Microstructural and Mechanical Characterization of Al Nanocomposites Using GCNs as a Reinforcement Fabricated by Induction Sintering

Abstract

1. Introduction

2. Results

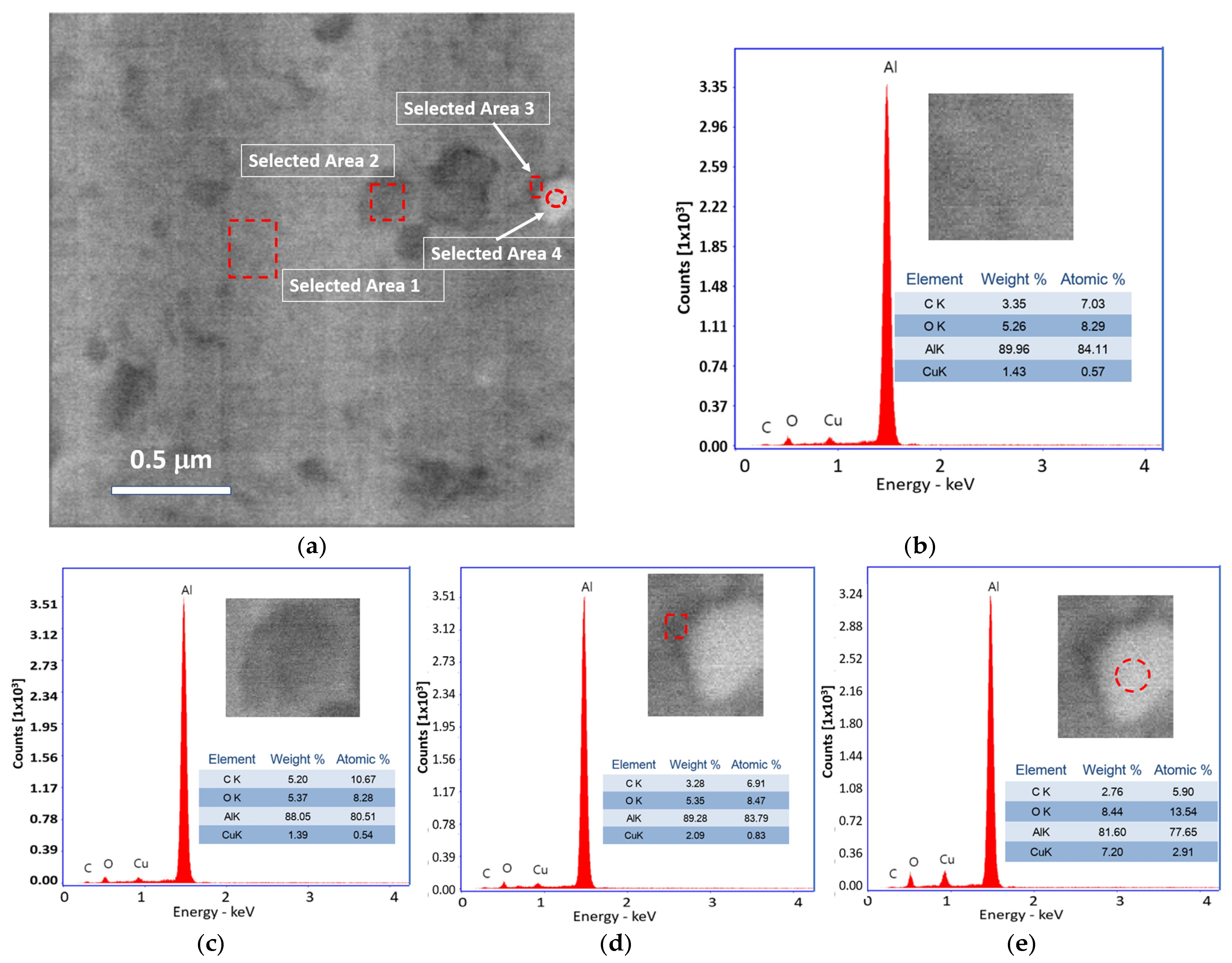

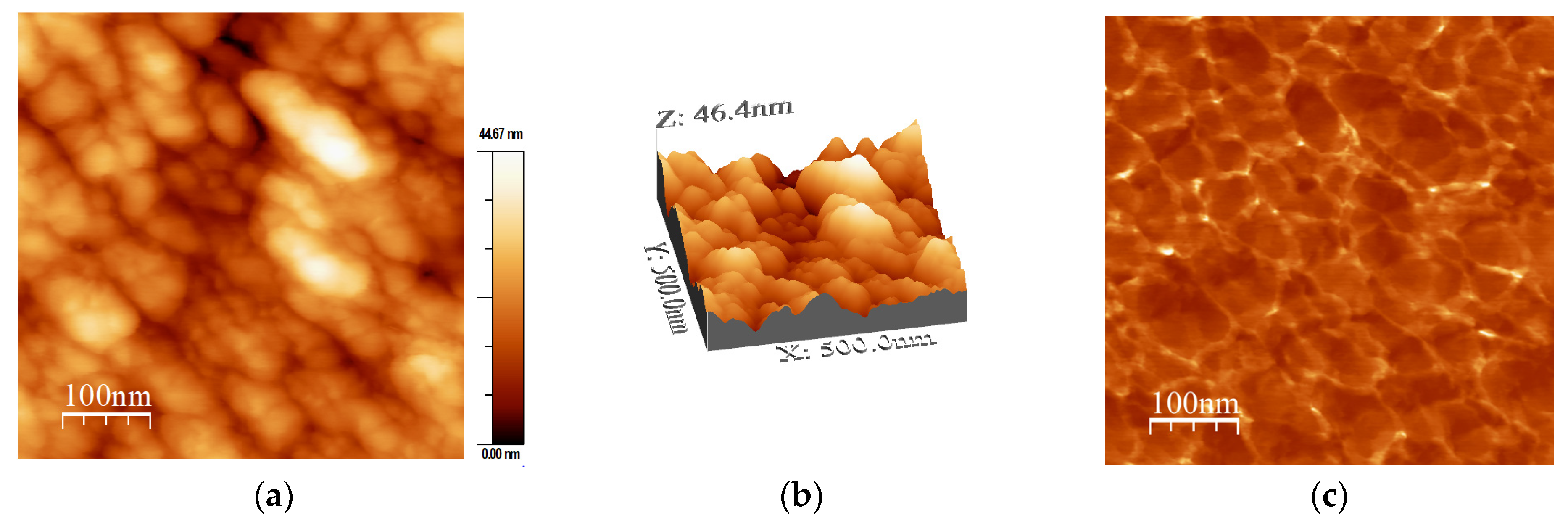

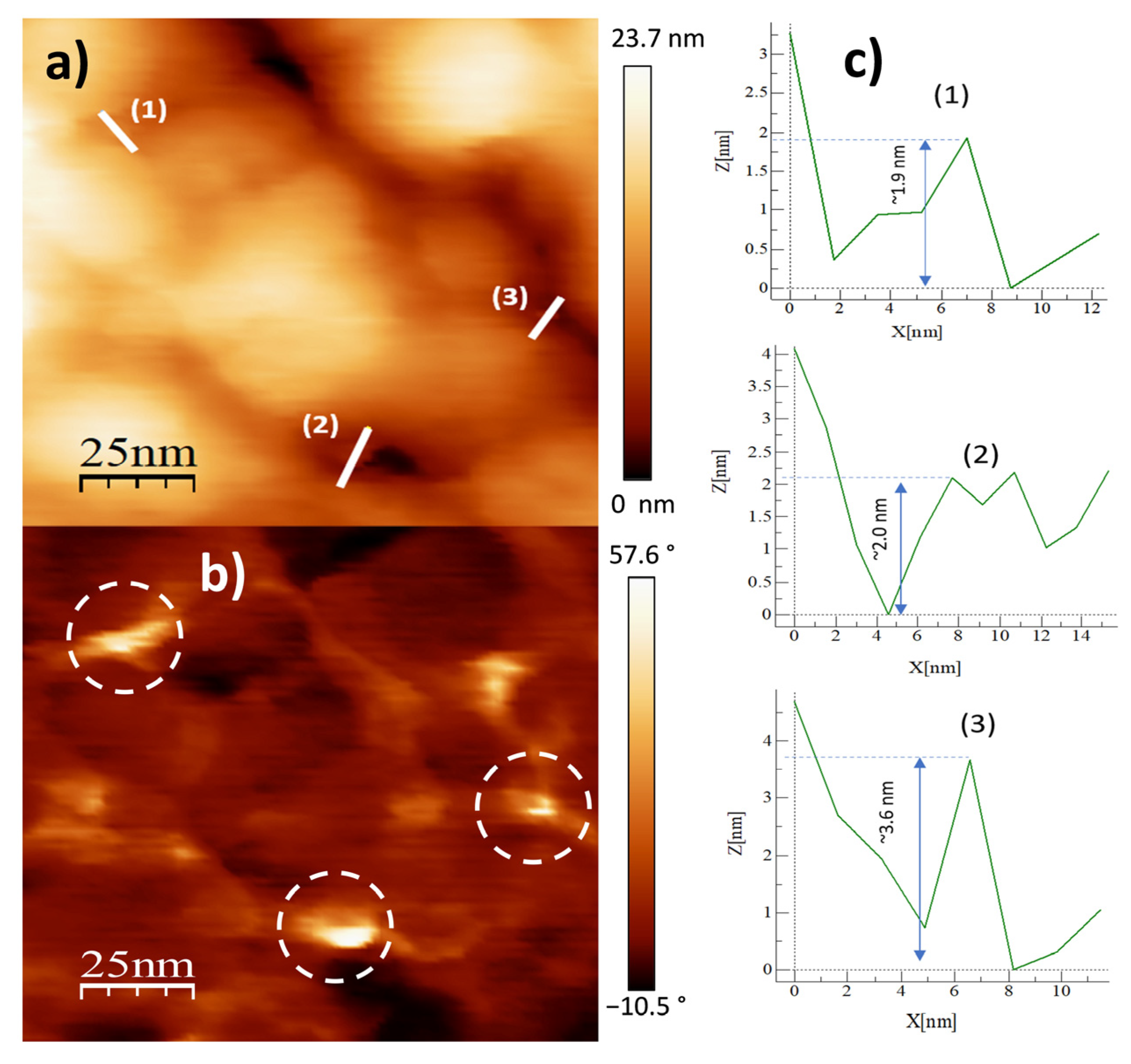

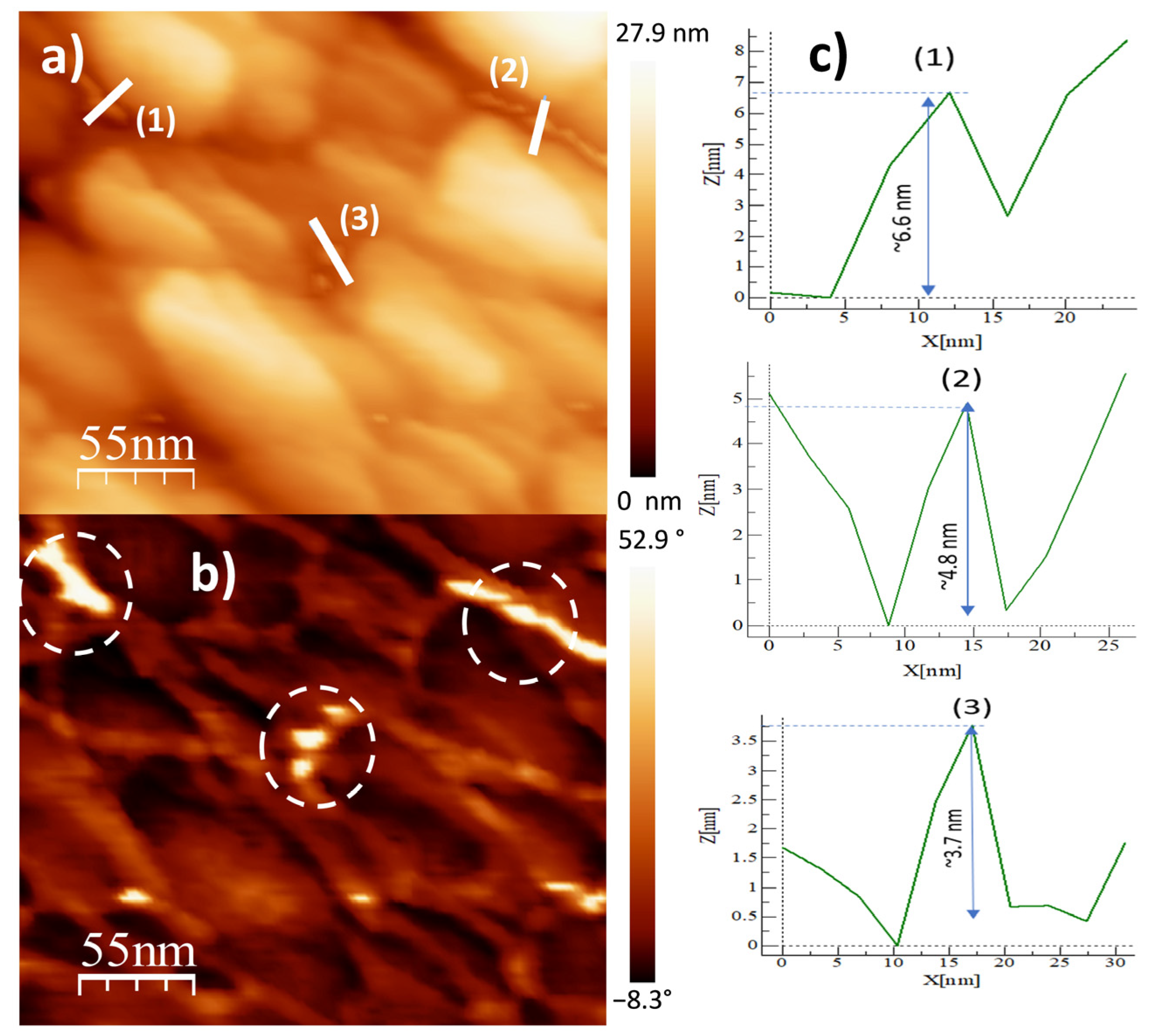

