Comparative Study of Biochar from Different Biomass Feedstocks: Toward Sustainable Resource Utilization and Environmental Applications

Abstract

1. Introduction

2. Results and Discussion

2.1. Proximate and Ultimate Analysis

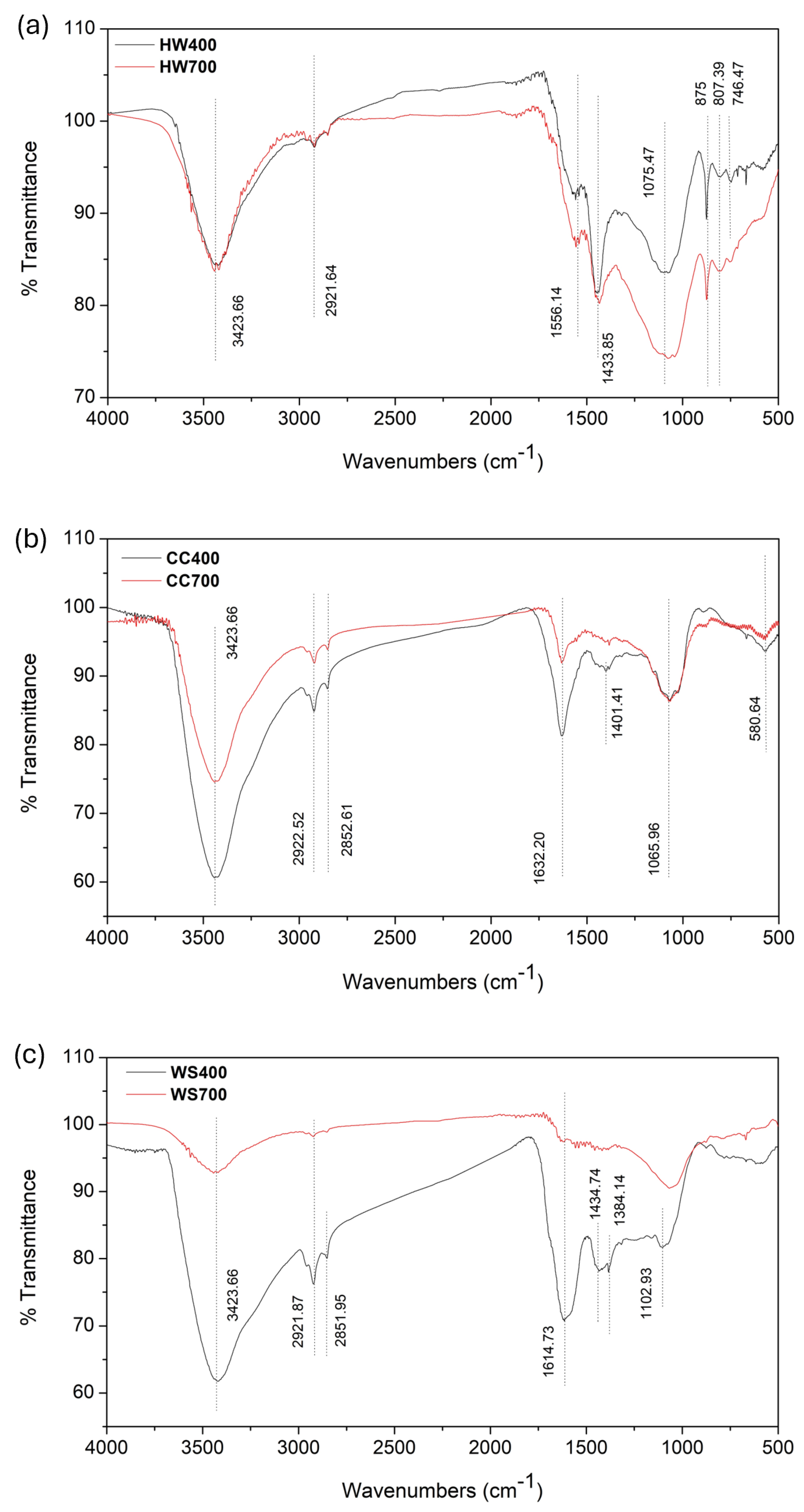

2.2. Fourier Transform Infrared Spectroscopy (FTIR)

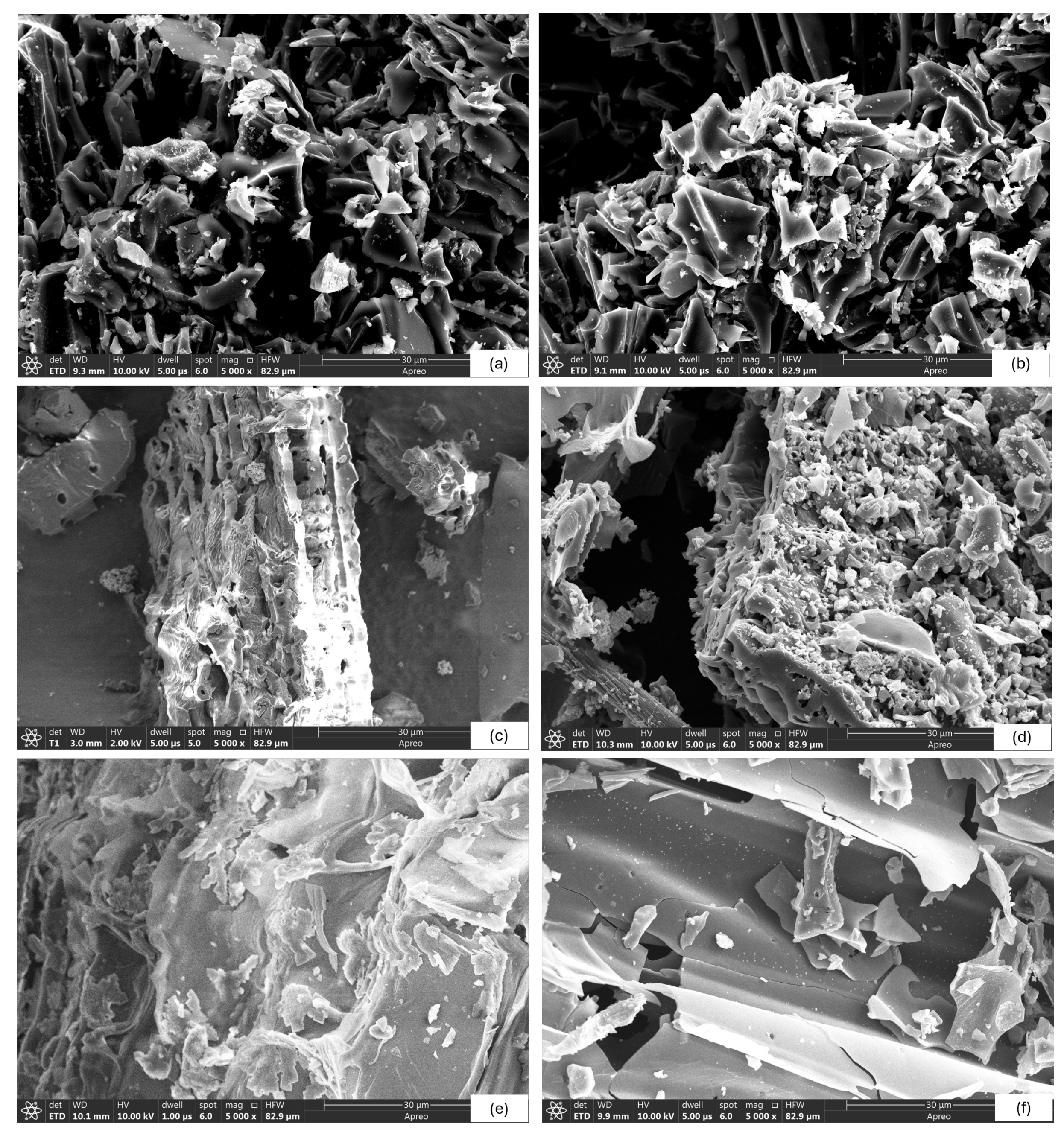

2.3. Scanning Electron Microscopy (SEM), Specific Surface Area (SSA), and EDS Observations

