Rolling Bearing Fault Diagnosis Based on an Improved HTT Transform

Abstract

:1. Introduction

2. Basic Theories

2.1. Hilbert Time–Time Transform

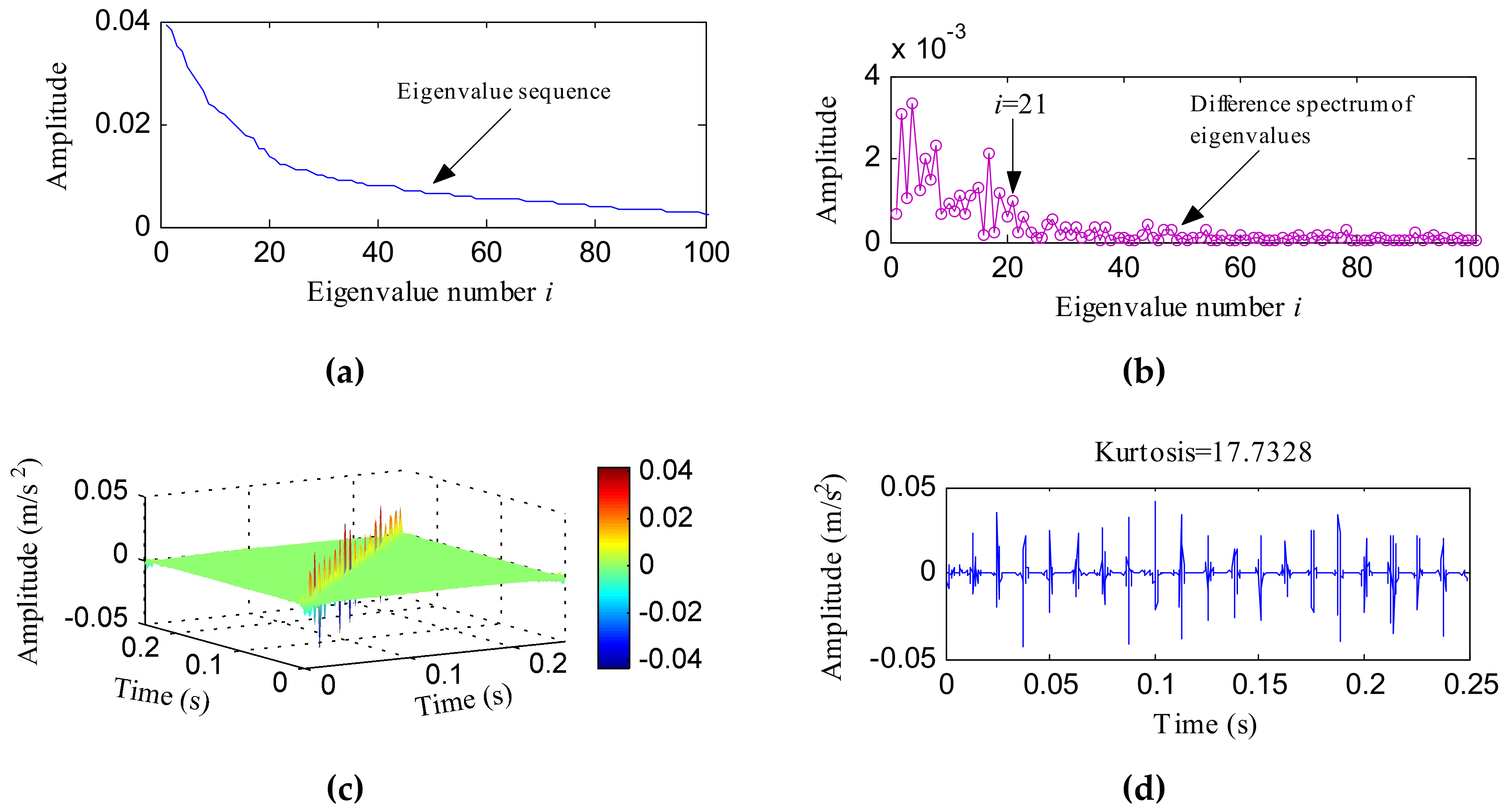

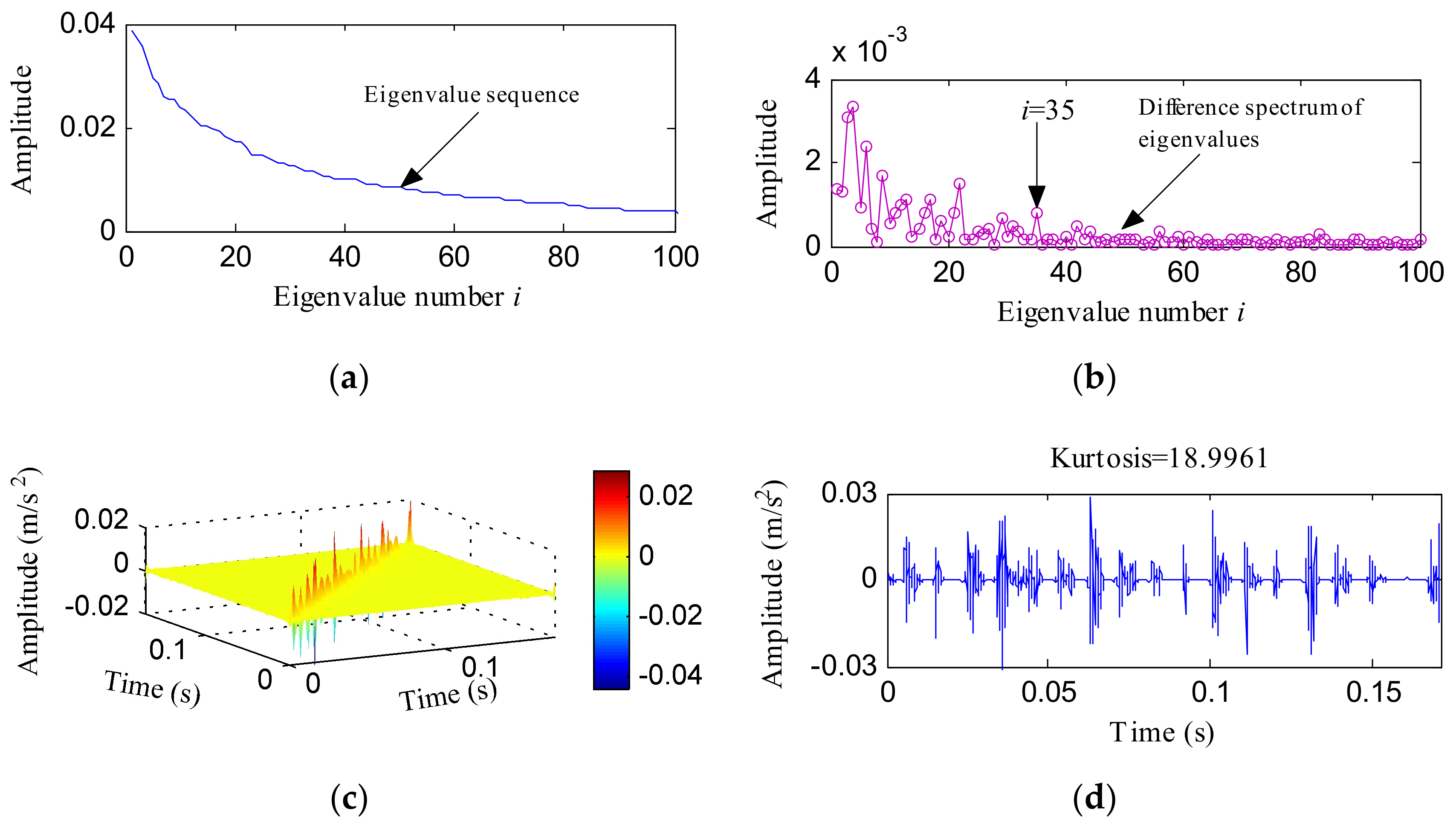

2.2. Principal Component Analysis for Matrix De-Noising

3. Improved Hilbert Time–time Transform

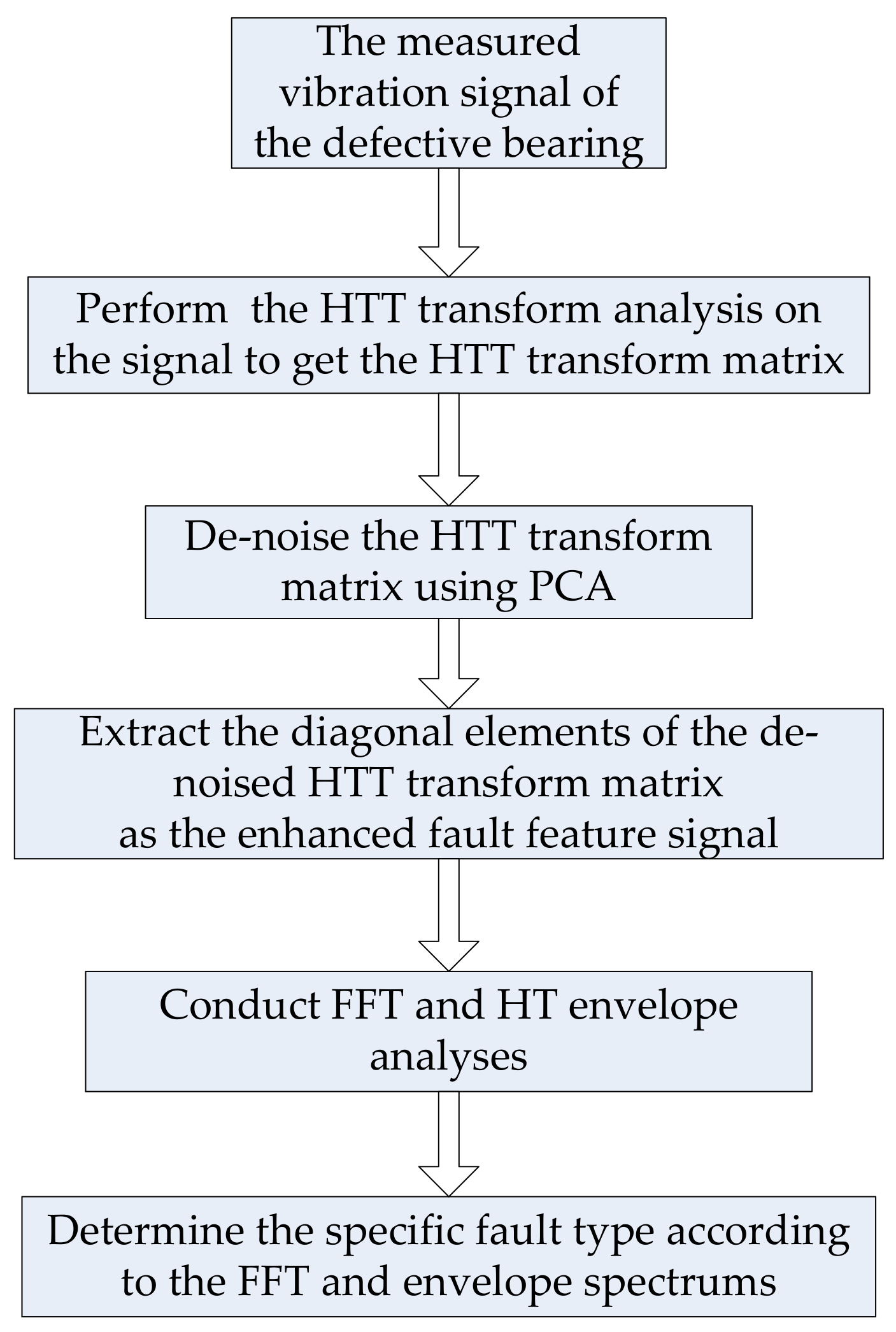

- Apply the HTT transform to the measured vibration signal to get the HTT transform matrix.

- Employ PCA de-noising of the HTT transform matrix to get the de-noised HTT transform matrix.

- Extract the diagonal elements of the de-noised HTT transform matrix to construct the enhanced fault feature signal.

- Conduct FFT analysis and HT envelope analyses on the enhanced fault feature signal to get the FFT and envelope spectrums.

- Determine the specific fault type of the bearing according to the FFT and envelope spectrums.

