The Effect of the Incorporation Level of Rosa rugosa Fruit Pomace and Its Drying Method on the Physicochemical, Microstructural, and Sensory Properties of Wheat Pasta

Abstract

1. Introduction

2. Results and Discussion

2.1. Basic Chemical Composition of Wheat Flour and Pomace

2.2. Culinary Properties of Pasta

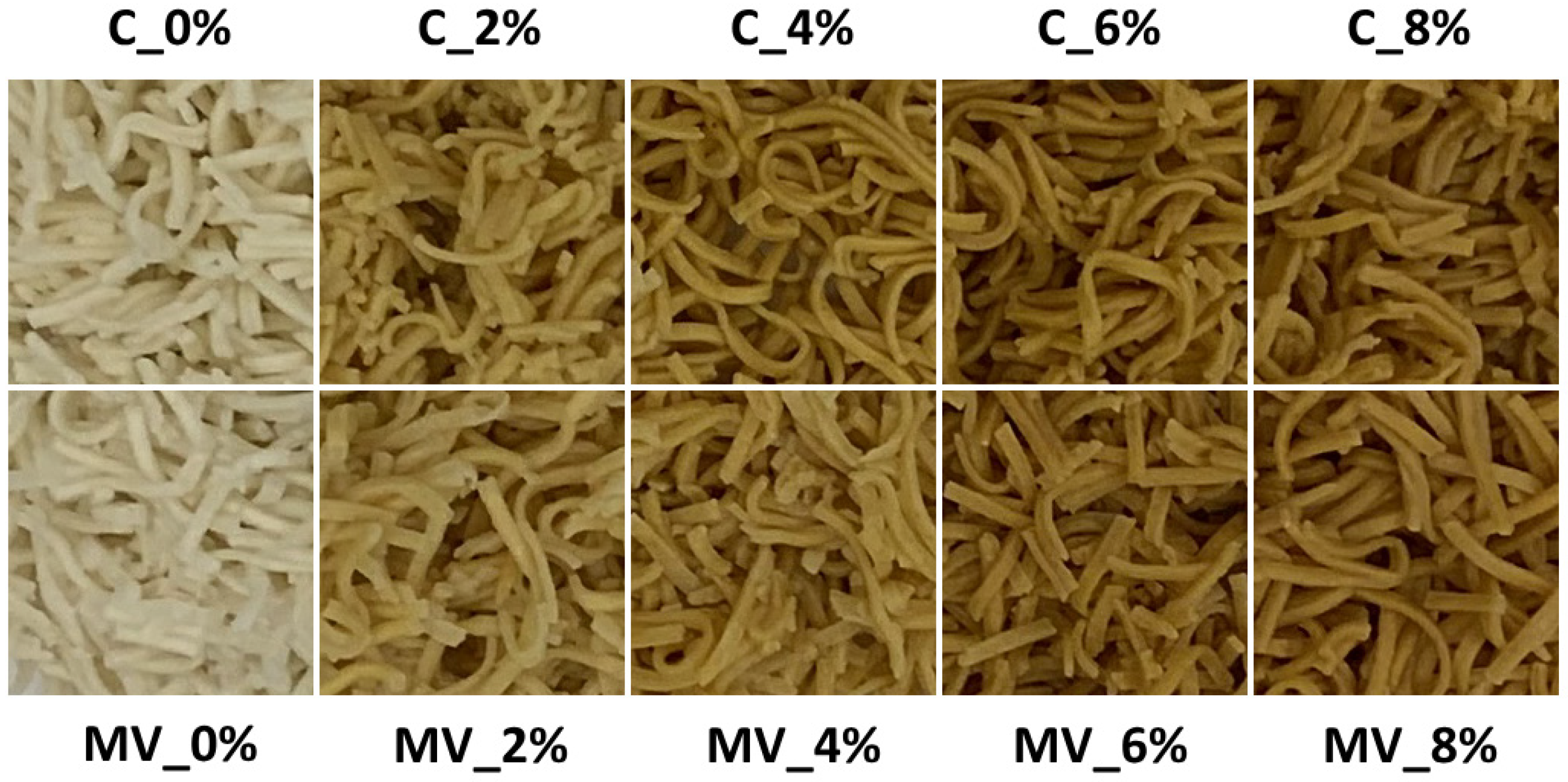

2.3. Pasta Color

2.4. Texture of Cooked Pasta

2.5. Ultrastructure of Pasta

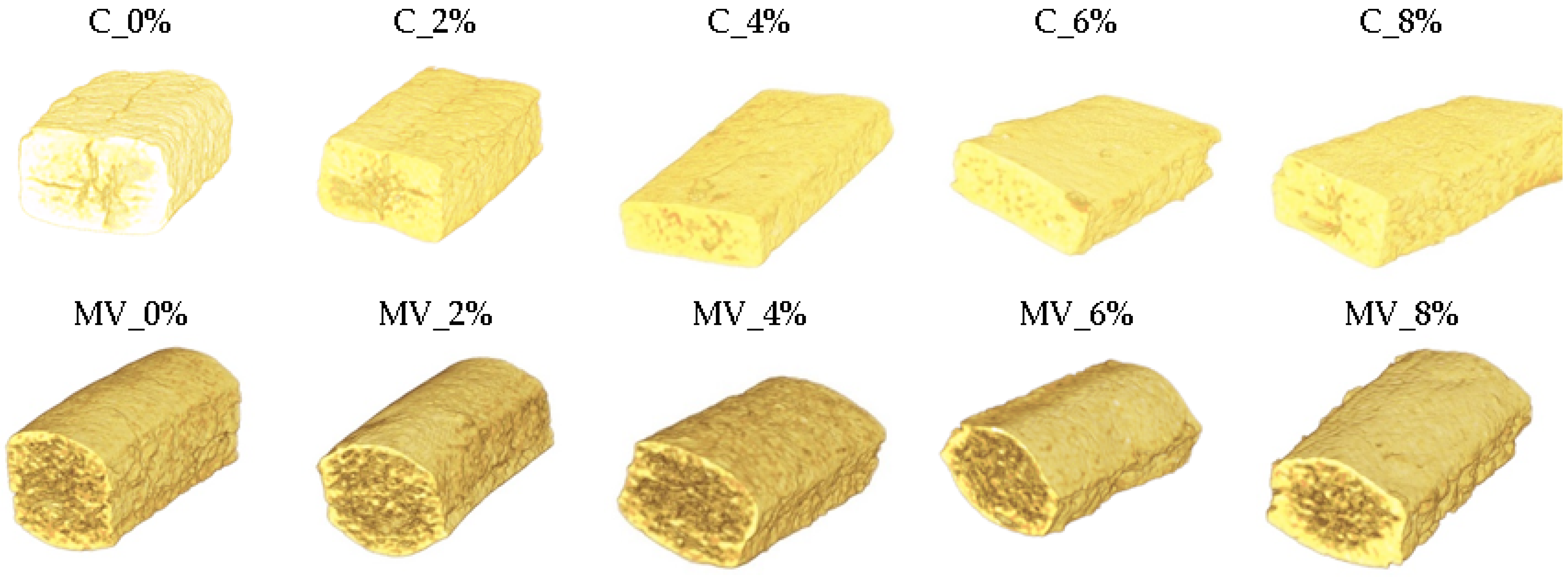

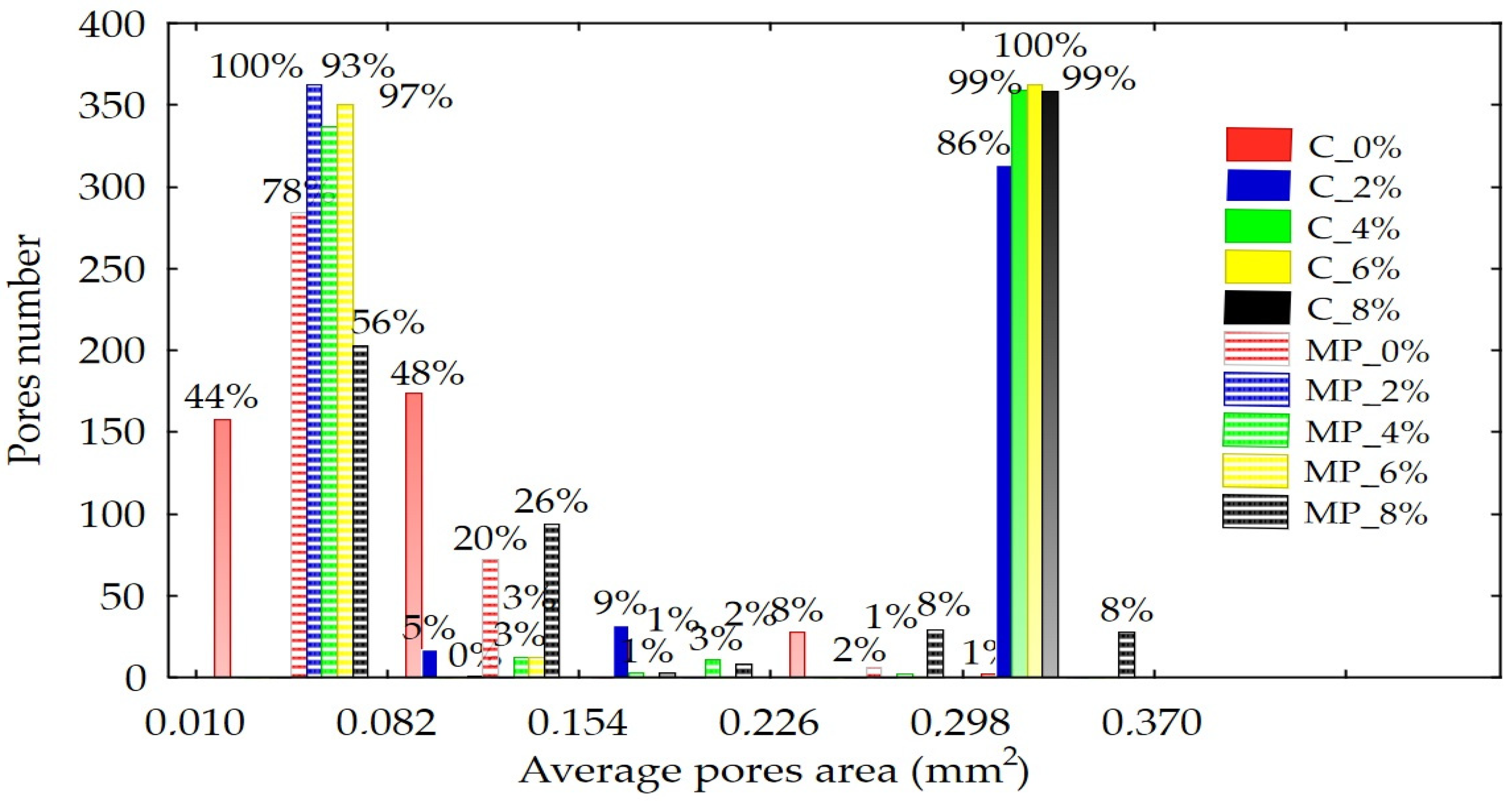

2.6. X-Ray Microtomography Results of Pasta Samples

2.7. Phenolics Content and Antioxidant Capacity

2.8. Sensory Properties

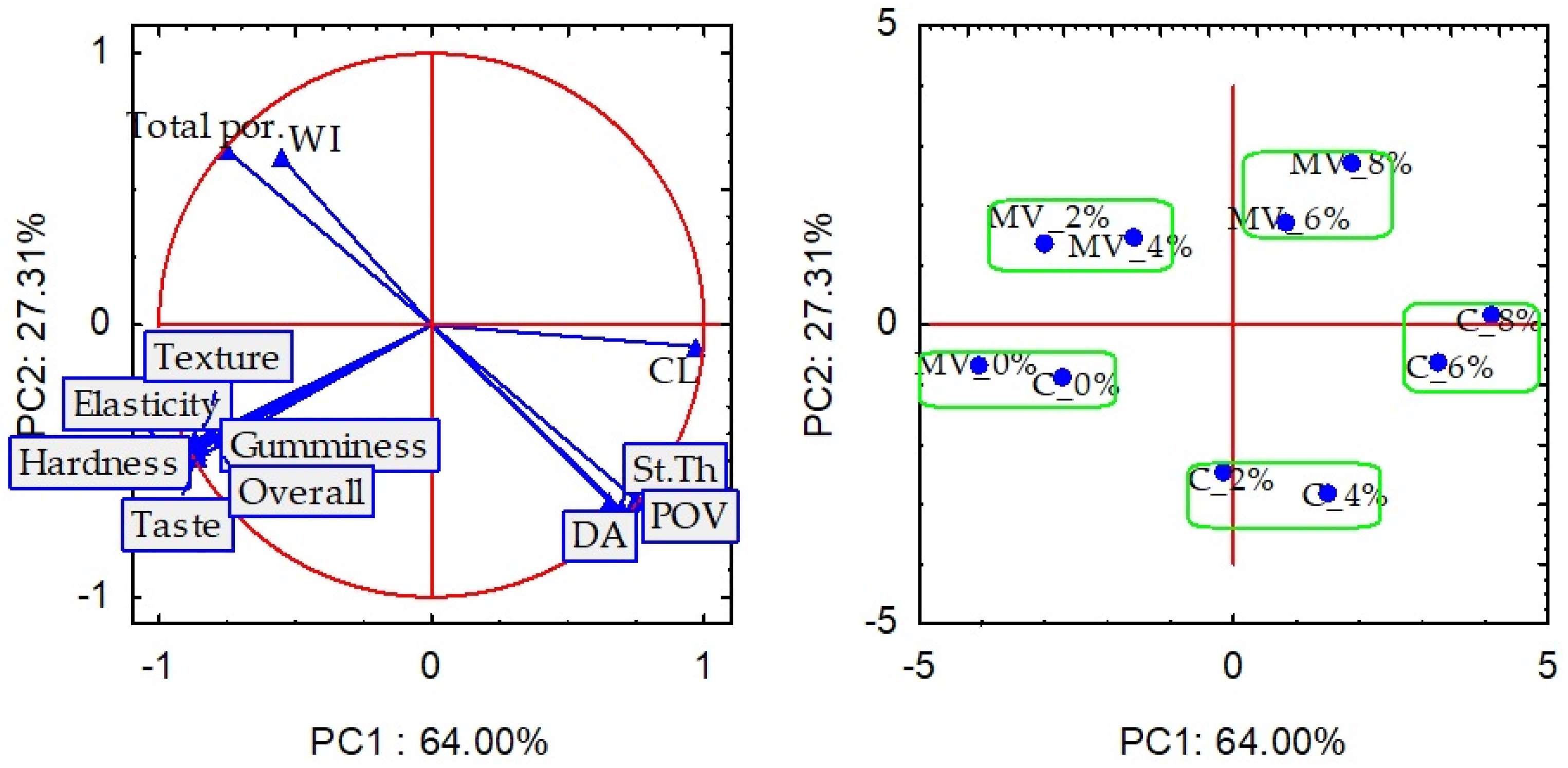

2.9. Correlation Analysis

3. Materials and Methods

3.1. Material

3.2. Pasta Preparation

3.3. Measurement of Culinary Properties of Pasta

3.4. Color Coordinates

3.5. Texture Measurement

3.6. Ultrastructural Analysis by Scanning Electron Microscopy