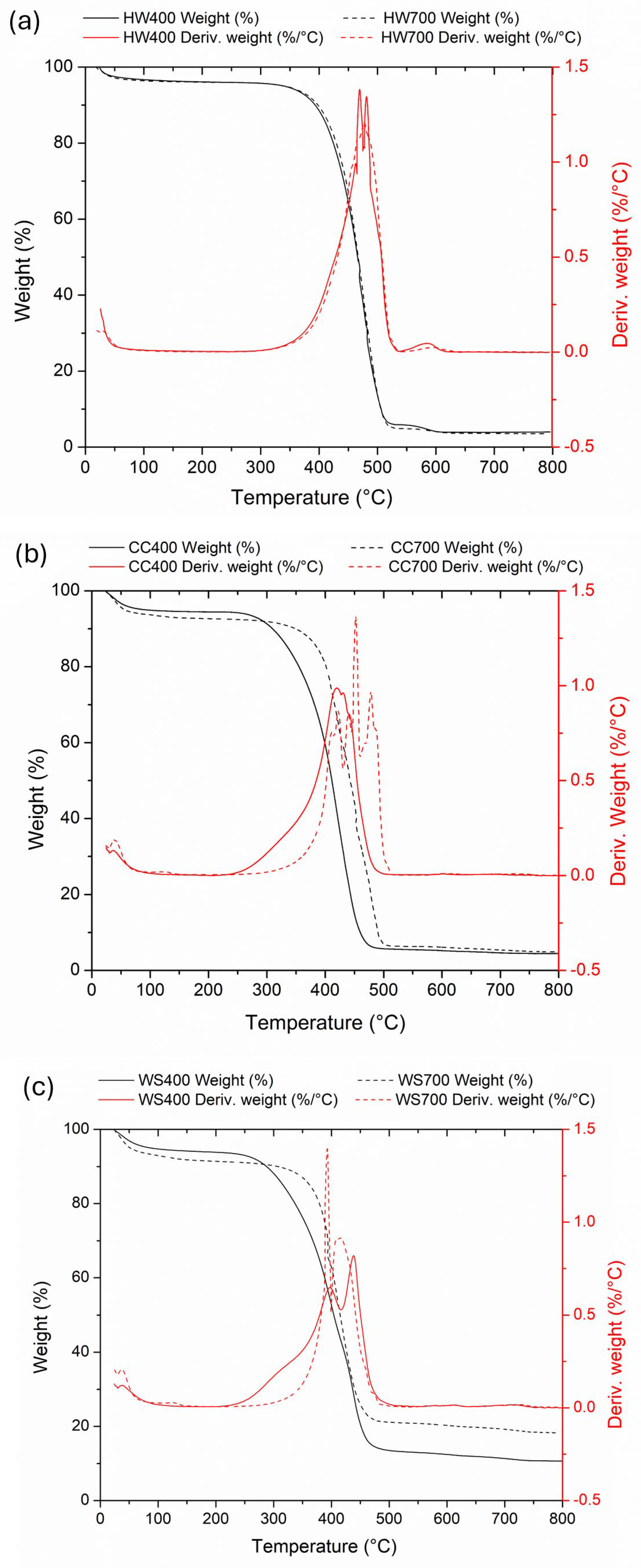

2.4. Thermal Stability Analysis by TGA-dTG

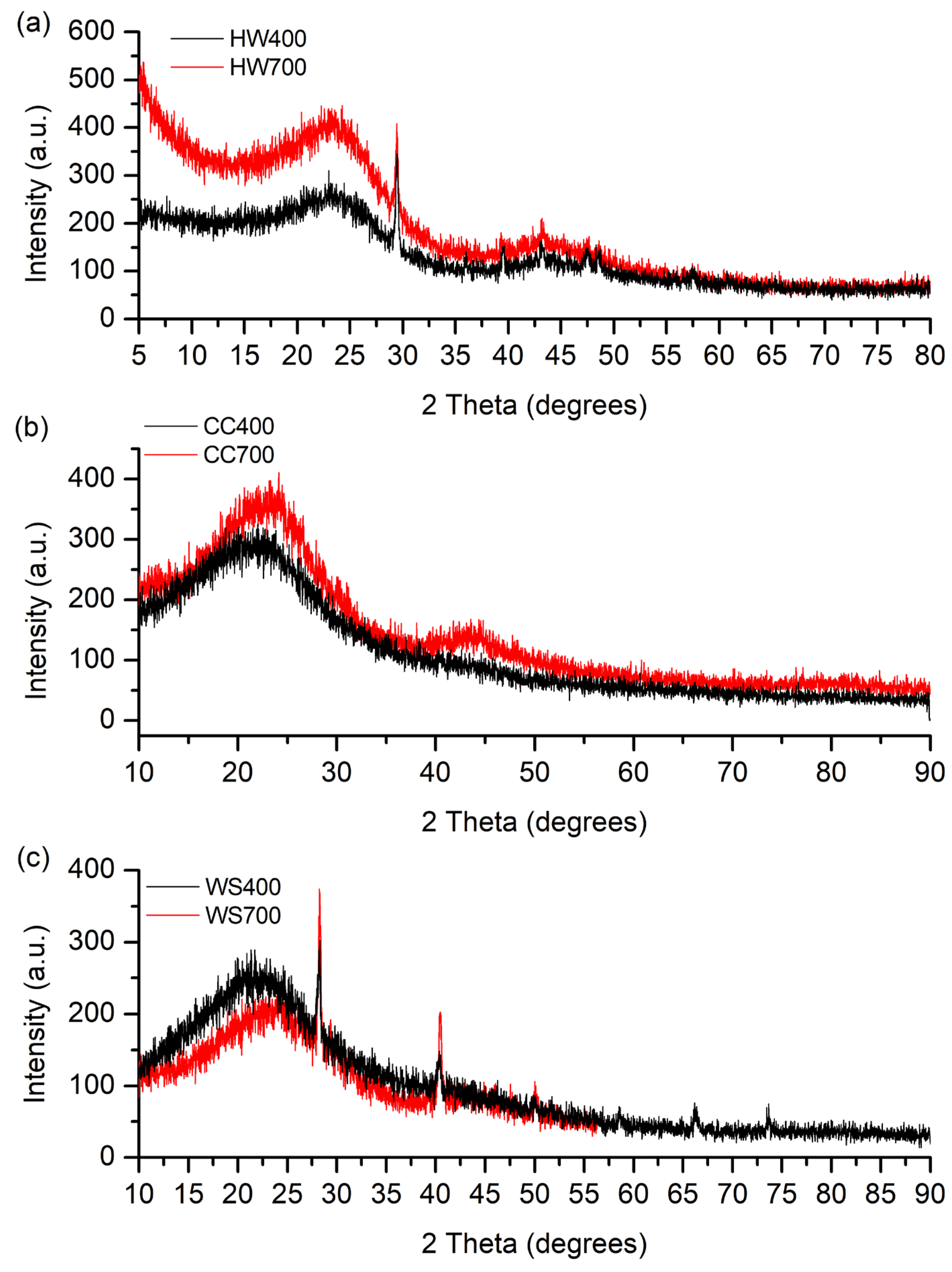

2.5. XRD Analysis

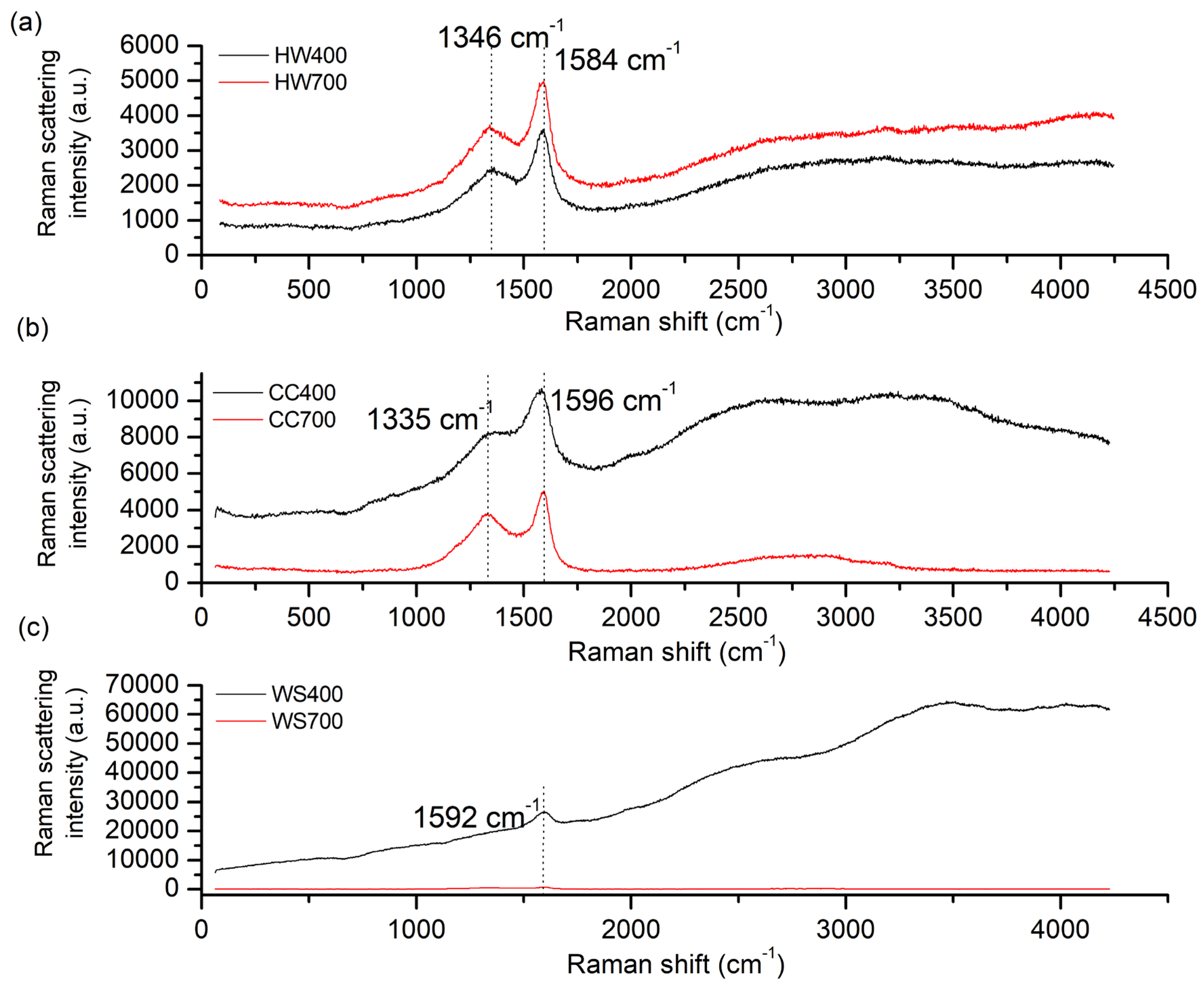

2.6. Raman Spectroscopy

3. Application of Biochars Based on Results of Characterization

4. Materials and Methods

4.1. Feedstock and Biochar Preparation

4.2. Biochar Characterization

4.3. pH

4.4. Moisture, Volatile Matter, and Ash Content

4.5. CHNS

4.6. FTIR

4.7. SEM

4.8. BET

4.9. XRD

4.10. Raman

4.11. TGA

4.12. EDS

4.13. Higher Heating Values (HHVs)

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zhang, H.; Cheng, Y.; Zhong, Y.; Ni, J.; Wei, R.; Chen, W. Roles of biochars’ properties in their water-holding capacity and bound water evaporation: Quantitative importance and controlling mechanism. Biochar 2024, 6, 30. [Google Scholar] [CrossRef]