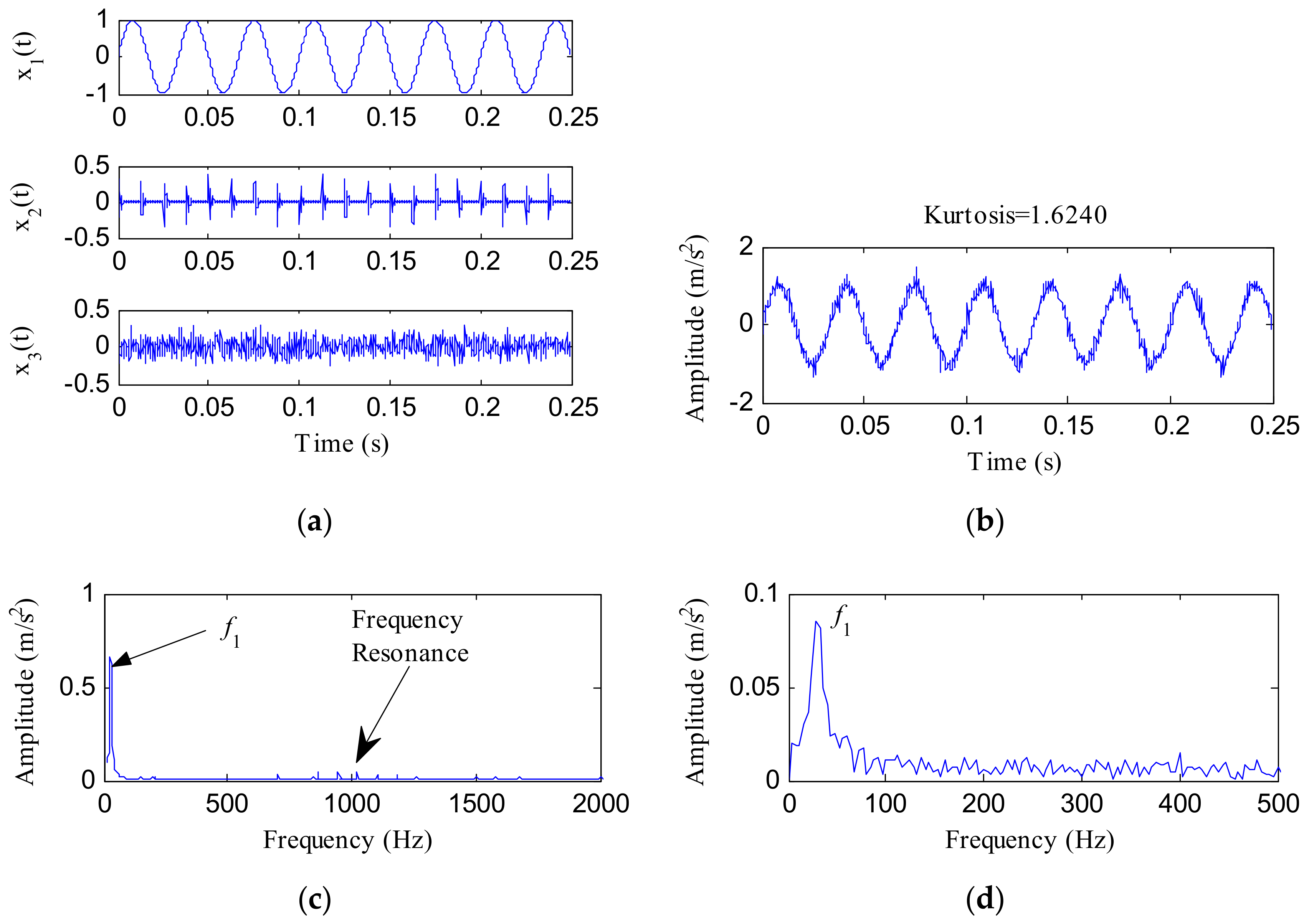

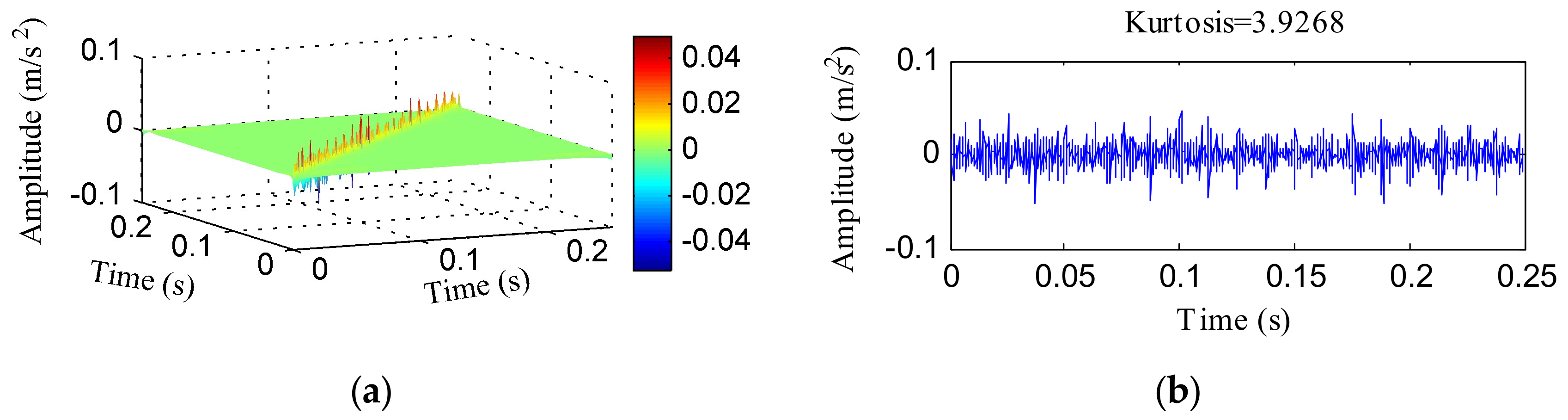

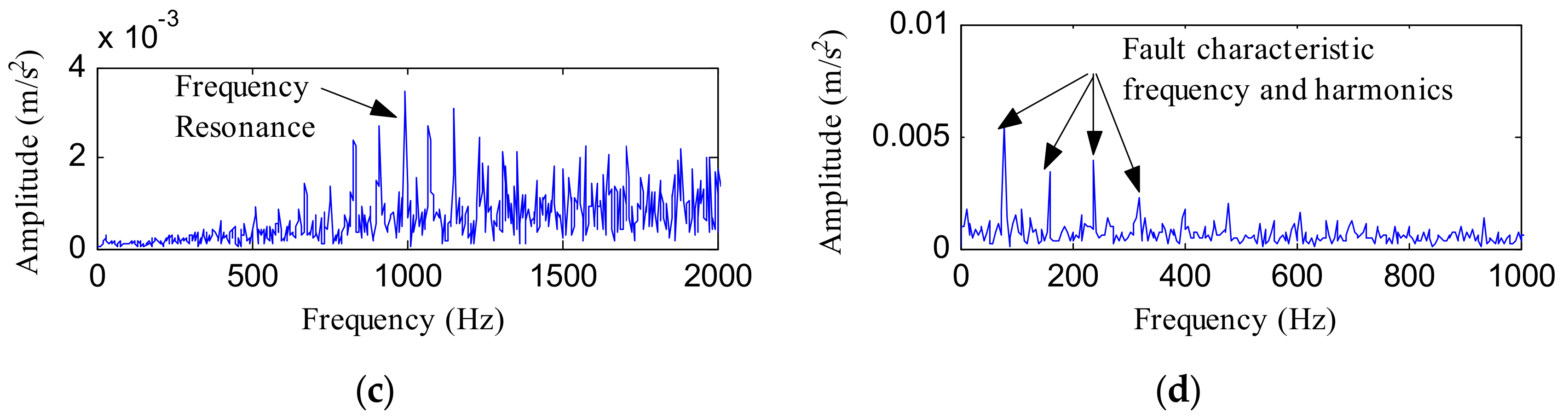

4. Simulation Analysis

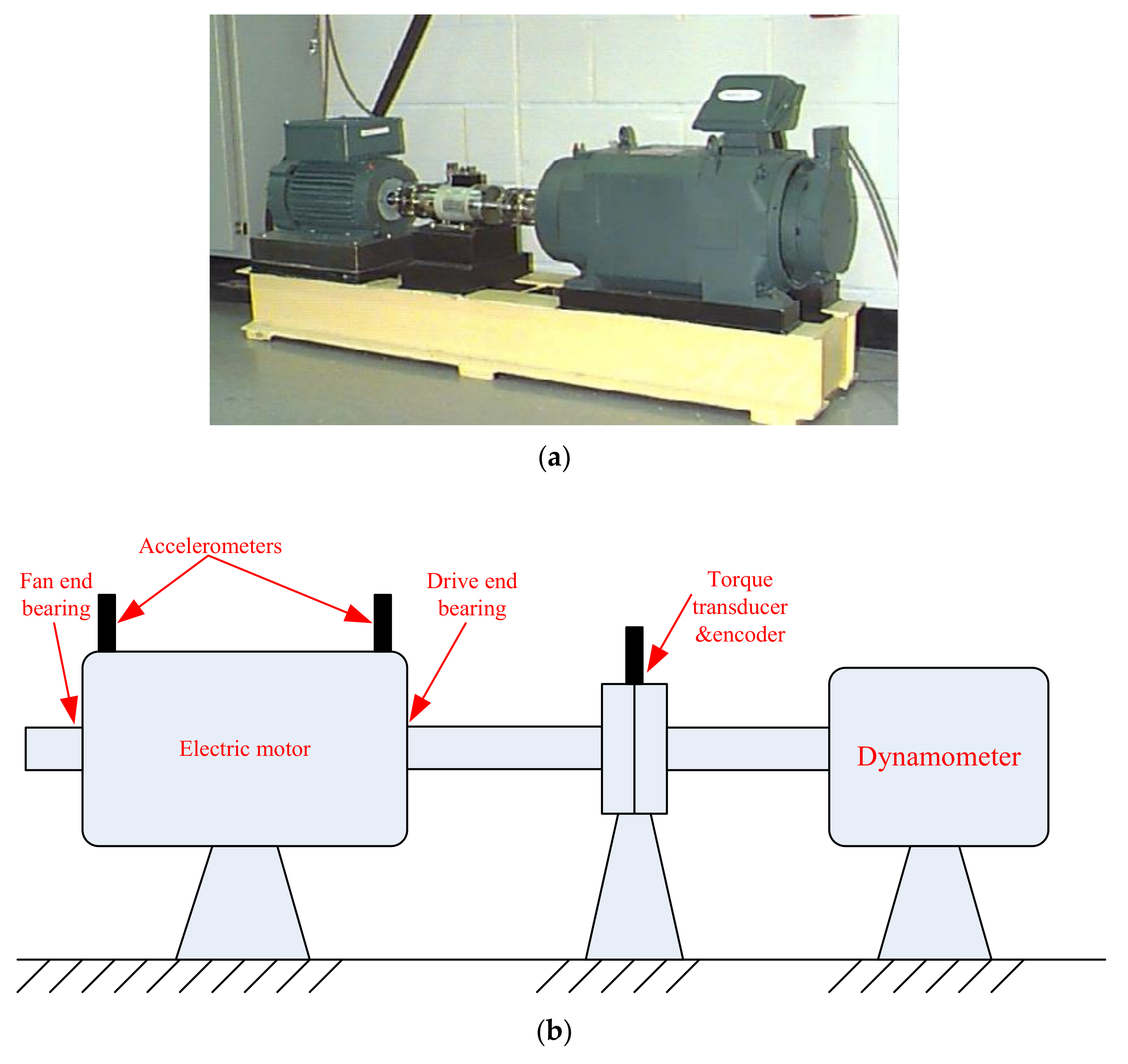

5. Applications

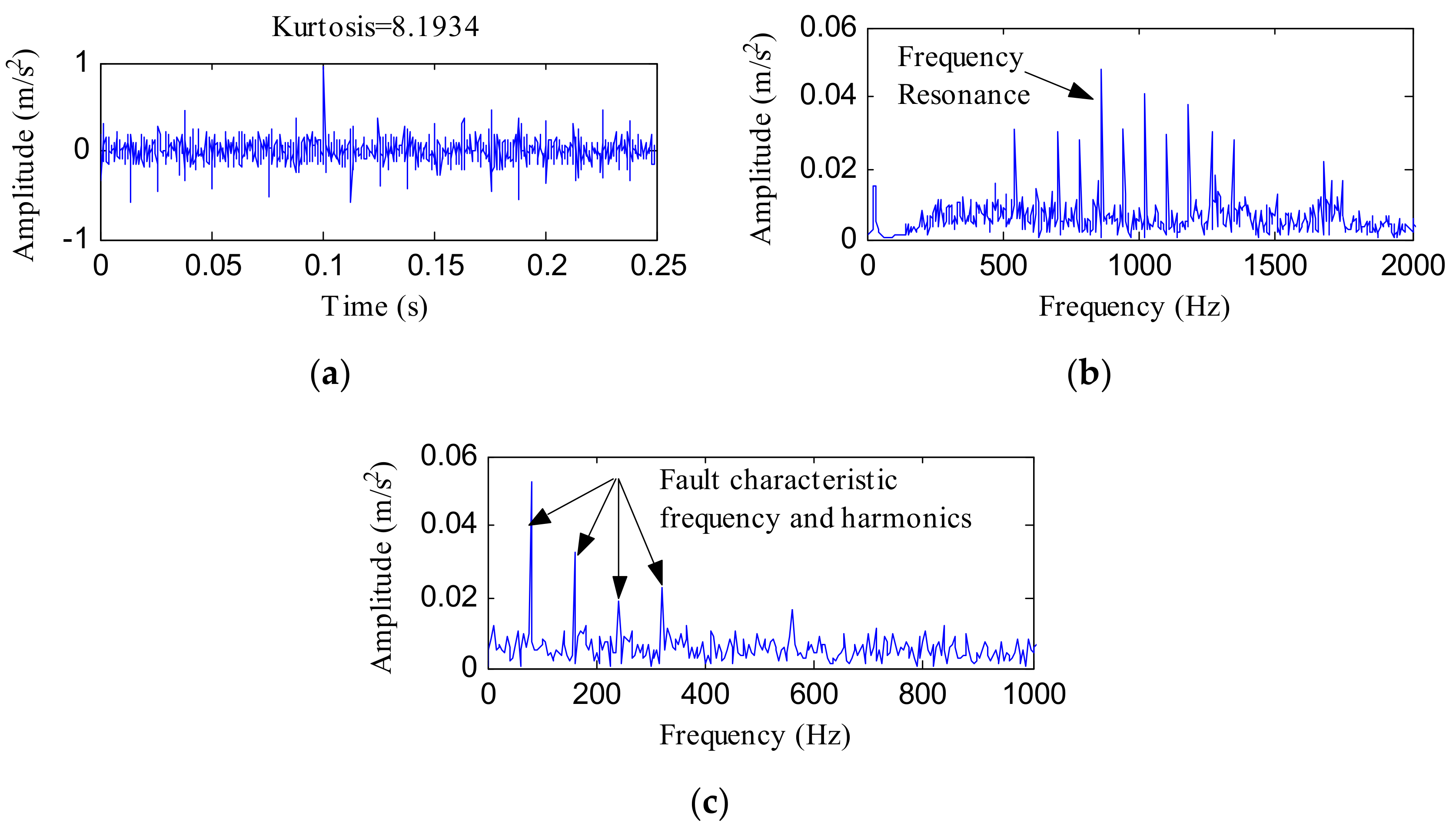

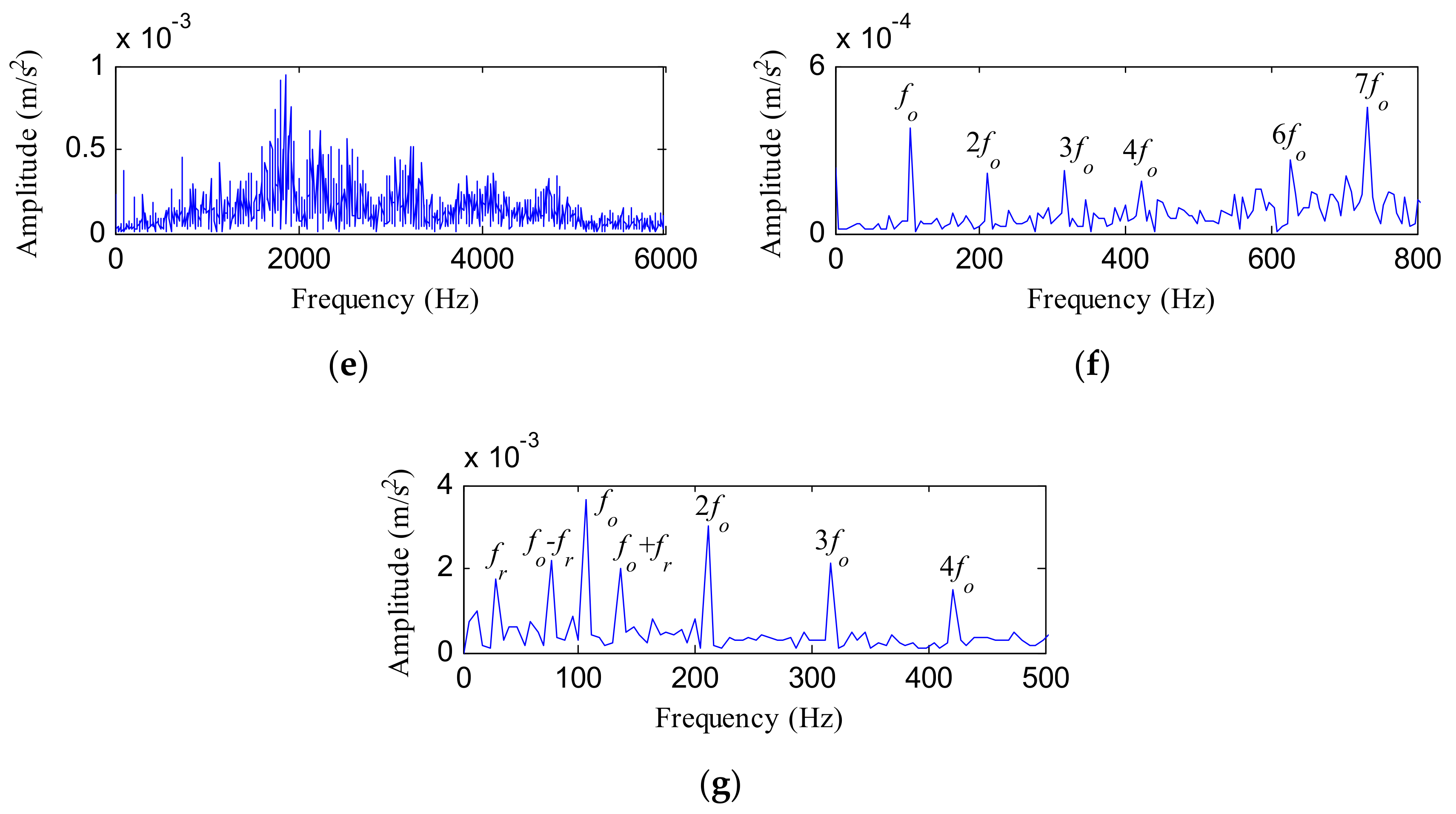

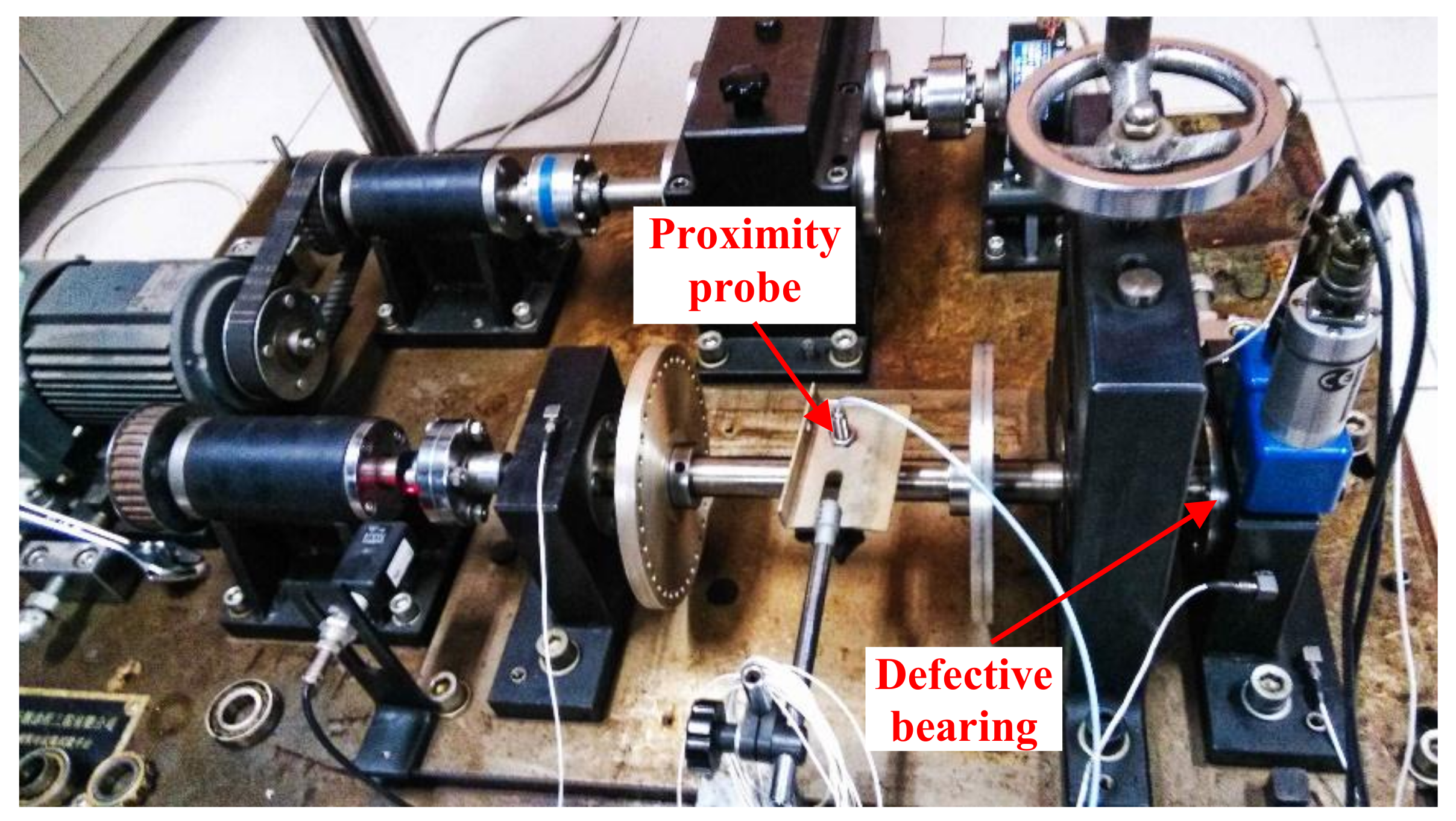

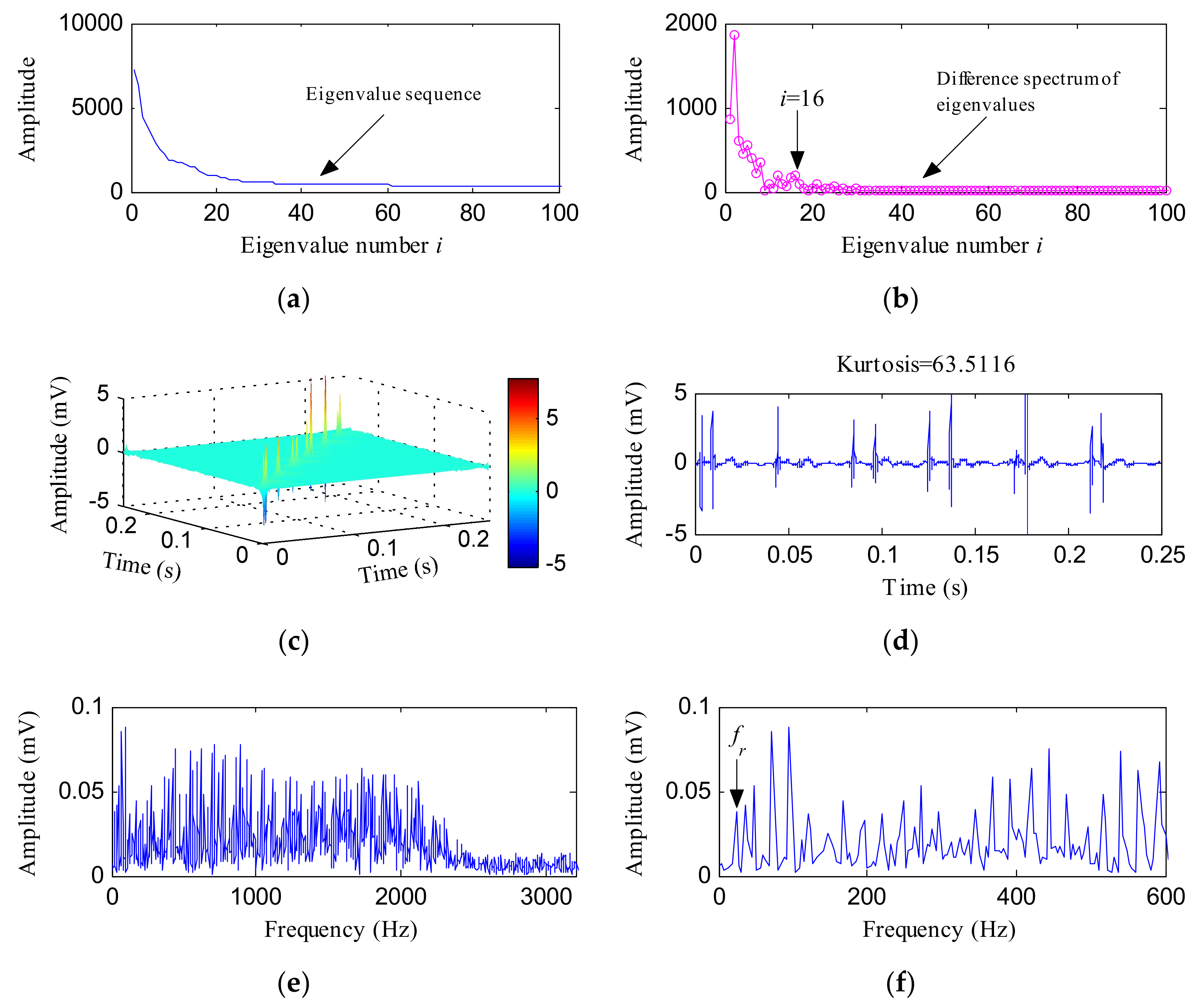

