Hard Carbons as Anodes in Sodium-Ion Batteries: Sodium Storage Mechanism and Optimization Strategies

Abstract

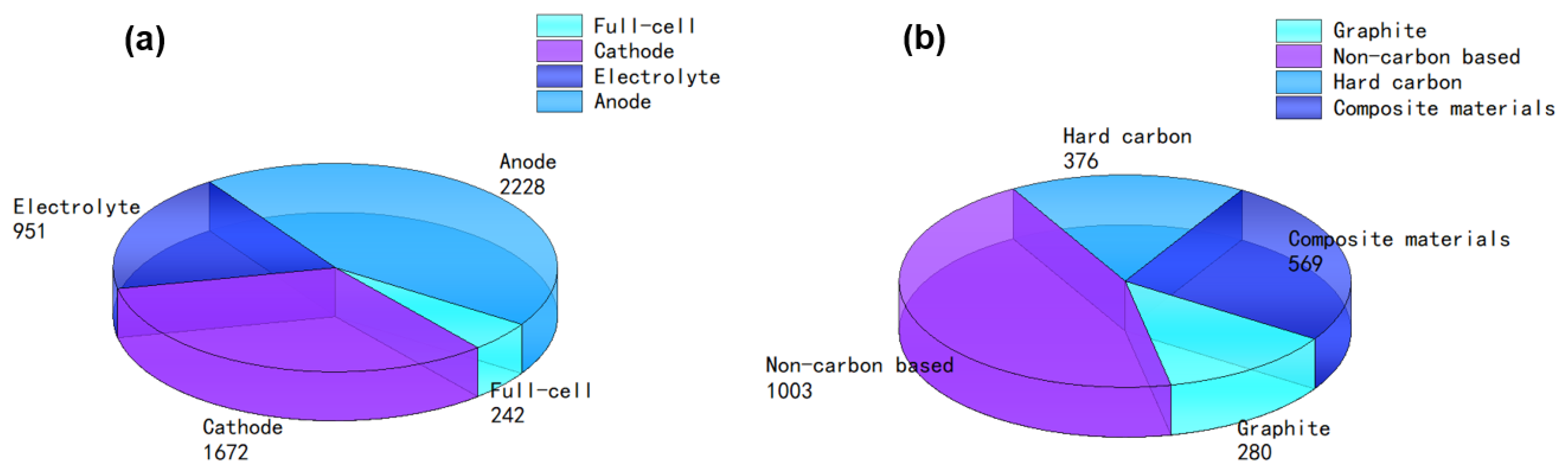

1. Introduction

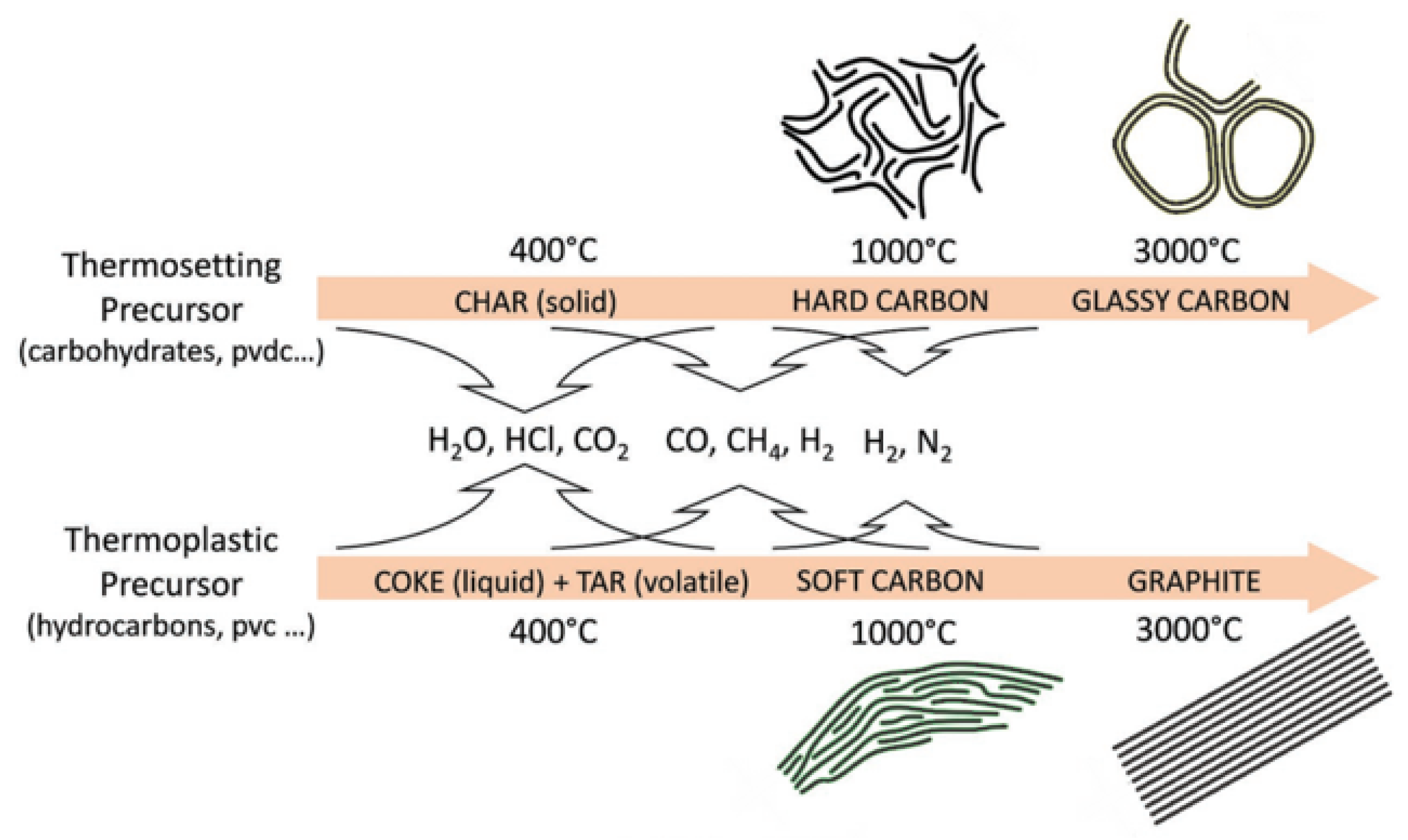

2. Carbon Based Anode Materials

2.1. Graphite

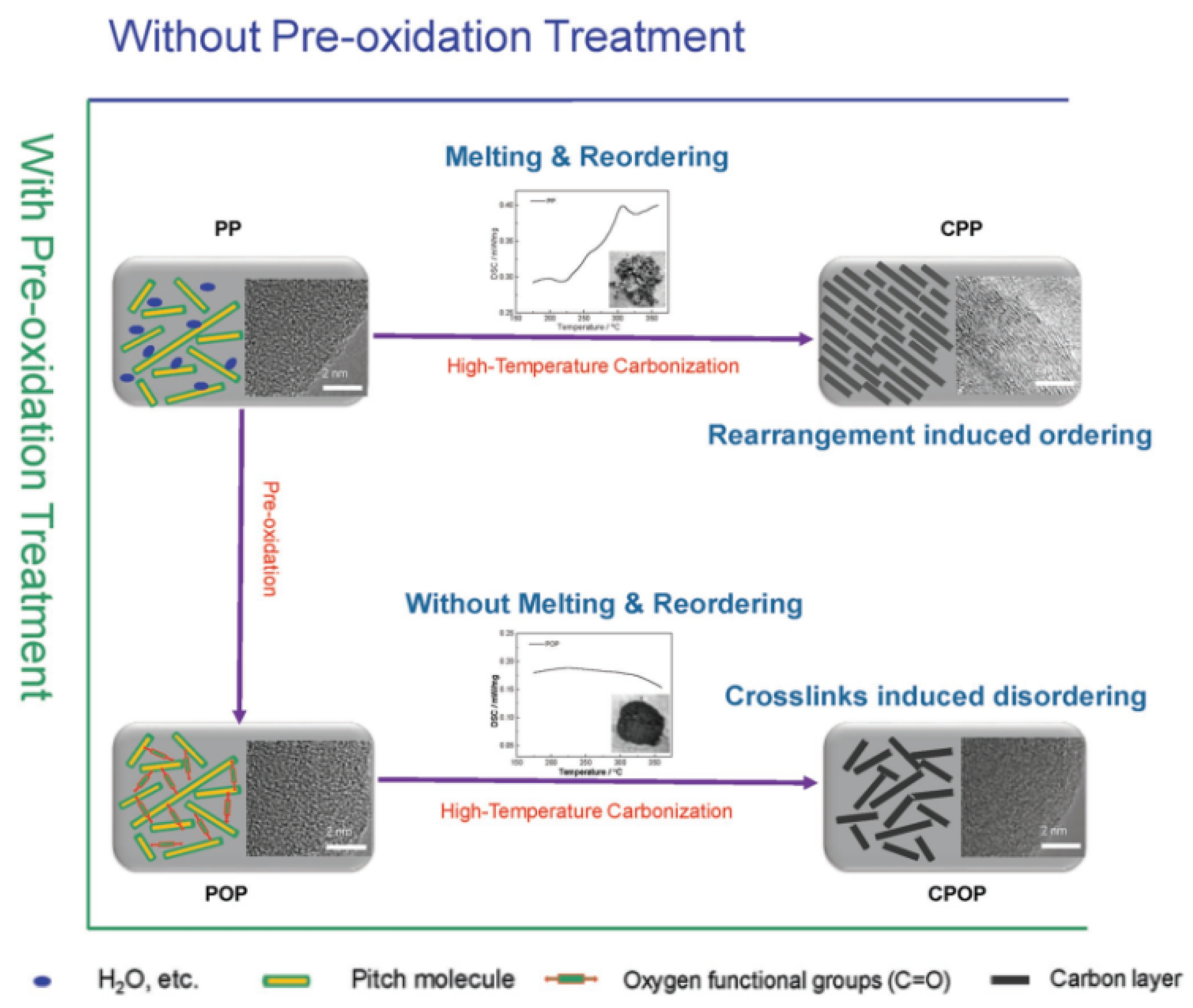

2.2. Soft Carbon

2.3. Hard Carbon

3. Hard Carbon Materials

3.1. Synthetic Raw Material

- Carbohydrate or other organic polymers; for example, sucrose [41,42], cellulose [43,44], and lignin [45] have been used as precursors for the fabrication of HC anodes. In particular, Hu [44] prepared nanofibers with a short-range ordered graphite lattice and porous structures using cellulose as a raw material at the low pyrolysis temperature of 1000 °C. It exhibited a high reversible capacity of 340 mAh g−1.

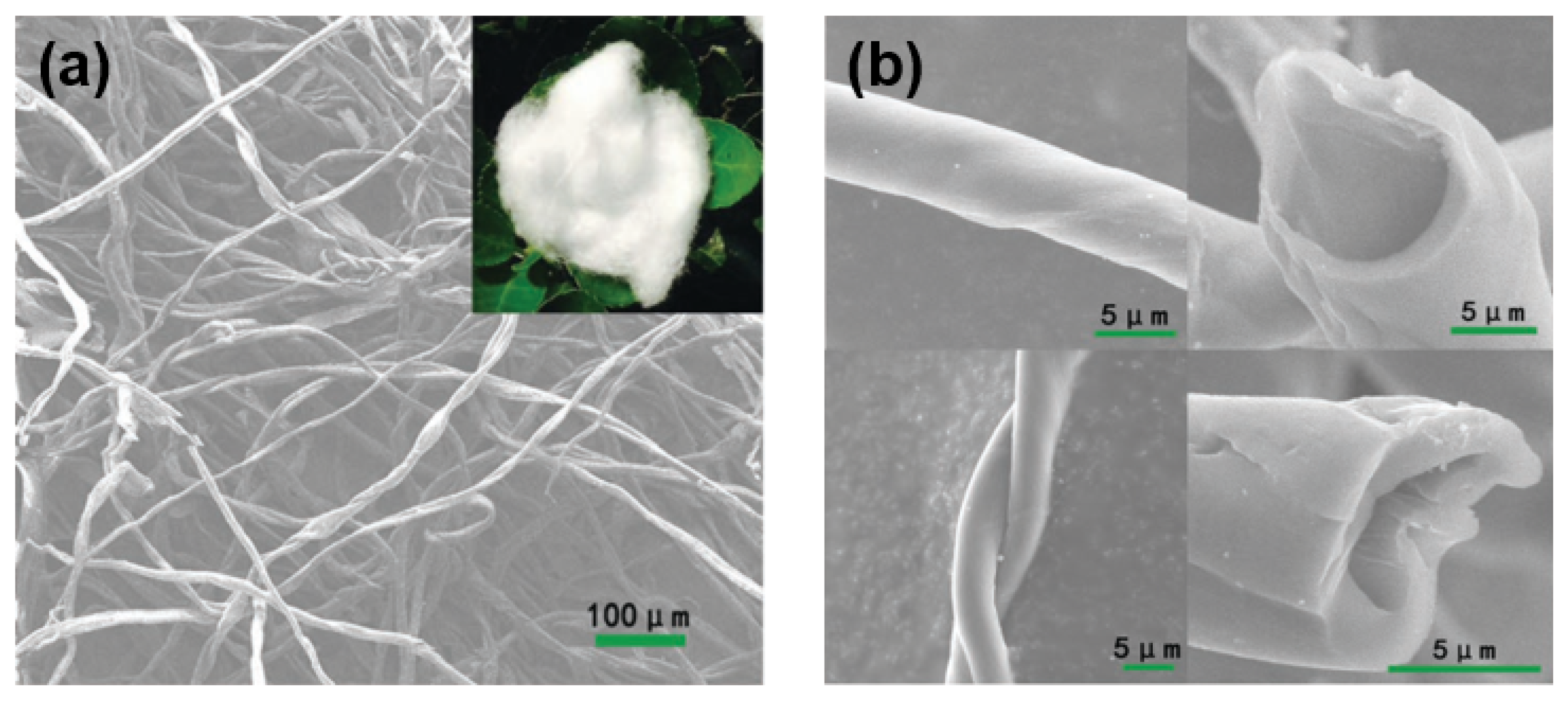

- Biomass source; such as peel [46,47,48], chitin [40], cotton [49], algae [50] and many others have also been used in the mass production of HC. The selection of a biomass source precursor plays an important part in the preparation of electrode materials with desired electrochemical properties [51]. According to a study reported by Xu and coauthors, an HC with a large layer spacing was fabricated based on a one-step pyrolysis of grapefruit peel in an inert atmosphere. The as-prepared HC anode has a reversible capacity of 430.5 mAh g−1 at a current density of 30 mA g−1 and remarkable cycling stability [47]. The produced HC showed a honeycomb-like structure and expanded cavities, which facilitated the diffusion of the electrolyte into the bulk of the material and shortened the distance of Sodium-ion insertion. These properties are beneficial to improve the rate capability and reversible capacity.

