A Feasibility Study of Transformer Winding Temperature and Strain Detection Based on Distributed Optical Fibre Sensors

Abstract

:1. Introduction

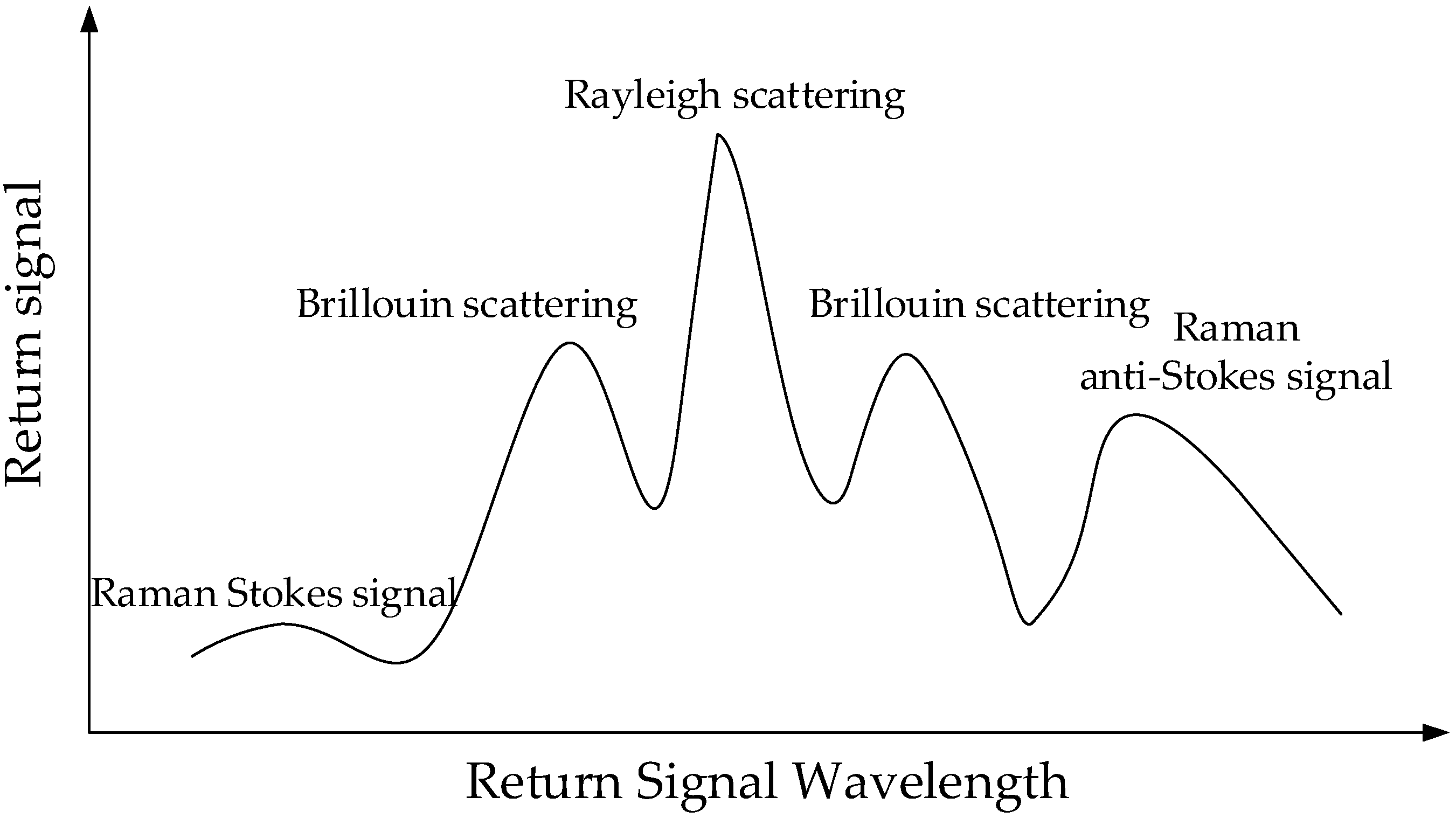

2. Detection Principle

3. Stability Analysis of Distributed Optical Fibres within the Transformer

