Impact of Yuanjiang Miscanthus lutarioriparius Aqueous Extract on Texture, Flavor Profile, and Antioxidant Activity of Yogurt During Storage

Abstract

1. Introduction

2. Results and Discussion

2.1. Changes in Titratable Acidity Yogurt Containing Aqueous Extract of Asparagus During Storage

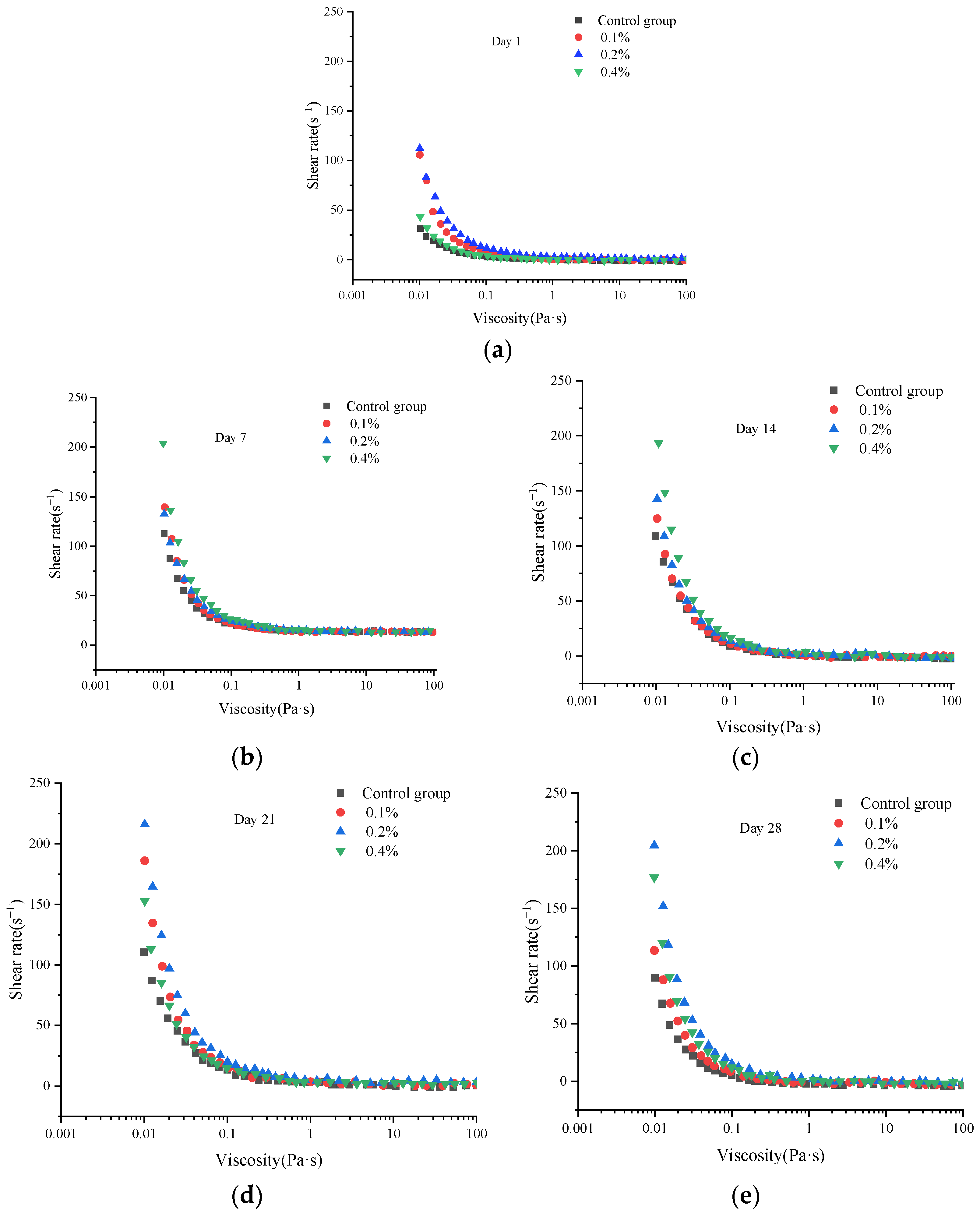

2.2. Changes in Viscosity of Yogurt Containing Aqueous Extract of Asparagus During Storage

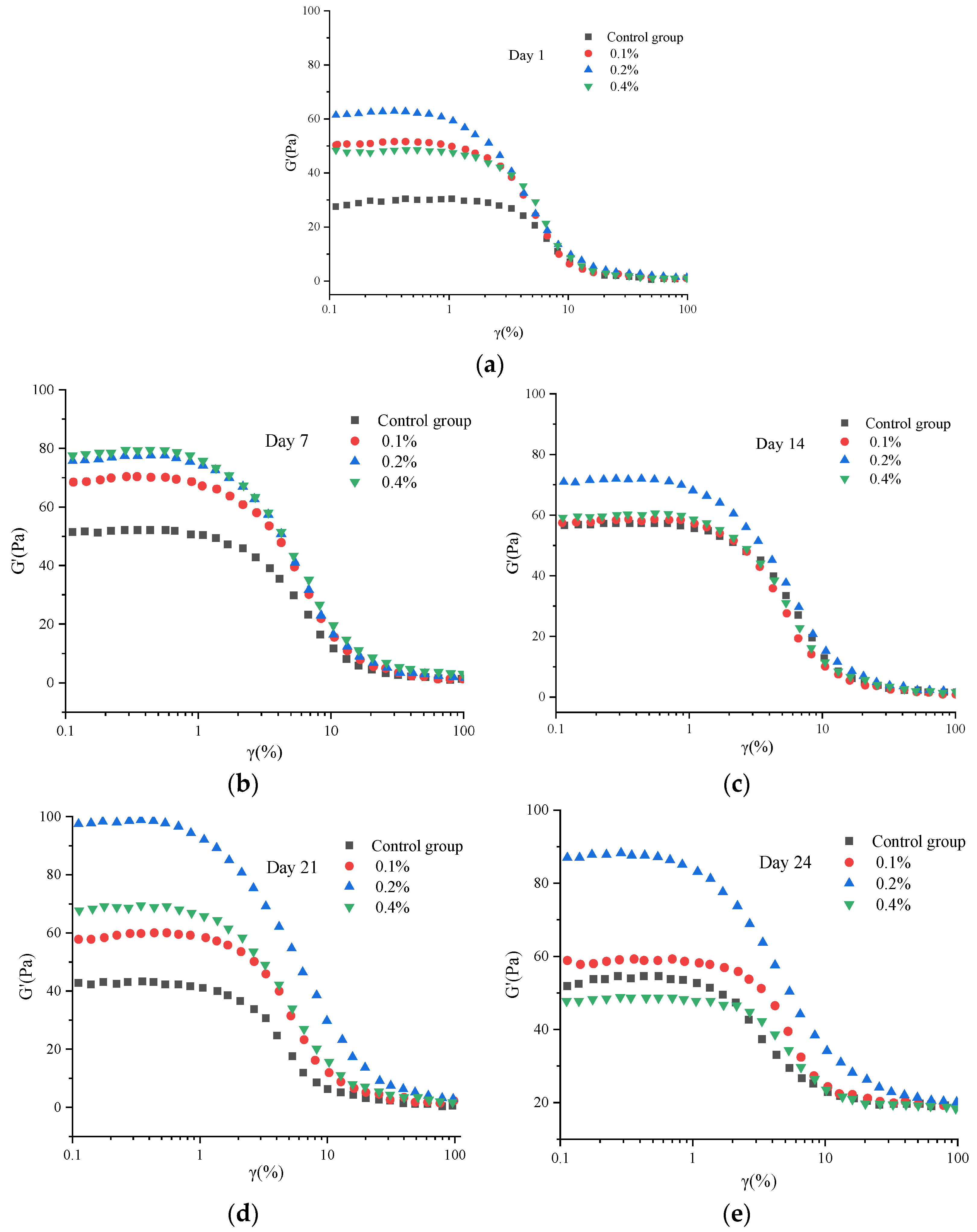

2.3. Strain Sweep Results and Analysis

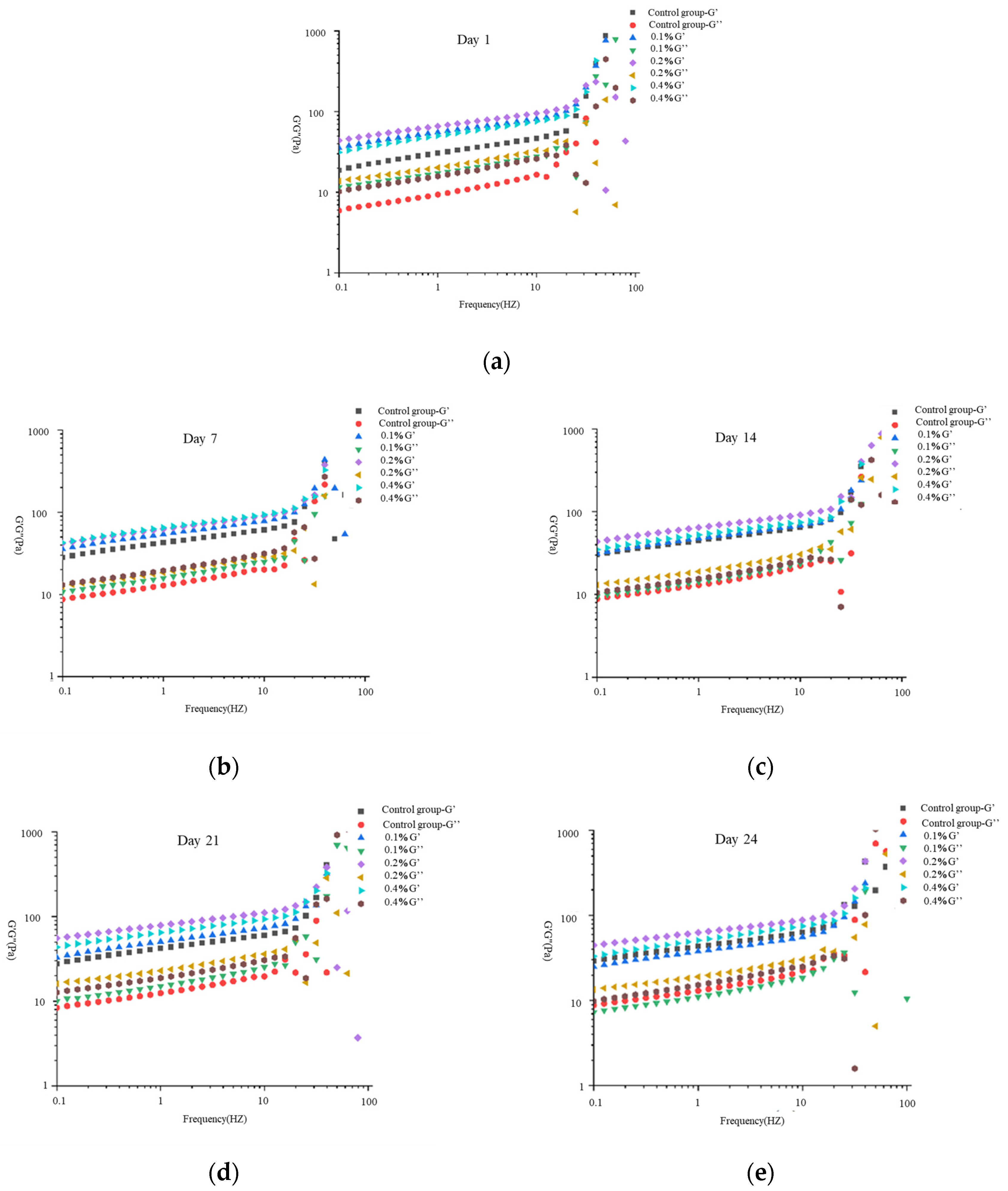

2.4. Frequency Sweep Results and Analysis

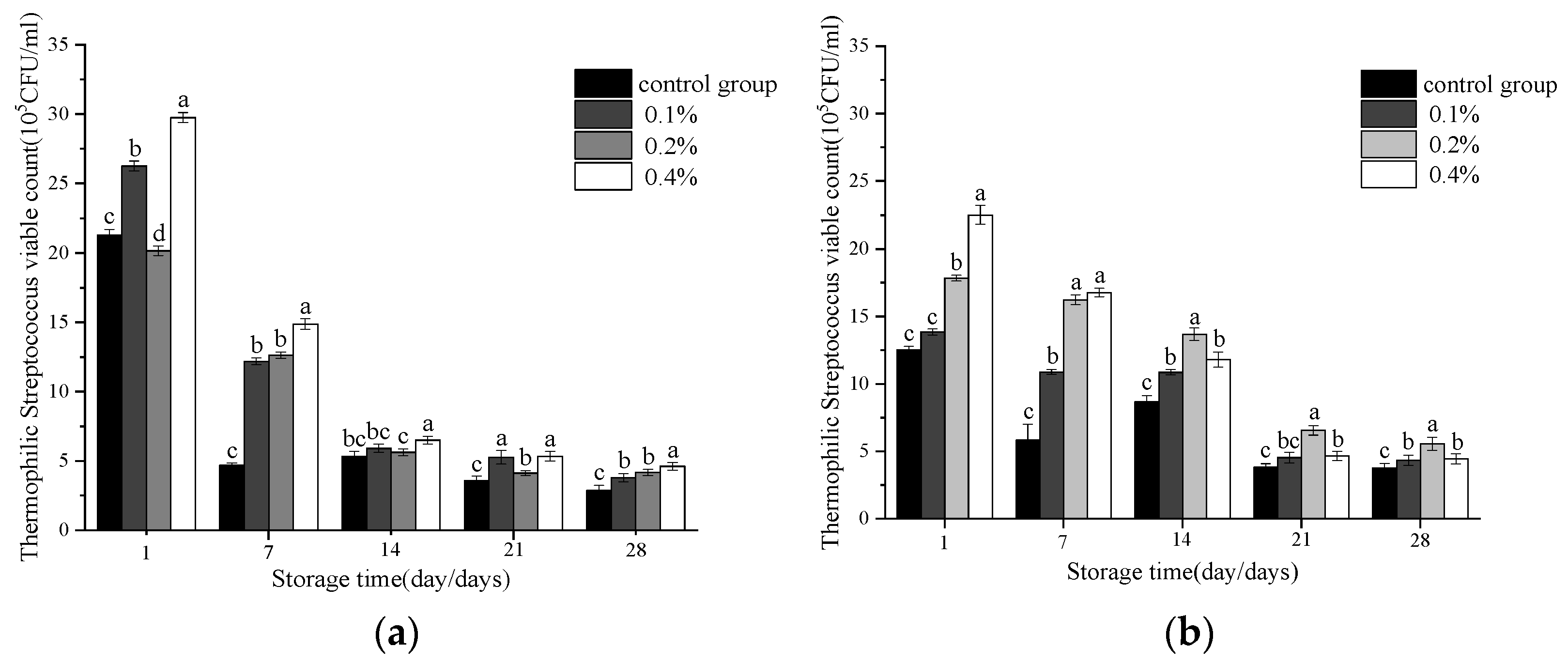

2.5. Changes in Viable Bacterial Count of Asparagus Yogurt During Storage Period

2.6. Changes in Texture Properties of Asparagus Yogurt During Storage

2.7. Chroma Changes in Yogurt During Storage

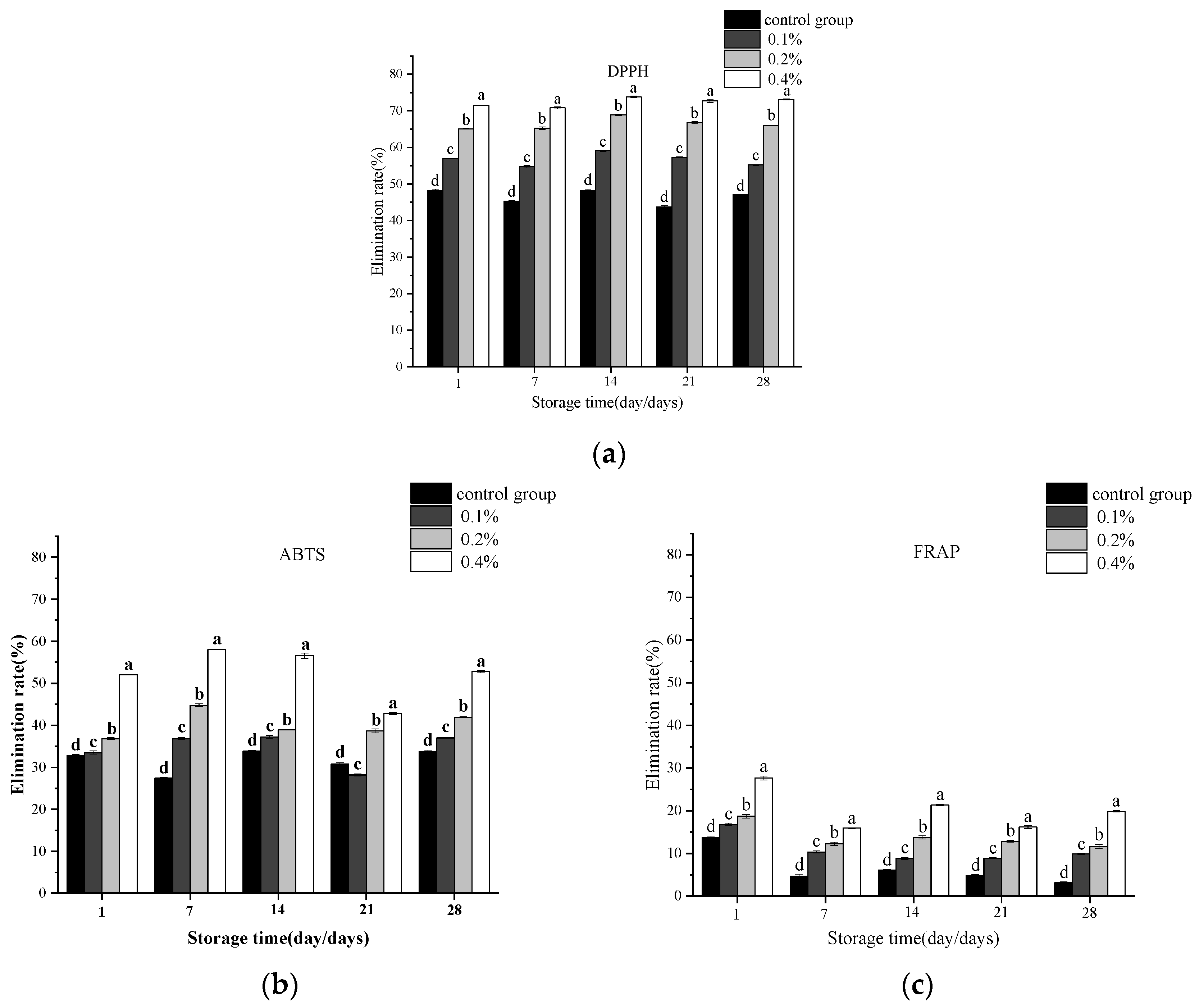

2.8. Changes in the Antioxidant Capacity of Asparagus Yogurt During the Storage Period

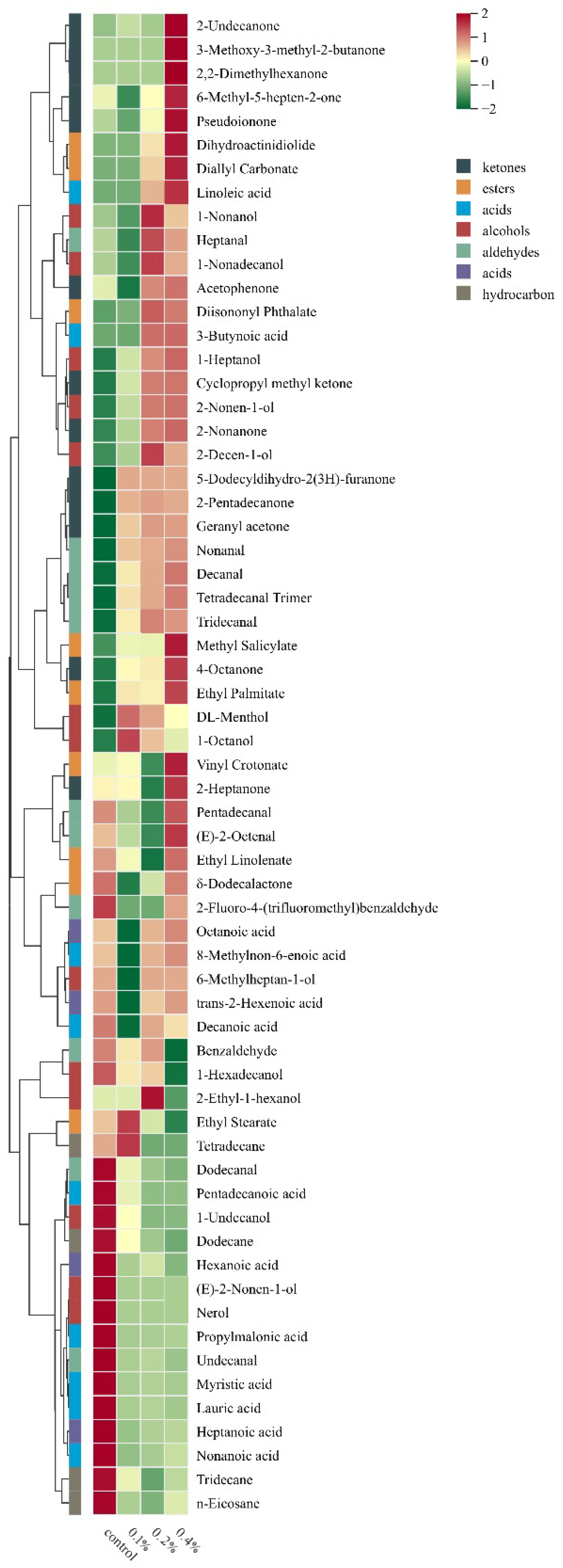

2.9. Changes in the Volatile Components in Yogurt During the Storage Period

