The Influence of Horse Age, High-Pressure Technique and Various Heat Treatment Methods on the Quality of Horse Meat

Abstract

1. Introduction

2. Results and Discussion

2.1. Chemical Composition

2.2. Physicochemical Properties

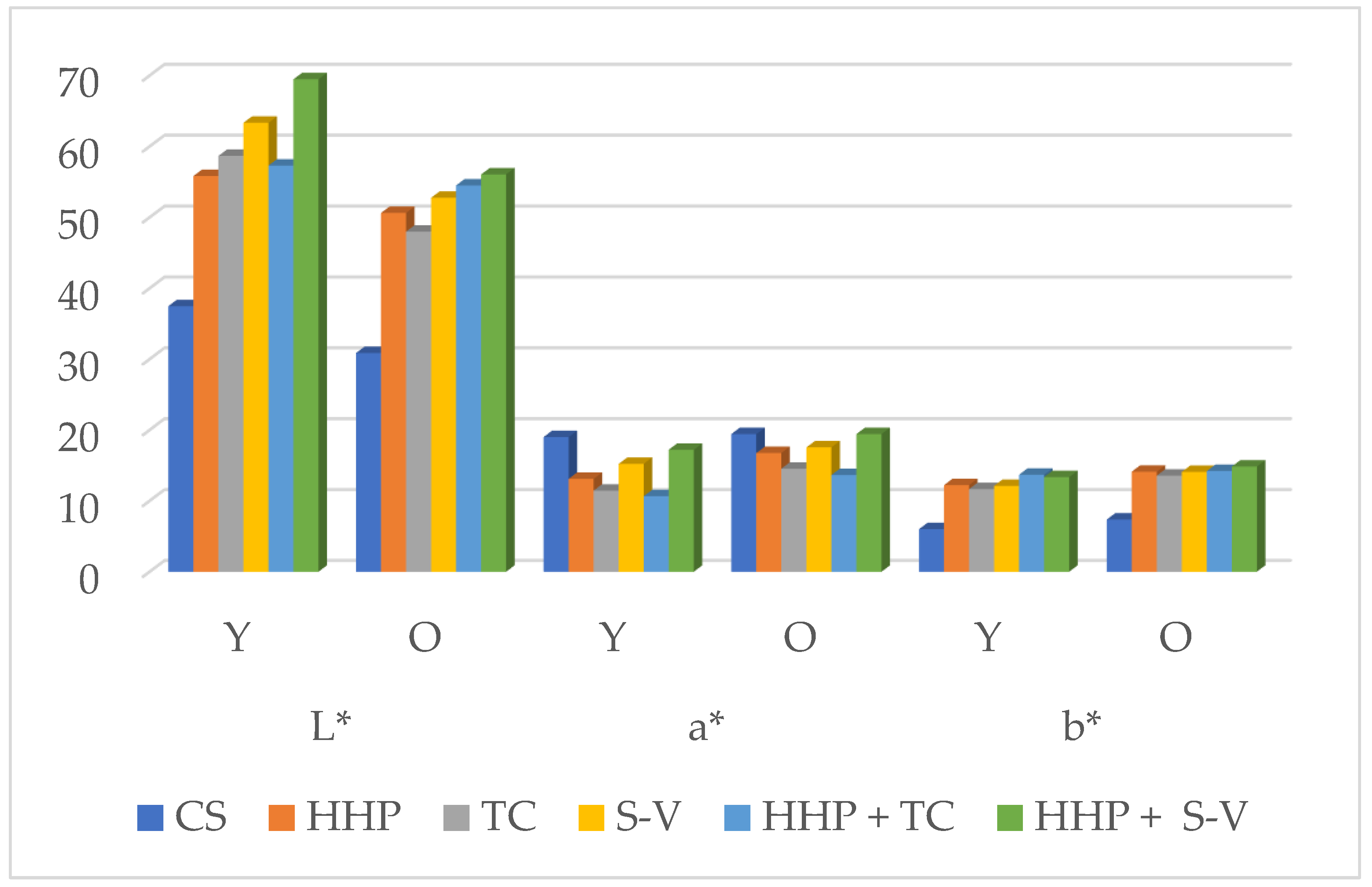

2.3. Color Parameters and the Level of Heme Pigments

2.4. Texture Parameters

2.5. Sensory Properties

3. Materials and Methods

3.1. Experimental Design

- I.

- Younger horses—2 to 7 years old.

- II.

- Older horses—7 to 12 years old.