3.7. Microstructure Analysis by X-Ray Microtomography

- percent object volume (%): total volume of binarized pasta structures within the VOI.

- total porosity: proportion of void space within the VOI.

- structure thickness: average thickness of pasta strands.

- degree of anisotropy: measure of directional dependency of structural features.

3.8. Antioxidant Properties of Extracts from Pasta Samples

3.9. Sensory Evaluation

3.10. Statistical Analysis

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Wrońska-Pilarek, D. Pollen morphology of Polish native species of the Rosa genus (Rosaceae) and its relation to systematics. Acta Soc. Bot. Pol. 2011, 80, 221–232. [Google Scholar] [CrossRef]

- Al-Yafeai, A.; Bellstedt, P.; Böhm, V. Bioactive Compounds and Antioxidant Capacity of Rosa Rugosa Depending on Degree of Ripeness. Antioxidants 2018, 7, 134. [Google Scholar] [CrossRef] [PubMed]

- Ercisli, S. Chemical Composition of Fruits in Some Rose (Rosa Spp.) Species. Food Chem. 2007, 104, 1379–1384. [Google Scholar] [CrossRef]

- Wang, Y.; Zhao, Y.; Liu, X.; Li, J.; Zhang, J.; Liu, D. Chemical Constituents and Pharmacological Activities of Medicinal Plants from Rosa Genus. Chinese Herb. Med. 2022, 14, 187–209. [Google Scholar] [CrossRef]

- Xie, J.; Li, M.X.; Du, Z.Z. Chemical Compounds, Anti-Aging and Antibacterial Properties of Rosa Rugosa Purple Branch. Ind. Crops Prod. 2022, 181. [Google Scholar] [CrossRef]

- Milala, J.; Kosmala, M.; Sójka, M.; Kołodziejczyk, K.; Klewicki, R.; Król, M.; Karlińska, E.; Rój, E. Rosa Rugosa Low Caloric Fiber Protein Preparations Rich in Antioxidant Flavanols and Ellagitannins. Molecules 2023, 28, 8921. [Google Scholar] [CrossRef]

- Wang, B.; Diao, Q.; Zhang, Z.; Liu, Y.; Gao, Q.; Zhou, Y.; Li, S. Antitumor Activity of Bee Pollen Polysaccharides from Rosa Rugosa. Mol. Med. Rep. 2013, 7, 1555–1558. [Google Scholar] [CrossRef]