2.10. Sensory Evaluation Score of Yogurt

3. Materials and Methods

3.1. Material

3.2. Test Method

3.2.1. Preparation of Yogurt with Aqueous Extract of Yuanjiang Asparagus

3.2.2. Storage Period

3.2.3. Physicochemical Analysis

3.2.4. Water Holding Capacity

3.2.5. Determination of Rheological Properties of Yogurt

3.2.6. Determination of Total Bacterial Colonies

3.2.7. Determination of Hardness, Consistency, Adhesiveness Index, and Cohesiveness

3.2.8. Determination of Chromaticity

3.2.9. Determination of Volatile Components

3.2.10. Sensory Evaluation

3.2.11. Determination of Storage Quality of Asparagus Aqueous Extract Yogurt

3.2.12. Data Processing

4. Conclusions

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Kazou, M.; Grafakou, A.; Tsakalidou, E.; Georgalaki, M. Zooming Into the Microbiota of Home-Made and Industrial Kefir Produced in Greece Using Classical Microbiological and Amplicon-Based Metagenomics Analyses. Front. Microbiol. 2021, 12, 621069. [Google Scholar] [CrossRef] [PubMed]

- Asefa, Z.; Tesfaye, A.; Desalegn, A.; Daba, T.; Haile, T. Formulation and Evaluation of Probiotic Starter Culture: Impact on Ethiopian Cottage Cheese “Ayib” Safety, Stability, Sensory Acceptability and Antioxidant Potential. One Health Outlook 2025, 7, 17. [Google Scholar] [CrossRef] [PubMed]

- Pires de Oliveira Galdino, I.K.C.; da Silva, M.O.M.; da Silva, A.P.A.; Santos, V.N.; Feitosa, R.L.P.; Ferreira, L.C.N.; Dantas, G.C.; Dos Santos Pereira, E.V.; de Oliveira, T.A.; Dos Santos, K.M.O.; et al. β-Glucosidase Activity and Antimicrobial Properties of Potentially Probiotic Autochthonous Lactic Cultures. PeerJ 2023, 11, e16094. [Google Scholar] [CrossRef] [PubMed]

- Babio, N.; Mena-Sánchez, G.; Salas-Salvadó, J. Eyond the nutritional value of yogurt: A diet quality indicator? Nutr. Hosp. 2017, 34, 26–30. [Google Scholar] [CrossRef]

- Martins, N.; Oliveira, M.B.P.P.; Ferreira, I.C.F.R. Development of Functional Dairy Foods. In Bioactive Molecules in Food; Springer: Cham, Switzerland, 2018; pp. 1–19. ISBN 978-3-319-54528-8. [Google Scholar]

- Sabaragamuwa, R.; Perera, C.O. Total Triterpenes, Polyphenols, Flavonoids, and Antioxidant Activity of Bioactive Phytochemicals of Centella Asiatica by Different Extraction Techniques. Foods 2023, 12, 3972. [Google Scholar] [CrossRef]

