1. Introduction

Trace gas sensors are used in numerous applications, such as environmental science (e.g., monitoring of atmospheric pollutants) [

1], medical diagnostics (e.g., breath analysis) [

2], industrial control [

3] and the detection of dangerous substances (e.g., toxic gases or explosives) [

4]. There are many methods that can be used to implement trace gas sensors. One of them, which is particularly well suited for such applications, is photoacoustic spectroscopy (PAS) [

5,

6,

7].

In photoacoustic spectroscopy, the investigated gas is illuminated with light, and its wavelength is adjusted to the absorption line of interest. Absorption of light results in an increase of the local temperature and pressure. Modulation of the light intensity or wavelength with a given frequency

f will thus lead to periodic temperature and pressure changes. Such pressure changes (i.e., photoacoustic signal) can be measured with a microphone or piezoelectric transducer. One of the most important facts about the induced photoacoustic signal is that its amplitude is proportional to the concentration of the absorbing gas. This allows the design of photoacoustic sensors that are capable of concentration measurements with the linearity of several orders of magnitude. For obvious reasons, solutions dedicated to trace gas detection applications are usually optimized towards the highest possible sensitivity, i.e., capability of detecting as low concentrations as possible. One of the methods of increasing sensitivity of the photoacoustic equipment is the use of an acoustic resonance for amplification of the photoacoustic signal. In such a case the signal gain is equal to the quality factor of the applied resonance [

8]. A particular solution of that kind uses a quartz tuning fork (QTF) as the photoacoustic signal detector/transducer. For this reason the described modification of photoacoustic spectroscopy is called QEPAS (Quartz Enhanced PhotoAcoustic Spectroscopy) [

8,

9,

10,

11,

12]. Due to the fact that QTFs may have quality factors of the order of 10

4–10

5 [

8,

13,

14,

15], a very high signal gain can be obtained.