5.1. Case 1: Outer Race Fault Detection

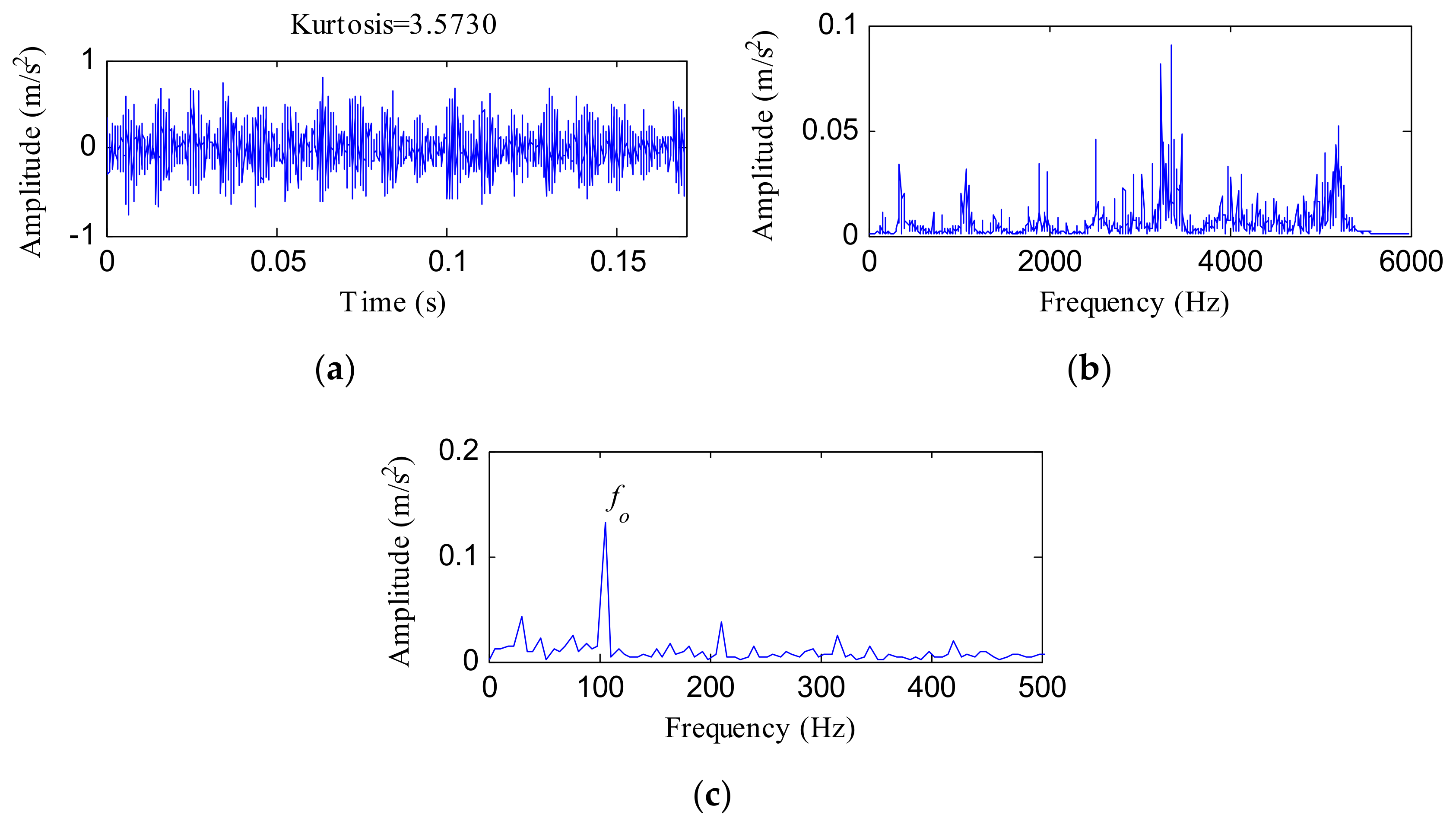

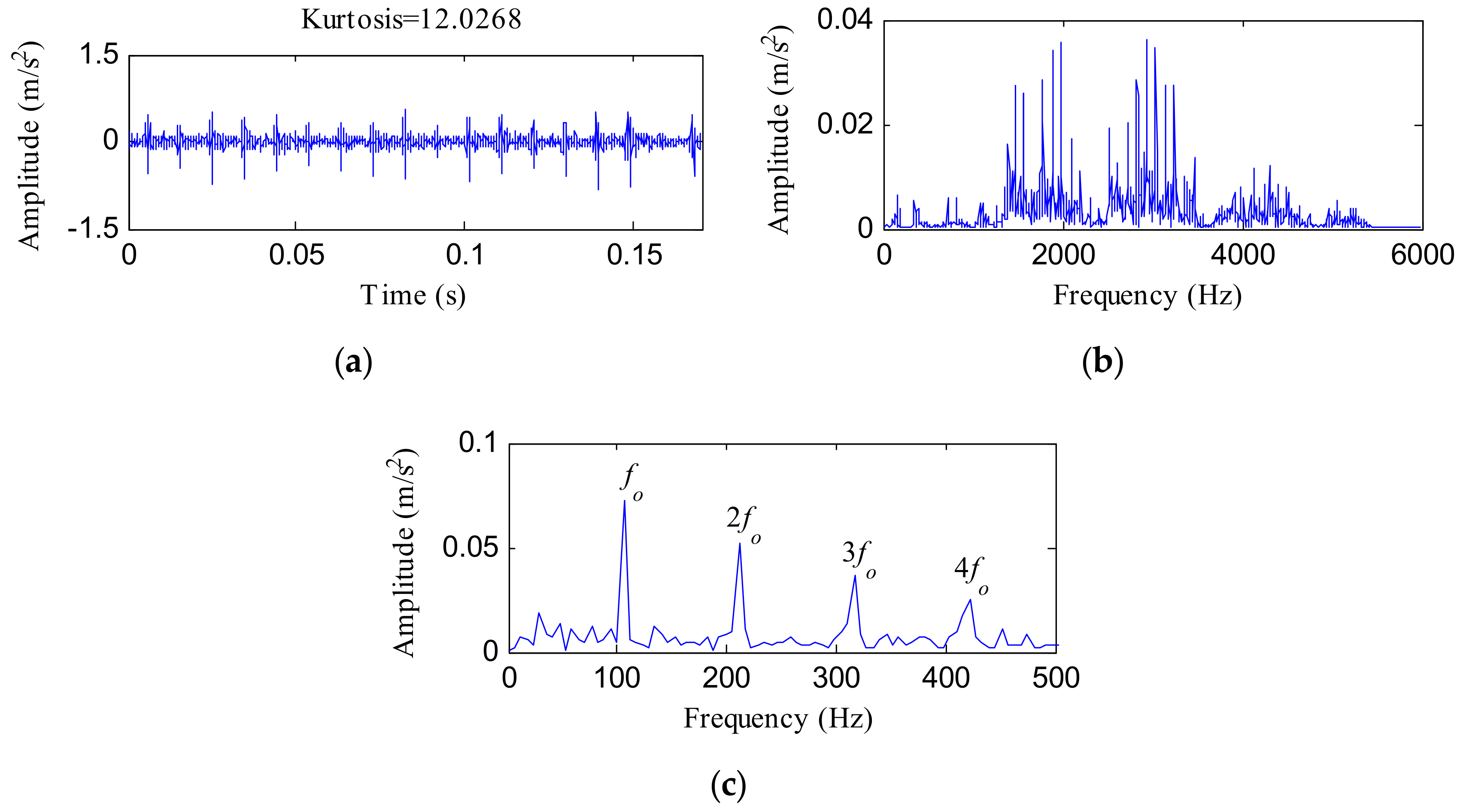

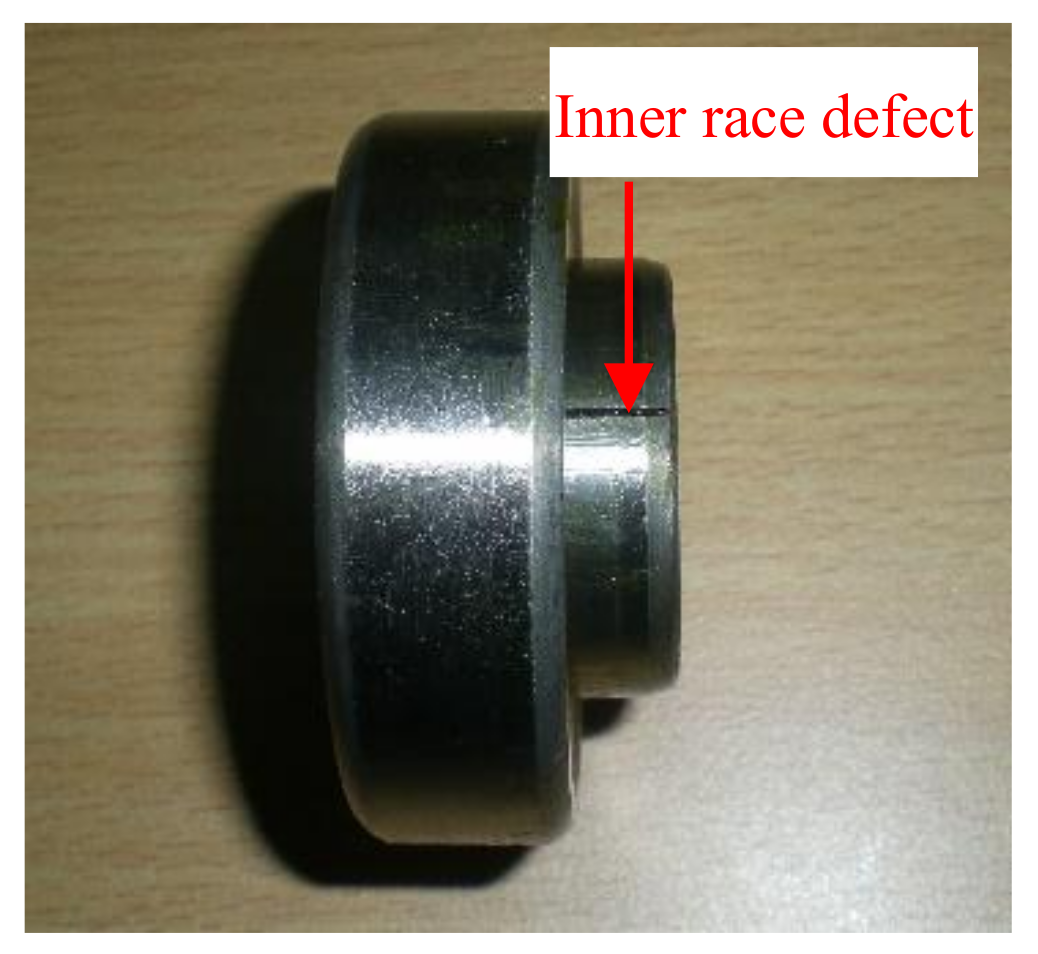

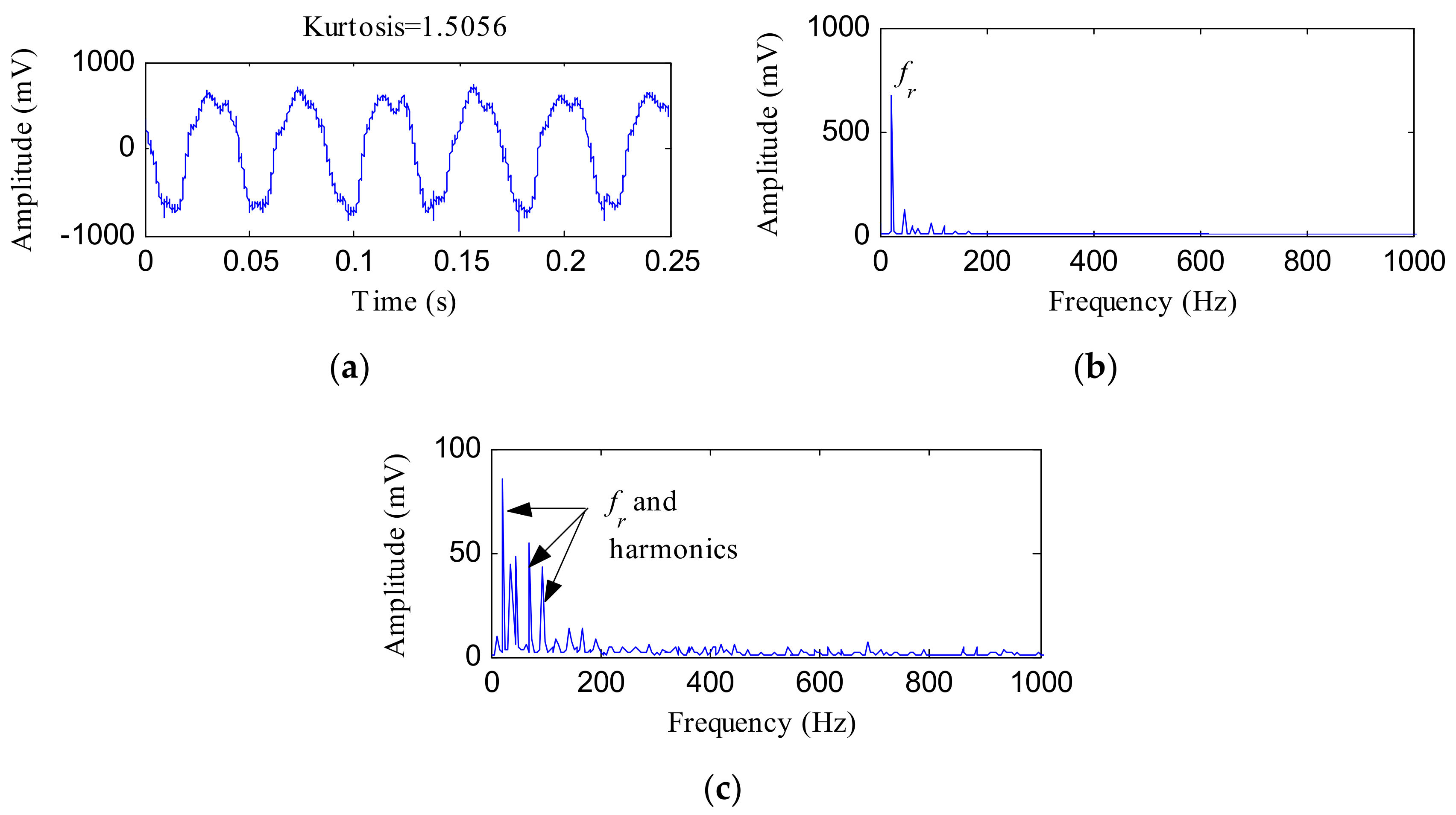

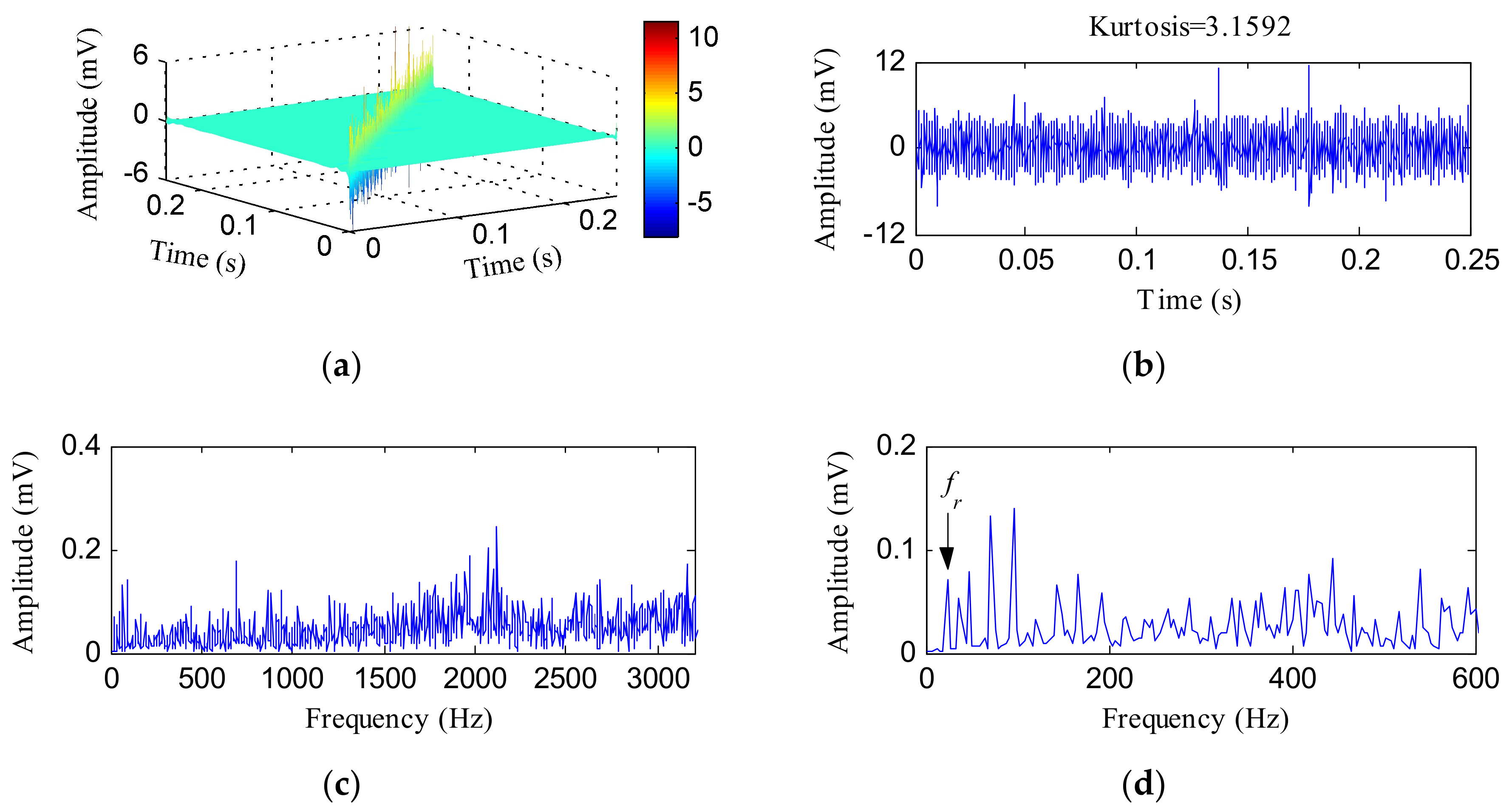

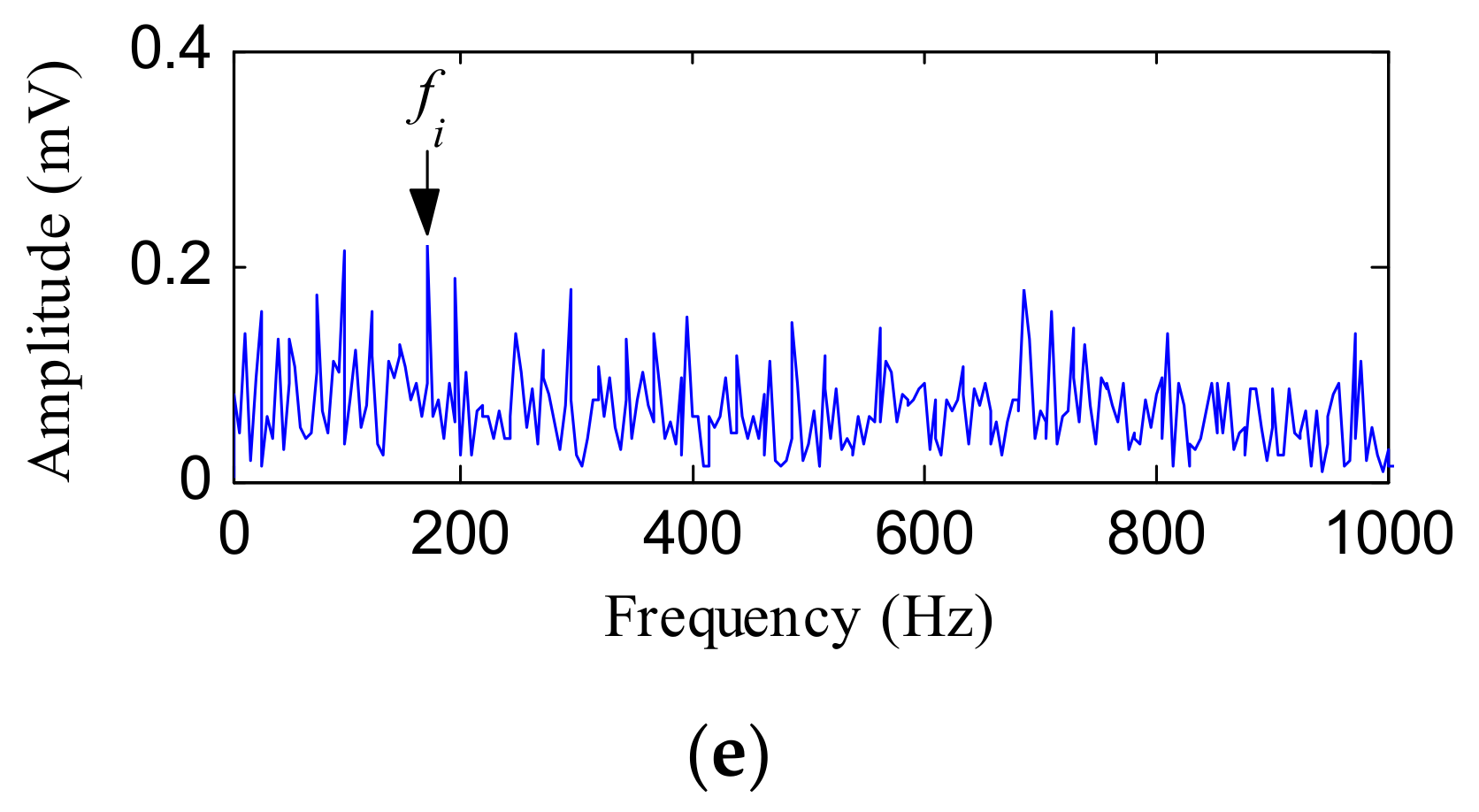

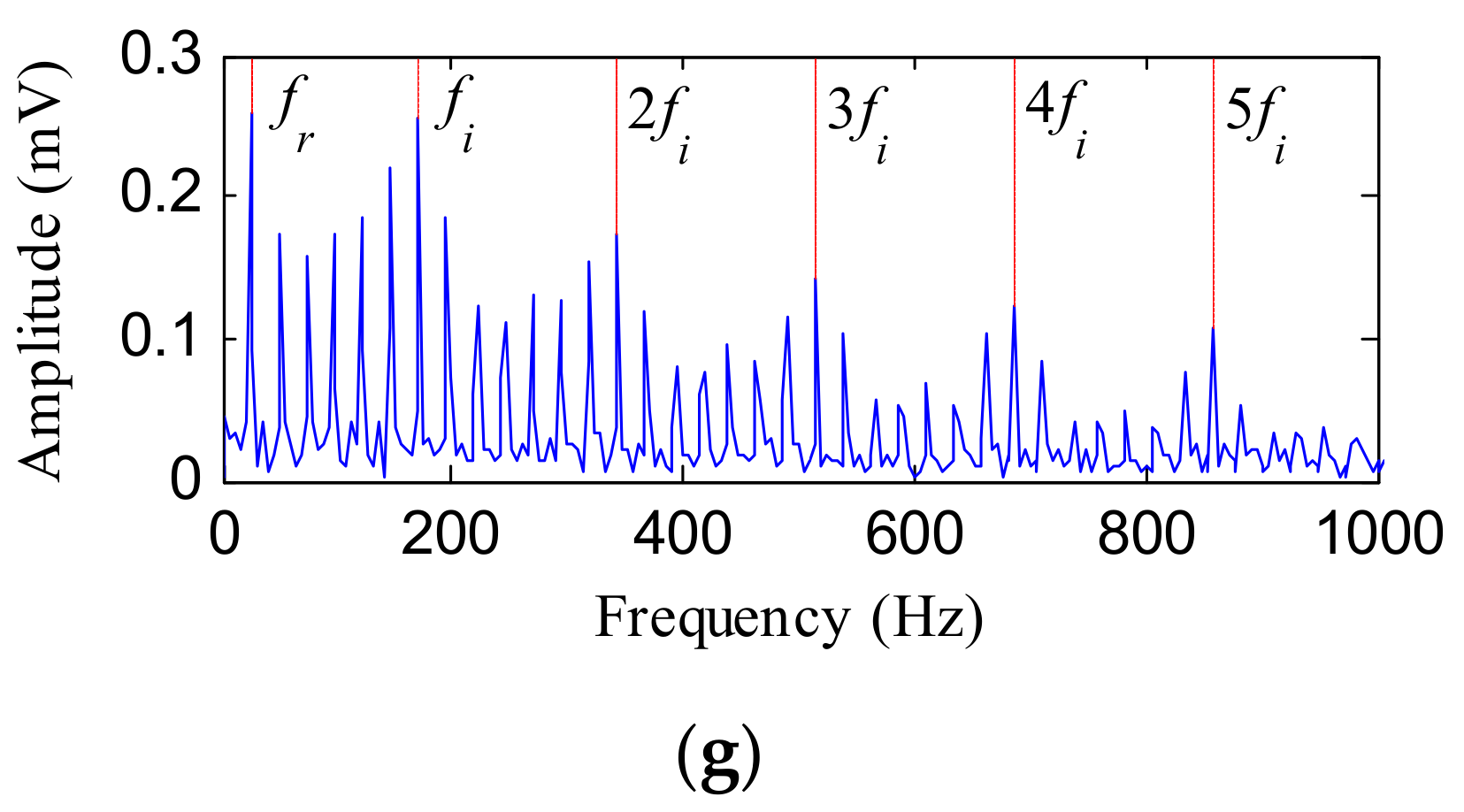

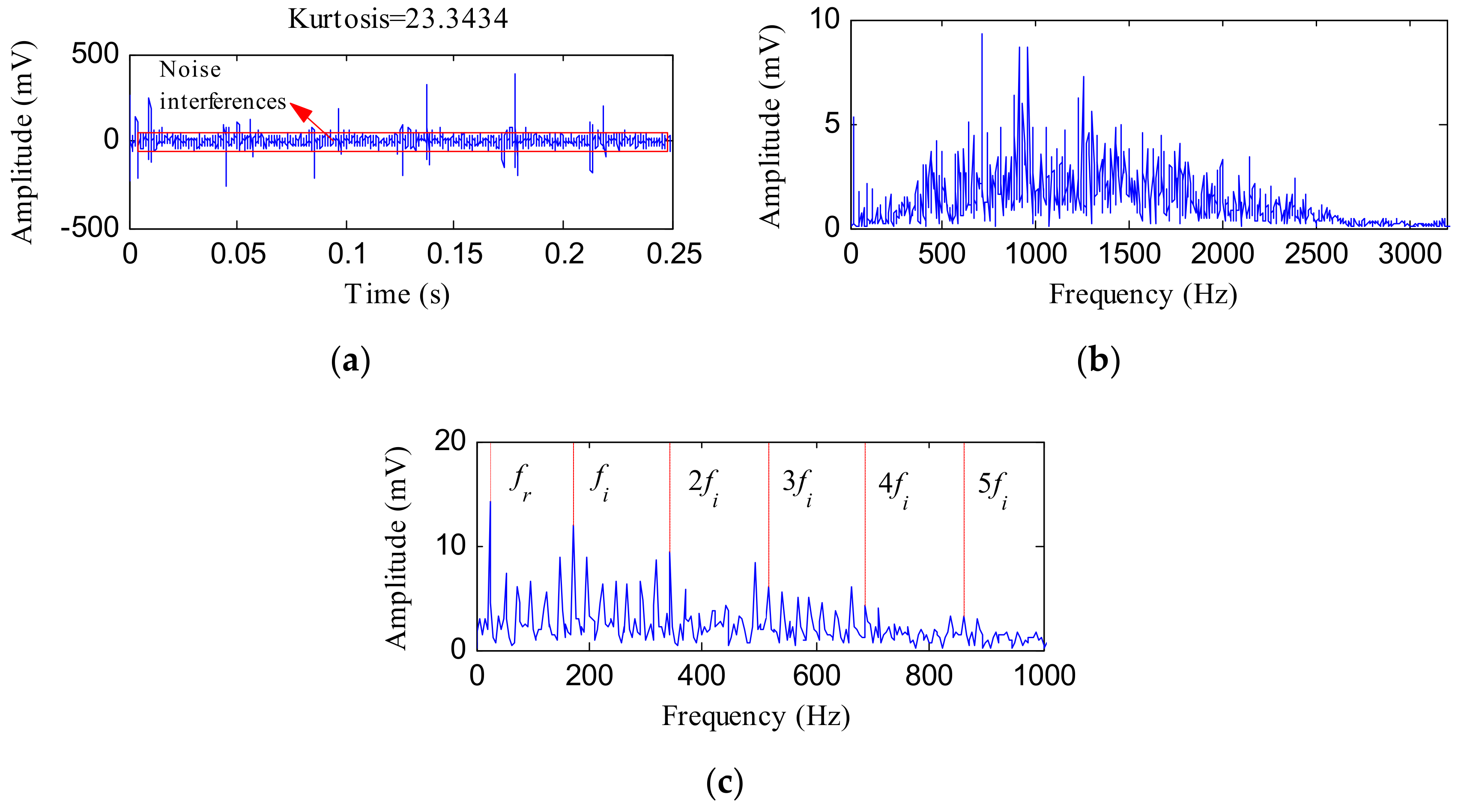

