Sensitivity Enhancement of Silicon-on-Insulator CMOS MEMS Thermal Hot-Film Flow Sensors by Minimizing Membrane Conductive Heat Losses

Abstract

1. Introduction

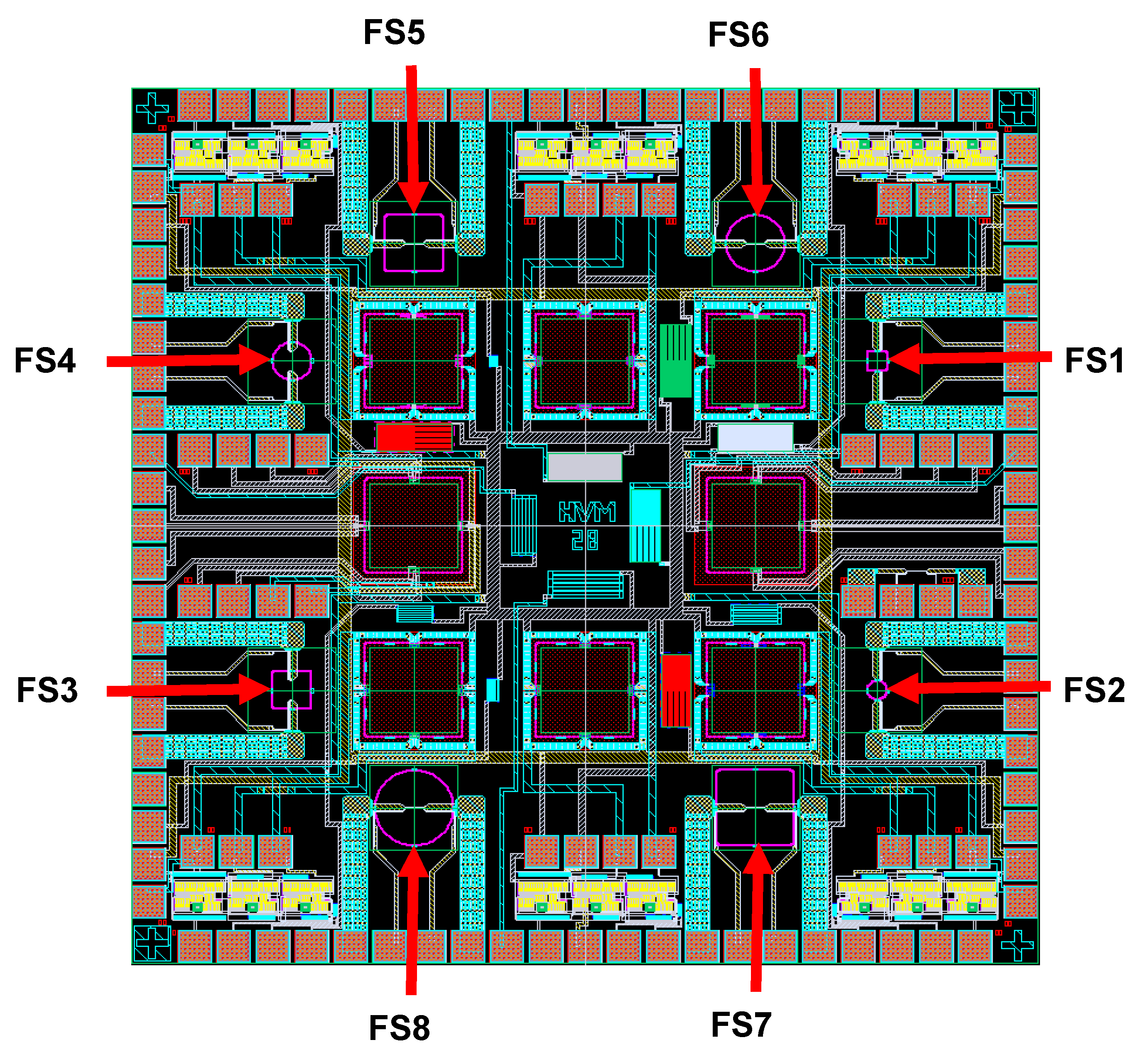

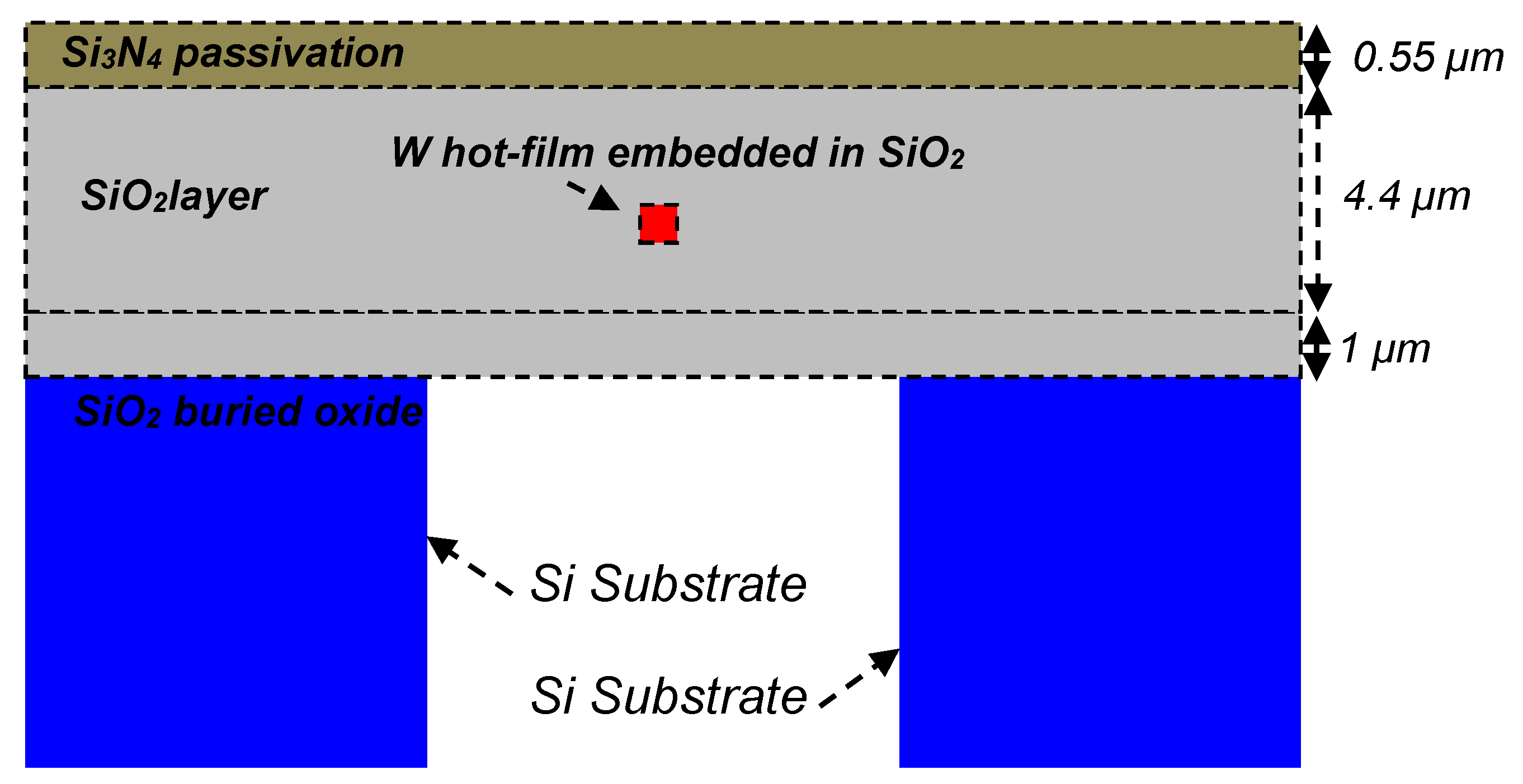

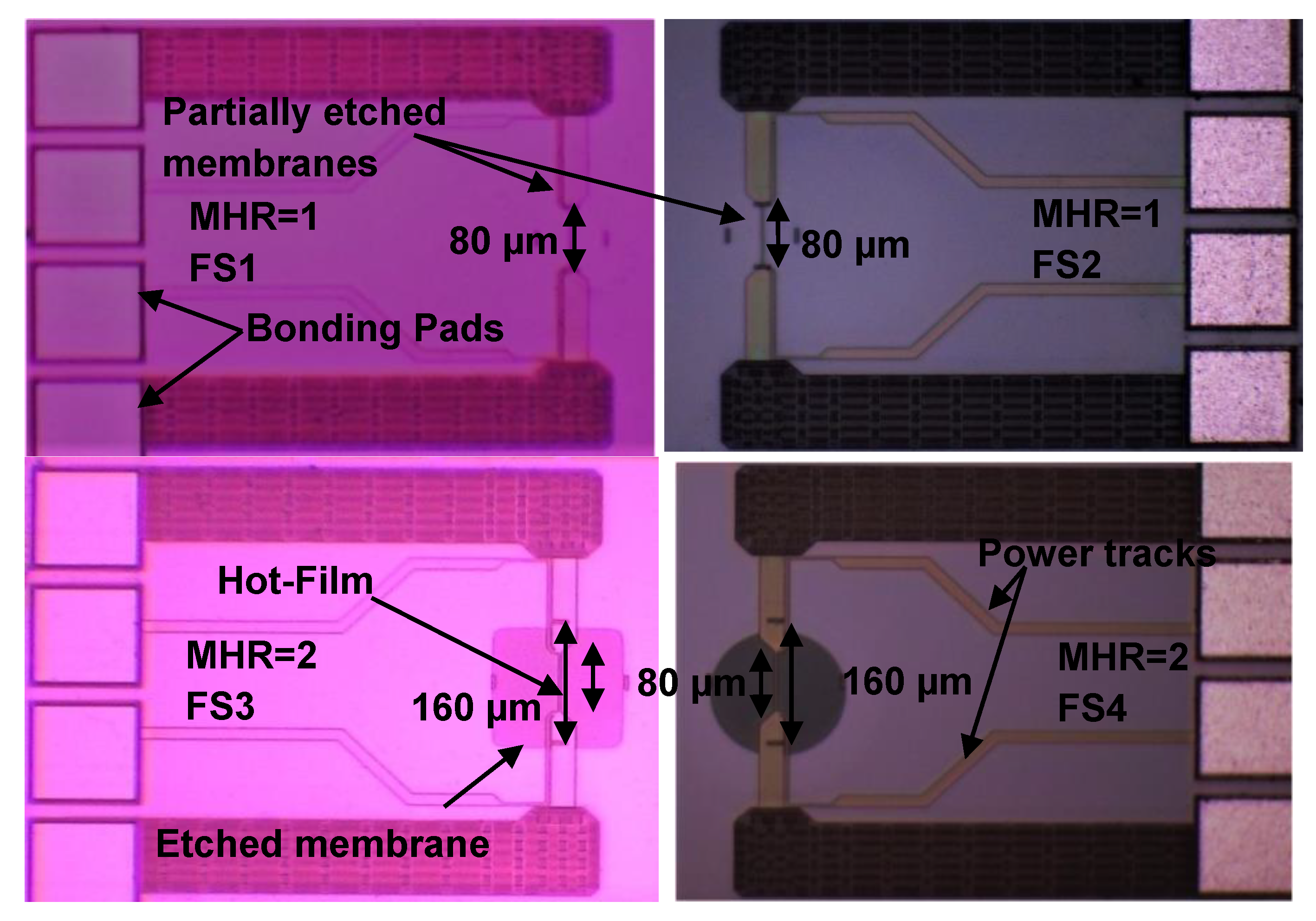

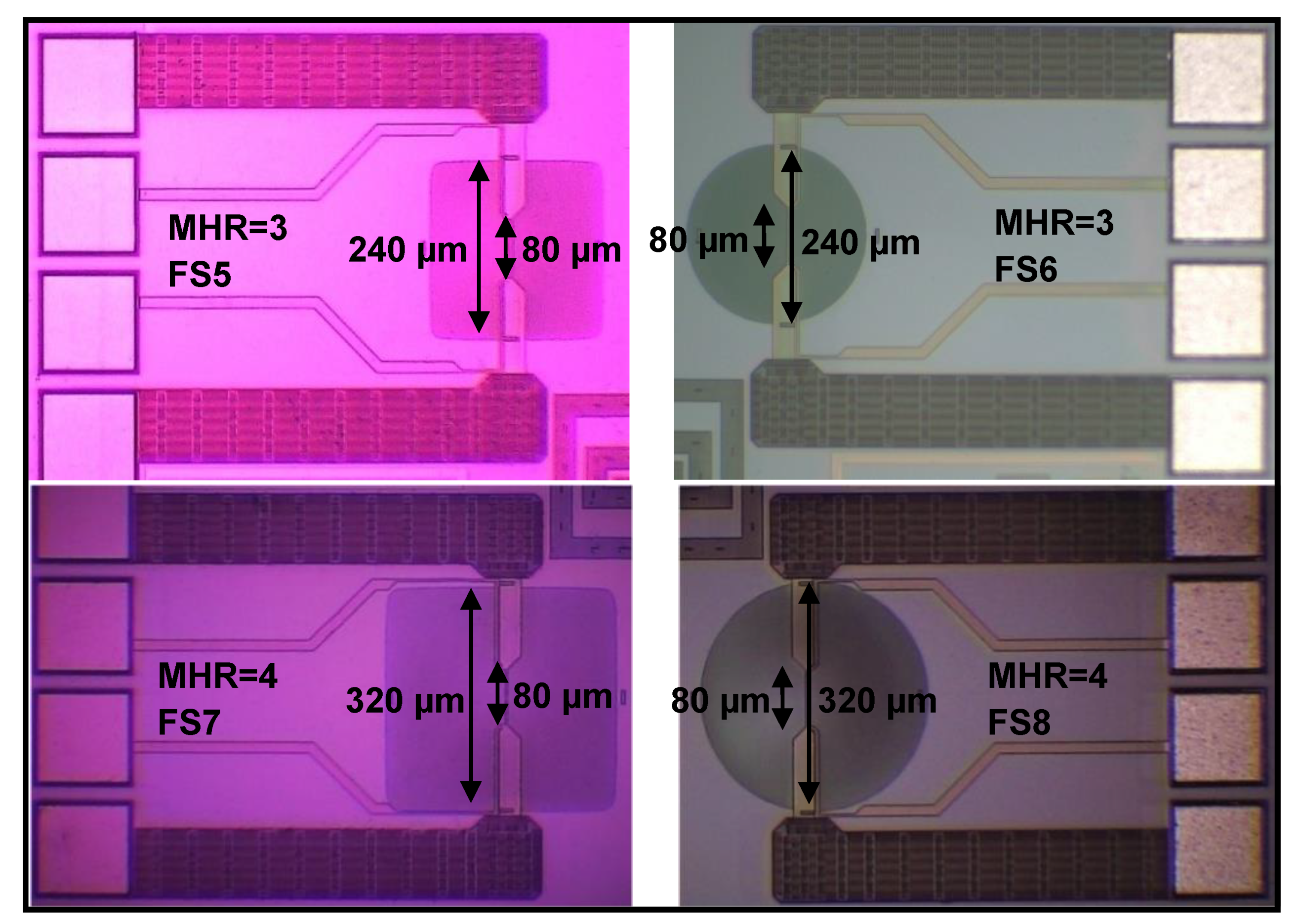

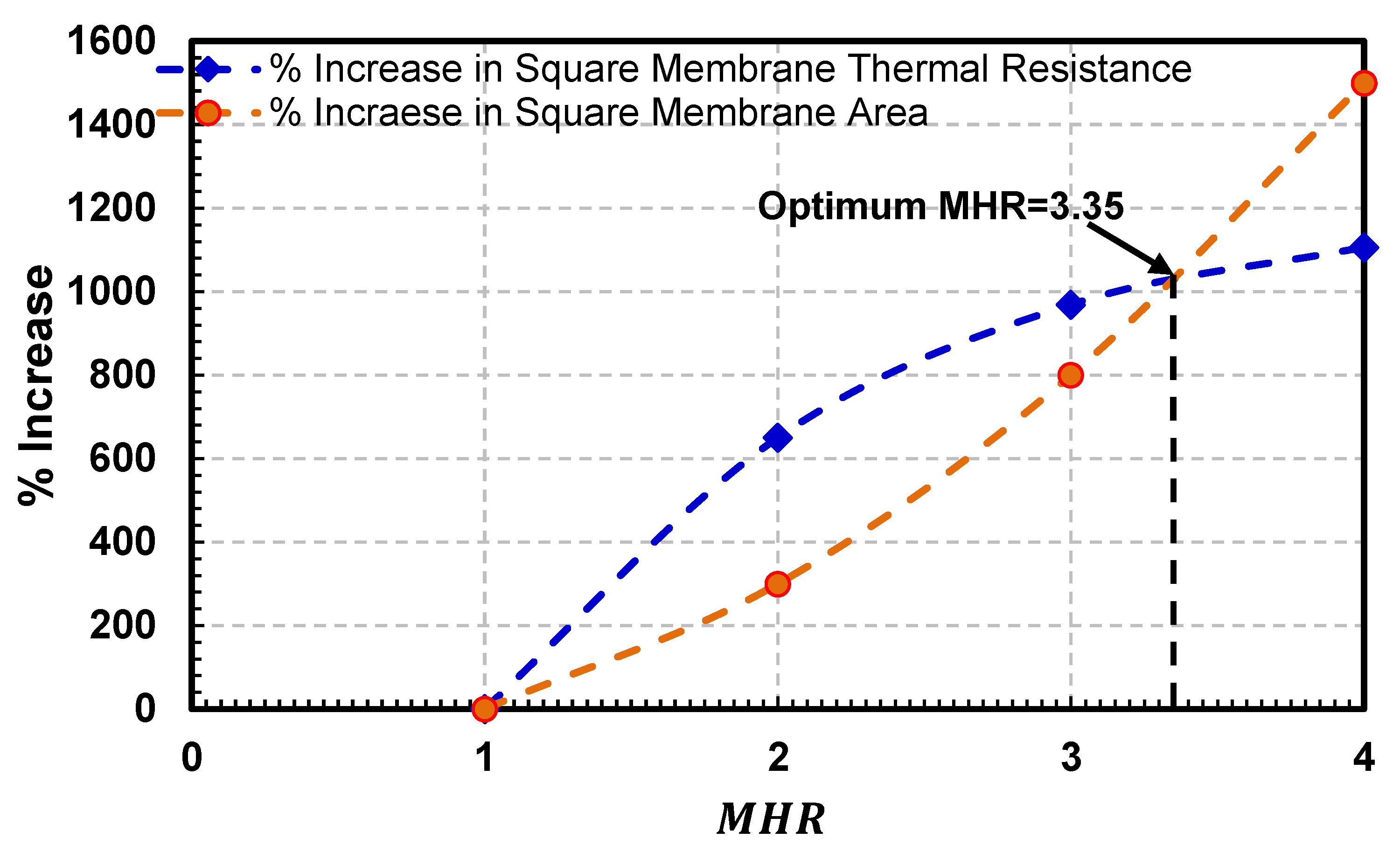

2. SOI CMOS MEMS Hot-Film Sensors Chip Design

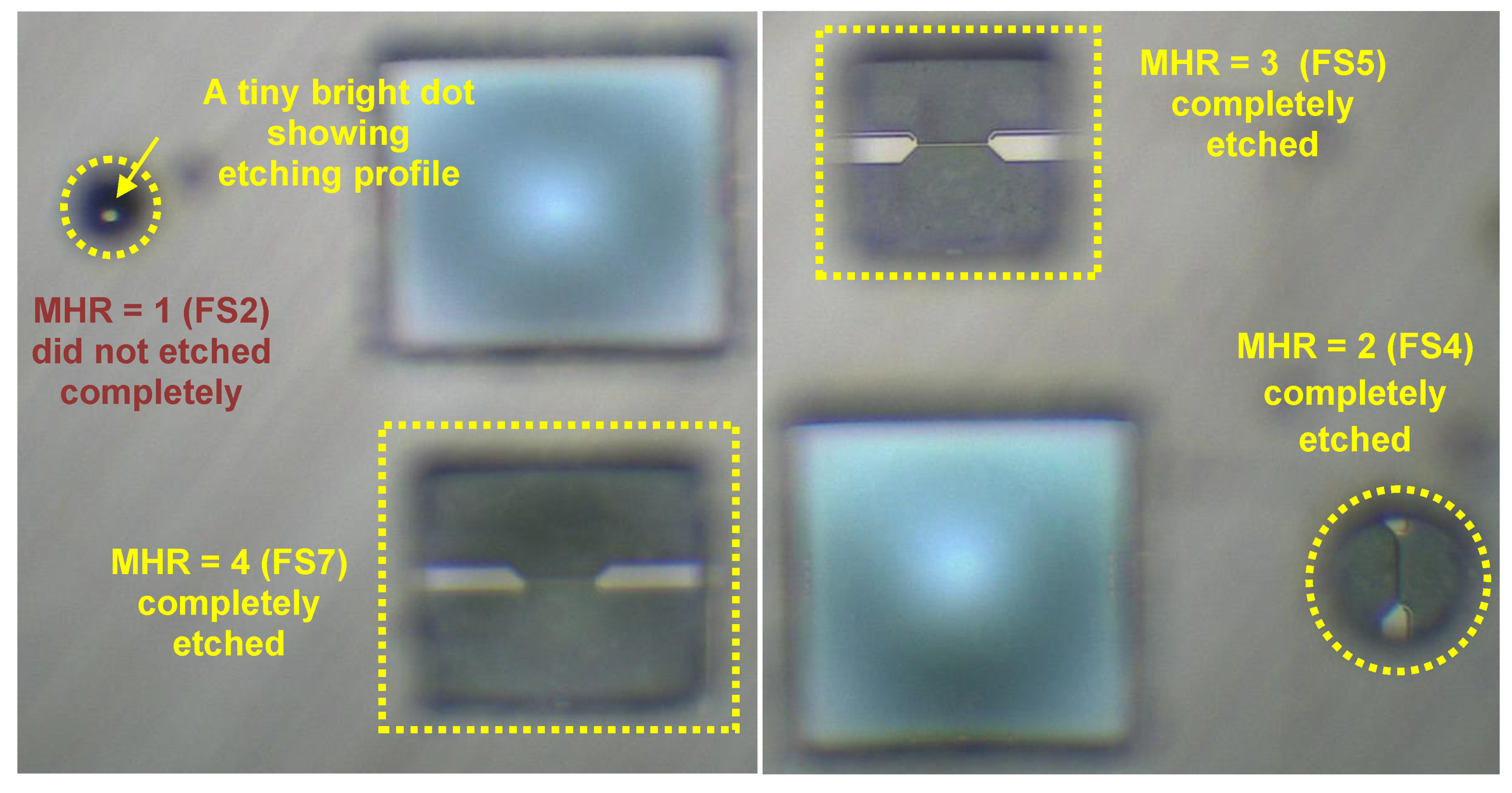

3. SOI CMOS MEMS Hot-Film Sensors Chip Fabrication

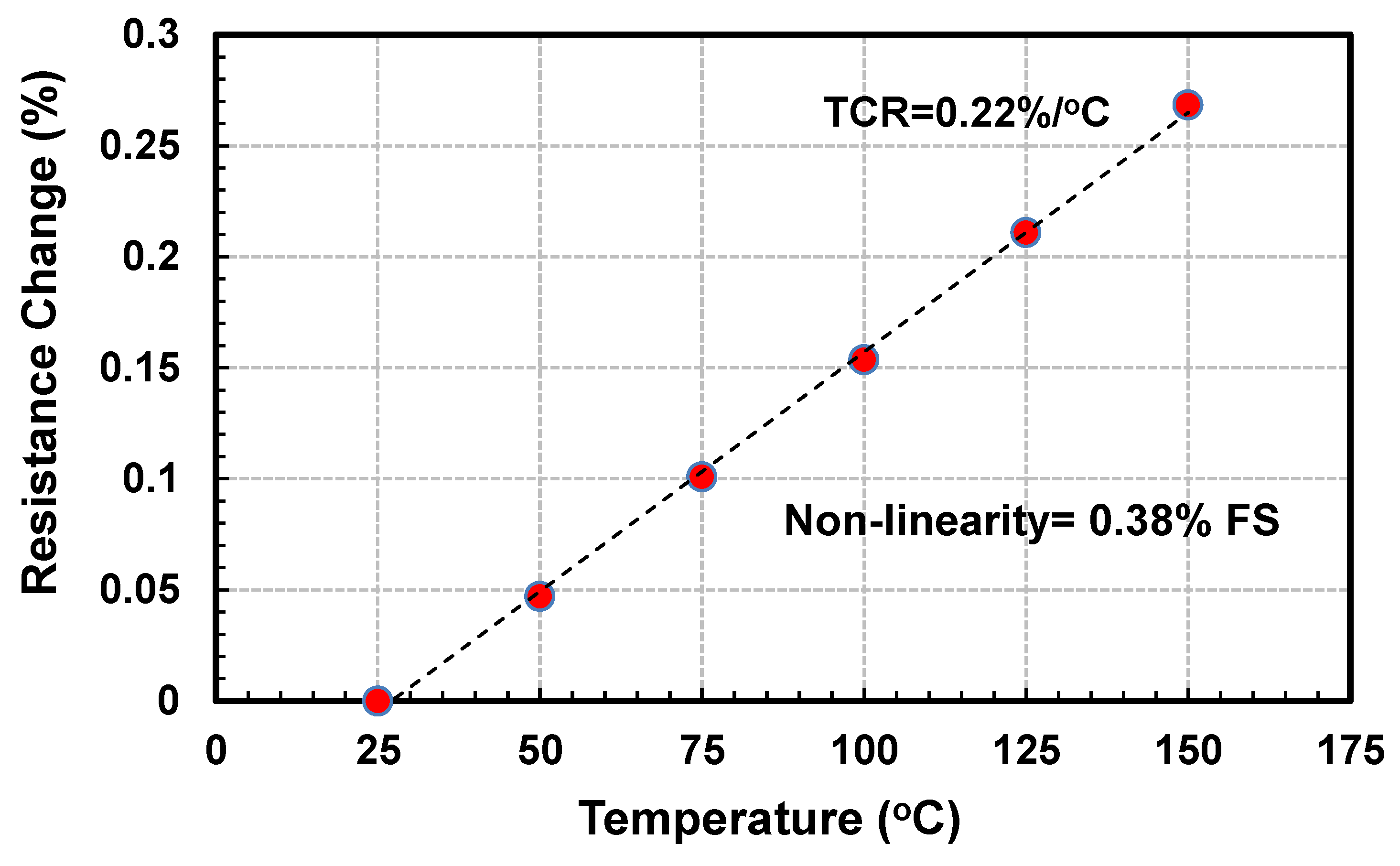

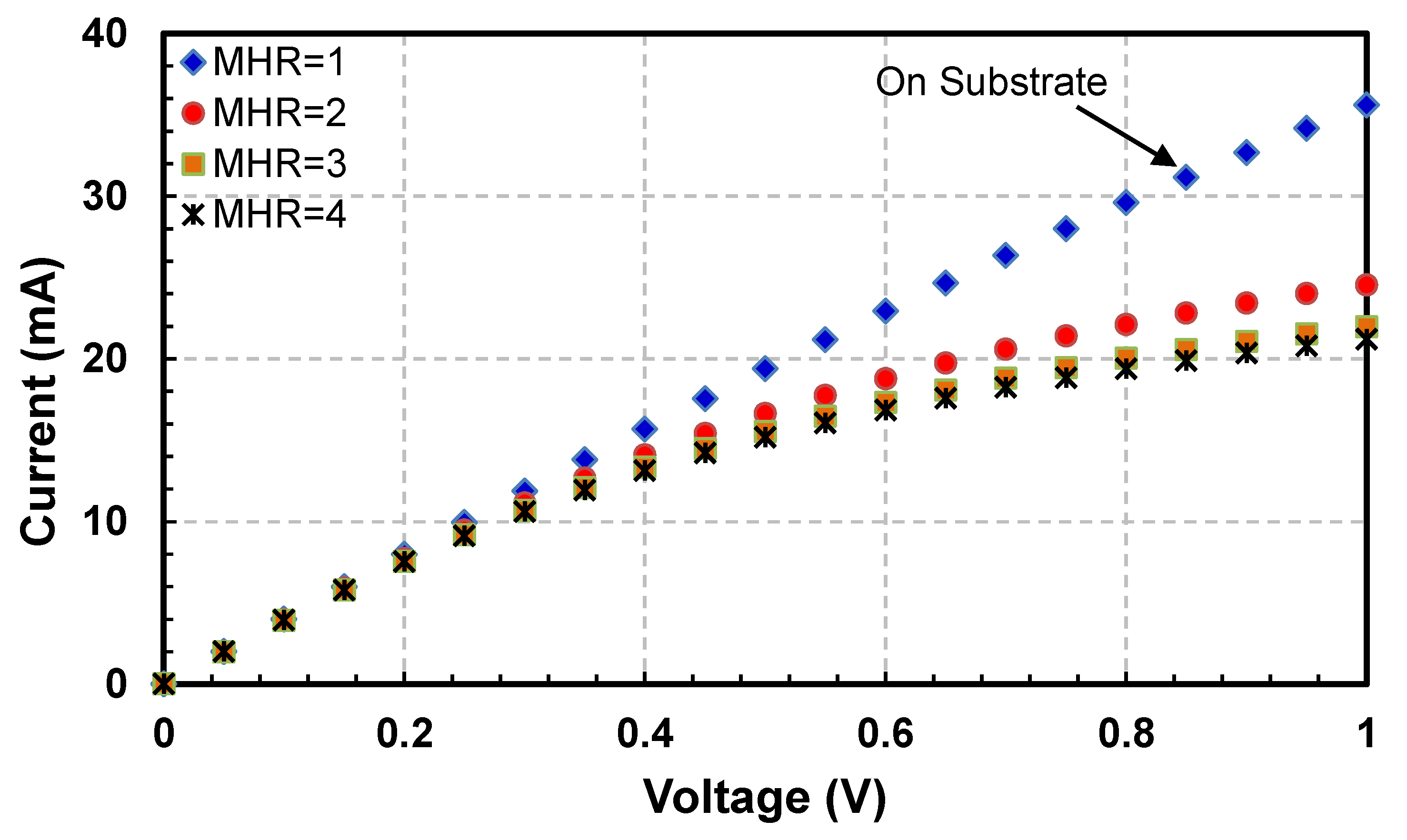

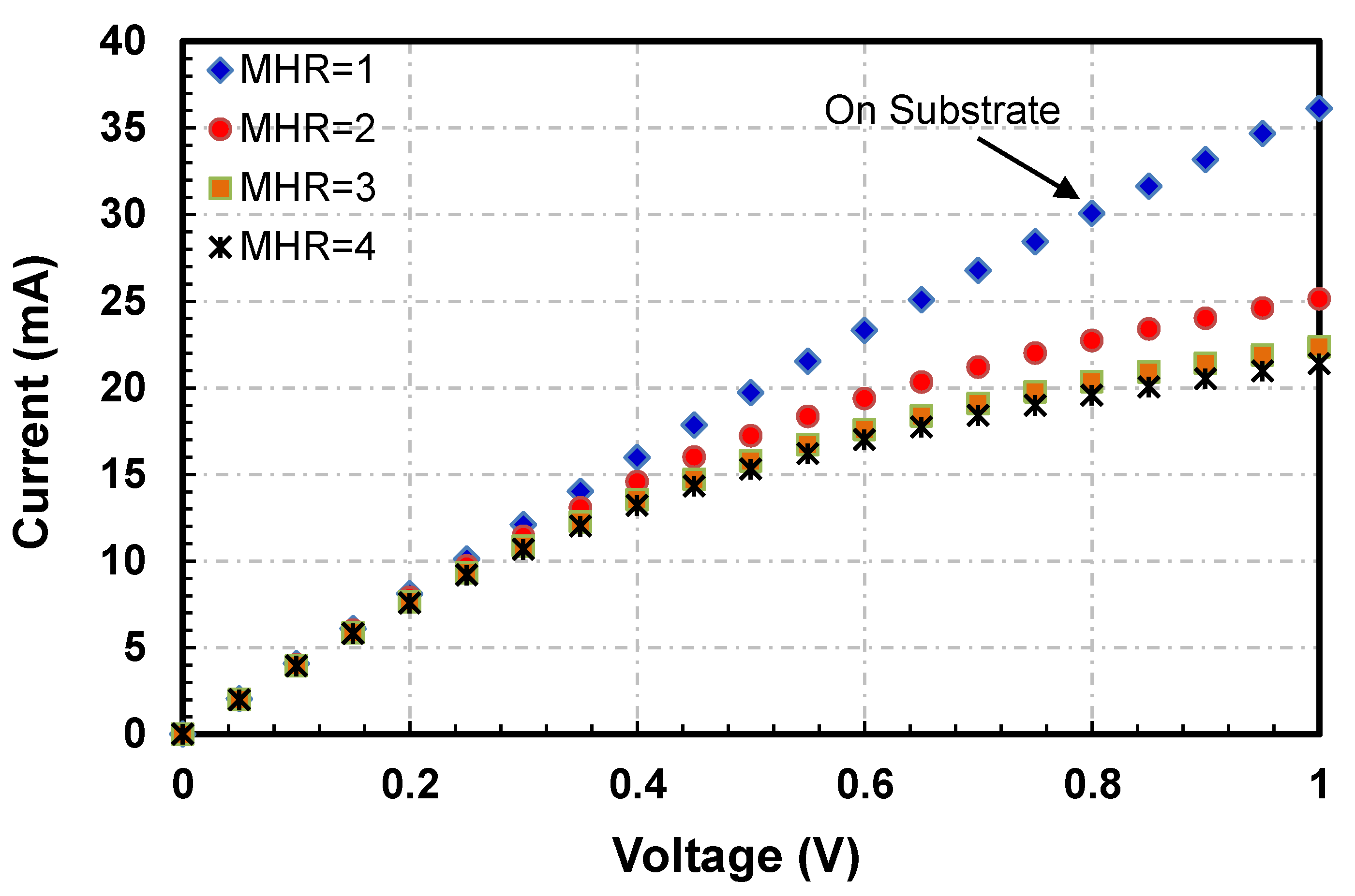

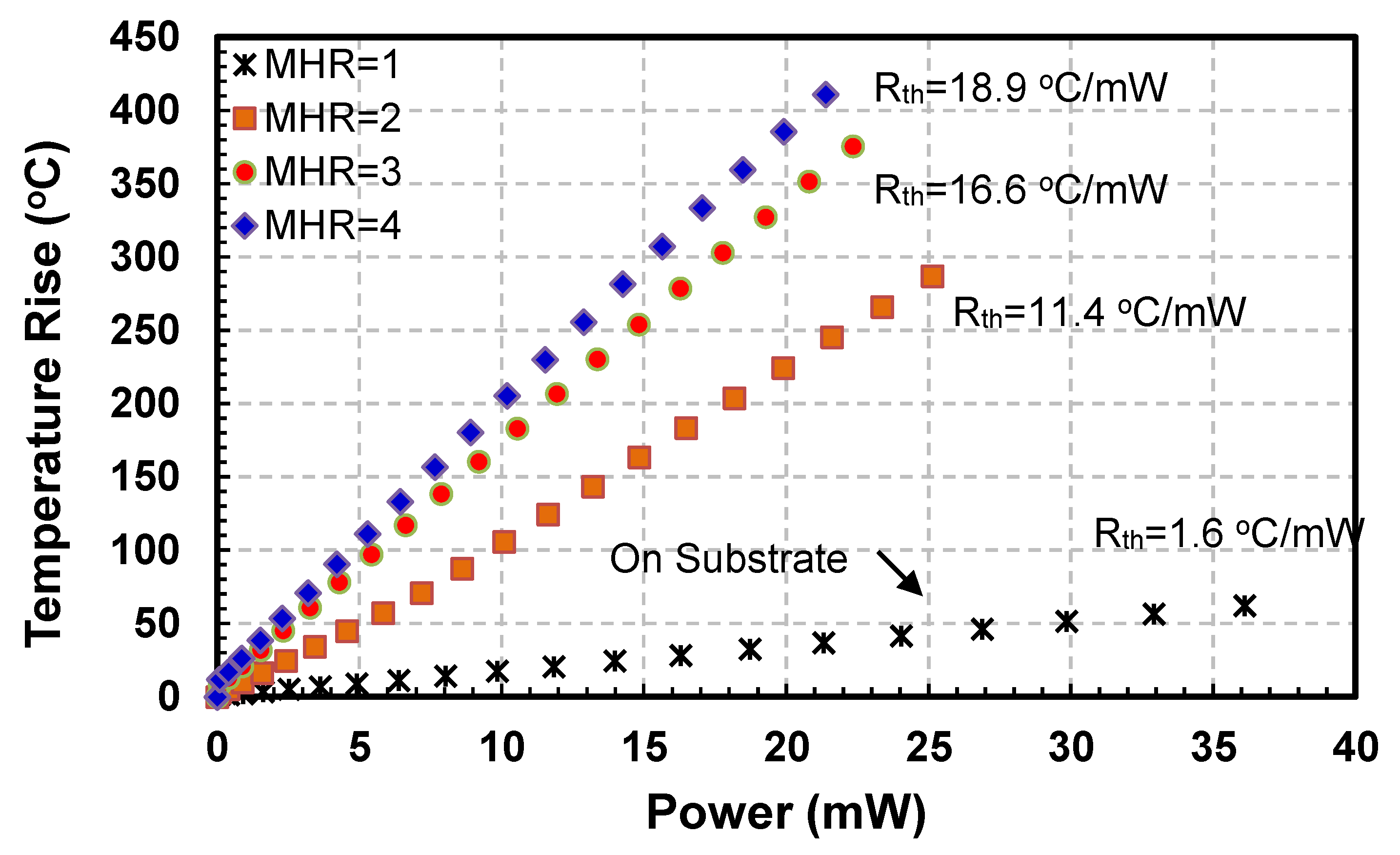

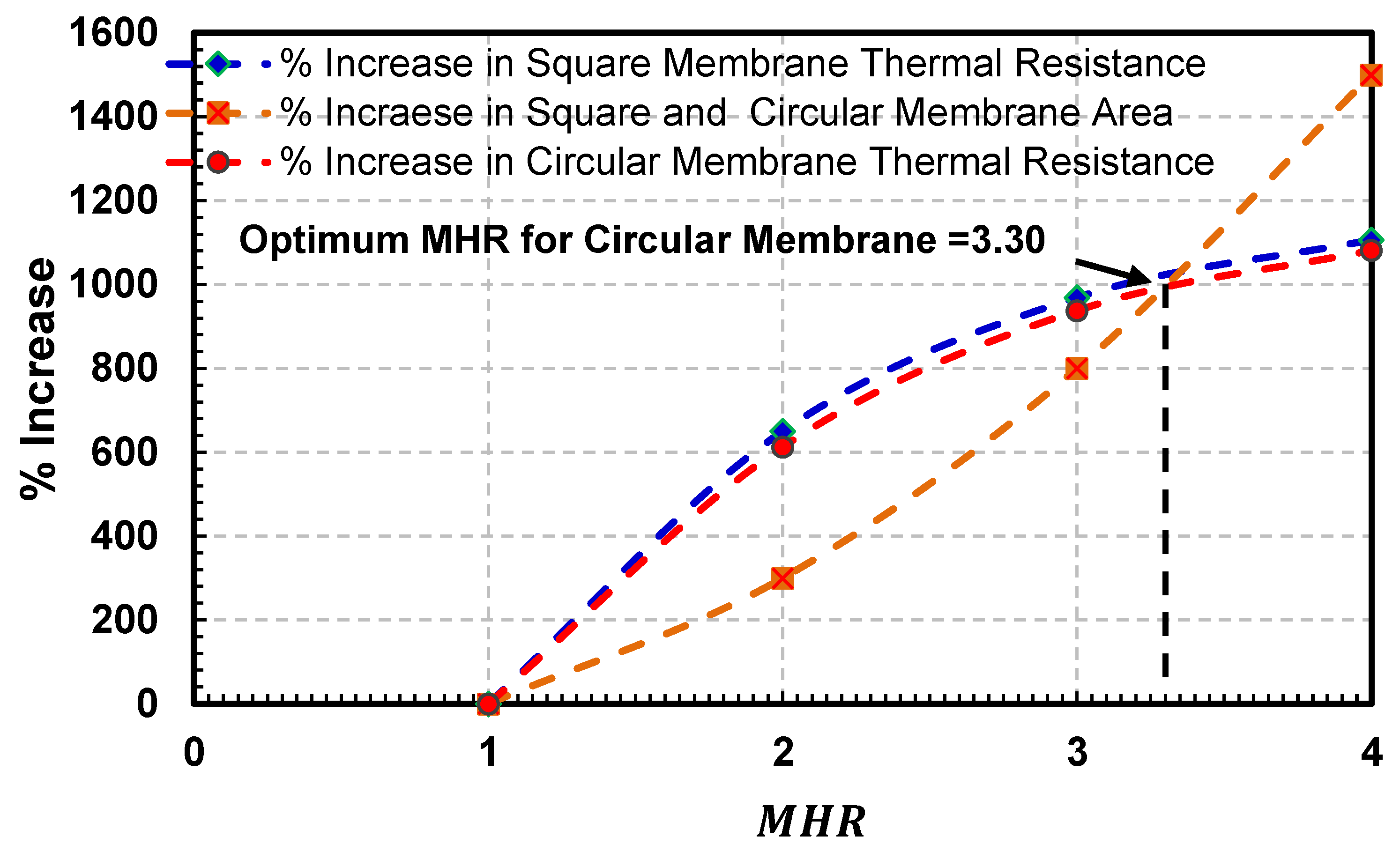

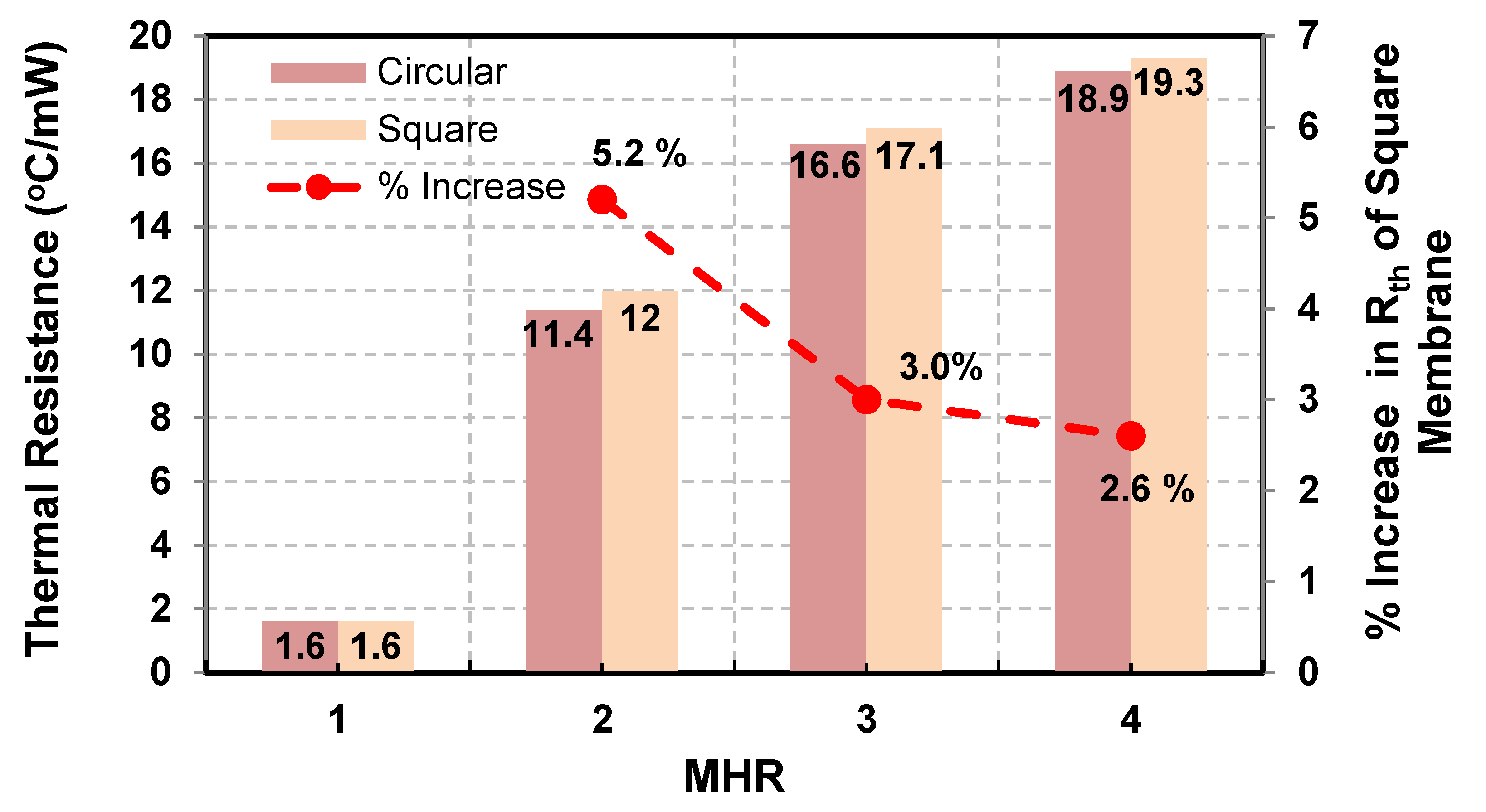

4. Experimental Results and Discussion

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Janson, S.; Helvajian, H.; Breuer, K. MEMS, microengineering and aerospace systems. AIAA Pap. 1999, 3802. [Google Scholar] [CrossRef]

- Xu, Y.; Jiang, F.; Newbern, S.; Huang, A.; Ho, C.-M.; Tai, Y.-C. Flexible shear-stress sensor skin and its application to unmanned aerial vehicles. Sens. Actuators A Phys. 2003, 105, 321–329. [Google Scholar] [CrossRef]

- Cubukcu, A.S.; Zernickel, E.; Buerklin, U.; Urban, G.A. A 2D thermal flow sensor with sub-mW power consumption. Sens. Actuators A Phys. 2010, 163, 449–456. [Google Scholar] [CrossRef]