- Afshar, M.; Mofatteh, S. Biochar for a sustainable future: Environmentally friendly production and diverse applications. Results Eng. 2024, 23, 102433. [Google Scholar] [CrossRef]

- Amalina, F.; Razak, A.S.A.; Krishnan, S.; Sulaiman, H.; Zularisam, A.W.; Nasrullah, M. Advanced techniques in the production of biochar from lignocellulosic biomass and environmental applications. Clean. Mater. 2024, 6, 100137. [Google Scholar] [CrossRef]

- Liang, L.P.; Xi, F.F.; Tan, W.S.; Meng, X.; Hu, B.W.; Wang, X.K. Review of organic and inorganic pollutants removal by biochar and biochar-based composites. Biochar 2021, 3, 255–281. [Google Scholar] [CrossRef]

- Wang, Y.; Chen, L.; Zhu, Y.; Fang, W.; Tan, Y.; He, Z.; Liao, H. Research status, trends, and mechanisms of biochar adsorption for wastewater treatment: A scientometric review. Environ. Sci. Eur. 2024, 36, 25. [Google Scholar] [CrossRef]

- Wei, B.; Peng, Y.; Lin, L.; Zhang, D.; Ma, L.; Jiang, L.; Li, Y.; He, T.; Wang, Z. Drivers of biochar-mediated improvement of soil water retention capacity based on soil texture: A meta-analysis. Geoderma 2023, 437, 116591. [Google Scholar] [CrossRef]

- Spokas, K.A.; Cantrell, K.B.; Novak, J.M.; Archer, D.V.; Ippolito, J.A.; Collins, H.P.; Boateng, A.A.; Lima, I.M.; Lamb, M.C.; McAloon, A.J.; et al. Biochar: A synthesis of its agronomic impact beyond carbon sequestration. J. Environ. Qual. 2012, 41, 973–989. [Google Scholar] [CrossRef]

- Gong, Y.; Hou, R.; Fu, Q.; Li, T.; Wang, J.; Su, Z.; Shen, W.; Zhou, W.; Wang, Y.; Li, M.O. Modified biochar reduces the greenhouse gas emission intensity and enhances the net ecosystem economic budget in black soil soybean fields. Soil Tillage Res. 2024, 237, 105978. [Google Scholar] [CrossRef]

- Kavan, K.V.; Panwar, N.L. Pyrolysis technologies for biochar production in waste management: A review. Clean Energy 2024, 8, 61–78. [Google Scholar] [CrossRef]

- Raut, N.A.; Kokare, D.M.; Randive, K.R.; Bhanvase, B.A.; Dhole, S.J. Introduction: Fundamentals of waste removal technologies. In 360-Degree Waste Management Volume 1, Fundamentals, Agricultural and Domestic Waste, and Remediation; Elsevier: Amsterdam, The Netherlands, 2023; pp. 1–16. [Google Scholar]

- United Nations, Department of Economic and Social Affairs, Population Division. World Population Prospects 2019: Highlights (ST/ESA/SER.A/423); UN: New York, NY, USA, 2019; p. 5, 12. [Google Scholar]

- Zezelj, B.; Maksimovic, R.; Todorovic, T.; Djatkov, D.J. Analysis of the Possibilities for Using Renewable Energy Sources in the Autonomous Province of Vojvodina. Sustainability 2020, 12, 5645. [Google Scholar] [CrossRef]

- Statistical Office of the Republic of Serbia. Generated Waste in the Republic of Serbia by Sections, 2023. Retrieved 4 July 2025. 2024. Available online: https://www.stat.gov.rs/en-us/vesti/statisticalrelease/?p=15202 (accessed on 9 December 2025).

- Panić, S.; Đurišić-Mladenović, N.; Petronijević, M.; Stijepović, I.; Milanović, M.; Kozma, G.; Kukovecz, A. Valorization of waste biomass towards biochar production—Characterization and perspectives for sustainable applications in Serbia. Environ. Technol. Innov. 2025, 37, 104043. [Google Scholar] [CrossRef]

- Kaur, K.; Kaur, R.; Kaur, H. A systematic review of lignocellulosic biomass for remediation of environmental pollutants. Appl. Surf. Sci. Adv. 2024, 19, 100547. [Google Scholar] [CrossRef]

- Qi, X.; Tong, X.; Pao, W.; Zeng, Q.; You, S.; Shen, J. Recent advances in polysaccharide-based adsorbents for wastewater treatment. J. Clean. Prod. 2021, 315, 128221. [Google Scholar] [CrossRef]

- Raud, M.; Kikas, T.; Sippula, O.; Shurpali, N.J. Potentials and challenges in lignocellulosic biofuel production technology. Renew. Sustain. Energy Rev. 2019, 111, 44–56. [Google Scholar] [CrossRef]

- Li, X.; Liu, N.; Zhang, J.M.; Sun, Z.T.; Fu, S.F.; Zhan, X.M.; Yang, J.F.; Zhou, R.X.; Zhang, H.D.; Liu, H.; et al. Pyrolysis temperature had effects on the physicochemical properties of biochar. Plant Soil Environ. 2023, 69, 363–373. [Google Scholar] [CrossRef]

- Wang, Y.; Shen, X.; Bian, R.; Liu, X.; Zheng, J.; Cheng, K.; Zhang, X.; Li, L.; Pan, G. Effect of pyrolysis temperature of biochar on Cd, Pb and As bioavailability and bacterial community composition in contaminated paddy soil. Ecotoxicol. Environ. Saf. 2022, 247, 114237. [Google Scholar] [CrossRef]

- Tarasov, D.; Leitch, M.; Fatehi, P. Lignin–carbohydrate complexes: Properties, applications, analyses, and methods of extraction: A review. Biotechnol. Biofuels 2018, 11, 269. [Google Scholar] [CrossRef]

- Tufail, T.; Saeed, F.; Afzaal, M.; Ul Ain, H.B.; Gilani, S.A.; Hussain, M.; Anjum, F.M. Wheat straw: A natural remedy against different maladies. Food Sci. Nutr. 2020, 9, 2335–2344. [Google Scholar] [CrossRef]

- Gandam, P.K.; Chinta, M.L.; Gandham, A.P.; Pabbathi, N.P.P.; Konakanchi, S.; Bhavanam, A.; Atchuta, S.R.; Baadhe, R.R.; Bhatia, R.K. A New Insight into the Composition and Physical Characteristics of Corncob—Substantiating Its Potential for Tailored Biorefinery Objectives. Fermentation 2022, 8, 704. [Google Scholar] [CrossRef]