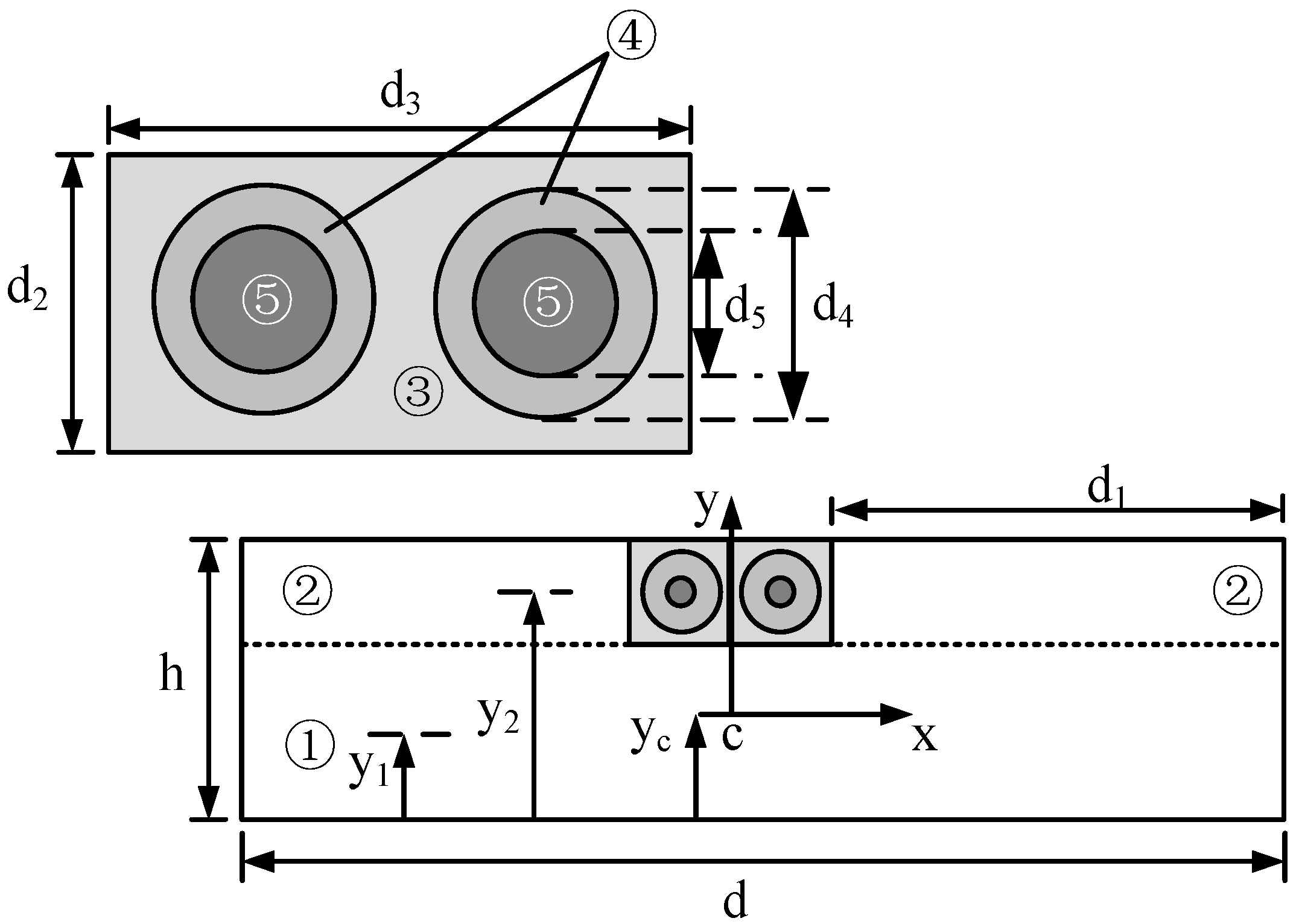

3.1. The Design of Optical Fibre Composite Wire

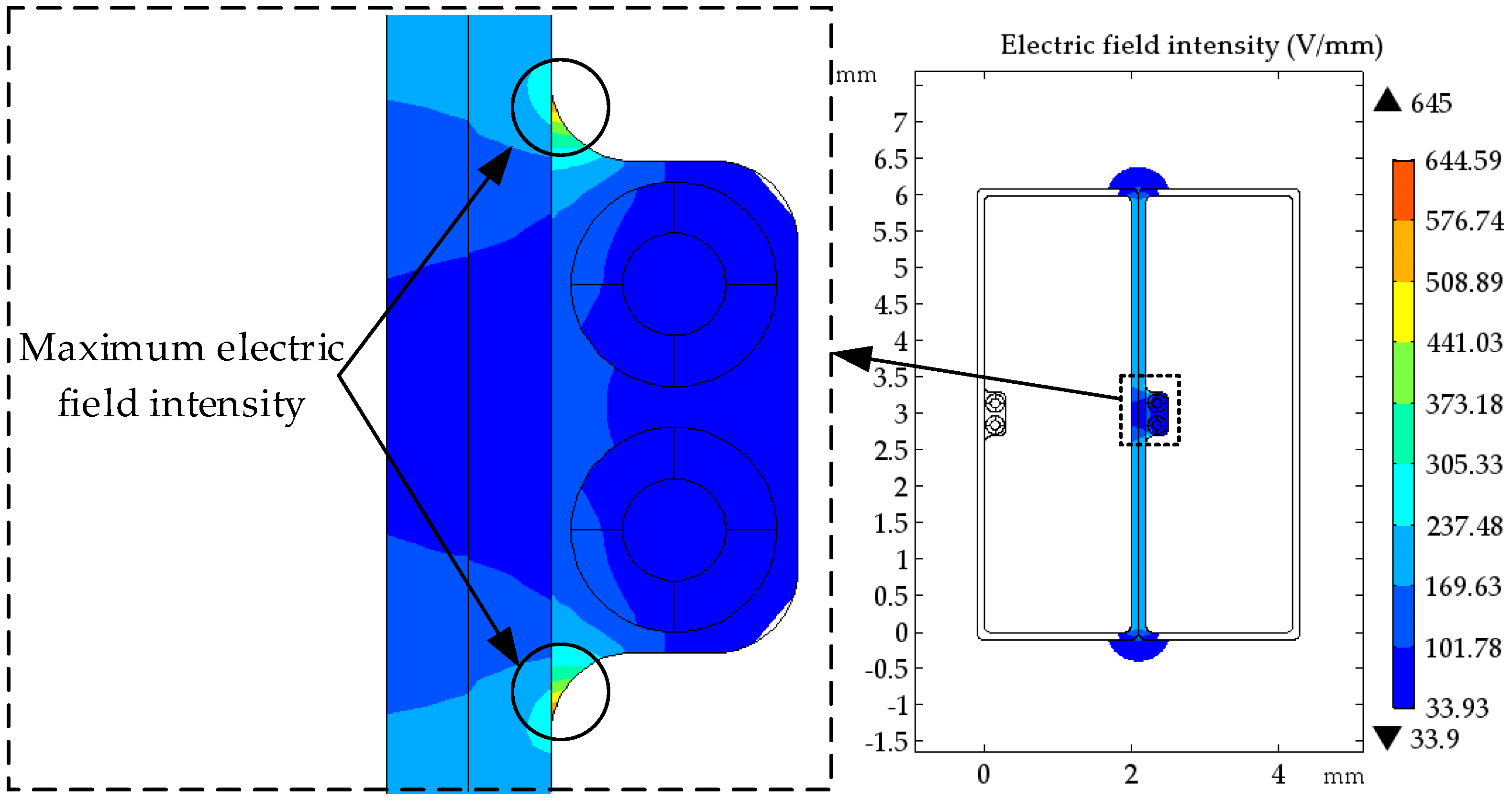

3.2. The Simulation of Inter-Turn Electric Field

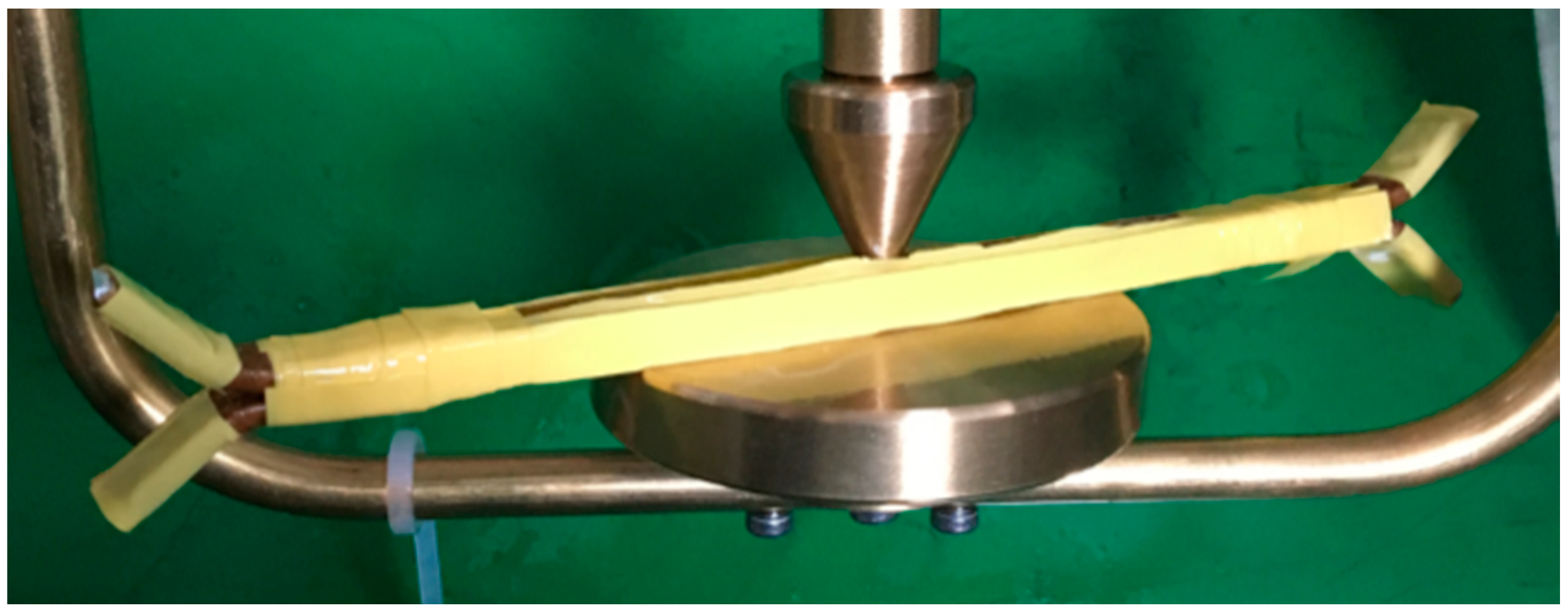

