Vanadium Ferrocyanides as a Highly Stable Cathode for Lithium-Ion Batteries

Abstract

1. Introduction

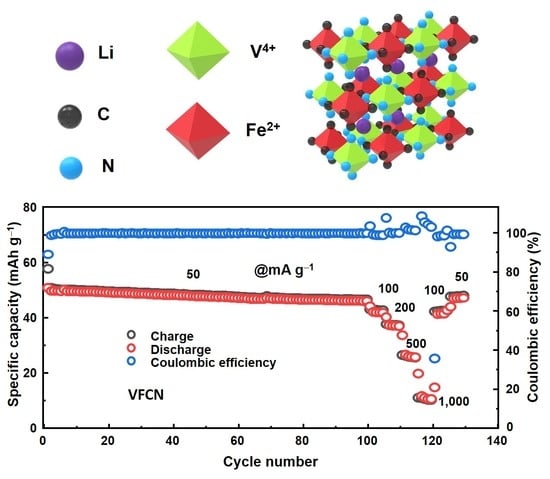

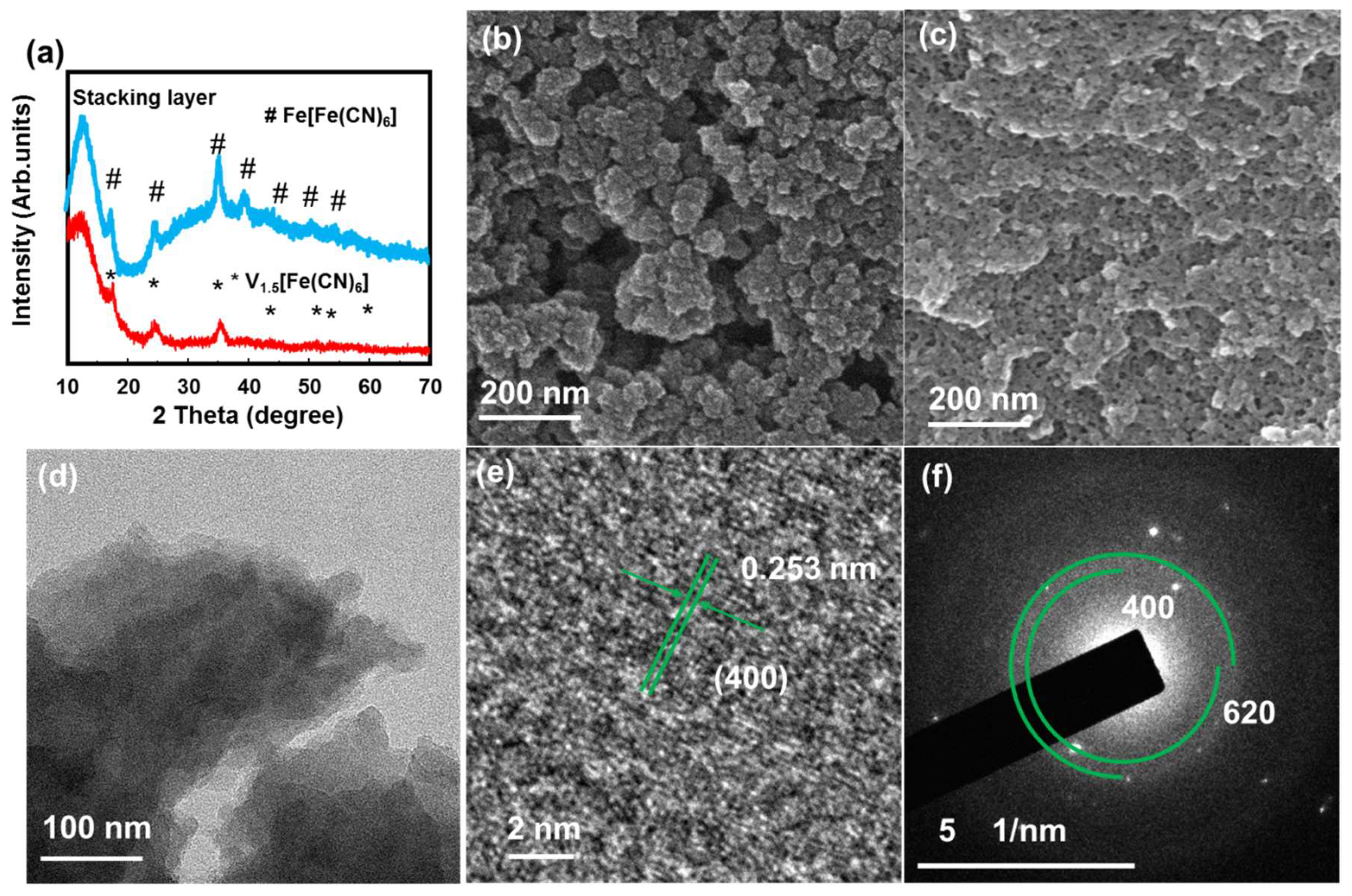

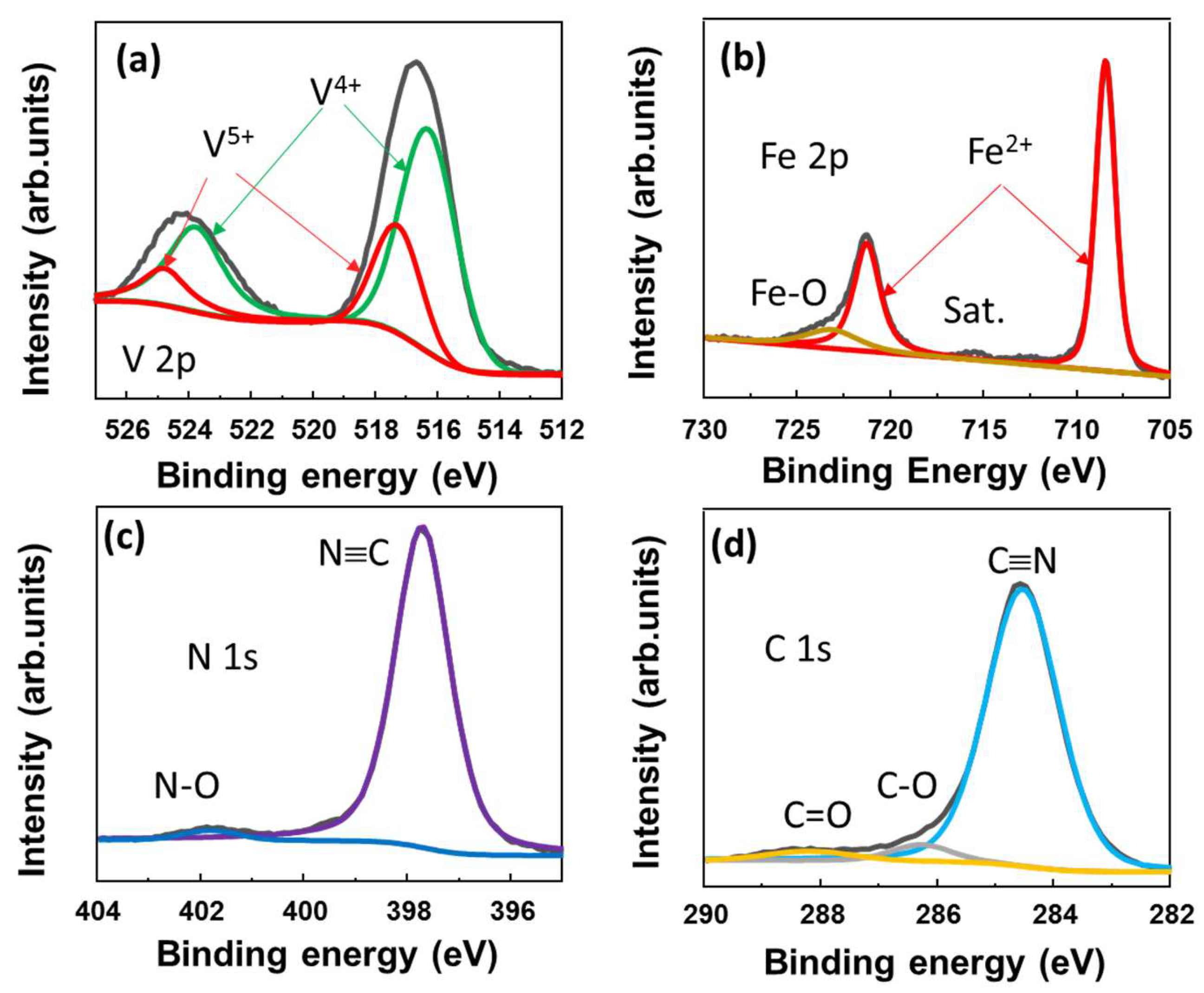

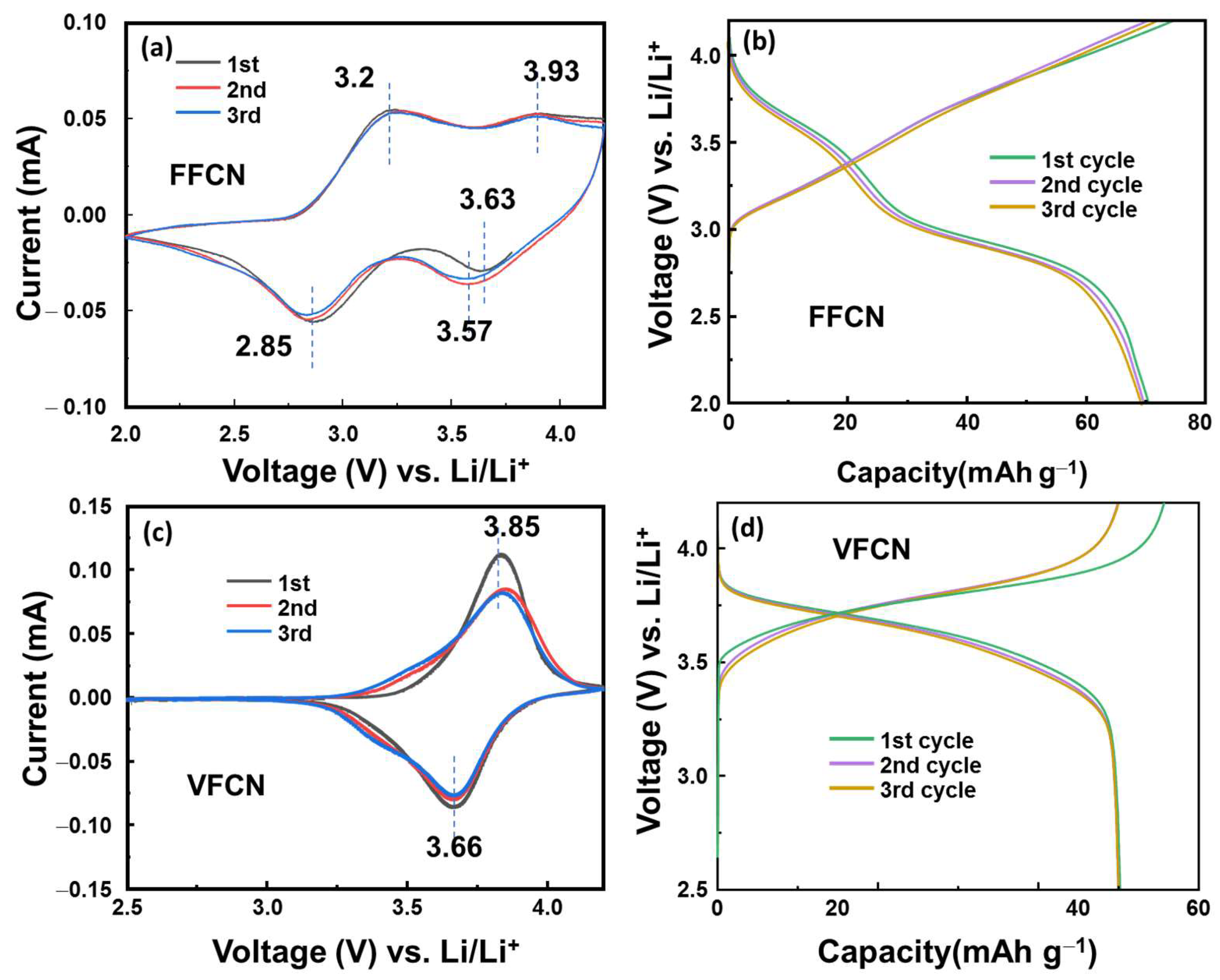

2. Results and Discussion

3. Materials and Methods

3.1. Chemicals

3.2. Vanadium Ferrocyanides (VFCN) Synthesis

3.3. Ferric Ferrocyanides (FFCN) Synthesis

3.4. Materials Characterizations

3.5. Electrochemical Measurements

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Sample Availability

References

- Sha, M.; Liu, L.; Zhao, H.; Lei, Y. Review on Recent Advances of Cathode Materials for Potassium-ion Batteries. Energy Environ. Mater. 2020, 3, 56–66. [Google Scholar] [CrossRef]