3.2. HHP Meat Processing and Cooking Procedure

3.3. Analytical Methods

3.4. Statistical Analysis

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Nowicka, P.; Wojdyło, A.; Oszmiański, J. Microbiological Hazards in Minimally Processed Foods and Effective Methods to Eliminate Them. Żywność. Nauka. Technol. Jakość 2014, 93, 5–18. (In Polish) [Google Scholar] [CrossRef]

- Makała, H. High-Pressure Method Applied in Processing of Meat and Meat Products. Żywność. Nauka. Technol. Jakość 2019, 26, 38–53. (In Polish) [Google Scholar] [CrossRef]

- Kucharyk, S.; Rudy, M.; Gil, M.; Stanisławczyk, R.; Mroczek, K. Unconventional methods for the preservation of meat products and their impact on human health and the environment. Pol. J. Sust. Devel. 2019, 23, 53–62. [Google Scholar] [CrossRef]

- Bolumar, T.; Orlien, V.; Sikes, A.; Aganovic, K.; Bak, K.H.; Guyon, C.; Stubler, A.S.; d Lamballerie, M.; Hertel, C.; Brüggemann, D.A. High-pressure processing of meat: Molecular impacts and industrial applications. Compr. Rev. Food Sci. Food Saf. 2021, 20, 332–368. [Google Scholar] [CrossRef]

- Gómez, I.; Janardhanan, R.; Ibañez, F.C.; Beriain, M.J. The Effects of Processing and Preservation Technologies on Meat Quality: Sensory and Nutritional Aspects. Foods 2020, 9, 1416. [Google Scholar] [CrossRef]

- Adisurya, I.P.K.; Sari, A.R. Effects of High-Pressure Processing on Milk, Meat, Fruit, and Vegetable: A Review. Adv. Biol. Sci. Res. 2022, 19, 302–308. [Google Scholar]

- Buckow, R.; Sikes, A.; Tume, R. Effect of High Pressure on Physicochemical Properties of Meat. Crit. Rev. Food Sci. Nutr. 2013, 53, 770–786. [Google Scholar] [CrossRef] [PubMed]

- Mohd Azmi, S.I.; Kumar, P.; Sharma, N.; Sazili, A.Q.; Lee, S.J.; Ismail-Fitry, M.R. Application of plant proteases in meat tenderiza-tion: Recent trends and future prospects. Foods 2023, 12, 1336. [Google Scholar] [CrossRef]

- Datta, N.; Deeth, H.C. High pressure processing. In Encyclopedia of Dairy Sciences; Roginski, H., Fuquay, J.W., Fox, P.F., Eds.; Academic Press: London, UK, 2003; pp. 1327–1333. [Google Scholar]

- Ma, H.J.; Ledward, D.A. High pressure/thermal treatment effects on the texture of beef muscle. Meat Sci. 2004, 68, 347–355. [Google Scholar] [CrossRef]

- Bak, K.H.; Bolumar, T.; Karlsson, A.H.; Lindahl, G.; Orlien, V. Effect of high pressure treatment on the color of fresh and processed meats: A review. Crit. Rev. Food Sci.Nutr. 2017, 59, 228–252. [Google Scholar] [CrossRef] [PubMed]

- Rostocki, A.J.; Ptasznik, S.; Makała, H.; Tarakowski, R. Assessment of the usefulness of high-pressure technology for meat maintenance. Case study. PostępyNauki.i Technol. Prz. Rol.-Spoż. 2018, 73, 5–16. (In Polish) [Google Scholar]

- Jofré, A.; Serra, X. Processing of meat products utilizing high pressure. In High Pressure Processing of Food; Balasubramaniam, V.M., Ed.; Springer Science-Business Media: New York, NY, USA, 2016; pp. 591–623. [Google Scholar]

- Orlien, V. High pressure treatment and the effects on meat proteins. Med. Res. Arch. 2017, 5, 1–10. [Google Scholar]

- Marcos, B.; Kerry, J.P.; Mullen, A.M. High pressure induced changes on sarcoplasmic protein fraction and quality indicators. Meat Sci. 2010, 85, 115–120. [Google Scholar] [CrossRef]

- Chan, J.T.Y.; Omana, D.A.; Betti, M. Application of high pressure processing to improve the functional properties of pale, soft, and exudative (PSE)-like turkey meat. Innov. Food Sci. Emerg. Technol. 2011, 12, 216–225. [Google Scholar] [CrossRef]

- Grossi, A.; Søltoft-Jensen, J.; Knudsen, J.C.; Christensen, M.; Orlien, V. Reduction of salt in pork sausages by the addition of carrot fibre or potato starch and high pressure treatment. Meat Sci. 2012, 92, 481–489. [Google Scholar] [CrossRef] [PubMed]