- Resin carbon; for example, phenolic resin [52], and polyacrylonitrile [53] are another group of HC precursors. New progress in the research of Zhong’s group has revealed that HC can originate from a polyacrylonitrile doped polar molecule (Melamine). After spinning, they carbonized it to form HC nanofibers, which show a high gravimetric capacity, high-power capability, and long-term cycling stability of 200 mAh g−1 at 1 A g−1 current density after 1200 cycles [54].

| Raw Material | Electrochemical Performance * (Capacity Performance and Cycling Stability) | Ref. | |

|---|---|---|---|

| Organic polymers | Sugarcane bagasse | ~290 mAh g−1 at 0.03 A g−1, 94% of capacity retention after 300 cycles. | [41] |

| Sucrose | 361 mAh g−1 at 0.02 A g−1, 93.4% of capacity retention after 100 cycles. | [42] | |

| Cellulose | ~300 mAh g−1 at 0.1 C, an average capacity loss of 0.047%/cycle. | [43] | |

| Ordered cellulose nanocrystals | 340 mAh g−1 at 0.1 A g−1, 88.5% of capacity retention after 400 cycles. | [44] | |

| Lignocellulose (peanut shell) | 348 mAh g−1 at 0.1 C, 81.3% of capacity retention after 120 cycles. | [45] | |

| Mango powder | ~520 mAh g−1 at 0.02 A g−1, ~204 mAh g−1 retained after 1000 cycles at 1 A g−1. | [46] | |

| Shaddock peel | 430.5 mAh g−1 at 0.03 A g−1, 97.5% of capacity retention after 200 cycles. | [47] | |

| Biomass source | Apricot shell | ~400 mAh g−1 at 0.1 C, 91.9% of capacity retention after 300 cycles. | [48] |

| Natural cotton | 315 mAh g−1 at 0.1 C, 96.8% of capacity retention after 100 cycles. | [49] | |

| Algae | 340 mAh g−1 at 0.025 A g−1, 160~170 mAh g−1 retained after 50 cycles. | [50] | |

| Resin carbon | Phenolic resin | 311 mAh g−1 at 0.02 A g−1, more than 80% of capacity retention after 100 cycles. | [52] |

| 3-aminophenol /formaldehyde resins | 360 mAh g−1 at 0.03 A g−1, 86.1% of capacity retention after 100 cycles. | [53] |

