Design and Electro-Thermo-Mechanical Behavior Analysis of Au/Si3N4 Bimorph Microcantilevers for Static Mode Sensing

Abstract

:1. Introduction

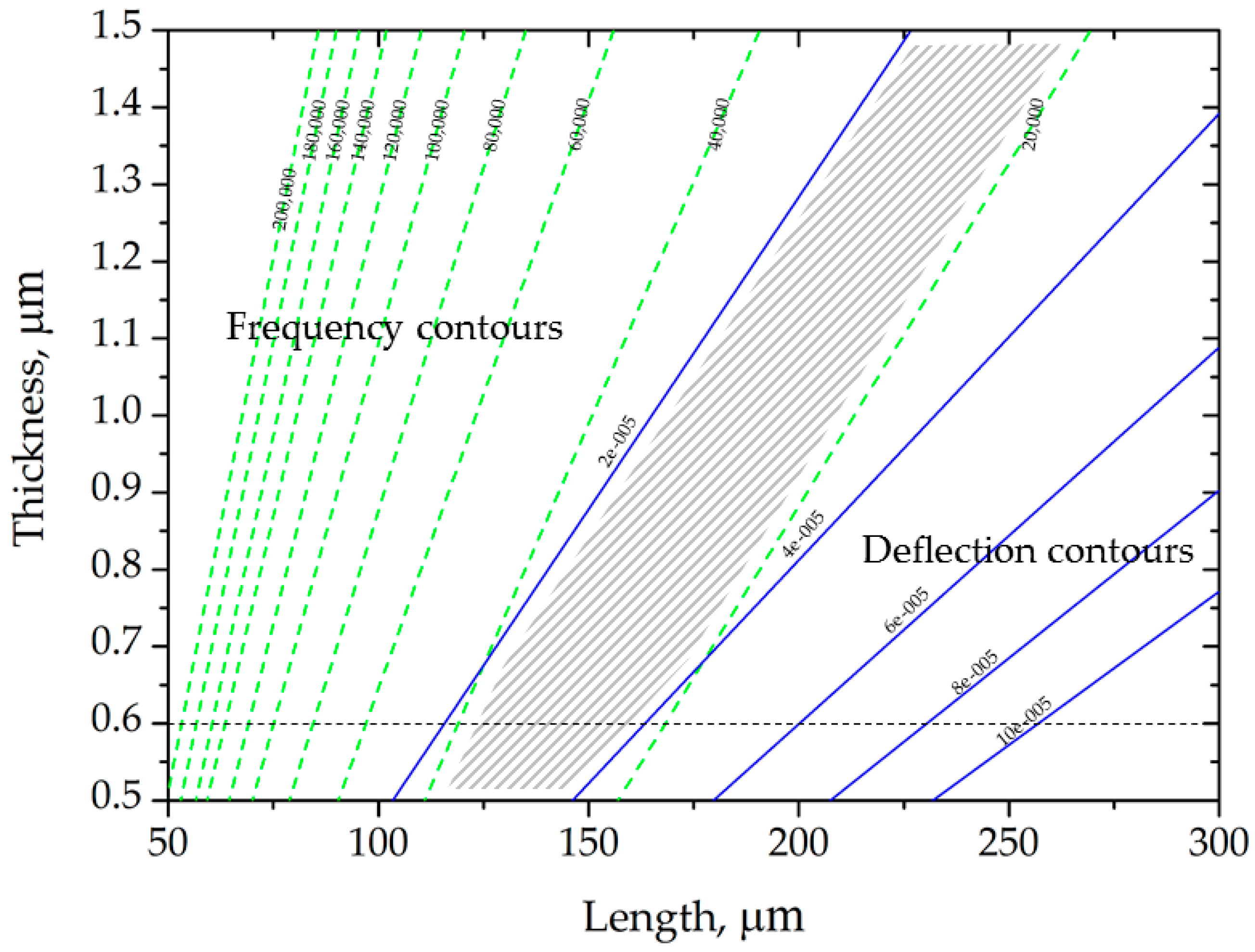

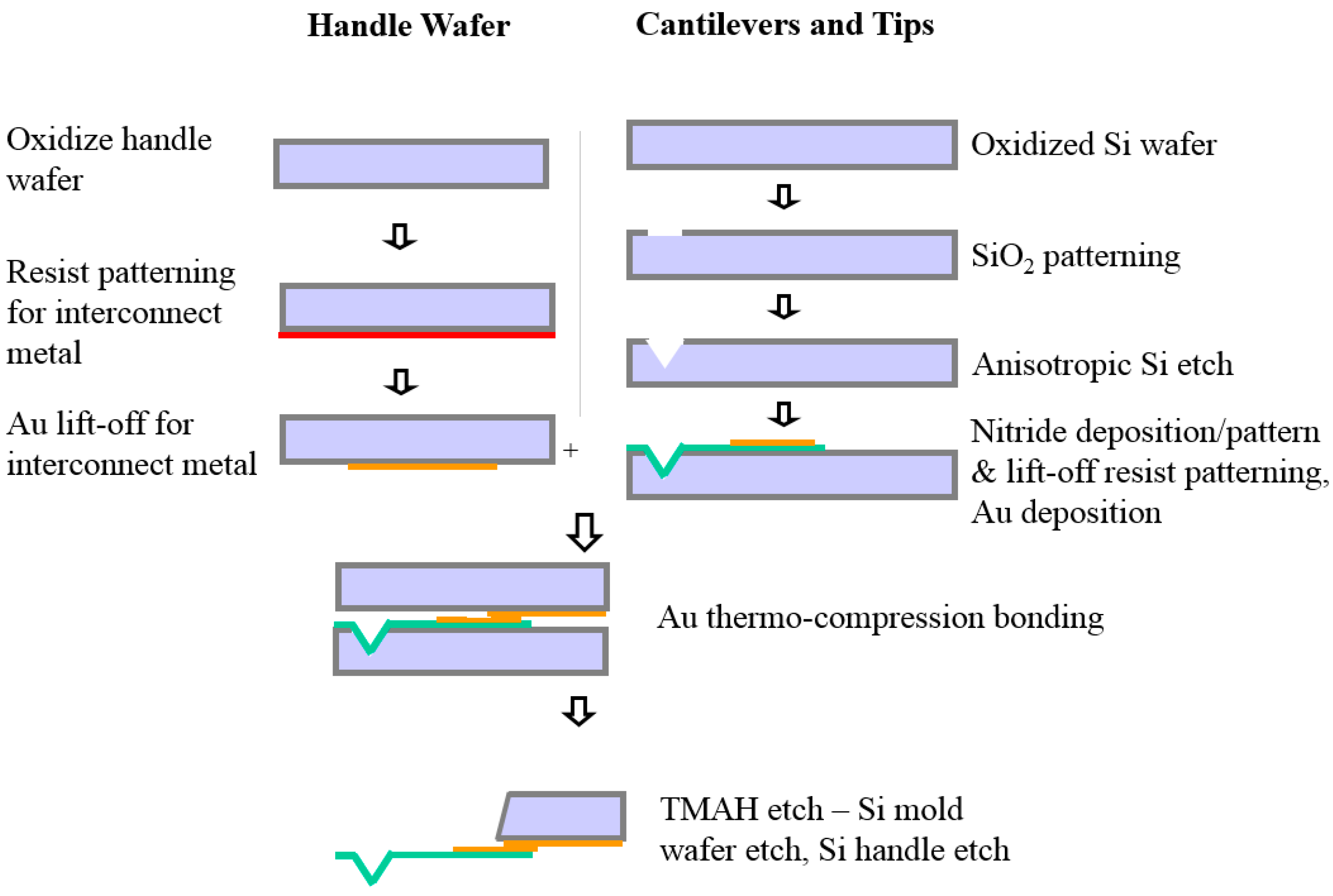

2. Design of Bimorph Microcantilevers

2.1. Design Methodology

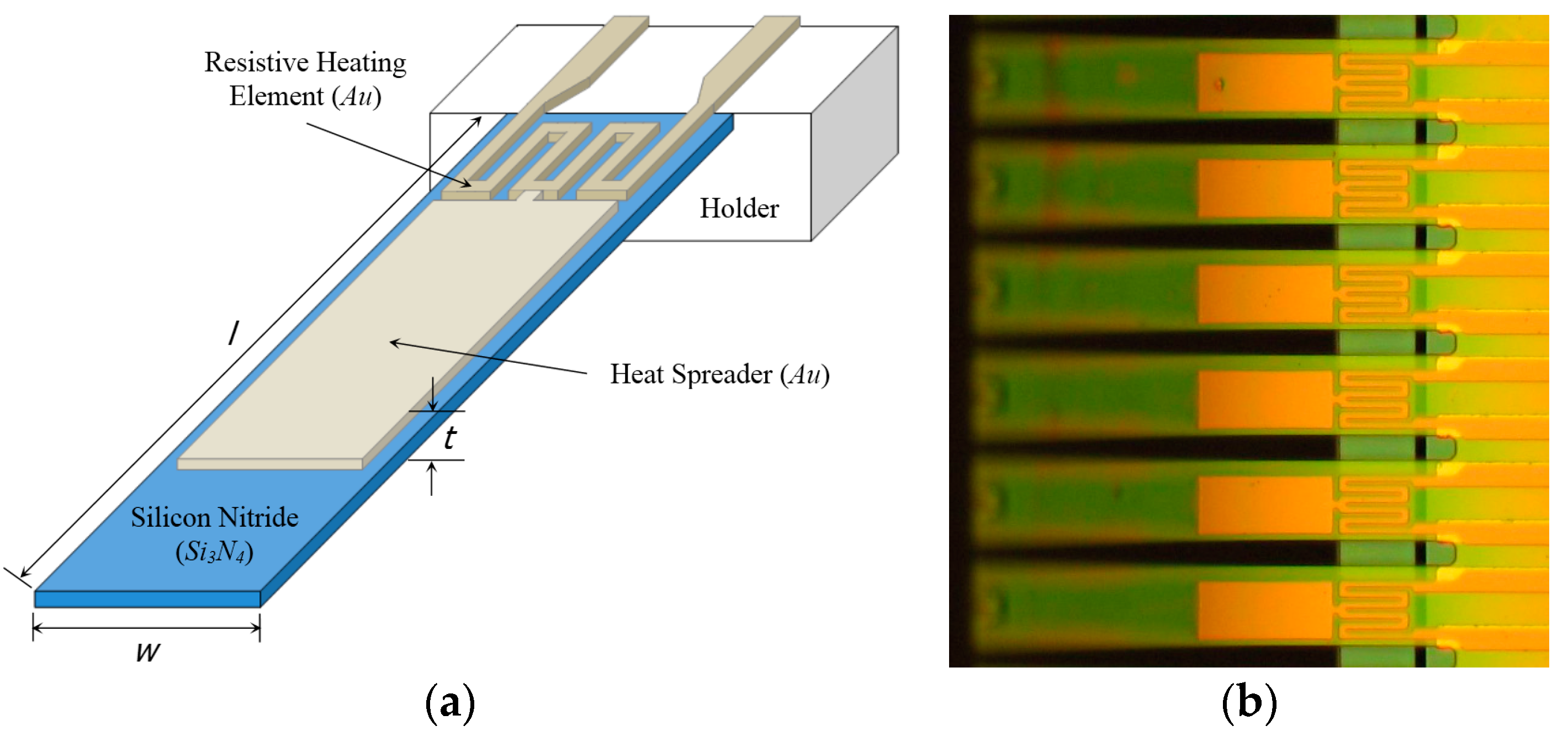

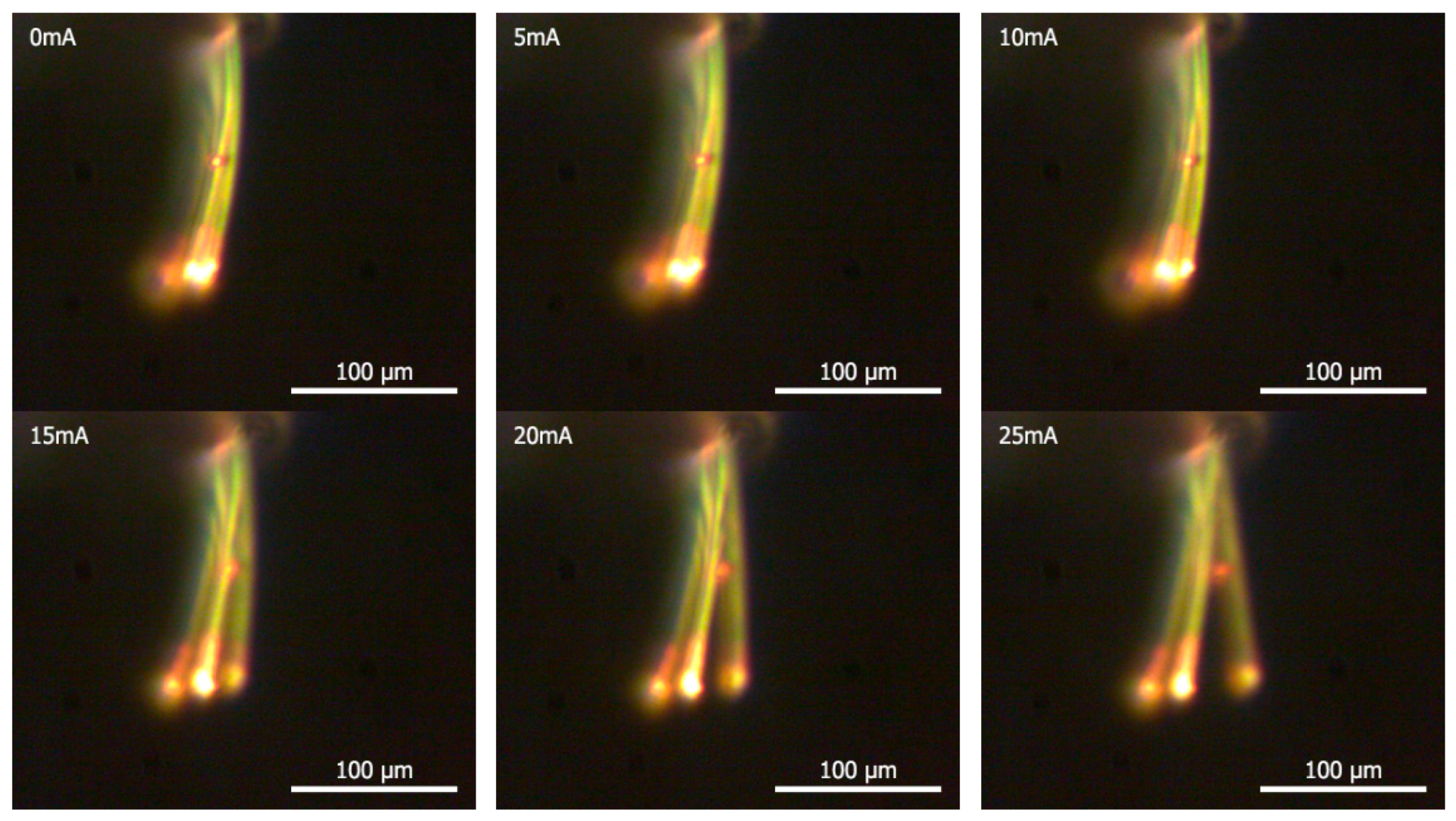

2.2. Thermal Bimorph Microcantilevers

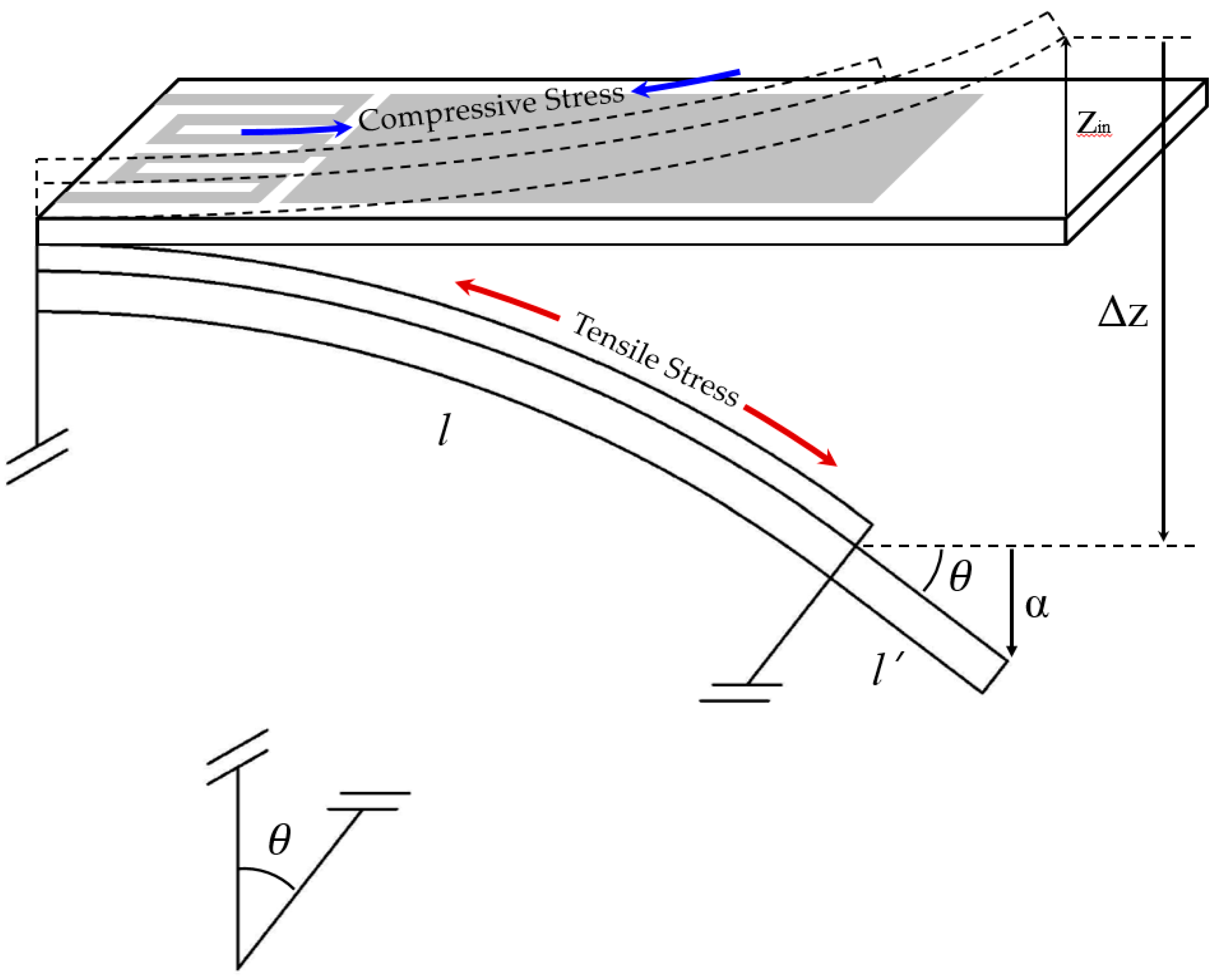

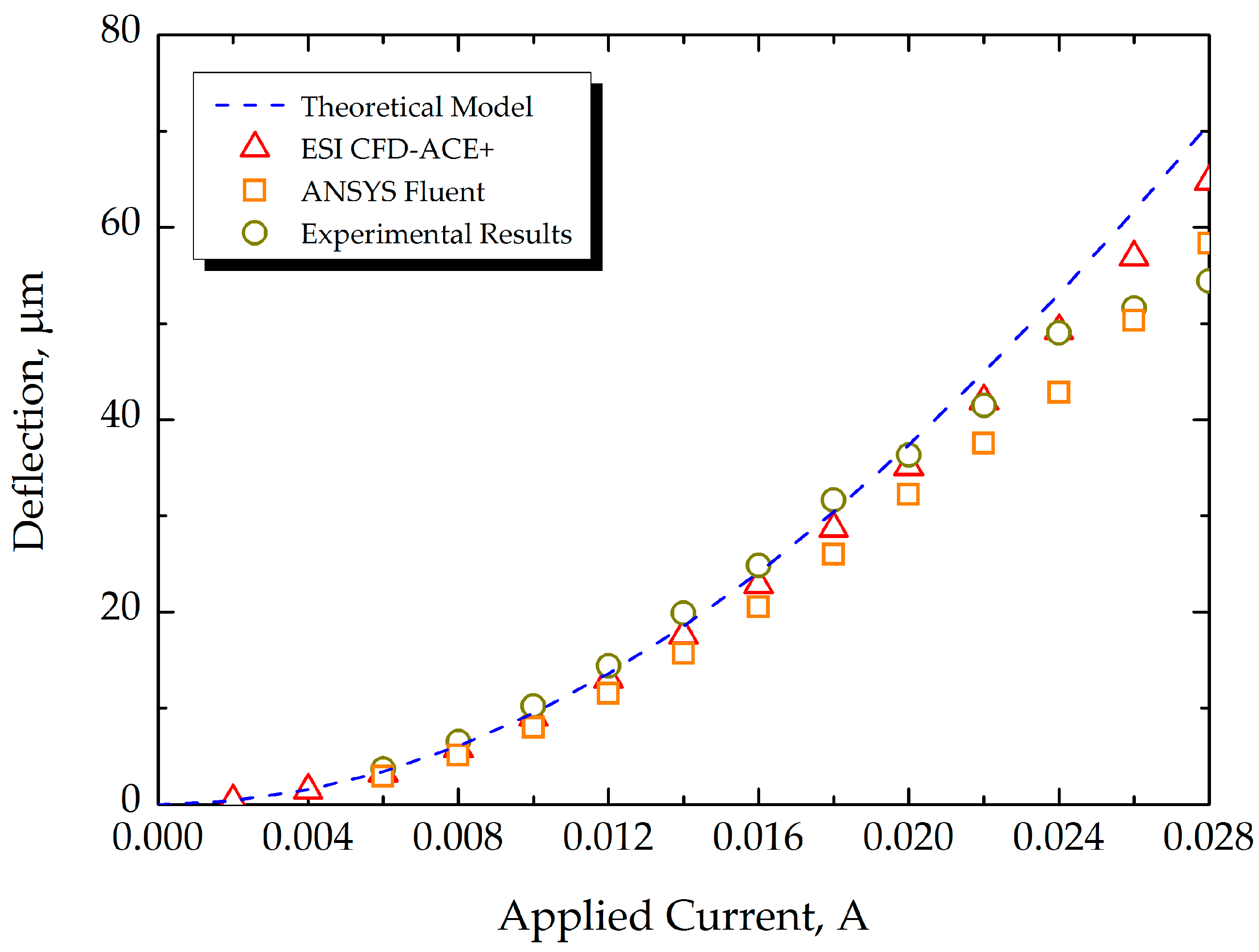

3. Theoretical Modeling of Bending Characteristics

3.1. Residual Stress