- Cao, Q.; Yan, J.; Sun, Z.; Gong, L.; Wu, H.; Tan, S.; Lei, Y.; Jiang, B.; Wang, Y. Simultaneous Optimization of Ultrasound-Assisted Extraction for Total Flavonoid Content and Antioxidant Activity of the Tender Stem of Triarrhena Lutarioriparia Using Response Surface Methodology. Food Sci. Biotechnol. 2021, 30, 37–45. [Google Scholar] [CrossRef]

- Mondal, S.; Rahaman, S.T. Flavonoids: A Vital Resource in Healthcare and Medicine. Pharm. Pharmacol. Int. J. 2020, 8, 91–104. [Google Scholar] [CrossRef]

- Matos, J.; Afonso, C.; Cardoso, C.; Serralheiro, M.L.; Bandarra, N.M. Yogurt Enriched with Isochrysis Galbana: An Innovative Functional Food. Foods 2021, 10, 1458. [Google Scholar] [CrossRef]

- Duan, W.; Guan, Q.; Zhang, H.-L.; Wang, F.-Z.; Lu, R.; Li, D.-M.; Geng, Y.; Xu, Z.-H. Improving Flavor, Bioactivity, and Changing Metabolic Profiles of Goji Juice by Selected Lactic Acid Bacteria Fermentation. Food Chem. 2023, 408, 135155. [Google Scholar] [CrossRef]

