A High-Efficiency Environmentally Friendly Polishing Slurry for K9 Glass Utilizing Cerium-Based Compounds

Abstract

1. Introduction

2. Results and Discussion

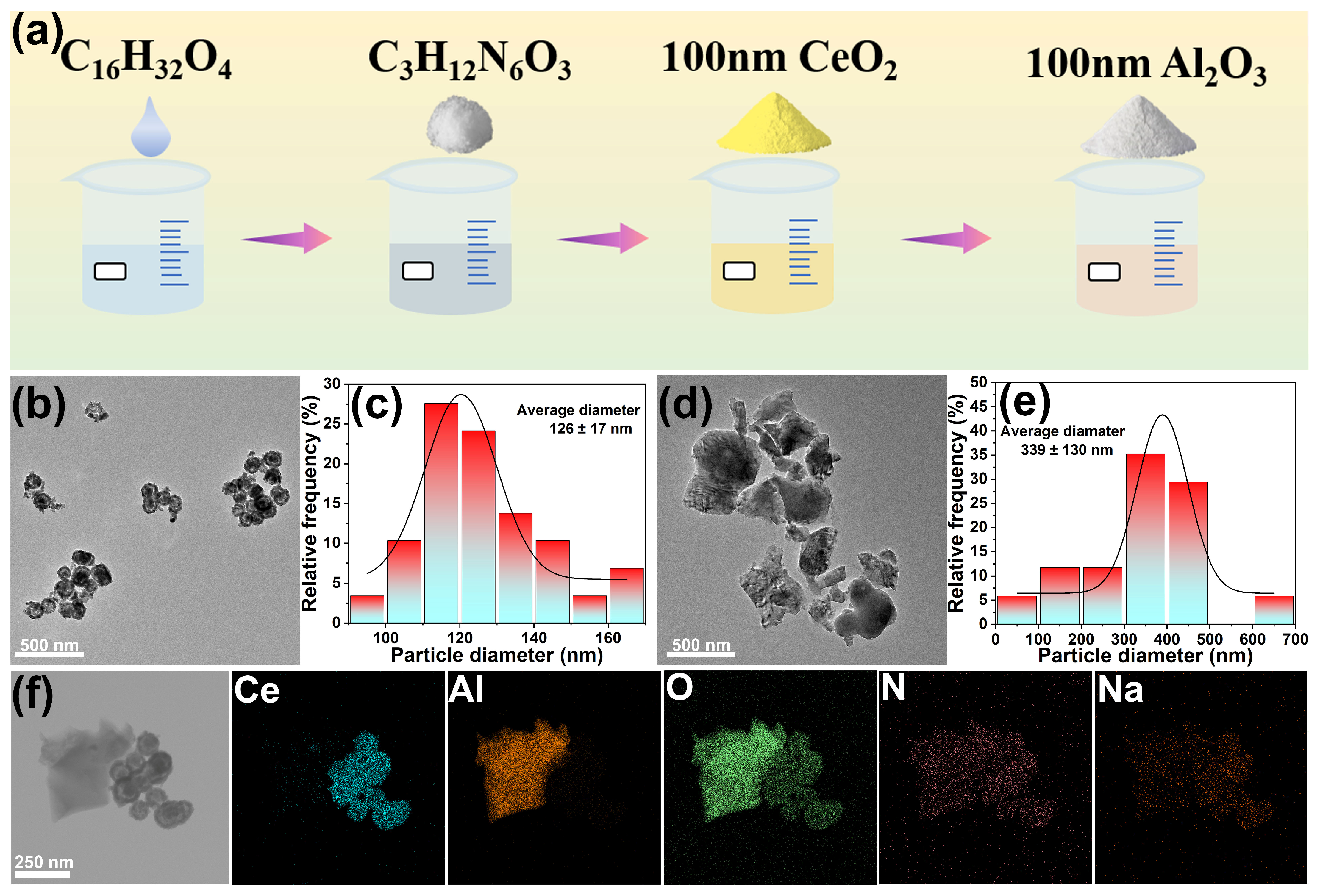

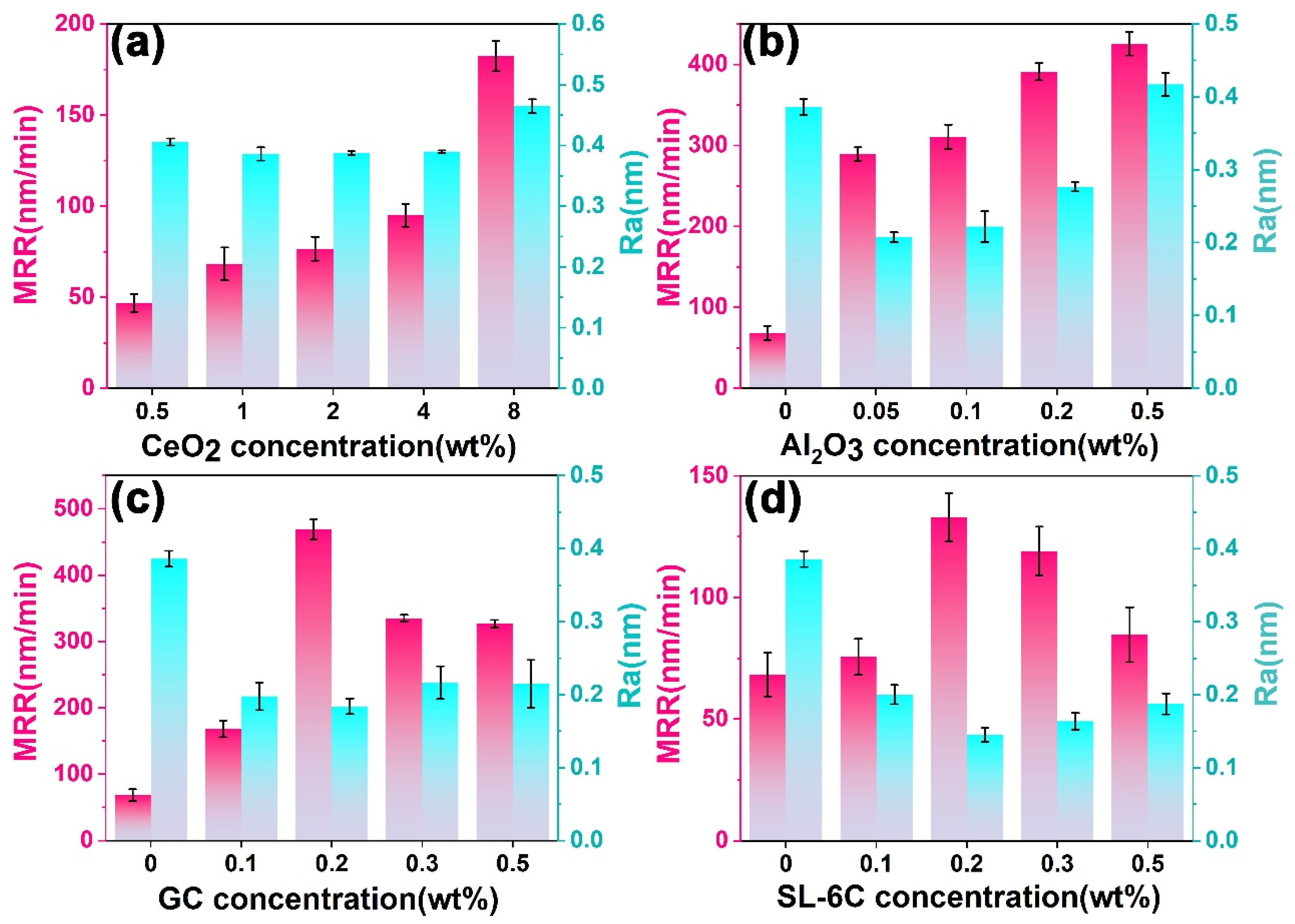

2.1. Analysis of Abrasive Morphology and Evaluation of CMP Efficiency

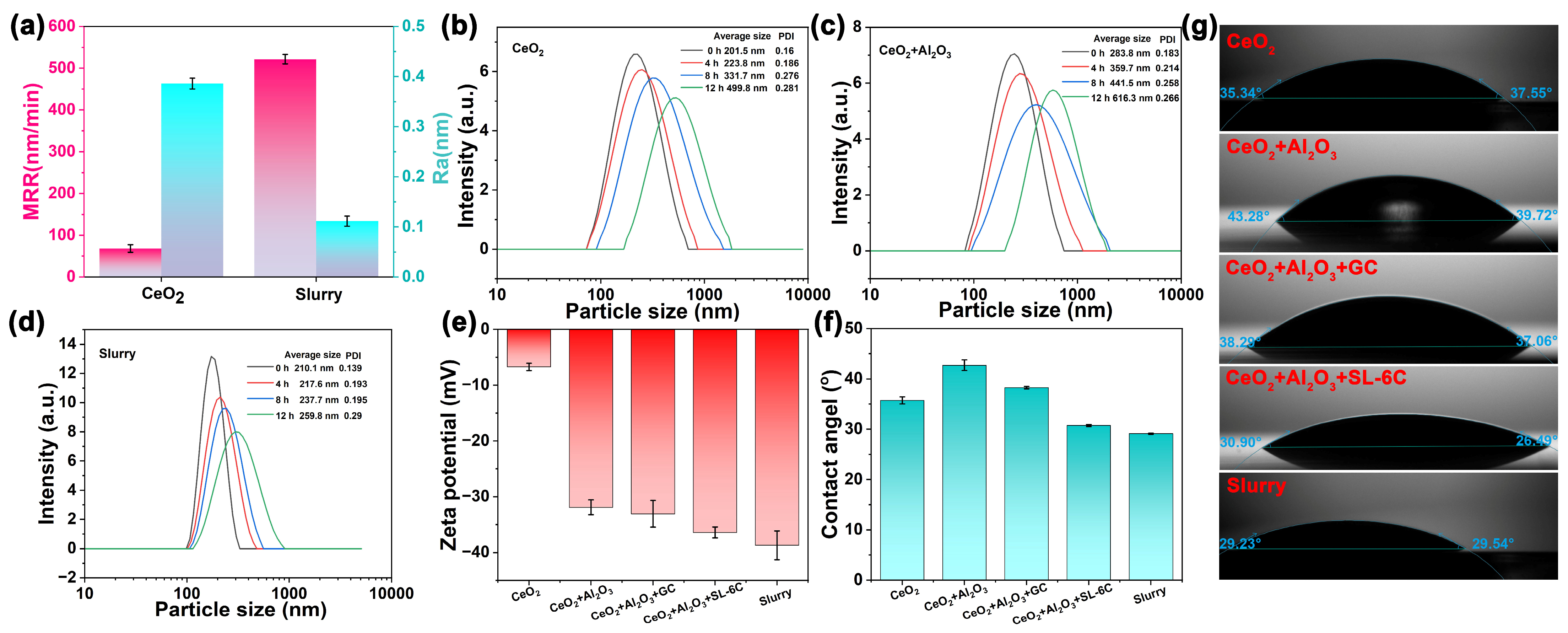

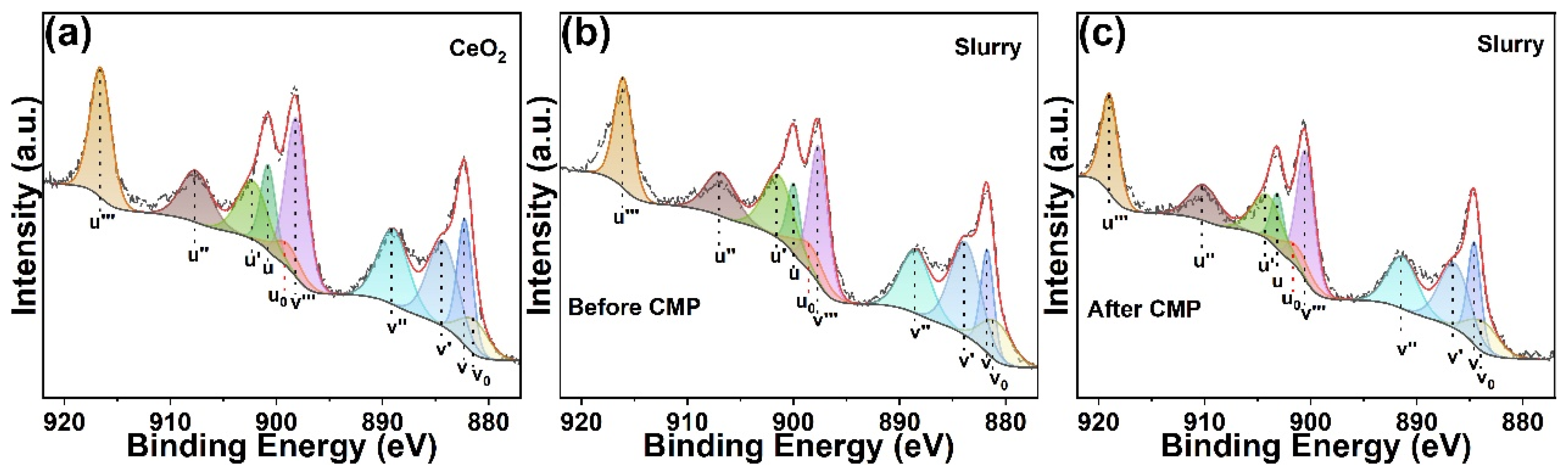

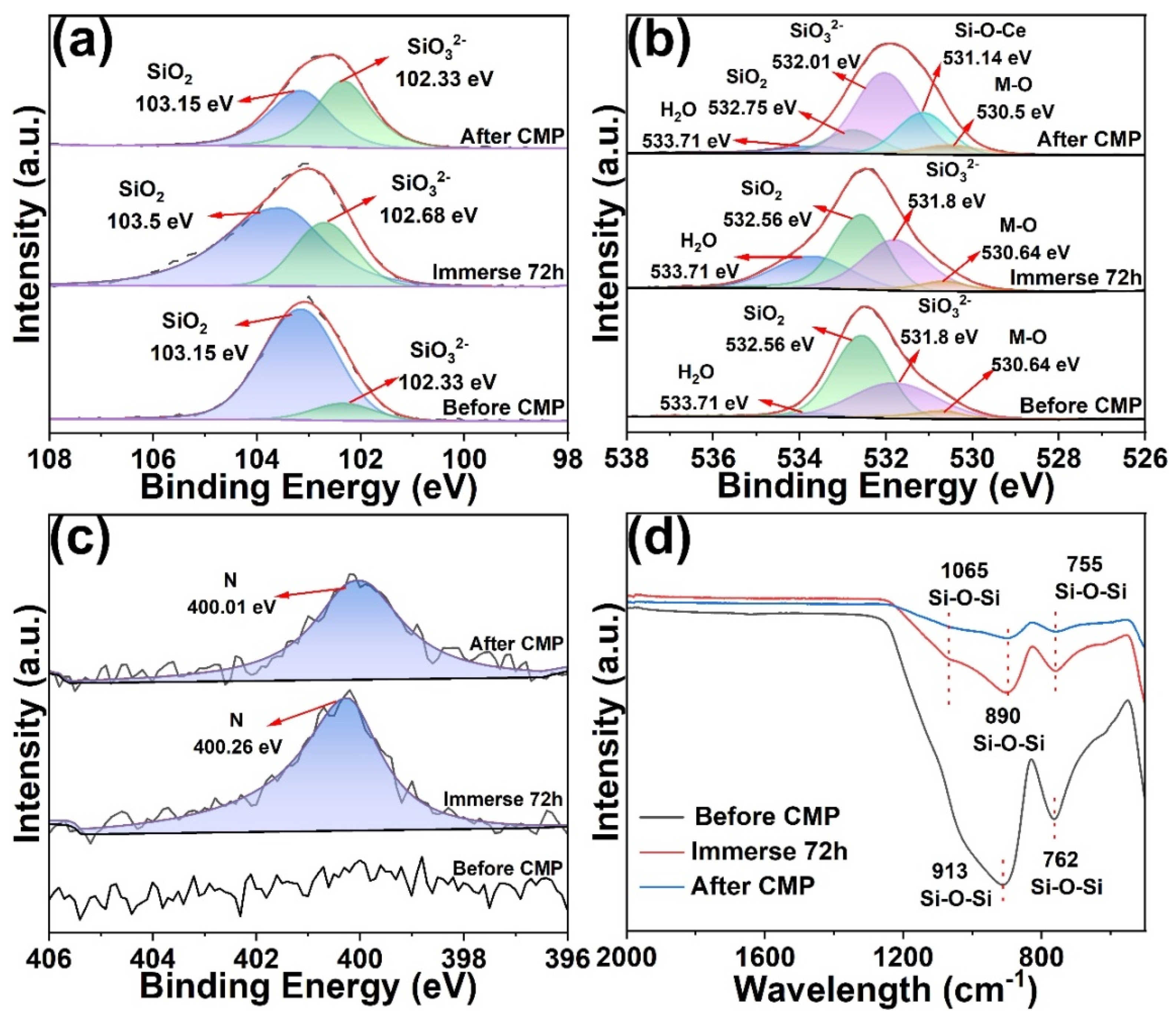

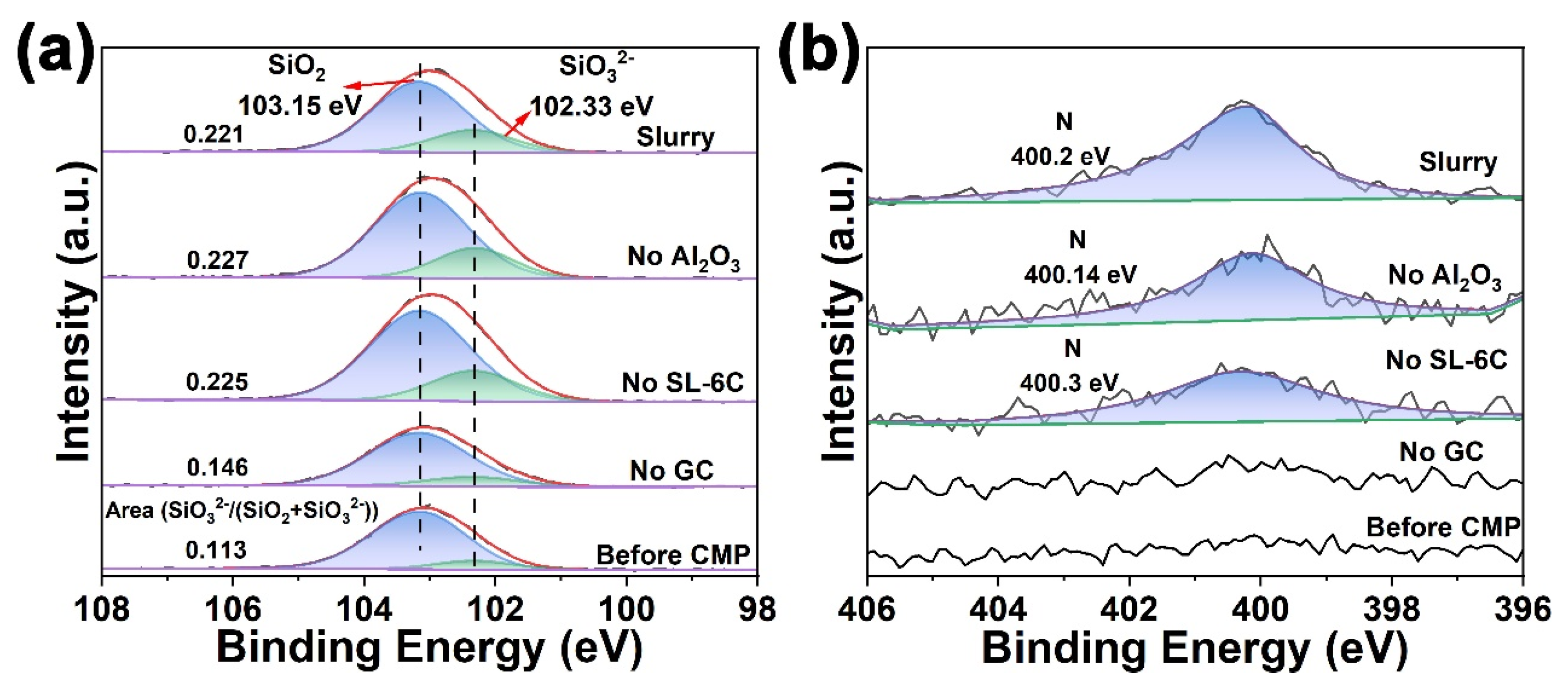

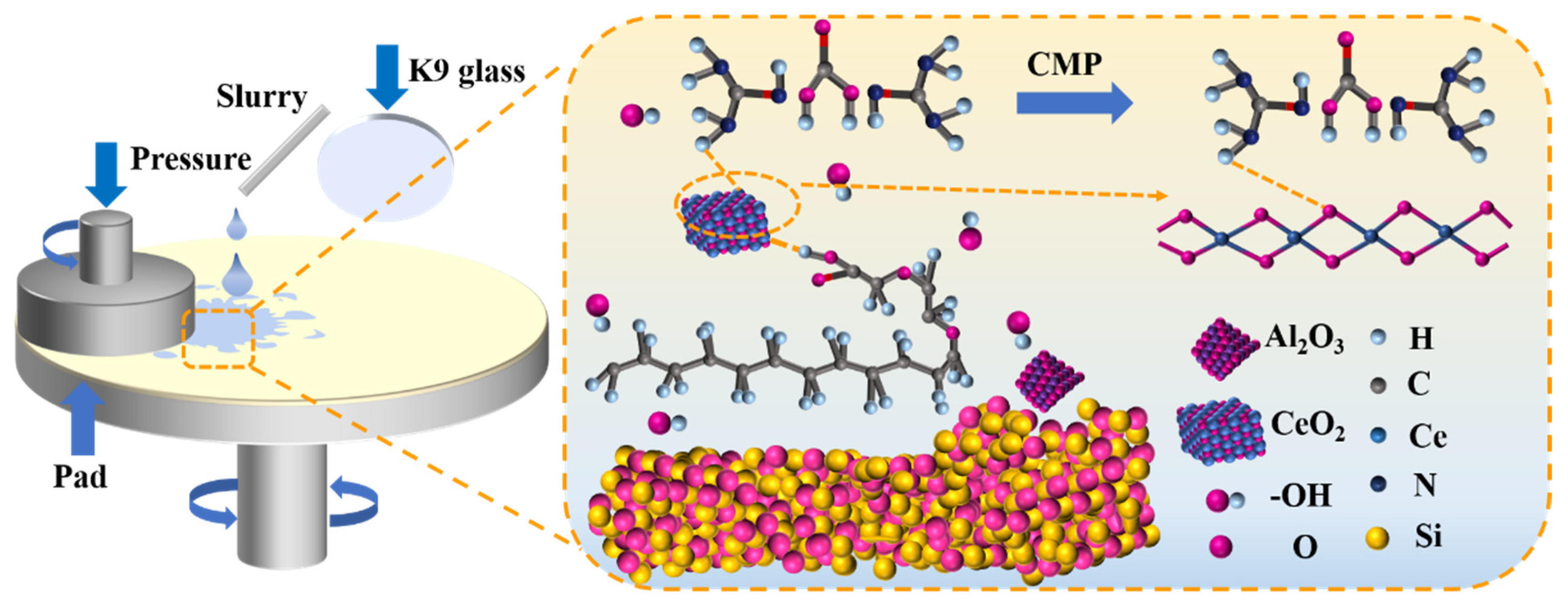

2.2. Analysis of CMP Mechanism

3. Materials and Methods

3.1. Materials

3.2. Preparation of CeO2 Abrasive and Slurry

3.3. Characterization

3.4. CMP Test

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Cheng, H.; Feng, Z.; Wang, Y.; Lei, S. Magnetic Bingham fluid-assisted deterministic polishing for super-smooth surfaces. Chin. Sci. Bull. 2005, 50, 172–178. [Google Scholar] [CrossRef]