3.2. Electro-Thermo-Mechanical Modeling

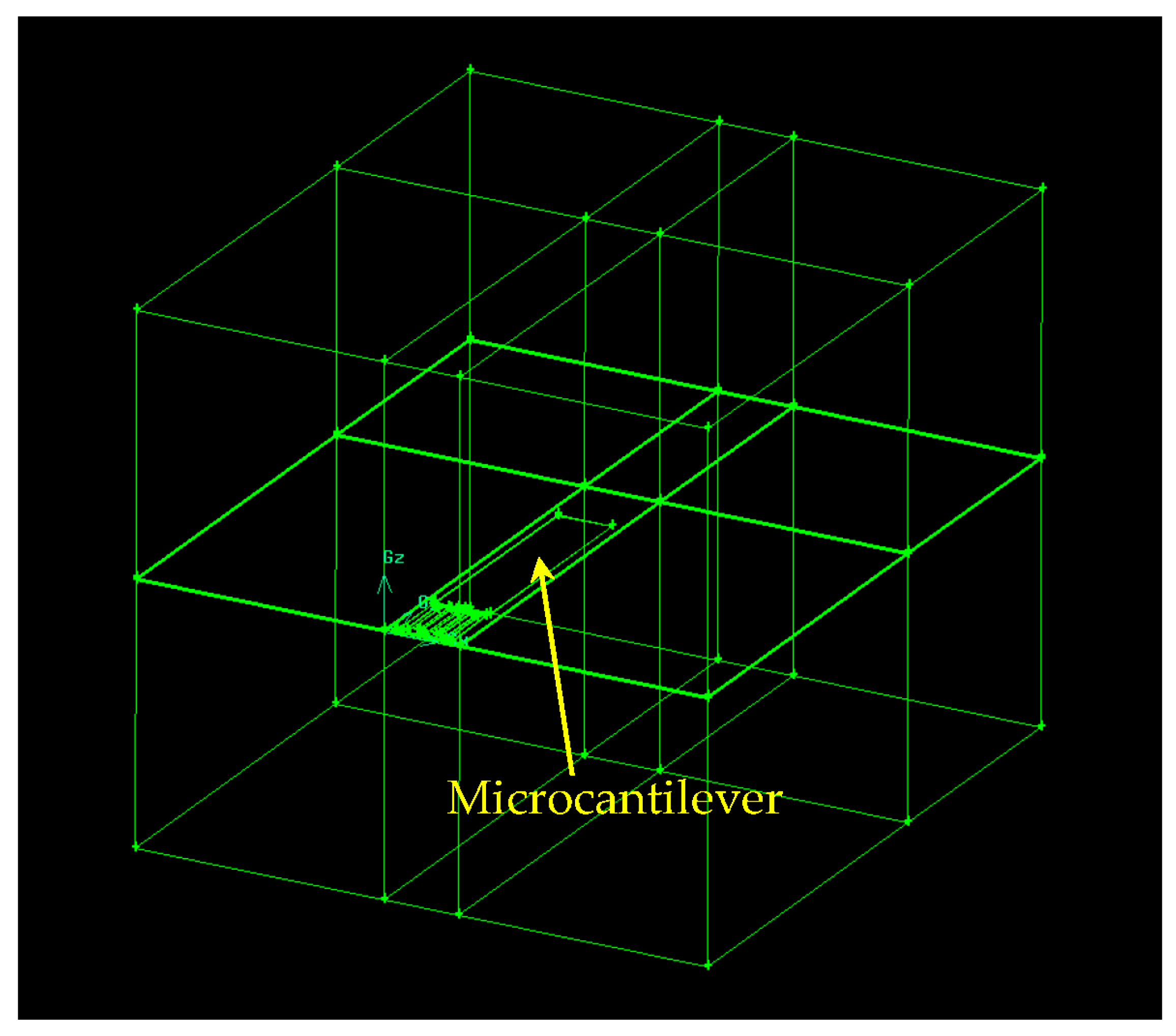

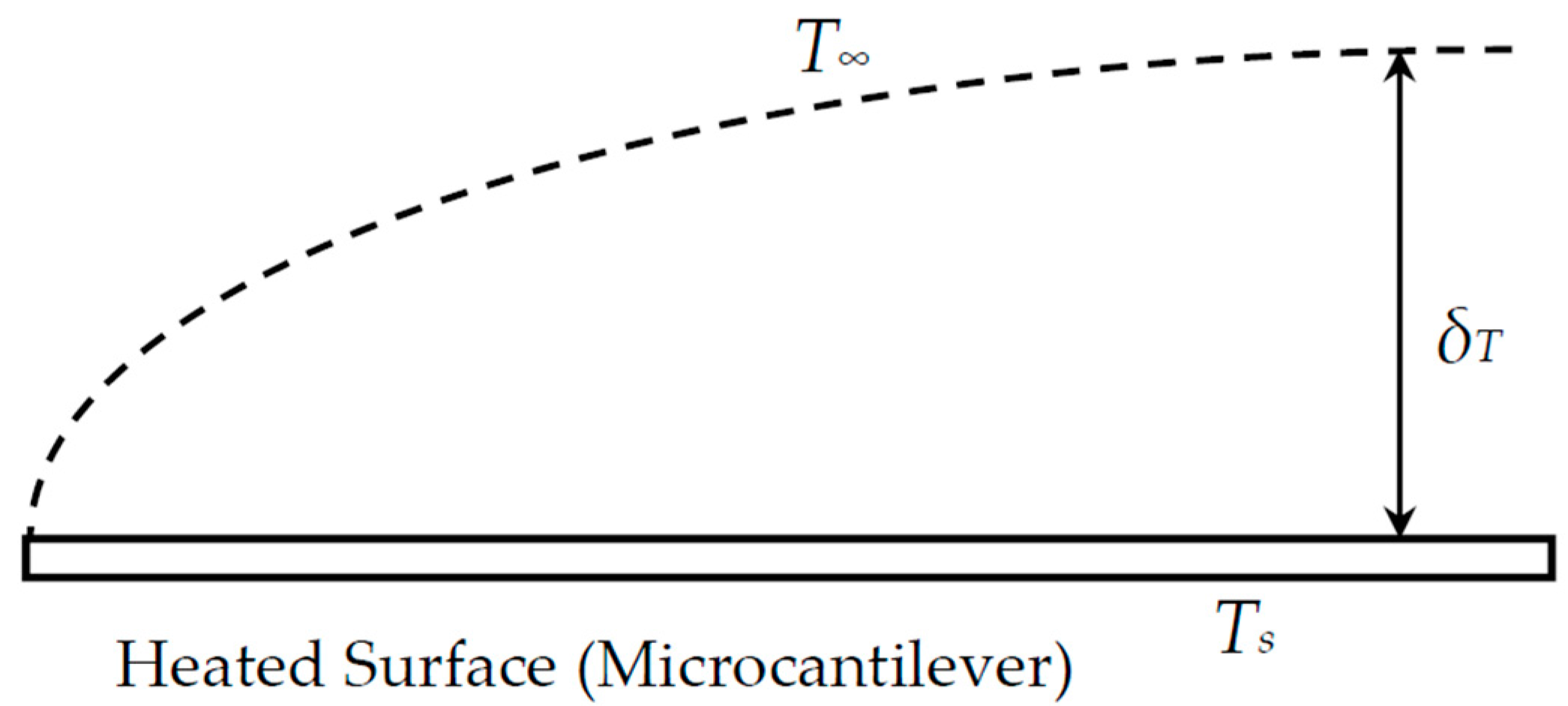

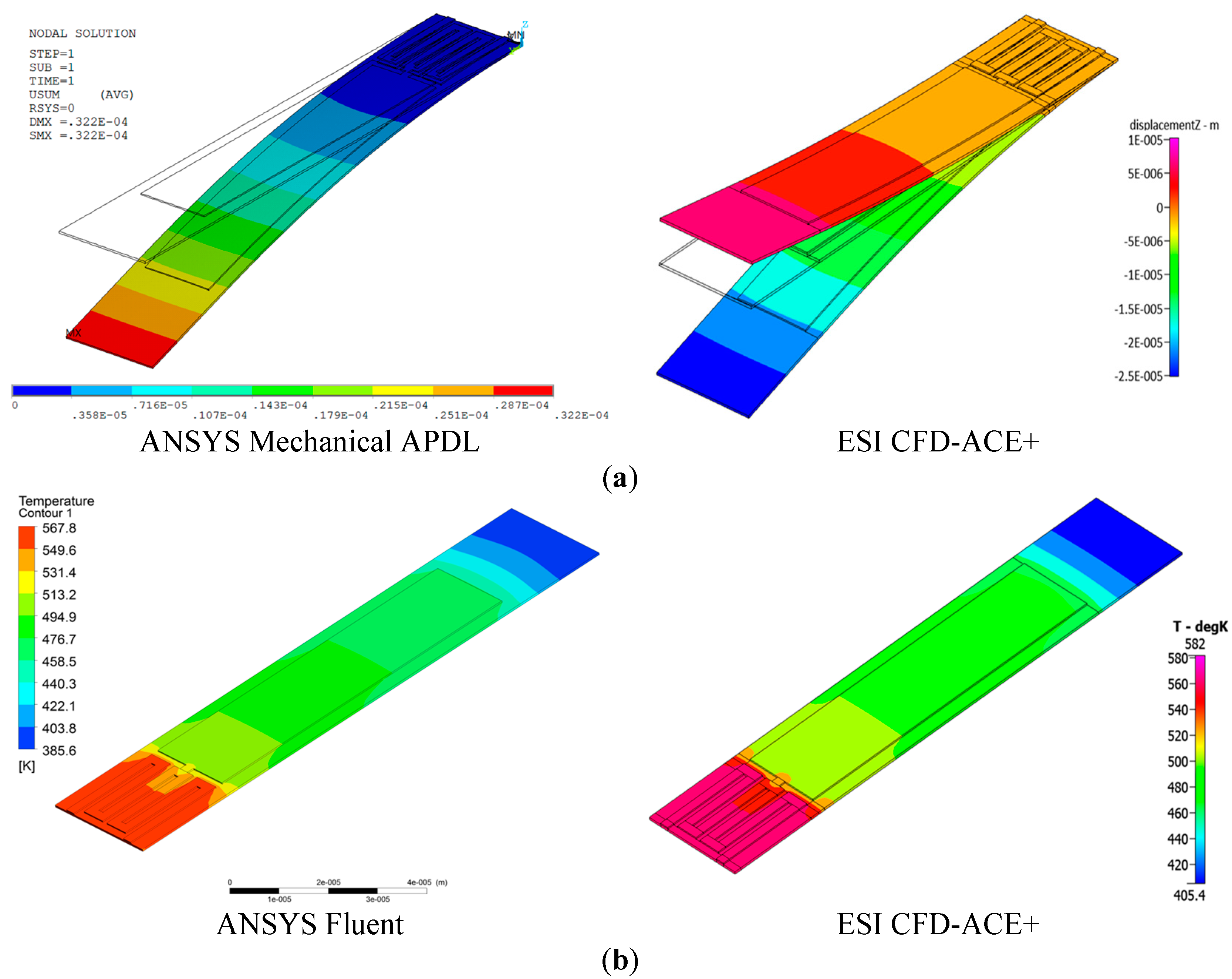

4. Numerical Modeling of Bending Characteristics

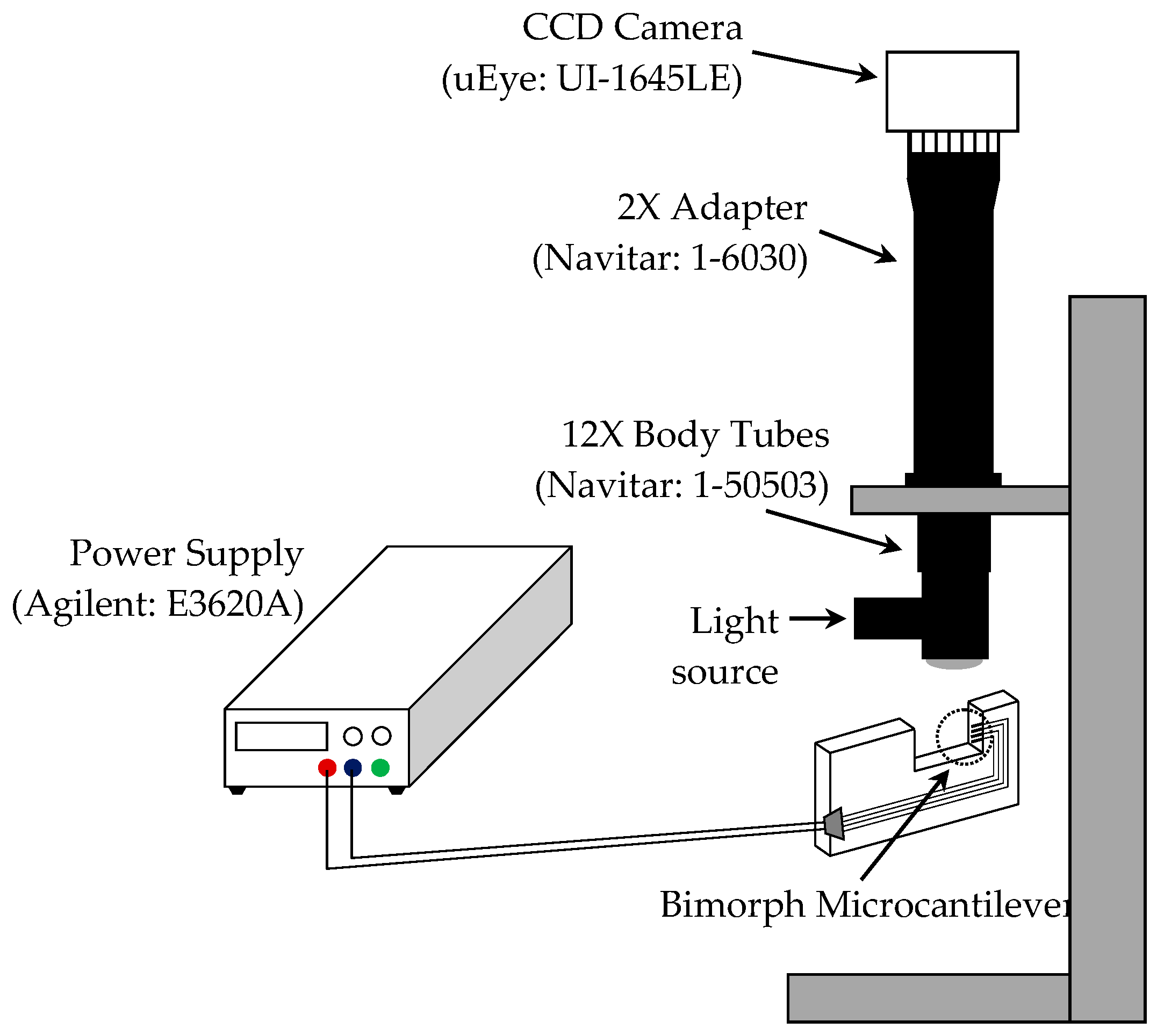

5. Experimental Measurements

6. Results and Discussion

7. Summary and Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Petersen, K.E. Silicon as a mechanical material. Proc. IEEE 1982, 70, 420–457. [Google Scholar] [CrossRef]

- Kang, S.-W.; Fragala, J.; Banerjee, D. Numerical modeling and experimental validation by calorimetric