kadono, T.; Kurita, K. Method of Producing Semiconductor Epitaxial Wafer, Semiconductor Epitaxial Wafer, and Method of Producing Solid-State Image Sensing Device. Japan Patent 5,673,811, 9 January 2015. [Google Scholar]

- Kurita, K. Progress of silicon wafer gettering technology. Oyo Buturi 2015, 84, 628–633. (In Japanese) [Google Scholar]

- Kurita, K.; Kadono, T.; Okuyama, R.; Hirose, R.; Onaka-Masada, A.; Koga, Y.; Okuda, H. Proximity gettering of C3H5 carbon cluster ion-implanted silicon wafers for CMOS image sensors: Gettering effects of transition metal, oxygen, and hydrogen impurities. Jpn. J. Appl. Phys. 2016, 55, 121301. [Google Scholar] [CrossRef]

- Yamada, I.; Matsuo, J. Solid surface process by gas cluster ion beam. Oyo Buturi 1997, 66, 559. (In Japanese) [Google Scholar]

- Yamada, I. Applications of gas cluster ion beams for materials processing. Mater. Sci. Eng. 1996, 217, 82–88. [Google Scholar] [CrossRef]

- Tanjyo, M.; Hamamoto, N.; Nagayama, T.; Umisedo, S.; Koga, Y.; Maehara, N.; Une, H.; Matsumoto, T.; Nagai, N.; Borland, J.O. Cluster Ion Implantation System: Claris for Beyond 45 nm Device Fabrication (II). ECS Trans. 2009, 18, 1059–1064. [Google Scholar]

- Okuyama, R.; Kadono, T.; Masada, A.; Hirose, R.; Koga, Y.; Okuda, H.; Kurita, K. Trapping and diffusion kinetic of hydrogen in carbon-cluster ion-implantation projected range in Czochralski silicon wafers. Jpn. J. Appl. Phys. 2017, 56, 601–606. [Google Scholar] [CrossRef]

- Kurita, K.; Kadono, T.; Okuyama, R.; Hirose, R.; Onaka-Masada, A.; Koga, Y.; Okuda, H. Proximity Gettering Technology for Advanced CMOS Image Sensors Using C3H5 Carbon Cluster Ion Implantation Technique. In Proceedings of the IEEE Electron Device Technology and Manufacturing Conference, Toyama, Japan, 28 February–2 March 2017; pp. 105–106. [Google Scholar] [CrossRef]

- Okuyama, R.; Shigematsu, S.; Hirose, R.; Masada, A.; Kadono, T.; Koga, Y.; Okuda, H.; Kurita, K. Trapping and diffusion behaviour of hydrogen simulated with TCAD in projection range of carbon-cluster implanted silicon epitaxial wafers for CMOS image sensors. Phys. Status Solidi C 2017, 14, 1700036. [Google Scholar] [CrossRef]

- Kurita, K.; Kadono, T.; Okuyama, R.; Shigematsu, S.; Hirose, R.; Onaka-Masada, A.; Koga, Y.; Okuda, H. Proximity gettering technology for advanced CMOS image sensors using carbon cluster ion-implantation technique: A review. Phys. Status Solidi A 2017, 214, 1700216. [Google Scholar] [CrossRef]

- Kelly, T.F.; Miller, M.K. Atom probe tomography. Rev. Sci. Instrum. 2007, 78, 031101. [Google Scholar] [CrossRef] [PubMed]

- Takahashi, H.; Kinochita, M.; Morita, K.; Shirai, T.; Sato, T.; Kimura, T.; Yuzurihara, H.; Inoue, S. A 3.9-/spl mu/m pixel pitch VGA format 10-b digital output CMOS image sensor with 1.5 transistor/pixel. IEEE J. Solid-State Circuits 2004, 39, 2417–2425. [Google Scholar] [CrossRef]

- Mori, M.; Katsuno, M.; Kasuga, S.; Murata, T.; Yamaguchi, T. 1/4-inch 2-mpixel MOS image sensor with 1.75 transistors/pixel. IEEE J. Solid-State Circuits 2004, 39, 2426–2430. [Google Scholar] [CrossRef]