- Zhang, Z.; Huang, J.; Geng, F.; Zhou, X.; Feng, S.; Ren, D.; Cheng, X.; Jiang, X.; Wu, W.; Zheng, W.; et al. Fluorescence and Raman spectra on surface of K9 glass by high fluence ultraviolet laser irradiation at 355nm. Opt. Commun. 2013, 308, 91–94. [Google Scholar] [CrossRef]

- Liu, L.; Wang, J.; Wang, X.; Zhang, F.-Y.; Wang, P.-P.; Zhang, Y.-L.; Sun, S.-F. Performance comparison of laser-etched microstructures on K9 glass and PMMA light guide plate. Optik 2021, 242, 167213. [Google Scholar] [CrossRef]

- Shang, X.; Shi, W.; Hai, W.; Su, J.; Dong, C. Optical characteristics of the undamaged and laser damaged K9 glass in terahertz band. Mater. Res. Express 2020, 7, 045202. [Google Scholar] [CrossRef]

- Qu, S.; Wang, Z.; Zhang, C.; Ma, Z.; Zhang, T.; Chen, H.; Wang, Z.; Yu, T.; Zhao, J. Material removal profile prediction and experimental validation for obliquely axial ultrasonic vibration-assisted polishing of K9 optical glass. Ceram. Int. 2021, 47, 33106–33119. [Google Scholar] [CrossRef]

- Tang, K.-E.; Yan, J.; Kwan, S.-Y.; Zhen, M.-Y.; Liu, C.-W. Using fast Fourier transform analysis for the rapid evaluation of the diffraction fringes of optical components produced through ultraprecision single-point diamond turning. Mech. Syst. Signal Process. 2025, 237, 113167. [Google Scholar] [CrossRef]

- Qu, S.; Zhang, C.; Liang, Y.; Ma, Z.; Meng, F.; Wang, Z.; Xu, P.; Yu, T.; Zhao, J. Experimental investigation of ultrasonic-vibration polishing of K9 optical glass based on ultrasonic atomization. Ceram. Int. 2022, 48, 9067–9074. [Google Scholar] [CrossRef]

