A Review of Natural Polysaccharides: Sources, Characteristics, Properties, Food, and Pharmaceutical Applications

Abstract

1. Introduction

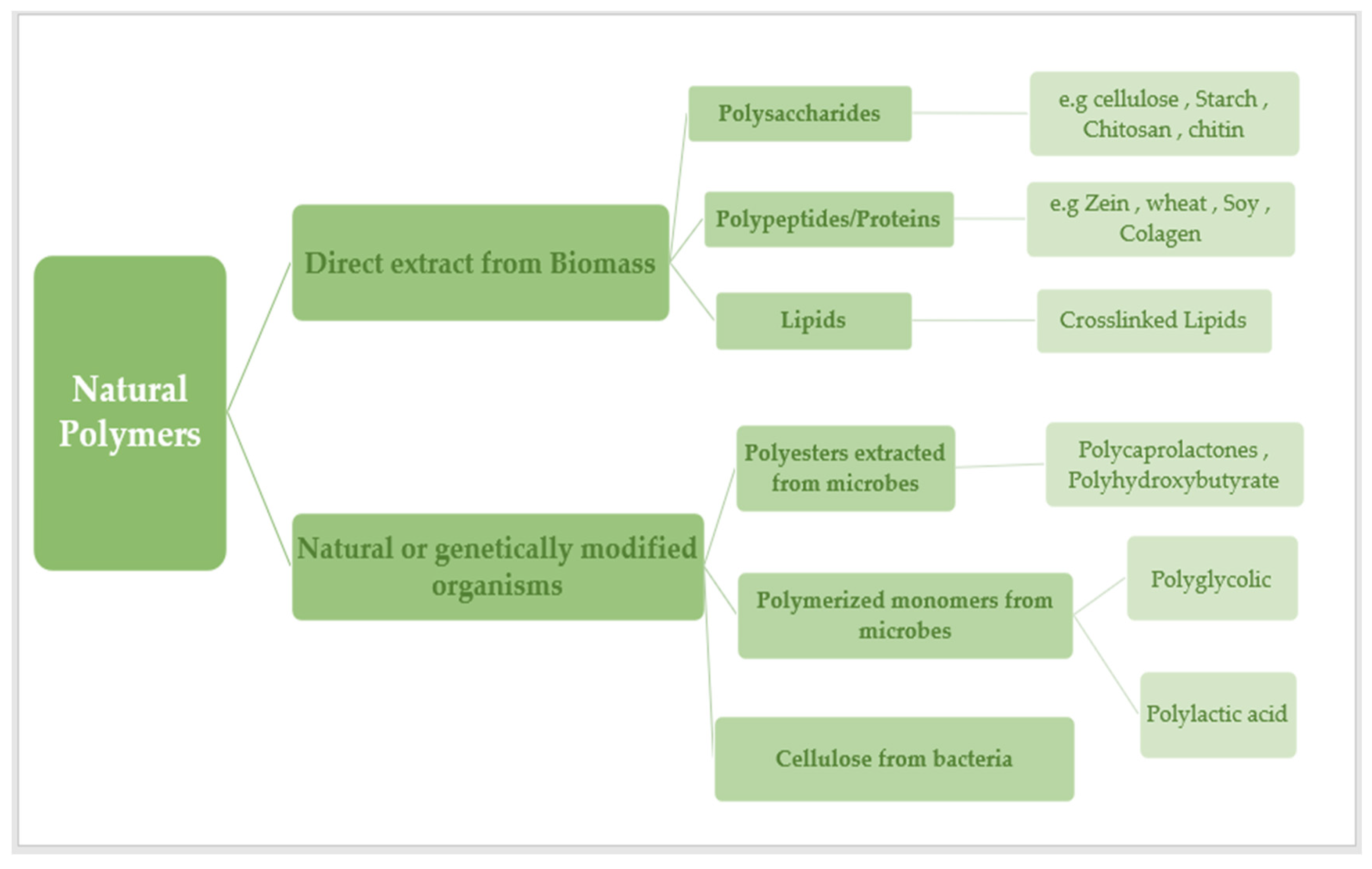

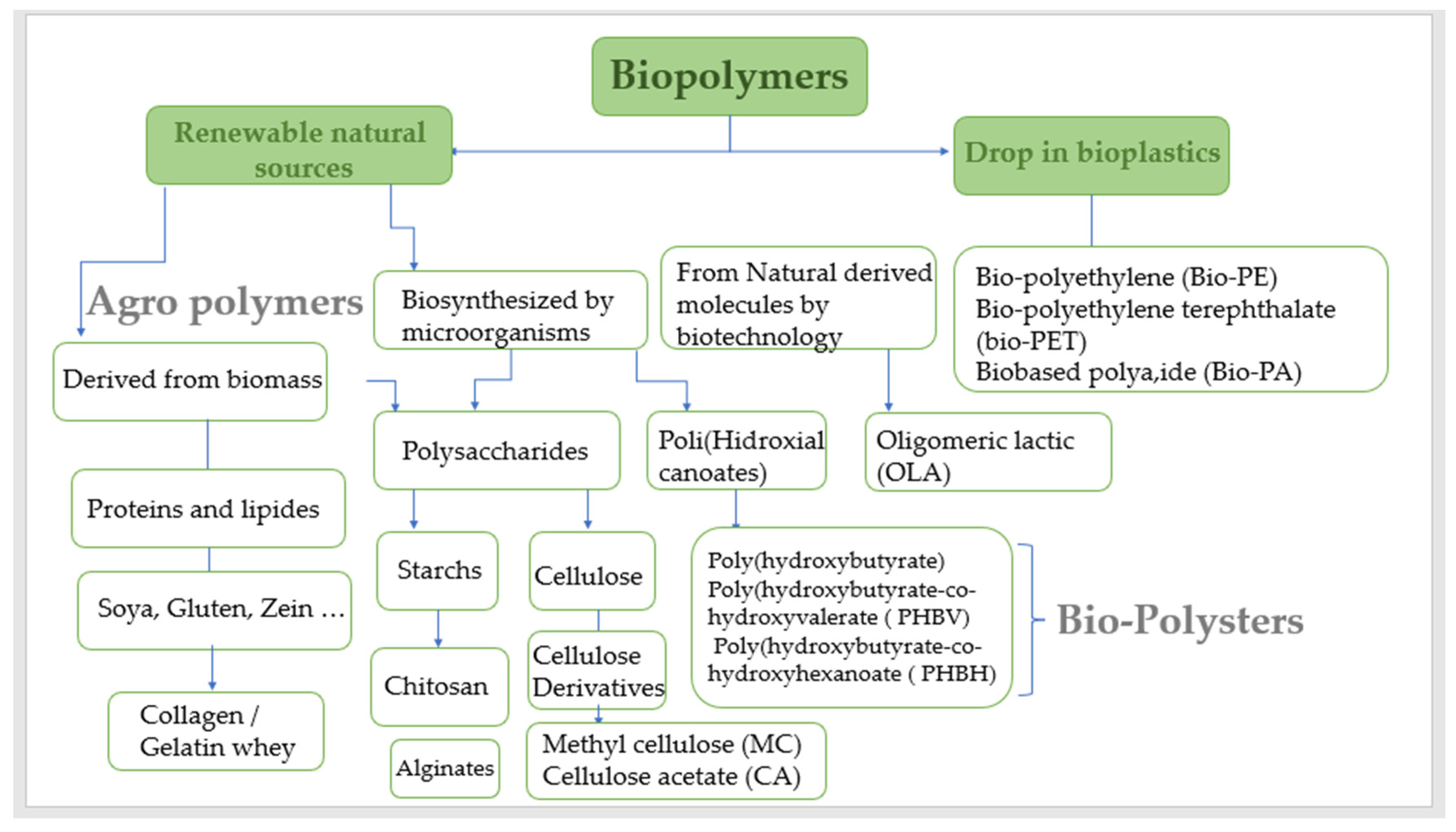

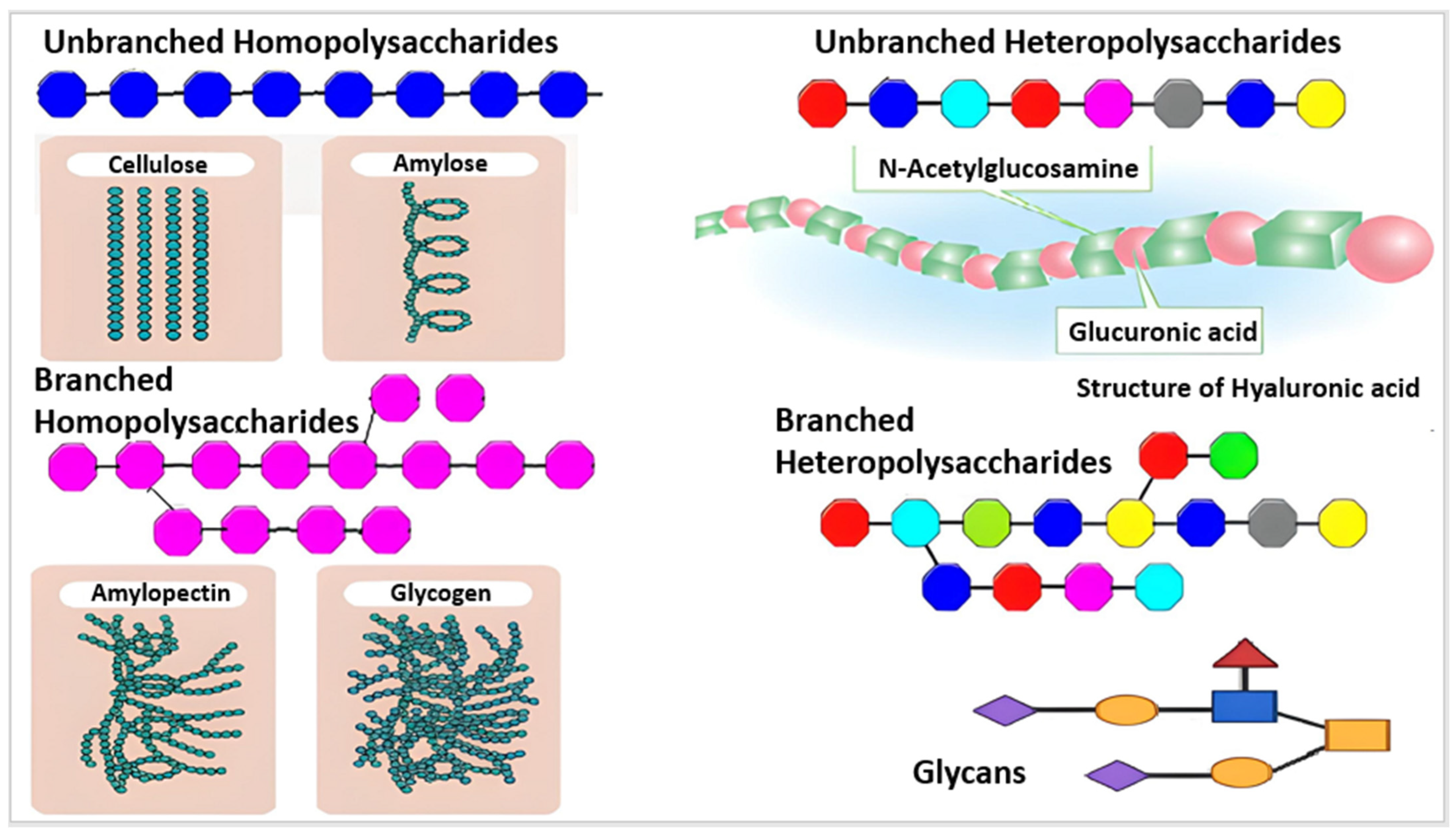

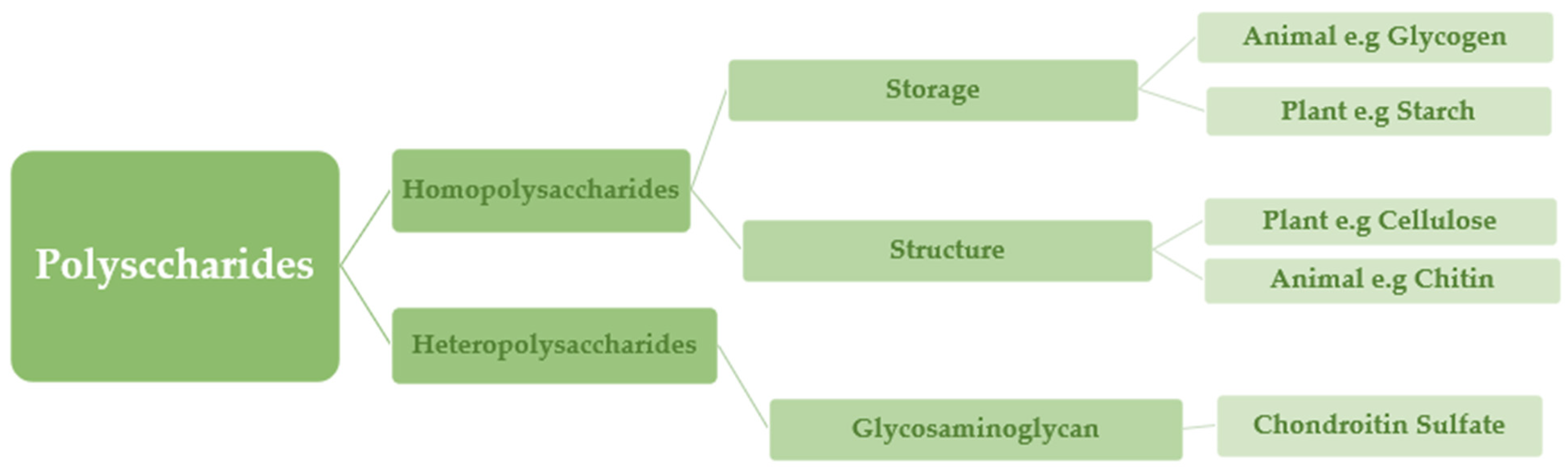

2. Classification of Natural Polysaccharides

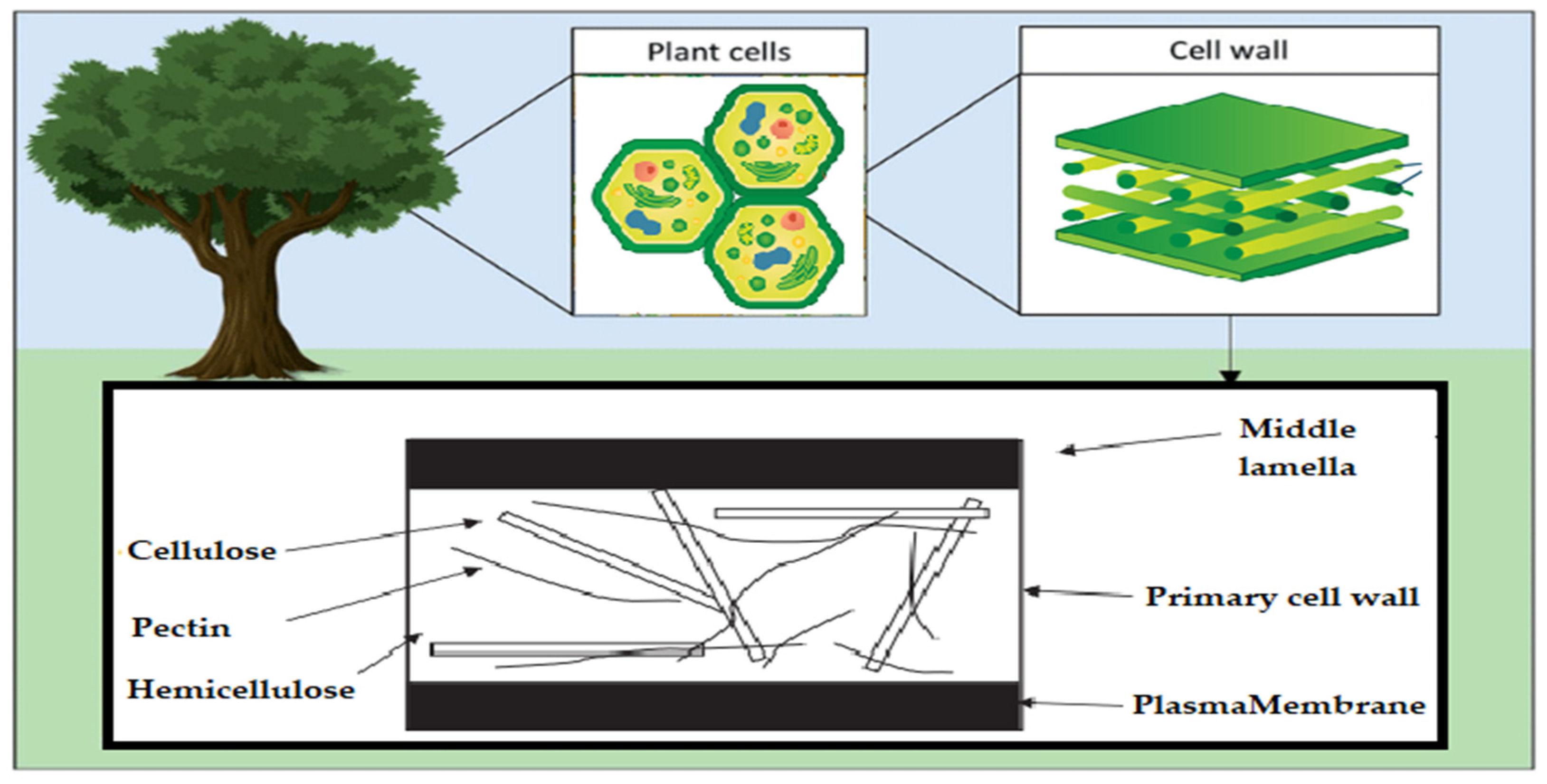

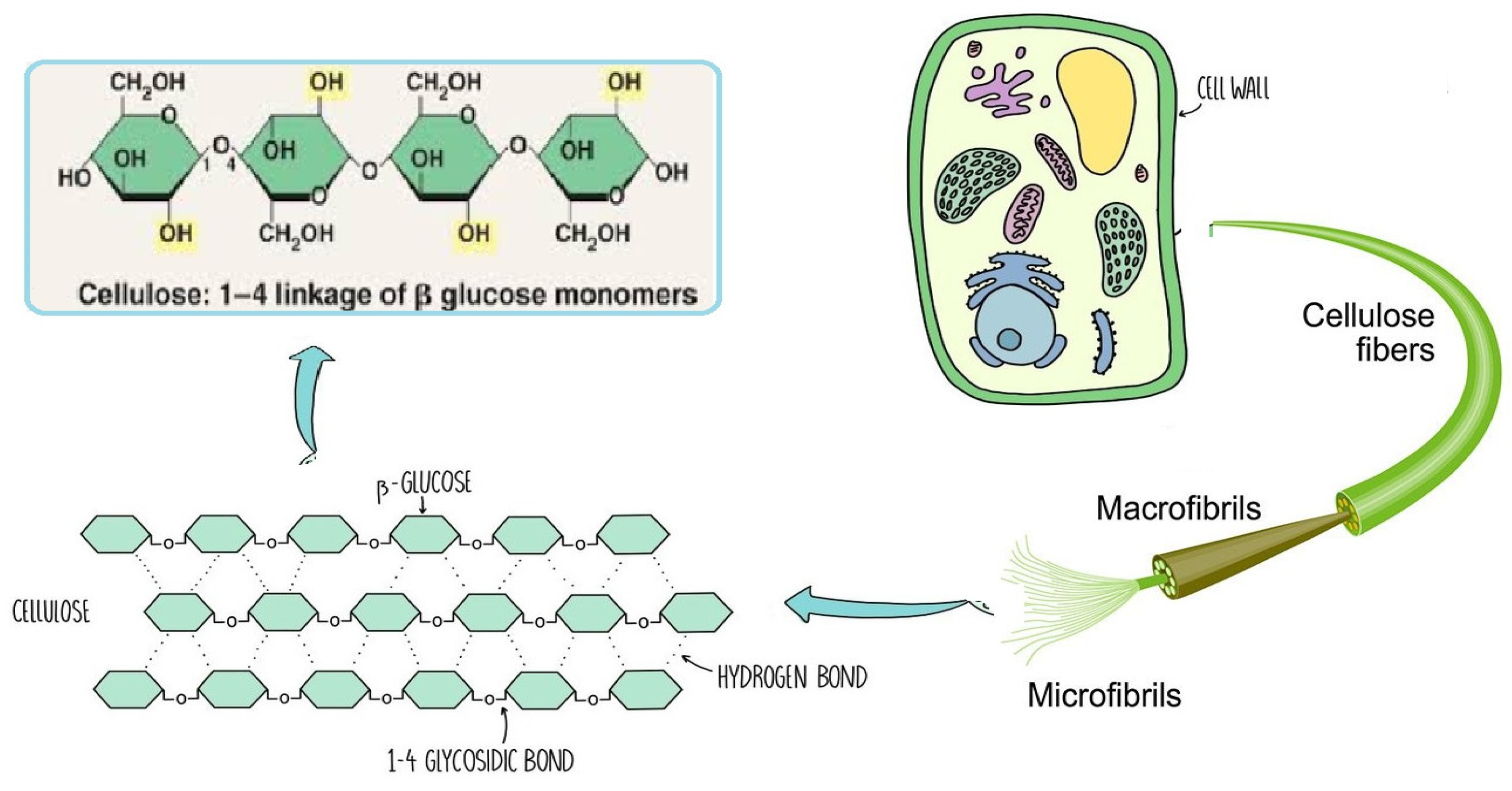

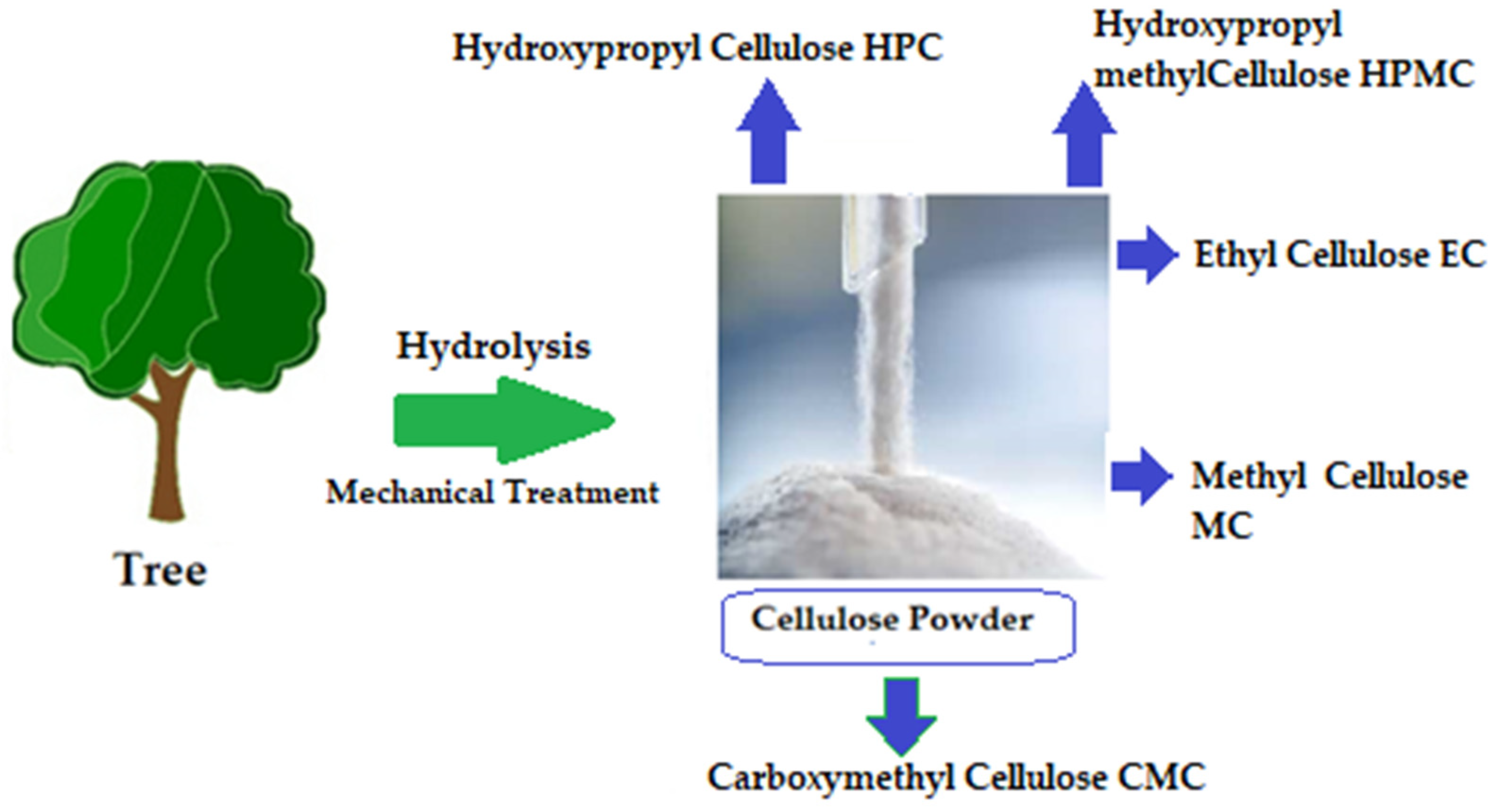

2.1. Cellulose

2.2. Hemicelluloses

2.3. Pectin

2.4. Starch

2.5. Glycogen

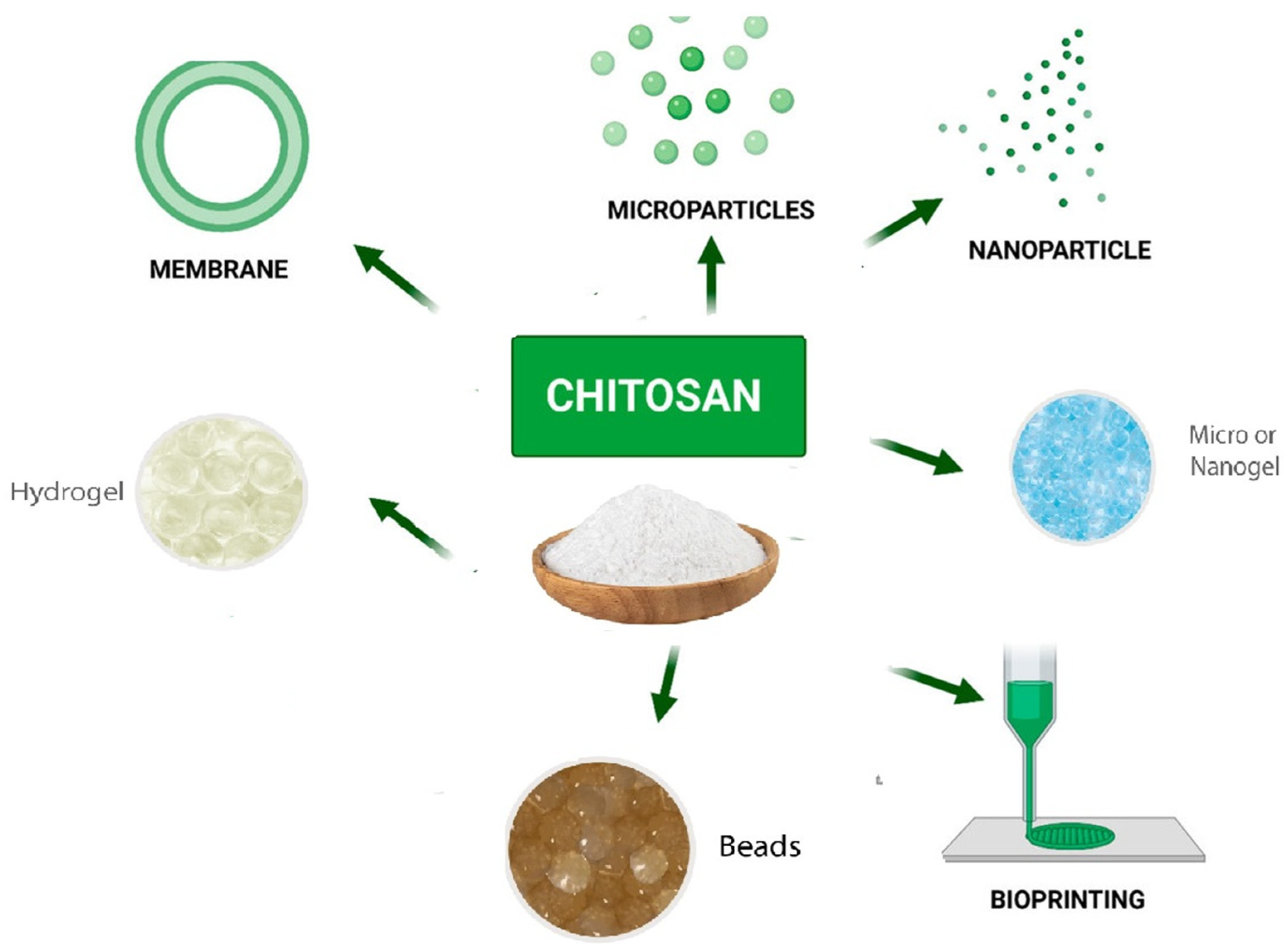

2.6. Chitin

2.7. Hyaluronic Acid

2.8. Alginate

3. Processing and Characterization of Natural Polymers

3.1. Blends and Composites

3.2. Processing Techniques

3.2.1. Extrusion Molding

3.2.2. Solvent Casting

3.2.3. Cellulose Nanoparticles

3.3. Characterization