- Tran, H.N.; You, S.J.; Chao, H.P. Effect of pyrolysis temperatures and times on the adsorption of cadmium onto orange peel derived biochar. Waste Manag. Res. 2016, 34, 129–138. [Google Scholar] [CrossRef]

- Weber, K.; Quicker, P. Properties of biochar. Fuel 2018, 217, 240–261. [Google Scholar] [CrossRef]

- Alves, A.K.; Hauschild, T.; Basegio, T.M.; Berutti, F.M. Infuence of lignin and cellulose from termiteprocessed biomass on biochar production and evaluation of chromium VI adsorption. Nature 2024, 14, 14937. [Google Scholar]

- Tomczyk, A.; Sokołowska, Z.; Boguta, P. Biochar physicochemical properties: Pyrolysis temperature and feedstock kind effects. Rev. Environ. Sci. Biotechnol. 2020, 19, 191–215. [Google Scholar] [CrossRef]

- Chaves Fernandes, B.C.; Ferreira Mendes, K.; Dias Júnior, A.F.; da Silva Caldeira, V.P.; da Silva Teófilo, T.M.; Severo Silva, T.; Mendonça, V.; de Freitas Souza, M.; Valadão Silva, D. Impact of Pyrolysis Temperature on the Properties of Eucalyptus Wood-Derived Biochar. Materials 2020, 13, 5841. [Google Scholar] [CrossRef]

- Ibitoye, S.E.; Loha, C.; Mahamood, R.M.; Jen, T.C.; Alam, M.; Sarkar, I.; Das, P.; Akinlabi, E.T. An overview of biochar production techniques and application in iron and steel industries. Bioresour. Bioprocess. 2024, 11, 65. [Google Scholar] [CrossRef] [PubMed]

- Zhang, J.; Liu, J.; Liu, R. Effects of pyrolysis temperature and heating time on biochar obtained from the pyrolysis of straw and lignosulfonate. Bioresour. Technol. 2015, 176, 288–291. [Google Scholar] [CrossRef]

- Chatterjee, R.; Sajjadi, B.; Chen, W.Y.; Mattern, D.L.; Hammer, N.; Raman, V.; Dorris, A. Effect of Pyrolysis Temperature on PhysicoChemical Properties and Acoustic-Based Amination of Biochar for Efficient CO2 Adsorption. Front. Energy Res. 2020, 8, 85. [Google Scholar] [CrossRef]

- Cantrell, K.B.; Hunt, P.G.; Uchimiya, M.; Novak, J.M.; Ro, K.S. Impact of pyrolysis temperature and manure source on physicochemical characteristics of biochar. Bioresour. Technol. 2012, 107, 419–428. [Google Scholar] [CrossRef]

- Al-Wabel, M.I.; Al-Omran, A.; El-Naggar, A.H.; Nadeem, M.; Usman, A.R.A. Pyrolysis temperature induced changes in characteristics and chemical composition of biochar produced from conocarpus wastes. Bioresour. Technol. 2013, 131, 374–379. [Google Scholar] [CrossRef]

- Zhao, B.; Xu, H.; Zhang, T.; Nan, X.; Ma, F. Effect of pyrolysis temperature on sulfur content, extractable fraction and release of sulfate in corn straw biochar. R. Soc. Chem. 2018, 8, 35611–35617. [Google Scholar] [CrossRef]

- Zornoza, R.; Moreno-Barriga, F.; Acosta, J.A.; Munoz, M.A.; Faz, A. Stability, nutrient availability and hydrophobicity of biochars derived from manure, crop residues, and municipal solid waste for their use as soil amendments. Chemosphere 2016, 144, 122–130. [Google Scholar] [CrossRef] [PubMed]

- Cheah, S.; Malone, S.C.; Feik, C.J. Speciation of Sulfur in Biochar Produced from Pyrolysis and Gasification of Oak and Corn Stover. Environ. Sci. Technol. 2014, 48, 8474–8480. [Google Scholar] [CrossRef] [PubMed]

- Park, J.H.; Choi, S.-H.; Bong, Y.-S. Geographical origin authentication of onions using stable isotope ratio and compositions of C, H, O, N, and S. Food Control 2019, 101, 121–125. [Google Scholar] [CrossRef]

- Spokas, K.A. Review of the stability of biochar in soils: Predictability of O:C molar ratios. Carbon Manag. 2010, 1, 289–303. [Google Scholar] [CrossRef]

- Mobarak, M.B.; Pinky, N.S.; Mustafi, S.; Chowdhury, F.; Nahar, A.; Akhtar, U.S.; Quddus, M.S.; Yasmin, S.; Alam, M.A. Unveiling the reactor effect: A comprehensive characterization of biochar derived from rubber seed shell via pyrolysis and in-house reactor. RSC Adv. 2024, 14, 29848. [Google Scholar] [CrossRef]

- Hadey, C.; Allouch, M.; Alami, M.; Boukhlifi, F.; Loulidi, I. Preparation Characterization of Biochars Obtained from Biomasses for Combustible Briquette Applications. Sci. World J. 2022, 2022, 2554475. [Google Scholar] [CrossRef]

- Altıkat, A.; Alma, M.H.; Altıkat, A.; Bilgili, M.E.; Altıkat, S. A Comprehensive Study of Biochar Yield and Quality Concerning Pyrolysis Conditions: A Multifaceted Approach. Sustainability 2023, 16, 937. [Google Scholar] [CrossRef]

- Ge, L.; Yao, L.; Wang, Y.; Zuo, M.; Liu, Y.; Wu, K.; Zhang, W.; Xu, C. The preparation, layered characterization and potential applications of corncob biochar. J. Anal. Appl. Pyrolysis 2024, 183, 106808. [Google Scholar] [CrossRef]

- Chen, L.; Wang, H.; Tu, Z.; Hu, J.; Wu, F. Renewable fuel and value-added chemicals potential of reed straw waste (RSW) by pyrolysis: Kinetics, thermodynamics, products characterization, and biochar application for malachite green removal. Renew. Energy 2024, 229, 120724. [Google Scholar] [CrossRef]

- Elnour, A.Y.; Alghyamah, A.A.; Shaikh, H.M.; Poulose, A.M.; Al-Zahrani, S.M.; Anis, A.; Al-Wabel, M.I. Effect of Pyrolysis Temperature on Biochar Microstructural Evolution, Physicochemical Characteristics, and Its Influence on Biochar/Polypropylene Composites. Appl. Sci. 2019, 9, 1149. [Google Scholar] [CrossRef]