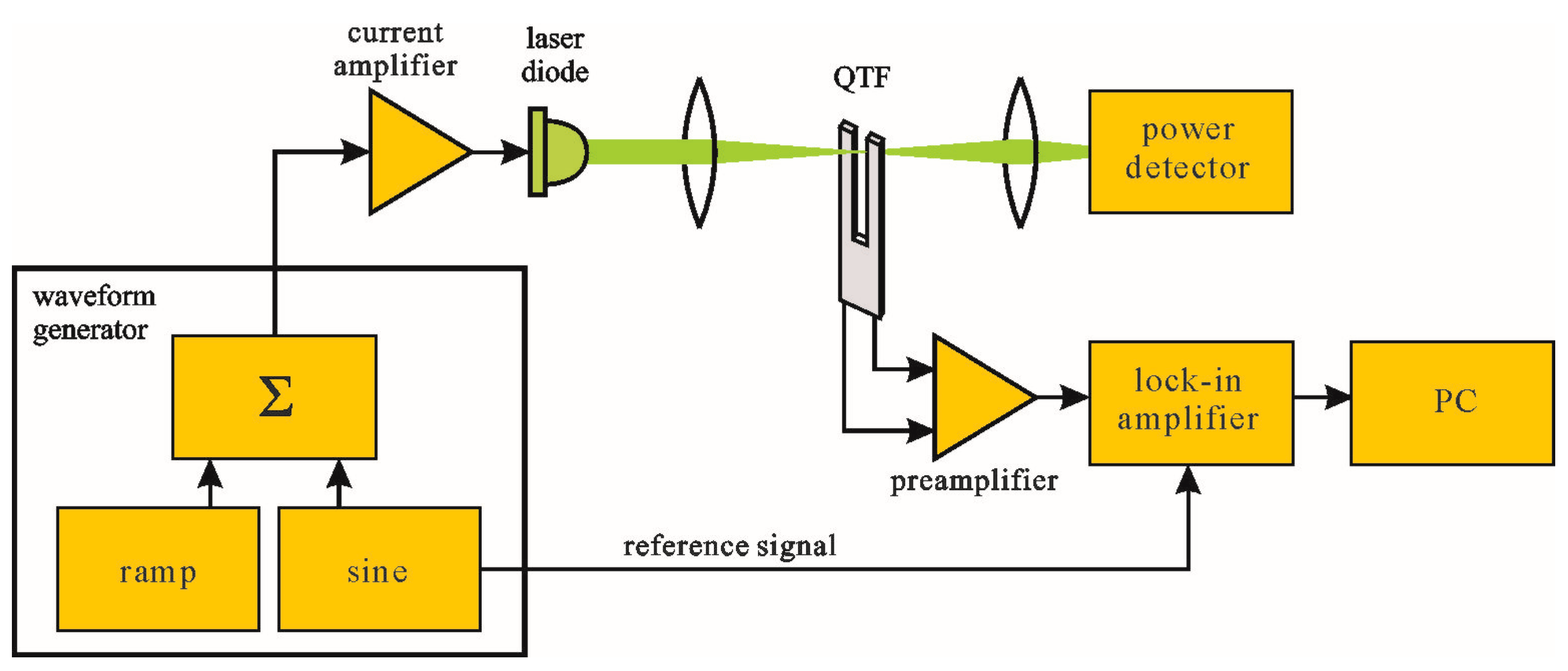

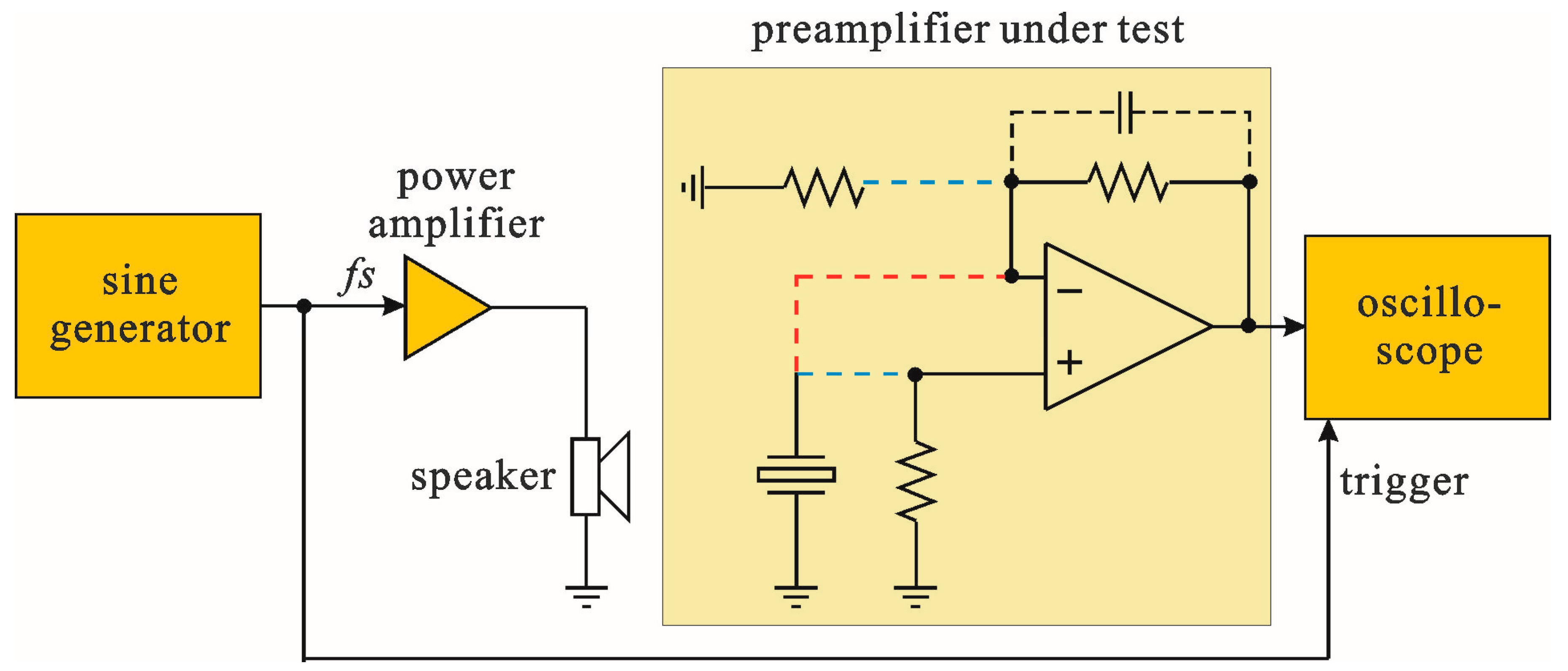

A simplified block diagram of a QEPAS setup is presented in

Figure 1. In the most common QEPAS implementation, a light beam produced with a laser diode is collimated between the QTF prongs. The laser diode is driven by a current amplifier, which in turn is controlled by a waveform generator. The output signal from the waveform generator consists of two components, slow ramp of relatively high amplitude and a small amplitude sine wave. Taking into consideration that wavelength of the light emitted by a laser diode depends on the current flowing through the diode, the slow ramp implements wavelength scanning, while the sine wave component results in additional small-deviation wavelength modulation. Absorption of the modulated light by the investigated gas produces local gas pressure changes, which periodically deflect prongs of the tuning fork synchronously to the light modulation. Each deflection of the prongs results in change of the charge/voltage at the resonator terminals (nodes). Such a signal is passed through a preamplifier, and then its amplitude is measured by a lock-in amplifier and can be recorded by a computer (PC). If the sine wave modulation frequency is appropriately selected, the QEPAS signal can be substantially amplified due to the resonance properties of the tuning fork.

All the preamplifiers dedicated to QEPAS applications that have been so far reported in the literature have been based on operational amplifiers working in transimpedance configurations [

8,

12,

13,

14,

15,

16]. However, QEPAS sensors are based on quartz tuning forks, and that quartz is a piezoelectric material with a relatively high voltage constant and relatively low charge constant [

17]. This lead us to the conclusion that a transimpedance amplifier is probably not an optimal solution, and that properties of the preamplifier can be substantially improved if the preamplifier is implemented in a different way.

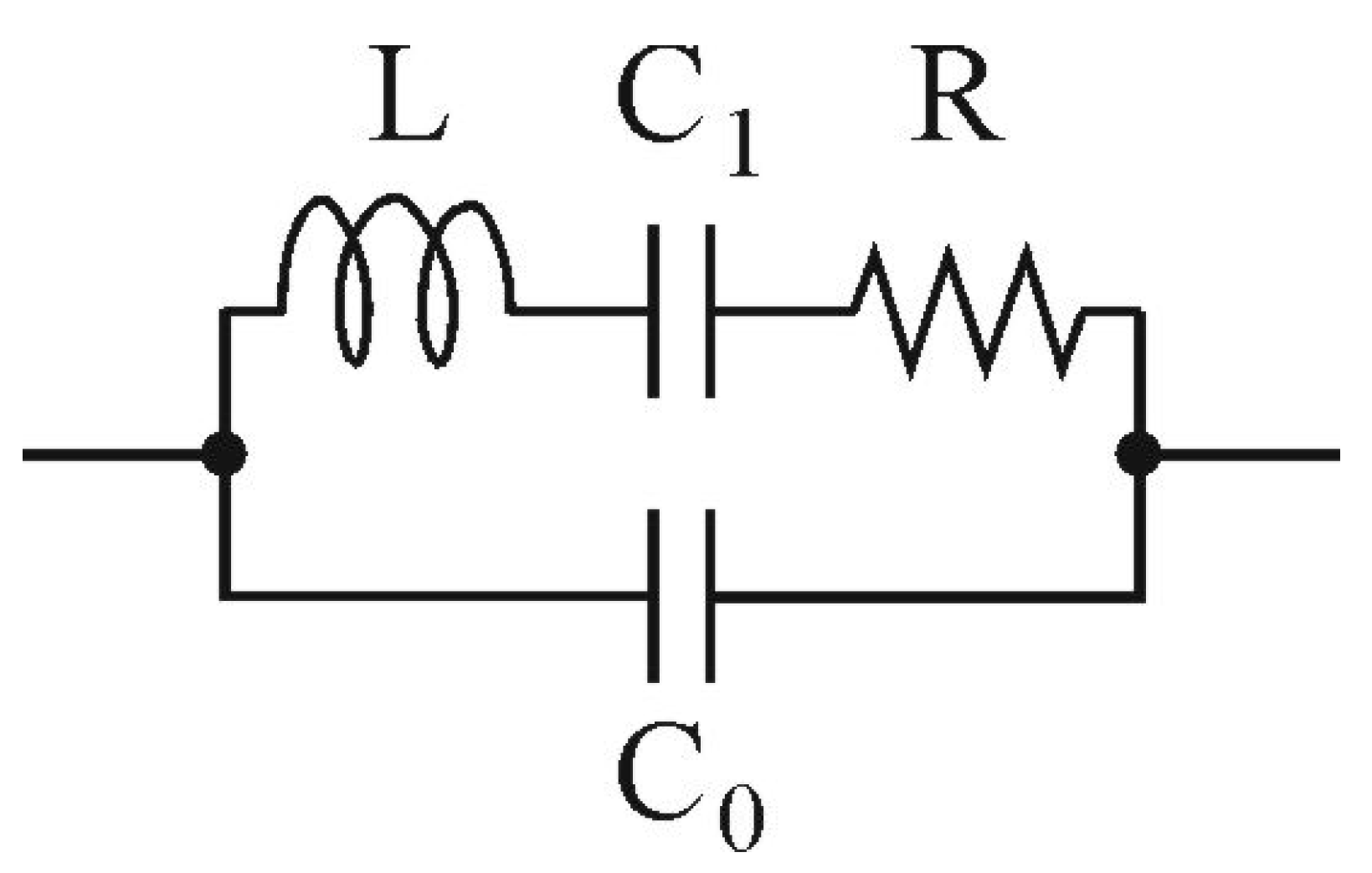

3. Theoretical Analysis of the Preamplifier Noise Properties

The system described in the previous section was used to determine the

fs and

fa frequencies of the QTF, operating under atmospheric pressure conditions in ambient temperature. This, in turn allowed us to determine the

L1 and

C1 parameters for known

C0, giving

C1 = 5.95 fF and

L1 = 4768 H, which seem to be within the typical range according to [

13,

14]. Moreover, due to the sufficient frequency resolution of the system, we also estimated

Q factor according to (4), and as a result we were able to estimate the value of

R = 190 kΩ.