- Fan, X.; Liu, M.; Shi, Z.; Zhang, T.; Du, L.; Wu, Z.; Zeng, X.; Wu, X.; Pan, D. Binary Probiotic Fermentation Promotes Signal (Cyclic AMP) Exchange to Increases the Number of Viable Probiotics, Anthocyanins and Polyphenol Content, and the Odor Scores of Wolfberry Fermented Beverages. Food Chem. 2024, 448, 139085. [Google Scholar] [CrossRef]

- Zhang, L.; Jiang, L.; Yan, W.; Tao, H.; Yao, C.; An, L.; Sun, Y.; Hu, T.; Sun, W.; Qian, X.; et al. Exogenous Additives Reshape the Microbiome and Promote the Reduction of Resistome in Co-Composting of Pig Manure and Mushroom Residue. J. Hazard. Mater. 2025, 481, 136544. [Google Scholar] [CrossRef]

- Lee, W.J.; Lucey, J.A. Structure and Physical Properties of Yogurt Gels: Effect of Inoculation Rate and Incubation Temperature. J. Dairy Sci. 2004, 87, 3153–3164. [Google Scholar] [CrossRef] [PubMed]

- Nanakali, N.M.; Muhammad Al-saadi, J.; Sulaiman Hadi, C. Functional and Physiochemical Properties of the Yoghurt Modified by Heat Lactosylation and Microbial Transglutaminase Cross-Linking of Milk Proteins. Food Sci. Nutr. 2023, 11, 722–732. [Google Scholar] [CrossRef] [PubMed]