3.3.1. Small-Angle X-ray Scattering (SAXS)

3.3.2. Nuclear Magnetic Resonance (NMR)

3.3.3. X-ray Diffraction

4. Cellulose and Starch Extraction, Purification, and Modification

4.1. Extraction, Purification, and Modification of Cellulose

4.1.1. Cellulose Extraction

4.1.2. Cellulose Modification

4.2. Starch Extraction, Purification, and Modification

4.2.1. Extraction Methods of Starch

4.2.2. Modification of Starch

5. Biological Applications of Natural Polymers

5.1. Anti-Inflammatory Activity

5.2. Hypoglycemic and Hypocholesterolemic Activities

5.3. Anticoagulant Activity

5.4. Antiviral Activity

6. Application of Natural Polymers in Food

- Stabilizing food microstructures through gelling, thickening, emulsion, and foaming as well as using processing aids including cryoprotectants to increase freeze–thaw stability, drying aids, and encapsulant material.

- Additional physiological and biological functionality, such as those provided by functional foods with specific health claims including lowering blood cholesterol levels, raising satiety, enhancing bioavailability, and inhibiting microbial growth [97].

Regulatory Aspects

7. Pharmaceutical Applications of Natural Polymers

7.1. Transdermal Drug Delivery Devices

7.2. Natural Polymers in Transdermal Drug Delivery

7.3. Natural Polymers in Topical Delivery Systems

7.4. Natural Polymer Implants

8. Environmental Impact of Natural Polymers

- High percentage of raw materials in the product;

- Clean (waste-free) and efficient production methods;

- The reduction in greenhouse gas emissions;

- Avoiding using additional chemicals, such as organic solvents;

- High manufacturing energy efficiency;

- A product with a high raw material content;