- Iqbal, A.; Schulz, P.; Rizvi, S.S.H. Valorization of Bioactive Compounds in Fruit Pomace from Agro-Fruit Industries: Present Insights and Future Challenges. Food Biosci. 2021, 44, 101384. [Google Scholar] [CrossRef]

- Simonato, B.; Trevisan, S.; Tolve, R.; Favati, F.; Pasini, G. Pasta Fortification with Olive Pomace: Effects on the Technological Characteristics and Nutritional Properties. LWT—Food Sci. Technol. 2019, 114, 108368. [Google Scholar] [CrossRef]

- Cendrowski, A.; Studnicki, M.; Kalisz, S. Impact of Different Solvents and Temperatures on the Extraction of Bioactive Compounds from Rose Fruits (Rosa Rugosa) Pomace. Appl. Sci. 2024, 14, 691. [Google Scholar] [CrossRef]

- Michalska-Ciechanowska, A.; Brzezowska, J.; Nicolet, N.; Haładyn, K.; Brück, W.M.; Hendrysiak, A.; Andlauer, W. Valorization of Rosehip (Rosa Canina L.) Pomace Using Unconventional Carbohydrate Carriers for Beverage Obtainment. Molecules 2025, 30, 141. [Google Scholar] [CrossRef]

- Klewicka, E.; Piekarska-Radzik, L.; Milala, J.; Klewicki, R.; Sójka, M.; Rosół, N.; Otlewska, A.; Matysiak, B. Antagonistic Activity of Lactic Acid Bacteria and Rosa Rugosa Thunb. Pseudo-Fruit Extracts against Staphylococcus Spp. Strains. Appl. Sci. 2022, 12, 4995. [Google Scholar] [CrossRef]

- Piekarska-Radzik, L.; Klewicka, E.; Milala, J.; Klewicki, R.; Rosół, N.; Matysiak, B.; Sójka, M.; Markowski, J. Impact of Polyphenols from Rosa Rugosa Thunb. Pseudofruits Pomace on Growth Oflactobacillus Bacteria. Zywn. Nauk. Technol. Jakosc/Food. Sci. Technol. Qual. 2019, 26, 73–87. [Google Scholar] [CrossRef]

- Saleh, M.; Al-Ismail, K.; Ajo, R. Pasta Quality as Impacted by the Type of Flour and Starch and the Level of Egg Addition. J. Texture Stud. 2017, 48, 370–381. [Google Scholar] [CrossRef]

- Piwińska, M.; Wyrwisz, J.; Kurek, M.A.; Wierzbicka, A. Effect of Drying Methods on the Physical Properties of Durum Wheat Pasta. CYTA-J. Food 2016, 14, 523–528. [Google Scholar] [CrossRef]

- Adduci, G.; Petrosino, F.; Manoli, E.; Cardaropoli, E.; Coppola, G.; Curcio, S. Transport Phenomena in Pasta Drying: A Dough-Air Double Domain Advanced Modeling. J. Food Eng. 2024, 376, 112052. [Google Scholar] [CrossRef]

- Carvalho, G.R.; Monteiro, R.L.; Laurindo, J.B.; Augusto, E.P.D. Microwave and microwave-vacuum drying as alternatives to convective drying in barley malt processing. Innov. Food Sci. Emerg. Technol. 2021, 73, 102770. [Google Scholar] [CrossRef]

- Lisiecka, K.; Wójtowicz, A.; Dziki, D.; Gawlik-Dziki, U. The Influence of Cistus Incanus L. Leaves on Wheat Pasta Quality. J. Food Sci. Technol. 2019, 56, 4311–4322. [Google Scholar] [CrossRef]

- Scaman, C.H.; Durance, T.D.; Drummond, L.; Sun, D.-W. Chapter 23—Combined Microwave Vacuum Drying. In Emerging Technologies for Food Processing, 2nd ed.; Sun, D.-W., Ed.; Academic Press: Cambridge, MA, USA, 2014; pp. 427–445. [Google Scholar] [CrossRef]

- Masato, O.; Kentaro, M.; Tatsuro, M.; Akio, F.; Yukako, H.; Yasuki, M. Effects of Drying Temperature on the Properties of Starch in Pasta. LWT 2021, 145, 111171. [Google Scholar] [CrossRef]

- Padalino, L.; Caliandro, R.; Chita, G.; Conte, A.; Del Nobile, M.A. Study of Drying Process on Starch Structural Properties and Their Effect on Semolina Pasta Sensory Quality. Carbohydr. Polym. 2016, 153, 229–235. [Google Scholar] [CrossRef]

- Ogawa, T.; Adachi, S. Drying and Rehydration of Pasta. Dry. Technol. 2017, 35, 1919–1949. [Google Scholar] [CrossRef]

- Ignaczak, A.; Woźniak, Ł.; Salamon, A.; Szczepańska-Stolarczyk, J.; Trych, U.; Chobot, M.; Kowalska, J.; Kowalska, H. Shaping the Physicochemical and Health-Promoting Properties of Carrot Snacks Produced by Microwave-Vacuum Drying with Preliminary Thermal and Enriching Treatment. Molecules 2024, 29, 5100. [Google Scholar] [CrossRef]

- Nguyen, N.P.M.; Marzec, A. Effect of Microwave–Vacuum Drying and Pea Protein Fortification on Pasta Characteristics. Processes 2024, 12, 22508. [Google Scholar] [CrossRef]

- Gonzalez-Cavieres, L.; Perez-Won, M.; Tabilo-Munizaga, G.; Jara-Quijada, E.; Diaz-Alvarez, R.; Lemus-Mondaca, R. Advances in vacuum microwave drying (VMD) systems for food products. Trends Food Sci. Technol. 2021, 116, 626–638. [Google Scholar] [CrossRef]

- O’Shea, N.; Arendt, E.K.; Gallagher, E. Dietary Fibre and Phytochemical Characteristics of Fruit and Vegetable By-Products and Their Recent Applications as Novel Ingredients in Food Products. Innov. Food Sci. Emerg. Technol. 2012, 16, 1–10. [Google Scholar] [CrossRef]