- Ma, Z.; Yuan, X.; Li, L.; Ma, Z.-F.; Wilkinson, D.P.; Zhang, L.; Zhang, J. A review of cathode materials and structures for rechargeable lithium–air batteries. Energy Environ. Sci. 2015, 8, 2144–2198. [Google Scholar] [CrossRef]

- Selvakumaran, D.; Pan, A.; Liang, S.; Cao, G. A review on recent developments and challenges of cathode materials for rechargeable aqueous Zn-ion batteries. J. Mater. Chem. A 2019, 7, 18209–18236. [Google Scholar] [CrossRef]

- Chakraborty, A.; Kunnikuruvan, S.; Kumar, S.; Markovsky, B.; Aurbach, D.; Dixit, M.; Major, D.T. Layered Cathode Materials for Lithium-Ion Batteries: Review of Computational Studies on LiNi1–x–yCoxMnyO2 and LiNi1–x–yCoxAlyO2. Chem. Mater. 2020, 32, 915–952. [Google Scholar] [CrossRef]

- Cho, E.; Seo, S.W.; Min, K. Theoretical Prediction of Surface Stability and Morphology of LiNiO2 Cathode for Li Ion Batteries. ACS Appl. Mater. Interfaces 2017, 9, 33257–33266. [Google Scholar] [CrossRef]

- Bianchini, M.; Roca-Ayats, M.; Hartmann, P.; Brezesinski, T.; Janek, J. There and Back Again-The Journey of LiNiO2 as a Cathode Active Material. Angew. Chem. Int. Ed. Engl. 2019, 58, 10434–10458. [Google Scholar] [CrossRef]

- Yoon, M.; Dong, Y.; Hwang, J.; Sung, J.; Cha, H.; Ahn, K.; Huang, Y.; Kang, S.J.; Li, J.; Cho, J. Reactive boride infusion stabilizes Ni-rich cathodes for lithium-ion batteries. Nat. Energy 2021, 6, 362–371. [Google Scholar] [CrossRef]

- Doerrer, C.; Capone, I.; Narayanan, S.; Liu, J.; Grovenor, C.R.M.; Pasta, M.; Grant, P.S. High Energy Density Single-Crystal NMC/Li6PS5Cl Cathodes for All-Solid-State Lithium-Metal Batteries. ACS Appl. Mater. Interfaces 2021, 13, 37809–37815. [Google Scholar] [CrossRef]

- Ryu, H.-H.; Namkoong, B.; Kim, J.-H.; Belharouak, I.; Yoon, C.S.; Sun, Y.-K. Capacity Fading Mechanisms in Ni-Rich Single-Crystal NCM Cathodes. ACS Energy Lett. 2021, 6, 2726–2734. [Google Scholar] [CrossRef]

- Nguyen, T.P.; Giang, T.T.; Kim, I.T. Restructuring NiO to LiNiO2: Ultrastable and reversible anodes for lithium-ion batteries. Chem. Eng. J. 2022, 437, 135294. [Google Scholar]

- Park, C.W.; Lee, J.-H.; Seo, J.K.; Jo, W.Y.; Whang, D.; Hwang, S.M.; Kim, Y.-J. Graphene collage on Ni-rich layered oxide cathodes for advanced lithium-ion batteries. Nat. Commun. 2021, 12, 2145. [Google Scholar] [CrossRef] [PubMed]

- Shim, J.-H.; Kim, Y.-M.; Park, M.; Kim, J.; Lee, S. Reduced Graphene Oxide-Wrapped Nickel-Rich Cathode Materials for Lithium Ion Batteries. ACS Appl. Mater. Interfaces 2017, 9, 18720–18729. [Google Scholar] [CrossRef] [PubMed]