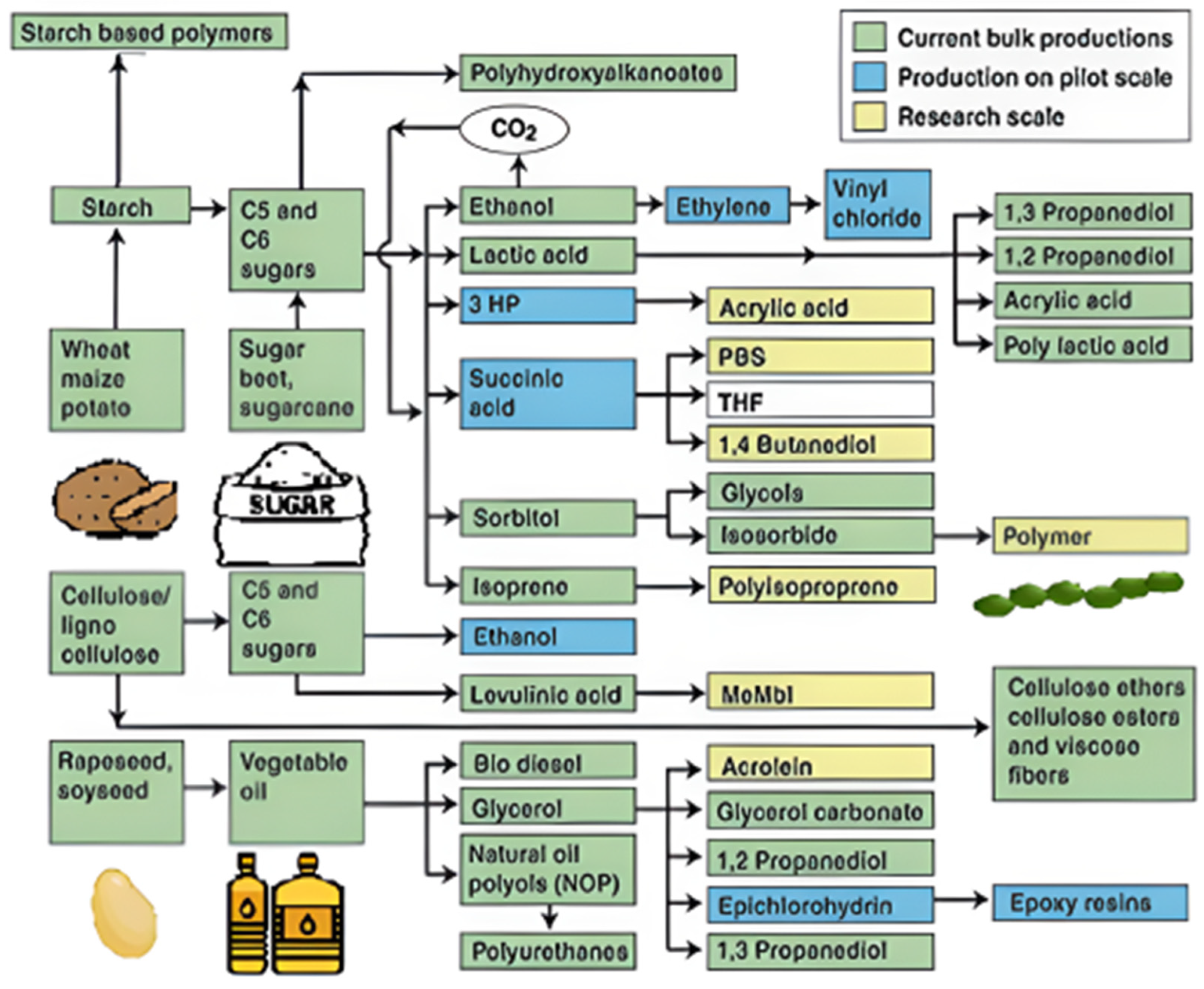

8.1. Renewable Polymers

8.1.1. Polylactic Acid

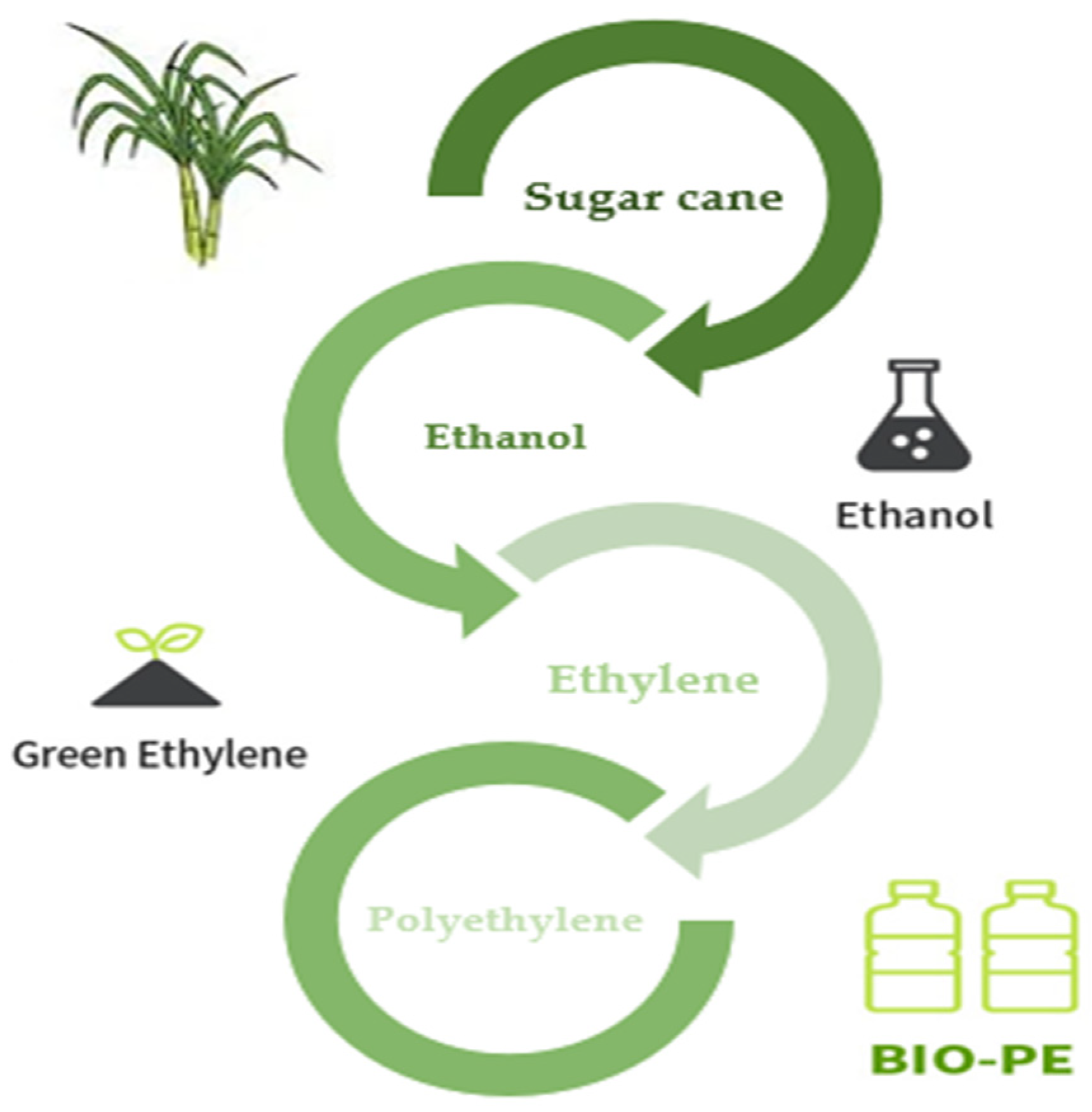

8.1.2. Bio-Polyethylene

8.1.3. Alginates

9. Economic Impacts of Natural Polymers

9.1. Certain Important Natural Polymers for Economy

9.2. Industry Use of Natural Biodegradable Polymers

| Natural Polymer | Examples |

|---|---|

| Polysaccharides | Starch, cellulose, chitin |

| Proteins | Collagen/gelatin, casein, albumin, fibrinogen, |

| Polyesters | Poly (hydroxyalkanoates) |

| Other polymers | Lignin, lipids, shellac, natural rubber |

10. Future Perspectives

10.1. Natural Polymer Bases in Gums for Food Applications

10.2. Natural Polymer Trends and Prospects in the Cosmetics Industry

11. Conclusions

Funding

Conflicts of Interest

References

- Balart, R.; Garcia-Garcia, D.; Fombuena, V.; Quiles-Carrillo, L.; Arrieta, M.P. Biopolymers from Natural Resources. Polymers 2021, 13, 2532. [Google Scholar] [CrossRef]

- Sharma, K.; Singh, V.; Arora, A. Natural Biodegradable Polymers as Matrices in Transdermal Drug Delivery. Int. J. Drug Dev. Res. 2011, 3, 85–103. [Google Scholar]

- Coviello, T.; Matricardi, P.; Marianecci, C.; Alhaique, F. Polysaccharide Hydrogels for Modified Release Formulations. J. Control. Release 2007, 119, 5–24. [Google Scholar] [CrossRef]

- Ahmad, Z.; Pandey, R.; Sharma, S.; Khuller, G.K. Alginate Nanoparticles as Antituberculosis Drug Carriers: Formulation Development, Pharmacokinetics and Therapeutic Potential. Indian J. Chest Dis. Allied Sci. 2006, 48, 171. [Google Scholar]

- Qi, L.; Xu, Z. In Vivo Antitumor Activity of Chitosan Nanoparticles. Bioorg. Med. Chem. Lett. 2006, 16, 4243–4245. [Google Scholar] [CrossRef]

- Olatunji, O.; Olubowale, M.; Okereke, C. Microneedle-Assisted Transdermal Delivery of Acetylsalicylic Acid (Aspirin) from Biopolymer Films Extracted from Fish Scales. Polym. Bull. 2018, 75, 4103–4115. [Google Scholar] [CrossRef]

- Biodegradable Natural Polymers. Available online: https://link.springer.com/chapter/10.1007/978-3-319-12478-0_2 (accessed on 3 December 2014).

- Zhou, C.Y.; Wang, Y.; Pan, D.D.; Sun, Y.Y.; Cao, J.X. The Effect of ATP Marination on the Depolymerization of Actin Filament in Goose Muscles during Postmortem Conditioning. Poult. Sci. 2018, 97, 684–694. [Google Scholar] [CrossRef]

- Rabetafika, H.N.; Paquot, M.; Dubois, P. Les Polymères Issus Du Végétal: Matériaux à Proprieties Spécifiques Pour Des Applications Ciblées En Industrie Plastique. Biotechnol. Agron. Soc. Environ. 2006, 10, 185–196. [Google Scholar]

- Pillai, O.; Dhanikula, A.B.; Panchagnula, R. Drug Delivery: An Odyssey of 100 Years. Curr. Opin. Chem. Biol. 2001, 5, 439–446. [Google Scholar] [CrossRef] [PubMed]

- Zhang, F.; Xu, S.; Wang, Z. Pre-Treatment Optimization and Properties of Gelatin from Freshwater Fish Scales. Food Bioprod. Process. 2011, 89, 185–193. [Google Scholar] [CrossRef]

- Liu, Z.; Jiao, Y.; Wang, Y.; Zhou, C.; Zhang, Z. Polysaccharides-Based Nanoparticles as Drug Delivery Systems. Adv. Drug Deliv. Rev. 2008, 60, 663–702. [Google Scholar] [CrossRef] [PubMed]

- D’Ayala, G.G.; Malinconico, M.; Laurienzo, P. Marine Derived Polysaccharides for Biomedical Applications: Chemical Modification Approaches. Molecules 2008, 13, 2069–2106. [Google Scholar] [CrossRef] [PubMed]

- Mohammed, A.M.A.; Yunus, N.Z.M.; Hezmi, M.A.; Rashid, A.S.A. Sequestration of Carbon Dioxide Using Ground Granulated Blast Furnaces Slag and Kaolin Mixtures. Glob. Nest J. 2021, 23, 105–111. [Google Scholar] [CrossRef]

- Dumitriu, S. Polysaccharides: Structural Diversity and Functional Versatility, 2nd ed.; CRC Press: Boca Raton, FL, USA, 2005. [Google Scholar]

- Yui, T.; Ogawa, K. X-Ray Diffraction Study of Polysaccharides. In Polysaccharides; CRC Press: Boca Raton, FL, USA, 2004. [Google Scholar]

- Pérez, S.; Mazeau, K. Conformations, Structures, and Morphologies of Celluloses. In Polysaccharides; CRC Press: Boca Raton, FL, USA, 2004. [Google Scholar]

- Allen, A.W.; Cook, J.G.; Armbruster, M.J. Habitat Suitability Index Models: Pronghorn; US Department of the Interior: Washington, DC, USA, 1984.

- Kulasinski, K.; Keten, S.; Churakov, S.V.; Derome, D.; Carmeliet, J. A Comparative Molecular Dynamics Study of Crystalline, Paracrystalline and Amorphous States of Cellulose. Cellulose 2014, 21, 1103–1106. [Google Scholar] [CrossRef]

- Koch, U.; Popelier, P.L.A. Characterization of C-H-O Hydrogen Bonds on the Basis of the Charge Density. J. Phys. Chem. 1995, 99, 9747–9754. [Google Scholar] [CrossRef]

- Hebeish, A.; Guthrie, J.T. The Chemistry and Technology of Cellulosic Copolymers; Springer Science & Business Media: Berlin, Germany, 1981. [Google Scholar]

- Roy, D.; Semsarilar, M.; Guthrie, J.T.; Perrier, S. Cellulose Modification by Polymer Grafting: A Review. Chem. Soc. Rev. 2009, 38, 2046–2064. [Google Scholar] [CrossRef]

- Farrán, A.; Cai, C.; Sandoval, M.; Xu, Y.; Liu, J.; Hernáiz, M.J.; Linhardt, R.J. Green Solvents in Carbohydrate Chemistry: From Raw Materials to Fine Chemicals. Chem. Rev. 2015, 115, 6811–6853. [Google Scholar] [CrossRef]

- Wang, M.; Sun, J.; Xu, B.; Chrusciel, M.; Gao, J.; Bazert, M.; Stelmaszewska, J.; Xu, Y.; Zhang, H.; Pawelczyk, L.; et al. Functional Characterization of MicroRNA-27a-3p Expression in Human Polycystic Ovary Syndrome. Endocrinology 2018, 159, 297–309. [Google Scholar] [CrossRef]

- Chang, C.; Duan, B.; Cai, J.; Zhang, L. Superabsorbent Hydrogels Based on Cellulose for Smart Swelling and Controllable Delivery. Eur. Polym. J. 2010, 46, 92–100. [Google Scholar] [CrossRef]

- Zielke, C.; Stradner, A.; Nilsson, L. Characterization of Cereal β-Glucan Extracts: Conformation and Structural Aspects. Food Hydrocoll. 2018, 79, 218–227. [Google Scholar] [CrossRef]

- Hu, X.; Zhao, J.; Zhao, Q.; Zheng, J. Structure and Characteristic of β-Glucan in Cereal: A Review. J. Food Process. Preserv. 2015, 39, 3145–3153. [Google Scholar] [CrossRef]

- Kuki, H.; Yokoyama, R.; Kuroha, T.; Nishitani, K. Xyloglucan Is Not Essential for the Formation and Integrity of the Cellulose Network in the Primary Cell Wall Regenerated from Arabidopsis Protoplasts. Plants 2020, 9, 629. [Google Scholar] [CrossRef]

- Li, Z.; Pan, X. Strategies to Modify Physicochemical Properties of Hemicelluloses from Biorefinery and Paper Industry for Packaging Material. Rev. Environ. Sci. Biotechnol. 2018, 17, 47–69. [Google Scholar] [CrossRef]

- Rao, J.; Lv, Z.; Chen, G.; Peng, F. Hemicellulose: Structure, Chemical Modification, and Application. Prog. Polym. Sci. 2023, 140, 101675. [Google Scholar] [CrossRef]

- Chandel, V.; Biswas, D.; Roy, S.; Vaidya, D.; Verma, A.; Gupta, A. Current Advancements in Pectin: Extraction, Properties and Multifunctional Applications. Foods 2022, 11, 2683. [Google Scholar] [CrossRef] [PubMed]

- Basak, S.; Annapure, U.S. Trends in “Green” and Novel Methods of Pectin Modification—A Review. Carbohydr. Polym. 2022, 278, 118967. [Google Scholar] [CrossRef] [PubMed]

- Kajiwara, K.; Miyamoto, T. ChemInform Abstract: Progress in Structural Characterization of Functional Polysaccharides. ChemInform 2010, 30, 1–55. [Google Scholar] [CrossRef]