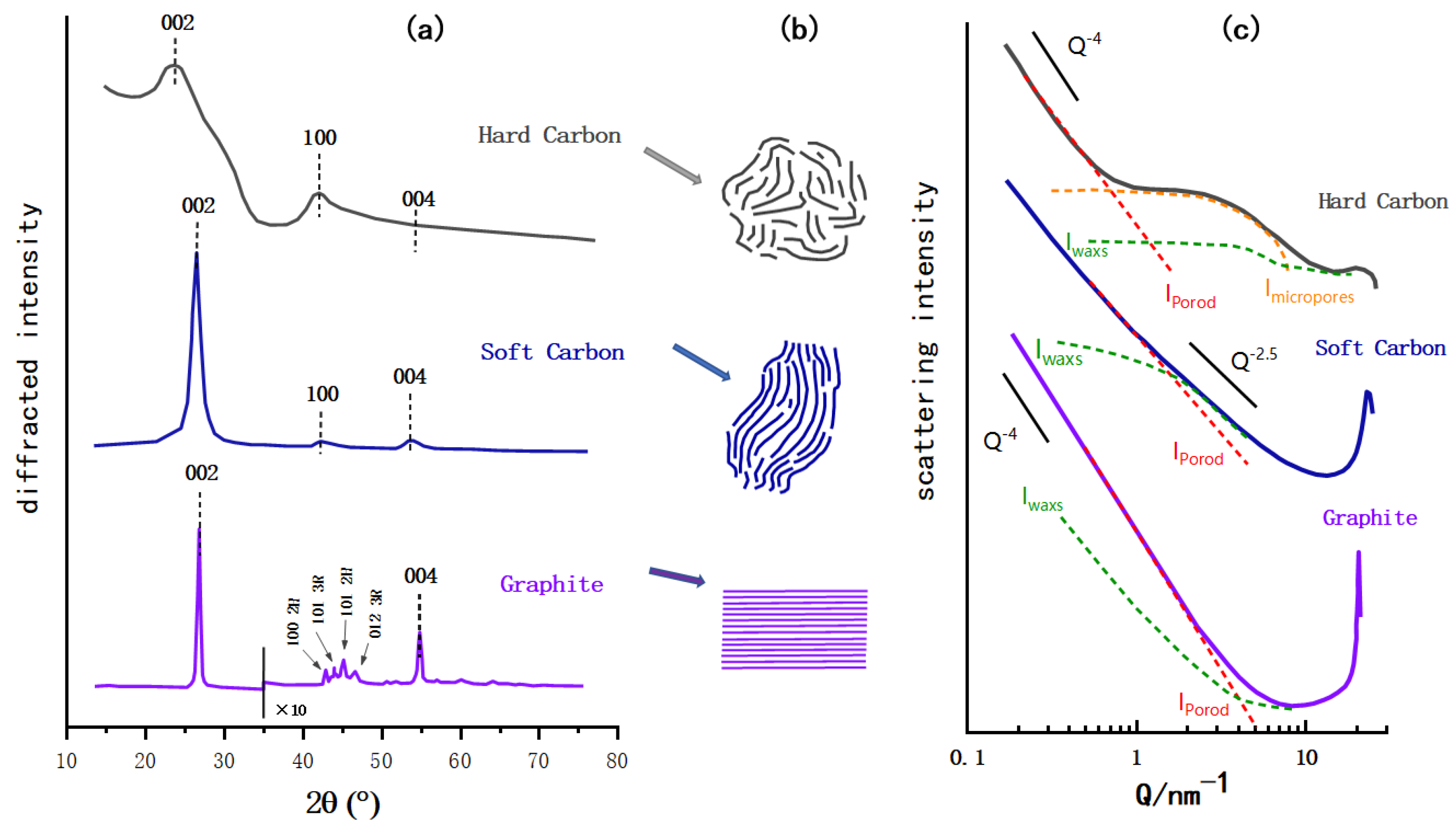

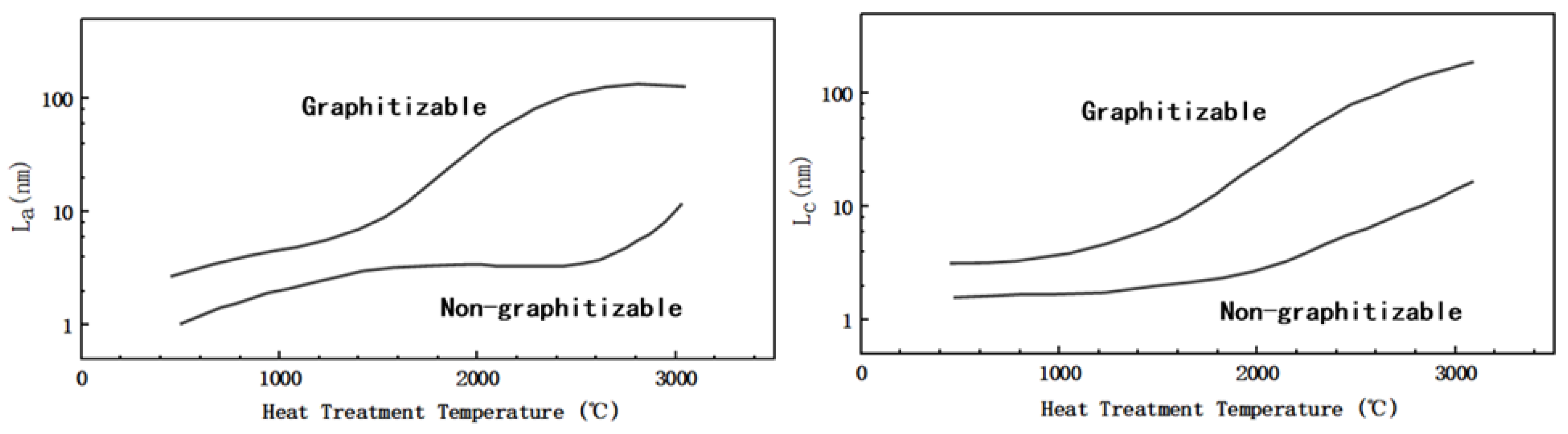

3.2. Structure of HC

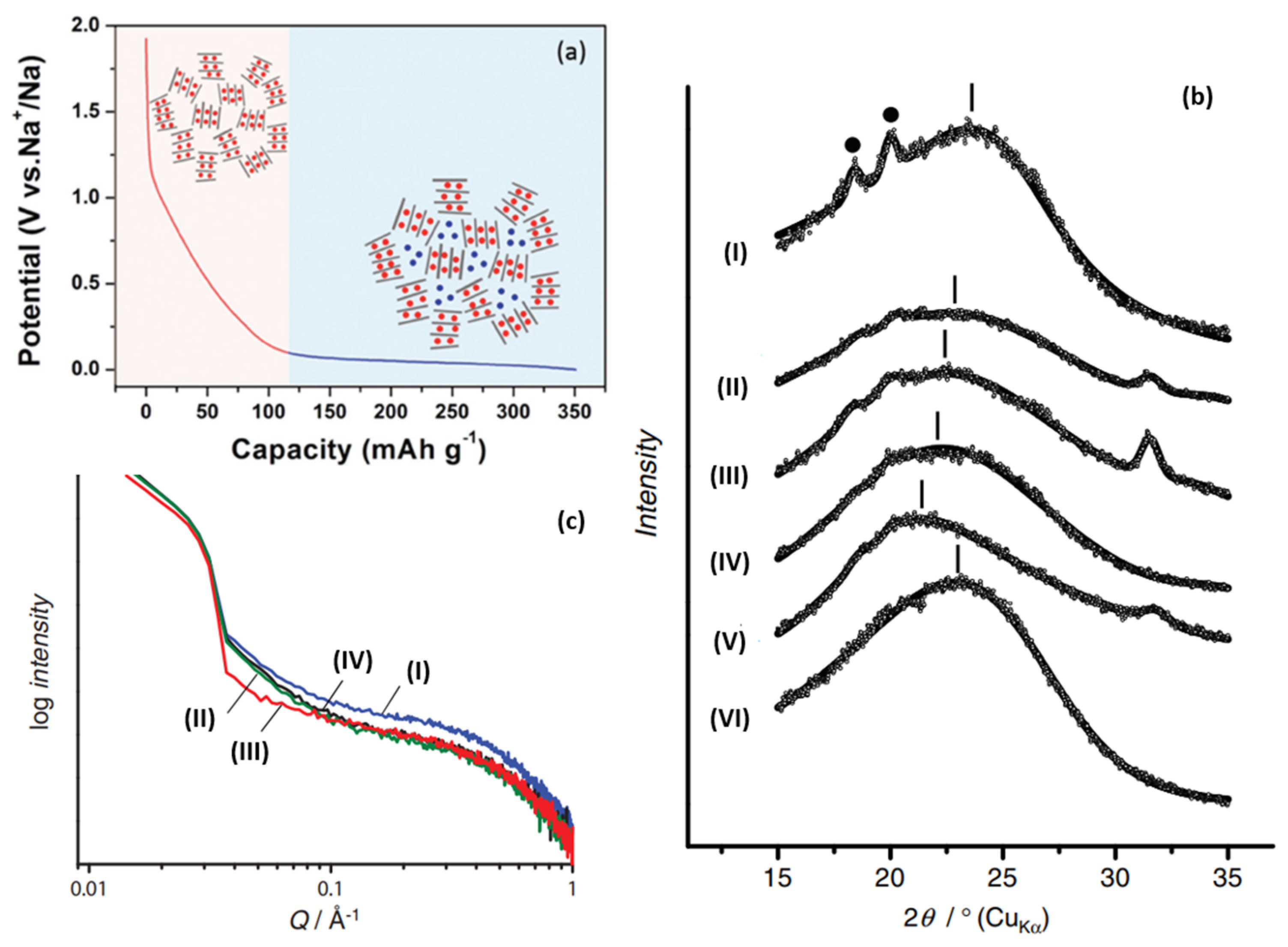

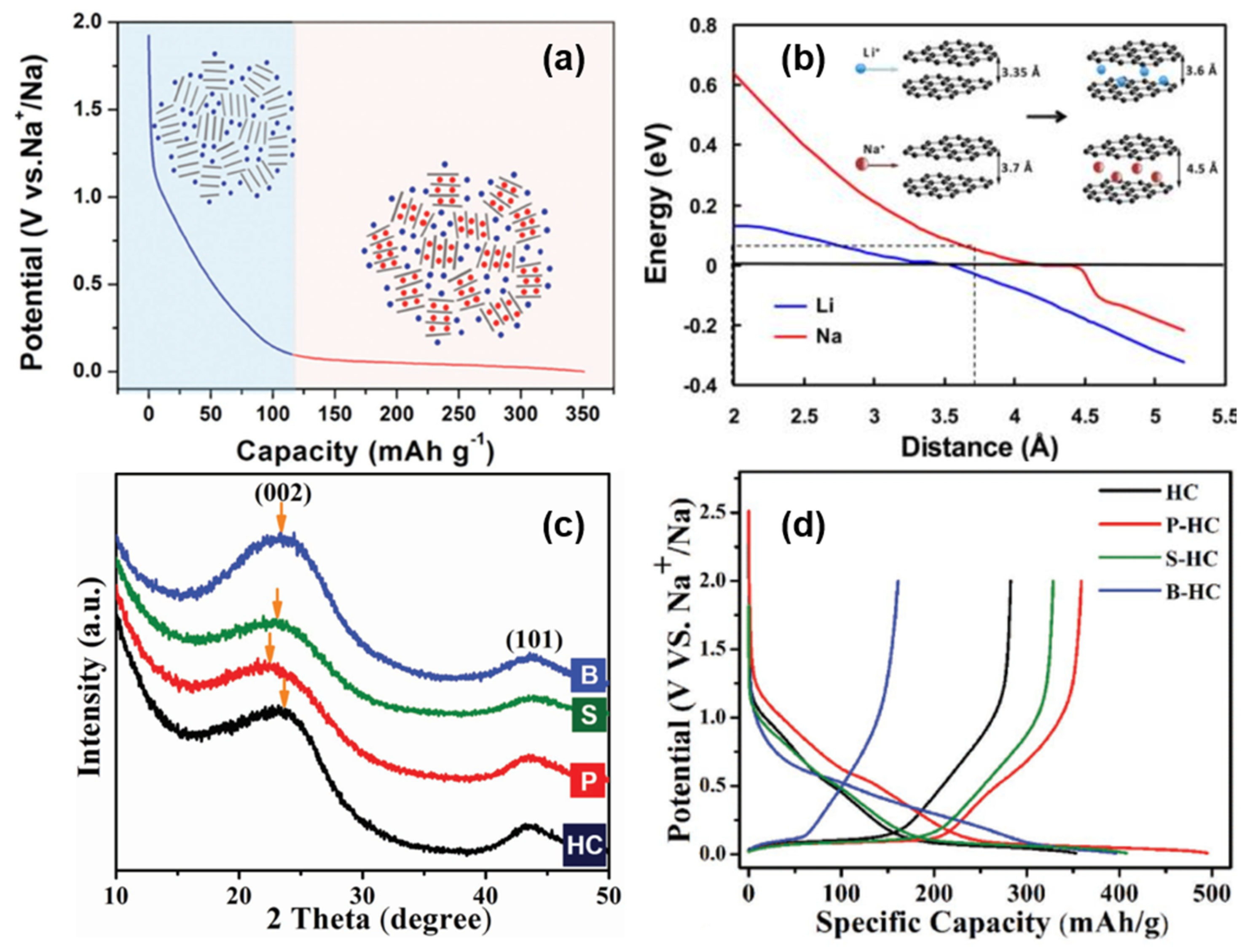

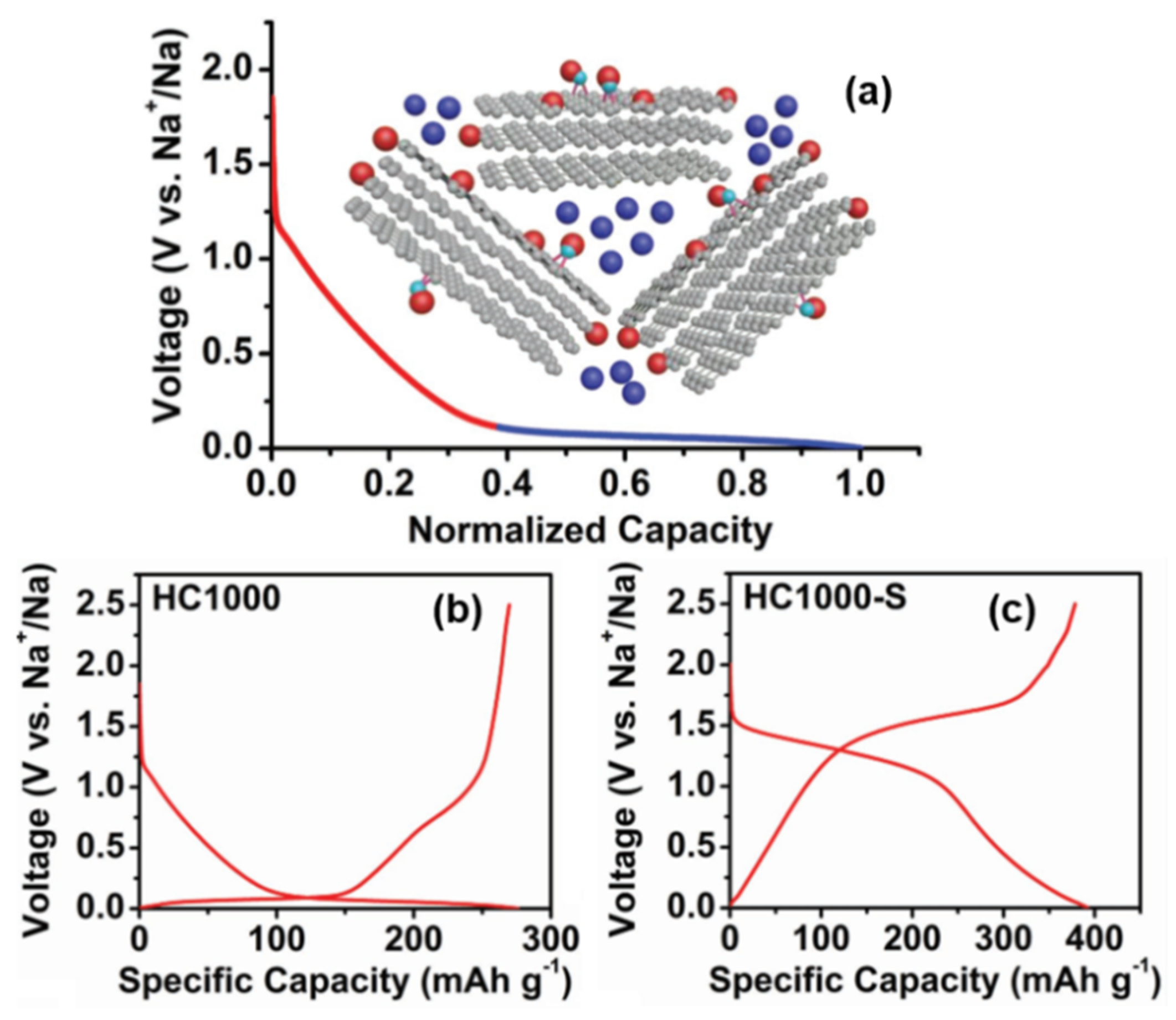

3.3. Sodium Storage Mechanism of HC

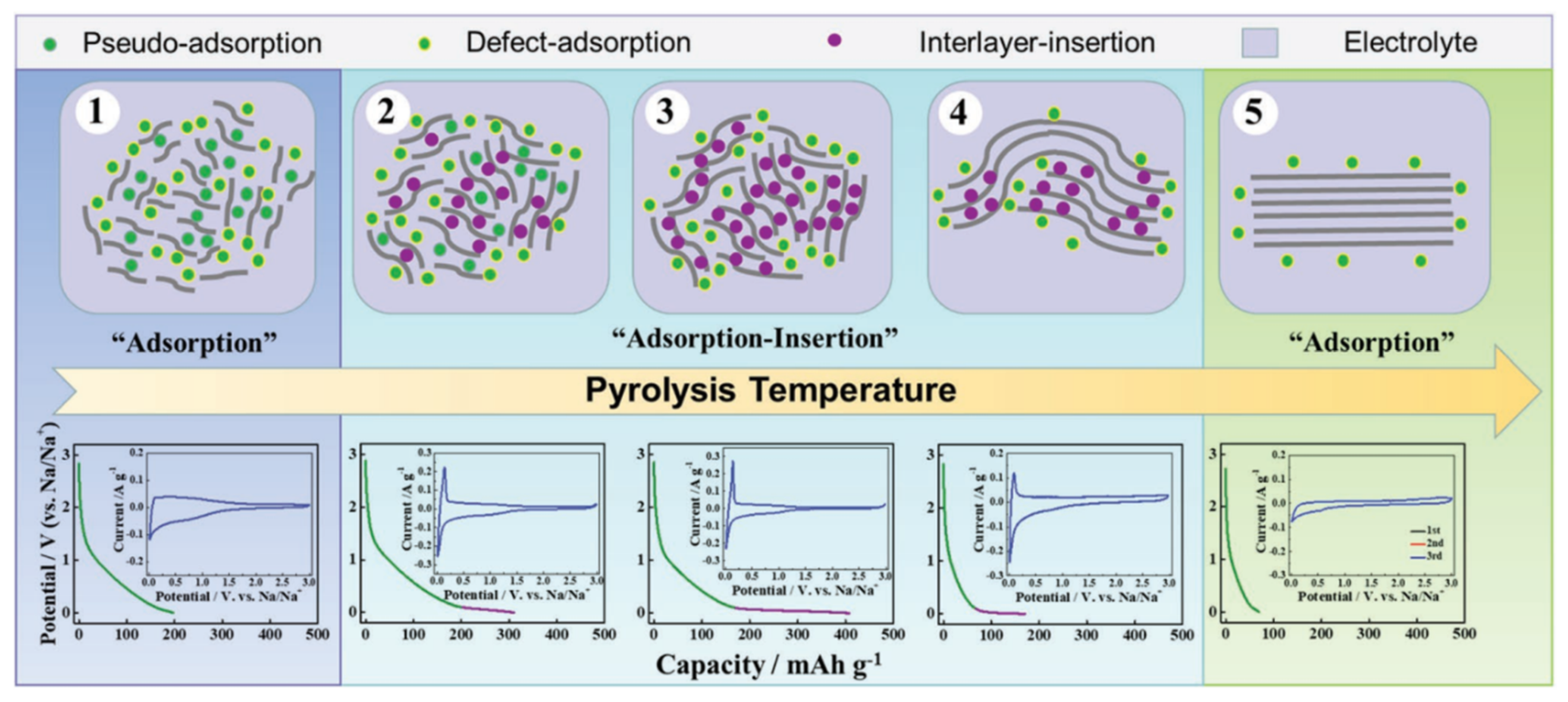

3.3.1. Intercalation-Adsorption

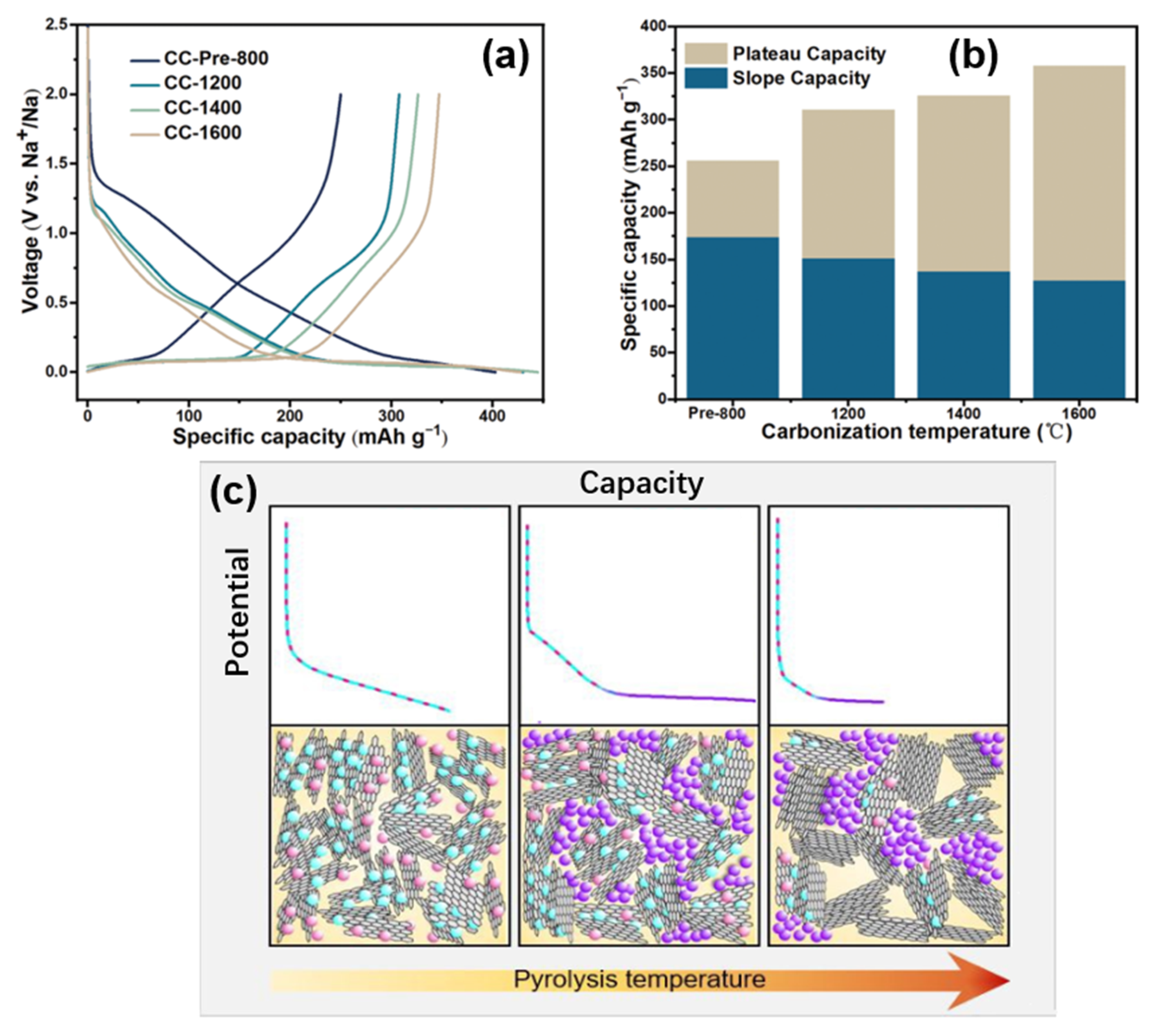

3.3.2. Adsorption-Intercalation

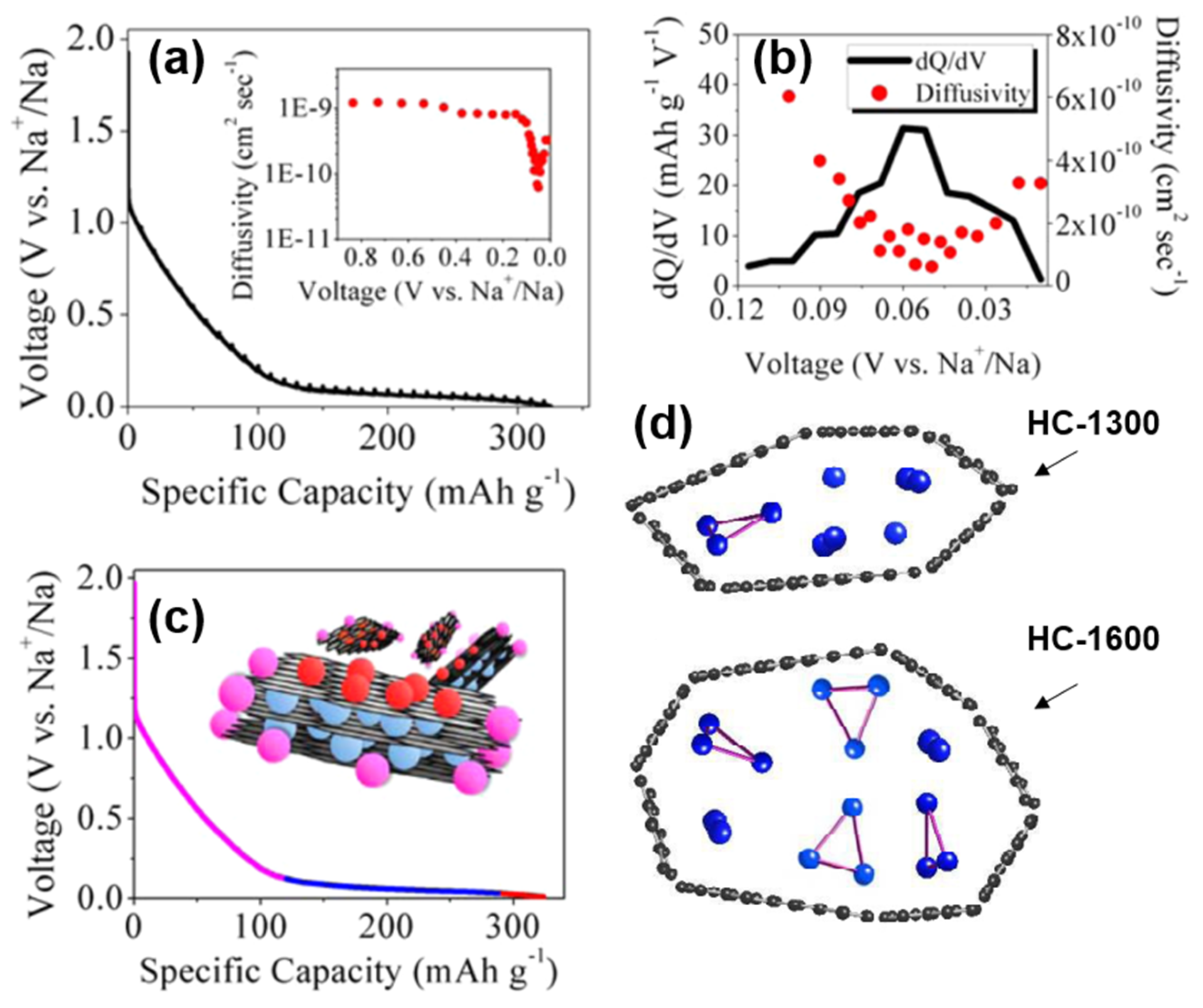

3.3.3. Intercalation-Pore Filling

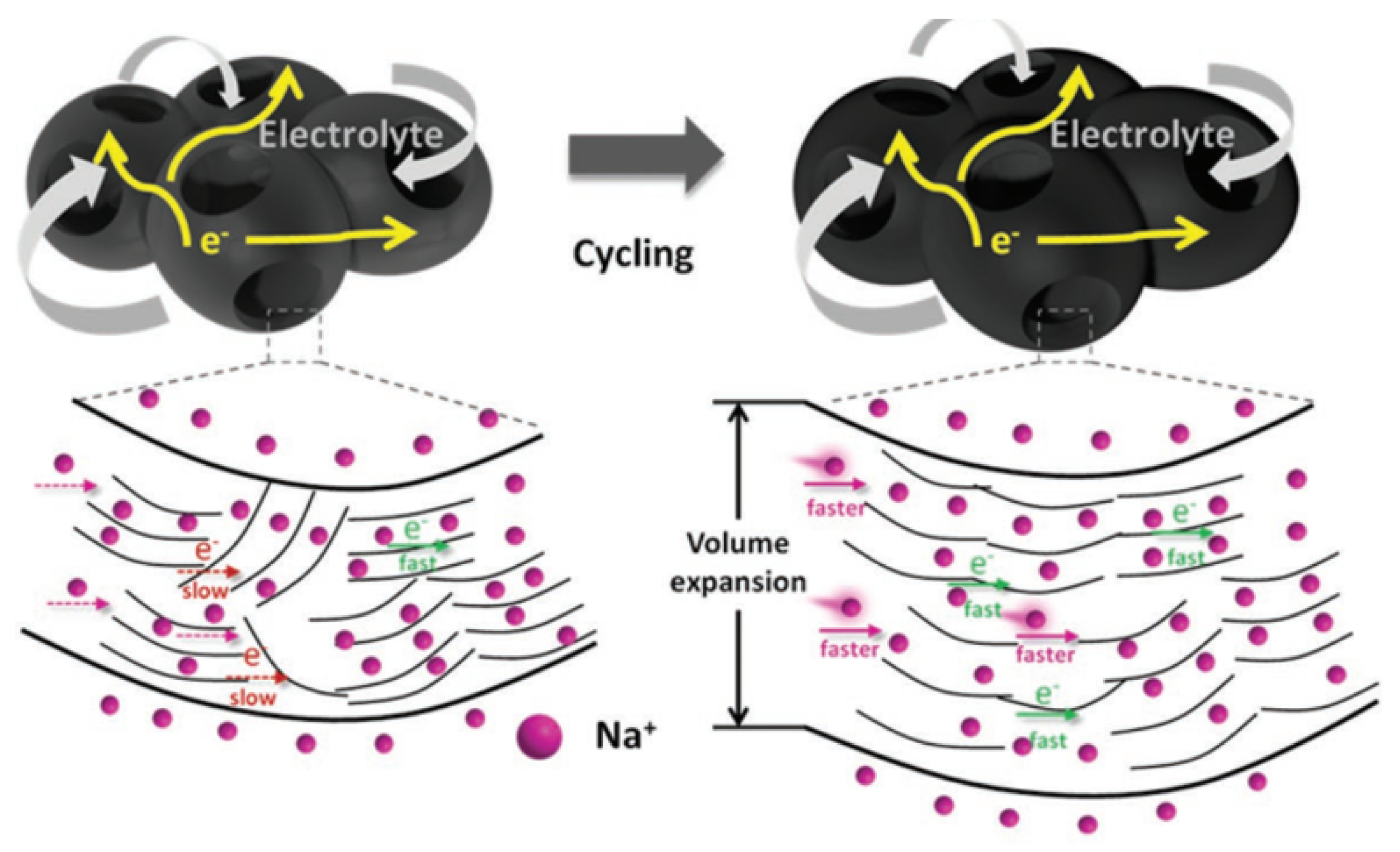

3.3.4. Adsorption-Intercalation-Pore Filling

4. Modification and Optimization Strategies of HC

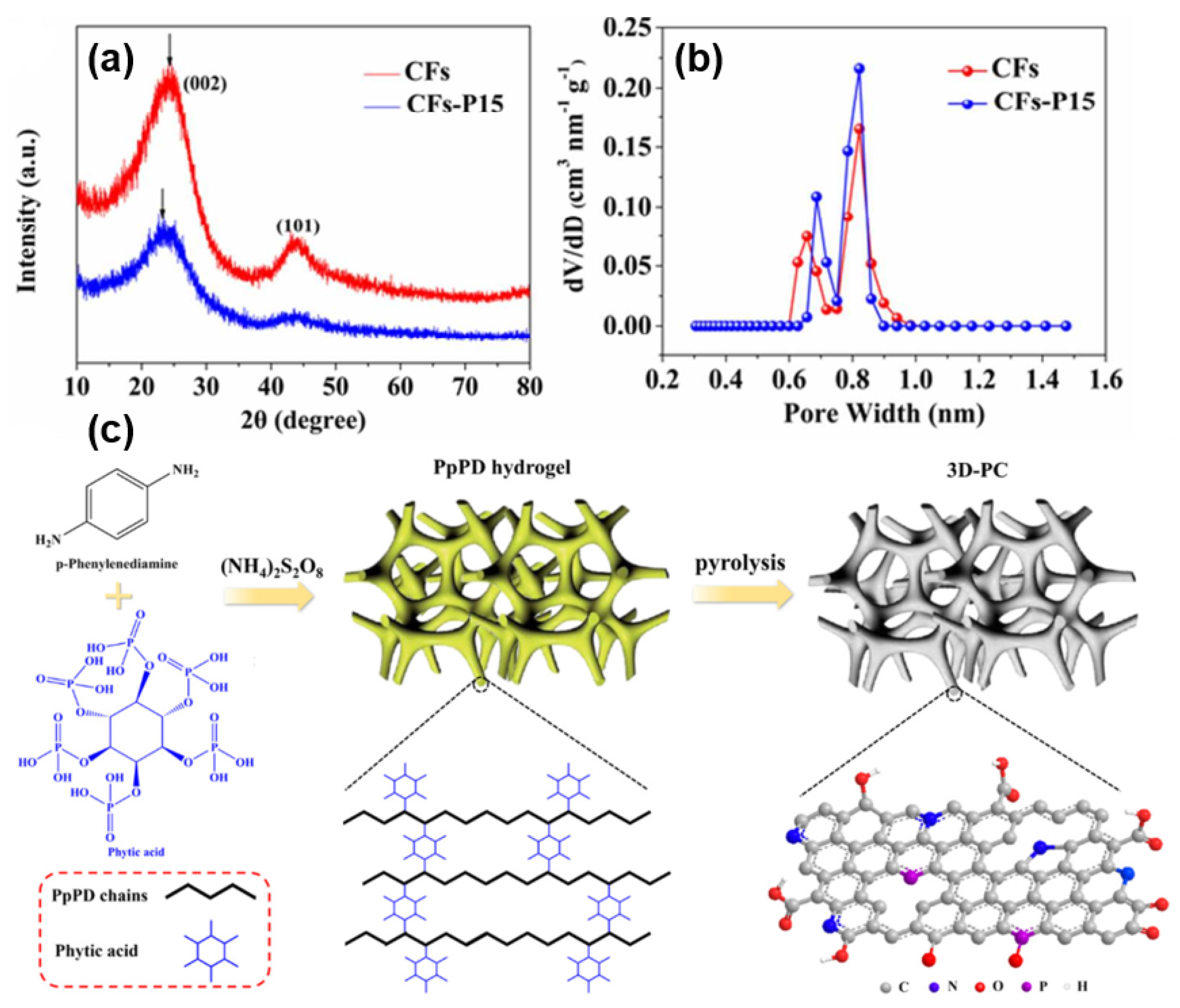

4.1. Heteroatom Doping

4.2. Structure and Morphology Designing

4.3. Preparation of Composite Materials

4.4. Optimization of Battery Conditions

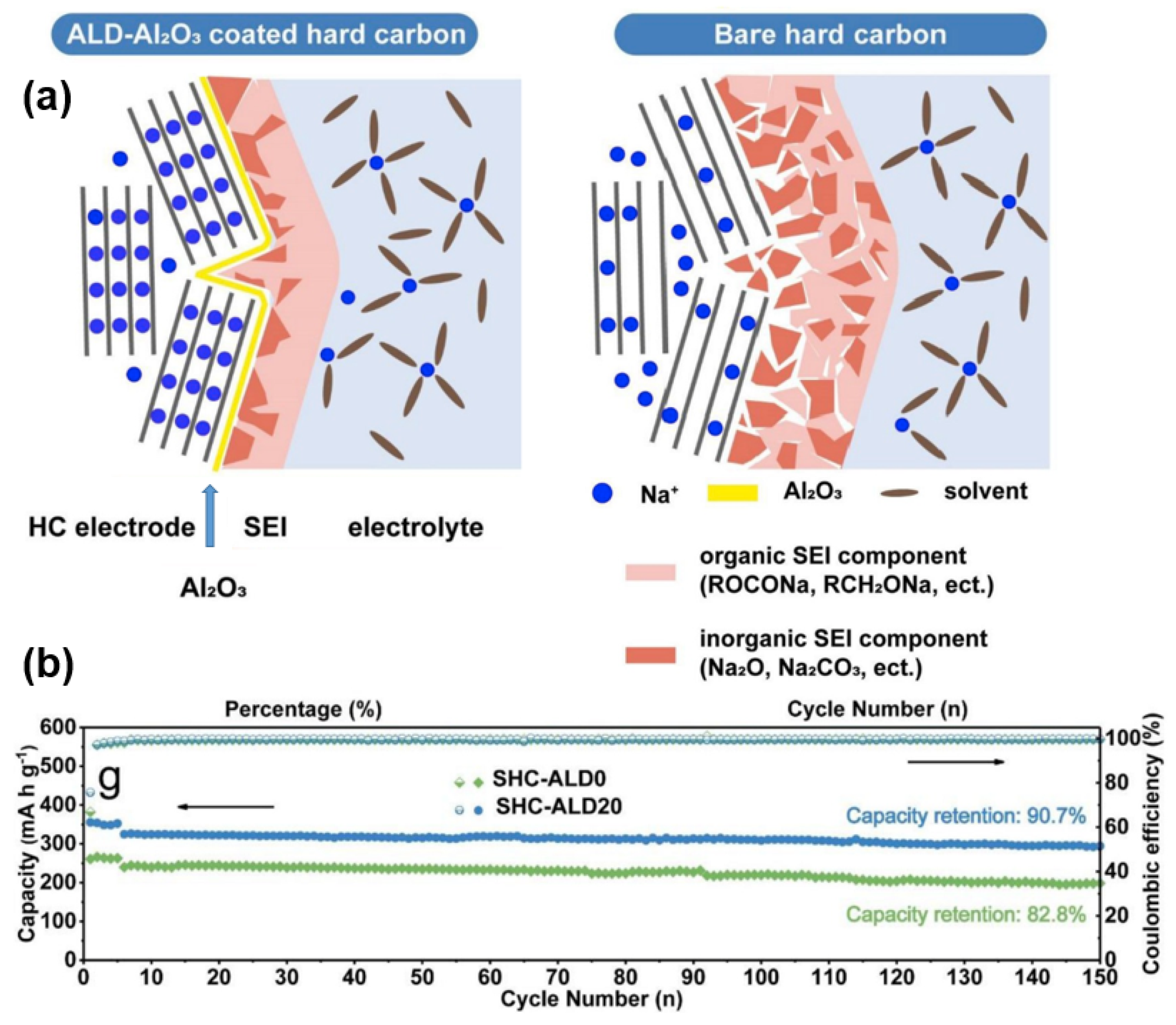

4.4.1. Electrolyte Optimization

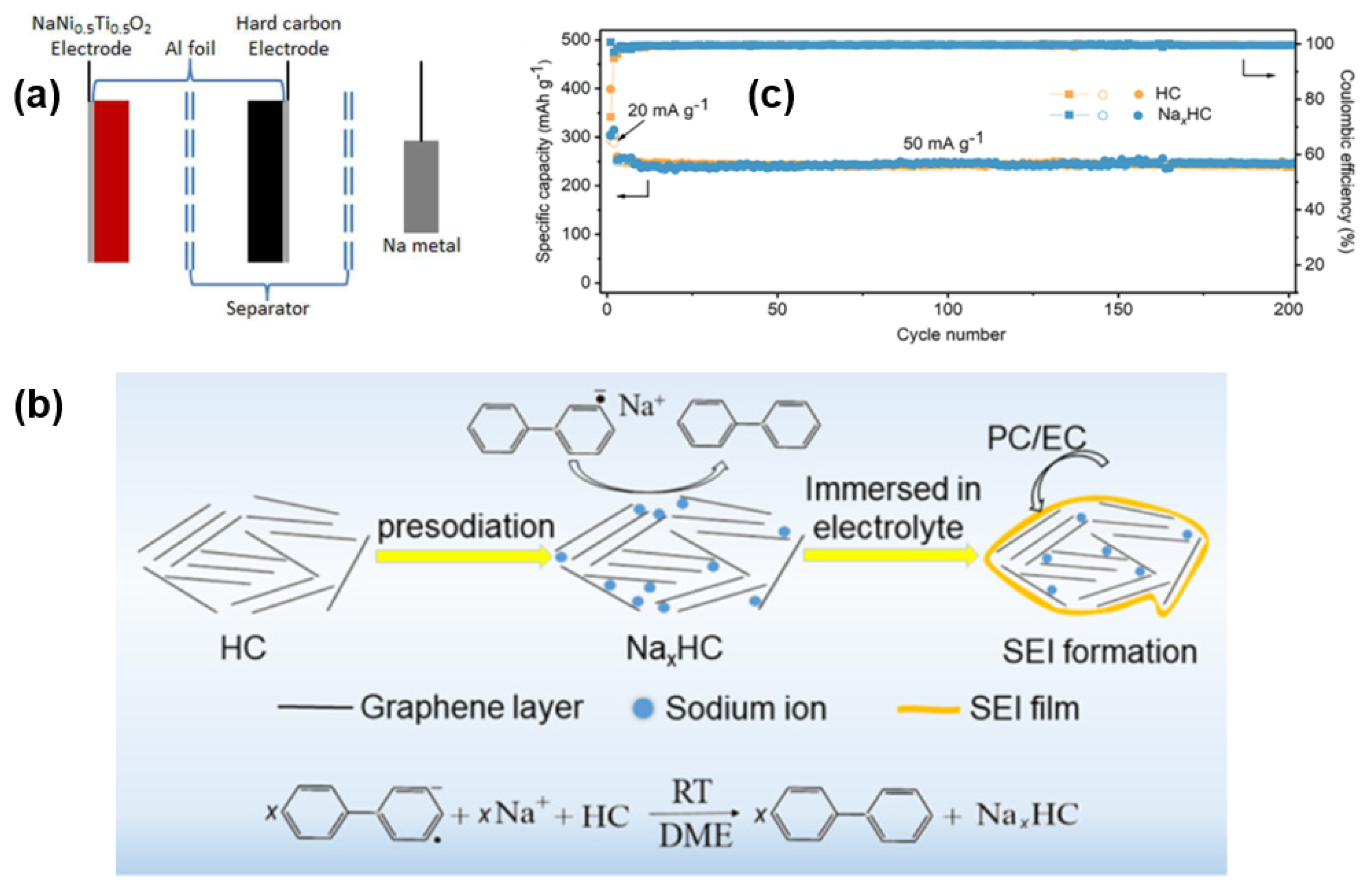

4.4.2. Anode Pre-Treatment

4.4.3. Self-Supporting Anode

5. Summary and Outlook

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- Megahed, S.; Scrosati, B. Lithium-ion rechargeable batteries. J. Power Source 1994, 51, 79–104. [Google Scholar] [CrossRef]

- Tarascon, J.M.; Armand, M. Issues and challenges facing rechargeable lithium batteries. Nature 2001, 414, 359–367. [Google Scholar] [CrossRef] [PubMed]

- Armand, M.; Tarascon, J.M. Building better batteries. Nature 2008, 451, 652–657. [Google Scholar] [CrossRef]

- Zhao, H.; Wu, Q.; Hu, S.; Xu, H.; Rasmussen, C.N. Review of energy storage system for wind power integration support. Appl. Energy 2015, 137, 545–553. [Google Scholar] [CrossRef]