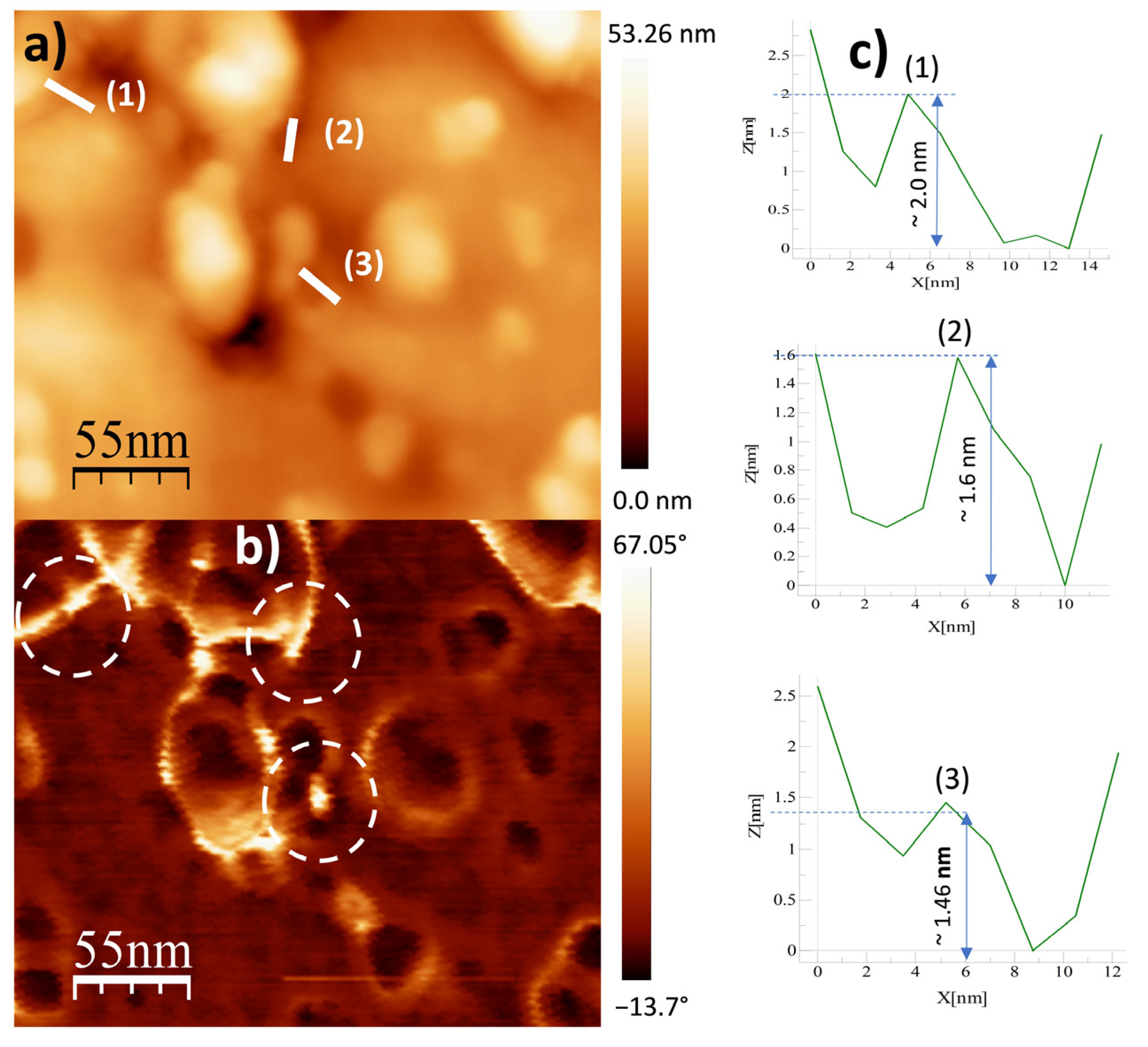

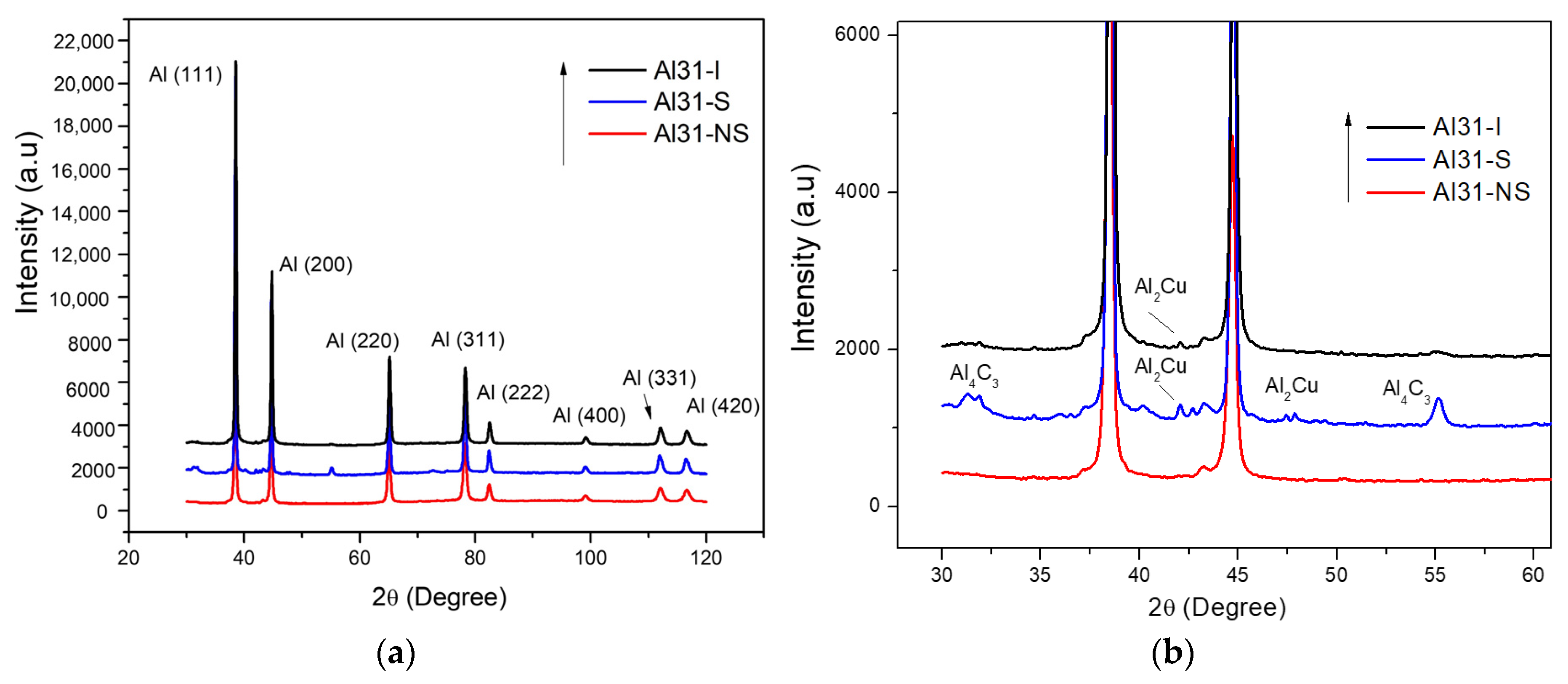

2.1. Microstructural Analysis

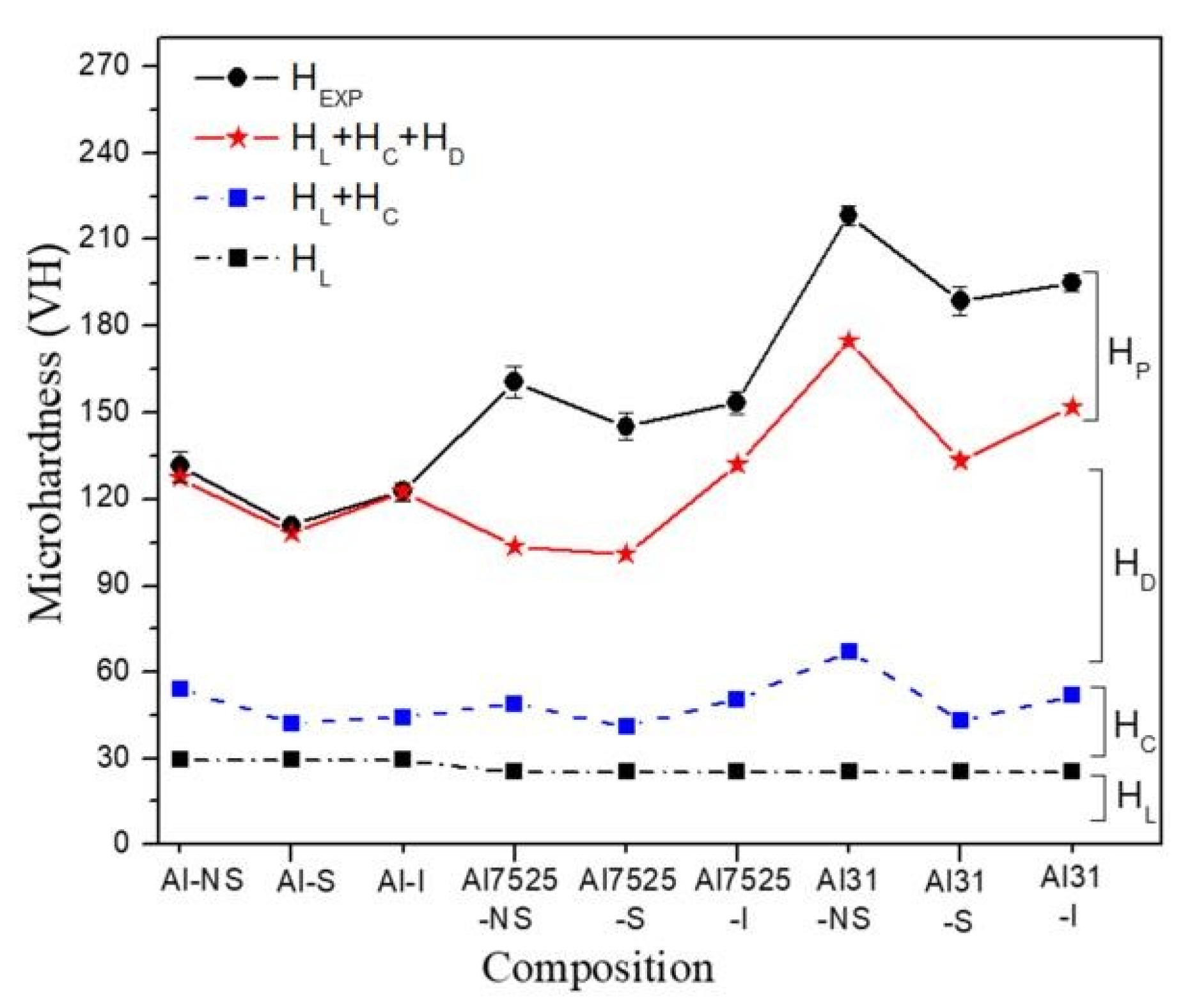

2.2. Hardness Contribution Analysis

3. Discussion

4. Materials and Methods

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Joy, J.; Krishnamoorthy, A.; Tanna, A.; Kamathe, V.; Nagar, R.; Srinivasan, S. Recent Developments on the Synthesis of Nanocomposite Materials via Ball Milling Approach for Energy Storage Applications. Appl. Sci. 2022, 12, 9312. [Google Scholar] [CrossRef]