- Biernacka, B.; Dziki, D.; Rózyło, R.; Wójcik, M.; Miś, A.; Romankiewicz, D.; Krzysiak, Z. Relationship between the Properties of Raw and Cooked Spaghetti—New Indices for Pasta Quality Evaluation. Int. Agrophysics 2018, 32, 217–223. [Google Scholar] [CrossRef]

- Pawlak, T.; Gawałek, J.; Ryniecki, A.; Stangierski, J.; Siatkowski, I.; Peplińska, B.; Pospiech, E. Microwave Vacuum Drying and Puffing of the Meat Tissue - Process Analysis. Dry. Technol. 2019, 37, 156–163. [Google Scholar] [CrossRef]

- Martinez, C.S.; Ribotta, P.D.; León, A.E.; Añón, M.C. Physical, Sensory and Chemical Evaluation of Cooked Spaghetti. J. Texture Stud. 2007, 38, 666–683. [Google Scholar] [CrossRef]

- Al-Yafeai, A.; Malarski, A.; Böhm, V. Characterization of Carotenoids and Vitamin E in R. Rugosa and R. Canina: Comparative Analysis. Food Chem. 2018, 242, 435–442. [Google Scholar] [CrossRef]

- Wojdyło, A.; Figiel, A.; Lech, K.; Nowicka, P.; Oszmiański, J. Effect of Convective and Vacuum-Microwave Drying on the Bioactive Compounds, Color, and Antioxidant Capacity of Sour Cherries. Food Bioprocess Technol. 2014, 7, 829–841. [Google Scholar] [CrossRef]

- Brescani, A.; Pagani, M.A.; Marti, A. Pasta-Making Process: A Narrative Review on the Relation between Process Variables and Pasta Quality. Foods 2022, 11, 256. [Google Scholar] [CrossRef]

- Bianchi, F.; Tolve, R.; Rainero, G.; Bordiga, M.; Brennan, C.S.; Simonato, B. Technological, Nutritional and Sensory Properties of Pasta Fortified with Agro-Industrial by-Products: A Review. Int. J. Food Sci. Technol. 2021, 56, 4356–4366. [Google Scholar] [CrossRef]

- Feng, Y.; Feng, X.; Liu, S.; Zhang, H.; Wang, J. Interaction Mechanism between Cereal Phenolic Acids and Gluten Protein: Protein Structural Changes and Binding Mode. J. Sci. Food Agric. 2022, 102, 7387–7396. [Google Scholar] [CrossRef]

- Kłosok, K.; Welc, R.; Fornal, E.; Nawrocka, A. Effects of Physical and Chemical Factors on the Structure of Gluten, Gliadins and Glutenins as Studied with Spectroscopic Methods. Molecules 2021, 26, 508. [Google Scholar] [CrossRef]

- Wang, J.; Li, Y.; Guo, X.; Zhu, K.; Wu, Z. A Review of the Impact of Starch on the Quality of Wheat-Based Noodles and Pasta: From the View of Starch Structural and Functional Properties and Interaction with Gluten. Foods 2024, 13, 1507. [Google Scholar] [CrossRef] [PubMed]

- Sung, W.C.; Stone, M. Characterization of Various Wheat Starch in Pasta Development. J. Mar. Sci. Technol. 2003, 11, 61–69. [Google Scholar] [CrossRef]

- Villeneuve, S.; Gélinas, P. Drying kinetics of whole durum wheat pasta according to temperature and rela-tive humidity. LWT - Food Sci. Technol. 2007, 40, 465–471. [Google Scholar] [CrossRef]

- Guo, Q.; He, Z.; Xia, X.; Qu, Y.; Zhang, Y. Effects of Wheat Starch Granule Size Distribution on Qualities of Chinese Steamed Bread and Raw White Noodles. Cereal Chem. 2014, 91, 623–630. [Google Scholar] [CrossRef]

- Yan, H.L.; Lu, Q.Y. Effect of A- and B-Granules of Wheat Starch on Chinese Noodle Quality. J. Cereal Sci. 2020, 91, 102860. [Google Scholar] [CrossRef]

- Gallo, V.; Romano, A.; Masi, P. Does the Presence of Fibres Affect the Microstructure and in Vitro Starch Digestibility of Commercial Italian Pasta? Food Struct. 2020, 24, 100139. [Google Scholar] [CrossRef]

- Liaudanskas, M.; Noreikienė, I.; Zymonė, K.; Juodytė, R.; Žvikas, V.; Janulis, V. Composition and Antioxidant Activity of Phenolic Compounds in Fruit of the Genus Rosa L. Antioxidants 2021, 10, 545. [Google Scholar] [CrossRef]

- Biernacka, B.; Dziki, D.; Różyło, R.; Gawlik-Dziki, U.; Nowak, R.; Pietrzak, W. Common Wheat Pasta Enriched with Ultrafine Ground Oat Husk: Physicochemical and Sensory Properties. Molecules 2023, 28, 7197. [Google Scholar] [CrossRef] [PubMed]

- Sujka, K.; Cacak-Pietrzak, G.; Sułek, A.; Murgrabia, K.; Dziki, D. Buckwheat Hull-Enriched Pasta: Physicochemical and Sensory Properties. Molecules 2022, 27, 4065. [Google Scholar] [CrossRef] [PubMed]

- Romankiewicz, D.; Hassoon, W.H.; Cacak-Pietrzak, G.; Sobczyk, M.; Wirkowska-Wojdyla, M.; Ceglinska, A.; Dziki, D. The Effect of Chia Seeds (Salvia Hispanica L.) Addition on Quality and Nutritional Value of Wheat Bread. J. Food Qual. 2017, 2017, 7352631. [Google Scholar] [CrossRef]

- Espinosa-Solis, V.; Zamudio-Flores, P.B.; Tirado-Gallegos, J.M.; Ramírez-Mancinas, S.; Olivas-Orozco, G.I.; Espino-Díaz, M.; Hernández-González, M.; García-Cano, V.G.; Sánchez-Ortíz, O.; Buenrostro-Figueroa, J.J.; et al. Evaluation of Cooking Quality, Nutritional and Texture Characteristics of Pasta Added with Oat Bran and Apple Flour. Foods 2019, 8, 299. [Google Scholar] [CrossRef]