- McGrath, R.D.; Doty, J.; Lupino, G.; Ricker, G.; Vallerga, V. Counting of Deep-Level Traps Using a Charge-Coupled Devices. IEEE Trans. Electron Devices 1987, 34, 2555–2557. [Google Scholar] [CrossRef]

- Mccolgin, W.C.; Lavine, J.P.; Stancampiano, C.V. Probing Metal Defects in CCD Image Sensors. MRS Proc. 1995, 378. [Google Scholar] [CrossRef]

- Mccolgin, W.C.; Lavine, J.; Stancampiano, C.V. Dark Current Spectroscopy of Metals in Silicon. MRS Proc. 1996, 422, 187. [Google Scholar] [CrossRef]

- Lang, D.V. Deep-level transient spectroscopy: A new method to characterize traps in semiconductors. J. Appl. Phys. 1974, 45, 3023–3032. [Google Scholar] [CrossRef]

- Schroder, D.K. Semiconductor Material and Device Characterization, 2nd ed.; Wiley: New York, NJ, USA, 1998; pp. 290–309. [Google Scholar]

- Domengie, F.; Regolini, J.L.; Bauza, D. Study of Metal Contamination in CMOS Image Sensors by Dark-Current and Deep-Level Transient Spectroscopies. J. Electr. Mater. 2010, 39, 625–629. [Google Scholar] [CrossRef]

- Russo, F.; Moccia, G.; Nardone, G.; Alfonsetti, R.; Polsinelli, G.; D’Angelo, A.; Patacchiola, A.; Liverani, M.; Pianezza, P.; Lippa, T.; et al. Proximity gettering of slow diffuser contaminants in CMOS image sensors. Solid-State Electron. 2014, 91, 91–99. [Google Scholar] [CrossRef]

- Russo, F.; Nardone, G.; Polignano, M.L.; D’Ercole, A.; Pennella, F.; Felice, M.D.; Monte, A.D.; Matarazzo, A.; Moccia, G.; Polsinelli, G.; et al. Dark Current Spectroscopy of Transition Metals in CMOS Image Sensors. ECS J. Solid State Sci. Technol. 2017, 6, 217–226. [Google Scholar] [CrossRef]

- Kurita, K.; Kadono, T.; Okuyama, R.; Hirose, R.; Onaka-Masada, A.; Koga, Y.; Okuda, H. Proximity Gettering Design of Silicon Wafers Using Hydrocarbon Molecular Ion Implantation Technique for Advanced CMOS Image Sensors. In Proceedings of the 22nd International Conference on Ion Implantation Technology (IIT 2018), Würzburg, Germany, 16–21 September 2018; p. 95. [Google Scholar]

- Kang, J.S.; Schroder, D.K. Gettering in silicon. J. Appl. Phys. 1989, 65, 2974–2985. [Google Scholar] [CrossRef]

- Benton, J.L.; Stolk, P.A.; Eaglesham, D.J.; Jacobson, D.C.; Cheng, J.Y.; Poate, J.M.; Ha, N.T.; Haynes, T.E.; Myers, S.M. Iron gettering mechanisms in silicon. J. Appl. Phys. 1996, 80, 3275. [Google Scholar] [CrossRef]

- Baldi, L.; Cerofolini, G.F.; Ferla, G.; Frigerio, G. Gold solubility in silicon and gettering by phosphorus. Phys. Status Solidi 1978, 48, 525–532. [Google Scholar] [CrossRef]

- Shigematsu, S.; Okuyama, R.; Hirose, R.; Masada, A.; Kadono, T.; Koga, Y.; Okuda, H.; Kurita, K. Oxygen Gettering Mechanism of Carbon Cluster Ion-Implanted Silicon Wafers for CMOS Image Sensors Revealed by Three-Dimensional Laser-Assisted Atom Probe Tomography. In Proceedings of the 19th Scientific International Symposium on SIMS and Related Techniques Based on Ion-Solid Interactions, Koyto, Japan, 11 May 2017; p. 22. [Google Scholar]

- Shirasawa, S.; Sueoka, K.; Yamaguchi, T.; Maekawa, K. Useful Database of Effective Gettering Sites for Metal Impurities in Si Wafers with First Principles Calculation. J. Electrochemica. Soc. 2015, 4, 351–355. [Google Scholar] [CrossRef]