- Grossi, A.; Olsen, K.; Bolumar, T.; Rinnan, Å.; Øgendal, L.H.; Orlien, V. The effect of high pressure on the functional properties of pork myofibrillar proteins. Food Chem. 2016, 196, 1005–1015. [Google Scholar] [CrossRef]

- Sun, X.D.; Holley, R.A. High hydrostatic pressure effects on the texture of meat and meat products. J. Food Sci. 2010, 75, 17–23. [Google Scholar] [CrossRef] [PubMed]

- Malinowska-Pańczyk, E.; Kołodziejska, I. Possibilities of using high pressure in meat and fish industry. Medycyna Wet. 2009, 65, 455–459. (In Polish) [Google Scholar]

- Arcos-Garcia, G.; Totosaus, A.; Guerrero, I.; Perez-Chabela, M.L. Physicochemical, sensory, functional and microbial characterization of horse meat. Rev. Bras. Agrociência 2002, 8, 43–46. [Google Scholar]

- Lorenzo, J.M.; Sarries, M.V.; Tateo, A.; Polidori, P.; Franco, D.; Lanza, M. Carcass characteristics, meat quality and nutritional value of horsemeat: A review. Meat Sci. 2014, 96, 1478–1488. [Google Scholar] [CrossRef]

- Seong, P.N.; Park, K.M.; Kang, G.H.; Cho, S.H.; Park, B.Y.; Chae, H.S.; Ba, H.V. The differences in chemical composition, physical quality traits and nutritional values of horse meat as affected by various retail cut types. Asian-Australas. J. Anim. Sci. 2016, 29, 89–99. [Google Scholar] [CrossRef] [PubMed]

- Dobranić, V.; Njari, B.; Mioković, B.; Cvrtila Fleck, Ž.; Kadivc, M. Chemical composition of horse meat. Meso 2009, XI, 62–67. [Google Scholar]

- Reesman, C.; Sullivan, G.; Danao, M.-G.; Mafi, G.G.; Pfeiffer, M.; Ramanathan, R. Effects of high-pressure processing on cooked color and eating qualities of dark-cutting beef. Appl. Food Res. 2023, 3, 100260. [Google Scholar] [CrossRef]

- Sun, S.; Sullivan, G.; Stratton, J.; Bower, C.; Cavender, G. Effect of HPP treatment on the safety and quality of beef steak intended for sous vide cooking. LWT-Food Sci. Technol. 2017, 86, 185–192. [Google Scholar] [CrossRef]

- Jaelan, N.H.A.; Kumar, P.; Sazili, A.Q.; Ismail-Fitry, M.R. Effect of High-Pressure Processing on the Quality of Beef and Buffalo Meat. J. Meat Sci. 2024, 19, 45–53. [Google Scholar] [CrossRef]

- Duma-Kocan, P.; Rudy, M.; Gil, M.; Żurek, J.; Stanisławczyk, R.; Krajewska, A.; Dziki, D. The Influence of High Hydrostatic Pressure on Selected Quality Features of Cold-Storage Pork Semimembranosus Muscle. Foods 2024, 13, 2089. [Google Scholar] [CrossRef]

- Cheah, P.; Ledward, D. High pressure effects on lipid oxidation in minced pork. Meat Sci. 1996, 43, 123–134. [Google Scholar] [CrossRef]

- Clariana, M.; García-Regueiro, J.A. Effect of high pressure processing on cholesterol oxidation products in vacuum packaged sliced dry-cured ham. Food Chem. Toxicol. 2011, 49, 1468–1471. [Google Scholar] [CrossRef]

- Tuboly, E.; Lebovics, V.K.; Gaál, Ö.; Mészáros, L.; Farkas, J. Microbiological and lipid oxidation studies on mechanically deboned turkey meat treated by high hydrostatic pressure. J. Food Eng. 2003, 56, 241–244. [Google Scholar] [CrossRef]

- Ma, Q.; Hamid, N.; Oey, I.; Kantono, K.; Farouk, M. The Impact of High-Pressure Processing on Physicochemical Properties and Sensory Characteristics of Three Different Lamb Meat Cuts. Molecules 2020, 25, 2665. [Google Scholar] [CrossRef]

- Stanisławczyk, R.; Żurek, J.; Rudy, M.; Gil, M.; Krajewska, A.; Dziki, D. Effect of Time and Temperature in Sous-Vide Heat Treatment on Selected Physicochemical Properties of Horsemeat. Processes 2023, 11, 3126. [Google Scholar] [CrossRef]