- Dominguez, M.; Jiménez, V.; Ricart, J.; Kowalski, L.; Torres, J.; Navarro, S.; Romeral, J.; Castañer, L. A hot film anemometer for the Martian atmosphere. Planet. Space Sci. 2008, 56, 1169–1179. [Google Scholar] [CrossRef]

- De Luca, A.; Haneef, I.; Coull, J.; Ali, S.; Falco, C.; Udrea, F. A thermopile based SOI CMOS MEMS wall shear stress sensor. In Proceedings of the IEEE International Semiconductor Conference (CAS 2013), Sinaia, Romania, 14–16 October 2013; pp. 59–62. [Google Scholar]

- De Luca, A.; Haneef, I.; Coull, J.D.; Ali, S.Z.; Falco, C.; Udrea, F. High-sensitivity single thermopile SOI CMOS MEMS thermal wall shear stress sensor. IEEE Sens. J. 2015, 15, 5561–5568. [Google Scholar] [CrossRef]

- Fleming, W.J. Overview of automotive sensors. IEEE Sens. J. 2001, 1, 296–308. [Google Scholar] [CrossRef]

- Hsiai, T.K.; Cho, S.K.; Wong, P.K.; Ing, M.H.; Salazar, A.; Hama, S.; Navab, M.; Demer, L.L.; Ho, C.-M. Micro sensors: Linking real-time oscillatory shear stress with vascular inflammatory responses. Ann. Biomed. Eng. 2004, 32, 189–201. [Google Scholar] [CrossRef]

- Li, C.; Wu, P.-M.; Hartings, J.A.; Wu, Z.; Ahn, C.H.; LeDoux, D.; Shutter, L.A.; Narayan, R.K. Smart catheter flow sensor for real-time continuous regional cerebral blood flow monitoring. Appl. Phys. Lett. 2011, 99, 233705. [Google Scholar] [CrossRef]