- Re, R.; Pellegrini, N.; Proteggente, A.; Pannala, A.; Yang, M.; Rice-Evans, C. Antioxidant Activity Applying an Improved ABTS Radical Cation Decolorization Assay. Free Radic. Biol. Med. 1999, 26, 1231–1237. [Google Scholar] [CrossRef]

- Brandt-Williams, W.; Cuvelier, M.E.; Berset, C. Use of a Free Radical Method to Evaluate Antioxidant Activity. LWT-Food Sci. Technol. 1995, 28, 25–30. [Google Scholar] [CrossRef]

- Wichchukit, S.; O’Mahony, M. The 9-point Hedonic Scale and Hedonic Ranking in Food Science: Some Reappraisals and Alternatives. J. Sci. Food Agric. 2015, 95, 2167–2178. [Google Scholar] [CrossRef]

| Raw Material | Protein | Fat | Insoluble Fiber | Soluble Fiber | Ash | Carbohydrates |

|---|---|---|---|---|---|---|

| WF | 9.62 ± 0.12a | 0.67 ± 0.04b | 1.43 ± 0.07a | 0.20 ± 0.01a | 0.47 ± 0.03a | 87.61 |

| RFP | 14.30 ± 0.25b | 0.37 ± 0.05a | 45.26 ± 0.52b | 16.05 ± 0.29b | 15.54 ± 0.08b | 8.48 |

| Pomace Content (%) | Drying Method | Weight Increase Index (-) | Cooking Loss (%) |

|---|---|---|---|

| 0 | 2.45 ± 0.07abc | 3.13 ± 0.11c | |

| 2 | 2.50 ± 0.10bc | 3.37 ± 0.06d | |

| 4 | C | 2.30 ± 0.00a | 3.64 ± 0.08ef |

| 6 | 2.37 ± 0.06ab | 3.85 ± 0.13f | |

| 8 | 2.50 ± 0.10bc | 4.15 ± 0.09g | |

| 0 | 2.57 ± 0.06cd | 2.68 ± 0.11a | |

| 2 | 2.80 ± 0.10e | 2.82 ± 0.04b | |

| 4 | MV | 2.70 ± 0.20de | 3.10 ± 0.05bc |

| 6 | 2.53 ± 0.06c | 3.55 ± 0.07de | |

| 8 | 2.53 ± 0.06c | 3.50 ± 0.02de | |

| Two-factor analysis of variance | |||

| Factor | p-value | ||

| Pomace content | 0.022 * | <0.001 * | |

| Drying method | <0.001 * | <0.001 * | |

| Pomace content × drying method | 0.027 * | 0.009 * | |

| Pomace Content (%) | Drying Method | L* | a* | b* | ΔE |

|---|---|---|---|---|---|

| 0 | C | 91.21 ± 0.33g | −0.50 ± 0.39a | 12.22 ± 0.74b | - |

| 2 | 84.93 ± 0.31ab | 2.63 ± 0.16bc | 25.94 ± 0.27d | 15.69 ± 0.35b | |

| 4 | 84.59 ± 0.20e | 2.91 ± 0.11c | 28.94 ± 0.41e | 18.58 ± 0.45c | |

| 6 | 81.44 ± 0.15b | 4.32 ± 0.10f | 32.38 ± 0.19h | 23.19 ± 0.17e | |

| 8 | 79.73 ± 0.33a | 4.84 ± 0.23g | 33.73 ± 0.59i | 25.24 ± 0.66g | |

| 0 | MV | 92.59 ± 0.10h | −0.54 ± 0.06a | 9.44 ± 0.23a | - |

| 2 | 87.82 ± 0.15f | 1.31 ± 0.06b | 22.05 ± 0.38c | 13.86 ± 0.40a | |

| 4 | 84.97 ± 0.34e | 2.84 ± 0.18bc | 29.13 ± 0.48f | 21.65 ± 0.57d | |

| 6 | 83.70 ± 0.17d | 3.23 ± 0.08d | 31.10 ± 0.33g | 23.96 ± 0.36f | |

| 8 | 82.63 ± 0.19c | 3.52 ± 0.09e | 32.14 ± 0.39h | 25.38 ± 0.42g | |

| Two-factor analysis of variance | |||||

| Factor | p-value | ||||

| Pomace content | <0.001 * | <0.001 * | <0.001 * | <0.001 * | |

| Drying method | <0.001 * | <0.001 * | <0.001 * | <0.001 * | |

| Pomace content × drying method | <0.001 * | <0.001 * | <0.001 * | <0.001 * | |

| Pomace Content (%) | Drying Method | L* | a* | b* | ΔE |

|---|---|---|---|---|---|

| 0 | C | 72.63 ± 0.35g | −2.04 ± 0.13a | 13.12 ± 0.63b | - |

| 2 | 63.40 ± 0.99e | 5.03 ± 0.62c | 33.09 ± 1.49d | 23.14b | |

| 4 | 58.68 ± 0.20c | 10.30 ± 1.05e | 38.99 ± 0.42f | 31.81cd | |

| 6 | 55.26 ± 0.71b | 12.11 ± 0.54f | 38.40 ± 0.87f | 33.79de | |

| 8 | 53.29 ± 0.72a | 12.82 ± 0.41f | 37.80 ± 0.99f | 34.70e | |

| 0 | MV | 70.81 ± 0.61f | −2.23 ± 0.11a | 11.48 ± 0.53a | - |

| 2 | 62.07 ± 0.79d | 3.66 ± 0.44b | 28.42 ± 1.04c | 19.91a | |

| 4 | 57.84 ± 0.90c | 7.87 ± 0.69d | 36.10 ± 0.95e | 29.63c | |

| 6 | 55.18 ± 0.65b | 9.68 ± 0.57e | 35.64 ± 1.16e | 30.03c | |

| 8 | 53.61 ± 0.48a | 10.54 ± 0.81e | 34.83 ± 1.18e | 31.70cd | |

| Two-factor analysis of variance | |||||

| Factor | p-value | ||||

| Pomace content | <0.001 * | <0.001 * | <0.001 * | <0.001 * | |

| Drying method | <0.001 * | <0.001 * | <0.001 * | <0.001 * | |

| Pomace content × drying method | <0.001 * | <0.001 * | 0.196 | 0.516 | |

| Pomace Content (%) | Drying Method | Elasticity (-) | Hardness (N) | Gumminess (N) |