- Stanisławczyk, R.; Żurek, J.; Rudy, M.; Gil, M.; Krajewska, A.; Dziki, D. Horse Meat Subjected to Sous-Vide Cooking: Texture Changes and Sensory Acceptability. Processes 2024, 12, 1577. [Google Scholar] [CrossRef]

- Stanisławczyk, R.; Żurek, J.; Rudy, M.; Gil, M.; Krajewska, A.; Dziki, D. Effect of Various Thermal Processing Methods on the Sensory, Textural, and Physicochemical Characteristics of Foal Meat. Molecules 2024, 29, 5464. [Google Scholar] [CrossRef]

- Stanisławczyk, R.; Rudy, M.; Gil, M. The influence of frozen storage and selected substances on the quality of horse meat. Meat Sci. 2019, 155, 74–78. [Google Scholar] [CrossRef]

- Stanisławczyk, R.; Rudy, M.; Gil, M.; Duma-Kocan, P. Influence of cold and frozen storage on the chemical content, hydration properties and texture parameters of horse meat. Med. Weter. 2019, 75, 242–246. [Google Scholar] [CrossRef]

- Stanisławczyk, R. The effect of age horses on changes in hydratation properties of horse meat during the cold and frozen storage. Chłodnictwo 2011, XLVI, 34–37. (In Polish) [Google Scholar]

- Stanisławczyk, R. The changes in the sensory properties of horse meat during the cold storage depending on the age of the horses. Chłodnictwo 2013, XLVIII, 34–37. (In Polish) [Google Scholar]

- Stanisławczyk, R.; Rudy, M.; Gil, M. Quality characteristics of horse meat as influence by the age of horse. Int. J. Food Prop. 2020, 23, 864–877. [Google Scholar] [CrossRef]

- Vaudagna, S.R.; Gonzalez, C.B.; Guignon, B.; Aparicio, C.; Otero, L.; Sanz, P.D. The effects of high hydrostatic pressure at subzero temperature on the quality of ready-to-eat cured beef carpaccio. Meat Sci. 2012, 92, 575–581. [Google Scholar] [CrossRef] [PubMed]

- Kim, Y.; Lee, E.; Lee, N.; Kim, Y.H.; Yamamoto, K. Effects of hydrostatic pressure treatment on the physicochemical, morphological, and textural properties of bovine semitendinosus muscle. Food Sci. Biotechnol. 2007, 16, 49–54. [Google Scholar]

- Kristensen, L.; Purslow, P.P. The effect of ageing on the water-holding capacity of pork: Role of cytoskeletal proteins. Meat Sci. 2001, 58, 17–23. [Google Scholar] [CrossRef]

- Berruga, M.I.; Vergara, H.; Linares, M.B. Control of microbial growth and rancidity in rabbit carcasses by modified atmosphere packaging. J. Sci. Food Agric. 2005, 85, 1987–1991. [Google Scholar] [CrossRef]

- Lorenzo, J.M.; Carballo, J. Changes in physico-chemical properties and volatile compounds throughout the manufacturing process of dry-cured foal loin. Meat Sci. 2015, 99, 44–51. [Google Scholar] [CrossRef]

- Tonial, I.B.; Aguiar, A.C.; Oliveira, C.C.; Bonnafé, E.G.; Visentainer, J.V. Fatty acid and cholesterol content, chemical composition and sensory evaluation of horsemeat. S. Afr. J. Anim. Sci. 2008, 39, 328–332. [Google Scholar] [CrossRef]

- Palo, P.D.; Maggiolino, A.; Centoducati, P.; Tateo, A. Slaughtering Age Effect on Carcass Traits and Meat Quality of Italian Heavy Draught Horse Foals. Asian-Aust J. Anim. Sci. 2013, 26, 1637–1643. [Google Scholar] [CrossRef]

- Bajovic, B.; Bolumar, T.; Heinz, V. Quality considerations with high pressure processing of fresh and value added meat products. Meat Sci. 2012, 92, 280–289. [Google Scholar] [CrossRef]

- McArdle, R.; Marcos, B.; Kerry, J.P.; Mullen, A.M. Monitoring the effects of high pressure processing and temperature on selected beef quality attributes. Meat Sci. 2010, 86, 629–634. [Google Scholar] [CrossRef]

- Kiełczyński, P.; Szalewski, M.; Balcerzak, A.; Malanowski, A.; Siegoczyński, R.M.; Ptasznik, S. Investigation of high pressure phase transitions in DAG (diacylglycerol) oil using the Bleustein-Gulyaev ultrasonic wave method. Food Res. Int. 2012, 49, 60–64. [Google Scholar] [CrossRef]