- Li, C.; Wu, P.-M.; Hartings, J.A.; Wu, Z.; Ahn, C.H.; Narayan, R.K. Cerebral blood flow sensor with in situ temperature and thermal conductivity compensation. In Proceedings of the 25th IEEE International Conference on Micro Electro Mechanical Systems (MEMS’12), Paris, France, 29 January–2 February 2012; pp. 1021–1024. [Google Scholar]

- Li, C.; Wu, P.-M.; Wu, Z.; Limnuson, K.; Mehan, N.; Mozayan, C.; Golanov, E.V.; Ahn, C.H.; Hartings, J.A.; Narayan, R.K. Highly accurate thermal flow microsensor for continuous and quantitative measurement of cerebral blood flow. Biomed. Microdevices 2015, 17, 1–7. [Google Scholar] [CrossRef] [PubMed]

- Kaanta, B.; Chen, H.; Lambertus, G.; Steinecker, W.; Zhdaneev, O.; Zhang, X. High sensitivity micro-thermal conductivity detector for gas chromatography. In Proceedings of the 22nd IEEE International Conference on Micro Electro Mechanical Systems(MEMS’ 09), Sorrento, Italy, 25–29 January 2009; pp. 264–267. [Google Scholar]

- Liu, H.-B.; Lin, N.; Pan, S.-S.; Miao, J.; Norford, L.K. High sensitivity, miniature, full 2-D anemometer based on MEMS hot-film sensors. IEEE Sens. J. 2013, 13, 1914–1920. [Google Scholar] [CrossRef]

- Bruschi, P.; Dei, M.; Piotto, M. A low-power 2-D wind sensor based on integrated flow meters. IEEE Sens. J. 2009, 9, 1688–1696. [Google Scholar] [CrossRef]