|---|---|---|---|---|

| 0 | 0.69± 0.02b | 5.62 ± 0.47c | 3.02 ± 0.23b | |

| 2 | 0.63 ± 0.01ab | 5.26 ± 0.23bc | 2.78 ± 0.13b | |

| 4 | C | 0.66 ± 0.02ab | 4.84 ± 0.26bc | 2.81 ± 0.96b |

| 6 | 0.58 ± 0.09a | 3.93 ± 0.15ab | 1.84 ± 0.13a | |

| 8 | 0.53 ± 0.03a | 3.03 ± 0.53a | 1.58 ± 0.21a | |

| 0 | 0.73 ± 0.02b | 5.75 ± 0.41c | 3.37 ± 0.06b | |

| 2 | 0.67 ± 0.03ab | 4.88 ± 0.52bc | 2.79 ± 0.15b | |

| 4 | MV | 0.64 ± 0.04ab | 4.93 ± 0.76bc | 2.58 ± 0.50b |

| 6 | 0.55 ± 0.06a | 4.43 ± 0.08ab | 2.09 ± 0.11a | |

| 8 | 0.54 ± 0.02a | 3.47 ± 0.32a | 1.81 ± 0.08a | |

| Two-factor analysis of variance | ||||

| Factor | p-value | |||

| Pomace content | 0.009 * | 0.001 * | <0.001 * | |

| Drying method | 0.807 | 0.705 | 0.485 | |

| Pomace content × drying method | 0.569 | 0.814 | 0.690 | |

| Pomace Content (%) | Drying Method | Surface Area (µm2) | Feret Diameter (-) | Shape Factor (-) |

|---|---|---|---|---|

| 0 | 241.51 ± 182.97b | 0.860 ± 0.09b | 0.757 ± 0.072c | |

| 2 | 255.28 ± 198.20b | 0.835 ± 0.128b | 0.731 ± 0.083bc | |

| 4 | C | 218.85 ± 166.09a | 0.802 ± 0.130ab | 0.728 ± 0.075bc |

| 6 | 248.85 ± 160.85b | 0.852 ± 0.123ab | 0.734 ± 0.085bc | |

| 8 | 206.12 ± 172.34a | 0.809 ± 0.124ab | 0.735 ± 0.067bc | |

| 0 | 239.86 ± 236.83b | 0.817 ± 0.147ab | 0.725 ± 0.098bc | |

| 2 | MV | 217.27 ± 174.43ab | 0.803 ± 0.131ab | 0.711 ±0.096ab |

| 4 | 165.15 ± 118.44a | 0.765 ± 0.149a | 0.683 ± 0.102a | |

| 6 | 212.37 ± 150.71ab | 0.795 ± 0.131ab | 0.703 ± 0.083ab | |

| 8 | 168.10 ± 133.72a | 0.814 ± 0.126ab | 0.716 ± 0.094ab | |

| Two-factor analysis of variance | ||||

| Factor | p-value | |||

| Pomace content | 0.032 * | 0.018 * | 0.034 * | |

| Drying method | 0.017 * | 0.002 * | <0.001 * | |

| Pomace content × drying method | 0.829 | 0.425 | 0.788 | |

| Pomace Content (%) | Drying Method | Percent Object Volume (%) | Closed Porosity (%) | Total Porosity (%) | Structure Thickness (mm) | Degree of Anisotropy (-) | |

|---|---|---|---|---|---|---|---|

| 0 | C | 69.14 ± 2.64b | 0.57 ± 0.15c | 30.86 ± 2.64b | 0.090 ± 0.001a | 1.96 ± 0.15a | |

| 2 | 97.70 ± 2.81c | 0.25 ± 0.07ab | 2.30 ± 2.81a | 0.330 ± 0.077b | 6.11± 2.24bc | ||

| 4 | 99.49 ± 0.41c | 0.09 ± 0.00ab | 0.51 ± 0.41a | 0.444 ± 0.007c | 6.85 ± 1.28c | ||

| 6 | 99.56 ± 0.07c | 0.19 ± 0.03ab | 0.44 ± 0.07a | 0.387 ± 0.022bc | 5.34 ± 2.40abc | ||

| 8 | 98.40 ± 1.14c | 0.29 ± 0.13ab | 1.60 ± 1.14a | 0.368 ± 0.067bc | 6.13 ± 3.20bc | ||

| 0 | MV | 50.72 ± 6.19a | 0.20 ± 0.05ab | 49.28 ± 6.19c | 0.104±0.006a | 3.10±0.24abc | |

| 2 | 45.97 ± 1.77a | 0.04 ± 0.04a | 54.03 ± 1.77c | 0.082±0.005a | 2.53±0.31ab | ||

| 4 | 50.17 ± 0.89a | 0.18 ± 0.09ab | 49.83 ± 0.89c | 0.098±0.007a | 3.30±0.03abc | ||

| 6 | 64.78±0.95b | 0.21±0.00ab | 35.22±0.95b | 0.114±0.015a | 3.17±0.57abc | ||

| 8 | 64.70±14.56b | 0.20±0.14ab | 35.30±14.56b | 0.105±0.026a | 2.85±0.05ab | ||

| Two-factor analysis of variance | |||||||

| Factor | p-value | ||||||

| Drying method | <0.001 * | 0.016 * | <0.001 * | <0.001 * | 0.007 * | ||

| Pomace content | <0.001 * | 0.012 * | 0.001 * | <0.001 * | 0.257 | ||

| Pomace content × drying method | 0.001 * | 0.026 * | 0.007 * | <0.001 * | 0.220 | ||