3.3. The Power Frequency Resistance Test of the Groove Wire

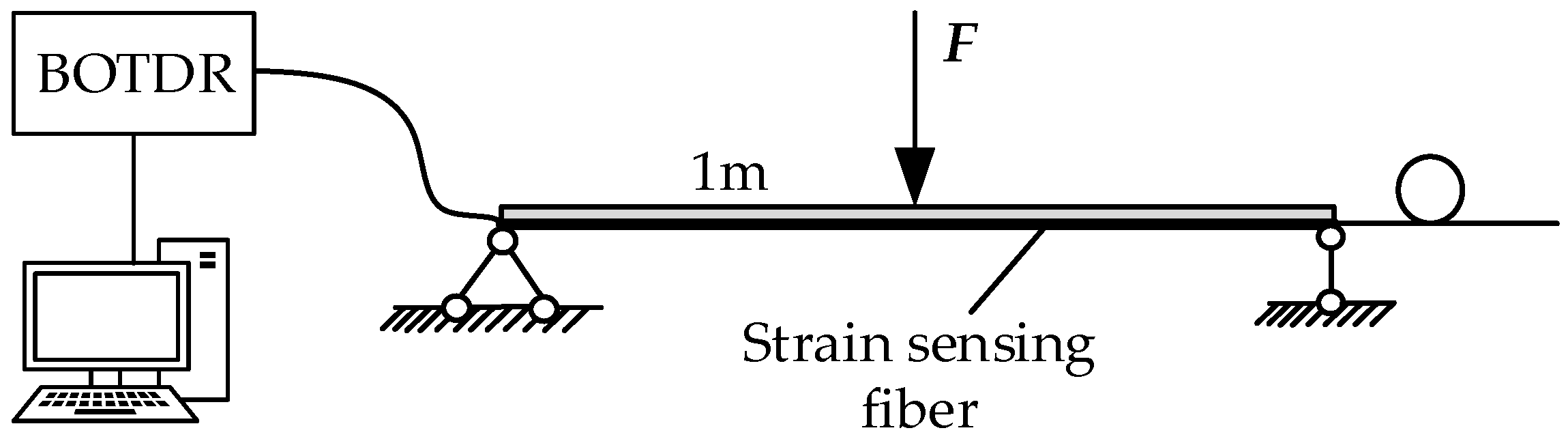

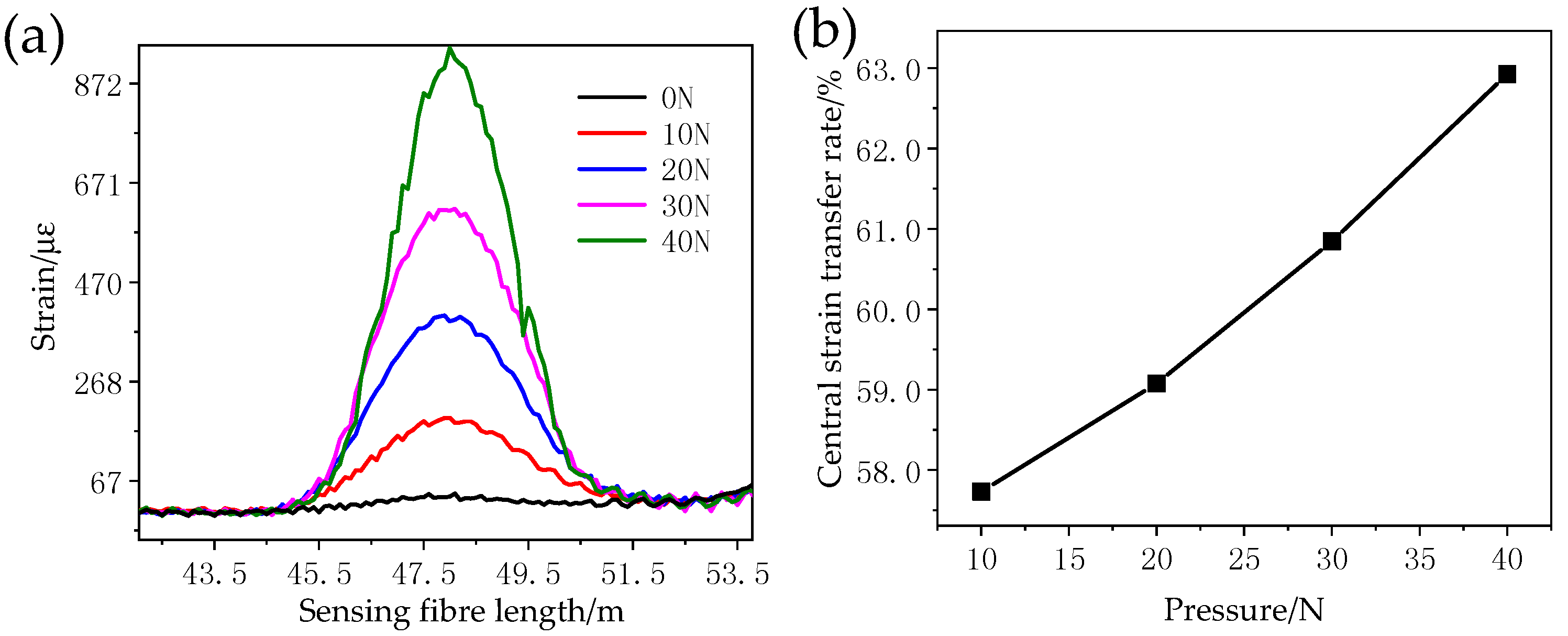

4. Optical Fibre Strain Transfer

4.1. The theoretical Calculation of Embedded Optical Fibre Strain Transfer

- Each interface of the sensor is always tightly connected under bending.

- Materials of different layers are all isotropic, linear elastic, bodies.

- The optical fibre centroid coincides with that of the glue layer.

- Both the wire and groove have no rounded corners.