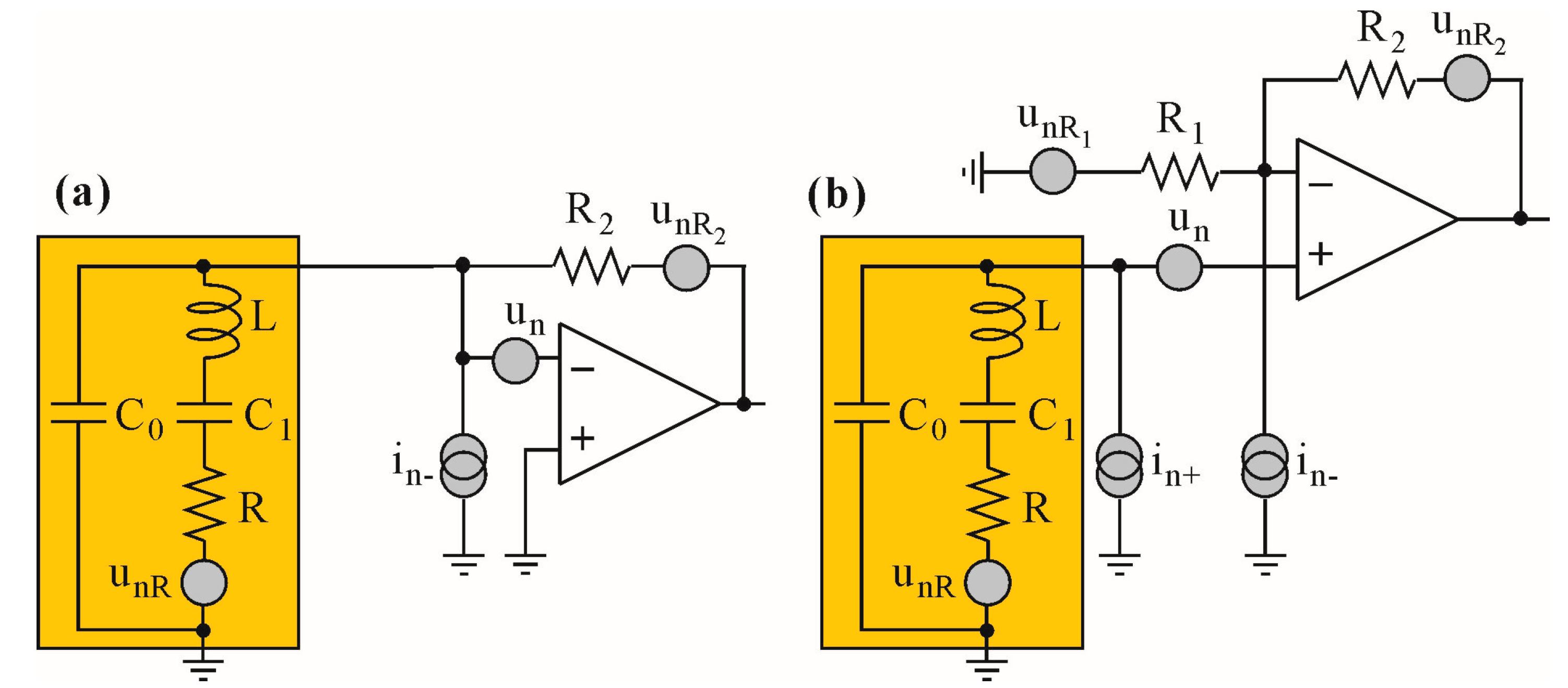

Since in QEPAS applications the QTF operates in close

fs proximity, it acts as a device in which the reactances of

L1,

C1 and

C0 do not contribute to the input parameters of preamplifier circuits shown in

Figure 7. Such parameters as gain, noise or sensitivity depend solely on

R,

R1,

R2 and noise sources.

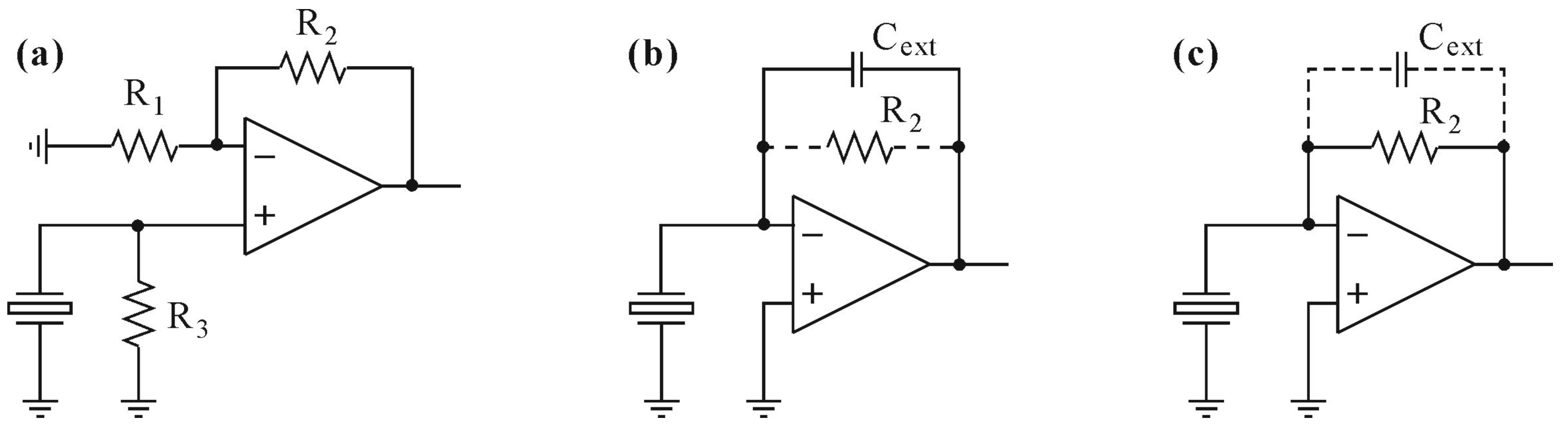

The electrical macromodels shown in

Figure 7 consist of voltage and current noise sources, i.e.,

un,

in+,

in− (representing amplifier noise sources), an ideal operational amplifier, thermal noise sources of the resistors

R1 and

R2 (

unR1 and

unR2, respectively) and the QTF model (see

Figure 3). The QTF model was enhanced with a noise source

unR, which represents both the thermal and flicker noise of the QTF [

23].