- Makinwa, K.; Huijsing, J. A wind sensor with an integrated low-offset instrumentation amplifier. In Proceedings of the 8th IEEE International Conference on Electronics, Circuits and Systems, Malta, 2–5 September 2001; pp. 1505–1508. [Google Scholar]

- Makinwa, K.; Huijsing, J. A wind-sensor interface using thermal sigma delta modulation techniques. Sens. Actuators A Phys. 2001, 92, 280–285. [Google Scholar] [CrossRef]

- Makinwa, K.A.; Huijsing, J.H. A smart wind sensor using thermal sigma-delta modulation techniques. Sens. Actuators A Phys. 2002, 97, 15–20. [Google Scholar] [CrossRef]

- Hua, X.; Yun-feng, X.; Bing-he, M.; Si-yu, H.; Shi-zhao, Z.; Zhe-wei, C. Application of thermal shear stress gauge in study on shear stress measurement on underwater bed surface. Procedia Eng. 2015, 116, 663–669. [Google Scholar] [CrossRef]

- Balakrishnan, V.; Phan, H.-P.; Dinh, T.; Dao, D.V.; Nguyen, N.-T. Thermal flow sensors for harsh environments. Sensors 2017, 17, 2061. [Google Scholar] [CrossRef] [PubMed]

- Kuo, J.T.; Yu, L.; Meng, E. Micromachined thermal flow sensors—A review. Micromachines 2012, 3, 550–573. [Google Scholar] [CrossRef]

- Wang, Y.-H.; Chen, C.-P.; Chang, C.-M.; Lin, C.-P.; Lin, C.-H.; Fu, L.-M.; Lee, C.-Y. MEMS-based gas flow sensors. Microfluid. Nanofluid. 2009, 6, 333–346. [Google Scholar] [CrossRef]