- Gruber, P.W.; Medina, P.A.; Keoleian, G.A.; Kesler, S.E.; Everson, M.P.; Wallington, T.J. Global Lithium Availability. J. Ind. Ecol. 2011, 15, 760–775. [Google Scholar] [CrossRef]

- Vikström, H.; Davidsson, S.; Höök, M. Lithium availability and future production outlooks. Appl. Energy 2013, 110, 252–266. [Google Scholar] [CrossRef]

- Usiskin, R.; Lu, Y.; Popovic, J.; Law, M.; Balaya, P.; Hu, Y.-S.; Maier, J. Fundamentals, status and promise of sodium-based batteries. Nat. Rev. Mater. 2021, 6, 1020–1035. [Google Scholar] [CrossRef]

- Kubota, K.; Komaba, S. Review—Practical Issues and Future Perspective for Na-Ion Batteries. J. Electrochem. Soc. 2015, 162, A2538–A2550. [Google Scholar] [CrossRef]

- Tian, Y.; Zeng, G.; Rutt, A.; Shi, T.; Kim, H.; Wang, J.; Koettgen, J.; Sun, Y.; Ouyang, B.; Chen, T.; et al. Promises and Challenges of Next-Generation “Beyond Li-ion” Batteries for Electric Vehicles and Grid Decarbonization. Chem. Rev. 2021, 121, 1623–1669. [Google Scholar] [CrossRef]

- Bianchini, M.; Fauth, F.; Brisset, N.; Weill, F.; Suard, E.; Masquelier, C.; Croguennec, L. Comprehensive Investigation of the Na3V2(PO4)2F3–NaV2(PO4)2F3 System by Operando High Resolution Synchrotron X-ray Diffraction. Chem. Mater. 2015, 27, 3009–3020. [Google Scholar] [CrossRef]

- Zhang, X.; Rui, X.; Chen, D.; Tan, H.; Yang, D.; Huang, S.; Yu, Y. Na3V2(PO4)3: An advanced cathode for sodium-ion batteries. Nanoscale 2019, 11, 2556–2576. [Google Scholar] [CrossRef] [PubMed]

- Vassilaras, P.; Toumar, A.J.; Ceder, G. Electrochemical properties of NaNi1/3Co1/3Fe1/3O2 as a cathode material for Na-ion batteries. Electrochem. Commun. 2014, 38, 79–81. [Google Scholar] [CrossRef]