- Liu, S.; Chen, Z.; Shao, J.; Luo, S.; Yu, D. Novel soybean dregs biochar concrete: Characterization and evaluation of the mechanical properties and microstructure. Constr. Build. Mater. 2025, 458, 139512. [Google Scholar] [CrossRef]

- Geetha, T.; Smitha, J.K.; Sebastian, M.; Litty, M.I.; Joseph, B.; Joseph, J.; Nisha, T.S. Synthesis and characterization of nano iron oxide biochar composite for efficient removal of crystal violet from water. Heliyon 2024, 10, e39450. [Google Scholar] [CrossRef] [PubMed]

- Liu, C.; Ye, J.; Lin, Y.; Wu, X.; Price, G.W.; Wang, Y. Effect of natural aging on biochar physicochemical property and mobility of Cd (II). Nature 2024, 14, 22214. [Google Scholar] [CrossRef] [PubMed]

- Qing, M.; Huang, S.; Liu, L.; Chen, Y.; Zhang, L.; Liu, W.; Yin, Y.; He, J.; Xiang, J. Construction of a food waste biochar model and determination of contaminant adsorption sites: Combining experimental characterization with quantum chemical calculations. J. Mol. Struct. 2024, 1310, 138273. [Google Scholar] [CrossRef]

- Abdel-Ghani, N.T.; El-Chaghaby, G.A.; Helal, F.S. Individual and competitive adsorption of phenol and nickel onto multiwalled carbon nanotubes. J. Adv. Res. 2015, 6, 405–415. [Google Scholar] [CrossRef]

- Yuan, J.; Wang, C.; Tang, Z.; Chu, T.; Zheng, C.; Han, Q.; Chen, H.; Tan, Y. Biochar derived from traditional Chinese medicine residues: An efficient adsorbent for heavy metal Pb (II). Arab. J. Chem. 2024, 17, 105606. [Google Scholar] [CrossRef]

- Huang, H.; Reddy, N.G.; Huang, X.; Chen, P.; Wang, P.; Zhang, Y.; Huang, Y.; Lin, P.; Garg, A. Efects of pyrolysis temperature. feedstock type and compaction on water retention of biochar amended soil. Nature 2021, 11, 7419. [Google Scholar]

- Zhang, X.; Zhang, P.; Yuan, X.; Li, Y.; Han, L. Effect of pyrolysis temperature and correlation analysis on the yield and physicochemical properties of crop residue biochar. Bioresour. Technol. 2019, 296, 122318. [Google Scholar] [CrossRef]

- Brown, R.A.; Kercher, A.K.; Nguyen, T.H.; Nagle, D.C.; Ball, W.P. Production and characterization of synthetic wood chars for use as surrogates for natural sorbents. Org. Geochem. 2006, 37, 321–333. [Google Scholar] [CrossRef]

- Singh, B.; Singh, B.; Cowie, A. Characterisation evaluation of biochars for their application as soil amendment Aust. J. Soil Res. 2010, 48, 516–525. [Google Scholar] [CrossRef]

- Wang, L.; Olsen, M.N.P.; Moni, C.; Dieguez-Alonso, A.; de la Rosa, J.M.; Stenrød, M.; Liu, X.; Mao, L. Comparison of properties of biochar produced from different types of lignocellulosic biomass by slow pyrolysis at 600 °C. Appl. Energy Combust. Sci. 2022, 12, 100090. [Google Scholar] [CrossRef]

- Yargicoglu, E.N.; Sadasivam, B.Y.; Reddy, K.R.; Spokas, K. Physical and chemical characterization of waste wood derived biochars. Waste Manag. 2015, 36, 256–268. [Google Scholar] [CrossRef]

- Queiroz, L.S.; da Costa, C.E.F.; de Souza, L.K.C. Biomass Conversion by Torrefaction Process, Encyclopedia of Renew. Energy Sustain. Environ. 2024, 1, 623–636. [Google Scholar]

- De la Rosa, J.M.; Santa-Olalla, A.; Campos, P.; López-Núñez, R.; González-Pérez, J.A.; Almendros, G.; Knicker, H.E.; Sánchez-Martín, Á.; Fernández-Boy, E. Impact of Biochar Amendment on Soil Properties Organic Matter Composition in Trace Element-Contaminated Soil. Int. J. Environ. Res. Public Health 2022, 19, 2140. [Google Scholar] [CrossRef] [PubMed]

- Merino, A.; Ferreiro, A.; Salgado, F.; Fontúrbel, M.T.; Barros, N.; Fernández, C.; Vega, J.A. Use of thermal analysis and solid-state 13C CP-MAS NMR spectroscopy to diagnose organic matter quality in relation to burn severity in Atlantic soils. Geoderma 2014, 226–227, 376–386. [Google Scholar] [CrossRef]

- Merino, A.; Chávez-Vergara, B.; Salgado, J.; Fonturbel, M.T.; García-Oliva, F.; Vega, J.A. Variability in the composition of charred litter generated by wildfire in different ecosystems. Catena 2015, 133, 52–63. [Google Scholar] [CrossRef]

- Keiluweit, M.; Nico, P.S.; Johnson, M.G.; Kleber, M. Dynamic molecular structure of plant biomass-derived black carbon (biochar). Environ. Sci. Technol. 2010, 44, 1247–1253. [Google Scholar] [CrossRef]

- Kloss, S.; Zehetner, F.; Dellantonio, A.; Hamid, R.; Ottner, F.; Liedtke, V.; Schwanninger, M.; Gerzabek, M.H.; Soja, G. Characterization of Slow Pyrolysis Biochars: Eff ects of Feedstocks Pyrolysis Temperature on Biochar Properties. J. Environ. Qual. 2012, 41, 990. [Google Scholar] [CrossRef]

- Kim, K.H.; Kim, J.Y.; Cho, T.S.; Choi, J.W. Influence of pyrolysis temperature on physicochemical properties of biochar obtained from the fast pyrolysis of pitch pine (Pinus rigida). Bioresour. Technol. 2012, 118, 158–162. [Google Scholar] [CrossRef]

- Pariyar, P.; Kumari, K.; Jain, M.K.; Jadhao, P.S. Evaluation of change in biochar properties derived from different feedstock and pyrolysis temperature for environmental and agricultural application. Sci. Total Environ. 2020, 713, 136433. [Google Scholar] [CrossRef]

- Yan, Y.; Manickam, S.; Lester, E.; Wu, T.; Pang, C.H. Synthesis of graphene oxide and graphene quantum dots from miscanthus via ultrasound-assisted mechano-chemical cracking method. Ultrason. Sonochem. 2021, 73, 105519. [Google Scholar] [CrossRef]