- Ma, S.; Chen, Y.; Wang, C.; Li, Y.; Xu, Y.; Wu, Y. Application of surfactants in enhancing chemical mechanical polishing slurry performance for microelectronics: A review. Mater. Today Commun. 2025, 46, 112547. [Google Scholar] [CrossRef]

- Venkataswamy, R.; Trimble, L.; McDonald, A.; Nevers, D.; Bengochea, L.V.; Carswell, A.; Rossner, A.; Seo, J. Environmental impact assessment of chemical mechanical planarization consumables: Challenges, future needs, and perspectives. ACS Sustain. Chem. Eng. 2024, 12, 11841–11855. [Google Scholar] [CrossRef]

- Ma, J.; Xu, N.; Cheng, J.; Pu, Y. A review on the development of ceria for chemical mechanical polishing. Powder Technol. 2024, 444, 119989. [Google Scholar] [CrossRef]

- Wang, Y.; Shi, Y.; Cheng, J.; Xu, Y.; Wang, Y.; Qiu, J. Recent advances in CeO2 based abrasives for chemical mechanical polishing. Phys. Chem. Chem. Phys. 2025, 27, 13213–13233. [Google Scholar] [CrossRef]

- Gu, R.; Qi, W.; Wang, F.; Tan, B.; Shi, Y. Research progress on the application of cerium oxide and titanium oxide abrasives modification in chemical mechanical polishing. ECS J. Solid State Sci. Technol. 2025, 14, 094001. [Google Scholar] [CrossRef]

- Zhao, Z.; Zhang, Z.; Shi, C.; Feng, J.; Zhuang, X.; Li, L.; Meng, F.; Li, H.; Xue, Z.; Liu, D. Dispersion and polishing mechanism of a novel CeO2-LaOF-based chemical mechanical polishing slurry for quartz glass. Materials 2023, 16, 1148. [Google Scholar] [CrossRef]

- Cui, X.; Zhang, Z.; Shi, C.; Peng, Q.; Liu, X.; Liu, X.; Zhou, H.; Feng, J.; Wen, W. Atomic surface induced by novel green chemical mechanical polishing for aspheric thin-walled crucibles with large diameters. J. Manuf. Process. 2024, 117, 59–70. [Google Scholar] [CrossRef]