- Park, S.; Song, J.; Kim, S.; Sambandam, B.; Mathew, V.; Kim, S.; Jo, J.; Kim, S.; Kim, J. Phase-pure Na3V2(PO4)2F3 embedded in carbon matrix through a facile polyol synthesis as a potential cathode for high performance sodium-ion batteries. Nano Res. 2019, 12, 911–917. [Google Scholar] [CrossRef]

- Wang, L.; Lu, Y.; Liu, J.; Xu, M.; Cheng, J.; Zhang, D.; Goodenough, J.B. A superior low-cost cathode for a Na-ion battery. Angew. Chem. Int. Ed. 2013, 52, 1964–1967. [Google Scholar] [CrossRef]

- Mu, L.; Ben, L.; Hu, Y.-S.; Li, H.; Chen, L.; Huang, X. Novel 1.5 V anode materials, ATiOPO4(A = NH4, K, Na), for room-temperature sodium-ion batteries. J. Mater. Chem. A 2016, 4, 7141–7147. [Google Scholar] [CrossRef]

- Senguttuvan, P.; Rousse, G.; Vezin, H.; Tarascon, J.M.; Palacín, M.R. Titanium(III) Sulfate as New Negative Electrode for Sodium-Ion Batteries. Chem. Mater. 2013, 25, 2391–2393. [Google Scholar] [CrossRef]

- Senguttuvan, P.; Rousse, G.; Seznec, V.; Tarascon, J.-M.; Palacín, M.R. Na2Ti3O7: Lowest Voltage Ever Reported Oxide Insertion Electrode for Sodium Ion Batteries. Chem. Mater. 2011, 23, 4109–4111. [Google Scholar] [CrossRef]

- Hariharan, S.; Saravanan, K.; Balaya, P. α-MoO3: A high performance anode material for sodium-ion batteries. Electrochem. Commun. 2013, 31, 5–9. [Google Scholar] [CrossRef]

- Gao, L.; Lu, D.; Yang, Y.; Guan, R.; Zhang, D.; Sun, C.; Liu, S.; Bian, X. Amorphous TiO2-x modified Sb nanowires as a high-performance sodium-ion battery anode. J. Non-Cryst. Solids 2022, 581, 121396. [Google Scholar] [CrossRef]