- Ou, Y.; Qu, F.; Wang, G.; Nie, M.; Li, Z.; Ou, W.; Xie, C. A MEMS thermal shear stress sensor produced by a combination of substrate-free structures with anodic bonding technology. Appl. Phys. Lett. 2016, 109, 023512. [Google Scholar] [CrossRef]

- Wu, C.-H.; Kang, D.; Chen, P.-H.; Tai, Y.-C. MEMS thermal flow sensors. Sens. Actuators A Phys. 2016, 241, 135–144. [Google Scholar] [CrossRef]

- Laconte, J.; Dupont, C.; Flandre, D.; Raskin, J.-P. SOI CMOS compatible low-power microheater optimization for the fabrication of smart gas sensors. IEEE Sens. J. 2004, 4, 670–680. [Google Scholar] [CrossRef]

- Sabaté, N.; Santander, J.; Fonseca, L.; Gràcia, I.; Cané, C. Multi-range silicon micromachined flow sensor. Sens. Actuators A Phys. 2004, 110, 282–288. [Google Scholar] [CrossRef]

- Buchner, R.; Sosna, C.; Maiwald, M.; Benecke, W.; Lang, W. A high-temperature thermopile fabrication process for thermal flow sensors. Sens. Actuators A Phys. 2006, 130, 262–266. [Google Scholar] [CrossRef]

- Yu, B.; Gan, Z.; Cao, S.; Xu, J.; Liu, S. A micro channel integrated gas flow sensor for high sensitivity. In Proceedings of the 11th IEEE Intersociety Conference on Thermal and Thermomechanical Phenomena in Electronic Systems (ITHERM’ 08), Orlando, FL, USA, 28–31 May 2008; pp. 215–220. [Google Scholar]

- Piotto, M.; Dei, M.; Butti, F.; Pennelli, G.; Bruschi, P. Smart flow sensor with on-chip CMOS interface performing offset and pressure effect compensation. IEEE Sens. J. 2012, 12, 3309–3317. [Google Scholar] [CrossRef]

- Issa, S.; Lang, W. Minimum detectable air velocity by thermal flow sensors. Sensors 2013, 13, 10944–10953. [Google Scholar] [CrossRef] [PubMed]

- Reyes-Romero, D.F.; Cubukcu, A.S.; Urban, G.A. Measurement and simulation of the frequency response of a thermal flow sensor at different flow speeds. Sens. Actuators A Phys. 2013, 189, 168–176. [Google Scholar] [CrossRef]

- Romero, D.F.R.; Kogan, K.; Cubukcu, A.S.; Urban, G.A. Simultaneous flow and thermal conductivity measurement of gases utilizing a calorimetric flow sensor. Sens. Actuators A Phys. 2013, 203, 225–233. [Google Scholar] [CrossRef]

- Bruschi, P.; Diligenti, A.; Navarrini, D.; Piotto, M. A double heater integrated gas flow sensor with thermal feedback. Sens. Actuators A Phys. 2005, 123, 210–215. [Google Scholar] [CrossRef]

- Hedrich, F.; Kliche, K.; Storz, M.; Billat, S.; Ashauer, M.; Zengerle, R. Thermal flow sensors for MEMS spirometric devices. Sens. Actuators A Phys. 2010, 162, 373–378. [Google Scholar] [CrossRef]

- Dalola, S.; Cerimovic, S.; Kohl, F.; Beigelbeck, R.; Schalko, J.; Ferrari, V.; Marioli, D.; Keplinger, F.; Sauter, T. MEMS thermal flow sensor with smart electronic interface circuit. IEEE Sens. J. 2012, 12, 3318–3328. [Google Scholar] [CrossRef]

- Nguyen, N.; Dötzel, W. Asymmetrical locations of heaters and sensors relative to each other using heater arrays: A novel method for designing multi-range electrocaloric mass-flow sensors. Sens. Actuators A Phys. 1997, 62, 506–512. [Google Scholar] [CrossRef]

- Meng, E.; Li, P.-Y.; Tai, Y.-C. A biocompatible Parylene thermal flow sensing array. Sens. Actuators A Phys. 2008, 144, 18–28. [Google Scholar] [CrossRef]

- Bruschi, P.; Nurra, V.; Piotto, M. A compact package for integrated silicon thermal gas flow meters. Microsyst. Technol. 2008, 14, 943–949. [Google Scholar] [CrossRef]

- Sturm, H.; Brauns, E.; Froehner, K.; Lang, W.; Buchner, R. Thermoelectric flow sensors on flexible substrates and their integration process. In Proceedings of the IEEE Conference on Sensors (SENSORS’10), Kona, HI, USA, 1–4 November 2010; pp. 575–579. [Google Scholar]

- Adamec, R.J.; Thiel, D.V. Self heated thermo-resistive element hot wire anemometer. IEEE Sens. J. 2010, 10, 847–848. [Google Scholar] [CrossRef]

- Hepp, C.; Krogmann, F.; Polak, J.; Lehmann, M.; Urban, G. AC characterisation of thermal flow sensor with fluid characterisation feature. In Proceedings of the 16th IEEE Conference on International Solid-State Sensors, Actuators and Microsystems, Beijing, China, 5–9 June 2011; pp. 1084–1087. [Google Scholar]

- Sturm, H.; Lang, W. Membrane-based thermal flow sensors on flexible substrates. Sens. Actuators A Phys. 2013, 195, 113–122. [Google Scholar] [CrossRef]

- Talic, A.; Cerimovic, S.; Beigelbeck, R.; Kohl, F.; Sauter, T.; Keplinger, F. MEMS flow sensors based on self-heated aGe-thermistors in a wheatstone bridge. Sensors 2015, 15, 10004–10025. [Google Scholar] [CrossRef]

- Zhu, P.; Ma, B.; Jiang, C.; Deng, J.; Wang, Y. Improved sensitivity of micro thermal sensor for underwater wall shear stress measurement. Microsyst. Technol. 2015, 21, 785–789. [Google Scholar] [CrossRef]

- Etxebarria, J.; Berganzo, J.; Elizalde, J.; Llamazares, G.; Fernández, L.J.; Ezkerra, A. Low cost polymeric on-chip flow sensor with nanoliter resolution. Sens. Actuators B Chem. 2016, 235, 188–196. [Google Scholar] [CrossRef]

- Kaltsas, G.; Nassiopoulou, A. Novel CMOS-compatible monolithic silicon gas flow sensor with porous silicon thermal isolation. Sens. Actuators A Phys. 1999, 76, 133–138. [Google Scholar] [CrossRef]

- Kaltsas, G.; Nassiopoulos, A.A.; Nassiopoulou, A.G. Characterization of a silicon thermal gas-flow sensor with porous silicon thermal isolation. IEEE Sens. J. 2002, 2, 463–475. [Google Scholar] [CrossRef]

- Matova, S.P.; Makinwa, K.A.; Huijsing, J.H. Compensation of packaging asymmetry in a 2-D wind sensor. IEEE Sens. J. 2003, 3, 761–765. [Google Scholar] [CrossRef]

- Fürjes, P.; Légrádi, G.; Dücső, C.; Aszódi, A.; Bársony, I. Thermal characterisation of a direction dependent flow sensor. Sens. Actuators A Phys. 2004, 115, 417–423. [Google Scholar] [CrossRef]

- Sun, J.-B.; Qin, M.; Huang, Q.-A. Flip-chip packaging for a two-dimensional thermal flow sensor using a copper pillar bump technology. IEEE Sens. J. 2007, 7, 990–995. [Google Scholar] [CrossRef]

- Kaltsas, G.; Petropoulos, A.; Tsougeni, K.; Pagonis, D.; Speliotis, T.; Gogolides, E.; Nassiopoulou, A. A novel microfabrication technology on organic substrates-application to a thermal flow sensor. J. Phys. Conf. Ser. 2007, 92, 012046. [Google Scholar] [CrossRef]

- Dijkstra, M.; de Boer, M.; Berenschot, J.; Lammerink, T.; Wiegerink, R.; Elwenspoek, M. Miniaturized thermal flow sensor with planar-integrated sensor structures on semicircular surface channels. Sens. Actuators A Phys. 2008, 143, 1–6. [Google Scholar] [CrossRef]

- Buchner, R.; Froehner, K.; Sosna, C.; Benecke, W.; Lang, W. Toward flexible thermoelectric flow sensors: A new technological approach. J. Microelectromech. Syst. 2008, 17, 1114–1119. [Google Scholar] [CrossRef]

- Stamatopoulos, C.; Petropoulos, A.; Mathioulakis, D.; Kaltsas, G. Study of an integrated thermal sensor in different operational modes, under laminar, transitional and turbulent flow regimes. Exp. Therm. Fluid Sci. 2008, 32, 1687–1693. [Google Scholar] [CrossRef]

- Vilares, R.; Hunter, C.; Ugarte, I.; Aranburu, I.; Berganzo, J.; Elizalde, J.; Fernandez, L. Fabrication and testing of a SU-8 thermal flow sensor. Sens. Actuators B Chem. 2010, 147, 411–417. [Google Scholar] [CrossRef]

- Xiang, D.; Yang, Y.; Xu, Y.; Li, Y. MEMS-based shear-stress sensor for skin-friction measurements. In Proceedings of the IEEE Conference on Instrumentation and Measurement Technology, Austin, TX, USA, 3–6 May 2010; pp. 656–661. [Google Scholar]

- Shen, G.-P.; Qin, M.; Huang, Q.-A.; Zhang, H.; Wu, J. A FCOB packaged thermal wind sensor with compensation. Microsyst. Technol. 2010, 16, 511–518. [Google Scholar] [CrossRef]

- Zhu, Y.-Q.; Chen, B.; Qin, M.; Huang, J.-Q.; Huang, Q.-A. Development of a self-packaged 2D MEMS thermal wind sensor for low power applications. J. Micromech. Microeng. 2015, 25, 085011. [Google Scholar] [CrossRef]

- Tang, J.; Zhang, W.; Liu, W.; Chen, H.; Sun, Y. Research on a micromachined flexible hot-wire sensor array for underwater wall shear stress measurement. Microsyst. Technol. 2016, 23, 2781–2788. [Google Scholar] [CrossRef]

- Sosna, C.; Walter, T.; Lang, W. Response time of thermal flow sensors. Procedia Eng. 2010, 5, 524–527. [Google Scholar] [CrossRef]

- Sosna, C.; Walter, T.; Lang, W. Response time of thermal flow sensors with air as fluid. Sens. Actuators A Phys. 2011, 172, 15–20. [Google Scholar] [CrossRef]

- Van Kuijk, J.; Lammerink, T.; De Bree, H.-E.; Elwenspoek, M.; Fluitman, J. Multi-parameter detection in fluid flows. Sens. Actuators A Phys. 1995, 47, 369–372. [Google Scholar] [CrossRef]

- Berthet, H.; Jundt, J.; Durivault, J.; Mercier, B.; Angelescu, D. Time-of-flight thermal flowrate sensor for lab-on-chip applications. Lab Chip 2011, 11, 215–223. [Google Scholar] [CrossRef] [PubMed]

- Liu, C.; Tai, Y.-C.; Huang, J.-B.; Ho, C.-M. Surface micromachined thermal shear stress sensor. Electr. Eng. 1994, 116, 81. [Google Scholar]

- Huang, J.-B.; Tung, S.; Ho, C.-M.; Liu, C.; Tai, Y.-C. Improved micro thermal shear-stress sensor. IEEE Trans. Instrum. Meas. 1996, 45, 570–574. [Google Scholar] [CrossRef]

- Jiang, F.; Tai, Y.-C.; Gupta, B.; Goodman, R.; Tung, S.; Huang, J.-B.; Ho, C.-M. A surface-micromachined shear stress imager. In Proceedings of the 9th IEEE Annual International Workshop on Micro Electro Mechanical Systems, San Diego, CA, USA, 11–15 February 1996; pp. 110–115. [Google Scholar]

- Kälvesten, E.; Vieider, C.; Löfdahl, L.; Stemme, G. An integrated pressure—flow sensor for correlation measurements in turbulent gas flows. Sens. Actuators A Phys. 1996, 52, 51–58. [Google Scholar] [CrossRef]

- Jiang, F.; Tai, Y.-C.; Walsh, K.; Tsao, T.; Lee, G.-B.; Ho, C.-M. A flexible MEMS technology and its first application to shear stress sensor skin. In Proceedings of the Tenth IEEE Annual International Workshop on Micro Electro Mechanical Systems (MEMS’97), Nagoya, Japan, 26–30 January 1997; pp. 465–470. [Google Scholar]

- Huang, J.; Jiang, F.; Tai, Y.; Ho, C. A micro-electro-mechanical-system-based thermal shear-stress sensor with self-frequency compensation. Meas. Sci. Technol. 1999, 10, 687. [Google Scholar] [CrossRef]

- Liu, C.; Huang, J.-B.; Zhu, Z.; Jiang, F.; Tung, S.; Tai, Y.-C.; Ho, C.-M. A micromachined flow shear-stress sensor based on thermal transfer principles. J. Microelectromech. Syst. 1999, 8, 90–99. [Google Scholar]