- Zhang, J.; Zhai, A. Microstructure, Thermodynamics and Rheological Properties of Different Types of Red Adzuki Bean Starch. Qual. Assur. Saf. Crops Foods 2020, 12, 89–99. [Google Scholar] [CrossRef]

- Farooq, U.; Di Mattia, C.; Faieta, M.; Flamminii, F.; Pittia, P. Colloidal Properties and Stability of Olive Oil-in Water Emulsions Stabilized by Starch Particles. Ital. J. Food Sci. 2021, 33, 4. [Google Scholar] [CrossRef]

- Bojarczuk, A.; Skąpska, S.; Mousavi Khaneghah, A.; Marszałek, K. Health Benefits of Resistant Starch: A Review of the Literature. J. Funct. Foods 2022, 93, 105094. [Google Scholar] [CrossRef]

- Tan, L.; Kong, L. Starch-Guest Inclusion Complexes: Formation, Structure, and Enzymatic Digestion. Crit. Rev. Food Sci. Nutr. 2020, 60, 780–789. [Google Scholar] [CrossRef] [PubMed]

- Zhu, Y.; Delbianco, M.; Seeberger, P.H. Automated Assembly of Starch and Glycogen Polysaccharides. J. Am. Chem. Soc. 2021, 143, 9758–9768. [Google Scholar] [CrossRef] [PubMed]

- Jolly, G.; Kuscu, M.C.; Kokate, P.; Younis, M. A Low-Energy Key Management Protocol for Wireless Sensor Networks. In Proceedings of the Proceedings—IEEE Symposium on Computers and Communications, Kemer-Antalya, Turkey, 30 June–3 July 2003. [Google Scholar]

- Kulkarni, V.; Butte, K.; Rathod, S. Natural Polymers—A Comprehensive Review. Int. J. Res. Pharm. Biomed. Sci. 2012, 3, 1597–1613. [Google Scholar]

- Guizzardi, S.; Uggeri, J.; Belletti, S.; Cattarini, G. Hyaluronate Increases Polynucleotides Effect on Human Cultured Fibroblasts. J. Cosmet. Dermatol. Sci. Appl. 2013, 3, 124. [Google Scholar] [CrossRef]

- Taravel, F.; Mazeau, K.; Tvaros¡ka, I. Computer Modeling of Polysaccharide–Polysaccharide Interactions. In Polysaccharides; CRC Press: Boca Raton, FL, USA, 2004. [Google Scholar]

- Oerther, S.; Le Gall, H.; Payan, E.; Lapicque, F.; Presle, N.; Hubert, P.; Dexheimer, J.; Netter, P.; Lapicque, F. Hyaluronate-Alginate Gel as a Novel Biomaterial: Mechanical Properties and Formation Mechanism. Biotechnol. Bioeng. 1999, 63, 206–215. [Google Scholar] [CrossRef]

- Bi, D.; Yang, X.; Yao, L.; Hu, Z.; Li, H.; Xu, X.; Lu, J. Potential Food and Nutraceutical Applications of Alginate: A Review. Mar. Drugs 2022, 20, 564. [Google Scholar] [CrossRef]

- Nafchi, A.M.; Moradpour, M.; Saeidi, M.; Alias, A.K. Thermoplastic Starches: Properties, Challenges, and Prospects. Starch-Staerke 2013, 65, 61–72. [Google Scholar] [CrossRef]

- Cazacu, I.; Miremont, G.; Geniaux, H.; Benard-Laribiere, A. Causality and Preventability of Adverse Drug Reactions of Analgesics. In Drug Safety; ADIS International Ltd.: Auckland, New Zealand, 2013; Volume 36. [Google Scholar]

- Onyeagoro, G.N. Reactive Compatibilization of Natural Rubber (NR)/Carboxylated Nitrile Rubber (XNBR) Blends by Maleic Anhydride-Grafted-Polyisoprene (MAPI) and Epoxy Resin Dual Compatibilizers. Int. Ref. J. Eng. Sci. 2013, 2, 7–16. [Google Scholar]

- Sirisinha, C.; Saeoui, P.; Guaysomboon, J. Oil and Thermal Aging Resistance in Compatibilized and Thermally Stabilized Chlorinated Polyethylene/Natural Rubber Blends. Polymer 2004, 45, 4909–4916. [Google Scholar] [CrossRef]

- Naskar, N.; Debnath, S.C.; Basu, D.K. Novel Method for Preparation of Carboxylated Nitrile Rubber-Natural Rubber Blends Using Bis(Diisopropyl)Thiophosphoryl Polysulfides. J. Appl. Polym. Sci. 2001, 80, 1725–1736. [Google Scholar] [CrossRef]

- Chumeka, W.; Pasetto, P.; Pilard, J.F.; Tanrattanakul, V. Bio-Based Triblock Copolymers from Natural Rubber and Poly(Lactic Acid): Synthesis and Application in Polymer Blending. Polymer 2014, 55, 4478–4487. [Google Scholar] [CrossRef]

- Hummel, D.O. Polymeren–Lehrbuch: Polymer Chemistry–an Introduction. Von RB Seymour und CE Carraher, jr. Marcel Dekker Inc. New York–Basel 1981. XVI, 576 S., Zeichn., geb., SFr. 80,–. Nachrichten Chem. 1981, 29, 629. [Google Scholar] [CrossRef]

- Sowunmi, S.; Ebewele, R.O.; Peters, O.; Conner, A.H. Differential Scanning Calorimetry of Hydrolysed Mangrove Tannin. Polym. Int. 2000, 49, 574–578. [Google Scholar] [CrossRef]

- Santos, T.M.; Men de Sá Filho, M.S.; Caceres, C.A.; Rosa, M.F.; Morais, J.P.S.; Pinto, A.M.B.; Azeredo, H.M.C. Fish Gelatin Films as Affected by Cellulose Whiskers and Sonication. Food Hydrocoll. 2014, 41, 113–118. [Google Scholar] [CrossRef]

- Turbak, A.F.; Snyder, F.W.; Sandberg, K.R. Microfibrillated Cellulose, a New Cellulose Product: Properties, Uses, and Commercial Potential. J. Appl. Polym. Sci. Appl. Polym. Symp. 1983, 37, 815–827. [Google Scholar]

- Herrick, F.W.; Casebier, R.L.; Hamilton, J.K.; Sandberg, K.R. Microfibrillated Cellulose: Morphology and Accessibility. J. Appl. Polym. Sci. Appl. Polym. Symp. 1983, 37, 797–813. [Google Scholar]

- Preston, R.D.; Nicolai, E.; Reed, R.; Millard, A. An Electron Microscope Study of Cellulose in the Wall of Valonia Ventricosa. Nature 1948, 162, 665–667. [Google Scholar] [CrossRef] [PubMed]

- Belton, P.S.; Tanner, S.F.; Cartier, N.; Chanzy, H. High-Resolution Solid-State 13C Nuclear Magnetic Resonance Spectroscopy of Tunicin, an Animal Cellulose. Macromolecules 1989, 22, 1615–1617. [Google Scholar] [CrossRef]

- Lee, K.Y.; Aitomäki, Y.; Berglund, L.A.; Oksman, K.; Bismarck, A. On the Use of Nanocellulose as Reinforcement in Polymer Matrix Composites. Compos. Sci. Technol. 2014, 105, 15–27. [Google Scholar] [CrossRef]

- Núñez, O.; Ikegami, T.; Kajiwara, W.; Miyamoto, K.; Horie, K.; Tanaka, N. Preparation of High Efficiency and Highly Retentive Monolithic Silica Capillary Columns for Reversed-Phase Chromatography by Chemical Modification by Polymerization of Octadecyl Methacrylate. J. Chromatogr. A 2007, 1156, 35–44. [Google Scholar] [CrossRef]

- Putnam, D.K.; Lowe, E.W.; Meiler, J. Reconstruction of SAXS Profiles from Protein Structures. Comput. Struct. Biotechnol. J. 2013, 8, e201308006. [Google Scholar] [CrossRef] [PubMed]

- Detduangchan, N.; Sridach, W.; Wittaya, T. Enhancement of the Properties of Biodegradable Rice Starch Films by Using Chemical Crosslinking Agents. Int. Food Res. J. 2014, 21, 1225–1253. [Google Scholar]

- David, A.; Lewandrowski, K.U.; Josten, C.; Ekkernkamp, A.; Clasbrummel, B.; Muhr, G. Surgical Correction of Talipes Equinovarus Following Foot and Leg Compartment Syndrome. Foot Ankle Int. 1996, 17, 334–339. [Google Scholar] [CrossRef] [PubMed]

- Ma, L.; Hu, X.; Song, L.; Chen, X.; Ouyang, M.; Billot, L.; Li, Q.; Malavera, A.; Li, X.; Muñoz-Venturelli, P.; et al. The Third Intensive Care Bundle with Blood Pressure Reduction in Acute Cerebral Haemorrhage Trial (INTERACT3): An International, Stepped Wedge Cluster Randomised Controlled Trial. Lancet 2023, 402, 27–40. [Google Scholar] [CrossRef] [PubMed]

- Thakur, R.; Pristijono, P.; Scarlett, C.J.; Bowyer, M.; Singh, S.P.; Vuong, Q.V. Starch-Based Films: Major Factors Affecting Their Properties. Int. J. Biol. Macromol. 2019, 132, 1079–1089. [Google Scholar] [CrossRef] [PubMed]

- Muhd Julkapli, N.; Bagheri, S. Nanocellulose as a Green and Sustainable Emerging Material in Energy Applications: A Review. Polym. Adv. Technol. 2017, 28, 1583–1594. [Google Scholar] [CrossRef]

- Gopakumar, D.A.; Thomas, S.; Owolabi, F.A.T.; Thomas, S.; Nzihou, A.; Rizal, S.; Abdul Khalil, H.P.S. Nanocellulose Based Aerogels for Varying Engineering Applications. Encycl. Renew. Sustain. Mater. 2020, 2, 155–165. [Google Scholar]

- Belitz, H.D.; Grosch, W.; Schieberle, P. Food Chemistry; Springer Science & Business Media: Berlin, Germany, 2009. [Google Scholar]

- Brostow, W.; Datashvili, T.; Miller, H. Wood and wood derived materials. J. Mater. Educ. 2010, 32, 125. [Google Scholar]

- Kalia, S.; Dufresne, A.; Cherian, B.M.; Kaith, B.S.; Avérous, L.; Njuguna, J.; Nassiopoulos, E. Cellulose-Based Bio- and Nanocomposites: A Review. Int. J. Polym. Sci. 2011, 2011, 837875. [Google Scholar] [CrossRef]

- Maniglia, B.C.; Castanha, N.; Le-Bail, P.; Le-Bail, A.; Augusto, P.E.D. Starch Modification through Environmentally Friendly Alternatives: A Review. Crit. Rev. Food Sci. Nutr. 2021, 61, 2482–2505. [Google Scholar] [CrossRef]

- Vanier, N.L.; El Halal, S.L.M.; Dias, A.R.G.; da Rosa Zavareze, E. Molecular Structure, Functionality and Applications of Oxidized Starches: A Review. Food Chem. 2017, 221, 1546–1559. [Google Scholar] [CrossRef]

- Maniñgat, C.C.; Juliano, B.O. Properties of Lintnerized Starch Granules from Rices Differing in Amylose Content and Gelatinization Temperature. Starch-Stärke 1979, 31, 5–10. [Google Scholar] [CrossRef]

- Lim, S.T.; Lee, J.H.; Shin, D.H.; Lim, H.S. Comparison of Protein Extraction Solutions for Rice Starch Isolation and Effects of Residual Protein Content on Starch Pasting Properties. Starch-Stärke 1999, 51, 120–125. [Google Scholar] [CrossRef]

- Muhamad, I.I.; Lazim, N.A.M.; Selvakumaran, S. Natural Polysaccharide-Based Composites for Drug Delivery and Biomedical Applications. In Natural Polysaccharides in Drug Delivery and Biomedical Applications; Academic Press: Cambridge, MA, USA, 2019. [Google Scholar]