- Wu, H.; Yip, K.; Tian, F.; Xie, Z.; Li, C.Z. Evolution of Char Structure during the Steam Gasification of Biochars Produced from the Pyrolysis of Various Mallee Biomass Components. Ind. Eng. Chem. Res. 2009, 48, 10431–10438. [Google Scholar] [CrossRef]

- Gavilan, L.; Ricketts, C.L.; Bejaoui, S.; Ricca, A.; Boersma, C.; Salama, F.; Mattioda, A.L. Raman spectroscopic study of pyrene in cosmic dust analogues: Evolution from the gas to the solid phase. ACS Earth Space Chem. 2022, 6, 2215–2225. [Google Scholar] [CrossRef]

- Brubaker, Z.E.; Langford, J.J.; Kapsimalis, R.J.; Niedziela, J.L. Quantitative analysis of Raman spectral parameters for carbon fibers: Practical considerations and connection to mechanical properties. J. Mater. Sci. 2021, 56, 15087–15121. [Google Scholar] [CrossRef]

- Gonz’alez-Hourcade, M.; dos Reis, G.S.; Grimm, A.; Dinh, V.M.; Lima, E.C.; Larsson, S.H.; Gentili, F.G. Microalgae biomass as a sustainable precursor to produce nitrogen-doped biochar for efficient removal of emerging pollutants from aqueous media. J. Clean. Prod. 2022, 348, 131280. [Google Scholar] [CrossRef]

- dos Reis, G.S.; Bergna, D.; Grimm, A.; Lima, E.C.; Hu, T.; Naushad, M.; Lassi, U. Preparation of highly porous nitrogen-doped biochar derived from birch tree wastes with superior dye removal performance. Colloids Surf. A Physicochem. Eng. Asp. 2023, 669, 131493. [Google Scholar] [CrossRef]

- Yin, Y.; Yin, J.; Zhang, W.; Tian, H.; Hu, Z.; Ruan, M.; Song, Z.; Liu, L. Effect of Char Structure Evolution During Pyrolysis on Combustion Characteristics and Kinetics of Waste Biomass. J. Energy Resour. Technol. 2018, 140, 072203. [Google Scholar] [CrossRef]

- Makowska, M.; Dziosa, K. Influence of different pyrolysis temperatures on chemical composition and graphite-like structure of biochar produced from biomass of green microalgae Chlorella sp. Environ. Technol. Innov. 2024, 35, 103667. [Google Scholar] [CrossRef]

- Marzeddu, S.; Decima, M.A.; Camilli, L.; Bracciale, M.P.; Genova, V.; Paglia, L.; Marra, F.; Damizia, M.; Stoller, M.; Chiavola, A.; et al. Physical-chemical characterization of different carbon-based sorbents for environmental applications. Materials 2022, 15, 7162. [Google Scholar] [CrossRef]

- Dayoub, E.B.; Tóth, Z.; Soós, G.; Anda, A. Chemical and Physical Properties of Selected Biochar Types and a Few Application Methods in Agriculture. Agronomy 2024, 14, 2540. [Google Scholar] [CrossRef]

- Ghorbani, M.; Amirahmadi, E.; Bernas, J.; Konvalina, P. Testing Biochar’s Ability to Moderate Extremely Acidic Soils in Tea-Growing Areas. Agronomy 2024, 14, 533. [Google Scholar] [CrossRef]

- Kujawska, J.; Wojta’s, E.; Charmas, B. Biochar Derived from Sewage Sludge: The Impact of Pyrolysis Temperature on Chemical Properties and Agronomic Potential. Sustainability 2024, 16, 8225. [Google Scholar] [CrossRef]

- Pambudi, S.; Saechua, W.; Jongyingcharoen, J.S. A thermogravimetric assessment of eco-friendly biochar from oxidative torrefaction of spent coffee grounds: Combustion behavior, kinetic parameters and potential emissions. Environ. Technol. Innov. 2024, 33, 103472. [Google Scholar] [CrossRef]

- Beljin, J.; Ðukanović, N.; Anojčić, J.; Simetić, T.; Apostolović, T.; Mutić, S.; Maletić, S. Biochar in the Remediation of Organic Pollutants in Water: A Review of Polycyclic Aromatic Hydrocarbon and Pesticide Removal. Nanomaterials 2025, 15, 26. [Google Scholar] [CrossRef]

- Nepal, J.; Ahmad, W.; Munsif, F.; Khan, A.; Zou, Z. Advances and prospects of biochar in improving soil fertility, biochemical quality, and environmental applications. Front. Environ. Sci. 2023, 11, 1114752. [Google Scholar] [CrossRef]

- Cancelliere, R.; Mele, P.; Bartolucci, L.; Cordiner, S.; da Silva Freitas, W.; Mazzuca, C.; Mecheri, B.; Micheli, L.; Mulone, V.; Paialunga, E.; et al. Mutual interaction of pyrolysis operating conditions surface morphology for the electrochemical performance of biochar-modified screen-printed electrodes. J. Environ. Chem. Eng. 2025, 13, 115477. [Google Scholar] [CrossRef]

- Yaashikaa, P.R.; Kumar, S.; Varjani, S.; Saravanan, A. A critical review on the biochar production techniques, characterization, stability and applications for circular bioeconomy. Biotechnol. Rep. 2020, 28, e00570. [Google Scholar] [CrossRef]

- Mutić, S.; Anojčić, J.; Đukanović, N.; Apostolović, T.; Simetić, T.; Petrović, J.; Beljin, J. Exploring wood-derived biochar potential for electrochemical sensing of fungicides mancozeb and maneb in environmental water samples. Talanta 2025, 287, 127648. [Google Scholar] [CrossRef]

- ASTM D1762–84; Standard Test Method for Chemical Analysis of Wood Charcoal. ASTM International: West Conshohocken, PA, USA, 1984.