- Liu, D.; Zhang, Z.; Feng, J.; Yu, Z.; Meng, F.; Xu, G.; Wang, J.; Wen, W.; Liu, W. Atomic-level flatness on oxygen-free copper surface in lapping and chemical mechanical polishing. Nanoscale Adv. 2022, 4, 4263–4271. [Google Scholar] [CrossRef]

- Wei, K.-H.; Wang, Y.-S.; Liu, C.-P.; Chen, K.-W.; Wang, Y.-L.; Cheng, Y.-L. The influence of abrasive particle size in copper chemical mechanical planarization. Surf. Coatings Technol. 2013, 231, 543–545. [Google Scholar] [CrossRef]

- Matijević, E.; Babu, S. Colloid aspects of chemical–mechanical planarization. J. Colloid Interface Sci. 2008, 320, 219–237. [Google Scholar] [CrossRef] [PubMed]

- Liu, L.; Zhang, Z.; Wu, B.; Hu, W.; Meng, F.; Li, Y. A review: Green chemical mechanical polishing for metals and brittle wafers. J. Phys. D Appl. Phys. 2021, 54, 373001. [Google Scholar] [CrossRef]

- Zhu, X.; Ding, J.; Mo, Z.; Jiang, X.; Sun, J.; Fu, H.; Gui, Y.; Ban, B.; Wang, L.; Chen, J. Evaluation of chemical mechanical polishing characteristics using mixed abrasive slurry: A study on polishing behavior and material removal mechanism. Appl. Surf. Sci. 2025, 679, 161157. [Google Scholar] [CrossRef]

- Liu, J.; Zhang, Z.; Shi, C.; Ren, Z.; Feng, J.; Zhou, H.; Liu, Z.; Meng, F.; Zhao, S. Novel green chemical mechanical polishing of fused silica through designing synergistic CeO2/h-BN abrasives with lubricity. Appl. Surf. Sci. 2023, 637, 157978. [Google Scholar] [CrossRef]

- Chen, X.; Zhang, Z.; Chen, L.; Yang, X.; Ju, B.; Liu, W.; Deng, X.; Wang, M.; Xu, Y. Atomic surface of fused silica with high material removal rate produced by novel chemical mechanical polishing using composite rare earth oxides. Colloids Surfaces A Physicochem. Eng. Asp. 2025, 712, 136420. [Google Scholar] [CrossRef]

- Lv, G.; Liu, S.; Cao, Y.; Zhang, Z.; Li, X.; Zhang, Y.; Liu, T.; Liu, B.; Wang, K. Effect of synergistic CeO2/MoS2 abrasives on surface roughness and material removal rate of quartz glass. Ceram. Int. 2024, 50, 48671–48679. [Google Scholar] [CrossRef]

- He, Q. Experimental study on polishing performance of CeO2 and nano-SiO2 mixed abrasive. Appl. Nanosci. 2018, 8, 163–171. [Google Scholar] [CrossRef]

- Cho, C.-W.; Kim, S.-K.; Paik, U.; Park, J.-G.; Sigmund, W.M. Atomic force microscopy study of the role of molecular weight of poly(acrylic acid) in chemical mechanical planarization for shallow trench isolation. J. Mater. Res. 2006, 21, 473–479. [Google Scholar] [CrossRef]

- Wortman-Otto, K.M.; Linhart, A.N.; Dudek, A.L.; Sherry, B.M.; Keleher, J.J. Role of molecular structure on modulating the interfacial dynamics for shallow trench isolation (STI) chemical mechanical planarization (CMP) applications. ECS J. Solid State Sci. Technol. 2021, 10, 024009. [Google Scholar] [CrossRef]

- Li, F.; Bai, Y.; Hu, H.; Qiao, G.; Li, L.; Zhang, F.; Zhang, X. pH-driven interfacial bond dynamics enable high-efficiency low-damage polishing of fused silica with CeO2 based slurries. J. Mater. Process. Technol. 2025, 341, 118896. [Google Scholar] [CrossRef]

- Ni, Z.; Fan, Q.; Chen, G.; Dai, M.; Chen, Z.; Bian, D.; Qian, S. Influence of cerium oxide abrasive particle morphologies on polishing performance. Cryst. Res. Technol. 2024, 59, 2300308. [Google Scholar] [CrossRef]

- Qu, S.; Cui, Z.; Chu, X.; Sun, X.; Dong, Z.; Yang, H.; Liu, Y.; Wang, Z.; Yu, T.; Zhao, J. Study on the polishing mechanism under the combined effect of K2CO3, KH550 and ultrasonic vibration for K9 optical glass. Appl. Surf. Sci. 2025, 693, 162746. [Google Scholar] [CrossRef]

- Zhang, X.; Meng, N.; Li, X.; Mei, X.; Yang, L.; He, Y. The role of ammonium citrate and dodecyl pyridinium chloride on chemical mechanical polishing relevant to SiO2 dielectric layer. J. Manuf. Process. 2023, 107, 333–344. [Google Scholar] [CrossRef]

- Yang, H.; Jia, L.; Haraguchi, J.; Wang, Y.; Xu, B.; Zhang, Q.; Nan, Z.; Zhang, M.; Ohno, T. Nitrogen and sulfur co-doped CeO2 nanorods for efficient photocatalytic VOCs degradation. Catal. Sci. Technol. 2022, 12, 5203–5209. [Google Scholar] [CrossRef]

- Cui, X.; Zhang, Z.; Yu, S.; Chen, X.; Shi, C.; Zhou, H.; Meng, F.; Yu, J.; Wen, W. Unprecedented atomic surface of silicon induced by environmentally friendly chemical mechanical polishing. Nanoscale 2023, 15, 9304–9314. [Google Scholar] [CrossRef]