- Mzoughi, Z.; Abdelhamid, A.; Rihouey, C.; Le Cerf, D.; Bouraoui, A.; Majdoub, H. Optimized Extraction of Pectin-like Polysaccharide from Suaeda Fruticosa Leaves: Characterization, Antioxidant, Anti-Inflammatory and Analgesic Activities. Carbohydr. Polym. 2018, 185, 127–137. [Google Scholar] [CrossRef] [PubMed]

- Chen, Y.; Yao, F.; Ming, K.; Wang, D.; Hu, Y.; Liu, J. Polysaccharides from Traditional Chinese Medicines: Extraction, Purification, Modification, and Biological Activity. Molecules 2016, 21, 1705. [Google Scholar] [CrossRef] [PubMed]

- Jiao, G.; Yu, G.; Zhang, J.; Ewart, H.S. Chemical Structures and Bioactivities of Sulfated Polysaccharides from Marine Algae. Mar. Drugs 2011, 9, 196–233. [Google Scholar] [CrossRef] [PubMed]

- Li, G.; Lou, H.X. Strategies to Diversify Natural Products for Drug Discovery. Med. Res. Rev. 2018, 38, 1255–1294. [Google Scholar] [CrossRef]

- Newman, D.J.; Cragg, G.M. Natural Products as Sources of New Drugs from 1981 to 2014. J. Nat. Prod. 2016, 79, 629–661. [Google Scholar] [CrossRef]

- Bost, J.; Maroon, A.; Maroon, J. Natural Anti-Inflammatory Agents for Pain Relief. Surg. Neurol. Int. 2010, 1, 80. [Google Scholar] [CrossRef]

- Yu, Y.; Shen, M.; Song, Q.; Xie, J. Biological Activities and Pharmaceutical Applications of Polysaccharide from Natural Resources: A Review. Carbohydr. Polym. 2018, 183, 91–101. [Google Scholar] [CrossRef]

- Nayak, A.K.; Ahmed, S.A.; Tabish, M.; Hasnain, M.S. Natural Polysaccharides in Tissue Engineering Applications. In Natural Polysaccharides in Drug Delivery and Biomedical Applications; Academic Press: Cambridge, MA, USA, 2019. [Google Scholar]

- Moradi, Z.; Kalanpour, N. Kefiran, a Branched Polysaccharide: Preparation, Properties and Applications: A Review. Carbohydr. Polym. 2019, 223, 115100. [Google Scholar] [CrossRef] [PubMed]

- Bhandari, M.R.; Jong-Anurakkun, N.; Hong, G.; Kawabata, J. α-Glucosidase and α-Amylase Inhibitory Activities of Nepalese Medicinal Herb Pakhanbhed (Bergenia Ciliata, Haw.). Food Chem. 2008, 106, 247–252. [Google Scholar] [CrossRef]

- Preetha, P.P.; Devi, V.G.; Rajamohan, T. Hypoglycemic and Antioxidant Potential of Coconut Water in Experimental Diabetes. Food Funct. 2012, 3, 753–757. [Google Scholar] [CrossRef] [PubMed]

- Lovati, M.R.; Manzoni, C.; Gianazza, E.; Arnoldi, A.; Kurowska, E.; Carroll, K.K.; Sirtori, C.R. Soy Protein Peptides Regulate Cholesterol Homeostasis in Hep G2 Cells. J. Nutr. 2000, 130, 2543–2549. [Google Scholar] [CrossRef] [PubMed]

- O’connor, L.E.; Berry, J.W.; Weiss, J.; Gilbert, P. Guilt, Fear, Submission, and Empathy in Depression. J. Affect. Disord. 2002, 71, 19–27. [Google Scholar] [CrossRef]

- Berge, R.K.; Tronstad, K.J.; Berge, K.; Rost, T.H.; Wergedahl, H.; Gudbrandsen, O.A.; Skorve, J. The Metabolic Syndrome and the Hepatic Fatty Acid Drainage Hypothesis. Biochimie 2005, 87, 15–20. [Google Scholar] [CrossRef]

- Costa, L.S.; Fidelis, G.P.; Cordeiro, S.L.; Oliveira, R.M.; Sabry, D.A.; Câmara, R.B.G.; Nobre, L.T.D.B.; Costa, M.S.S.P.; Almeida-Lima, J.; Farias, E.H.C.; et al. Biological Activities of Sulfated Polysaccharides from Tropical Seaweeds. Biomed. Pharmacother. 2010, 64, 21–28. [Google Scholar] [CrossRef]

- de Jesus Raposo, M.F.; de Morais, A.M.M.B.; de Morais, R.M.S.C. Bioactivity and Applications of Polysaccharides from Marine Microalgae. In Polysaccharides; Springer International Publishing: Cham, Switzerland, 2014; pp. 1–38. [Google Scholar]

- Mohan, K.; Ravichandran, S.; Muralisankar, T.; Uthayakumar, V.; Chandirasekar, R.; Seedevi, P.; Rajan, D.K. Potential Uses of Fungal Polysaccharides as Immunostimulants in Fish and Shrimp Aquaculture: A Review. Aquaculture 2019, 500, 250–263. [Google Scholar] [CrossRef]

- Olennikov, D.N.; Kashchenko, N.I.; Chirikova, N.K.; Koryakina, L.P.; Vladimirov, L.N. Bitter Gentian Teas: Nutritional and Phytochemical Profiles, Polysaccharide Characterisation and Bioactivity. Molecules 2015, 20, 20014–20030. [Google Scholar] [CrossRef]

- Peng, X.; Usman, B.; Kaushik, N.; Hoffman, J.; Wang, D.; Saenko, K. VisDA: The Visual Domain Adaptation Challenge. arXiv 2017, arXiv:1710.06924. [Google Scholar]

- Walstra, P. Physical Chemistry of Foods; Marcel Dekker: New York, NY, USA, 2003; ISBN 0824793552. [Google Scholar]

- Telis, V.R.N. Biopolymer Engineering in Food Processing; CRC Press: Boca Raton, FL, USA, 2012. [Google Scholar]

- Phillips, G.O. Handbook of Hydrocolloids; Woodhead Publishing: Thorston, UK, 2009; ISBN 9781845694142. [Google Scholar]

- Sayas-Barberá, E.; Pérez-Álvarez, J.A.; Navarro-Rodríguez de Vera, C.; Fernández-López, M.; Viuda-Martos, M.; Fernández-López, J. Sustainability and Gender Perspective in Food Innovation: Foods and Food Processing Coproducts as Source of Macro- and Micro-Nutrients for Woman-Fortified Foods. Foods 2022, 11, 3661. [Google Scholar] [CrossRef] [PubMed]

- Kyriakopoulou, K.; Keppler, J.K.; van der Goot, A.J. Functionality of Ingredients and Additives in Plant-Based Meat Analogues. Foods 2021, 10, 600. [Google Scholar] [CrossRef]

- Viebke, C.; Al-Assaf, S.; Phillips, G.O. Food Hydrocolloids and Health Claims. Bioact. Carbohydr. Diet. Fibre 2014, 4, 101–114. [Google Scholar] [CrossRef]

- Kim, J.K.; Kim, H.J.; Chung, J.Y.; Lee, J.H.; Young, S.B.; Kim, Y.H. Natural and Synthetic Biomaterials for Controlled Drug Delivery. Arch. Pharm. Res. 2014, 37, 60–68. [Google Scholar] [CrossRef] [PubMed]

- Cleary, G.W. Transdermal Delivery Systems: A Medical Rationale. In Topical Drug Bioavailability, Bioequivalence, and Penetration; Springer: Boston, MA, USA, 1993. [Google Scholar]

- Fujimoto, T.; Enomoto, K.; Matuo, K.; Tojo, K. In Vivo Evaluation of Skin Permeability of Drugs after Applying Adhesive Transdermal Patches; American Institute of Chemical Engineers: New York, NY, USA, 2006. [Google Scholar]

- Sirbubalo, M.; Tucak, A.; Muhamedagic, K.; Hindija, L.; Rahić, O.; Hadžiabdić, J.; Cekic, A.; Begic-Hajdarevic, D.; Husic, M.C.; Dervišević, A.; et al. 3d Printing—A “Touch-Button” Approach to Manufacture Microneedles for Transdermal Drug Delivery. Pharmaceutics 2021, 13, 924. [Google Scholar] [CrossRef] [PubMed]

- Sun, Y.; Tojo, K.; Chien, Y.W. Kinetics and Thermodynamics of Drug Permeation through Silicone Elastomers (II) Effect of Penetrant Lipophilicity. Drug Dev. Ind. Pharm. 1986, 12, 327–348. [Google Scholar] [CrossRef]

- Musabayane, C.T.; Munjeri, O.; Bwititi, P.; Osim, E.E. Orally Administered, Insulin-Loaded Amidated Pectin Hydrogel Beads Sustain Plasma Concentrations of Insulin in Streptozotocin-Diabetic Rats. J. Endocrinol. 2000, 164, 1–6. [Google Scholar] [CrossRef]

- Suksaeree, J.; Boonme, P.; Taweepreda, W.; Ritthidej, G.C.; Pichayakorn, W. Characterization, in Vitro Release and Permeation Studies of Nicotine Transdermal Patches Prepared from Deproteinized Natural Rubber Latex Blends. Chem. Eng. Res. Des. 2012, 90, 906–914. [Google Scholar] [CrossRef]

- Musabayane, C.T.; Tufts, M.A.; Mapanga, R.F. Synergistic Antihyperglycemic Effects between Plant-Derived Oleanolic Acid and Insulin in Streptozotocin-Induced Diabetic Rats. Ren. Fail. 2010, 32, 832–839. [Google Scholar] [CrossRef]

- Shi, W.; Dumont, M.J.; Ly, E.B. Synthesis and Properties of Canola Protein-Based Superabsorbent Hydrogels. Eur. Polym. J. 2014, 54, 172–180. [Google Scholar] [CrossRef]

- Deming, T.J. Synthetic Polypeptides for Biomedical Applications. Prog. Polym. Sci. 2007, 32, 858–875. [Google Scholar] [CrossRef]

- Jadach, B.; Świetlik, W.; Froelich, A. Sodium Alginate as a Pharmaceutical Excipient: Novel Applications of a Well-Known Polymer. J. Pharm. Sci. 2022, 111, 1250–1261. [Google Scholar] [CrossRef] [PubMed]

- Abd El-Hack, M.E.; El-Saadony, M.T.; Shafi, M.E.; Zabermawi, N.M.; Arif, M.; Batiha, G.E.; Khafaga, A.F.; Abd El-Hakim, Y.M.; Al-Sagheer, A.A. Antimicrobial and Antioxidant Properties of Chitosan and Its Derivatives and Their Applications: A Review. Int. J. Biol. Macromol. 2020, 164, 2726–2744. [Google Scholar] [CrossRef]

- Zhu, J.; Tang, X.; Jia, Y.; Ho, C.T.; Huang, Q. Applications and Delivery Mechanisms of Hyaluronic Acid Used for Topical/Transdermal Delivery—A Review. Int. J. Pharm. 2020, 578, 119127. [Google Scholar] [CrossRef]

- Chaturvedi, M.; Kumar, M.; Pathak, K. A Review on Mucoadhesive Polymer Used in Nasal Drug Delivery System. J. Adv. Pharm. Technol. Res. 2011, 2, 215–222. [Google Scholar] [CrossRef] [PubMed]

- Duan, X.; Mao, S. New Strategies to Improve the Intranasal Absorption of Insulin. Drug Discov. Today 2010, 15, 416–427. [Google Scholar] [CrossRef] [PubMed]

- Patil, S.B.; Sawant, K.K. Development, Optimization and in Vitro Evaluation of Alginate Mucoadhesive Microspheres of Carvedilol for Nasal Delivery. J. Microencapsul. 2009, 26, 432–443. [Google Scholar] [CrossRef]

- Grinberg, O.; Gedanken, A. The Development and Characterization of Starch Microspheres Prepared by a Sonochemical Method for the Potential Drug Delivery of Insulin. Macromol. Chem. Phys. 2010, 211, 924–931. [Google Scholar] [CrossRef]