| Pomace Content (%) | Drying Method | TPC (mg GAE/g d.m.) | EC50DPPH (mg d.m./mL) | EC50ABTS (mg d.m./mL) |

|---|---|---|---|---|

| 0 | 1.03 ± 0.07a | 391.1 ± 4.8g | 645.9 ± 14.6h | |

| 2 | 1.45 ± 0.03b | 369.0 ± 3.5f | 498.4 ± 8.7f | |

| 4 | C | 1.60 ± 0.24b | 350.6 ± 3.8e | 458.8 ± 14.9e |

| 6 | 2.07 ± 0.06c | 253.8 ± 5.9c | 366.1 ± 10.9d | |

| 8 | 2.43 ± 0.05d | 187.9 ± 0.5b | 261.0 ± 9.4b | |

| 0 | 1.14 ± 0.03a | 340.8 ± 4.3e | 537.9 ± 11.0g | |

| 2 | 1.66 ± 0.06b | 322.8 ± 2.4d | 389.1 ± 5.3d | |

| 4 | MV | 2.04 ± 0.01c | 253.6 ± 8.7c | 314.1 ± 0.5c |

| 6 | 2.35 ± 0.10d | 191.5 ± 4.8b | 273.7 ± 9.2b | |

| 8 | 2.77 ± 0.06e | 156.8 ± 5.8a | 217.1 ± 5.4a | |

| Two-factor analysis of variance | ||||

| Factor | p-value | |||

| Pomace content | <0.001 * | <0.001 * | <0.001 * | |

| Drying method | <0.001 * | <0.001 * | <0.001 * | |

| Pomace content × drying method | 0.054 | <0.001 * | <0.001 * | |

| Pomace Content (%) | Drying Method | Appearance (pkt) | Smell (pkt) | Taste (pkt) | Texture (pkt) | Overall Acceptability (pkt) |

|---|---|---|---|---|---|---|

| 0 | C | 6.6 ± 0.8a | 7.9 ± 0.8bc | 7.9 ± 0.7cd | 6.9 ± 0.7d | 7.2 ± 0.8e |

| 2 | 7.6 ± 0.9b | 8.3 ± 0.8c | 7.8 ± 1.0bcd | 6.7 ± 0.6cd | 6.9 ± 0.8e | |

| 4 | 7.9 ± 0.6bcd | 8.3 ± 0.8c | 7.4 ± 1.0bc | 6.2 ± 0.8bc | 6.0 ± 0.9c | |

| 6 | 8.1 ± 0.7cd | 7.5 ± 0.9b | 6.4 ± 0.8a | 6.0 ± 0.9ab | 5.3 ± 1.1ab | |

| 8 | 8.0 ± 0.7bcd | 6.5 ± 0.9a | 6.1 ± 1.0a | 5.8 ± 1.1ab | 5.9 ± 1.1bc | |

| 0 | MV | 6.4 ± 0.7a | 7.9 ± 0.8bc | 8.1 ± 0.6d | 7.1 ± 0.7d | 7.1 ± 0.8e |

| 2 | 7.7 ± 0.8bc | 8.3 ± 0.8c | 7.6 ± 0.9bcd | 6.6 ± 0.7cd | 6.8 ± 0.8de | |

| 4 | 8.0 ± 0.5bdc | 8.3 ± 0.7c | 7.3 ± 1.0b | 6.3 ± 0.8bc | 6.2 ± 0.8cd | |

| 6 | 8.2 ± 0.6d | 7.5 ± 0.9b | 6.5 ± 0.9a | 5.9 ± 1.0ab | 5.9 ± 1.3bc | |

| 8 | 7.9 ± 0.9bcd | 6.6 ± 1.0a | 6.2 ± 0.9a | 5.6 ± 1.1a | 5.2 ± 1.4a | |

| Two-factor analysis of variance | ||||||

| Factor | p-value | |||||

| Pomace content | <0.001 * | <0.001 * | <0.001 * | <0.001 * | <0.001 * | |

| Drying method | 0.900 | 0.868 | 0.877 | 0.784 | 0.643 | |

| Pomace content × drying method | 0.665 | 0.969 | 0.729 | 0.690 | <0.001 * | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cacak-Pietrzak, G.; Marzec, A.; Rakocka, A.; Cendrowski, A.; Stępniewska, S.; Nowak, R.; Krajewska, A.; Dziki, D. The Effect of the Incorporation Level of Rosa rugosa Fruit Pomace and Its Drying Method on the Physicochemical, Microstructural, and Sensory Properties of Wheat Pasta. Molecules 2025, 30, 3170. https://doi.org/10.3390/molecules30153170

Cacak-Pietrzak G, Marzec A, Rakocka A, Cendrowski A, Stępniewska S, Nowak R, Krajewska A, Dziki D. The Effect of the Incorporation Level of Rosa rugosa Fruit Pomace and Its Drying Method on the Physicochemical, Microstructural, and Sensory Properties of Wheat Pasta. Molecules. 2025; 30(15):3170. https://doi.org/10.3390/molecules30153170

Chicago/Turabian StyleCacak-Pietrzak, Grażyna, Agata Marzec, Aleksandra Rakocka, Andrzej Cendrowski, Sylwia Stępniewska, Renata Nowak, Anna Krajewska, and Dariusz Dziki. 2025. "The Effect of the Incorporation Level of Rosa rugosa Fruit Pomace and Its Drying Method on the Physicochemical, Microstructural, and Sensory Properties of Wheat Pasta" Molecules 30, no. 15: 3170. https://doi.org/10.3390/molecules30153170

APA StyleCacak-Pietrzak, G., Marzec, A., Rakocka, A., Cendrowski, A., Stępniewska, S., Nowak, R., Krajewska, A., & Dziki, D. (2025). The Effect of the Incorporation Level of Rosa rugosa Fruit Pomace and Its Drying Method on the Physicochemical, Microstructural, and Sensory Properties of Wheat Pasta. Molecules, 30(15), 3170. https://doi.org/10.3390/molecules30153170