- Kiełczyński, P.; Szalewski, M.; Balcerzak, A.; Wieja, K.; Rostocki, A.J.; Siegoczyński, R.M.; Ptasznik, S. Application of ultrasonic wave celerity measurement for evaluation of physicochemical properties of olive oil at high pressure and various temperatures. LWT-Food Sci. Technol. 2014, 57, 253–259. [Google Scholar] [CrossRef]

- Huang, Y.; Gan, Y.; Li, F.; Yan, C.; Li, H.; Feng, Q. Effects of high pressure in combination with thermal treatment on lipid hydrolysis and oxidation in pork. LWT–Food Sci. Technol. 2015, 63, 136–143. [Google Scholar] [CrossRef]

- Orlien, V.; Hansen, E.; Skibsted, L.H. Lipid oxidation in high-pressure processed chicken breast muscle during chill storage: Critical working pressure in relation to oxidation mechanism. Eur. Food Res. Technol. 2000, 211, 99–104. [Google Scholar] [CrossRef]

- Wiggers, S.B.; Kröger-Ohlsen, M.V.; Skibsted, L.H. Lipid oxidation in high-pressure processed chicken breast during chill storage and subsequent heat treatment: Effect of working pressure, packaging atmosphere and storage time. Eur. Food Res. Technol. 2004, 219, 167–170. [Google Scholar] [CrossRef]

- Rivas-Cañedo, A.; Fernández-García, E.; Nuñez, M. Volatile compounds in fresh meats subjected to high pressure processing: Effect of the packaging material. Meat Sci. 2009, 81, 321–328. [Google Scholar] [CrossRef] [PubMed]

- Rödel, W.; Scheuer, R. Das Redoxpotentialbei Fleisch und Fleischerzeugnissen. Fleischwirtschaft 1998, 78, 974–981. [Google Scholar]

- Hughes, J.M.; Oiseth, S.K.; Purslow, P.P.; Warner, R.D. A structural approach to understanding the interactions between colour, water holding capacity and tenderness. Meat Sci. 2014, 98, 520–532. [Google Scholar] [CrossRef]

- Stanisławczyk, R.; Znamirowska, A. Changes in Physico-chemical Properties of Horsemeat during Frozen Storage. Acta Sci. Pol. Technol. Aliment. 2005, 4, 89–96. [Google Scholar]

- Jastrzębska, E.; Daszkiewicz, T.; Górecka-Bruzda, A.; Feliś, D. Current Situation and Prospects for the Horse Meat Market in Poland and the World. Med. Wet. 2019, 75, 196–202. [Google Scholar] [CrossRef]

- Lušnic Polak, M.; Mervič, U.; Demšar, L. Nutritional Value of Horse Meat and Products on the Slovenian Market. Meso 2017, XIX, 73–81. [Google Scholar] [CrossRef]

- Souza, C.; Boler, D.D.; Clark, D.; Kutzler, L.; Holmer, S.; Summerfield, J.; Cannon, J.; Smit, N.; McKeith, F.; Killefer, J. The effects of high pressure processing on pork quality, palatability, and further processed products. Meat Sci. 2011, 87, 419–427. [Google Scholar] [CrossRef]

- Ferrini, G.; Comaposada, J.; Arnau, J.; Gou, P. Colour modification in a cured meat model dried by Quick-Dry-Slice process and high pressure processed as a function of NaCl, KCl, K-lactate and water contents. Innov. Food Sci. Emerg. Technol. 2012, 13, 69–74. [Google Scholar] [CrossRef]

- Tintchev, F.; Wackerbarth, H.; Kuhlmann, U.; Toepfl, S.; Knorr, D.; Hildebrandt, P.; Heinz, V. Molecular effects of high-pressure processing on food studied by resonance Raman. Ann. N. Y. Acad. Sci. 2010, 1189, 34–42. [Google Scholar] [CrossRef] [PubMed]

- Jung, S.; Ghoul, M.; de Lamballerie-Anton, M. Influence of high pressure on the color and microbial quality of beef meat. LWT-Food Sci. Technol. 2003, 36, 625–631. [Google Scholar] [CrossRef]

- Cheftel, J.C.; Culioli, J. Effects of high pressure on meat: A review. Meat Sci. 1997, 46, 211–236. [Google Scholar] [CrossRef] [PubMed]

- Torres, A.; Velazquez, G. Commercial opportunities and research challenges in the high pressure processing of foods. J. Food Eng. 2005, 67, 95–112. [Google Scholar] [CrossRef]