- Wu, L.; Pei, F.; Mao, R.; Wu, F.; Wu, Y.; Qian, J.; Cao, Y.; Ai, X.; Yang, H. SiC–Sb–C nanocomposites as high-capacity and cycling-stable anode for sodium-ion batteries. Electrochim. Acta 2013, 87, 41–45. [Google Scholar] [CrossRef]

- Tang, J.; Peng, X.; Lin, T.; Huang, X.; Luo, B.; Wang, L. Confining ultrafine tin monophosphide in Ti3C2Tx interlayers for rapid and stable sodium ion storage. eScience 2021, 1, 203–211. [Google Scholar] [CrossRef]

- Zhao, L.; Zhao, J.; Hu, Y.-S.; Li, H.; Zhou, Z.; Armand, M.; Chen, L. Disodium Terephthalate (Na2C8H4O4) as High Performance Anode Material for Low-Cost Room-Temperature Sodium-Ion Battery. Adv. Energy Mater. 2012, 2, 962–965. [Google Scholar] [CrossRef]

- Abouimrane, A.; Weng, W.; Eltayeb, H.; Cui, Y.; Niklas, J.; Poluektov, O.; Amine, K. Sodium insertion in carboxylate based materials and their application in 3.6 V full sodium cells. Energy Environ. Sci. 2012, 5, 9632–9638. [Google Scholar] [CrossRef]

- Alcantara, R.; Jiménez-Mateos, J.M.; Lavela, P.; Tirado, J.L. Carbon black: A promising electrode material for sodium-ion batteries. Electrochem. Commun. 2001, 3, 639–642. [Google Scholar] [CrossRef]

- Cheng, D.-L.; Yang, L.-C.; Zhu, M. High-performance anode materials for Na-ion batteries. Rare Met. 2018, 37, 167–180. [Google Scholar] [CrossRef]

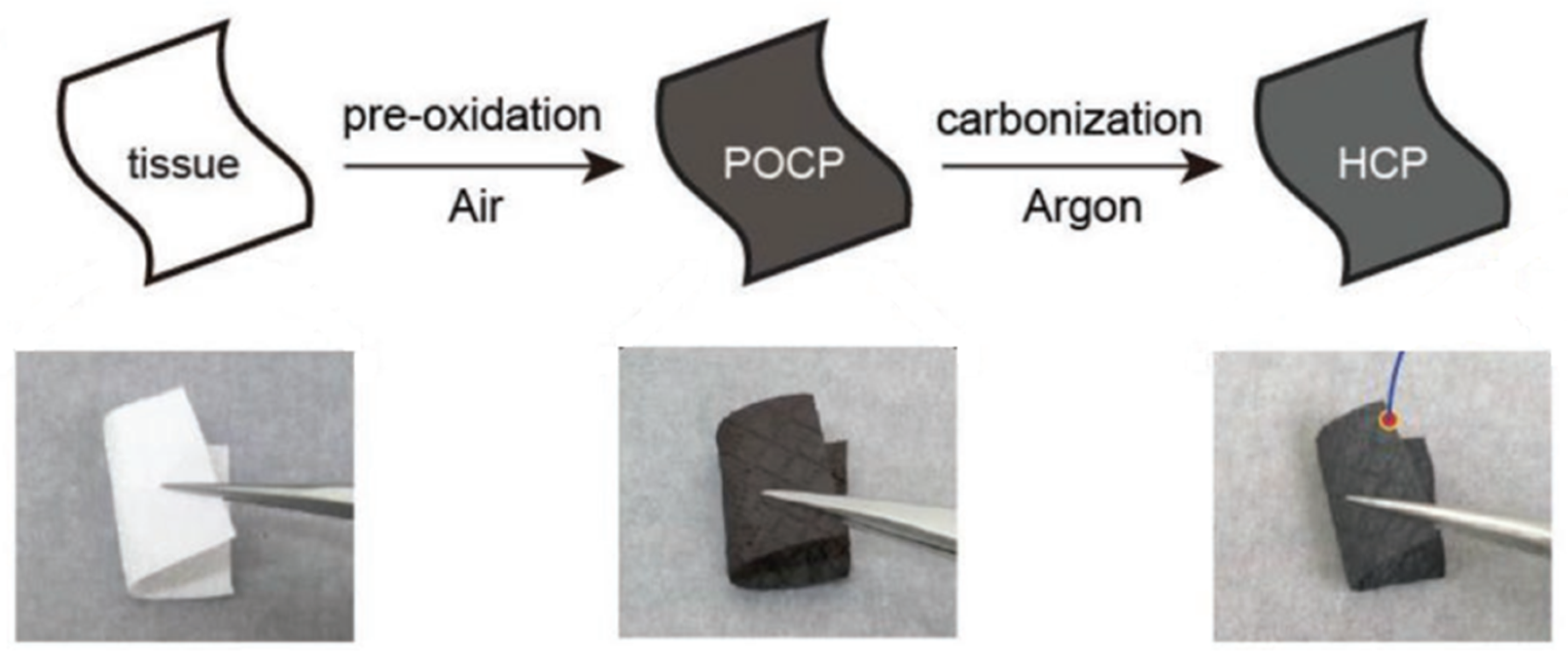

- Lu, Y.; Zhao, C.; Qi, X.; Qi, Y.; Li, H.; Huang, X.; Chen, L.; Hu, Y.-S. Pre-Oxidation-Tuned Microstructures of Carbon Anodes Derived from Pitch for Enhancing Na Storage Performance. Adv. Energy Mater. 2018, 8, 1800108. [Google Scholar] [CrossRef]

- Wang, Y.-X.; Chou, S.-L.; Liu, H.-K.; Dou, S.-X. Reduced graphene oxide with superior cycling stability and rate capability for sodium storage. Carbon 2013, 57, 202–208. [Google Scholar] [CrossRef]

- Yao, X.; Ke, Y.; Ren, W.; Wang, X.; Xiong, F.; Yang, W.; Qin, M.; Li, Q.; Mai, L. Defect-Rich Soft Carbon Porous Nanosheets for Fast and High-Capacity Sodium-Ion Storage. Adv. Energy Mater. 2018, 9, 1803260. [Google Scholar] [CrossRef]

- Asenbauer, J.; Eisenmann, T.; Kuenzel, M.; Kazzazi, A.; Chen, Z.; Bresser, D. The success story of graphite as a lithium-ion anode material—Fundamentals, remaining challenges, and recent developments including silicon (oxide) composites. Sustain. Energy Fuels 2020, 4, 5387–5416. [Google Scholar] [CrossRef]

- Nobuhara, K.; Nakayama, H.; Nose, M.; Nakanishi, S.; Iba, H. First-principles study of alkali metal-graphite intercalation compounds. J. Power Source 2013, 243, 585–587. [Google Scholar] [CrossRef]

- Wan, J.; Shen, F.; Luo, W.; Zhou, L.; Dai, J.; Han, X.; Bao, W.; Xu, Y.; Panagiotopoulos, J.; Fan, X.; et al. In Situ Transmission Electron Microscopy Observation of Sodiation–Desodiation in a Long Cycle, High-Capacity Reduced Graphene Oxide Sodium-Ion Battery Anode. Chem. Mater. 2016, 28, 6528–6535. [Google Scholar] [CrossRef]

- Wen, Y.; He, K.; Zhu, Y.; Han, F.; Xu, Y.; Matsuda, I.; Ishii, Y.; Cumings, J.; Wang, C. Expanded graphite as superior anode for sodium-ion batteries. Nat. Commun. 2014, 5, 4033. [Google Scholar] [CrossRef] [PubMed]

- Kim, H.; Hong, J.; Park, Y.-U.; Kim, J.; Hwang, I.; Kang, K. Sodium Storage Behavior in Natural Graphite using Ether-based Electrolyte Systems. Adv. Funct. Mater. 2015, 25, 534–541. [Google Scholar] [CrossRef]

- Jache, B.; Adelhelm, P. Use of graphite as a highly reversible electrode with superior cycle life for sodium-ion batteries by making use of co-intercalation phenomena. Angew. Chem. Int. Ed. 2014, 53, 10169–10173. [Google Scholar] [CrossRef]

- Winter, M.; Novák, P.; Monnier, A. Graphites for Lithium-Ion Cells: The Correlation of the First-Cycle Charge Loss with the Brunauer-Emmett-Teller Surface Area. J. Electrochem. Soc. 1998, 145, 428. [Google Scholar] [CrossRef]

- Cao, Y.; Xiao, L.; Sushko, M.; Wang, W.; Schwenzer, B.; Xiao, J.; Nie, Z.; Saraf, L.V.; Yang, Z.; Liu, J. Sodium ion insertion in hollow carbon nanowires for battery applications. Nano Lett. 2012, 12, 3783–3787. [Google Scholar] [CrossRef]

- Li, Y.; Hu, Y.-S.; Qi, X.; Rong, X.; Li, H.; Huang, X.; Chen, L. Advanced sodium-ion batteries using superior low cost pyrolyzed anthracite anode: Towards practical applications. Energy Storage Mater. 2016, 5, 191–197. [Google Scholar] [CrossRef]

- Stevens, D.A.; Dahn, J.R. High Capacity Anode Materials for Rechargeable Sodium-Ion Batteries. J. Electrochem. Soc. 2000, 147, 1271. [Google Scholar] [CrossRef]

- Yang, T.; Qian, T.; Wang, M.; Shen, X.; Xu, N.; Sun, Z.; Yan, C. A Sustainable Route from Biomass Byproduct Okara to High Content Nitrogen-Doped Carbon Sheets for Efficient Sodium Ion Batteries. Adv. Mater. 2016, 28, 539–545. [Google Scholar] [CrossRef]

- Hao, R.; Yang, Y.; Wang, H.; Jia, B.; Ma, G.; Yu, D.; Guo, L.; Yang, S. Direct chitin conversion to N-doped amorphous carbon nanofibers for high-performing full sodium-ion batteries. Nano Energy 2018, 45, 220–228. [Google Scholar] [CrossRef]

- Rath, P.C.; Patra, J.; Huang, H.; Bresser, D.; Wu, T.; Chang, J. Carbonaceous Anodes Derived from Sugarcane Bagasse for Sodium-Ion Batteries. ChemSusChem 2019, 12, 2302–2309. [Google Scholar] [CrossRef] [PubMed]

- Xiao, L.; Lu, H.; Fang, Y.; Sushko, M.L.; Cao, Y.; Ai, X.; Yang, H.; Liu, J. Low-Defect and Low-Porosity Hard Carbon with High Coulombic Efficiency and High Capacity for Practical Sodium Ion Battery Anode. Adv. Energy Mater. 2018, 8, 1703238. [Google Scholar] [CrossRef]

- Simone, V.; Boulineau, A.; de Geyer, A.; Rouchon, D.; Simonin, L.; Martinet, S. Hard carbon derived from cellulose as anode for sodium ion batteries: Dependence of electrochemical properties on structure. J. Energy Chem. 2016, 25, 761–768. [Google Scholar] [CrossRef]

- Zhu, H.; Shen, F.; Luo, W.; Zhu, S.; Zhao, M.; Natarajan, B.; Dai, J.; Zhou, L.; Ji, X.; Yassar, R.S.; et al. Low temperature carbonization of cellulose nanocrystals for high performance carbon anode of sodium-ion batteries. Nano Energy 2017, 33, 37–44. [Google Scholar] [CrossRef]

- Dou, X.; Hasa, I.; Saurel, D.; Jauregui, M.; Buchholz, D.; Rojo, T.; Passerini, S. Impact of the Acid Treatment on Lignocellulosic Biomass Hard Carbon for Sodium-Ion Battery Anodes. ChemSusChem 2018, 11, 3276–3285. [Google Scholar] [CrossRef]

- Gaddam, R.R.; Niaei, A.H.F.; Hankel, M.; Searles, D.J.; Kumar, N.A.; Zhao, X.S. Capacitance-enhanced sodium-ion storage in nitrogen-rich hard carbon. J. Mater. Chem. A 2017, 5, 22186–22192. [Google Scholar] [CrossRef]

- Sun, N.; Liu, H.; Xu, B. Facile synthesis of high performance hard carbon anode materials for sodium ion batteries. J. Mater. Chem. A 2015, 3, 20560–20566. [Google Scholar] [CrossRef]

- Zhu, Y.; Chen, M.; Li, Q.; Yuan, C.; Wang, C. A porous biomass-derived anode for high-performance sodium-ion batteries. Carbon 2018, 129, 695–701. [Google Scholar] [CrossRef]

- Li, Y.; Hu, Y.-S.; Titirici, M.-M.; Chen, L.; Huang, X. Hard Carbon Microtubes Made from Renewable Cotton as High-Performance Anode Material for Sodium-Ion Batteries. Adv. Energy Mater. 2016, 6, 1600659. [Google Scholar] [CrossRef]

- Gibertini, E.; Liberale, F.; Dossi, C.; Binda, G.; Mattioli, B.; Bettinetti, R.; Maspero, A.; Fiore, M.; Ruffo, R.; Magagnin, L. Algae-derived hard carbon anodes for Na-ion batteries. J. Appl. Electrochem. 2021, 51, 1665–1673. [Google Scholar] [CrossRef]

- Thompson, M.J.; Xia, Q.; Hu, Z.; Zhao, X.S. A review on biomass-derived hard carbon materials for sodium-ion batteries. Mater. Adv. 2021, 2, 5881–5905. [Google Scholar] [CrossRef]