- Woo, M.-H.; Didwal, P.N.; Kim, H.-J.; Lim, J.-S.; Nguyen, A.-G.; Jin, C.-S.; Rye Chang, D.; Park, C.-J. Reinforcing effect of single-wall carbon nanotubes on the LiNi0.6Co0.2Mn0.2O2 composite cathode for high-energy–density all-solid-state Li-ion batteries. Appl. Surf. Sci. 2021, 568, 150934. [Google Scholar] [CrossRef]

- You, Y.; Wu, X.L.; Yin, Y.X.; Guo, Y.G. High-quality Prussian blue crystals as superior cathode materials for room-temperature sodium-ion batteries. Energy Environ. Sci. 2014, 7, 1643–1647. [Google Scholar] [CrossRef]

- Qian, J.F.; Wu, C.; Cao, Y.L.; Ma, Z.F.; Huang, Y.H.; Ai, X.P.; Yang, H.X. Prussian Blue Cathode Materials for Sodium-Ion Batteries and Other Ion Batteries. Adv. Energy Mater. 2018, 8, 1702619. [Google Scholar] [CrossRef]

- Wang, L.; Song, J.; Qiao, R.; Wray, L.A.; Hossain, M.A.; Chuang, Y.D.; Yang, W.; Lu, Y.; Evans, D.; Lee, J.J.; et al. Rhombohedral prussian white as cathode for rechargeable sodium-ion batteries. J. Am. Chem. Soc. 2015, 137, 2548–2554. [Google Scholar] [CrossRef]

- Wang, B.; Han, Y.; Wang, X.; Bahlawane, N.; Pan, H.; Yan, M.; Jiang, Y. Prussian Blue Analogs for Rechargeable Batteries. iScience 2018, 3, 110–133. [Google Scholar] [CrossRef]

- Yang, M.; Luo, J.; Guo, X.; Chen, J.; Cao, Y.; Chen, W. Aqueous Rechargeable Sodium-Ion Batteries: From Liquid to Hydrogel. Batteries 2022, 8, 180. [Google Scholar] [CrossRef]

- Xie, B.X.; Sun, B.Y.; Gao, T.Y.; Ma, Y.L.; Yin, G.P.; Zuo, P.J. Recent progress of Prussian blue analogues as cathode materials for nonaqueous sodium-ion batteries. Coord. Chem. Rev. 2022, 460, 214478. [Google Scholar] [CrossRef]

- Yang, D.; Xu, J.; Liao, X.Z.; He, Y.S.; Liu, H.; Ma, Z.F. Structure optimization of Prussian blue analogue cathode materials for advanced sodium ion batteries. Chem. Commun. 2014, 50, 13377–13380. [Google Scholar] [CrossRef]

- Luo, Y.; Peng, J.; Yin, S.; Xue, L.; Yan, Y. Acid-Assisted Ball Mill Synthesis of Carboxyl-Functional-Group-Modified Prussian Blue as Sodium-Ion Battery Cathode. Nanomaterials 2022, 12, 1290. [Google Scholar] [CrossRef] [PubMed]

- Li, P.; Hu, N.; Wang, J.; Wang, S.; Deng, W. Recent Progress and Perspective: Na Ion Batteries Used at Low Temperatures. Nanomaterials 2022, 12, 3529. [Google Scholar] [CrossRef] [PubMed]

- Xu, Z.; Sun, Y.; Xie, J.; Nie, Y.; Xu, X.W.; Tu, J.; Zhang, J.; Qiu, L.C.; Zhu, T.J.; Zhao, X.B. Scalable Preparation of Mn/Ni Binary Prussian Blue as Sustainable Cathode for Harsh-Condition-Tolerant Sodium-Ion Batteries. ACS Sustain. Chem. Eng. 2022, 10, 13277–13287. [Google Scholar] [CrossRef]

- Matsuda, T.; Takachi, M.; Moritomo, Y. A sodium manganese ferrocyanide thin film for Na-ion batteries. Chem. Commun. 2013, 49, 2750–2752. [Google Scholar] [CrossRef] [PubMed]

- Song, J.; Wang, L.; Lu, Y.; Liu, J.; Guo, B.; Xiao, P.; Lee, J.J.; Yang, X.Q.; Henkelman, G.; Goodenough, J.B. Removal of interstitial H2O in hexacyanometallates for a superior cathode of a sodium-ion battery. J. Am. Chem. Soc. 2015, 137, 2658–2664. [Google Scholar] [CrossRef] [PubMed]