- Estrada-Guel, I.; Anderson-Okonkwo, O.; Robles-Hernandez, F.C. In-Situ Transformation of Amorphous Soot into Carbon-Nanostructures by High Energy Ball Milling. Microsc. Microanal. 2016, 22 (Suppl. 3), 1902–1903. [Google Scholar] [CrossRef]

- Mendoza-Duarte, J.M.; Estrada-Guel, I.; Carreño-Gallardo, C.; Martínez-Sánchez, R. Study of Al composites prepared by high-energy ball milling. Eff. Process. Cond. 2015, 643 (Suppl. 1), S172–S177. [Google Scholar] [CrossRef]

- Chen, X.H.; Yang, H.S.; Wu, G.T.; Wang, M.; Deng, F.M.; Zhang, X.B.; Peng, J.C.; Li, W.Z. Generation of curved or closed-shell carbon nanostructures by ball-milling of graphite. J. Cryst. Growth 2000, 218, 57–61. [Google Scholar] [CrossRef]

- Ramírez-Cano, P.G.; Estrada-Guel, I.; Mendoza-Ruiz, D.C.; Reyes-Gasga, J.; Yacamán, M.J.; Márquez-Lucero, A.; Martínez-Sánchez, R. Mechanical and structural characterization of graphite coated silver nanoparticles-reinforced aluminum. Rev. Adv. Mater. Sci. 2000, 218, 276–279. [Google Scholar]

- Robles Hernández, F.C.; Calderon, H.A. Nanostructured Al/Al4C3 composites reinforced with graphite or fullerene and man- ufactured. by mechanical milling and spark plasma sintering. Mater. Chem. Phys. 2012, 132, 815–822. [Google Scholar] [CrossRef]

- Liu, Y.; Chen, G.; Zhang, H.; Yang, C.; Zhang, S.; Liu, Q.; Zhou, M.; Shi, Q. In situ exfoliation of graphite for fabrication of graphene/aluminum composites by friction stir processing. Mater. Lett. 2021, 301, 130280. [Google Scholar] [CrossRef]

- Bastwros, M.; Kim, G.-Y.; Zhu, C.; Zhang, K.; Wang, S.; Wang, X. Effect of ball milling on graphen e reinforced Al6061 composite fabricated by semi-solid sintering. Compos. Part B 2014, 60, 111–118. [Google Scholar] [CrossRef]

- Mendoza-Duarte, J.M.; Robles-Hernandez, F.C.; Carreño-Gallardo, C.; Estrada-Guel, I.; Martínez-Sánchez, R. Al-Graphite Com-posites Prepared by Powder Metallurgy Applying an Innovative Sintering Route; Which Avoids Carbides Formation. Microsc. Microanal. 2018, 24 (Suppl. 1), 2286–2287. [Google Scholar] [CrossRef]

- Ujah, C.O.; Kallon, D.V.V. Trends in Aluminium Matrix Composite Development. Crystals 2022, 12, 1357. [Google Scholar] [CrossRef]

- Balogh, L.; Ungár, T.; Zhao, Y.; Zhu, Y.T.; Horita, Z.; Xu, C.; Langdon, T.G. Influence of stacking fault energy on microstructural characteristics of ultrafine-grain copper and copper–zinc alloys. Acta Mater. 2009, 56, 809–820. [Google Scholar] [CrossRef]

- Balogh, L.; Nauyoks, S.; Zerda, T.W.; Pantea, C.; Stelmakh, S.; Palosz, B.; Ungár, T. Structure of diamond–silicon carbide nano- composites as a function of sintering temperature at 8GPa. Mater. Sci. Eng. A 2008, 487, 180–188. [Google Scholar] [CrossRef]

- Cahn, R.W.; Haasen, P.; Argon, A.S. Physical Metallurgy. Mechanical Properties of Single Phase; Elsevier: Amsterdam, The Netherlands, 1996. [Google Scholar]

- Goussous, S.; Xu, W.; Wu, X.; Xia, K. Al-C nanocomposites consolidated by back pressure equal channel angular pressing. Compos. Sci. Technol. 2009, 69, 1997–2001. [Google Scholar] [CrossRef]

- Arik, H. Effect of mechanical alloying process on mechanical properties of α-Si3N4 reinforced aluminum-based composite materials. Mater. Design 2008, 29, 1856–1861. [Google Scholar] [CrossRef]

- Gallegos-Orozco, V.; Santos-Beltrán, A.; Santos-Beltrán, M.; Medrano-Prieto, H.; Gallegos-Orozco, C.; Estrada-Guel, I. Effect on Microstructure and Hardness of Reinforcement in Al–Cu with Al4C3 Nanocomposites. Metals 2021, 11, 1203. [Google Scholar] [CrossRef]

- Khakbiz, M.; Akhlaghi, F. Synthesis and structural characterization of Al–B4C nano-composite powders by mechanical alloying. J. Alloy. Compd. 2009, 479, 334–341. [Google Scholar] [CrossRef]

- Abdoli, H.; Asgharzadeh, H.; Salahi, E. Sintering behavior of al-aln nano structured composite powder synthesized by high energy ball milling. J. Alloy. Compd. 2009, 473, 116–122. [Google Scholar] [CrossRef]