- Wang, H.-L.; Shi, Z.-Q.; Jin, J.; Chong, C.-B.; Wang, C.-Y. Properties and sodium insertion behavior of Phenolic Resin-based hard carbon microspheres obtained by a hydrothermal method. J. Electroanal. Chem. 2015, 755, 87–91. [Google Scholar] [CrossRef]

- Bin, D.-S.; Li, Y.; Sun, Y.-G.; Duan, S.-Y.; Lu, Y.; Ma, J.; Cao, A.-M.; Hu, Y.-S.; Wan, L.-J. Structural Engineering of Multishelled Hollow Carbon Nanostructures for High-Performance Na-Ion Battery Anode. Adv. Energy Mater. 2018, 8, 1800855. [Google Scholar] [CrossRef]

- Ding, C.; Huang, L.; Lan, J.; Yu, Y.; Zhong, W.; Yang, X. Superresilient Hard Carbon Nanofabrics for Sodium-Ion Batteries. Small 2020, 16, e1906883. [Google Scholar] [CrossRef]

- Saurel, D.; Orayech, B.; Xiao, B.; Carriazo, D.; Li, X.; Rojo, T. From Charge Storage Mechanism to Performance: A Roadmap toward High Specific Energy Sodium-Ion Batteries through Carbon Anode Optimization. Adv. Energy Mater. 2018, 8, 1703268. [Google Scholar] [CrossRef]

- Muñoz-Márquez, M.; Saurel, D.; Gómez-Cámer, J.L.; Casas-Cabanas, M.; Castillo-Martínez, E.; Rojo, T. Na-Ion Batteries for Large Scale Applications: A Review on Anode Materials and Solid Electrolyte Interphase Formation. Adv. Energy Mater. 2017, 7, 1700463. [Google Scholar] [CrossRef]

- Saurel, D.; Segalini, J.; Jauregui, M.; Pendashteh, A.; Daffos, B.; Simon, P.; Casas-Cabanas, M. A SAXS outlook on disordered carbonaceous materials for electrochemical energy storage. Energy Storage Mater. 2019, 21, 162–173. [Google Scholar] [CrossRef]

- Dou, X.; Hasa, I.; Saurel, D.; Vaalma, C.; Wu, L.; Buchholz, D.; Bresser, D.; Komaba, S.; Passerini, S. Hard carbons for sodium-ion batteries: Structure, analysis, sustainability, and electrochemistry. Mater. Today 2019, 23, 87–104. [Google Scholar] [CrossRef]

- Emmerich, F.G. Evolution with heat treatment of crystallinity in carbons. Carbon 1995, 33, 1709–1715. [Google Scholar] [CrossRef]

- Stevens, D.A.; Dahn, J.R. The Mechanisms of Lithium and Sodium Insertion in Carbon Materials. J. Electrochem. Soc. 2001, 148, A803. [Google Scholar] [CrossRef]

- Komaba, S.; Murata, W.; Ishikawa, T.; Yabuuchi, N.; Ozeki, T.; Nakayama, T.; Ogata, A.; Gotoh, K.; Fujiwara, K. Electrochemical Na Insertion and Solid Electrolyte Interphase for Hard-Carbon Electrodes and Application to Na-Ion Batteries. Adv. Funct. Mater. 2011, 21, 3859–3867. [Google Scholar] [CrossRef]

- Irisarri, E.; Ponrouch, A.; Palacin, M.R. Review—Hard Carbon Negative Electrode Materials for Sodium-Ion Batteries. J. Electrochem. Soc. 2015, 162, A2476–A2482. [Google Scholar] [CrossRef]

- Qiu, S.; Xiao, L.; Sushko, M.L.; Han, K.S.; Shao, Y.; Yan, M.; Liang, X.; Mai, L.; Feng, J.; Cao, Y.; et al. Manipulating Adsorption–Insertion Mechanisms in Nanostructured Carbon Materials for High-Efficiency Sodium Ion Storage. Adv. Energy Mater. 2017, 7, 1700403. [Google Scholar] [CrossRef]

- Xiao, L.; Cao, Y.; Henderson, W.A.; Sushko, M.L.; Shao, Y.; Xiao, J.; Wang, W.; Engelhard, M.H.; Nie, Z.; Liu, J. Hard carbon nanoparticles as high-capacity, high-stability anodic materials for Na-ion batteries. Nano Energy 2016, 19, 279–288. [Google Scholar] [CrossRef]

- Li, Z.; Bommier, C.; Chong, Z.S.; Jian, Z.; Surta, T.W.; Wang, X.; Xing, Z.; Neuefeind, J.C.; Stickle, W.F.; Dolgos, M.; et al. Mechanism of Na-Ion Storage in Hard Carbon Anodes Revealed by Heteroatom Doping. Adv. Energy Mater. 2017, 7, 1602894. [Google Scholar] [CrossRef]

- Bai, P.; He, Y.; Zou, X.; Zhao, X.; Xiong, P.; Xu, Y. Elucidation of the Sodium-Storage Mechanism in Hard Carbons. Adv. Energy Mater. 2018, 8, 1703217. [Google Scholar] [CrossRef]

- Li, Y.; Lu, Y.; Meng, Q.; Jensen, A.C.S.; Zhang, Q.; Zhang, Q.; Tong, Y.; Qi, Y.; Gu, L.; Titirici, M.; et al. Regulating Pore Structure of Hierarchical Porous Waste Cork-Derived Hard Carbon Anode for Enhanced Na Storage Performance. Adv. Energy Mater. 2019, 9, 1902852. [Google Scholar] [CrossRef]

- Au, H.; Alptekin, H.; Jensen, A.C.S.; Olsson, E.; O’Keefe, C.A.; Smith, T.; Crespo-Ribadeneyra, M.; Headen, T.F.; Grey, C.P.; Cai, Q.; et al. A revised mechanistic model for sodium insertion in hard carbons. Energy Environ. Sci. 2020, 13, 3469–3479. [Google Scholar] [CrossRef]

- Bommier, C.; Surta, T.W.; Dolgos, M.; Ji, X. New Mechanistic Insights on Na-Ion Storage in Nongraphitizable Carbon. Nano Lett 2015, 15, 5888–5892. [Google Scholar] [CrossRef]

- Bommier, C.; Ji, X.; Greaney, P.A. Electrochemical Properties and Theoretical Capacity for Sodium Storage in Hard Carbon: Insights from First Principles Calculations. Chem. Mater. 2018, 31, 658–677. [Google Scholar] [CrossRef]

- Morita, R.; Gotoh, K.; Fukunishi, M.; Kubota, K.; Komaba, S.; Nishimura, N.; Yumura, T.; Deguchi, K.; Ohki, S.; Shimizu, T.; et al. Combination of solid state NMR and DFT calculation to elucidate the state of sodium in hard carbon electrodes. J. Mater. Chem. A 2016, 4, 13183–13193. [Google Scholar] [CrossRef]

- Morikawa, Y.; Nishimura, S.; Hashimoto, R.; Ohnuma, M.; Yamada, A. Mechanism of Sodium Storage in Hard Carbon: An X-Ray Scattering Analysis. Adv. Energy Mater. 2019, 10, 1903176. [Google Scholar] [CrossRef]

- Wang, Z.; Feng, X.; Bai, Y.; Yang, H.; Dong, R.; Wang, X.; Xu, H.; Wang, Q.; Li, H.; Gao, H.; et al. Probing the Energy Storage Mechanism of Quasi-Metallic Na in Hard Carbon for Sodium-Ion Batteries. Adv. Energy Mater. 2021, 11, 2003854. [Google Scholar] [CrossRef]

- Sun, N.; Guan, Z.; Liu, Y.; Cao, Y.; Zhu, Q.; Liu, H.; Wang, Z.; Zhang, P.; Xu, B. Extended “Adsorption–Insertion” Model: A New Insight into the Sodium Storage Mechanism of Hard Carbons. Adv. Energy Mater. 2019, 9, 1901351. [Google Scholar] [CrossRef]

- Fong, R.; von Sacken, U.; Dahn, J.R. Studies of Lithium Intercalation into Carbons Using Nonaqueous Electrochemical Cells. J. Electrochem. Soc. 1990, 137, 2009–2013. [Google Scholar] [CrossRef]

- Bommier, C.; Luo, W.; Gao, W.-Y.; Greaney, A.; Ma, S.; Ji, X. Predicting capacity of hard carbon anodes in sodium-ion batteries using porosity measurements. Carbon 2014, 76, 165–174. [Google Scholar] [CrossRef]

- Yan, Z.; Yang, Q.-W.; Wang, Q.; Ma, J. Nitrogen doped porous carbon as excellent dual anodes for Li- and Na-ion batteries. Chin. Chem. Lett. 2020, 31, 583–588. [Google Scholar]

- Wang, P.; Qiao, B.; Du, Y.; Li, Y.; Zhou, X.; Dai, Z.; Bao, J. Fluorine-Doped Carbon Particles Derived from Lotus Petioles as High-Performance Anode Materials for Sodium-Ion Batteries. J. Phys. Chem. C 2015, 119, 21336–21344. [Google Scholar] [CrossRef]

- Hou, H.; Shao, L.; Zhang, Y.; Zou, G.; Chen, J.; Ji, X. Large-Area Carbon Nanosheets Doped with Phosphorus: A High-Performance Anode Material for Sodium-Ion Batteries. Adv. Sci. 2017, 4, 1600243. [Google Scholar] [CrossRef]

- Jin, Q.; Li, W.; Wang, K.; Feng, P.; Li, H.; Gu, T.; Zhou, M.; Wang, W.; Cheng, S.; Jiang, K. Experimental design and theoretical calculation for sulfur-doped carbon nanofibers as a high performance sodium-ion battery anode. J. Mater. Chem. A 2019, 7, 10239–10245. [Google Scholar] [CrossRef]

- Chen, C.; Huang, Y.; Zhu, Y.; Zhang, Z.; Guang, Z.; Meng, Z.; Liu, P. Nonignorable Influence of Oxygen in Hard Carbon for Sodium Ion Storage. ACS Sustain. Chem. Eng. 2020, 8, 1497–1506. [Google Scholar] [CrossRef]

- Fu, L.; Tang, K.; Song, K.; van Aken, P.A.; Yu, Y.; Maier, J. Nitrogen doped porous carbon fibres as anode materials for sodium ion batteries with excellent rate performance. Nanoscale 2014, 6, 1384–1389. [Google Scholar] [CrossRef] [PubMed]

- Xu, K.; Li, Y.; Liu, Y.; Zhong, G.; Wang, C.; Su, W.; Li, X.; Yang, C. Na+-storage properties derived from a high pseudocapacitive behavior for nitrogen-doped porous carbon anode. Mater. Lett. 2020, 261, 127064. [Google Scholar] [CrossRef]

- Wang, S.; Xia, L.; Yu, L.; Zhang, L.; Wang, H.; Lou, X.W.D. Free-Standing Nitrogen-Doped Carbon Nanofiber Films: Integrated Electrodes for Sodium-Ion Batteries with Ultralong Cycle Life and Superior Rate Capability. Adv. Energy Mater. 2016, 6, 1502217. [Google Scholar] [CrossRef]

- Wang, Z.; Li, Y.; Lv, X.-J. N-doped ordered mesoporous carbon as a high performance anode material in sodium ion batteries at room temperature. RSC Adv. 2014, 4, 62673–62677. [Google Scholar] [CrossRef]

- Lu, Y.; Li, D.; Lyu, C.; Liu, H.; Liu, B.; Lyu, S.; Rosenau, T.; Yang, D. High nitrogen doped carbon nanofiber aerogels for sodium ion batteries: Synergy of vacancy defects to boost sodium ion storage. Appl. Surf. Sci. 2019, 496, 143717. [Google Scholar] [CrossRef]

- Qiao, Y.; Han, R.; Pang, Y.; Lu, Z.; Zhao, J.; Cheng, X.; Zhang, H.; Yang, Z.; Yang, S.; Liu, Y. 3D well-ordered porous phosphorus doped carbon as an anode for sodium storage: Structure design, experimental and computational insights. J. Mater. Chem. A 2019, 7, 11400–11407. [Google Scholar] [CrossRef]

- Wu, F.; Dong, R.; Bai, Y.; Li, Y.; Chen, G.; Wang, Z.; Wu, C. Phosphorus-Doped Hard Carbon Nanofibers Prepared by Electrospinning as an Anode in Sodium-Ion Batteries. ACS Appl Mater Interfaces 2018, 10, 21335–21342. [Google Scholar] [CrossRef]

- Feng, P.; Wang, W.; Wang, K.; Cheng, S.; Jiang, K. A high-performance carbon with sulfur doped between interlayers and its sodium storage mechanism as anode material for sodium ion batteries. J. Alloys Compd. 2019, 795, 223–232. [Google Scholar] [CrossRef]

- Hong, Z.; Zhen, Y.; Ruan, Y.; Kang, M.; Zhou, K.; Zhang, J.-M.; Huang, Z.; Wei, M. Rational Design and General Synthesis of S-Doped Hard Carbon with Tunable Doping Sites toward Excellent Na-Ion Storage Performance. Adv. Mater. 2018, 30, e1802035. [Google Scholar] [CrossRef]

- Lee, G.-H.; Hwang, T.; Kim, J.-B.; Yang, J.; Zou, F.; Cho, M.; Kang, Y.-M. Origin of enhanced reversible Na ion storage in hard carbon anodes through p-type molecular doping. J. Mater. Chem. A 2022, 10, 16506–16513. [Google Scholar] [CrossRef]