- Shirasawa, S.; Sueoka, K.; Yamaguchi, T.; Maekawa, K. First principles analysis on proximity gettering sites formed by C3H5 cluster ion implantations. In Proceedings of the 76th Autumn Meeting of Japan Society of Applied Physics and Related Societies, Nagoya, Japan, 14 September 2015. (In Japanese). [Google Scholar]

- Shirasawa, S.; Sueoka, K.; Yamaguchi, T.; Maekawa, K. Density functional theory calculations for estimation of gettering sites of C, H, intrinsic point defects and related complexes in Si wafers. Mater. Sci. Semicond. Process. 2016, 44, 13–17. [Google Scholar] [CrossRef]

- Lee, K.; Tani, T.; Naganuma, H.; Ohara, Y.; Fukushima, T.; Koyanagi, M. Impact of Cu contamination on memory retention characteristics in thinned DRAM chip for 3-D integration. IEEE Electron Dev. Lett. 2012, 33, 1297–1299. [Google Scholar] [CrossRef]

- Lee, K.; Tanikawa, T.; Naganuma, H.; Bea, J.C.; Murugesan, M.; Fukushima, T.; Koyanagi, M. Impact of Cu contamination in 3D integration process on memory retention characteristics in thinned DRAM chip. In Proceedings of the IEEE International Reliability Physics Symposium (IRPS14), Waikoloa, HI, USA, 1 June 2014; pp. 3E4.1–3E4.6. [Google Scholar] [CrossRef]

- Lee, K.W.; Tanikawa, S.; Murugesan, M.; Naganuma, H.; Bea, J.C.; Fukushima, T.; Tanaka, T.; Koyanagi, M. Impact of 3-D integration process on memory retention characteristics in thinned DRAM chip for 3-D high-reliable 3-D DRAM. IEEE Trans. Electron Dev. 2014, 51, 379–385. [Google Scholar] [CrossRef]

- Vici, A.; Russo, F.; Lovisi, N.; Latessa, L.; Marchioni, A.; Casella, A.; Irrera, F. Through-silicon-trench in back-side-illuminated CMOS image sensors for the improvement of gate oxide long term performance. In Proceedings of the International Electron Devices Meeting (IEDM), San Francisco, CA, USA, 2–5 December 2018; pp. 745–750. [Google Scholar]

- Onaka-Masada, A.; Okuyama, R.; Nakai, T.; Shigematsu, S.; Okuda, H.; Kobayashi, K.; Hirose, R.; Kadono, T.; Yoshihiro, K.; Shinohara, M.; et al. Gettering mechanism in hydrocarbon–molecular–ion–implanted epitaxial silicon wafers revealed by three-dimensional atom imaging. Jpn. J. Appl. Phys. 2018, 57, 091302. [Google Scholar] [CrossRef]

- Onaka-Masada, A.; Okuyama, R.; Shigematsu, S.; Okuda, H.; Hirose, R.; Kadono, T.; Yoshihiro, K.; Sueoka, K.; Kurita, K. Gettering Sinks for Metallic Impurities Formed by Carbon-Cluster Ion Implantation in Epitaxial Silicon Wafers for CMOS Image Sensor. IEEE J. Electron Device Soc. 2018, 6, 1205–1211. [Google Scholar] [CrossRef]

- Yamaguchi, T.; Kamino, T.; Goto, Y.; Kimura, M.; Inoue, M.; Matsuura, M. White Spots Reduction by Ultimate Proximity Metal Gettering at Carbon Complexes Formed underneath Contact Area in CMOS Image Sensors. In Proceedings of the 2016 IEEE Symposium on VLSI Technology, Honolulu, HI, USA, 14–16 June 2016. [Google Scholar] [CrossRef]

- Yamaguchi, T. White Spots Reduction of CMOS Image Sensors by Proximity Metal Gettering Technology. In Proceedings of the 145th Committee on Processing and Characterization of Crystals of The Japan Society for the Promotion of Science, Tokyo, Japan, 21 July 2017; pp. 20–24. (In Japanese). [Google Scholar]

- Yamaguchi, T.; Kamino, T.; Goto, Y.; Kimura, M.; Inoue, M.; Matsuura, M. Investigate of Implantation Damage Recover and Gettering Technology for CMOS Image Sensor. In Proceedings of the 2018 8th Forum on the Science and Technology of Silicon Materials, Okayama, Japan, 21 November 2018; pp. 170–177. [Google Scholar]