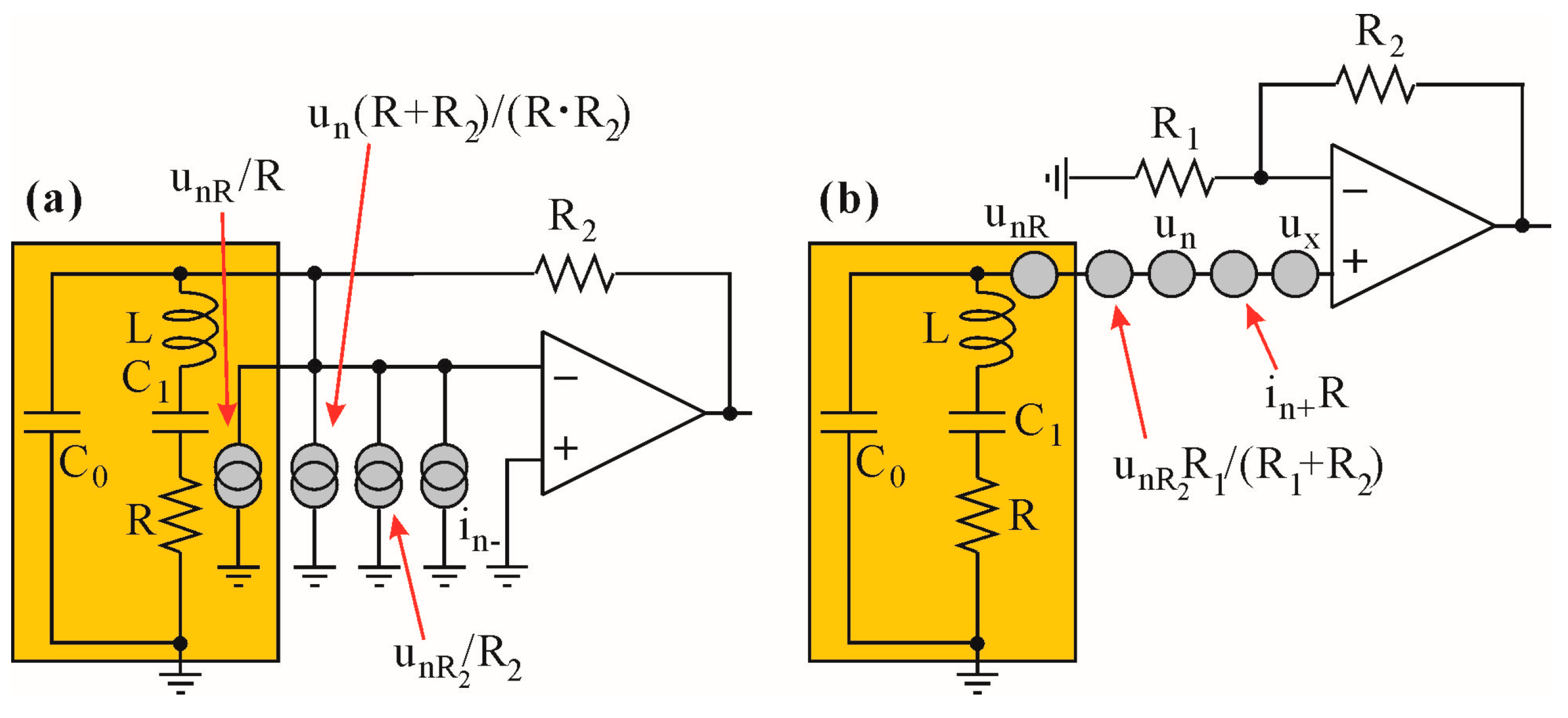

In order to estimate and compare the overall contribution of noise sources in macromodels of transimpedance and voltage topologies from

Figure 7, we have transformed all sources to either current (

Figure 8a) or voltage sources (

Figure 8b) referred to the amplifier inputs. It is worth mentioning that the noise model of the charge amplifier is identical to the transimpedance one with respect to circuit 20’s gain and bandwidth, which mainly result from the

Cext connected in parallel to

R2 (see

Figure 2b), where

kf = (

C0 +

C1)/

Cext.

In order to transform the sources, additional arithmetic operations were performed. The

unR2 source was transformed from the amplifier’s output to its inverting input (see

Figure 8a). For this reason its amplitude was divided by the close loop transimpedance gain (

ki) of the amplifier. The voltage noise

un source is placed between the feedback node and the inverting input. However, from a mathematical point of view, it can be treated as a voltage source connected to a non-inverting input. Therefore, its contribution to the feedback node results from voltage gain of the close loop amplifier, divided by transimpedance gain, i.e., (

R2 +

R)/

R2·R. This way, the

un source is transformed to the feedback node and converts into a noise current source connected in parallel to the amplifier’s noise

in− source. Therefore, assuming the independence of noise processes, the total current variance

itot referred to the input node (QTF) can be derived as:

The overall variance of voltage noise sources referring to the non-inverting input of the circuit in

Figure 8b can be derived when all of the noise sources are converted to the voltage sources referred to the input. Therefore, we have converted the

in- and

unR1 sources to current sources connected in parallel to

R1, and furthermore, we transferred these sources to the non-inverting input as voltage source

ux, i.e.,:

The remaining

unr2 source can be easily transferred to the non-inverting input by dividing its amplitude by the voltage close loop gain

kf of the circuit in

Figure 7b, i.e.,

kf = (1 +

R2/R1). This way we obtained a compact form of variance of the input voltage source of the circuit in

Figure 8b, as derived in (8):

The qualitative comparison of total noise described in (6) and (8) requires some simplifications. First of all, the output noise of both architectures shown in

Figure 8 results from amplification of (6) and (8) by the transimpedance (

ki =

R2) and voltage (

kf) gain, respectively. Moreover, some of the factors in (6) and (8) can be neglected due to the major influence of other factors. Therefore, (6) multiplied by

ki can be estimated by (9), whereas (8) leads to (10) when multiplied by

kf:

One can see that the output noise derived in (10) contains two additional components, i.e.,:

which result from the presence of an additional resistor

R1 and the obvious fact that the non-inverting input is not connected to the ground. However, the total noise in both cases (i.e., transimpedance and voltage topology) is strictly determined by either the values of

R2 and

R2/R (so obviously

ki and the

ki to series resonance resistance ratio values) or the

R2/R1 values (where

R2/R1 ≅

kf). Therefore, for (

R2/R) ≈ (

R2/R1) and

R2 much greater than

R1, the overall noise is slightly higher in the case of the voltage op-amp topology, due to the presence of additional

in− and

unR1 sources. However, it is a rather small difference.

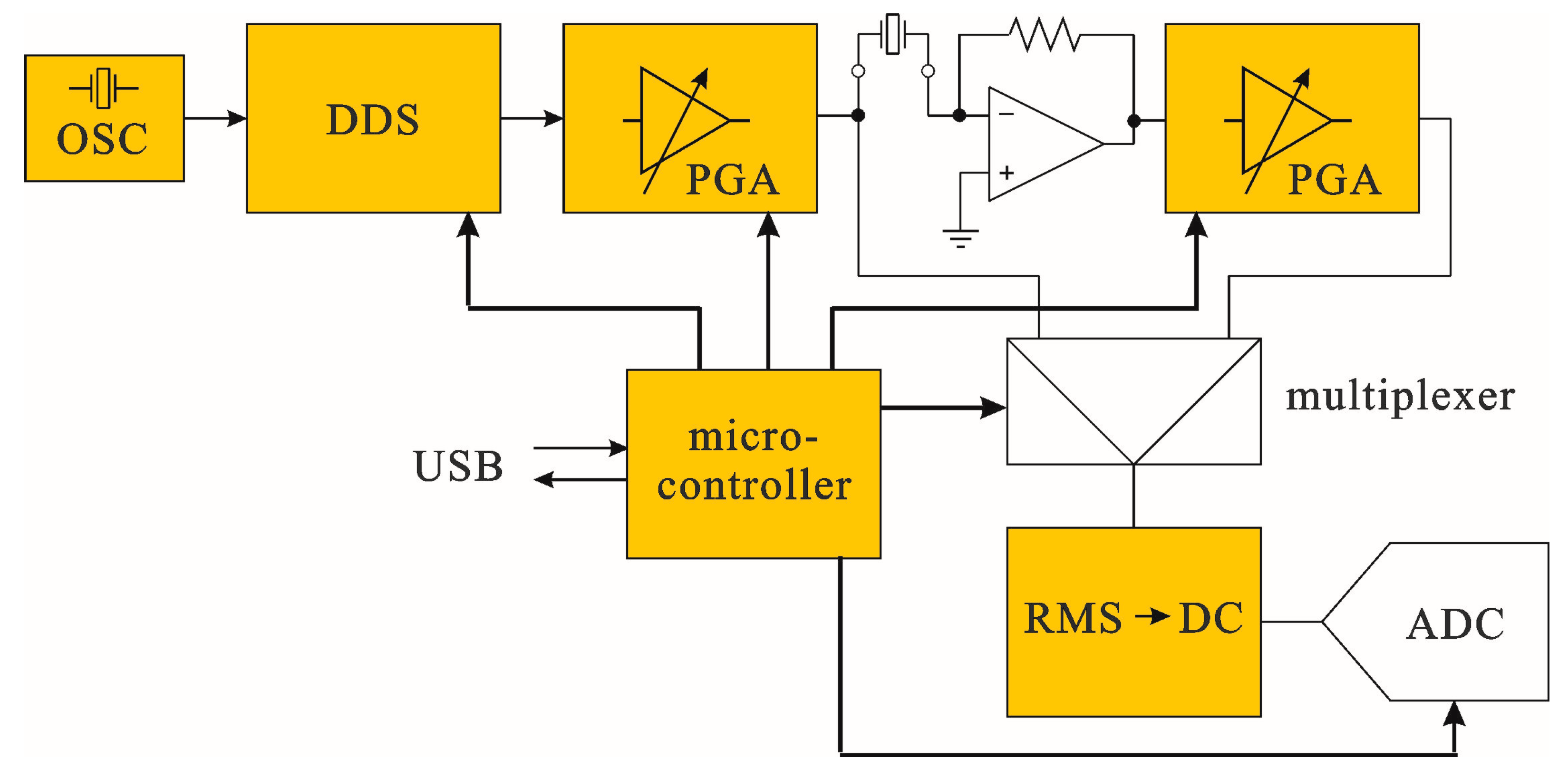

5. Measurements of QTF Source Parameters

The investigated circuits shown in

Figure 2 and

Figure 9 were implemented in the Texas Instruments Analog System Lab Kit PRO. We stimulated the QTF connected to the input of voltage amplifier, charge amplifier and transimpedance amplifier with identical amplitude of the acoustic signal (as described in previous subsection) at the

fs frequency. This way, we were able to estimate the amplitude of the voltage and current signals (in the case of the voltage amplifier and charge/transimpedance topology, respectively) for a particular acoustic signal level. Since the voltage and charge/transimpedance amplifier topology represent opposite conditions, i.e., theoretically infinite input impedance (for voltage amplifier) and zero impedance (for charge and transimpedance amplifier) of the QTF load, we were able to estimate the Thevenin model’s parameter of the QTF at the

fs frequency.