- Asakura, D.; Okubo, M.; Mizuno, Y.; Kudo, T.; Zhou, H.S.; Ikedo, K.; Mizokawa, T.; Okazawa, A.; Kojima, N. Fabrication of a Cyanide-Bridged Coordination Polymer Electrode for Enhanced Electrochemical Ion Storage Ability. J. Phys. Chem. C 2012, 116, 8364–8369. [Google Scholar] [CrossRef]

- Qian, J.F.; Zhou, M.; Cao, Y.L.; Ai, X.P.; Yang, H.X. Nanosized Na4Fe(CN)6/C Composite as a Low-Cost and High-Rate Cathode Material for Sodium-Ion Batteries. Adv. Energy Mater. 2012, 2, 410–414. [Google Scholar] [CrossRef]

- Baster, D.; Oveisi, E.; Mettraux, P.; Agrawal, S.; Girault, H.H. Sodium chromium hexacyanoferrate as a potential cathode material for aqueous sodium-ion batteries. Chem. Commun. 2019, 55, 14633–14636. [Google Scholar] [CrossRef]

- Paulitsch, B.; Yun, J.; Bandarenka, A.S. Electrodeposited Na2VOx[Fe(CN)6] films As a Cathode Material for Aqueous Na-Ion Batteries. ACS Appl. Mater. Interfaces 2017, 9, 8107–8112. [Google Scholar] [CrossRef]

- Lim, C.Q.X.; Tan, Z.-K. Prussian White with Near-Maximum Specific Capacity in Sodium-Ion Batteries. ACS Appl. Energy Mater. 2021, 4, 6214–6220. [Google Scholar] [CrossRef]

- Baster, D.; Kondracki, L.; Oveisi, E.; Trabesinger, S.; Girault, H.H. Prussian Blue Analogue-Sodium-Vanadium Hexacyanoferrate as a Cathode Material for Na-Ion Batteries. ACS Appl. Energy Mater. 2021, 4, 9758–9765. [Google Scholar] [CrossRef]

- Pan, Z.T.; He, Z.H.; Hou, J.F.; Kong, L.B. Sodium vanadium hexacyanoferrate as a high-rate capability and long-life cathode material for Na-ion batteries. J. Energy Storage 2022, 53, 105165. [Google Scholar] [CrossRef]

- Vanýsek, P. Electrochemical Series. In Corrosion: Materials; Cramer, S.D., Covino, B.S., Jr., Eds.; ASM International: Almere, The Netherland, 2005; pp. 665–671. [Google Scholar] [CrossRef]

- Wang, W.; Gang, Y.; Hu, Z.; Yan, Z.; Li, W.; Li, Y.; Gu, Q.-F.; Wang, Z.; Chou, S.-L.; Liu, H.-K.; et al. Reversible structural evolution of sodium-rich rhombohedral Prussian blue for sodium-ion batteries. Nat. Commun. 2020, 11, 980. [Google Scholar] [CrossRef] [PubMed]

- Nguyen, T.P.; Kim, I.T. Self-Assembled Few-Layered MoS2 on SnO2 Anode for Enhancing Lithium-Ion Storage. Nanomaterials 2020, 10, 2558. [Google Scholar] [CrossRef]

- Nguyen, T.P.; Choi, K.S.; Kim, S.Y.; Lee, T.H.; Jang, H.W.; Van Le, Q.; Kim, I.T. Strategy for controlling the morphology and work function of W2C/WS2 nanoflowers. J. Alloys Compd. 2020, 829, 154582. [Google Scholar] [CrossRef]

- Nie, P.; Shen, L.; Pang, G.; Zhu, Y.; Xu, G.; Qing, Y.; Dou, H.; Zhang, X. Flexible metal–organic frameworks as superior cathodes for rechargeable sodium-ion batteries. J. Mater. Chem. A 2015, 3, 16590–16597. [Google Scholar] [CrossRef]

- Wu, X.; Deng, W.; Qian, J.; Cao, Y.; Ai, X.; Yang, H. Single-crystal FeFe(CN)6 nanoparticles: A high capacity and high rate cathode for Na-ion batteries. J. Mater. Chem. A 2013, 1, 10130–10134. [Google Scholar] [CrossRef]