detection of energetic materials using thermal bimorph microcantilever array: A case study on sensing vapors of volatile organic compounds (VOCs). Sensors 2015, 15, 21785–21806. [Google Scholar] [CrossRef] [PubMed]

- Vashist, S.K. A review of microcantilevers for sensing applications. Nanotechnology 2007, 3, 1–15. [Google Scholar]

- Lang, H.P.; Hegner, M.; Gerber, C. Cantilever array sensors. Materialstoday 2005, 8, 30–36. [Google Scholar] [CrossRef]

- Baller, M.K.; Lang, H.P.; Fritz, J.; Gerber, C.; Gimzewski, J.K.; Drechsler, U.; Rothuizen, H.; Despont, M.; Vettiger, P.; Battiston, F.M.; et al. A cantilever array-based artificial nose. Ultramicroscopy 2000, 82, 1–9. [Google Scholar] [CrossRef]

- Barnes, J.R.; Stephenson, R.J.; Welland, M.E.; Gerber, C.; Gimzewski, J.K. Photothermal spectroscopy with femtojoule sensitivity using a micromechanical device. Nature 1994, 372, 79–81. [Google Scholar] [CrossRef]

- Ruan, W.; Li, Y.; Tan, Z.; Liu, L.; Jiang, K.; Wang, Z. In situ synthesized carbon nanotube networks on a microcantilever for sensitive detection of explosive vapors. Sens. Actuator B Chem. 2013, 176, 141–148. [Google Scholar] [CrossRef]