- Zhang, X.; LaPointe, G.; Liu, Y.; Wang, X.; Xiao, L.; Zhao, X.; Li, W. Comparative Analysis of Exopolysaccharide-Producing Lactiplantibacillus Plantarum with Ropy and Non-Ropy Phenotypes on the Gel Properties and Protein Conformation of Fermented Milk. Food Chem. 2023, 420, 136117. [Google Scholar] [CrossRef] [PubMed]

- Kong, X.; Xiao, Z.; Du, M.; Wang, K.; Yu, W.; Chen, Y.; Liu, Z.; Cheng, Y.; Gan, J. Physicochemical, Textural, and Sensorial Properties of Soy Yogurt as Affected by Addition of Low Acyl Gellan Gum. Gels 2022, 8, 453. [Google Scholar] [CrossRef]

- Riantiningtyas, R.R.; Sager, V.F.; Chow, C.Y.; Thybo, C.D.; Bredie, W.L.P.; Ahrné, L. 3D Printing of a High Protein Yoghurt-Based Gel: Effect of Protein Enrichment and Gelatine on Physical and Sensory Properties. Food Res. Int. 2021, 147, 110517. [Google Scholar] [CrossRef]

- Gonçalves, R.F.S.; Rodrigues, R.; Vicente, A.A.; Pinheiro, A.C. Incorporation of Solid Lipid Nanoparticles into Stirred Yogurt: Effects in Physicochemical and Rheological Properties during Shelf-Life. Nanomaterials 2023, 13, 93. [Google Scholar] [CrossRef]

- Bianco, S.; Panja, S.; Adams, D.J. Using Rheology to Understand Transient and Dynamic Gels. Gels 2022, 8, 132. [Google Scholar] [CrossRef]

- Sharifi-Rad, J.; Rodrigues, C.F.; Stojanović-Radić, Z.; Dimitrijević, M.; Aleksić, A.; Neffe-Skocińska, K.; Zielińska, D.; Kołożyn-Krajewska, D.; Salehi, B.; Milton Prabu, S.; et al. Probiotics: Versatile Bioactive Components in Promoting Human Health. Med. Kaunas Lith. 2020, 56, 433. [Google Scholar] [CrossRef]

- Zaib, S.; Hayat, A.; Khan, I. Probiotics and Their Beneficial Health Effects. Mini Rev. Med. Chem. 2024, 24, 110–125. [Google Scholar] [CrossRef]

- Xu, J.; Zhang, T.; Chen, H.; Dai, Y.; Li, Z.; He, J.; Ju, R.; Hou, A. Study on the Fermented Grain Characteristics and Volatile Flavor Substances during the Tuqu Fermentation of Hunan Light-Flavor Baijiu. Foods 2024, 13, 899. [Google Scholar] [CrossRef]

- Wang, L.; Zhang, F.; Zheng, B.; Zhang, Y.; Pan, L. Stability and Flavor of Set Yogurt Fortified with Tremella Fuciformis Polysaccharide during Cold Storage. Curr. Res. Food Sci. 2023, 7, 100536. [Google Scholar] [CrossRef] [PubMed]

- Liu, H.-C.; Urban, M.W. Optical Coherence Viscometry. Appl. Phys. Lett. 2021, 118, 164102. [Google Scholar] [CrossRef] [PubMed]

- Lu, W.; Zhang, Y.; Xiao, C.; Chen, D.; Ye, Q.; Zhang, C.; Meng, X.; Wang, S. The Comprehensive Utilization of Bean Dregs in High-Fiber Tofu. Foods 2022, 11, 1475. [Google Scholar] [CrossRef] [PubMed]

- Chileh Chelh, T.; Rincon-Cervera, M.A.; Gomez-Mercado, F.; Lopez-Ruiz, R.; Gallon-Bedoya, M.; Ezzaitouni, M.; Guil-Guerrero, J.L. Wild Asparagus Shoots Constitute a Healthy Source of Bioactive Compounds. Molecules 2023, 28, 5786. [Google Scholar] [CrossRef]

- Zhao, M.; Li, H.; Zhang, D.; Li, J.; Wen, R.; Ma, H.; Zou, T.; Hou, Y.; Song, H. Variation of Aroma Components of Pasteurized Yogurt with Different Process Combination before and after Aging by DHS/GC-O-MS. Molecules 2023, 28, 1975. [Google Scholar] [CrossRef]

- Arslaner, A. The Effects of Adding Garlic (Allium sativum L.) on the Volatile Composition and Quality Properties of Yogurt. Food Sci. Technol. 2020, 40, 582–591. [Google Scholar] [CrossRef]

- Chi, X.; Yang, Q.; Su, Y.; Zhang, J.; Sun, B.; Ai, N. Improvement of Rheological and Sensory Properties of Lactobacillus helveticus Fermented Milk by Prebiotics. Food Chem. X 2024, 23, 101679. [Google Scholar] [CrossRef]

- Dan, T.; Hu, H.; Tian, J.; He, B.; Tai, J.; He, Y. Influence of Different Ratios of Lactobacillus Delbrueckii Subsp. Bulgaricus and Streptococcus Thermophilus on Fermentation Characteristics of Yogurt. Molecules 2023, 28, 2123. [Google Scholar] [CrossRef]

- Wu, R.; Yu, M.; Liu, X.; Meng, L.; Wang, Q.; Xue, Y.; Wu, J.; Yue, X. Changes in Flavour and Microbial Diversity during Natural Fermentation of Suan-Cai, a Traditional Food Made in Northeast China. Int. J. Food Microbiol. 2015, 211, 23–31. [Google Scholar] [CrossRef]

- Chi, X.; Yang, Q.; Su, Y.; Xi, Y.; Wang, W.; Sun, B.; Ai, N. Effect of Prebiotics on Rheological Properties and Flavor Characteristics of Streptococcus Thermophilus Fermented Milk. Curr. Res. Food Sci. 2024, 9, 100839. [Google Scholar] [CrossRef]