- De Oliveira, F.A.; Neto, O.C.; dos Santos, L.M.R.; Ferreira, E.H.R.; Rosenthal, A. Effect of high pressure on fish meat quality—A review. Trends Food Sci. Technol. 2017, 66, 1–19. [Google Scholar] [CrossRef]

- Hać-Szymańczuk, E.; Mroczek, J. Applying high pressure techniques in food technology, and meat processing in particular. Med. Weter. 2006, 62, 637–640. (In Polish) [Google Scholar]

- Morton, J.D.; Pearson, R.G.; Lee, H.Y.-Y.; Smithson, S.; Mason, S.L.; Bickerstaffe, R. High pressure processing improves the tenderness and quality of hot-boned beef. Meat Sci. 2017, 133, 69–74. [Google Scholar] [CrossRef]

- Rodríguez-Calleja, J.; Cruz-Romero, M.; O’sullivan, M.; García-López, M.; Kerry, J. High-pressure-based hurdle strategy to extend the shelf-life of fresh chicken breast fillets. Food Control 2012, 25, 516–524. [Google Scholar] [CrossRef]

- Kruk, Z.A.; Yun, H.; Rutley, D.L.; Lee, E.J.; Kim, Y.J.; Jo, C. The effect of high pressure on microbial population, meat quality and sensory characteristics of chicken breast fillet. Food Control 2011, 22, 6–12. [Google Scholar] [CrossRef]

- Council Regulation. No 1099/2009 of 24 September 2009 on the protection of animals at the time of killing. Off. J. Eur. Union L 2009, 303, 1–30. [Google Scholar]

- PN-ISO 1442; Meat and Meat Products–Determination of Moisture Content (Reference Method). Polish Committee for Standardization: Warsaw, Poland, 2000.

- PN-A-04018: 1975/Az3; Agricultural Food Products. Determination of Nitrogen by the Kjeldahl Method and Expressing as Protein. Polish Committee for Standardization: Warsaw, Poland, 2002.

- PN-ISO 1444; Meat and Meat Products–Determination of Free Fat Content. Polish Committee for Standardization: Warsaw, Poland, 2000.

- Krzywicki, K. The determination of heam pigments in meat. Meat Sci. 1982, 7, 29–36. [Google Scholar] [CrossRef]

- Znaniecki, P. Outline of Circulation, Assessment and Processing of Raw Materials of Animalorigin; PWRiL: Warsaw, Poland, 1983; pp. 226–227. (In Polish) [Google Scholar]

- Van Oeckel, M.J.; Warnants, N.; Boucqueé, C.V. Comparison of different methods for measuring water holding capacity and juiciness of pork versus online screening methods. Meat Sci. 1999, 51, 313–320. [Google Scholar] [CrossRef] [PubMed]

- Pikul, J.; Leszczyński, D.E.; Kummerow, F.A. Evaluation of three modified TBA methods for measuring lipid oxidation in chicken meat. J. Agric. Food Chem. 1989, 37, 1309–1313. [Google Scholar] [CrossRef]

- ISO 8586: 2023; Sensory Analysis—Selection and Training of Sensory Assessors. International Organization for Standardization: Geneva, Switzerland, 2023.

- ISO 8587: 2006; Sensory Analysis—Methodology, International Organization for Standardization (ISO). International Organization for Standardization: Geneva, Switzerland, 2006.

- Stanislawczyk, R.; Rudy, M.; Gil, M.; Duma-Kocan, P.; Żurek, J. Influence of Horse Age, Marinating Substances, and Frozen Storage on Horse Meat Quality. Animals 2021, 11, 2666. [Google Scholar] [CrossRef] [PubMed]

| Specification | Age | CS | HHP | TC | S-V | HHP + TC | HHP + S-V | ANOVA | p-Value |

|---|---|---|---|---|---|---|---|---|---|

| Protein (%) | Y O | 20.20 a ± 0.13 20.50 a ± 0.14 | 20.15 a ± 0.14 20.78 a ± 0.77 | 20.10 a ± 0.10 20.30 a ± 0.11 | 19.90 a ± 0.09 20.90 a ± 0.12 | 20.10 a,x ± 0.07 21.45 a,y ± 0.01 | 20.20 a ± 0.01 20.40 a ± 0.14 | A × T | 0.0005 |

| Fat (%) | Y O | 3.98 a,x ± 0.47 7.15 a,y ± 0.84 | 3.05 a,b,x ± 0.27 8.00 a,b,y ± 0.77 | 5.63 c,x ± 0.24 8.95 b,y ± 0.56 | 4.10 a,b,x ± 0.21 7.15 a,y ± 0.09 | 5.20 b,c,x ± 0.28 9.70 b,y ± 0.01 | 3.80 a,x ± 0.01 6.90 a,y ± 0.41 | A × T A T | 0.0001 0.0001 0.0001 |