- Toda, M.; Inomata, N.; Ono, T.; Voiculescu, I. Cantilever beam temperature sensors for biological applications. IEEJ Trans. Electr. Electron. Eng. 2017, 12, 153–160. [Google Scholar] [CrossRef]

- Lee, S.; Kang, D.; Je, Y.; Moon, W. Resonant frequency variations in a piezoelectric microcantilever sensor under varying operational conditions. J. Micromech. Microeng. 2012, 22, 105035. [Google Scholar] [CrossRef]

- Inomata, N.; Toda, M.; Sato, M.; Ishijima, A.; Ono, T. Pico calorimeter for detection of heat produced in an individual brown fat cell. Appl. Phys. Lett. 2012, 100, 154104. [Google Scholar] [CrossRef]

- Ansari, M.Z.; Cho, C.; Kim, J.; Bang, B. Comparison between deflection and vibration characteristics of rectangular and trapezoidal profile microcantilevers. Sensors 2009, 9, 2706–2718. [Google Scholar] [CrossRef] [PubMed]

- Ansari, M.Z.; Cho, C. Deflection, frequency, and stress characteristics of rectangular, triangular, and step profile microcantilevers for biosensors. Sensors 2009, 9, 6046–6057. [Google Scholar] [CrossRef] [PubMed]

- Stoney, G.G. The tension of metallic films deposited by electrolysis. Proc. R. Soc. Lond. Ser. A 1909, 82, 172–175. [Google Scholar] [CrossRef]

- Komelli, M.; Menon, C. Resonance vibration of a thermally-actuated optical fiber with arbitrary periodic excitation: Analysis and optimization. Int. J. Mech. Sci. 2017, 123, 287–296. [Google Scholar] [CrossRef]

- Wang, Z.; Yue, R.; Zhang, R.; Liu, L. Design and optimization of laminated piezoresistive. Sens. Actuator A Phys. 2005, 120, 325–336. [Google Scholar] [CrossRef]

- Rahaeifard, M. Static behavior of bilayer microcantilevers under thermal actuation. Int. J. Eng. Sci. 2016, 107, 28–35. [Google Scholar] [CrossRef]