- Hung, S.-T.; Wong, S.-C.; Fang, W. The development and application of microthermal sensors with a mesh-membrane supporting structure. Sens. Actuators A Phys. 2000, 84, 70–75. [Google Scholar] [CrossRef]

- Mailly, F.; Giani, A.; Bonnot, R.; Temple-Boyer, P.; Pascal-Delannoy, F.; Foucaran, A.; Boyer, A. Anemometer with hot platinum thin film. Sens. Actuators A Phys. 2001, 94, 32–38. [Google Scholar] [CrossRef]

- Yoshino, T.; Suzuki, Y.; Kasagi, N.; Kamiunten, S. Assessment of the wall shear stress measurement with arrayed micro hot-film sensors in a turbulent channel flow. In Proceedings of the Second International Symposium on Turbulence and Shear Flow Phenomena, Stockholm, Sweden, 27–29 June 2001; pp. 153–158. [Google Scholar]

- Xu, Y.; Jiang, F.; Lin, Q.; Clendenen, J.; Tung, S.; Tai, Y.-C. Underwater shear-stress sensor. In Proceedings of the Fifteenth IEEE International Conference on Micro Electro Mechanical Systems (MEMS’ 02), Las Vegas, NV, USA, 24–24 January 2002; pp. 340–343. [Google Scholar]

- Xu, Y.; Tai, Y.-C.; Huang, A.; Ho, C.-M. IC-integrated flexible shear-stress sensor skin. J. Microelectromech. Syst. 2003, 12, 740–747. [Google Scholar]

- Xu, Y.; Clendenen, J.; Tung, S.; Jiang, F.; Tai, Y.-C. Underwater flexible shear-stress sensor skins. In Proceedings of the 17th IEEE International Conference on Micro Electro Mechanical Systems (MEMS ’04), Maastricht, The Netherlands, 25–29 January 2004; pp. 833–836. [Google Scholar]

- Soundararajan, G.; Rouhanizadeh, M.; Yu, H.; DeMaio, L.; Kim, E.; Hsiai, T.K. MEMS shear stress sensors for microcirculation. Sens. Actuators A Phys. 2005, 118, 25–32. [Google Scholar] [CrossRef]

- Kim, I.C.; Lee, S.J. Characterization of a miniature thermal shear-stress sensor with backside connections. Sens. Actuators A Phys. 2006, 128, 305–311. [Google Scholar] [CrossRef]

- Liang, Y.; Yi, O.; Sha-Li, S.; Jin, M.; Da-Peng, C.; Tian-Chun, Y. Micro thermal shear stress sensor based on vacuum anodic bonding and bulk-micromachining. Chin. Phys. B 2008, 17, 2130. [Google Scholar] [CrossRef]

- Breuer, K.S.; Bayt, R.L.; Nayaar, A. Measurement of shear stress and temperature using MEMS fabricated sensors. In Proceedings of ASME MEMS; ASME: New York, NY, USA, 1999. [Google Scholar]

- Breuer, K. MEMS sensors for aerodynamic measurements-the good, the bad (and the ugly). In Proceedings of the 38th Aerospace Sciences Meeting and Exhibit, Reno, NV, USA, 10–13 January 2000; p. 251. [Google Scholar]

- Cain, A.; Chandrasekaran, V.; Nishida, T.; Sheplak, M. Development of a wafer-bonded, silicon-nitride membrane thermal shear-stress sensor with platinum sensing element. In Proceedings of the Technical Digest, Solid-State Sensor and Actuator Workshop, Hilton Head, SC, USA, 8–11 June 2000; pp. 300–303. [Google Scholar]

- Fan, Z.; Engel, J.M.; Chen, J.; Liu, C. Parylene surface-micromachined membranes for sensor applications. J. Microelectromech. Syst. 2004, 13, 484–490. [Google Scholar] [CrossRef]

- Haneef, I.; Umer, M.; Mansoor, M.; Akhtar, S.; Rafiq, M.; Ali, S.; Udrea, F. A tungsten based SOI CMOS MEMS wall shear stress sensor. In Proceedings of the IEEE Conference on Sensors (SENSORS’14), Valencia, Spain, 2–5 November 2014; pp. 1475–1478. [Google Scholar]

- Wang, X.-Q.; Han, Z.; Jiang, F.; Tsao, T.; Lin, Q.; Tai, Y.-C.; Koosh, V.; Goodman, R.; Lew, J.; Ho, C.-M. A fully integrated shear stress sensor. In Proceedings of the International Conference on Solid-State Sensors and Actuators (Transducer), Sandai, Japan, 7–10 June 1999; pp. 1074–1077. [Google Scholar]

- Yoshino, T.; Suzuki, Y.; Kasagi, N.; Kamiunten, S. Optimum design of microthermal flow sensor and its evaluation in wall shear stress measurement. In Proceedings of the Sixteenth IEEE Annual International Conference on Micro Electro Mechanical Systems (MEMS’03), Kyoto, Japan, 23 January 2003; pp. 193–196. [Google Scholar]

- Shi, S.; Chen, D.; Bai, H.; Ding, D.; Ou, Y.; Ye, T.; Shen, G. A novel micro thermal shear stress sensor with a cavity underneath. In Proceedings of the 1st IEEE International Conference on Nano/Micro Engineered and Molecular Systems, Zhuhai, China, 18–21 January 2006; pp. 466–469. [Google Scholar]

- Potts, J.R.; Lunnon, I.; Crowther, W.J.; Johnson, G.A.; Hucker, M.J.; Warsop, C. Development of a transonic wind tunnel test bed for MEMS flow control actuators and sensors. In Proceedings of the 47th AIAA Aerospace Sciences Meeting, Orlando, FL, USA, 5–8 January 2009; p. 319. [Google Scholar]

- Liang, J.-M.; Yang, D.-G.; Li, J.-Q.; Jiang, W.-M.; Li, C.-Y. Calibration of a thermal MEMS shear stress sensor array. In Proceedings of the IEEE Symposium on Piezoelectricity, Acoustic Waves and Device Applications (SPAWDA’12), Shanghai, China, 23–25 November 2012; pp. 433–437. [Google Scholar]

- Ma, R.-H.; Wang, D.-A.; Hsueh, T.-H.; Lee, C.-Y. A MEMS-based flow rate and flow direction sensing platform with integrated temperature compensation scheme. Sensors 2009, 9, 5460–5476. [Google Scholar] [CrossRef] [PubMed]

- Laghrouche, M.; Montes, L.; Boussey, J.; Meunier, D.; Ameur, S.; Adane, A. In situ calibration of wall shear stress sensor for micro fluidic application. Procedia Eng. 2011, 25, 1225–1228. [Google Scholar] [CrossRef]

- Saremi, S.; Alyari, A.; Feili, D.; Seidel, H. A MEMS-based hot-film thermal anemometer with wide dynamic measurement range. In Proceedings of the IEEE Conference on Sensors (SENSORS’2014), Valencia, Spain, 2–5 November 2014; pp. 420–423. [Google Scholar]

- Shibata, S.; Niimi, Y.; Shikida, M. Flexible thermal MEMS flow sensor based on Cu on polyimide substrate. In Proceedings of the IEEE Conference on Sensors (SENSORS’14), Valencia, Spain, 2–5 November 2014; pp. 424–427. [Google Scholar]

- Imaeda, K.; Shibata, S.; Matsushima, M.; Kawabe, T.; Shikida, M. Responsible time shorting of flexible thermal flow sensor for medical applications. In Proceedings of the IEEE Conference on Sensors (SENSORS’15), Busan, South Korea, 1–4 November 2015; pp. 1–4. [Google Scholar]

- Miau, J.; Leu, T.; Yu, J.; Tu, J.; Wang, C.; Lebiga, V.; Mironov, D.; Pak, A.; Zinovyev, V.; Chung, K. Mems thermal film sensors for unsteady flow measurement. Sens. Actuators A Phys. 2015, 235, 1–13. [Google Scholar] [CrossRef]

- Wu, S.; Lin, Q.; Yuen, Y.; Tai, Y.-C. MEMS flow sensors for nano-fluidic applications. Sens. Actuators A Phys. 2001, 89, 152–158. [Google Scholar] [CrossRef]

- Chen, J.; Fan, Z.; Zou, J.; Engel, J.; Liu, C. Two-dimensional micromachined flow sensor array for fluid mechanics studies. J. Aerosp. Eng. 2003, 16, 85–97. [Google Scholar] [CrossRef]

- Miau, J.-J.; Tu, J.; Chou, J.; Lee, G. Sensing flow separation on a circular cylinder by micro-electrical-mechanical-system thermal-film sensors. AIAA J. 2006, 44, 2224–2230. [Google Scholar] [CrossRef]

- Liu, K.; Yuan, W.; Deng, J.; Ma, B.; Jiang, C. Detecting boundary-layer separation point with a micro shear stress sensor array. Sens. Actuators A Phys. 2007, 139, 31–35. [Google Scholar] [CrossRef]

- Tung, S.; Rokadia, H.; Li, W.J. A micro shear stress sensor based on laterally aligned carbon nanotubes. Sens. Actuators A Phys. 2007, 133, 431–438. [Google Scholar] [CrossRef]

- Tan, Z.; Shikida, M.; Hirota, M.; Xing, Y.; Sato, K.; Iwasaki, T.; Iriye, Y. Characteristics of on-wall in-tube flexible thermal flow sensor under radially asymmetric flow condition. Sens. Actuators A Phys. 2007, 138, 87–96. [Google Scholar] [CrossRef]

- Yu, H.; Ai, L.; Rouhanizadeh, M.; Hamilton, R.; Hwang, J.; Meng, E.; Kim, E.S.; Hsiai, T.K. Polymer-based cardiovascular shear stress sensors. In Proceedings of the 2nd ASME Conference on Frontiers in Biomedical Devices, Irvine, CA, USA, 7–8 June 2007; pp. 29–30. [Google Scholar]

- Qu, Y.; Chow, W.W.; Ouyang, M.; Tung, S.C.; Li, W.J.; Han, X. Ultra-low-powered aqueous shear stress sensors based on bulk EG-CNTs integrated in microfluidic systems. IEEE Trans. Nanotechnol. 2008, 7, 565–572. [Google Scholar]

- Chang, L.-Y.; Li, P.-Y.; Zhao, L.; Hoang, T.; Meng, E. Integrated flow sensing for focal biochemical stimulation. In Proceedings of the 3rd IEEE International Conference on Nano/Micro Engineered and Molecular Systems, Sanya, China, 6–9 January 2008. [Google Scholar]

- Li, C.; Wu, P.-M.; Han, J.; Ahn, C.H. A flexible polymer tube lab-chip integrated with microsensors for smart microcatheter. Biomed. Microdevices 2008, 10, 671–679. [Google Scholar] [CrossRef]

- Wiegerink, R.; Lammerink, T.; Dijkstra, M.; Haneveld, J. Thermal and Coriolis type micro flow sensors based on surface channel technology. Procedia Chem. 2009, 1, 1455–1458. [Google Scholar] [CrossRef]

- Liu, P.; Zhu, R.; Que, R. A flexible flow sensor system and its characteristics for fluid mechanics measurements. Sensors 2009, 9, 9533–9543. [Google Scholar] [CrossRef] [PubMed]

- Kiełbasa, J. Measurement of gas flow velocity: Anemometer with a vibrating hot wire. Rev. Sci. Instrum. 2010, 81, 015101. [Google Scholar] [CrossRef]

- Ito, Y.; Higuchi, T.; Takahashi, K. Submicroscale flow sensor employing suspended hot film with carbon nanotube fins. J. Therm. Sci. Technol. 2010, 5, 51–60. [Google Scholar] [CrossRef]

- Bailey, S.C.; Kunkel, G.J.; Hultmark, M.; Vallikivi, M.; Hill, J.P.; Meyer, K.A.; Tsay, C.; Arnold, C.B.; Smits, A.J. Turbulence measurements using a nanoscale thermal anemometry probe. J. Fluid Mech. 2010, 663, 160–179. [Google Scholar] [CrossRef]

- Kuo, J.T.; Chang, L.-Y.; Li, P.-Y.; Hoang, T.; Meng, E. A microfluidic platform with integrated flow sensing for focal chemical stimulation of cells and tissue. Sens. Actuators B Chem. 2011, 152, 267–276. [Google Scholar] [CrossRef]

- Que, R.; Zhu, R. Aircraft aerodynamic parameter detection using micro hot-film flow sensor array and BP neural network identification. Sensors 2012, 12, 10920–10929. [Google Scholar] [CrossRef] [PubMed]

- Sun, J.; Cui, D.; Zhang, L.; Chen, X.; Cai, H.; Li, H. Fabrication and characterization of a double-heater based MEMS thermal flow sensor. Sens. Actuators A Phys. 2013, 193, 25–29. [Google Scholar] [CrossRef]

- Miao, Z.; Chao, C.Y.; Chiu, Y.; Lin, C.-W.; Lee, Y.-K. Design and fabrication of micro hot-wire flow sensor using 0.35μm CMOS MEMS technology. In Proceedings of the 9th IEEE International Conference on Nano/Micro Engineered and Molecular Systems (NEMS, 2014), Waikiki Beach, HI, USA, 13–16 April 2014; pp. 289–293. [Google Scholar]