| Water (%) | Y O | 73.80 a,x ± 0.62 71.25 a,y ± 0.27 | 75.25 a,b,x ± 0.07 69.35 a,b,y ± 0.77 | 73.43 a,x ± 0.12 70.15 b,y ± 0.34 | 74.90 a,x ± 0.14 70.10 b,y ± 0.50 | 73.00 b,x ± 0.21 68.25 b,y ± 0.01 | 74.50 a,x ± 0.01 72.05 a,y ± 0.76 | A × T A T | 0.0001 0.0001 0.0001 |

| Specification | Age | CS | HHP | TC | S-V | HHP + TC | HHP + S-V | ANOVA | p-Value |

|---|---|---|---|---|---|---|---|---|---|

| Forced drip [cm2] | Y O | 5.82 x ± 0.08 2.94 y ± 1.11 | 5.48 x ± 0.40 3.97 y ± 0.16 | A | 0.0001 | ||||

| Thermal drip [%] | Y O | 27.92 x ± 0.58 21.91 y ± 0.74 | 23.04 x ± 0.21 17.32 y ± 0.27 | A | 0.0001 | ||||

| TBARS [mg MDA/kg] | Y O | 1.13 a,x ± 0.01 1.88 a,y ± 0.01 | 2.17 b ± 0.01 2.44 b ± 0.01 | 1.26 a,x ± 0.01 1.93 a,y ± 0.01 | 1.11 a ± 0.01 1.34 a ± 0.01 | 2.21 b ± 0.01 2.57 b ± 0.01 | 2.37 b ± 0.01 2.67 b ± 0.01 | A × T A | 0.0001 0.0001 |

| Water activity | Y O | 0.981 ± 0.01 0.983 ± 0.01 | 0.985 ± 0.01 0.984 ± 0.01 | 0.987 ± 0.01 0.984 ± 0.01 | 0.983 ± 0.01 0.980 ± 0.01 | 0.980 ± 0.01 0.981 ± 0.01 | 0.981 ± 0.01 0.987 ± 0.01 | ||

| Oxidation– reduction potential [mV] | Y O | 368.00 a,x ± 0.01 390.00 a,y ± 0.01 | 389.40 b,x ± 0.01 400.30 a,b,y ± 0.01 | 359.89 a,x ± 0.02 385.34 a,y ± 0.01 | 361.67 a,x ± 0.01 381.20 a,y ± 0.01 | 403.00 c ± 0.01 408.00 a,b ± 0.01 | 398.00 b,c,x ± 0.01 410.00 b,y ± 0.01 | A × T A | 0.0001 0.0001 |

| Weight loss [%] | Y O | 42.00 a ± 0.01 39.28 a ± 0.01 | 48.56 b ± 0.01 45.92 b ± 0.02 | 40.76 a ± 0.01 38.59 a ± 0.01 | 46.46 c ± 0.01 43.06 c ± 0.01 | 45.82 c ± 0.01 42.91 c ± 0.01 | T | 0.0001 |

| Specification | Age | CS | HPP | TC | S-V | HPP + TC | HPP + S-V | ANOVA | p-Value |

|---|---|---|---|---|---|---|---|---|---|

| Shear force [N/cm2] | Y O | 40.18 a ± 1.17 60.49 a ± 3.60 | 88.75 b ± 8.16 98.29 b ± 7.86 | 129.34 d ± 5.11 146.33 d ± 3.90 | 126.78 d ± 4.12 136.34 d ± 5.11 | 142.24 c,x ± 2.77 181.42 c,y ± 4.15 | 141.91 c ± 6.48 157.93 c ± 8.90 | A × T A T | 0.0005 0.0001 0.0001 |

| Hardness 1 [N] | Y O | 192.07 a ± 11.18 210.73 a ± 10.69 | 239.82 b ± 12.73 246.59 b ± 12.23 | 243.67 b ± 4.56 260.67 b ± 3.22 | 233.34 b ± 8.45 250.87 b ± 9.98 | 289.74 c ± 11.43 299.54 c ± 12.38 | 271.45 c ± 11.33 288.92 c ± 11.57 | T | 0.0001 |