4.2. Strain Transfer Test

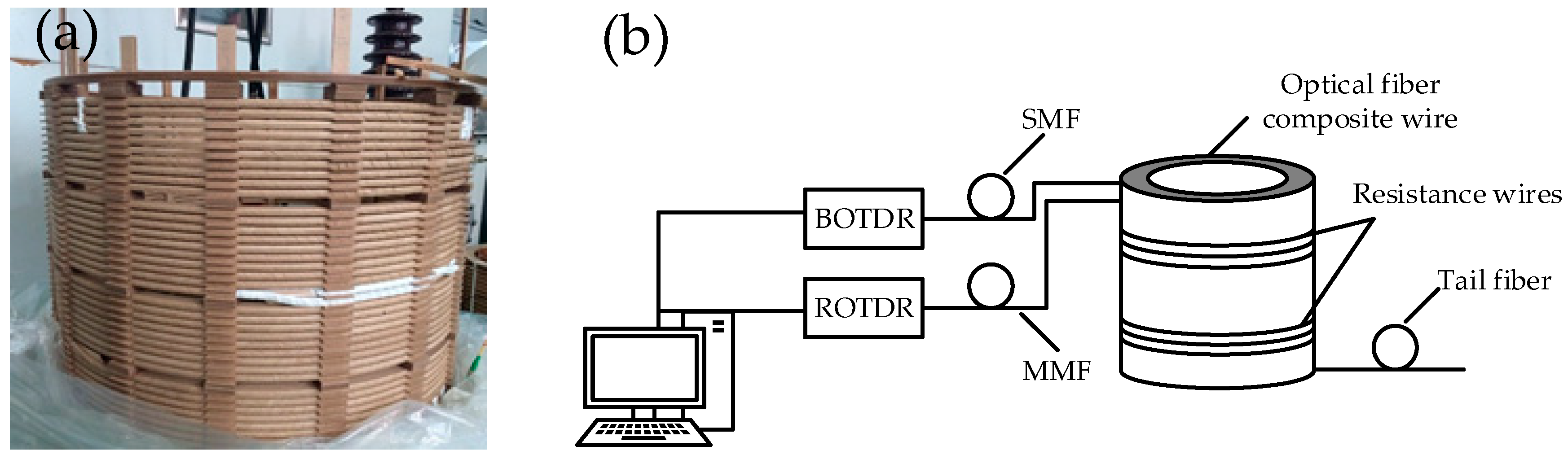

5. Detection of the Temperature of, and Strain in, the Transformer Winding

5.1. Building the Test Platform

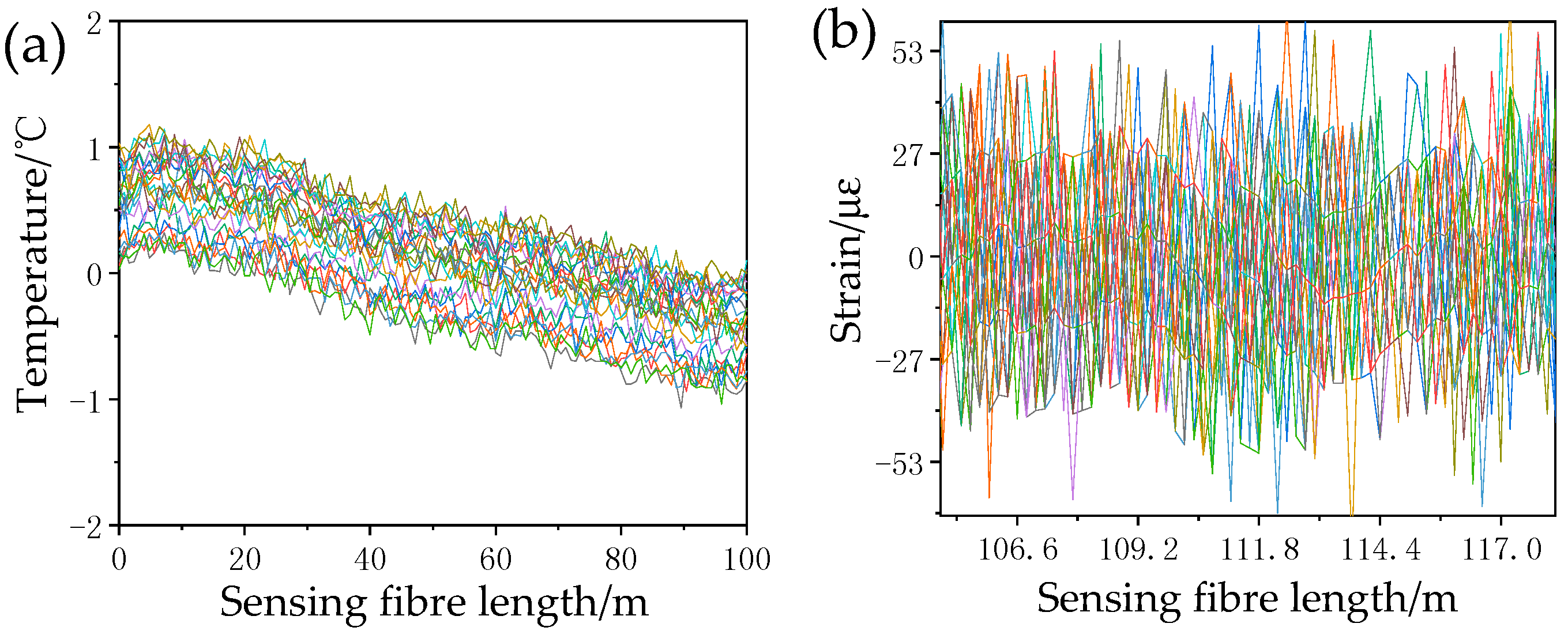

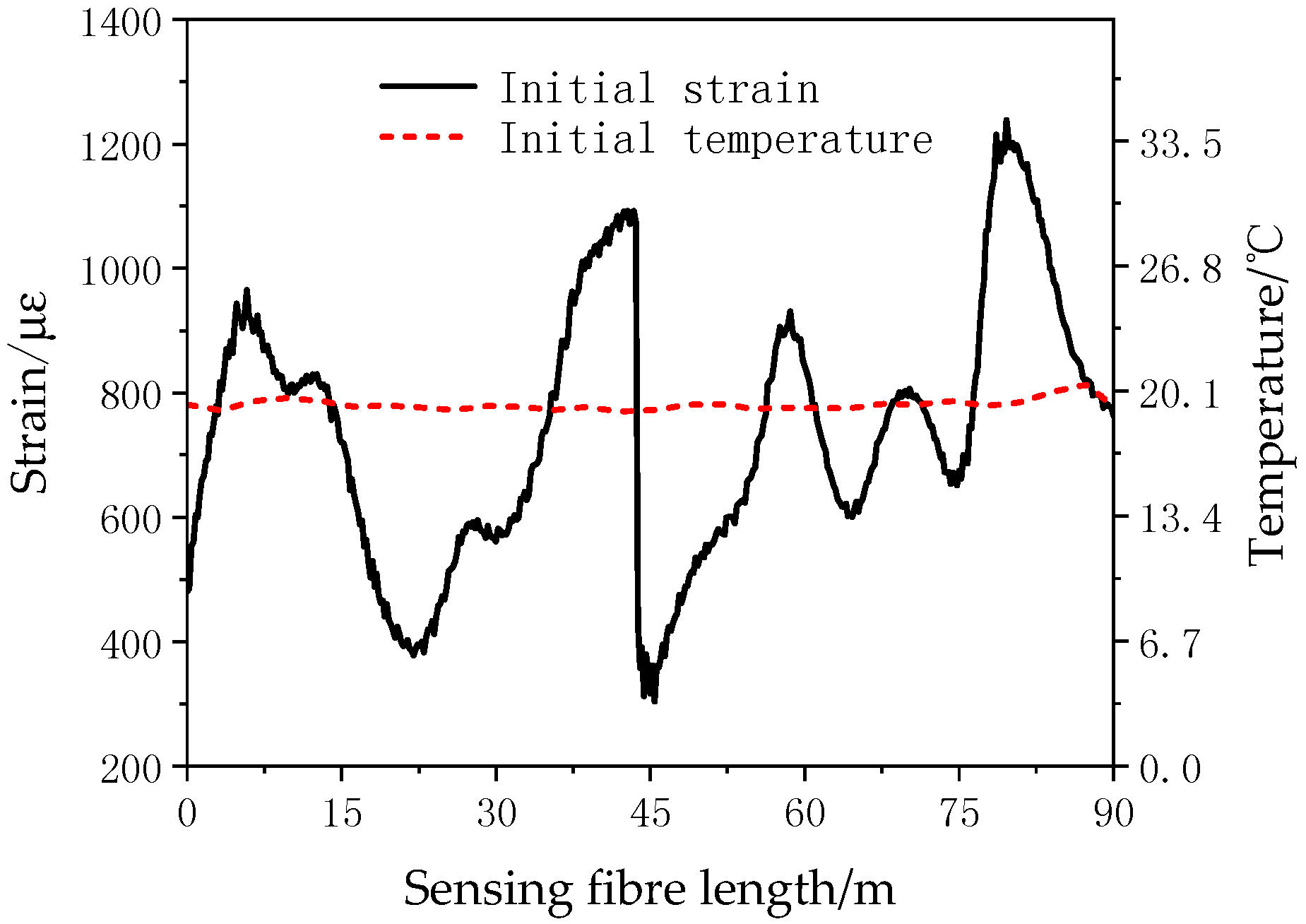

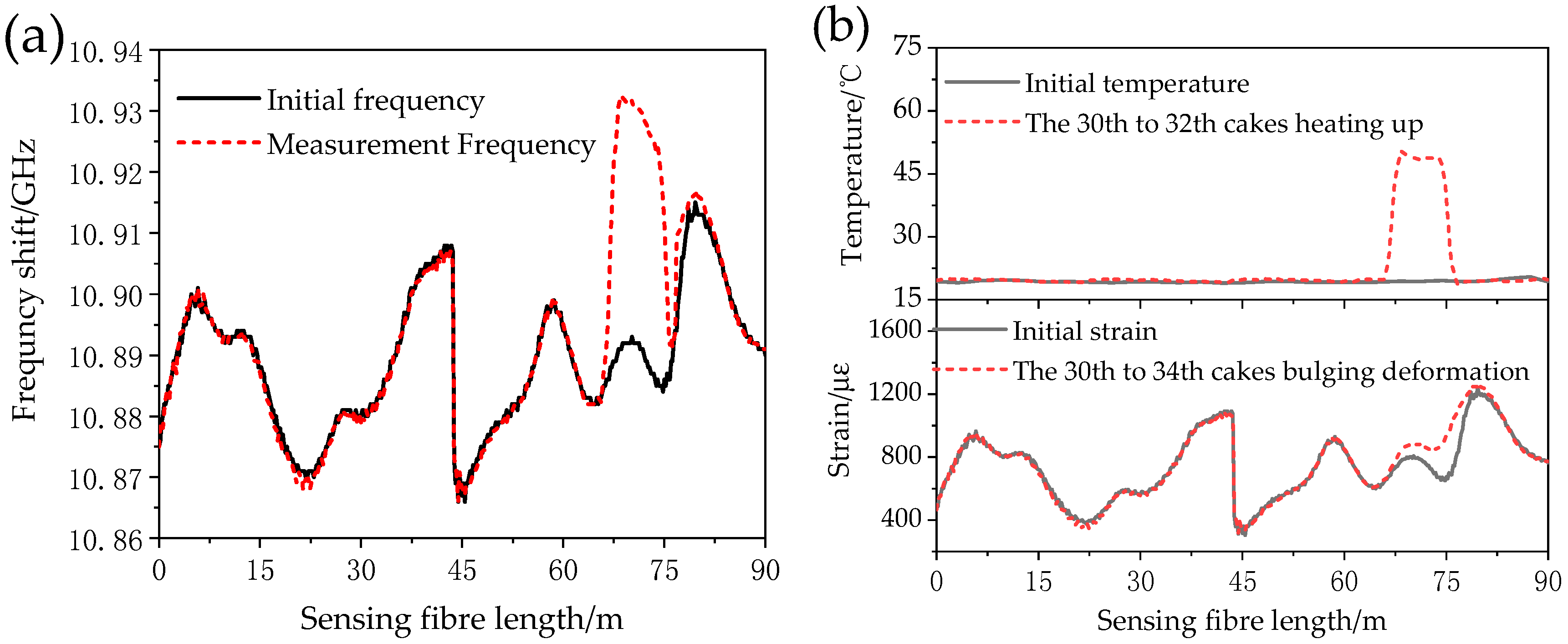

5.2. Temperature Rise Test

5.3. Winding Temperature Rise and Deformation Test

6. Conclusions

- The wire grooving slightly increased the maximum inter-turn field strength, but was not enough to affect the inter-turn insulation strength of the wire; the embedded optical fibre was able to transfer the wire strain and temperature, and the change in strain, as measured by BOTDR, reflected the change of state of the winding.