- Li, H.; Xia, M.; Wang, X.; Chong, B.; Ou, H.; Lin, B.; Yang, G. Efficient reduction of CO2 to C2 hydrocarbons by tandem nonthermal plasma and photocatalysis. Appl. Catal. B Environ. 2024, 342, 123423. [Google Scholar] [CrossRef]

- Shiu, Y.-J.; Cheng, Y.-C.; Tsai, W.-L.; Wu, C.-C.; Chao, C.-T.; Lu, C.-W.; Chi, Y.; Chen, Y.T.; Liu, S.-H.; Chou, P.-T. Pyridyl Pyrrolide boron complexes: The facile generation of thermally activated delayed fluorescence and preparation of organic light-emitting diodes. Angew. Chem. Int. Ed. 2016, 55, 3017–3021. [Google Scholar] [CrossRef] [PubMed]

- Cheng, J.; Shi, Y.; Wang, Y.; Qiu, J.; Xu, Y.; Wang, Y.; Niu, X.; Tan, B. Dual modification of Co doped CeO2 abrasives for enhanced chemical mechanical polishing performance. Ceram. Int. 2025, 51, 39227–39237. [Google Scholar] [CrossRef]

- Khan, M.A.; Ilyas, M.; Kalsoom, S.; Abbas, M.; Zohaib, H.M.; Ilyas, M.; Balouch, F.N.; Rasheed, M.; Iqbal, J. In-silico optimization of resveratrol interaction with nano-borophene: A DFT-guided study of supramolecular artistry. Comput. Biol. Chem. 2024, 112, 108179. [Google Scholar] [CrossRef]

- Sekkal, W.; Zaoui, A.; Benzerzour, M.; Abriak, N. Role of porosity on the stiffness and stability of (001) surface of the nanogranular C-S-H gel. Cem. Concr. Res. 2016, 87, 45–52. [Google Scholar] [CrossRef]

- Son, J.H.; Park, G.; Lee, D.-H.; Lee, Y.; Yun, Y.S.; Park, J.H.; Seo, J.-C.; Han, S.J. Selenium-promoted molten metal catalysts for methane pyrolysis: Modulating surface tension and catalytic activity. Appl. Catal. B Environ. 2025, 366, 125009. [Google Scholar] [CrossRef]

- Lv, G.; Cao, Y.; Liu, S.; Zhang, Z.; Li, X.; Wu, H.; Liu, T.; Liu, B.; Wang, K. Development and characterization of a novel alginate-based slurry and its fused silica CMP investigations. Ceram. Int. 2025, 51, 27146–27155. [Google Scholar] [CrossRef]

- Lv, G.; Hao, E.; Zhang, Z.; Liu, S.; Cao, Y.; Liu, T.; Li, X.; Wang, K. Effect of a novel alginate/5-aminovaleric acid slurry with CeO2/MoS2 abrasives on surface roughness and material removal rate of quartz glass. Appl. Surf. Sci. 2025, 698, 163096. [Google Scholar] [CrossRef]

- Zhang, Y.; Liang, J.; Jing, P.; Chi, K.; Yu, J.; Jia, X.; Xu, X.; Liu, B.; Bai, T.; Zhang, J. Promoting effect of LaOF on chemical mechanical polishing performance of cerium-based abrasives. J. Rare Earths 2025, 43, 2005–2015. [Google Scholar] [CrossRef]

- Kikugawa, M.; Goto, Y.; Yamazaki, K.; Manaka, Y.; Nanba, T.; Matsumoto, H.; Sato, A.; Aoki, M. Design of ammonia synthesis Ru catalysts with mesoporous structures through the Si-doping of cerium–lanthanum oxide. Appl. Catal. A Gen. 2025, 707, 120525. [Google Scholar] [CrossRef]

- Li, C.; Wang, Y. Iron/silicon oxy-hydroxide co-precipitate trace-incorporated [-Fe-O]m-[Si-O-]n colloids: A facile strategy for silica xerogel strengthening and toughening. Constr. Build. Mater. 2025, 461, 139895. [Google Scholar] [CrossRef]

- Liu, Z.; Zhang, Z.; Feng, J.; Yi, X.; Shi, C.; Gu, Y.; Zhao, F.; Liu, S.; Li, J. A novel atomic removal model for chemical mechanical polishing using developed mesoporous shell/core abrasives based on molecular dynamics. Nanoscale 2024, 16, 85–96. [Google Scholar] [CrossRef] [PubMed]

- Kubota, A. Chemical mechanical polishing of synthetic quartz using UV/ozone-treated CeO2 slurry. Mater. Lett. 2025, 382, 137856. [Google Scholar] [CrossRef]

- Gao, S.; Li, T.; Zhang, Y.; Yuan, S.; Kang, R. Insights into interfacial mechanism of CeO2/Silicon and atomic-scale removal process during chemo-mechanical grinding of silicon. Langmuir 2023, 39, 16606–16617. [Google Scholar] [CrossRef] [PubMed]

| Abrasives | Chemical Additives | Types of Glass | Ra (nm) | MRR (nm/min) | Ref. |