- Hasegawa, Y.; Yamada, T.; Shikida, M. Fabrication of smooth-surfaced flexible thermal sensor for detecting wall shear stress. In Proceedings of the 29th IEEE International Conference on Micro Electro Mechanical Systems (MEMS’16), Shanghai, China, 24–28 January 2016; pp. 1010–1013. [Google Scholar]

- Yu, J.-M.; Leu, T.-S.; Miau, J.-J.; Chen, S.-J. MEMS flexible thermal flow sensor for measurement of boundary layer separation. Mod. Phys. Lett. B 2016, 30, 1650177. [Google Scholar] [CrossRef]

- Ghouila-Houri, C.; Gerbedoen, J.-C.; Claudel, J.; Gallas, Q.; Garnier, E.; Merlen, A.; Viard, R.; Talbi, A.; Pernod, P. Wall shear stress and flow direction thermal MEMS sensor for separation detection and flow control applications. Procedia Eng. 2016, 168, 774–777. [Google Scholar] [CrossRef]

- Yu, H.; Ai, L.; Rouhanizadeh, M.; Patel, D.; Kim, E.S.; Hsiai, T.K. Flexible polymer sensors for in vivo intravascular shear stress analysis. J. Microelectromech. Syst. 2008, 17, 1178–1186. [Google Scholar]

- Gardner, J.W.; Varadan, V.K. Microsensors, MEMS and Smart Devices; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2001. [Google Scholar]

- Uma, S.; McConnell, A.; Asheghi, M.; Kurabayashi, K.; Goodson, K. Temperature-dependent thermal conductivity of undoped polycrystalline silicon layers. Int. J. Thermophys. 2001, 22, 605–616. [Google Scholar] [CrossRef]

- Assael, M.; Antoniadis, K.; Wu, J. New measurements of the thermal conductivity of PMMA, BK7, and Pyrex 7740 up to 450K. Int. J. Thermophys. 2008, 29, 1257–1266. [Google Scholar] [CrossRef]

- Petropoulos, A.; Goustouridis, D.; Speliotes, T.; Kaltsas, G. Demonstration of a new technology which allows direct sensor integration on flexible substrates. Eur. Phys. J. Appl. Phys. 2009, 46, 12507. [Google Scholar] [CrossRef][Green Version]

- Shin, Y.S.; Cho, K.; Lim, S.H.; Chung, S.; Park, S.-J.; Chung, C.; Han, D.-C.; Chang, J.K. PDMS-based micro PCR chip with parylene coating. J. Micromech. Microeng. 2003, 13, 768. [Google Scholar] [CrossRef]

- Xu, Y.; Chiu, C.-W.; Jiang, F.; Lin, Q.; Tai, Y.-C. A MEMS multi-sensor chip for gas flow sensing. Sens. Actuators A Phys. 2005, 121, 253–261. [Google Scholar] [CrossRef]

- Xu, Y.; Lin, Q.; Lin, G.; Katragadda, R.B.; Jiang, F.; Tung, S.; Tai, Y.-C. Micromachined thermal shear-stress sensor for underwater applications. J. Microelectromech. Syst. 2005, 14, 1023–1030. [Google Scholar]

- Haneef, I.; Ali, S.Z.; Udrea, F.; Coull, J.D.; Hodson, H.P. High performance SOI-CMOS wall shear stress sensors. In Proceedings of the IEEE Conference on Sensors, Atlanta, GA, USA, 28–31 October 2007; pp. 1060–1064. [Google Scholar]

- Haneef, I.; Coull, J.D.; Ali, S.Z.; Udrea, F.; Hodson, H.P. Laminar to turbulent flow transition measurements using an array of SOI-CMOS MEMS wall shear stress sensors. In Proceedings of the IEEE Sensors, Lecce, Italy, 26–29 October 2008; pp. 57–61. [Google Scholar]

- Ernst, H.; Jachimowicz, A.; Urban, G.A. High resolution flow characterization in Bio-MEMS. Sens. Actuators A Phys. 2002, 100, 54–62. [Google Scholar] [CrossRef]

- Won, S.S.; Kawahara, M.; Glinsek, S.; Lee, J.; Kim, Y.; Jeong, C.K.; Kingon, A.I.; Kim, S.-H. Flexible vibrational energy harvesting devices using strain-engineered perovskite piezoelectric thin films. Nano Energy 2019, 55, 182–192. [Google Scholar] [CrossRef]

- Orrego, S.; Shoele, K.; Ruas, A.; Doran, K.; Caggiano, B.; Mittal, R.; Kang, S.H. Harvesting ambient wind energy with an inverted piezoelectric flag. Appl. Energy 2017, 194, 212–222. [Google Scholar] [CrossRef]

- Mansoor, M.; Haneef, I.; Akhtar, S.; Rafiq, M.A.; De Luca, A.; Ali, S.Z.; Udrea, F. An SOI CMOS-Based Multi-Sensor MEMS Chip for Fluidic Applications. Sensors 2016, 16, 1608. [Google Scholar] [CrossRef]

- Haneef, I.; Hodson, H.P.; Miller, R.; Udrea, F. Shear Stress Sensors. U.S. Patent 9080907 B2, 14 July 2015. [Google Scholar]

- Udrea, F.; Gardner, J.; Setiadi, D.; Covington, J.; Dogaru, T.; Lu, C.; Milne, W. Design and simulations of SOI CMOS micro-hotplate gas sensors. Sens. Actuators B Chem. 2001, 78, 180–190. [Google Scholar] [CrossRef]

- Mansoor, M.; Haneef, I.; Akhtar, S.; Rafiq, M.; Ali, S.; Udrea, F. SOI CMOS multi-sensors MEMS chip for aerospace applications. In Proceedings of the IEEE Conference on Sensors, Valencia, Spain, 2–5 November 2014; pp. 1204–1207. [Google Scholar]

- Lai, S.; Johnson, D.; Westerman, R. Aspect ratio dependent etching lag reduction in deep silicon etch processes. J. Vac. Sci. Technol. A Vac. Surf. Films 2006, 24, 1283–1288. [Google Scholar] [CrossRef]

- Yeom, J.; Wu, Y.; Shannon, M.A. Critical aspect ratio dependence in deep reactive ion etching of silicon. In Proceedings of the 12th International Conference on Solid-State Sensors, Actuators and Microsystems (TRANSDUCERS’03), Boston, MA, USA, 8–12 June 2003; pp. 1631–1634. [Google Scholar]

- Kleiner, M.B.; Kuhn, S.A.; Weber, W. Thermal conductivity measurements of thin silicon dioxide films in integrated circuits. IEEE Trans. Electron Devices 1996, 43, 1602–1609. [Google Scholar] [CrossRef]

- Berns, A.; Buder, U.; Obermeier, E.; Wolter, A.; Leder, A. AeroMEMS sensor array for high-resolution wall pressure measurements. Sens. Actuators A Phys. 2006, 132, 104–111. [Google Scholar] [CrossRef]

| First Author, Year | [Ref] | Type | Sensor Material | Sensor Size (l × w × t, all in µm) | Substrate Material |

|---|---|---|---|---|---|

| Kuijk, 1995 | [61] | TOF | Platinum | 300 × 100 × NR | Glass |

| Tung, 2007 | [99] | Hot-Film | MW CNT | 360 × 90 × NR | Glass |

| Qu, 2008 | [102] | Hot-Film | EG CNT | 1 × 1 × 0.1 | Glass |

| Zhu, 2015 | [57] | Calorimetric | Platinum | NR × NR × 0.2 | Silicon-in-Glass(SIG) |

| Makinwa, 2001 | [15] | Calorimetric | Polysilicon | 2000 × 200 × NR | Silicon/Ceramic for protection |

| Dominguez, 2008 | [4] | Hot-Film | Platinum | NR × NR × 0.07 | Silicon |

| *Makinwa, 2002 | [17] | Calorimetric | Polysilicon | 0.4 mm2 area | Silicon/Ceramic for protection |

| Matova, 2003 | [47] | Calorimetric | P doped Silicon | NR × NR × NR | Silicon/Ceramic for protection |

| Kaltsas, 1999 | [45] | Calorimetric | Polysilicon | NR × NR × NR | Porous Silicon |

| Kaltsas, 2002 | [46] | Calorimetric | Polysilicon | NR × NR × NR | Porous Silicon |

| Stamatopoulos, 2008 | [53] | Calorimetric | Polysilicon | NR × NR × NR | Porous Silicon |

| Sun, 2013 | [112] | Hot-Film | Chromium/Platinum | 1500 × 250 × 0.17 | P-doped Silicon (Beam Material) |

| Wu, 2001 | [95] | Hot-Film | Polysilicon | NR × NR × NR | SiN |

| Furjes, 2004 | [48] | Calorimetric | Platinum | 100 × 100 × 1 | SiN |

| Dijkstra, 2008 | [51] | Calorimetric | Platinum | NR × NR × 0.2 | SiN |

| Wiegerink, 2009 | [105] | Hot-Film | Aluminum | NR × NR × NR | SiN |

| Xiang, 2010 | [55] | Calorimetric | Polysilicon | NR × NR × 1 | Silicon |

| *Sun, 2007 | [49] | Calorimetric | Polysilicon | 600 × 60 × NR | Ceramic Al2O3 |

| Shen, 2010 | [56] | Calorimetric | Platinum | 1000 × 1000 × 0.2 | Ceramic (Exact ceramic name not reported) |

| Miau, 2015 | [94] | Hot-Film | Platinum | 200 × 260 × 0.1 | Polyimide |

Hot-wire/Hot-film type thermal flow sensors;

Hot-wire/Hot-film type thermal flow sensors;  Calorimetric (Calori) type thermal flow sensors;

Calorimetric (Calori) type thermal flow sensors;  Time of flight (TOF) type thermal flow sensors;

Time of flight (TOF) type thermal flow sensors;  CMOS Sensors;

CMOS Sensors;  Sensors fabricated on Glass substrate;

Sensors fabricated on Glass substrate;  Sensors fabricated on Silicon substrate;

Sensors fabricated on Silicon substrate;  Sensors fabricated on Porous Silicon substrate;

Sensors fabricated on Porous Silicon substrate;  Sensors fabricated on Other Ceramic substrate;

Sensors fabricated on Other Ceramic substrate;  Sensors fabricated on Silicon Nitride substrate/Membrane;

Sensors fabricated on Silicon Nitride substrate/Membrane;  Sensors fabricated on Silicon Oxide substrate/Membrane;

Sensors fabricated on Silicon Oxide substrate/Membrane;  Sensors fabricated on Polyimide substrate/Membrane;

Sensors fabricated on Polyimide substrate/Membrane;  Sensors fabricated on Parylene substrate/Membrane;

Sensors fabricated on Parylene substrate/Membrane;  Sensors fabricated on Kapton substrate/Membrane;

Sensors fabricated on Kapton substrate/Membrane;  Sensors fabricated on Silicon Nitride/Silicon Oxide Membrane; SiN: Silicon Nitride; SiO: Silicon Oxide; *: CMOS Sensors; NR: Not Reported by the Author(s).

Sensors fabricated on Silicon Nitride/Silicon Oxide Membrane; SiN: Silicon Nitride; SiO: Silicon Oxide; *: CMOS Sensors; NR: Not Reported by the Author(s).| First Author, Year | [Ref] | Type | Sensor Material | Sensor Size (l × w × t, all in µm) | Substrate Material |

|---|---|---|---|---|---|

| Miau, 2006 | [97] | Hot-Film | Platinum | 260 × 200 × 0.1 | Polyimide |

| Liu, 2007 | [98] | Hot-Film | Platinum | 2100 × 1500 × 500 | Polyimide |

| Tan, 2007 | [100] | Hot-Film | Gold//Chromium | 4000 × 90 × 0.3 | Polyimide |

| Buchner, 2008 | [52] | Calorimetric | Titanium-Tungsten | NR × NR × NR | Polyimide |

| Liu, 2009 | [106] | Hot-Film | Chromium/Nickel/Platinum | 3000 × 300 × 0.23 | Polyimide |

| Que, 2012 | [111] | Hot-Film | Cr/Ni/Pt | NR × NR × NR | Polyimide |

| Li, 2015 | [11] | Hot-Film | Gold | NR × NR × NR | Polyimide |

| Tang, 2016 | [58] | Hot-Film | Platinum | NR × 5 × 0.2 | Polyimide |

| Yu, 2016 | [115] | Hot-Film | Chromium/Platinum | 200 × 260 × 0.12 | Polyimide |

| Yu, 2007 | [101] | Hot-Film | Titanium/Platinum | 160 × 80 × 0.1 | Parylene C |

| Yu, 2008 | [117] | Hot-Film | Titanium/Platinum | 280 × 2 × 0.075 | Parylene C |

| Chang, 2008 | [103] | Hot-Film | Platinum | NR × NR × NR | Parylene C |

| Kuo, 2011 | [110] | Hot-Film | Platinum | NR × NR × NR | Parylene C |

| Hasegawa, 2016 | [114] | Hot-Film | Gold/Copper | NR × NR × 0.26 | Parylene (Exact type NR) |