- Gupta, M.K.; Torrico, D.D.; Ong, L.; Gras, S.L.; Dunshea, F.R.; Cottrell, J.J. Plant and Dairy-Based Yogurts: A Comparison of Consumer Sensory Acceptability Linked to Textural Analysis. Foods 2022, 11, 463. [Google Scholar] [CrossRef] [PubMed]

- He, T.; Yu, J.; Wu, S.; Tang, X.; Liu, C.; Zhou, H. Effects of Exogenous Supplementation with Yuanjiang Miscanthus lutarioriparius Aqueous Extract on Fermented Yogurt. China Dairy 2022, 0, 86–91. [Google Scholar]

- Tang, J.; Tang, X.; Zhang, F.; Luo, J.; Liu, C.; Zhou, H. Effect of Exogenous Addition of Lactobacillus paracasei LZ9077 on Properties of Set-Type Yogurt. J. Dairy Sci. Technol. 2023, 46, 1–6. [Google Scholar]

- GB 5009.239-2016; National Food Safety Standard—Determination of Acidity in Food. National Health and Family Planning Commission of the People’s Republic of China: Beijing, China, 2016.

- Li, G.L.; Liu, J.; Li, X.; Ma, L. Storage Quality of Yam and Hawthorn Yogurt and Its Antioxidation in Simulated Gastrointestinal Fluid. China Brew. 2021, 40, 124–128. [Google Scholar] [CrossRef]

- Shen, S.; Chen, D.; Li, X.; Li, T.; Yuan, M.; Zhou, Y.; Ding, C. Optimization of Extraction Process and Antioxidant Activity of Polysaccharides from Leaves of Paris polyphylla. Carbohydr. Polym. 2014, 104, 80–86. [Google Scholar] [CrossRef]

- Gao, F.; Li, D.; Li, H.; Chen, H.; Mao, X.; Wang, P. Influence of Post-Heating Treatment on the Sensory and Textural Properties of Stirred Fermented Milk. Foods 2023, 12, 3042. [Google Scholar] [CrossRef]

- GB 4789.35-2023; National Food Safety Standard—Food Microbiological Examination—Examination of Lactic Acid Bacteria. National Health Commission of the People’s Republic of China: Beijing, China; State Administration for Market Regulation: Beijing, China, 2023.

- Bustamante, M.; Giménez, P.; Just-Borràs, A.; Solé-Clua, I.; Gombau, J.; Heras, J.M.; Sieczkowski, N.; Gil, M.; Pérez-Navarro, J.; Gómez-Alonso, S.; et al. Use of Glutathione, Pure or as a Specific Inactivated Yeast, as an Alternative to Sulphur Dioxide for Protecting White Grape Must from Browning. Foods 2024, 13, 310. [Google Scholar] [CrossRef]

- Bakırcı, İ.; Terzioğlu, M.; Akkaya, İ. Volatile Compounds, Antioxidant Activity, ACE Inhibitory Activity, HMF Content and Microstructure of Fruit Yoghurts. Mljekarstvo 2023, 73, 250–262. [Google Scholar] [CrossRef]

- Wright, B.J.; Zevchak, S.E.; Wright, J.M.; Drake, M.A. The Impact of Agglomeration and Storage on Flavor and Flavor Stability of Whey Protein Concentrate 80% and Whey Protein Isolate. J. Food Sci. 2009, 74, S17–S29. [Google Scholar] [CrossRef]

| Control Group | 0.1% | 0.2% | 0.4% | ||

|---|---|---|---|---|---|

| Hardness g | 1 | 43.90 ± 0.23 d | 55.09 ± 0.37 c | 58.38 ± 0.47 b | 61.08 ± 0.31 a |

| 7 | 72.57 ± 0.46 d | 87.78 ± 0.26 c | 95.06 ± 0.56 b | 104.13 ± 0.68 a | |

| 14 | 62.06 ± 0.54 c | 91.63 ± 0.55 b | 95.67 ± 0.93 b | 168.85 ± 0.37 a | |

| 21 | 40.92 ± 1.01 b | 39.87 ± 1.26 b | 43.09 ± 0.50 a | 44.76 ± 0.20 a | |

| Consistency g·s | 1 | 123.4 ± 0.34 d | 144.79 ± 0.60 c | 152.51 ± 0.38 b | 184.78 ± 0.44 a |

| 7 | 356.53 ± 2.88 d | 455.65 ± 2.68 c | 488.29 ± 2.12 b | 515.06 ± 4.72 a | |

| 14 | 431.65 ± 2.34 d | 470.43 ± 1.21 c | 512.55 ± 4.14 b | 541.94 ± 3.55 a | |

| 21 | 441.02 ± 2.71 d | 481.96 ± 1.17 c | 535.61 ± 2.41 b | 553.52 ± 2.14 a | |

| Cohesion g | 1 | 97.00 ± 0.51 d | 106.15 ± 0.45 c | 108.69 ± 0.45 a | 107.40 ± 0.43 b |

| 7 | 157.11 ± 1.49 d | 168.93 ± 0.53 c | 172.36 ± 1.67 b | 218.98 ± 1.19 a | |

| 14 | 124.63 ± 0.71 c | 117.96 ± 0.87 d | 131.72 ± 0.88 b | 142.87 ± 1.67 a | |

| 21 | 94.24 ± 1.26 c | 98.10 ± 1.31 b | 105.51 ± 0.81 a | 98.72 ± 0.65 b | |

| Viscosity index | 1 | 23.50 ± 0.37 b | 24.00 ± 0.12 b | 24.23 ± 0.57 b | 25.65 ± 0.40 a |