- Woo, W.; Balogh, L.; Ungár, T.; Choo, H.; Feng, Z. Grain structure and dislocation density measurements in a friction -stir welded aluminum alloy using X-ray peak profile analysis. Mater. Sci. Eng. A Struct. 2008, 498, 308–313. [Google Scholar] [CrossRef]

- Santos-Beltrán, V.; Gallegos-Orozco, R.; Reyes, G.; Miki-Yoshida, M.; Estrada-Guel, I.; Martínez-Sánchez, R. Mechanical and microstructural characterization of dispersion strengthened Al–C system nanocomposites. J. Alloy. Compd. 2010, 489, 626–630. [Google Scholar] [CrossRef]

- Wang, R.; Han, Y.; Yu, H.; Su, Q.; Li, H.; Cheng, K.; Zhou, J.; Tang, S.; Ju, W. Exceptional Strengthening Efficiency and Har dness of Ti/Mg-9Al-Zn-0.3Mn Matrix Composite. Materials 2022, 15, 7075. [Google Scholar] [CrossRef]

- Feijoo, I.; Pena, G.; Cristóbal, M.J.; Cabeza, M.; Rey, P. Effect of Carbon Nanotube Content and Mechanical Milling Conditions on the Manufacture of AA7075/MWCNT Composites. Metals 2022, 12, 1020. [Google Scholar] [CrossRef]

- Matweb Material Properties Data. Aluminum. Al. Available online: https://www.matweb.com/search/DataSheet.aspx?MatGUID=0cd1edf33ac145ee93a0aa6fc666c0e0 (accessed on 20 December 2022).

- Huang, K.; Logé, R.E.; LMTM—PX Group Chair; Ecole Polytechnique Fédérale de Lausanne (EPFL). Zener Pinning; Elsevier: Neuchâtel, Switzerland, 2016. [Google Scholar] [CrossRef]

- Matvienko, O.; Daneyko, O.; Kovalevskaya, T.; Khrustalyov, A.; Zhukov, I.; Vorozhtsov, A. Investigation of Stresses Induced Due to the Mismatch of the Coefficients of Thermal Expansion of the Matrix and the Strengthening Particle in Aluminum Based Composites. Metals 2021, 11, 279. [Google Scholar] [CrossRef]

- Santos Beltrán, A.; Gallegos Orozco, V.; Santos Beltrán, M.; Gómez Esparza, C.; Ronquillo Ornelas, I.; Gallego s Orozco, C.; Ledezma Beng, L.E.; Martínez Sánchez, R. Statistic al and Microstructural Analyses of Al–C–Cu. Composites Synthesized Using the State Solid Route. Materials 2021, 14, 1969. [Google Scholar] [CrossRef] [PubMed]

- Nie, J.H.; Jia, C.C.; Shi, N.; Zhang, Y.F.; Li, Y.; Jia, X. Aluminum matrix composites reinforced by molybdenum-coated carbon nanotubes. Int. J. Miner. Metall. Mater. 2011, 18, 695–702. [Google Scholar] [CrossRef]

- Wang, X.; Xiao, W.; Wang, J.; Sun, L.; Shi, J.; Guo, H.; Liu, Y.; Wang, L. Enhanced interfacial strength of graphene reinforced aluminum composites via X (Cu; Ni; Ti)-coating: Molecular-dynamics insights. Adv. Powder Technol. 2021, 32, 2585–2590. [Google Scholar] [CrossRef]

- Yang, S.; Zhuo, K.; Sun, D.; Wang, X.; Wang, J. Preparation of graphene by exfoliating graphite in aqueous fulvic acid solution and its application in corrosion protection of aluminum. J. Colloid Interface Sci. 2019, 543, 263–272. [Google Scholar] [CrossRef]

- Wang, J.; Guo, L.-n.; Lin, W.-m.; Chen, J.; Liu, C.-l.; Chen, S.-d.; Zhang, S.; Zhen, T.-t. Effect of the graphene content on the microstructures and properties of graphene/aluminum composites. New Carbon Mater. 2019, 34, 275–285. [Google Scholar] [CrossRef]

- Dixit, S.; Mahata, A.; Mahapatra, D.R.; Kailas, S.V.; Chattopadhyay, K. Multi-layer graphene reinforced aluminum—Manufacturing of high strength composite by friction stir alloying, Composites. Part B Eng. 2018, 136, 63–71. [Google Scholar] [CrossRef]

- Chen, W.; Yang, T.; Dong, L.; Elmasry, A.; Song, J.; Deng, N.; Elmarakbi, A.; Liu, T.; Lv, H.B.; Fu, Y.Q. Advances in graphene reinforced metal matrix nanocomposites: Mechanisms, processing, modelling, properties and applications. Nanotechnol. Precis. Eng. 2020, 3, 189–210. [Google Scholar] [CrossRef]

- Meyers, M.A.; Mishra, A.; Benson, D.J. Mechanical properties of nanocrystalline materials. Prog. Mater. Sci. 2006, 51, 427–556. [Google Scholar] [CrossRef]