| Hardness 2 [N] | Y O | 116.76 a ± 10.21 129.78 a ± 11.72 | 143.19 b ± 11.06 172.37 b ± 11.07 | 140.33 b ± 4.11 164.32 b ± 4.01 | 145.67 b ± 7.43 158.32 b ± 9.12 | 161.55 c ± 15.19 181.62 c ± 13.10 | 160.98 c ± 19.01 174.47 c ± 13.20 | T | 0.0019 |

| Stiffness 5 [N] | Y O | 14.18 a ± 1.37 19.37 a ± 1.65 | 16.52 b ± 2.51 25.60 b ± 1.86 | 16.14 b ± 1.01 22.66 b ± 1.45 | 16.45 b ± 1.87 22.23 b ± 2.11 | 18.89 c ± 2.59 28.11 c ± 2.57 | 20.35 c ± 1.66 28.69 c ± 1.86 | T | |

| Stiffness 8 [N] | Y O | 30.28 a ± 6.68 49.66 a ± 5.87 | 35.55 b ± 4.94 56.26 b ± 5.70 | 37.67 b ± 1.12 51.33 b ± 4.23 | 38.45 b ± 2.05 56.34 b ± 1.45 | 45.78 c ± 4.42 68.93 c ± 4.02 | 48.21 c ± 5.09 70.78 c ± 20.41 | T | 0.0001 |

| Adhesiveness (mJ) | Y O | 1.93 ± 0.20 2.13 ± 0.92 | 2.43 ± 0.25 2.73 ± 0.01 | 2.45 ± 0.13 2.78 ± 0.14 | 1.87 ± 0.13 2.03 ± 0.11 | 2.10 ± 0.01 2.13 ± 0.78 | 2.66 ± 0.72 2.30 ± 0.26 | ||

| Cohesiveness | Y O | 0.20 ± 0.03 0.20 ± 0.07 | 0.22 ± 0.09 0.24 ± 0.07 | 0.23 ± 0.04 0.56 ± 0.03 | 0.30 ± 0.01 0.35 ± 0.01 | 0.27 ± 0.03 0.28 ± 0.06 | 0.29 ± 0.05 0.31 ± 0.05 | ||

| Springiness [mm] | Y O | 4.83 ± 0.26 5.52 ± 0.73 | 4.92 ± 0.52 5.18 ± 0.23 | 5.19 ± 0.17 5.86 ± 0.21 | 4.98 ± 0.30 6.55 ± 0.32 | 5.22 ± 0.52 5.29 ± 0.90 | 5.49 ± 0.51 5.53 ± 0.27 | ||

| Resilience | Y O | 0.08 ± 0.02 0.09 ± 0.01 | 0.09 ± 0.02 0.15 ± 0.04 | 0.11 ± 0.01 0.23 ± 0.02 | 0.19 ± 0.01 0.32 ± 0.02 | 0.11 ± 0.02 0.11 ± 0.01 | 0.15 ± 0.02 0.13 ± 0.01 | ||

| Chewiness [mJ] | Y O | 185.53 a ± 9.60 219.15 a ± 10.08 | 259.58 b ± 11.71 306.56 b ± 6.18 | 284.66 b ± 8.69 324.67 b ± 9.21 | 295.45 b ± 9.98 325.54 b ± 7.35 | 408.35 c ± 9.06 443.67 c ± 11.79 | 432.13 c ± 13.82 495.29 c ± 10.88 | T |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Stanisławczyk, R.; Żurek, J.; Rudy, M.; Gil, M.; Krajewska, A.; Dziki, D. The Influence of Horse Age, High-Pressure Technique and Various Heat Treatment Methods on the Quality of Horse Meat. Molecules 2025, 30, 3749. https://doi.org/10.3390/molecules30183749

Stanisławczyk R, Żurek J, Rudy M, Gil M, Krajewska A, Dziki D. The Influence of Horse Age, High-Pressure Technique and Various Heat Treatment Methods on the Quality of Horse Meat. Molecules. 2025; 30(18):3749. https://doi.org/10.3390/molecules30183749

Chicago/Turabian StyleStanisławczyk, Renata, Jagoda Żurek, Mariusz Rudy, Marian Gil, Anna Krajewska, and Dariusz Dziki. 2025. "The Influence of Horse Age, High-Pressure Technique and Various Heat Treatment Methods on the Quality of Horse Meat" Molecules 30, no. 18: 3749. https://doi.org/10.3390/molecules30183749

APA StyleStanisławczyk, R., Żurek, J., Rudy, M., Gil, M., Krajewska, A., & Dziki, D. (2025). The Influence of Horse Age, High-Pressure Technique and Various Heat Treatment Methods on the Quality of Horse Meat. Molecules, 30(18), 3749. https://doi.org/10.3390/molecules30183749