Any capacitance

Cext connected in parallel with

R2 reduces the bandwidth of the amplifier in both topologies. Therefore, it is not recommended to use

R2 of the order of several megaohms, because in such a case the upper limit frequency:

is solely defined not only by the bandwidth of the op-amp itself, but by the parasitic capacitances present in the circuit. The use of moderate voltage and transimpedance gain (e.g.,

kf = 21 V/V and

ki = 100 kΩ respectively) eliminates the influence of the op-amp parameters on the waveforms at the

fs frequency. Therefore, in the experiment

R1 = 4.7 kMΩ and

R2 = 100 kMΩ were assumed. In the case of the charge amplifier, the gain is defined by the (

C0 +

C1)/

Cext ratio. One can see that it is difficult to obtain high gain ratios in the case of the charge amplifier due to extremely low

Cext values. In the case of our QTF, in order to obtain gain close to 6 V/V, it was necessary to use

Cext = 400 fF, whereas parasitic capacitances of this order are present on the board. Therefore, extreme care must be taken during the design of the charge amplifier PCB. The resistor

R2, which is only necessary for bias in the charge configuration, was 100 MΩ.

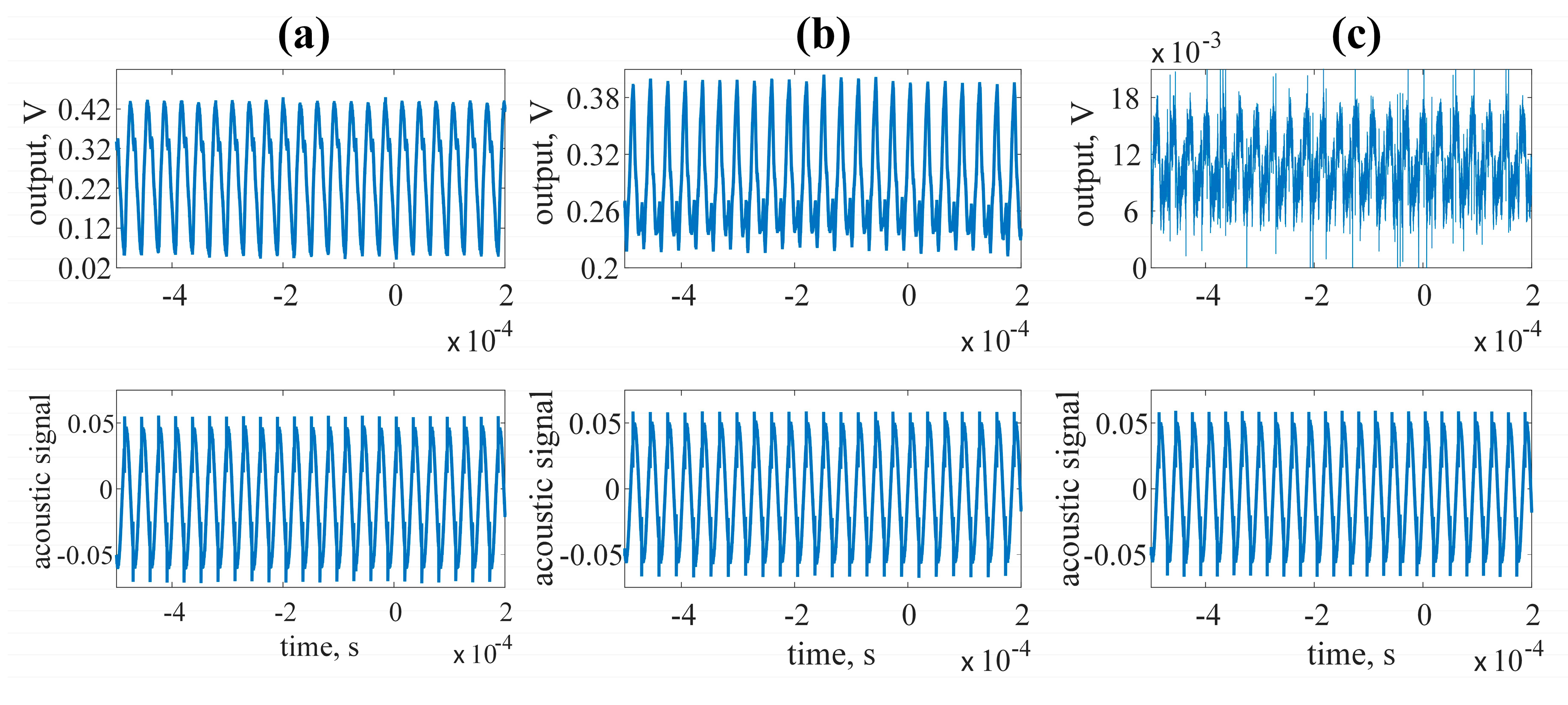

Figure 10a–c show the output waveforms of the op-amp working in the voltage, charge and transimpedance amplifier configurations respectively. The acoustic signal was obtained from a high frequency speaker connected to a power amplifier. The output power was 0.7 W, the operating frequency was set to

fs and the speaker was placed in close proximity of the QTF (4 cm). The obtained AC amplitudes were

uv = 208 mV and

ui = 6.5 mV for the voltage and transimpedance amplifier respectively. In the case of the charge amplifier configuration the output amplitude was 90 mV.

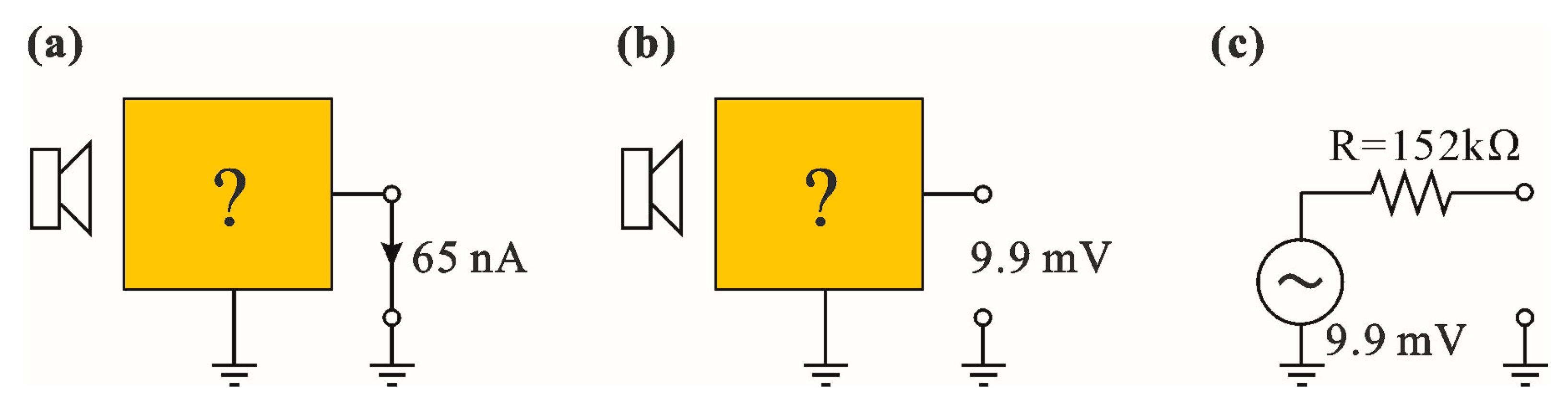

At resonance the influence of reactances on the QTF impedance is negligible. For this reason, the QTF can be represented as an ordinary non-ideal voltage or current source, depending on the topology of the amplifier (in this case the voltage or transimpedance respectively). Knowing the amplitudes of output waveforms (