- Klein, C.A. How accurate are Stoney’s equation and recent modifications. J. Appl. Phys. 2000, 88, 5487–5489. [Google Scholar] [CrossRef]

- Chu, W.-H.; Mehregany, M.; Mullen, R.L. Analysis of tip deflection and force of a bimetallic cantilever microactuator. J. Micromech. Miroeng. 1993, 3, 4–7. [Google Scholar] [CrossRef]

- Hsueh, C.-H. Modeling of elastic deformation of multilayers due to residual stresses and external bending. J. Appl. Phys. 2002, 91, 9652–9656. [Google Scholar] [CrossRef]

- Ramos, D.; Mertens, J.; Calleja, M.; Tamayo, J. Study of the origin of bending induced by bimetallic effect on microcantilever. Sensors 2007, 7, 1757–1765. [Google Scholar] [CrossRef] [PubMed]

- Lee, C.-Y.; Tasi, C.-H.; Chen, L.-W.; Fu, L.-M.; Chen, Y.-C. Elastic-plastic modeling of heat-treated bimorph micro-cantilevers. Microsyst. Technol. 2006, 12, 979–986. [Google Scholar] [CrossRef]

- Fu, J.Y.; Chen, D.P.; Ye, T.C.; Jiao, B.B.; Ou, Y. Modeling and optimal design of multilayer thermal cantilever microactuators. Sci. China Ser. E-Technol. Sci. 2009, 52, 1167–1170. [Google Scholar] [CrossRef]

- Pal, S.; Xie, H. Distributed and lumped element models for a bimorph-actuated micromirror. J. Micromech. Microeng. 2010, 20, 045020. [Google Scholar] [CrossRef]

- Jiang, J.; Hilleringmann, U.; Shui, X. Electro-thermo-mechanical analytical modeling of multilayer cantilever microactuator. Sens. Actuator A Phys. 2007, 137, 302–307. [Google Scholar] [CrossRef]

- Hodge, T.C.; Bidstrup-Allen, S.A.; Kohl, P.A. Stresses in thin film metallization. IEEE Trans. Compon. Packag. Manuf. Technol. Part A 1997, 20, 241–250. [Google Scholar] [CrossRef]

- Kozanoglu, B.; Lopez, J. Thermal boundary layer and the characteristic length on natural convection over a Horizontal Plate. Heat Mass Transf. 2007, 43, 333–339. [Google Scholar] [CrossRef]

- Bullen, D.; Wang, X.; Zou, J.; Chung, S.-W.; Mirkin, C.A.; Liu, C. Design, fabrication, and characterization of thermally actuated probe arrays for dip pen nanolithography. J. Microelectromech. Syst. 2004, 13, 594–602. [Google Scholar] [CrossRef]

- Langer, G.; Hartmann, J.; Reichling, M. Thermal conductivity of thin metallic film measured by photothermal profile analysis. Rev. Sci. Instrum. 1997, 68, 1510–1513. [Google Scholar] [CrossRef]

- Jou, J.H.; Liao, C.N.; Jou, K.W. A method for the determination of gold thin-films mechanical-properties. Thin Solid Films 1994, 238, 70–72. [Google Scholar] [CrossRef]

- Khan, A.; Philip, J.; Hess, P. Young’s modulus of silicon nitride used in scanning force microscope cantilevers. J. Appl. Phys. 2004, 95, 1667–1672. [Google Scholar] [CrossRef]

- Pamula, V.K.; Jog, A.; Fair, R.B. Mechanical property measurement of thin-film gold using thermally acutated bimetallic cantilever beams. In Proceedings of the Fourth International Conference on Modeling and Simulation of Microsystems, Hilton Head Island, SC, USA, 19–21 March 2001. [Google Scholar]

- Piccirillo, A.; Gobbi, A.L. Physical-Electrical Properties of Silicon Nitride Deposited by PECVD on I II-V Semiconductors. J. Electrochem. Soc. 1990, 137, 3910–3917. [Google Scholar] [CrossRef]

- De Vries, J.W.C. Temperature and thickness dependence of the resistivity of thin polycrystalline aluminum, cobalt, nickel, palladium, silver and gold films. Thin Solid Films 1988, 167, 25–32. [Google Scholar] [CrossRef]

| Property | Si3N4 | Au |

|---|---|---|

| Thermal Conductivity (k), [W/m·K] | 1.7 [27] | 150 [28] |

| Thermal Expansion Coefficient (α), [K−1] | 0.3 × 10−6 [27] | 14.6 × 10−6 [29] |

| Elastic Properties E: Young’s Modulus [GPa]/ν: Poisson’s Ratio | 224.6 [27]/0.253 [30] | 74.5 [27]/0.35 [31] |

| Electrical Resistivity (R), [Ωm] | 1 × 1010 [32] | 2.214 × 10−8 [33] |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kang, S.-W.; Fragala, J.; Kim, S.-H.; Banerjee, D. Design and Electro-Thermo-Mechanical Behavior Analysis of Au/Si3N4 Bimorph Microcantilevers for Static Mode Sensing. Sensors 2017, 17, 2510. https://doi.org/10.3390/s17112510

Kang S-W, Fragala J, Kim S-H, Banerjee D. Design and Electro-Thermo-Mechanical Behavior Analysis of Au/Si3N4 Bimorph Microcantilevers for Static Mode Sensing. Sensors. 2017; 17(11):2510. https://doi.org/10.3390/s17112510

Chicago/Turabian StyleKang, Seok-Won, Joe Fragala, Su-Ho Kim, and Debjyoti Banerjee. 2017. "Design and Electro-Thermo-Mechanical Behavior Analysis of Au/Si3N4 Bimorph Microcantilevers for Static Mode Sensing" Sensors 17, no. 11: 2510. https://doi.org/10.3390/s17112510

APA StyleKang, S.-W., Fragala, J., Kim, S.-H., & Banerjee, D. (2017). Design and Electro-Thermo-Mechanical Behavior Analysis of Au/Si3N4 Bimorph Microcantilevers for Static Mode Sensing. Sensors, 17(11), 2510. https://doi.org/10.3390/s17112510