- The optical fibre is subject to tensile and compressive forces during wire winding and a certain pre-stress developed after the wire was wound. The optical fibre shall be laid at the pressure withstanding side as much as possible to avoid the bending of the optical fibre.

- Brillouin-Raman joint measuring was able to distinguish the optical fibre temperature and strain information, and monitor (in real-time) the winding temperature and strain distribution, and locate hot-spots and deformation positions. At the same time, the strong insulation properties of the optical fibre determined its potential for the on-line monitoring of transformer state and could overcome the shortcomings in traditional detection methods.

- In future research, the correlation between the change of optical fibre strain curve and the winding wire deformation and type, and pattern recognition will be studied so as to provide more accurate state information for engineers responsible for transformer maintenance.

Author Contributions

Funding

Conflicts of Interest

References

- Nordman, H.; Rafsback, N.; Susa, D. Temperature responses to step changes in the load current of power transformers. IEEE Trans. Power Deliv. 2003, 18, 1110–1117. [Google Scholar] [CrossRef]

- Radakovic, Z.; Feser, K. A new method for the calculation of the hot-spot temperature in power transformers with ONAN cooling. IEEE Trans. Power Deliv. 2003, 18, 1284–1292. [Google Scholar] [CrossRef]

- Swift, G.; Molinski, T.S.; Lehn, W. A fundamental approach to transformer thermal modeling. I. Theory and equivalent circuit. IEEE Trans. Power Deliv. 2001, 16, 171–175. [Google Scholar] [CrossRef]

- Wen, J.; Pan, X.; Lin, Y. On-line temperature monitoring system of HV electric apparatus based on optical-fibre fluorescence. J. Shenyang Univ. Technol. 2005, 27, 435–438. [Google Scholar]

- Wang, H. Research on temperature measurement of oil immersed transformer windings based on fluorescent optical fibre sensing. J. Xi’an Univ. 2018, 21, 23–27. [Google Scholar]

- Koo, K.P.; Kersey, A.D. Bragg grating-based laser sensors systems with interferometric interrogation and wavelength division multiplexing. J. Light. Technol. 1995, 13, 1243–1249. [Google Scholar] [CrossRef]

- Deng, J.; Wang, L.; Nie, D. Development of oil-immersed transformers with built-in fibre bragg grating sensors. Proc. CSEE 2013, 33, 160–167. [Google Scholar]

- Picanço, A.F.; Martinez, M.L.B.; Rosa, P.C. Bragg system for temperature monitoring in distribution transformers. Electr. Power Syst. Res. 2010, 80, 77–83. [Google Scholar] [CrossRef]

- Ribeiro, A.B.L.; Eira, N.F.; Sousa, J.M. Multipoint fibre-optic hot-spot sensing network integrated into high power transformer for continuous monitoring. IEEE Sens. J. 2008, 8, 1264–1267. [Google Scholar] [CrossRef]

- Ou, X.; Ji, S.; Peng, J. Study on on-line detecting of transformer winding deformation based on parameter identification of leakage reactance. High Volltage Appar. 2010, 46, 41–44. [Google Scholar]

- Dick, E.P.; Erven, C.C. Transformer diagnostic testing by frequency response analysis. IEEE Trans. Power Appar. Syst. 1978, 6, 2144–2153. [Google Scholar] [CrossRef]

- De Rybel, T.; Singh, A.; Vandermaar, J.A. Apparatus for online power transformer winding monitoring using bushing tap injection. IEEE Trans. Power Deliv. 2009, 24, 996–1003. [Google Scholar] [CrossRef]

- Bagheri, M.; Naderi, M.S.; Blackburn, T. Practical challenges in online transformer winding deformation diagnostics. In Proceedings of the 2nd International Conference on Electric Power and Energy Conversion Systems (EPECS), Sharjah, UAE, 15–17 November 2011; pp. 1–6. [Google Scholar]

- Sun, Y.; Shi, B.; Chen, S. Feasibility study on corrosion monitoring of a concrete column with central rebar using BOTDR. Smart Struct. Syst. 2014, 13, 41–53. [Google Scholar] [CrossRef]

- MacPherson, W.N.; Silva-Lopez, M.; Barton, J.S. Tunnel monitoring using multicore fibre displacement sensor. Meas. Sci. Technol. 2006, 17, 1180. [Google Scholar] [CrossRef]

- Lü, A.; Li, Y.; Li, J. Finite element analysis of the degree of anchorage of photoelectric composite submarine cable with optical fibre strain. Trans. China Electrotech. Soc. 2014, 29, 261–268. [Google Scholar]

- Yilmaz, G.; Karlik, S.E. A distributed optical fiber sensor for temperature detection in power cables. Sens. Actuators A Phys. 2006, 125, 148–155. [Google Scholar] [CrossRef]