Figure 10), we were able to estimate the short circuit current

ui/

ki = 65 nA (

Figure 11a), and the open circuit amplitude

uv/

kf = 9.9 mV (

Figure 11b). This way, we estimated the internal resistance

R of the Thevenin source representing QTF (

Figure 11c), i.e.,

R = (

uv·

ki)/(

ku·

ui) = 152 kΩ. One can see that the measured

R value is close to the estimate based on (4) and (5), i.e., 190 kΩ.

The measurements clearly showed that voltage and transimpedance topologies enforce different behavior of the QTF source. The open circuit voltage uv/kf = 9.9 mV is easy to detect and amplify with an ordinary op-amp, such as TL08x or TL07x used in the experiment. However, in the short circuit mode of the QTF operation (transimpedance topology), one needs at least ki = R2 = 152 kΩ of the transimpedance gain in order to obtain the same signal level (9.9 mV) as the one present at the open circuit QTF nodes (without any amplifier at all).

The measurements performed with QTF stimulated by the acoustic signal are valuable, since in the QEPAS technique, QTF is used exactly in the same way, as an acoustic to electrical signal transducer. Let us compare the empirical behavior of QTF in both considered preamplifier topologies, i.e., voltage and transimpedance. In the voltage topology, we obtained uv = 208 mV for kf = 21 V/V (R1 = 4.7 kΩ and R2 = 100 kΩ). In order to obtain the same output signal in the case of the transimpedance topology, we should apply R2 = 208 mV/65 nA = 3.2 MΩ. From now on, the (9) and (10) seem to be more obvious options. The input current noise in− has to be amplified over an order of magnitude in the case of the transimpedance topology (i.e., R2 = 3.2 MΩ for transimpedance and R2 = 100 kΩ for the voltage mode topology for the identical output uv). Therefore, even though the in+ in (10) is present, its contribution is negligible due to significantly lower R2 in the case of the voltage topology. Moreover, the ((unR2 + un2)·R22/R2) term is much higher in the case of transimpedance configuration. First of all, unR2 results from the thermal noise, which is proportional to the value of R, however R2 is 32 times higher in comparison to the voltage topology. Moreover, in order to obtain the same level of signal at the outputs of both topologies, (ki/R) ≅ (((R2 + R1)/R1)), which obviously enhances influence of the thermal R2 noise. One can see that if the presented case study is applied to both topologies, the noise level is approximately an order of magnitude higher for the same output signal level in the case of the transimpedance topology. For this reason the rough signal-to-noise ratio (SNR) is an order of magnitude higher for the voltage preamplifier topology.

In order to confirm the theoretical considerations we performed two types of measurements for all three topologies. In the first one, with the MDO3024 oscilloscope, we recorded m = 107 samples for each topology with and without the acoustic signal applied. The bandwidth of the measurements was limited to 500 kHz, and AC coupling was used. In the second case, we utilized the MDO3024 with additional spectrum analyzer. In this case, the bandwidth was only 10 kHz–100 kHz, whereas the resolution bandwidth (RBW) was 50 Hz.

To calculate the signal-to-noise ratio (

SNR) in the first case, we used Equation (13), where

ui stands for subsequent signal samples from the output of the preamplifier, and

uni stands for the samples recorded without the acoustic stimulation:

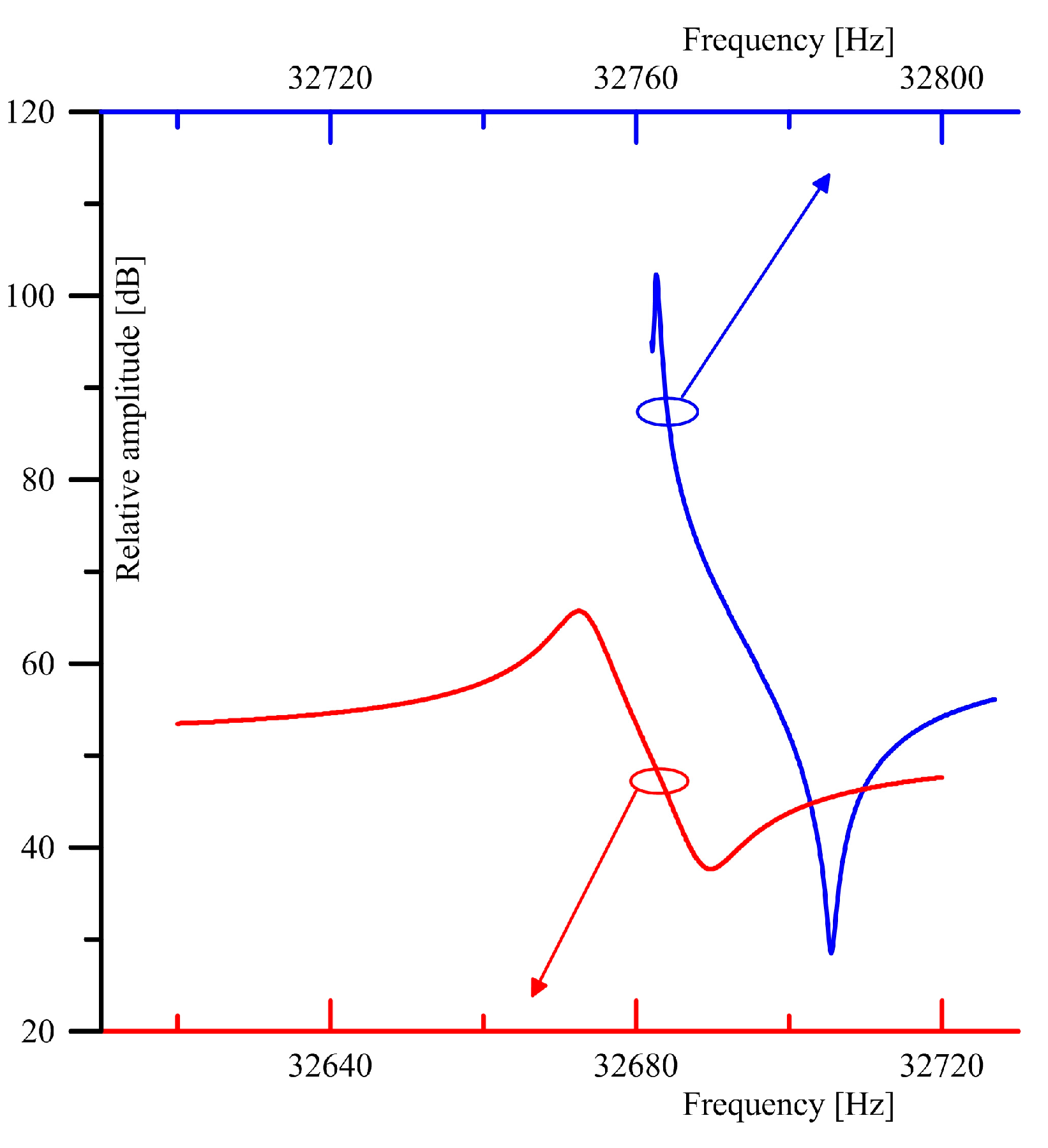

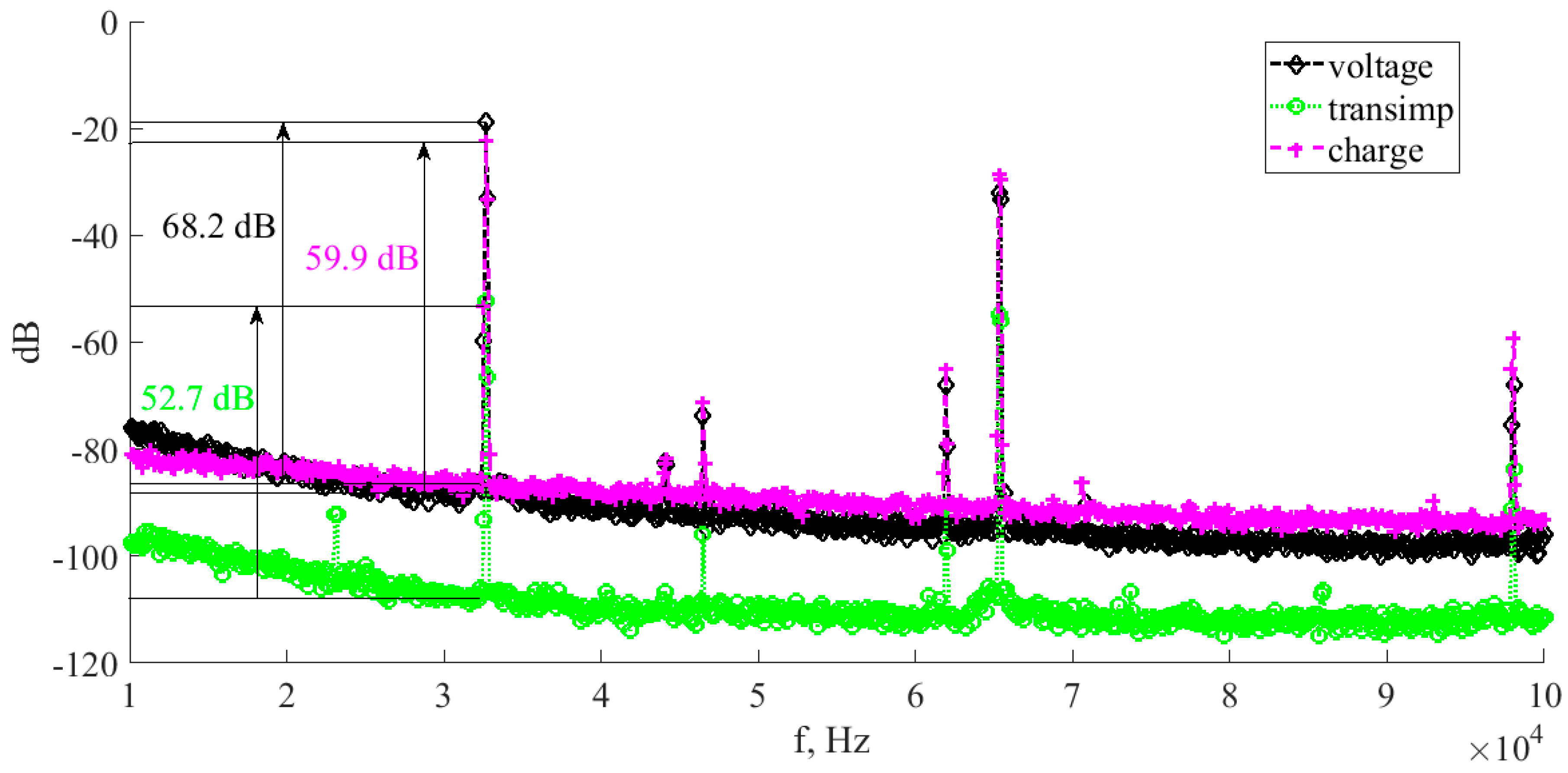

Our second proposed technique for an

SNR assessment was to estimate the signal to noise ratio in the narrow bandwidth neighborhood of the

fs frequency. For this purpose, we registered output power spectra of the voltage, transimpedance and charge amplifiers. The results are shown in

Figure 12 and

Table 1.

Results of both mentioned methods used to estimate wideband and narrowband

SNR of all three analyzed preamplifier topologies are given in

Table 1.

The signal-to-noise values in

Table 1 prove previous considerations regarding voltage and transimpedance topologies. One can see that the

SNR in the case of voltage preamplifier is 18.5 dB higher in comparison to the transimpedance configuration.

Narrow bandwidth SNR estimates show better results for all considered topologies. In such a case, EMI influence is minimized to a very narrow part of the spectrum, which is similar to the 1/f noise. However, it turns out that in the case of the voltage preamplifier, the SNR yields 15.5 dB improvement over the transimpedance topology (SNR = 68.2 dB, 59.9 dB and 52.7 dB for the voltage, charge and transimpedance topologies, respectively).