- Illum, L.; Watts, P.; Fisher, A.N.; Hinchcliffe, M.; Norbury, H.; Jabbal-Gill, I.; Nankervis, R.; Davis, S.S. Intranasal Delivery of Morphine. J. Pharmacol. Exp. Ther. 2002, 301, 391–400. [Google Scholar] [CrossRef]

- Coucke, D.; Schotsaert, M.; Libert, C.; Pringels, E.; Vervaet, C.; Foreman, P.; Saelens, X.; Remon, J.P. Spray-Dried Powders of Starch and Crosslinked Poly(Acrylic Acid) as Carriers for Nasal Delivery of Inactivated Influenza Vaccine. Vaccine 2009, 27, 1279–1286. [Google Scholar] [CrossRef]

- Xu, E.Y.; Guo, J.; Xu, Y.; Li, H.Y.; Seville, P.C. Influence of Excipients on Spray-Dried Powders for Inhalation. Powder Technol. 2014, 256, 217–223. [Google Scholar] [CrossRef]

- Illum, L. Nasal Drug Delivery—Possibilities, Problems and Solutions. J. Control. Release 2003, 87, 187–198. [Google Scholar] [CrossRef]

- Pal, D.; Nayak, A.K. Novel Tamarind Seed Polysaccharide-Alginate Mucoadhesive Microspheres for Oral Gliclazide Delivery: In Vitro-in Vivo Evaluation. Drug Deliv. 2012, 19, 123–131. [Google Scholar] [CrossRef] [PubMed]

- Li, Q.; Williams, C.G.; Sun, D.D.N.; Wang, J.; Leong, K.; Elisseeff, J.H. Photocrosslinkable Polysaccharides Based on Chondroitin Sulfate. J. Biomed. Mater. Res. A 2004, 68, 28–33. [Google Scholar] [CrossRef] [PubMed]

- Bragd, P.L.; Van Bekkum, H.; Besemer, A.C. TEMPO-Mediated Oxidation of Polysaccharides: Survey of Methods and Applications. Top. Catal. 2004, 27, 49–66. [Google Scholar] [CrossRef]

- Ngwuluka, N.C. Responsive Polysaccharides and Polysaccharides-Based Nanoparticles for Drug Delivery. In Stimuli Responsive Polymeric Nanocarriers for Drug Delivery Applications: Volume 1: Types and Triggers; Woodhead Publishing: Thorston, UK, 2018. [Google Scholar]

- Alvarez-Lorenzo, C.; Blanco-Fernandez, B.; Puga, A.M.; Concheiro, A. Crosslinked Ionic Polysaccharides for Stimuli-Sensitive Drug Delivery. Adv. Drug Deliv. Rev. 2013, 65, 1148–1171. [Google Scholar] [CrossRef] [PubMed]

- Chourasia, M.K.; Jain, S.K. Polysaccharides for Colon Targeted Drug Delivery. Drug Deliv. 2004, 11, 129–148. [Google Scholar] [CrossRef] [PubMed]

- Suginta, W.; Khunkaewla, P.; Schulte, A. Electrochemical Biosensor Applications of Polysaccharides Chitin and Chitosan. Chem. Rev. 2013, 113, 5458–5479. [Google Scholar] [CrossRef]

- Sinha, A.; Sinha, M.; Burgert, S. Reinfusion of Drained Blood as an Alternative to Homologous Blood Transfusion after Total Knee Replacement. Int. Orthop. 2001, 25, 257–259. [Google Scholar] [CrossRef][Green Version]

- Luo, Y.; Wang, Q. Recent Development of Chitosan-Based Polyelectrolyte Complexes with Natural Polysaccharides for Drug Delivery. Int. J. Biol. Macromol. 2014, 64, 353–367. [Google Scholar] [CrossRef]

- Arca, H.Ç.; Günbeyaz, M.; Şenel, S. Chitosan-Based Systems for the Delivery of Vaccine Antigens. Expert. Rev. Vaccines 2009, 8, 937–953. [Google Scholar] [CrossRef] [PubMed]

- Mohammed, A.S.A.; Naveed, M.; Jost, N. Polysaccharides; Classification, Chemical Properties, and Future Perspective Applications in Fields of Pharmacology and Biological Medicine (A Review of Current Applications and Upcoming Potentialities). J. Polym. Environ. 2021, 29, 2359–2371. [Google Scholar] [CrossRef] [PubMed]

- Ivanova, E.P.; Bazaka, K.; Crawford, R.J. Natural Polymer Biomaterials: Advanced Applications. New Funct. Biomater. Med. Healthc. 2014, 1, 32–70. [Google Scholar]

- Braga, M.E.M.; Pato, M.T.V.; Silva, H.S.R.C.; Ferreira, E.I.; Gil, M.H.; Duarte, C.M.M.; de Sousa, H.C. Supercritical Solvent Impregnation of Ophthalmic Drugs on Chitosan Derivatives. J. Supercrit. Fluids 2008, 44, 245–257. [Google Scholar] [CrossRef]

- Dias, A.M.A.; Braga, M.E.M.; Seabra, I.J.; Ferreira, P.; Gil, M.H.; De Sousa, H.C. Development of Natural-Based Wound Dressings Impregnated with Bioactive Compounds and Using Supercritical Carbon Dioxide. Int. J. Pharm. 2011, 408, 9–19. [Google Scholar] [CrossRef] [PubMed]

- Yang, C.C.; Lin, C.C.; Liao, J.W.; Yen, S.K. Vancomycin-Chitosan Composite Deposited on Post Porous Hydroxyapatite Coated Ti6Al4V Implant for Drug Controlled Release. Mater. Sci. Eng. C 2013, 33, 2203–2212. [Google Scholar] [CrossRef] [PubMed]

- Hartmann, H.; Hossfeld, S.; Schlosshauer, B.; Mittnacht, U.; Pêgo, A.P.; Dauner, M.; Doser, M.; Stoll, D.; Krastev, R. Hyaluronic Acid/Chitosan Multilayer Coatings on Neuronal Implants for Localized Delivery of SiRNA Nanoplexes. J. Control. Release 2013, 168, 289–297. [Google Scholar] [CrossRef] [PubMed]

- Ahmed, R.A.; Fekry, A.M.; Farghali, R.A. A Study of Calcium Carbonate/Multiwalled-Carbon Nanotubes/Chitosan Composite Coatings on Ti-6Al-4V Alloy for Orthopedic Implants. Appl. Surf. Sci. 2013, 285, 309–316. [Google Scholar] [CrossRef]

- Ma, S.L.; Lu, Z.W.; Wu, Y.T.; Zhang, Z.B. Partitioning of Drug Model Compounds between Poly(Lactic Acid)s and Supercritical CO2 Using Quartz Crystal Microbalance as an in Situ Detector. J. Supercrit. Fluids 2010, 54, 129–136. [Google Scholar] [CrossRef]

- Skoczinski, P.; Carus, M.; Tweddle, G.; Ruiz, P.; de Guzman, D.; Ravenstijn, J.; Käb, H.; Hark, N.; Dammer, L.; Raschka, A. Bio-Based Building Blocks and Polymers: Global Capacities, Production and Trends 2022–2027. Ind. Biotechnol. 2023, 19, 185–194. [Google Scholar] [CrossRef]

- Docksai, R. Market for Bioplastics. Futurist 2012, 46, 9. [Google Scholar]

- de Frutos, M.Á.; Manzano, C. Market Transparency, Market Quality, and Sunshine Trading. J. Financ. Mark. 2014, 17, 174–198. [Google Scholar] [CrossRef][Green Version]

- Mülhaupt, R. Green Polymer Chemistry and Bio-Based Plastics: Dreams and Reality. Macromol. Chem. Phys. 2013, 214, 159–174. [Google Scholar] [CrossRef]

- Carus, M.; Carrez, D.; Kaeb, H.; Venus, J. Level Playing Field for Bio-Based Chemistry and Materials; Nova Institute: Melbourne, Australia, 2011; pp. 4–18. [Google Scholar]

- Gawel, E.; Pannicke, N.; Hagemann, N. A Path Transition towards a Bioeconomy—The Crucial Role of Sustainability. Sustainability 2019, 11, 3005. [Google Scholar] [CrossRef]

- Brostow, W.; Datashvili, T.; Jiang, P.; Miller, H. Recycled HDPE Reinforced with Sol-Gel Silica Modified Wood Sawdust. Eur. Polym. J. 2016, 76, 28–39. [Google Scholar] [CrossRef]

- Sun, Q.; Mekonnen, T.; Misra, M.; Mohanty, A.K. Novel Biodegradable Cast Film from Carbon Dioxide Based Copolymer and Poly(Lactic Acid). J. Polym. Environ. 2016, 24, 23–36. [Google Scholar] [CrossRef]

- Adkins, J.; Pugh, S.; McKenna, R.; Nielsen, D.R. Engineering Microbial Chemical Factories to Produce Renewable “Biomonomers”. Front. Microbiol. 2012, 3, 313. [Google Scholar] [CrossRef] [PubMed]

- Rajput, S.D.; Hundiwale, D.G.; Mahulikar, P.P.; Gite, V.V. Fatty Acids Based Transparent Polyurethane Films and Coatings. Prog. Org. Coat. 2014, 77, 1360–1368. [Google Scholar] [CrossRef]

- Maiti, B.; De, P. RAFT Polymerization of Fatty Acid Containing Monomers: Controlled Synthesis of Polymers from Renewable Resources. RSC Adv. 2013, 3, 24983–24990. [Google Scholar] [CrossRef]

- Klemm, D.; Heublein, B.; Fink, H.P.; Bohn, A. Cellulose: Fascinating Biopolymer and Sustainable Raw Material. Angew. Chem. Int. Ed. 2005, 44, 3358–3393. [Google Scholar] [CrossRef]

- Trinh, B.M.; Mekonnen, T. Hydrophobic Esterification of Cellulose Nanocrystals for Epoxy Reinforcement. Polymer 2018, 155, 64–74. [Google Scholar] [CrossRef]

- Copeland, L.; Blazek, J.; Salman, H.; Tang, M.C. Form and Functionality of Starch. Food Hydrocoll. 2009, 23, 1527–1534. [Google Scholar] [CrossRef]

- Erwin, P.; Pohlen, M.; Beckman, J.E. The Outer Disks of Early-Type Galaxies. I. Surface-Brightness Profiles of Barred Galaxies. Astron. J. 2008, 135, 20–54. [Google Scholar] [CrossRef]

- Dorozhkin, S.V. Calcium Orthophosphate-Based Biocomposites and Hybrid Biomaterials. J. Mater. Sci. 2009, 44, 2343–2387. [Google Scholar] [CrossRef]

- Rinderer, T.E.; Harris, J.W.; Hunt, G.J.; De Guzman, L.I. Breeding for Resistance to Varroa Destructor in North America. Apidologie 2010, 41, 409–424. [Google Scholar] [CrossRef]

- Chen, G.; Li, S.; Jiao, F.; Yuan, Q. Catalytic Dehydration of Bioethanol to Ethylene over TiO2/γ-Al2O3 Catalysts in Microchannel Reactors. Catal. Today 2007, 125, 111–119. [Google Scholar] [CrossRef]

- Available online: http://www.sojitz.com/en/news/2012/07/20120705.php (accessed on 3 February 2013).