5.2. Case 2: Inner Race Fault Detection

6. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Adamczak, S.; Stepien, K.; Wrzochal, M. Comparative study of measurement systems used to evaluate vibrations of rolling bearings. Procedia Eng. 2017, 192, 971–975. [Google Scholar] [CrossRef]

- Chen, X.; Zhang, B.; Feng, F.; Jiang, P. Optimal resonant band demodulation based on an improved correlated kurtosis and its application in bearing fault diagnosis. Sensors 2017, 17, 360. [Google Scholar] [CrossRef] [PubMed]

- Jia, F.; Lei, Y.; Shan, H.; Lin, J. Early fault diagnosis of bearings using an improved spectral kurtosis by maximum correlated kurtosis deconvolution. Sensors 2015, 15, 29363–29377. [Google Scholar] [CrossRef] [PubMed]

- Cao, H.; Fan, F.; Zhou, K.; He, Z. Wheel-bearing fault diagnosis of trains using empirical wavelet transform. Measurement 2016, 82, 439–449. [Google Scholar] [CrossRef]

- Glowacz, A.; Glowacz, W.; Glowacz, Z.; Kozik, J. Early fault diagnosis of bearing and stator faults of the single-phase induction motor using acoustic signals. Measurement 2018, 113, 1–9. [Google Scholar] [CrossRef]

- Glowacz, A. Fault diagnostics of acoustic signals of loaded synchronous motor using SMOFS-25-EXPANDED and selected classifiers. Tehnicki Vjesnik 2016, 23, 1365–1372. [Google Scholar]

- Glowacz, A. Acoustic based fault diagnosis of three-phase induction motor. Appl. Acoust. 2018, 137, 82–89. [Google Scholar] [CrossRef]