- Tang, Y.; Zhang, W.X.; Xue, L.H.; Ding, X.L.; Wang, T.; Liu, X.X.; Liu, J.; Li, X.C.; Huang, Y.H. Polypyrrole-promoted superior cyclability and rate capability of NaxFe[Fe(CN)6] cathodes for sodium-ion batteries. J. Mater. Chem. A 2016, 4, 6036–6041. [Google Scholar] [CrossRef]

- Sun, J.G.; Ye, H.L.; Oh, J.A.S.; Plewa, A.; Sun, Y.; Wu, T.; Sun, Q.M.; Zeng, K.Y.; Lu, L. Elevating the discharge plateau of prussian blue analogs through low-spin Fe redox induced intercalation pseudocapacitance. Energy Storage Mater. 2021, 43, 182–189. [Google Scholar] [CrossRef]

- Hemmelmann, H.; Dinter, J.K.; Elm, M.T. Thin Film NCM Cathodes as Model Systems to Assess the Influence of Coating Layers on the Electrochemical Performance of Lithium Ion Batteries. Adv. Mater. Interfaces 2021, 8, 2002074. [Google Scholar] [CrossRef]

- Zhang, Z.; Yang, J.; Huang, W.; Wang, H.; Zhou, W.; Li, Y.; Li, Y.; Xu, J.; Huang, W.; Chiu, W.; et al. Cathode-Electrolyte Interphase in Lithium Batteries Revealed by Cryogenic Electron Microscopy. Matter 2021, 4, 302–312. [Google Scholar] [CrossRef]

- Pender, J.P.; Jha, G.; Youn, D.H.; Ziegler, J.M.; Andoni, I.; Choi, E.J.; Heller, A.; Dunn, B.S.; Weiss, P.S.; Penner, R.M.; et al. Electrode Degradation in Lithium-Ion Batteries. ACS Nano 2020, 14, 1243–1295. [Google Scholar] [CrossRef] [PubMed]

- Fang, C.; Tran, T.-N.; Zhao, Y.; Liu, G. Electrolyte decomposition and solid electrolyte interphase revealed by mass spectrometry. Electrochim. Acta 2021, 399, 139362. [Google Scholar] [CrossRef]

- Shi, S.; Sun, Z.; Hu, Y.H. Synthesis, stabilization and applications of 2-dimensional 1T metallic MoS2. J. Mater. Chem. A 2018, 6, 23932–23977. [Google Scholar] [CrossRef]

- Shen, L.; Wang, Z.; Chen, L. Prussian Blues as a Cathode Material for Lithium Ion Batteries. Chem. A Eur. J. 2014, 20, 12559–12562. [Google Scholar] [CrossRef] [PubMed]

- Singh, J.; Hong, K.; Cho, Y.; Akhtar, M.S.; Kang, J.; Rai, A.K. Metal-Organic Framework Fabricated V2O5 Cathode Material for High-Performance Lithium-Ion Batteries. Coatings 2022, 12, 844. [Google Scholar] [CrossRef]

- Yamada, T.; Shiraishi, K.; Kitagawa, H.; Kimizuka, N. Applicability of MIL-101(Fe) as a cathode of lithium ion batteries. Chem. Commun. 2017, 53, 8215–8218. [Google Scholar] [CrossRef]

- Férey, G.; Millange, F.; Morcrette, M.; Serre, C.; Doublet, M.-L.; Grenèche, J.-M.; Tarascon, J.-M. Mixed-Valence Li/Fe-Based Metal–Organic Frameworks with Both Reversible Redox and Sorption Properties. Angew. Chem. Int. Ed. 2007, 46, 3259–3263. [Google Scholar] [CrossRef]

- Xie, C.-C.; Yang, D.-H.; Zhong, M.; Zhang, Y.-H. Improving the Performance of a Ternary Prussian Blue Analogue as Cathode of Lithium Battery via Annealing Treatment. Z. Anorg. Allg. Chem. 2016, 642, 289–293. [Google Scholar] [CrossRef]