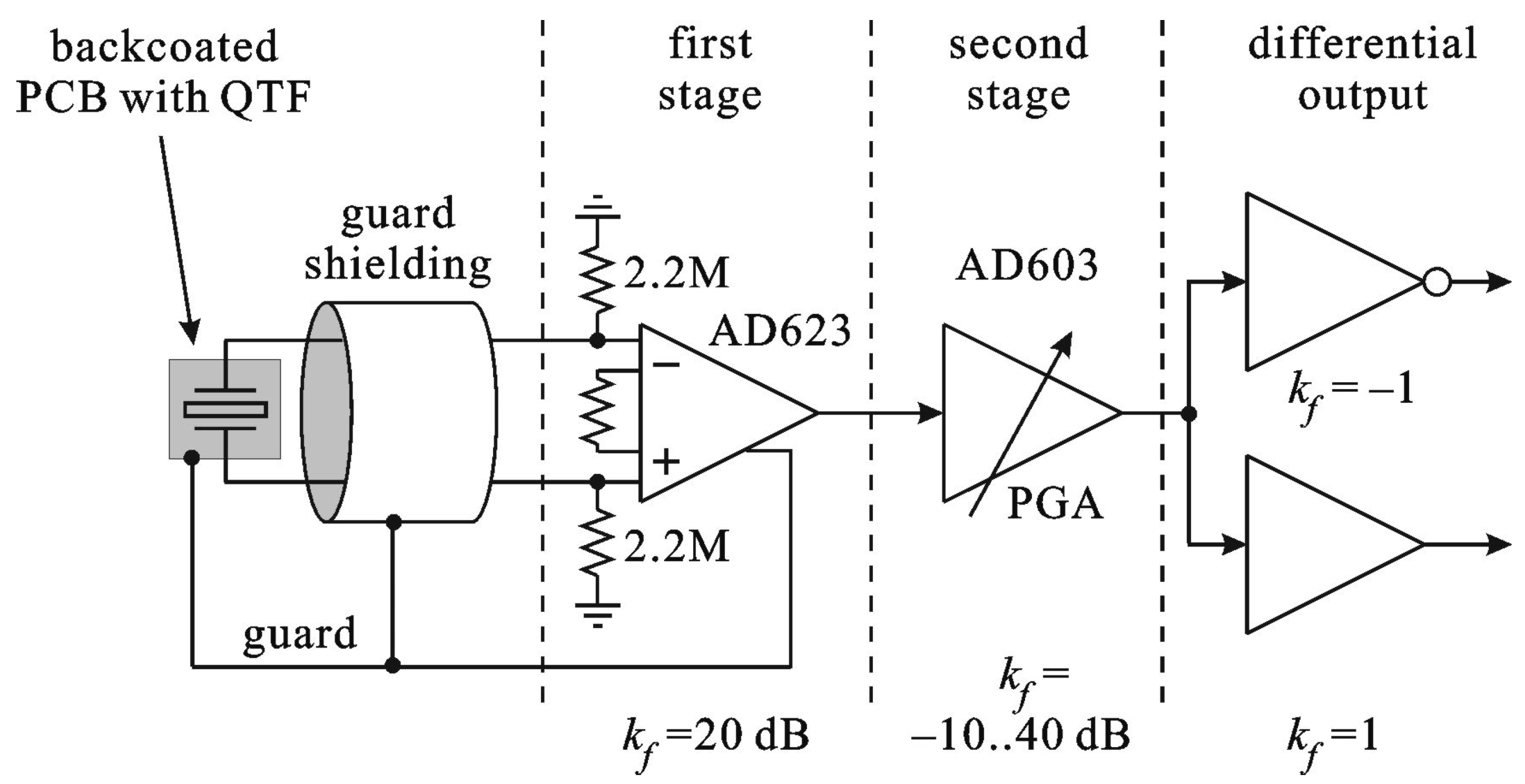

6. The Proposal of the High Sensitivity Preamp–Discussion

The theoretical consideration and measurement results led us to the concept of a multistage high sensitivity preamp dedicated for the QEPAS. First of all, the voltage amplifier topology seems to be the obvious choice when the noise and signal amplitudes are considered. Moreover, due to rather high R values, the input stage of the amplifier should be fully differential, so that any external electromagnetic (EM) disturbances would not interfere with the weak signal available at the QTF nodes. The input resistance of the op-amp should be of at least an order of magnitude higher than QTF’s R. Since the R value is high, we suggest guard shielding, which minimizes leakage of the input voltage stage. In the tested solution, we used AD 623 instrumentation amplifier at the first stage.

The scenario of the acoustic stimulation used in our measurements was rather optimistic, since we used a powerful source of acoustic signal. In real QEPAS applications, the required

kf gain of the op-amp is unknown, due to unknown concentration of the measured gas solution. Therefore, the preamplifier should have a variable gain stage.

Figure 13 shows a block diagram of the proposed QEPAS multistage preamplifier.

In order to minimize the noise contribution to the system presented in

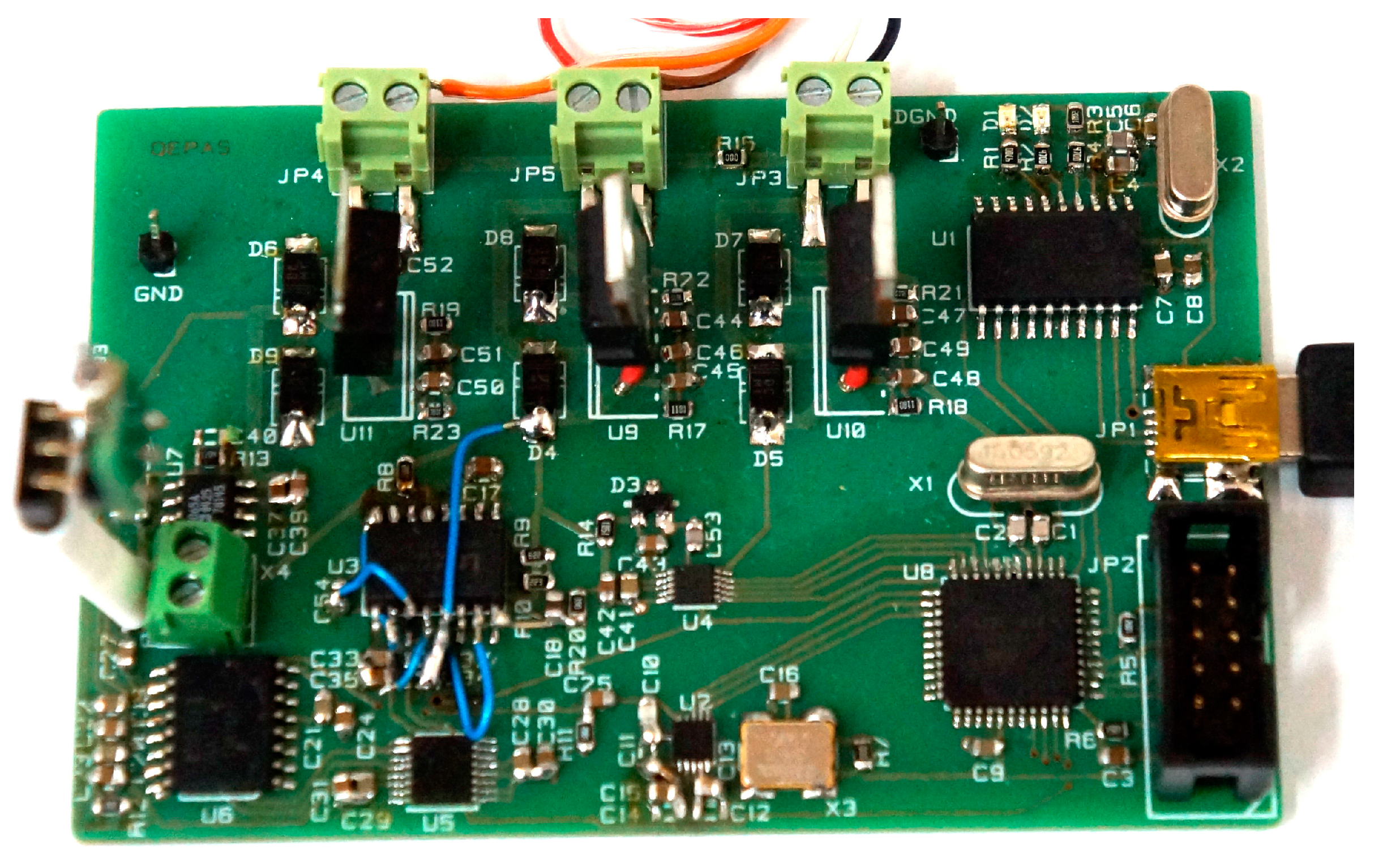

Figure 13, we used a PGA (AD 603 dedicated for radio frequency applications) with externally limited bandwidth as a middle stage. This way the noise amplitude added to the signal of the first stage is minimized. The third stage of the designed preamplifier contains two amplifiers, i.e., inverting and non-inverting, in order to produce differential output signal. This way, the output signal is insensitive to additive electromagnetic interferences (EMI). The printed circuit board (PCB) of the proposed solution is shown in

Figure 14.

The proposed amplifier circuit was assembled on a 50 mm × 38 mm × 1.55 mm two-layer PCB made from an FR-4 material. Whereas the bottom layer of the PCB consists mainly of a ground shielding and some supply nodes, the top layer is used for signal paths. The AD623 and AD603 circuits are located in the top-middle part of the PCB (see

Figure 14), in close proximity to the QTF connections. The differential amplifier output stage is located at the left edge of the board. This way, we minimized the asymmetric signal path, and therefore, reduced EMI influence. The circuit was subjected to the

SNR measurements as described previously. The first method utilizing (13) yielded

SNR = 37.13 dB, and the second one (i.e., with the narrow band spectrum analysis) gave

SNR = 64 dB. Narrowband

SNR is slightly worse in comparison to the presented measurements of the basic preamplifier structures due to the fact that the preamplifier was designed as a high-dynamic and programmable circuit that could be used in practical QEPAS applications. Such an approach resulted in a much more complex solution, with additional components that slightly increased noise level. Better wideband

SNR results were obtained from the use of differential signal path, which reduces influence of EMI.