- Horcas, I.; Fernandez, R.; Gomez-Rodriguez, J.M.; Colchero, J.; Gomez-Herrero, J.; Baro, A.M. WSXM: A2 software for scanning probe microscopy and a tool for nanotechnology. Rev. Sci. Instrum. 2007, 78, 13705. [Google Scholar] [CrossRef] [PubMed]

| Sample | ρ (×10−14 m−2) | d (nm) |

|---|---|---|

| Al-NS | 24.6 | 51.5 |

| Al-S | 18.9 | 90.9 |

| Al-I | 27.3 | 82.6 |

| Al7525-NS | 12.5 | 51.9 |

| Al7525-S | 14.0 | 72.3 |

| Al7525-I | 24.3 | 49.4 |

| Al31-NS | 39.0 | 30.0 |

| Al31-S | 33.6 | 68.7 |

| Al31-I | 32.6 | 47.7 |

| Sample | HL (VH) | HC (VH) | HD (VH) | HP HEXP − (HL + HC + HD) (VH) | HEXP (VH) | Std Dev. |

|---|---|---|---|---|---|---|

| Al-NS | 29.48 | 24.8 | 73.2 | 4.03 | 131.54 | 5.22 |

| Al-S | 29.48 | 12.9 | 65.7 | 2.6 | 110.77 | 1.49 |

| Al-I | 29.48 | 14.7 | 78.4 | –0.02 | 122.6 | 3.09 |

| Al7525-NS | 25.3 | 23.6 | 54.5 | 57.1 | 160.62 | 5.42 |

| Al7525-S | 25.3 | 15.7 | 59.7 | 44.3 | 145.11 | 4.64 |

| Al7525-I | 25.3 | 25.2 | 81.4 | 21.5 | 153.4 | 3.96 |

| Al31-NS | 25.3 | 41.9 | 107.9 | 43.3 | 218.44 | 3.24 |

| Al31-S | 25.3 | 17.7 | 90.4 | 55.3 | 188.83 | 4.79 |

| Al31-I | 25.3 | 26.54 | 100.1 | 43.2 | 195.16 | 2.85 |

| Sample | NS | Std Dev. | CFS | Std Dev. | HFIS | Std Dev. |

|---|---|---|---|---|---|---|

| Al | 131.54 | 5.22 | 110.77 | 1.49 | 122.6 | 3.09 |

| Al-75/25 | 160.62 | 5.42 | 145.11 | 4.64 | 153.4 | 3.96 |

| Al-31 | 218.44 | 3.24 | 188.83 | 4.79 | 195.16 | 2.85 |

| Composition | Tensile Strength, σmax (MPa) | Microhardness (VH) | Method | Refs. |

|---|---|---|---|---|

| Al- 3 wt. %GNP/Cu | - | ~195 | Mechanical milling and sintered by HFIS | This work |

| Al- 0.5 wt. %graphene | ~131 | ~50 | Field-activated and pressure-assisted synthesis (FAPAS) | [30] |

| 2024Al- 5 wt. %graphite | - | ~117 | Fraction stir processing (FSP) | [7] |

| Al- 23 wt. %multilayer graphite | ~147 | ~48 | Friction stir alloying (FSA) | [31] |

| 1060Al- 1.5 wt. % graphene | 497 | 165 * | Deformation-driven metallurgy (DDM) | [32] |

| Al | C | Cu | Not Sintered (Green) | Sintered (CSF) | Sintered (HFIS) |

|---|---|---|---|---|---|

| 100.0 | 0.0 | 0.0 | Al-NS | Al-S | Al-I |

| 99.0 | 0.75 | 0.25 | Al7525-NS | Al7525-S | Al7525-I |

| 96.0 | 3.0 | 1.0 | Al31-NS | Al31-S | Al31-I |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Orozco, V.G.; Beltrán, A.S.; Beltrán, M.S.; Prieto, H.M.; Orozco, C.G.; Guel, I.E.; Sánchez, R.M.; Duarte, J.M.M. Microstructural and Mechanical Characterization of Al Nanocomposites Using GCNs as a Reinforcement Fabricated by Induction Sintering. Int. J. Mol. Sci. 2023, 24, 5558. https://doi.org/10.3390/ijms24065558

Orozco VG, Beltrán AS, Beltrán MS, Prieto HM, Orozco CG, Guel IE, Sánchez RM, Duarte JMM. Microstructural and Mechanical Characterization of Al Nanocomposites Using GCNs as a Reinforcement Fabricated by Induction Sintering. International Journal of Molecular Sciences. 2023; 24(6):5558. https://doi.org/10.3390/ijms24065558

Chicago/Turabian StyleOrozco, Verónica Gallegos, Audel Santos Beltrán, Miriam Santos Beltrán, Hansel Medrano Prieto, Carmen Gallegos Orozco, Ivanovich Estrada Guel, Roberto Martínez Sánchez, and José Manuel Mendoza Duarte. 2023. "Microstructural and Mechanical Characterization of Al Nanocomposites Using GCNs as a Reinforcement Fabricated by Induction Sintering" International Journal of Molecular Sciences 24, no. 6: 5558. https://doi.org/10.3390/ijms24065558

APA StyleOrozco, V. G., Beltrán, A. S., Beltrán, M. S., Prieto, H. M., Orozco, C. G., Guel, I. E., Sánchez, R. M., & Duarte, J. M. M. (2023). Microstructural and Mechanical Characterization of Al Nanocomposites Using GCNs as a Reinforcement Fabricated by Induction Sintering. International Journal of Molecular Sciences, 24(6), 5558. https://doi.org/10.3390/ijms24065558