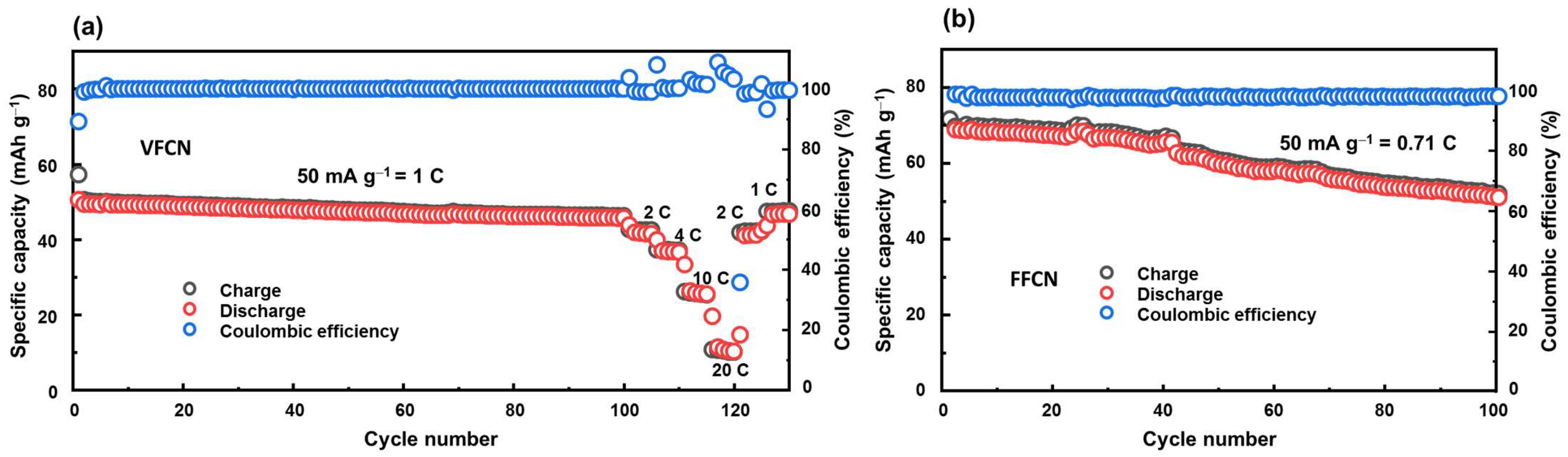

| Materials | Redox Potential (V) vs. Li/Li+ | Specific Capacity (mAh g−1)/Rate (mA g−1) | At Cycle Number | Reference |

|---|---|---|---|---|

| Fe(2+)Fe(2+)(CN)6 | 2.8/3.1 and 3.8/3.9 | 96/25 | 50 | [46] |

| Fe(3+)4[Fe(2+)(CN)6]3 | 2.7/3.1 and 3.4/3.9 | 71/25 | 50 | [46] |

| V2O5 | 2.3/2.5 and 3.4/3.7 | 169/133 | 50 | [47] |

| MIL-101(Fe) | 2.6/3.2 | 72/15 | 100 | [48] |

| MIL-53(Fe) | ~2.7/3.0 | 70/8 | 50 | [49] |

| Na1.1(VO)1.07Cu0.35Fe(CN)6 | ~2.5/2.7 and 3.4/3.5 | 93/50 | 50 | [50] |

| FFCN (Fe(3+)Fe(3+)(CN)6) | 2.8/3.2 and 3.6/3.9 | 52/50 | 100 | This work |

| VFCN | 3.66/3.85 3.3/3.4 and 3.7/3.8 (After 50 cycles) | 48/50 | 130 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nguyen, T.P.; Kim, I.T. Vanadium Ferrocyanides as a Highly Stable Cathode for Lithium-Ion Batteries. Molecules 2023, 28, 461. https://doi.org/10.3390/molecules28020461

Nguyen TP, Kim IT. Vanadium Ferrocyanides as a Highly Stable Cathode for Lithium-Ion Batteries. Molecules. 2023; 28(2):461. https://doi.org/10.3390/molecules28020461

Chicago/Turabian StyleNguyen, Thang Phan, and Il Tae Kim. 2023. "Vanadium Ferrocyanides as a Highly Stable Cathode for Lithium-Ion Batteries" Molecules 28, no. 2: 461. https://doi.org/10.3390/molecules28020461

APA StyleNguyen, T. P., & Kim, I. T. (2023). Vanadium Ferrocyanides as a Highly Stable Cathode for Lithium-Ion Batteries. Molecules, 28(2), 461. https://doi.org/10.3390/molecules28020461