| 7 | 66.39 ± 0.80 d | 69.56 ± 0.22 c | 76.46 ± 1.73 b | 86.27 ± 0.66 a | |

| 14 | 23.34 ± 2.18 c | 19.33 ± 0.98 d | 37.91 ± 1.31 b | 46.18 ± 1.04 a | |

| 21 | 14.81 ± 0.61 b | 15.53 ± 0.27 ab | 16.27 ± 0.74 a | 16.28 ± 0.26 a |

| Storage Time | Control Group | 0.1% | 0.2% | 0.4% | |

|---|---|---|---|---|---|

| L | 1 | 71.90 ± 0.51 a | 71.57 ± 0.25 a | 70.93 ± 1.17 a | 70.48 ± 0.35 a |

| 7 | 71.88 ± 0.27 a | 71.17 ± 0.31 ab | 70.40 ± 0.72 b | 70.26 ± 0.23 b | |

| 14 | 71.85 ± 0.73 a | 71.21 ± 0.48 ab | 68.64 ± 0.43 bc | 68.02 ± 2.02 c | |

| 21 | 71.08 ± 0.41 ab | 72.31 ± 0.42 a | 70.96 ± 0.65 ab | 69.84 ± 0.97 b | |

| 28 | 70.36 ± 0.81 a | 72.08 ± 0.52 a | 70.76 ± 0.57 a | 70.16 ± 1.53 a | |

| a | 1 | −2.48 ± 0.03 a | −2.46 ± 0.16 a | −2.57 ± 0.29 a | −2.45 ± 0.14 a |

| 7 | −2.47 ± 0.06 a | −2.31 ± 0.11 a | −2.44 ± 0.11 a | −2.30 ± 0.07 a | |

| 14 | −2.50 ± 0.12 b | −2.43 ± 0.13 a | −2.08 ± 0.05 b | −2.28 ± 0.16 ab | |

| 21 | −2.37 ± 0.06 a | −2.68 ± 0.06 b | −2.49 ± 0.11 ab | −2.37 ± 0.09 a | |

| 28 | −2.39 ± 0.17 a | −2.55 ± 0.08 a | −2.65 ± 0.24 a | −2.35 ± 0.07 a | |

| b | 1 | 1.03 ± 0.42 c | 1.75 ± 0.60 c | 4.1 ± 0.55 b | 3.48 ± 0.93 b |

| 7 | 0.94 ± 0.43 b | 1.42 ± 0.53 b | 4.04 ± 0.52 a | 3.51 ± 0.89 a | |

| 14 | 1.49 ± 0.48 c | 2.01 ± 0.67 bc | 3.85 ± 0.11 ab | 4.67 ± 1.56 a | |

| 21 | 1.23 ± 0.31 c | 3.41 ± 0.51 b | 3.79 ± 0.60 b | 5.51 ± 0.83 a | |

| 28 | 1.50 ± 0.37 c | 3.54 ± 0.62 b | 4.94 ± 0.06 a | 5.81 ± 0.43 a |

| Project | Appearance | Organizational Status | Flavor | Taste |

|---|---|---|---|---|

| 20 points | 20 points | 30 points | 30 points | |

| 1 | Uniform in color, without lumps or whey separation 12–20 | The curd is uniform and fine, with a smooth surface free of bubbles or only a few bubbles. 12–20 | Have a yogurt flavor, a moderate asparagus aroma, and is highly acceptable with no other off-flavors 20–30 | The yogurt is moderately sweet and sour, with a moderate asparagus flavor. It has a delicate and thick texture 20–30 |

| 2 | The uniformity of color is average, with a few lumps and a small amount of whey precipitated 6–11 | The curd is relatively uniform, with a rough surface and a few bubbles 6–11 | Have a yogurt flavor, but the asparagus smell is either too strong or too weak, with a slight off-flavor, which is acceptable 10–19 | The yogurt is slightly sour or sweet, and the asparagus has a stronger or lighter flavor with a slight frosty texture 10–19 |

| 3 | The color uniformity is poor, with severe lumps and serious whey precipitation < 6 | There is no curd and it is in a paste-like state < 6 | Do not have the inherent flavor of yogurt, and the asparagus smell is too strong or absent. It has a strong off-flavor and is unacceptable < 10 | The sourness of yogurt is unacceptable. The frosted texture is severe, and the asparagus flavor is too strong or absent < 10 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

He, S.; Wang, J.; Tang, X.; Fan, X.; Luo, J.; He, T.; Zhou, H. Impact of Yuanjiang Miscanthus lutarioriparius Aqueous Extract on Texture, Flavor Profile, and Antioxidant Activity of Yogurt During Storage. Molecules 2025, 30, 4042. https://doi.org/10.3390/molecules30204042

He S, Wang J, Tang X, Fan X, Luo J, He T, Zhou H. Impact of Yuanjiang Miscanthus lutarioriparius Aqueous Extract on Texture, Flavor Profile, and Antioxidant Activity of Yogurt During Storage. Molecules. 2025; 30(20):4042. https://doi.org/10.3390/molecules30204042

Chicago/Turabian StyleHe, Siyi, Jianglin Wang, Xia Tang, Xiankang Fan, Jie Luo, Tong He, and Hui Zhou. 2025. "Impact of Yuanjiang Miscanthus lutarioriparius Aqueous Extract on Texture, Flavor Profile, and Antioxidant Activity of Yogurt During Storage" Molecules 30, no. 20: 4042. https://doi.org/10.3390/molecules30204042

APA StyleHe, S., Wang, J., Tang, X., Fan, X., Luo, J., He, T., & Zhou, H. (2025). Impact of Yuanjiang Miscanthus lutarioriparius Aqueous Extract on Texture, Flavor Profile, and Antioxidant Activity of Yogurt During Storage. Molecules, 30(20), 4042. https://doi.org/10.3390/molecules30204042