| Li, 2008 | [104] | Hot-Film | Gold | NR × NR × 0.1 | Kapton |

| Li, 2011 | [9] | Hot-Film | Gold | NR × NR × 0.12 | Kapton |

| Li, 2012 | [10] | Hot-Film | Gold | NR × NR × 0.12 | Kapton |

| Kaltsas, 2007 | [50] | Hot-Film +Calorimetric | Platinum | NR × NR × 0.3 | SU-8 |

| Vilares, 2010 | [54] | Calorimetric | Titanium/Platinum | 2500 × 10 × 0.15 | PMMA |

| Berthet, 2011 | [62] | TOF | Titanium/Platinum | 500 × 20 × 20 | Pyrex |

| First Author, Year | [Ref] | Type | Sensor Material | Sensor Size (l × w × t, all in µm) | Membrane Material | Membrane Size (l × w × t, all in µm) | MHR |

|---|---|---|---|---|---|---|---|

| Liu, 1994 | [63] | Hot-Film | Polysilicon | 100 × 2 × 0.45 | SiN | 200 × 200 × 1.2 | 2 |

| Jiang, 1996 | [65] | Hot-Film | Polysilicon | 150 × 3 × 0.25 | SiN | 200 × 200 × 1.2 | 1.33 |

| Huang, 1996 | [64] | Hot-Film | Polysilicon | 80 × 2 × NR | SiN | 200 × 200 × 1.2 | 2.5 |

| Jiang, 1997 | [67] | Hot-Film | Polysilicon | 150 × 3 × 0.25 | SiN | 200 × 200 × 1.2 | 1.33 |

| Huang, 1999 | [68] | Hot-Film | Polysilicon | (100,150,200) × (2,3,4) × 1 | SiN | 200 × 200 × 2 | 2 |

| Liu, 1999 | [69] | Hot-Film | Polysilicon | 100 × 2 × 0.45 | SiN | 200 × 200 × 1.5 | 2 |

| Hung, 2000 | [70] | Hot-Film | Platinum | NR × NR × 0.18 | SiN | 600 × 600 × 0.2 | - |

| Mailly, 2001 | [71] | Hot-Film | Platinum | NR × NR × 0.3 | SiN | 650 × 650 × 0.5 | - |

| Yoshino, 2001 | [72] | Hot-Film | Platinum | 200 × 23 × 0.1 300 × 32 × 0.1 | SiN | 400 × 400 × 1.0 500 × 500 × 1.0 | 2 |

| Xu, 2002 | [73] | Hot-Film | Polysilicon | 150 × 2 × 0.5 | SiN | 210 × (45 -210) × 4.2 | 1.4 |

| Xu, 2004 | [75] | Hot-Film | Polysilicon | 150 × 2 × 0.5 | SiN | 210 × (75 -210) × 4.2 | 1.4 |

| Xu, 2005 | [123] | Hot-Film | Polysilicon | 150 × 7 × 0.5 | SiN | 210 × 210 × 1.5 | 1.4 |

| Xu, 2005 | [124] | Hot-Film | Polysilicon | 180 - 210 × NR × 0.5 | SiN | 210 × 45 - 210 × 4.2 | 1 – 1.16 |

| Soundrarajan, 2005 | [76] | Hot-Film | Polysilicon | 80 × 2 × 3 | SiN | NR × NR × 0.3 | - |

| Kim, 2006 | [77] | Hot-Film | Gold | 600 × 50 × 0.45 | SiN | 1000 × 1000 × 1.3 | 1.66 |

| Liang, 2008 | [78] | Hot-Film | Titanium/Platinum | 100 × 2 × 0.2 | SiN | 200 × 200 × 1.5 | 2 |

| Sabate, 2004 | [25] | Calorimetric | Nickel | NR × 40 × 0.15 | SiN | 750 × 750 × 0.3 | - |

| Buchner, 2006 | [26] | Calorimetric | Polysilicon | NR × NR × 0.3 | SiN | 1000 × 1000 × NR | - |

| Adamec, 2010 | [39] | Calorimetric | Nickel | NR × NR × NR | SiN | NR × NR ×NR | - |

| Sosna, 2010 | [59] | TOF | NR | 1000 × 10 × 0.3 | SiN | 1000 × 1000 × 0.6,0.3 600 × 800 × 0.6 | 1 |

| Sosna, 2011 | [60] | TOF | NR | 1000 × 10 × 0.3 | SiN | 1000 × 1000 × 0.6,0.3 | 1 |

| Laconte, 2004 | [24] | Calorimetric | Polysilicon | 240 × 240 × 0.34 (Active area) | SiN/SiO | 440 × 440 × 1 640 × 640 × 1 840 × 840 × 1 | 1.83 |

| Yu, 2008 | [27] | Calorimetric | Platanium | NR × NR × NR | SiN/SiO | 1800 × 1800 × NR | - |

| Cubckcu, 2010 | [3] | Calorimetric | Germanium | NR × NR × NR | SiN/SiO | 1000 × 1000 × 1.4 | - |

| Hsiai, 2004 | [8] | Hot-Film | Polysilicon | 80 × 2 × 0.5 | SiN/SiO | 100 × 100 × 1.5 | 1.25 |

| *Piotto, 2012 | [28] | Calorimetric | Polysilicon | NR × NR × NR | SiO | NR × NR × NR | - |

| *Haneef, 2007 | [125] | Hot-Film | Aluminum | 130 × 3 × 0.72 | SiO | 500 × 500 × NR | 3.84 |

| *Haneef, 2008 | [126] | Hot-Film | Aluminum | 130 × 3 × 0.72 18.5 × 1.1 × 0.72 | SiO | 500 × 500 × NR 266 × 266 × NR | 3.8414.3 |

| Kalvesten, 1996 | [66] | Hot-Film | Polysilicon | 300 × 60 × 30 | Polysilicon | 1500 × 1500 × 30 | 5 |

| *Xu, 2003 | [74] | Hot-Film | Polysilicon | 200 × NR × 0.32 | Parylene N | 250 × 100 × 1.5 | 1.25 |

| First Author, Year | [Ref] | Type | Sensor Material | Sensor Size (l × w × t, all in µm) | Membrane Material | Membrane Size (Dia × t, all in µm) | MHR |

|---|---|---|---|---|---|---|---|

| Breuer, 1999, 2000 | [79,80] | Hot-Film | Platinum | 100 × 5 × 0.1 | SiN | [210 × 0.15] | 2.1 |

| Qu, 2016 | [22] | Hot-Film | Platinum | 140 × NR × NR | SiN | NR × NR × 1.5 | - |

| Cain, 2000 | [81] | Hot-Film | Platinum | 200 × 4 × 0.15 | SiN | [200 × 0.15] | 1 |

| Cubckcu, 2010 | [3] | Calorimetric | Germanium | NR × NR × NR | SiN/SiO | [1000 × 1.4] | - |

| Reyes-Romero, 2013 | [30] | Calorimetric | Chromium | NR × NR × NR | SiN/SiO | [1000 × 1.4] | - |

| Reyes-Romero, 2013 | [31] | Calorimetric | Chromium | NR × NR × NR | SiN/SiO | [1000 × 1.4] | - |

| *Haneef, 2014 | [83] | Hot Film | Tungsten | 200 × 2 × 0.3 | SiO (with SiN passivation) | [250 × NR] | 1.25 |

| *De Luca, 2013 | [5] | Calorimetric+ Hot-Film | Tungsten | 400 × 2 × NR | SiO | [1200 × NR] | 3 |

| *De Luca, 2015 | [6] | Calorimetric | Tungsten | 400 × 2 × NR | SiO | [1200 × NR] | 3 |

| Fan, 2004 | [82] | Hot-Film | Gold | [NR × 0.2] | Parylene C | [400 × 12] | - |

| First Author, Year | [Ref] | Type | Sensor Material | Sensor Size (l × w × t, All in µm) | Membrane material | Membrane Size (l × w × t, all in µm) | MHR |

|---|---|---|---|---|---|---|---|

| Yoshino, 2003 | [85] | Hot-Film | Platinum | 250 × 30 × 0.1 | SiN | 350 × 200 × 1.0 | 1.4 |

| Ma, 2009 | [89] | Hot-Film | Platinum | 4400 ID ×300 × 0.1 | SiN | NR × NR × 1 | - |

| Saremi, 2014 | [91] | Hot-Film | Platinum | 2700 × 13 × 0.3 | SiN | 3000 × 1000 × 450 | 1.11 |

| Shi, 2006 | [86] | Hot-Film | Polysilicon | 200 × 4 × 0.45 | SiN | 250 × 200 × 1.5 | 1.25 |

| Ernst, 2002 | [127] | Calorimetric | Germanium | 574 × 6 × 0.2 | SiN | 900 × 700 × 1.4 | 1.56 |

| Hedrich, 2010 | [33] | Calorimetric | Polysilicon | NR × NR × 0.3 | SiN | 300 × 600 × 0.15 | - |

| Dalola, 2012 | [34] | Hot-Film and Calorimetric | Germanium | 600 × 35 × 0.26 | SiN/SiO | 1000 × 500 × 1.6 | 1.66 |

| Talic, 2015 | [42] | Calorimetric +Hot-Film | Chromium | NR × NR × 0.13 | SiN/SiO | 1000 × 500 × 1.57 | - |

| Bruschi, 2005 | [32] | Calorimetric | Polysilicon | NR × NR × NR | SiO | 45 × 60 × NR | - |

| Liu, 2013 | [13] | Hot-Film | Titanium/Platinum | NR × NR × 0.11 | SiO | NR × NR × NR | - |

| *Wang, 1999 | [84] | Hot-Film | Polysilicon | NR × NR × 0.32 | Parylene N | NR × NR × 3.5 NR × NR × 0.7 | - |

| Wu, 2016 | [23] | Hot-Film | Platinum | NR × 10 × 0.5 | Parylene C | NR × NR ×NR | - |

| Shibata, 2014 | [92] | Hot-Film | Gold/copper | NR × NR × 0.26 | Polyimide | NR × NR × 5 | - |

| Imaeda, 2015 | [93] | Hot-Film | Gold/Copper | NR × NR × 0.26 | Polyimide | 1600 × 1700 × 5 | - |

| Hepp, 2011 | [40] | Calorimetric | Platinum | NR × NR × NR | Polyimide | NR × NR × 6 | - |

| Strum, 2013 | [41] | Calorimetric | Tungsten -Titanium | NR × NR × NR | Polyimide | 200 - 600 × 800 × 9.6 | - |

| Meng, 2008 | [36] | TOF Calorimetric Hot-Film | Platinum | 200 × 25 × 0.1 | Parylene C | NR × NR × 6 | - |

| Sturm, 2010 | [38] | Calorimetric | Titanium/ Tungsten | NR × NR × NR | SiN/Polyimide | NR × NR ×NR | - |

| Etxebarria, 2016 | [44] | Calorimetric | Nickel | NR × NR × 0.1 | Polymer (Exact name NR) | NR × NR ×NR | - |

| Nguyen, 1997 | [35] | Calorimetric | Polysilicon | NR × NR × NR | Silicon | NR × NR ×NR | - |

| SensorNomenclature | Membrane Shape | Membrane Size (Side Length/Diameter) µm | Heater (Hot-Film) Size (l × w × t) µm | Membrane to Heater Ratio (MHR) |

|---|---|---|---|---|

| FS1 | Square | 80 | All heaters/hot-films have the same size (80 × 2 × 0.3) | 1 |

| FS2 | Circular | |||

| FS3 | Square | 160 | 2 | |

| FS4 | Circular | |||

| FS5 | Square | 240 | 3 | |

| FS6 | Circular | |||

| FS7 | Square | 320 | 4 | |

| FS8 | Circular |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mehmood, Z.; Haneef, I.; Ali, S.Z.; Udrea, F. Sensitivity Enhancement of Silicon-on-Insulator CMOS MEMS Thermal Hot-Film Flow Sensors by Minimizing Membrane Conductive Heat Losses. Sensors 2019, 19, 1860. https://doi.org/10.3390/s19081860

Mehmood Z, Haneef I, Ali SZ, Udrea F. Sensitivity Enhancement of Silicon-on-Insulator CMOS MEMS Thermal Hot-Film Flow Sensors by Minimizing Membrane Conductive Heat Losses. Sensors. 2019; 19(8):1860. https://doi.org/10.3390/s19081860

Chicago/Turabian StyleMehmood, Zahid, Ibraheem Haneef, Syed Zeeshan Ali, and Florin Udrea. 2019. "Sensitivity Enhancement of Silicon-on-Insulator CMOS MEMS Thermal Hot-Film Flow Sensors by Minimizing Membrane Conductive Heat Losses" Sensors 19, no. 8: 1860. https://doi.org/10.3390/s19081860

APA StyleMehmood, Z., Haneef, I., Ali, S. Z., & Udrea, F. (2019). Sensitivity Enhancement of Silicon-on-Insulator CMOS MEMS Thermal Hot-Film Flow Sensors by Minimizing Membrane Conductive Heat Losses. Sensors, 19(8), 1860. https://doi.org/10.3390/s19081860