- Saxena, M.K.; Raju, S.; Arya, R. Raman optical fiber distributed temperature sensor using wavelet transform based simplified signal processing of Raman backscattered signals. Opt. Laser Technol. 2015, 65, 14–24. [Google Scholar] [CrossRef]

- Anoop, S.; Ilango, K.; Dhieep, A. Thermal stress monitoring and pre-fault detection system in power transformers using fibre optic technology. In Proceedings of the International Conference on Intelligent Computing, Instrumentation and Control Technologies (ICICICT), Thalassery, India, 6–7 July 2017; pp. 886–891. [Google Scholar]

- Deng, J.G.; Nie, D.X.; Pi, B.X. Hot-spot temperature and temperature decay rate measurement in the oil immersed power transformer through FBG based quasi-distributed sensing system. Microw. Opt. Technol. Lett. 2017, 59, 472–475. [Google Scholar] [CrossRef]

- Cheng, Z.; Cheng, L.; Li, W. An on-line transformer windings temperature measurement system based on fiber Bragg grating. In Proceedings of the 5th Photonics and Optoelectronics Meetings on Optoelectronic Sensing and Imaging (POEM), Wuhan, China, 1–2 November 2012; p. 8332. [Google Scholar]

- Anoop, S.; Naufal, N. Monitoring of winding temperature in power transformers—A study. In Proceedings of the International Conference on Intelligent Computing, Instrumentation and Control Technologies (ICICICT), Thalassery, India, 6–7 July 2017; pp. 1334–1337. [Google Scholar]

- Dakin, J.P.; Pratt, D.J.; Bibby, G.W.; Ross, J.N. Distributed optical fiber Raman temperature sensor using a semiconductor light source and detector. Electron. Lett. 1985, 21, 569–570. [Google Scholar] [CrossRef]

- Kulkarni, S.V.; Khaparde, S.A. Transformer Engineering: Design, Technology and Diagnostics, 2nd ed.; CRC Press: New York, NY, USA, 2016; p. 265. [Google Scholar]

- Wan, K.T.; Leung, C.K.Y.; Olson, N.G. Investigation of the strain transfer for surface-attached optical fibre strain sensors. Smart Mater. Struct. 2008, 17, 035037. [Google Scholar] [CrossRef]

- Shan, H. Mechanics of Materials (II), 4th ed.; Higher Education Press: Beijing, China, 2016; p. 22. [Google Scholar]

- Wu, Z.; Shi, B.; Harada, T. An experimental study on the measuring characteristics of BOTDR for structure health monitoring. China Civ. Eng. J. 2005, 38, 56–60. [Google Scholar]

| Material | Transformer Oil | Insulation Paper | Insulation Paint | Optical Fibre Core | Optical Fibre Coating |

|---|---|---|---|---|---|

| Relative dielectric constant | 2.2 | 3.6 | 3.0 | 3.5 | 2.9 |

| ROTDR | BOTDR | ||

|---|---|---|---|

| Temperature range/°C | −190~700 | Strain range/% | ±1.5 |

| Accuracy/°C | ±1 | Pulse width/ns | 20 |

| Resolution/°C | ≤0.5 | Frequency sweep step/MHz | 5 |

| Response time/s | 2~10 | Calculation times | 213 |

| Measuring distance/km | 2 | Measuring distance/km | 1 |

| Sample interval/m | 0.4~0.8 | Sample interval/m | 0.2 |

| Test Results | First Measurement | Second Measurement |

|---|---|---|

| Temperature rise position/cake | 10–12 | 30–32 |

| Actual position/m | 22.5–29.5 | 67.5–74.5 |

| Measurement position/m | 21–31.5 | 65.6–76.0 |

| Mean optical fibre temperature/°C | 39.2 | 59.6 |

| Mean thermocouple temperature/°C | 40.1 | 61.2 |

| Test Results | Temperature Measurement | Strain Measurement |

|---|---|---|

| Temperature rise position/cake | 30–32 | - |

| Deformation position/cake | - | 30–34 |

| Actual position/m | 67.5–74.5 | 67.5–79 |

| Measuring position/m | 65.8–76.5 | 65–82.2 |

| Mean optical fibre temperature/°C | 48.3 | |

| Mean thermocouple temperature°C | 50.2 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, Y.; Tian, Y.; Fan, X.; Bu, Y.; He, P.; Li, H.; Yin, J.; Zheng, X. A Feasibility Study of Transformer Winding Temperature and Strain Detection Based on Distributed Optical Fibre Sensors. Sensors 2018, 18, 3932. https://doi.org/10.3390/s18113932

Liu Y, Tian Y, Fan X, Bu Y, He P, Li H, Yin J, Zheng X. A Feasibility Study of Transformer Winding Temperature and Strain Detection Based on Distributed Optical Fibre Sensors. Sensors. 2018; 18(11):3932. https://doi.org/10.3390/s18113932

Chicago/Turabian StyleLiu, Yunpeng, Yuan Tian, Xiaozhou Fan, Yanan Bu, Peng He, Huan Li, Junyi Yin, and Xiaojiang Zheng. 2018. "A Feasibility Study of Transformer Winding Temperature and Strain Detection Based on Distributed Optical Fibre Sensors" Sensors 18, no. 11: 3932. https://doi.org/10.3390/s18113932

APA StyleLiu, Y., Tian, Y., Fan, X., Bu, Y., He, P., Li, H., Yin, J., & Zheng, X. (2018). A Feasibility Study of Transformer Winding Temperature and Strain Detection Based on Distributed Optical Fibre Sensors. Sensors, 18(11), 3932. https://doi.org/10.3390/s18113932