- Glowacz, A.; Glowacz, Z. Diagnosis of stator faults of the single-phase induction motor using acoustic signals. Appl. Acoust. 2017, 117, 20–27. [Google Scholar] [CrossRef]

- Praveenkumar, T.; Sabhrish, B.; Saimurugan, M.; Ramachandran, K.I. Pattern recognition based on-line vibration monitoring system for fault diagnosis of automobile gearbox. Measurement 2018, 114, 233–242. [Google Scholar] [CrossRef]

- Sawczuk, W. The application of vibration accelerations in the assessment of average friction coefficient of a railway brake disc. Meas. Sci. Rev. 2017, 17, 125–134. [Google Scholar] [CrossRef]

- Li, Z.; Jiang, Y.; Hu, C.; Peng, Z. Recent progress on decoupling diagnosis of hybrid failures in gear transmission systems using vibration sensor signal: A review. Measurement 2016, 90, 4–19. [Google Scholar] [CrossRef]

- Gao, Z.; Cecati, C.; Ding, S.X. A survey of fault diagnosis and fault-tolerant techniques—Part I: Fault diagnosis with model-based and signal-based approaches. IEEE Trans. Ind. Electron. 2015, 62, 3757–3767. [Google Scholar] [CrossRef]

- Camarena-Martinez, D.; Valtierra-Rodriguez, M.; Amezquita-Sanchez, J.P.; Granados-Lieberman, D.; Romero-Troncoso, R.J.; Garcia-Perez, A. Shannon entropy and K-means method for automatic diagnosis of broken rotor bars in induction motors using vibration signals. Shock Vib. 2016, 2016, 1–10. [Google Scholar] [CrossRef]

- Lei, Y.; Jia, F.; Lin, J.; Xing, S.; Ding, S.X. An intelligent fault diagnosis method using unsupervised feature learning towards mechanical big data. IEEE Trans. Ind. Electron. 2016, 63, 3137–3147. [Google Scholar] [CrossRef]

- Glowacz, A. Recognition of acoustic signals of loaded synchronous motor using FFT, MSAF-5 and LSVM. Arch. Acoust. 2015, 40, 197–203. [Google Scholar] [CrossRef]

- Leite, V.C.; da Silva, J.G.; Veloso, G.F.; da Silva, L.E.; Lambert-Torres, G.; Bonaldi, E.L.; de Oliveira, L.E. Detection of localized bearing faults in induction machines by spectral kurtosis and envelope analysis of stator current. IEEE Trans. Ind. Electron. 2015, 62, 1855–1865. [Google Scholar] [CrossRef]

- Yan, X.; Jia, M.; Xiang, L. Compound fault diagnosis of rotating machinery based on OVMD and a 1.5-dimension envelope spectrum. Meas. Sci. Technol. 2016, 27, 075002. [Google Scholar]

- Zhao, H.; Li, L. Fault diagnosis of wind turbine bearing based on variational mode decomposition and Teager energy operator. IET Renew. Power Gen. 2016, 11, 453–460. [Google Scholar] [CrossRef]

- Xiang, J.; Zhong, Y.; Gao, H. Rolling element bearing fault detection using PPCA and spectral kurtosis. Measurement 2015, 75, 180–191. [Google Scholar] [CrossRef]

- Lv, Y.; Zhu, Q.; Yuan, R. Fault diagnosis of rolling bearing based on fast nonlocal means and envelop spectrum. Sensors 2015, 15, 1182–1198. [Google Scholar] [CrossRef] [PubMed]

- Zhao, M.; Jia, X. A novel strategy for signal denoising using reweighted SVD and its applications to weak fault feature enhancement of rotating machinery. Mech. Syst. Signal Process. 2017, 94, 129–147. [Google Scholar] [CrossRef]

- Li, J.; Li, M.; Zhang, J. Rolling bearing fault diagnosis based on time-delayed feedback monostable stochastic resonance and adaptive minimum entropy deconvolution. J. Sound Vib. 2017, 401, 139–151. [Google Scholar] [CrossRef]

- Tang, G.; Wang, X.; He, Y. Diagnosis of compound faults of rolling bearings through adaptive maximum correlated kurtosis deconvolution. J. Mech. Sci. Tehcnol. 2016, 30, 43–54. [Google Scholar] [CrossRef]

- Raj, A.S. A novel application of Lucy-Richardson deconvolution: Bearing fault diagnosis. J. Vib. Control 2015, 21, 1055–1067. [Google Scholar] [CrossRef]

- Al-Bugharbee, H.; Trendafilova, I. A fault diagnosis methodology for rolling element bearings based on advanced signal pretreatment and autoregressive modelling. J. Sound Vib. 2016, 369, 246–265. [Google Scholar] [CrossRef]

- Barbini, L.; Ompusunggu, A.P.; Hillis, A.J.; Bois, J.L.D.; Bartic, A. Phase editing as a signal pre-processing step for automated bearing fault detection. Mech. Syst. Signal Process. 2016, 91, 407–421. [Google Scholar] [CrossRef]

- Burriel-Valencia, J.; Puche-Panadero, R.; Martinez-Roman, J.; Sapena-Bano, A.; Pineda-Sanchez, M. Short-frequency fourier transform for fault diagnosis of induction machines working in transient regime. IEEE Trans. Instrum. Meas. 2017, 66, 432–440. [Google Scholar] [CrossRef]

- Glowacz, A. Dc motor fault analysis with the use of acoustic signals, coiflet wavelet transform, and K-nearest neighbor classifier. Arch. Acoust. 2015, 40, 321–327. [Google Scholar] [CrossRef]

- Soualhi, A.; Medjaher, K.; Zerhouni, N. Bearing health monitoring based on Hilbert–Huang transform, support vector machine, and regression. IEEE Trans. Instrum. Meas. 2015, 64, 52–62. [Google Scholar] [CrossRef]

- Chen, J.; Pan, J.; Li, Z.; Zi, Y.; Chen, X. Generator bearing fault diagnosis for wind turbine via empirical wavelet transform using measured vibration signals. Renew. Energy 2016, 89, 80–92. [Google Scholar] [CrossRef]

- Shi, J.; Liang, M.; Necsulescu, D.S.; Guan, Y. Generalized stepwise demodulation transform and synchrosqueezing for time–frequency analysis and bearing fault diagnosis. J. Sound Vib. 2016, 368, 202–222. [Google Scholar] [CrossRef]

- Huang, N.; Zhang, S.; Cai, G.; Xu, D. Power quality disturbances recognition based on a multiresolution generalized S-transform and a PSO-improved decision tree. Energies 2015, 8, 549–572. [Google Scholar] [CrossRef]

- Pinnegar, C.R.; Mansinha, L. A method of time–time analysis: The TT-transform. Digit. Signal Process. 2003, 13, 588–603. [Google Scholar] [CrossRef]

- Pinnegar, C.R. Time–frequency and time–time filtering with the S-transform and TT-transform. Digit. Signal Process. 2005, 15, 604–620. [Google Scholar] [CrossRef]

- Mohanty, S.R.; Kishor, N.; Ray, P.K.; Catalo, J.P.S. Comparative study of advanced signal processing techniques for islanding detection in a hybrid distributed generation system. IEEE Trans. Sustain. Energy 2017, 6, 122–131. [Google Scholar] [CrossRef]

- Biswal, B.; Biswal, M.K.; Dash, P.K.; Mishra, S. Power quality event characterization using support vector machine and optimization using advanced immune algorithm. Neurocomputing 2013, 103, 75–86. [Google Scholar] [CrossRef]

- Fan, X.; Zuo, M.J. Gearbox fault detection using Hilbert and TT-transform. Key Eng. Mater. 2005, 293–294, 79–86. [Google Scholar] [CrossRef]

- Shakya, P.; Darpe, A.K.; Kulkarni, M. Bearing damage classification using instantaneous energy density. J. Vib. Control 2015, 23, 2578–2618. [Google Scholar] [CrossRef]

- Liu, Z.; Wang, T.; Tang, T.; Wang, Y. A principal components rearrangement method for feature representation and its application to the fault diagnosis of CHMI. Energies 2017, 10, 1273. [Google Scholar] [CrossRef]

- Chen, G.; Chen, J.; Zi, Y.; Pan, J.; Han, W. An unsupervised feature extraction method for nonlinear deterioration process of complex equipment under multi dimensional no-label signals. Sens. Actuators A Phys. 2018, 269, 464–473. [Google Scholar] [CrossRef]

- Zhao, X.; Ye, B. Selection of effective singular values using difference spectrum and its application to fault diagnosis of headstock. Mech. Syst. Signal Process. 2011, 25, 1617–1631. [Google Scholar] [CrossRef]

- Yan, X.; Jia, M.; Zhang, W.; Zhu, L. Fault diagnosis of rolling element bearing using a new optimal scale morphology analysis method. ISA Trans. 2018, 73, 165–180. [Google Scholar] [CrossRef] [PubMed]

- Case Western Reserve University Bearing Data Center Website. Available online: https://csegroups.case.edu/bearingdatacenter/home (accessed on 8 June 2016).

| Roller diameter | Pith diameter | Number of the roller | Contact Angle |

|---|---|---|---|

| 7.94 mm | 39 mm | 9 | 0° |

| Roller diameter | Pith diameter | Number of the roller | Contact Angle |

|---|---|---|---|

| 7.5 mm | 38.5 mm | 12 | 0° |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pang, B.; Tang, G.; Tian, T.; Zhou, C. Rolling Bearing Fault Diagnosis Based on an Improved HTT Transform. Sensors 2018, 18, 1203. https://doi.org/10.3390/s18041203

Pang B, Tang G, Tian T, Zhou C. Rolling Bearing Fault Diagnosis Based on an Improved HTT Transform. Sensors. 2018; 18(4):1203. https://doi.org/10.3390/s18041203

Chicago/Turabian StylePang, Bin, Guiji Tang, Tian Tian, and Chong Zhou. 2018. "Rolling Bearing Fault Diagnosis Based on an Improved HTT Transform" Sensors 18, no. 4: 1203. https://doi.org/10.3390/s18041203

APA StylePang, B., Tang, G., Tian, T., & Zhou, C. (2018). Rolling Bearing Fault Diagnosis Based on an Improved HTT Transform. Sensors, 18(4), 1203. https://doi.org/10.3390/s18041203