|---|---|---|---|---|---|

| CeO2 + LaOF | SNLS + PAAS | Quartz glass | 0.23 | 530.52 | [13] |

| CeO2 + diamond | / | Glass | 0.6 | 109.6 | [19] |

| CeO2 + h-BN | KOL | Fused silica | 0.124 | 532 | [20] |

| CeO2 + Er2O3 | STPP + ChCl | Fused silica | 0.07 | 625.5 | [21] |

| CeO2 + MoS2 | KOL | Quartz glass | 0.48 | 400.5 | [22] |

| CeO2 + Al2O3 | GC + SL-6C | K9 | 0.11 | 521.71 | This work |

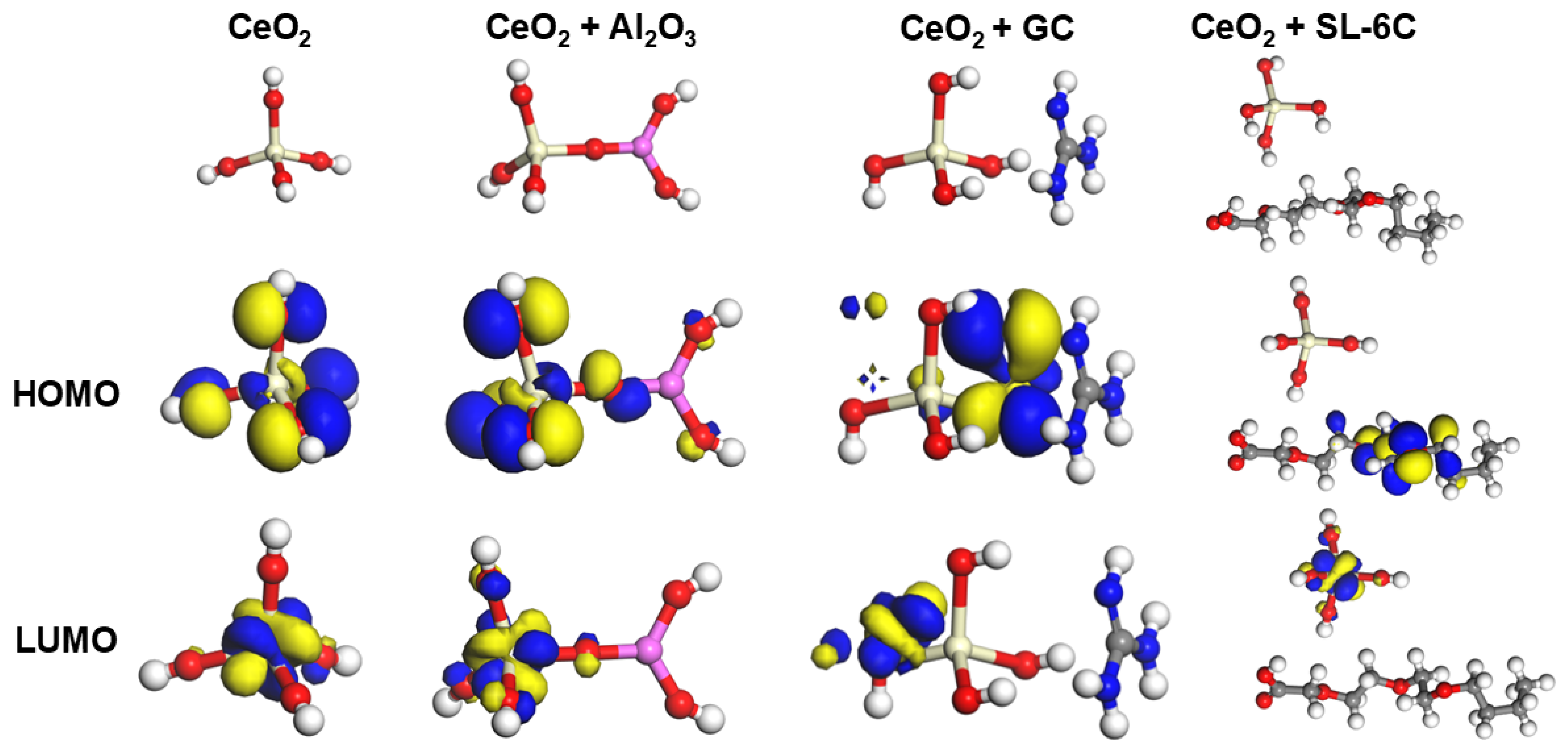

| Structure | CeO2 | CeO2 + Al2O3 | CeO2 + GC | CeO2 + SL-6C |

|---|---|---|---|---|

| HUMO (eV) | −8.151 | −6.586 | −6.109 | −6.646 |

| LUMO (eV) | −6.049 | −4.851 | −4.650 | −4.797 |

| HOMO-LUMO gap (eV) | 2.102 | 1.735 | 1.459 | 1.849 |

| Surface energy (kJ/A2) | −36.9 | −37.6 | −37.9 | −40.7 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, S.; Ye, R.; Zou, Z.; He, Z.; Feng, K.; Cui, H.; Chi, R.; Chen, Y.; Luo, Y. A High-Efficiency Environmentally Friendly Polishing Slurry for K9 Glass Utilizing Cerium-Based Compounds. Molecules 2025, 30, 4546. https://doi.org/10.3390/molecules30234546

Li S, Ye R, Zou Z, He Z, Feng K, Cui H, Chi R, Chen Y, Luo Y. A High-Efficiency Environmentally Friendly Polishing Slurry for K9 Glass Utilizing Cerium-Based Compounds. Molecules. 2025; 30(23):4546. https://doi.org/10.3390/molecules30234546

Chicago/Turabian StyleLi, Shaoping, Rui Ye, Zhemin Zou, Zhaobo He, Kai Feng, Huidong Cui, Ruan Chi, Yukun Chen, and Yue Luo. 2025. "A High-Efficiency Environmentally Friendly Polishing Slurry for K9 Glass Utilizing Cerium-Based Compounds" Molecules 30, no. 23: 4546. https://doi.org/10.3390/molecules30234546

APA StyleLi, S., Ye, R., Zou, Z., He, Z., Feng, K., Cui, H., Chi, R., Chen, Y., & Luo, Y. (2025). A High-Efficiency Environmentally Friendly Polishing Slurry for K9 Glass Utilizing Cerium-Based Compounds. Molecules, 30(23), 4546. https://doi.org/10.3390/molecules30234546