- Koga, Y.; Kadono, T.; Shigematsu, S.; Hirose, R.; Masada, O.A.; Okuyama, R.; Okuda, H.; Kurita, K. Room-temperature bonding of epitaxial layer to carbon-cluster ion-implanted silicon wafers for CMOS image sensors. Jpn. J. Appl. Phys. 2018, 57, 061302. [Google Scholar] [CrossRef]

- Kurita, K.; Koga, Y.; Kadono, T.; Shigematsu, S.; Hirose, R.; Masada, O.A.; Okuyama, R.; Okuda, H. Proximity Gettering Design of Hydrocarbon Molecular Ion Implanted Silicon Wafers using Direct Bonding Technique for Advanced CMOS image sensors: A review. ECS Transaction. 2018, 86, 77–93. [Google Scholar] [CrossRef]

- Suga, T.; Takahashi, Y.; Takagi, H.; Gibbesch, B.; Elssner, G. Structure of Al-Al and Al-Si3N4 interfaces bonded at room temperature by means of the surface activation method. Acta Metall. Mater. 1992, 40, S133–S137. [Google Scholar] [CrossRef]

- Takagi, H.; Kikuchi, K.; Maeda, R. Surface activated bonding of silicon wafers at room temperature. Appl. Phys. Lett. 1996, 68, 2222–2224. [Google Scholar] [CrossRef]

- Takagi, H.; Maeda, R.; Chung, T.R.; Hosoda, H.; Suga, T. Effect of Surface Roughness on Room-Temperature Wafer Bonding by Ar Beam Surface Activation. Jpn. J. Appl. Phys. 1998, 37, 4197–4203. [Google Scholar] [CrossRef]

- Okuyama, R.; Masada, O.A.; Kobayashi, K.; Shigematsu, S.; Kadono, T.; Hirose, R.; Koga, Y.; Okuda, H.; Kurita, K. Diffusion behavior of hydrogen in molecular ion implanted silicon epitaxial wafers for advanced CMOS image sensor. In Proceedings of the 2018 8th Forum on the Science and Technology of Silicon Materials, Okayama, Japan, 21 November 2018; pp. 187–200. [Google Scholar]

- Sez, S.M. Physic of Semiconductor Devices, 2nd ed.; Wiley: New York, NJ, USA, 1981; Chapter 8; pp. 379–385. [Google Scholar]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kurita, K.; Kadono, T.; Shigematsu, S.; Hirose, R.; Okuyama, R.; Onaka-Masada, A.; Okuda, H.; Koga, Y. Proximity Gettering Design of Hydrocarbon–Molecular–Ion–Implanted Silicon Wafers Using Dark Current Spectroscopy for CMOS Image Sensors. Sensors 2019, 19, 2073. https://doi.org/10.3390/s19092073

Kurita K, Kadono T, Shigematsu S, Hirose R, Okuyama R, Onaka-Masada A, Okuda H, Koga Y. Proximity Gettering Design of Hydrocarbon–Molecular–Ion–Implanted Silicon Wafers Using Dark Current Spectroscopy for CMOS Image Sensors. Sensors. 2019; 19(9):2073. https://doi.org/10.3390/s19092073

Chicago/Turabian StyleKurita, Kazunari, Takeshi Kadono, Satoshi Shigematsu, Ryo Hirose, Ryosuke Okuyama, Ayumi Onaka-Masada, Hidehiko Okuda, and Yoshihiro Koga. 2019. "Proximity Gettering Design of Hydrocarbon–Molecular–Ion–Implanted Silicon Wafers Using Dark Current Spectroscopy for CMOS Image Sensors" Sensors 19, no. 9: 2073. https://doi.org/10.3390/s19092073

APA StyleKurita, K., Kadono, T., Shigematsu, S., Hirose, R., Okuyama, R., Onaka-Masada, A., Okuda, H., & Koga, Y. (2019). Proximity Gettering Design of Hydrocarbon–Molecular–Ion–Implanted Silicon Wafers Using Dark Current Spectroscopy for CMOS Image Sensors. Sensors, 19(9), 2073. https://doi.org/10.3390/s19092073