- Teli, M.D.; Chiplunkar, V. Role of Thickeners in Final Performance of Reactive Prints. Text. Dye. Print. 1986, 19, 13–19. [Google Scholar]

- Qin, Y.; Cai, L.; Feng, D.; Shi, B.; Liu, J.; Zhang, W.; Shen, Y. Combined Use of Chitosan and Alginate in the Treatment of Wastewater. J. Appl. Polym. Sci. 2007, 104, 3581–3587. [Google Scholar] [CrossRef]

- Xie, Z.P.; Huang, Y.; Chen, Y.L.; Jia, Y. A New Gel Casting of Ceramics by Reaction of Sodium Alginate and Calcium Iodate at Increased Temperatures. J. Mater. Sci. Lett. 2001, 20, 1255–1257. [Google Scholar] [CrossRef]

- Timothy, F.; Devinder, M.; Iain, H. F-35 Joint Strike Fighter Structural Prognosis and Health Management an Overview. In ICAF 2009, Bridging the Gap between Theory and Operational Practice: Proceedings of the 25th Symposium of the International Committee on Aeronautical Fatigue, Rotterdam, The Netherlands, 27–29 May 2009; Springer: Dordrecht, The Netherlands, 2009. [Google Scholar]

- Sell, S.A.; Wolfe, P.S.; Garg, K.; McCool, J.M.; Rodriguez, I.A.; Bowlin, G.L. The Use of Natural Polymers in Tissue Engineering: A Focus on Electrospun Extracellular Matrix Analogues. Polymers 2010, 2, 522–553. [Google Scholar] [CrossRef]

- Holland, N.D.; Clague, D.A.; Gordon, D.P.; Gebruk, A.; Pawson, D.L.; Vecchione, M. “Lophenteropneust” Hypothesis Refuted by Collection and Photos of New Deep-Sea Hemichordates. Nature 2005, 434, 374–376. [Google Scholar] [CrossRef] [PubMed]

- Anyika, M.; Gholami, H.; Ashtekar, K.D.; Acho, R.; Borhan, B. Point-to-Axial Chirality Transfer—A New Probe for “Sensing” the Absolute Configurations of Monoamines. J. Am. Chem. Soc. 2014, 136, 550–553. [Google Scholar] [CrossRef] [PubMed]

- Patwary, S.; Maraz, K.M.; Shahida, S.; Ahmed, A.; Khan, R.A. A Review on the Properties and Applications of Biodegradable Polymers. GSC Adv. Res. Rev. 2021, 9, 13–27. [Google Scholar] [CrossRef]

- Dziuba, R.; Grabowska, K.; Wawro, D.; Wietecha, J.; Wysokińska, Z. Natural Polymers on the Global and European Market-Presentation of Research Results in the Łukasiewicz Research Network—Institute of Biopolymers and Chemical Fibers-Case Studies on the Cellulose and Chitosan Fibers. Autex Res. J. 2021, 21, 445–458. [Google Scholar] [CrossRef]

- Kukoyi, A.R. Economic Impacts of Natural Polymers. Nat. Polym. 2015, 339–362. [Google Scholar] [CrossRef]

- Samir, A.; Ashour, F.H.; Hakim, A.A.A.; Bassyouni, M. Recent Advances in Biodegradable Polymers for Sustainable Applications. Npj Mater. Degrad. 2022, 6, 68. [Google Scholar] [CrossRef]

- Stamboulis, A.; Baillie, C.A.; Garkhail, S.K.; Van Melick, H.G.H.; Peijs, T. Environmental Durability of Flax Fibres and Their Composites Based on Polypropylene Matrix. Appl. Compos. Mater. 2000, 7, 273–294. [Google Scholar] [CrossRef]

- Williams, G.I.; Wool, R.P. Composites from Natural Fibers and Soy Oil Resins. Appl. Compos. Mater. 2000, 7, 421–432. [Google Scholar] [CrossRef]

- Corbière-Nicollier, T.; Gfeller Laban, B.; Lundquist, L.; Leterrier, Y.; Månson, J.A.E.; Jolliet, O. Life Cycle Assessment of Biofibres Replacing Glass Fibres as Reinforcement in Plastics. Resour. Conserv. Recycl. 2001, 33, 267–287. [Google Scholar] [CrossRef]

- Kolybaba, M.; Tabil, L.G.; Panigrahi, S.; Crerar, W.J.; Powell, T.; Wang, B. Biodegradable Polymers: Past, Present, and Future. In ASABE/CSBE North Central Intersectional Meeting; American Society of Agricultural and Biological Engineers: St. Joseph, MI, USA, 2013. [Google Scholar]

- Percival, S.L.; Thomas, J.; Linton, S.; Okel, T.; Corum, L.; Slone, W. The Antimicrobial Efficacy of Silver on Antibiotic-Resistant Bacteria Isolated from Burn Wounds. Int. Wound J. 2012, 9, 488–493. [Google Scholar] [CrossRef]

- Narancic, T.; Cerrone, F.; Beagan, N.; O’Connor, K.E. Recent Advances in Bioplastics: Application and Biodegradation. Polymers 2020, 12, 920. [Google Scholar] [CrossRef] [PubMed]

- Tarazona, N.A.; Machatschek, R.; Balcucho, J.; Castro-Mayorga, J.L.; Saldarriaga, J.F.; Lendlein, A. Opportunities and Challenges for Integrating the Development of Sustainable Polymer Materials within an International Circular (Bio)Economy Concept. MRS Energy Sustain. 2022, 9, 28–34. [Google Scholar] [CrossRef] [PubMed]

- Farber, T.M.; Clewell, A.E.; Endres, J.R.; Hauswirth, J.; Van Gemert, M.; Schauss, A.G.; Sheane, C.A. Safety Assessment of a Novel Ingredient for Removable Chewing Gum. Food Chem. Toxicol. 2010, 48, 831–838. [Google Scholar] [CrossRef] [PubMed][Green Version]

- Jamshidian, M.; Jalal, S.; Jansen, C. MissMech: An R Package for Testing Homoscedasticity, Multivariate Normality, and Missing Completely at Random (MCAR). J. Stat. Softw. 2014, 56, 1–31. [Google Scholar] [CrossRef]

- Darge, H.F.; Andrgie, A.T.; Tsai, H.C.; Lai, J.Y. Polysaccharide and Polypeptide Based Injectable Thermo-Sensitive Hydrogels for Local Biomedical Applications. Int. J. Biol. Macromol. 2019, 133, 545–563. [Google Scholar] [CrossRef] [PubMed]

- Tchobanian, A.; Van Oosterwyck, H.; Fardim, P. Polysaccharides for Tissue Engineering: Current Landscape and Future Prospects. Carbohydr. Polym. 2019, 205, 601–625. [Google Scholar] [CrossRef] [PubMed]

- Pandya, U.; Dhuldhaj, U.; Sahay, N.S. Bioactive Mushroom Polysaccharides as Antitumor: An Overview. Nat. Prod. Res. 2019, 33, 2668–2680. [Google Scholar] [CrossRef] [PubMed]

- Maciel, J.V.; Durigon, A.M.M.; Souza, M.M.; Quadrado, R.F.N.; Fajardo, A.R.; Dias, D. Polysaccharides Derived from Natural Sources Applied to the Development of Chemically Modified Electrodes for Environmental Applications: A Review. Trends Environ. Anal. Chem. 2019, 22, e00062. [Google Scholar] [CrossRef]

- Layek, B.; Mandal, S. Natural Polysaccharides for Controlled Delivery of Oral Therapeutics: A Recent Update. Carbohydr. Polym. 2020, 230, 115617. [Google Scholar] [CrossRef]

- Gopinath, V.; Saravanan, S.; Al-Maleki, A.R.; Ramesh, M.; Vadivelu, J. A Review of Natural Polysaccharides for Drug Delivery Applications: Special Focus on Cellulose, Starch and Glycogen. Biomed. Pharmacother. 2018, 107, 96–108. [Google Scholar] [CrossRef]

- Saidin, N.M.; Anuar, N.K.; Meor Mohd Affandi, M.M.R. Roles of Polysaccharides in Transdermal Drug Delivery System and Future Prospects. J. Appl. Pharm. Sci. 2018, 8, 141–157. [Google Scholar]

- Van Dam, J.E.G.; Van Den Broek, L.A.M.; Boeriu, C.G. Polysaccharides in Human Health Care. Nat. Prod. Commun. 2017, 12, 1934578X1701200604. [Google Scholar] [CrossRef]

| Source | Polymer |

|---|---|

| Cells walls of plants | Pectin |

| Seeds and roots | Galactomannans |

| Seaweeds | Carragenans, alginates, agar |

| Animal cell walls | Hyaluronan |

| Shells of aquatic animals | Chitin |

| Wood | Cellulose, lignin, hemicellulose |

| Skins and bones of animals and scales of fish | Gelatin |

| Bacteria | Xanthan, hyaluronan, gellan |

| Fungi | Cardlan, scleroglucan, schizophylla |

| Synthetic Polymer | Natural Polymer | Compatibilizer | Processing Technique | Reference |

|---|---|---|---|---|

| Polypropylene | Sawdust | Maleic anhydride | Extrusion | [14] |

| Polypropylene | Wood fibers | Ethylene–propylene or ethylene–propylidene copolymer Maleate polypropylene Calcium stearate | Injection forming | [46] |

| Low density polyethylene | Lignocellulosic fibers Sawdust | Ionomer polyethylene Maleate polypropylene Low molecular weight polypropylnene Maleic anhydride | Extrusion Injection | [46] |

| Polyurethane | Mechanical pulp | Isocyanates | Pressing | [46] |

| Phenol formaldehyde | Lignocellulose | Chemical modified fibers | Pressing | [46] |

| Polyester + PE + PP | Wood fibers | Phenol resins | Pressing | [46] |

| Carboxylated Nitrile Rubber | Natural rubber | Maleic anhydride grafted polyisoprene epoxy resin | Roll milling | [47] |

| Chlorinated Polyethylene | Natural rubber | Maleic anhydrided grafted ethylene propylene diene rubber EPDM-g-MA | Thermal mixing followed by roll milling | [48] |

| Carboxylated nitrile rubber | Natural rubber | Bis(disopropyl) thiophosphoryl polysulfides | Thermal mixing followed by roll milling | [49] |

| Poly(lactic acid) | Natural rubber | Poly(lactic acid)- natural rubber tri block copolymer | [50] |

| Botanical | Plants | Starch, pectin, cellulose |

| Trees | Cellulose | |

| Tree gum exudates | Gum arabic (acasia), gum tragacanth, karaya | |

| Seeds | Guar gum, tara gum, locust bean gum, | |

| Tubers | Konjac mannan (glucomannan), potato starch | |

| Algal | Red seaweed | Agar, carrageenan |

| Brown seaweed | Alginate | |

| Microbial | Xanthan gum, dextran, gellan gum, cellulose | |

| Animal | Gelatin, caseinate, whey protein, chitosan |

| Claim | Hydrocolloid |

|---|---|

| Maintenance of normal blood cholesterol concentrations | Beta-glucan, konjacmannan glucomannan, pectins, guar gum |

| Maintenance or achievement of a normal body weight | Konjacmannan glucomannan |

| Reduction in postprandial glycemic responses | Beta-glucan, pectins |

| Polymer | API/Implant | References |

|---|---|---|

| Chitosan | Flurbiprofen | [133] |

| Timolol maleaic | [133] | |

| Thymol | [134] | |

| Quercetin | [134] | |

| Dexamethason | [133] | |

| Vancomycin | [135] | |

| Hyaluronic acid/chitosan multilayer coating | Chitosan Imidazole/siRNA nanoplex | [136] |

| Chitosan/carbonnanotube | Titanium implant | [137] |

| Collagen/cellulose | Juca extract | [138] |

| Agarose | Thymolol | [134] |

| Quercetin | ||

| Poly (Lactic acid) | Ibuprofen | [138] |

| Acetylsalicylic acid |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Benalaya, I.; Alves, G.; Lopes, J.; Silva, L.R. A Review of Natural Polysaccharides: Sources, Characteristics, Properties, Food, and Pharmaceutical Applications. Int. J. Mol. Sci. 2024, 25, 1322. https://doi.org/10.3390/ijms25021322

Benalaya I, Alves G, Lopes J, Silva LR. A Review of Natural Polysaccharides: Sources, Characteristics, Properties, Food, and Pharmaceutical Applications. International Journal of Molecular Sciences. 2024; 25(2):1322. https://doi.org/10.3390/ijms25021322

Chicago/Turabian StyleBenalaya, Ikbel, Gilberto Alves, João Lopes, and Luís R. Silva. 2024. "A Review of Natural Polysaccharides: Sources, Characteristics, Properties, Food, and Pharmaceutical Applications" International Journal of Molecular Sciences 25, no. 2: 1322. https://doi.org/10.3390/ijms25021322

APA StyleBenalaya, I., Alves, G., Lopes, J., & Silva, L. R. (2024). A Review of Natural Polysaccharides: Sources, Characteristics, Properties, Food, and Pharmaceutical Applications. International Journal of Molecular Sciences, 25(2), 1322. https://doi.org/10.3390/ijms25021322