- Palamanit, A.; Khongphakdi, P.; Tirawanichakul, Y.; Phusunti, N. Investigation of yields qualities of pyrolysis products obtained from oil palm biomass using an agitated bed pyrolysis reactor. Biofuel Res. J. 2019, 24, 1065–1079. [Google Scholar] [CrossRef]

| Parameters | HW400 | HW700 | CC400 | CC700 | WS400 | WS700 |

|---|---|---|---|---|---|---|

| pH | 9.06 ± 0.01 | 9.40 ± 0.26 | 7.94 ± 0.13 | 9.45 ± 0.10 | 9.21 ± 0.02 | 10.3 ± 0.20 |

| Ash (% w/w) | 3.25 ± 0.14 | 5.98 ± 1.12 | 9.4 ± 1.45 | 16.2 ± 2.24 | 15.2 ± 1.05 | 24.8 ± 2.56 |

| Moisture (% w/w) | 2.81 ± 0.11 | 3.03 ± 0.13 | 4.09 ± 0.21 | 2.81 ± 0.12 | 4.28 ± 0.32 | 5.25 ± 0.21 |

| Volatile matter (% w/w) | 41.4 ± 5.12 | 24.8 ± 3.15 | 56.1 ± 6.25 | 24.1 ± 4.12 | 54.1 ± 4.15 | 10.2 ± 3.19 |

| Fixed carbon a (% w/w) | 52.5 ± 1.79 | 66.2 ± 1.47 | 30.4 ± 2.64 | 56.9 ± 2.16 | 26.4 ± 1.84 | 59.7 ± 1.99 |

| C (% w/w) | 82.4 ± 1.47 | 89.8 ± 2.47 | 71.9 ± 0.12 | 82.9 ± 0.42 | 66.7 ± 2.38 | 66.3 ± 2.23 |

| H (% w/w) | 0.40 ± 0.07 | 0.90 ± 0.05 | 4.41 ± 0.14 | 1.61 ± 0.08 | 4.30 ± 0.25 | 1.66 ± 0.01 |

| N (% w/w) | 0.42 ± 0.08 | 0.40 ± 0.04 | 0.64 ± 0.12 | 0.33 ± 0.01 | 1.41 ± 0.60 | 0.94 ± 0.07 |

| S (% w/w) | <0.03 | <0.03 | 4.09 ± 0.14 | 4.36 ± 0.82 | 2.84 ± 0.72 | 2.01 ± 0.32 |

| O (% w/w) | 12.5 ± 0.19 | 7.79 ± 0.50 | 5.21 ± 0.28 | 1.42 ± 1.34 | 8.47 ± 7.51 | 6.55 ± 2.53 |

| O/C (molar ratio) | 0.11 | 0.07 | 0.05 | 0.01 | 0.09 | 0.07 |

| H/C (molar ratio) | 0.06 | 0.12 | 0.73 | 0.23 | 0.77 | 0.30 |

| (O + N)/C (molar ratio) | 0.12 | 0.07 | 0.06 | 0.02 | 0.11 | 0.09 |

| HHV (MJ/kg) | 27.0 ± 0.51 | 30.7 ± 0.8 | 29.8 ± 0.19 | 30.2 ± 0.25 | 27.2 ± 1.26 | 23.7 ± 0.82 |

| TG | Temperature Interval | Biochars | |||||

|---|---|---|---|---|---|---|---|

| HW400 | HW700 | CC400 | CC700 | WS400 | WS700 | ||

| Total Weight Loss (%) | 20–800 °C | 96.0 | 96.5 | 95.5 | 95.1 | 89.3 | 81.8 |

| Moisture | 20–105 °C | 3.37 | 3.63 | 5.16 | 6.40 | 5.33 | 7.17 |

| Moisture and very labile OM | 105–200 °C | 0.539 | 0.342 | 0.388 | 0.929 | 0.813 | 1.420 |

| Labile OM | 200–400 °C | 7.52 | 6.39 | 34.9 | 11.9 | 41.2 | 28.5 |

| Intermediate OM | 400–600 °C | 84.5 | 85.6 | 54.2 | 74.6 | 40.2 | 42.6 |

| Recalcitrant OM | 600–800 °C | 0.129 | 0.542 | 0.775 | 1.26 | 1.79 | 2.04 |

| Biochar | Key Physico-Chemical Characteristics | Recommended Applications | Explanation |

|---|---|---|---|

| HW700 | High aromaticity (low H/C and O/C ratios); high specific surface area; very low sulfur content; high graphitization | Long-term carbon sequestration; adsorption of organic pollutants; high-temperature industrial applications (catalysis, energy systems) | High structural stability and durability; large surface area enhances adsorption; low sulfur minimizes SOx emissions |

| CC700 | Strong development of microporosity; high specific surface area | Heavy metal adsorption in water and soil; catalytic applications; water treatment | Developed pore structure promotes adsorption and catalytic activity |

| WS700 | High ash content; strong alkalinity (pH 10.3); presence of mineral phases (SiO2 and CaCO3); good thermal stability | Soil remediation and pH correction; metal(loid) immobilization; agricultural soil amendment | Mineral-rich composition improves soil properties and stabilizes contaminants |

| HW400 | Higher content of oxygen- and nitrogen-containing functional groups; moderate surface area | Nutrient retention in soils; short- to medium-term soil amendment; adsorption of polar compounds | Abundance of polar functional groups increases reactivity and cation exchange capacity |

| CC400 | Pronounced surface functionalization; lower specific surface area than CC700 | Soil fertility enhancement; reactive environmental applications | Retains labile functional groups that enhance chemical interactions |

| WS400 | High surface functionalization; lowest specific surface area | Short-term soil amendment; nutrient retention; applications where surface polarity is required | Enhanced polarity and reactivity compensate for lower porosity |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license.

Share and Cite

Đukanović, N.; Apostolović, T.; Anojčić, J.; Mutić, S.; Marjanović Srebro, T.; Kozma, G.; Deák, C.; Maletić, S.; Beljin, J. Comparative Study of Biochar from Different Biomass Feedstocks: Toward Sustainable Resource Utilization and Environmental Applications. Molecules 2026, 31, 37. https://doi.org/10.3390/molecules31010037

Đukanović N, Apostolović T, Anojčić J, Mutić S, Marjanović Srebro T, Kozma G, Deák C, Maletić S, Beljin J. Comparative Study of Biochar from Different Biomass Feedstocks: Toward Sustainable Resource Utilization and Environmental Applications. Molecules. 2026; 31(1):37. https://doi.org/10.3390/molecules31010037

Chicago/Turabian StyleĐukanović, Nina, Tamara Apostolović, Jasmina Anojčić, Sanja Mutić, Tijana Marjanović Srebro, Gábor Kozma, Cora Deák, Snežana Maletić, and Jelena Beljin. 2026. "Comparative Study of Biochar from Different Biomass Feedstocks: Toward Sustainable Resource Utilization and Environmental Applications" Molecules 31, no. 1: 37. https://doi.org/10.3390/molecules31010037

APA StyleĐukanović, N., Apostolović, T., Anojčić, J., Mutić, S., Marjanović Srebro, T., Kozma, G., Deák, C., Maletić, S., & Beljin, J. (2026). Comparative Study of Biochar from Different Biomass Feedstocks: Toward Sustainable Resource Utilization and Environmental Applications. Molecules, 31(1), 37. https://doi.org/10.3390/molecules31010037