- Li, J.; Ding, Z.; Pan, L.; Li, J.; Wang, C.; Wang, G. Facile self-templating synthesis of layered carbon with N, S dual doping for highly efficient sodium storage. Carbon 2021, 173, 31–40. [Google Scholar] [CrossRef]

- Chen, C.; Huang, Y.; Meng, Z.; Lu, M.; Xu, Z.; Liu, P.; Li, T. Experimental design and theoretical evaluation of nitrogen and phosphorus dual-doped hierarchical porous carbon for high-performance sodium-ion storage. J. Mater. Sci. Technol. 2021, 76, 11–19. [Google Scholar] [CrossRef]

- Chen, C.; Huang, Y.; Meng, Z.; Xu, Z.; Liu, P.; Li, T. Multi-heteroatom doped porous carbon derived from insect feces for capacitance-enhanced sodium-ion storage. J. Energy Chem. 2021, 54, 482–492. [Google Scholar] [CrossRef]

- Zhou, C.; Wang, D.; Li, A.; Pan, E.; Liu, H.; Chen, X.; Jia, M.; Song, H. Three-dimensional porous carbon doped with N, O and P heteroatoms as high-performance anode materials for sodium ion batteries. Chem. Eng. J. 2020, 380, 122457. [Google Scholar] [CrossRef]

- Xu, D.; Chen, C.; Xie, J.; Zhang, B.; Miao, L.; Cai, J.; Huang, Y.; Zhang, L. A Hierarchical N/S-Codoped Carbon Anode Fabricated Facilely from Cellulose/Polyaniline Microspheres for High-Performance Sodium-Ion Batteries. Adv. Energy Mater. 2016, 6, 1501929. [Google Scholar] [CrossRef]

- Li, Y.; Wang, Z.; Li, L.; Peng, S.; Zhang, L.; Srinivasan, M.; Ramakrishna, S. Preparation of nitrogen- and phosphorous co-doped carbon microspheres and their superior performance as anode in sodium-ion batteries. Carbon 2016, 99, 556–563. [Google Scholar] [CrossRef]

- Li, Y.; Chen, M.; Liu, B.; Zhang, Y.; Liang, X.; Xia, X. Heteroatom Doping: An Effective Way to Boost Sodium Ion Storage. Adv. Energy Mater. 2020, 10, 2000927. [Google Scholar] [CrossRef]

- Guo, R.; Li, L.; Wang, B.; Xiang, Y.; Zou, G.; Zhu, Y.; Hou, H.; Ji, X. Functionalized carbon dots for advanced batteries. Energy Storage Mater. 2021, 37, 8–39. [Google Scholar] [CrossRef]

- Li, Y.; Xu, S.; Wu, X.; Yu, J.; Wang, Y.; Hu, Y.-S.; Li, H.; Chen, L.; Huang, X. Amorphous monodispersed hard carbon micro-spherules derived from biomass as a high performance negative electrode material for sodium-ion batteries. J. Mater. Chem. A 2015, 3, 71–77. [Google Scholar] [CrossRef]

- Hou, H.; Banks, C.E.; Jing, M.; Zhang, Y.; Ji, X. Carbon Quantum Dots and Their Derivative 3D Porous Carbon Frameworks for Sodium-Ion Batteries with Ultralong Cycle Life. Adv. Mater. 2015, 27, 7861–7866. [Google Scholar] [CrossRef] [PubMed]

- Li, D.; Chen, H.; Liu, G.; Wei, M.; Ding, L.-X.; Wang, S.; Wang, H. Porous nitrogen doped carbon sphere as high performance anode of sodium-ion battery. Carbon 2015, 94, 888–894. [Google Scholar] [CrossRef]

- Ni, D.; Sun, W.; Wang, Z.; Bai, Y.; Lei, H.; Lai, X.; Sun, K. Heteroatom-Doped Mesoporous Hollow Carbon Spheres for Fast Sodium Storage with an Ultralong Cycle Life. Adv. Energy Mater. 2019, 9, 1900036. [Google Scholar] [CrossRef]

- Xia, J.; Yan, D.; Guo, L.; Dong, X.; Li, W.; Lu, A. Hard Carbon Nanosheets with Uniform Ultramicropores and Accessible Functional Groups Showing High Realistic Capacity and Superior Rate Performance for Sodium-Ion Storage. Adv. Mater. 2020, 32, e2000447. [Google Scholar] [CrossRef]

- Su, D.; Huang, M.; Zhang, J.; Guo, X.; Chen, J.; Xue, Y.; Yuan, A.; Kong, Q. High N-doped hierarchical porous carbon networks with expanded interlayers for efficient sodium storage. Nano Res. 2020, 13, 2862–2868. [Google Scholar] [CrossRef]

- Wan, Y.; Song, K.; Chen, W.; Qin, C.; Zhang, X.; Zhang, J.; Dai, H.; Hu, Z.; Yan, P.; Liu, C.; et al. Ultra-High Initial Coulombic Efficiency Induced by Interface Engineering Enables Rapid, Stable Sodium Storage. Angew. Chem. Int. Ed. 2021, 60, 11481–11486. [Google Scholar] [CrossRef]

- Yu, Z.-E.; Lyu, Y.; Wang, Y.; Xu, S.; Cheng, H.; Mu, X.; Chu, J.; Chen, R.; Liu, Y.; Guo, B. Hard carbon micro-nano tubes derived from kapok fiber as anode materials for sodium-ion batteries and the sodium-ion storage mechanism. Chem. Commun. 2020, 56, 778–781. [Google Scholar] [CrossRef]

- Lyu, T.; Lan, X.; Liang, L.; Lin, X.; Hao, C.; Pan, Z.; Tian, Z.Q.; Shen, P.K. Natural mushroom spores derived hard carbon plates for robust and low-potential sodium ion storage. Electrochim. Acta 2021, 365, 137356. [Google Scholar] [CrossRef]

- Pei, L.; Yang, L.; Cao, H.; Liu, P.; Zhao, M.; Xu, B.; Guo, J. Cost-effective and renewable paper derived hard carbon microfibers as superior anode for sodium-ion batteries. Electrochim. Acta 2020, 364, 137313. [Google Scholar] [CrossRef]

- Li, Y.; Hu, Y.-S.; Li, H.; Chen, L.; Huang, X. A superior low-cost amorphous carbon anode made from pitch and lignin for sodium-ion batteries. J. Mater. Chem. A 2016, 4, 96–104. [Google Scholar] [CrossRef]

- Xie, F.; Xu, Z.; Jensen, A.C.S.; Au, H.; Lu, Y.; Araullo-Peters, V.; Drew, A.J.; Hu, Y.-S.; Titirici, M.-M. Hard–Soft Carbon Composite Anodes with Synergistic Sodium Storage Performance. Adv. Funct. Mater. 2019, 29, 1901072. [Google Scholar] [CrossRef]

- He, X.-X.; Zhao, J.-H.; Lai, W.-H.; Li, R.; Yang, Z.; Xu, C.-M.; Dai, Y.; Gao, Y.; Liu, X.-H.; Li, L.; et al. Soft-Carbon-Coated, Free-Standing, Low-Defect, Hard-Carbon Anode to Achieve a 94% Initial Coulombic Efficiency for Sodium-Ion Batteries. ACS Appl. Mater. Interfaces 2021, 13, 44358–44368. [Google Scholar] [CrossRef] [PubMed]

- Liu, M.; Zhang, P.; Qu, Z.; Yan, Y.; Lai, C.; Liu, T.; Zhang, S. Conductive carbon nanofiber interpenetrated graphene architecture for ultra-stable sodium ion battery. Nat. Commun. 2019, 10, 3917. [Google Scholar] [CrossRef] [PubMed]

- Lu, H.; Chen, X.; Jia, Y.; Chen, H.; Wang, Y.; Ai, X.; Yang, H.; Cao, Y. Engineering Al2O3 atomic layer deposition: Enhanced hard carbon-electrolyte interface towards practical sodium ion batteries. Nano Energy 2019, 64, 103903. [Google Scholar] [CrossRef]

- Hou, C.; Yang, W.; Xie, X.; Sun, X.; Wang, J.; Naik, N.; Pan, D.; Mai, X.; Guo, Z.; Dang, F.; et al. Agaric-like anodes of porous carbon decorated with MoO2 nanoparticles for stable ultralong cycling lifespan and high-rate lithium/sodium storage. J. Colloid. Interface Sci. 2021, 596, 396–407. [Google Scholar] [CrossRef]

- Zhang, D.; Sun, W.; Zhang, Y.; Dou, Y.; Jiang, Y.; Dou, S.X. Engineering Hierarchical Hollow Nickel Sulfide Spheres for High-Performance Sodium Storage. Adv. Funct. Mater. 2016, 26, 7479–7485. [Google Scholar] [CrossRef]

- Zhao, X.; Gong, F.; Zhao, Y.; Huang, B.; Qian, D.; Wang, H.-E.; Zhang, W.; Yang, Z. Encapsulating NiS nanocrystal into nitrogen-doped carbon framework for high performance sodium/potassium-ion storage. Chem. Eng. J. 2020, 392, 123675. [Google Scholar] [CrossRef]

- Yang, M.; Ning, Q.; Fan, C.; Wu, X. Large-scale Ni-MOF derived Ni3S2 nanocrystals embedded in N-doped porous carbon nanoparticles for high-rate Na+ storage. Chin. Chem. Lett. 2021, 32, 895–899. [Google Scholar] [CrossRef]

- Zhang, C.; Wei, D.; Wang, F.; Zhang, G.; Duan, J.; Han, F.; Duan, H.; Liu, J. Highly active Fe7S8 encapsulated in N-doped hollow carbon nanofibers for high-rate sodium-ion batteries. J. Energy Chem. 2021, 53, 26–35. [Google Scholar] [CrossRef]

- Cao, L.; Gao, X.; Zhang, B.; Ou, X.; Zhang, J.; Luo, W.B. Bimetallic Sulfide Sb2S3@FeS2 Hollow Nanorods as High-Performance Anode Materials for Sodium-Ion Batteries. ACS Nano 2020, 14, 3610–3620. [Google Scholar] [CrossRef]

- Zhao, W.; Gao, L.; Yue, L.; Wang, X.; Liu, Q.; Luo, Y.; Li, T.; Shi, X.; Asiri, A.M.; Sun, X. Constructing a hollow microflower-like ZnS/CuS@C heterojunction as an effective ion-transport booster for an ultrastable and high-rate sodium storage anode. J. Mater. Chem. A 2021, 9, 6402–6412. [Google Scholar] [CrossRef]

- Wang, S.; Fang, Y.; Wang, X.; Lou, X.-W. Hierarchical Microboxes Constructed by SnS Nanoplates Coated with Nitrogen-Doped Carbon for Efficient Sodium Storage. Angew. Chem. Int. Ed. 2019, 58, 760–763. [Google Scholar] [CrossRef]

- Fang, Y.; Luan, D.; Chen, Y.; Gao, S.; Lou, X.W.D. Rationally Designed Three-Layered Cu2 S@Carbon@MoS2 Hierarchical Nanoboxes for Efficient Sodium Storage. Angew. Chem. Int. Ed. 2020, 59, 7178–7183. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Z.; Huang, Y.; Liu, X.; Wang, X.; Liu, P. Core–Shell Co, Zn Bimetallic Selenide Embedded Nitrogen-Doped Carbon Polyhedral Frameworks Assist in Sodium-Ion Battery Ultralong Cycle. ACS Sustain. Chem. Eng. 2020, 8, 8381–8390. [Google Scholar] [CrossRef]

- He, H.; Sun, D.; Tang, Y.; Wang, H.; Shao, M. Understanding and improving the initial Coulombic efficiency of high-capacity anode materials for practical sodium ion batteries. Energy Storage Mater. 2019, 23, 233–251. [Google Scholar] [CrossRef]

- Ponrouch, A.; Marchante, E.; Courty, M.; Tarascon, J.-M.; Palacín, M.R. In search of an optimized electrolyte for Na-ion batteries. Energy Environ. Sci. 2012, 5, 8572–8583. [Google Scholar] [CrossRef]

- Kamath, G.; Cutler, R.W.; Deshmukh, S.A.; Shakourian-Fard, M.; Parrish, R.; Huether, J.; Butt, D.P.; Xiong, H.; Sankaranarayanan, S.K.R.S. In Silico Based Rank-Order Determination and Experiments on Nonaqueous Electrolytes for Sodium Ion Battery Applications. J. Phys. Chem. C 2014, 118, 13406–13416. [Google Scholar] [CrossRef]

- Schafzahl, L.; Hanzu, I.; Wilkening, M.; Freunberger, S.A. An Electrolyte for Reversible Cycling of Sodium Metal and Intercalation Compounds. ChemSusChem 2017, 10, 401–408. [Google Scholar] [CrossRef]

- Zhu, Y.-E.; Yang, L.; Zhou, X.; Li, F.; Wei, J.; Zhou, Z. Boosting the rate capability of hard carbon with an ether-based electrolyte for sodium ion batteries. J. Mater. Chem. A 2017, 5, 9528–9532. [Google Scholar] [CrossRef]

- Zhang, J.; Wang, D.-W.; Lv, W.; Zhang, S.; Liang, Q.; Zheng, D.; Kang, F.; Yang, Q.-H. Achieving superb sodium storage performance on carbon anodes through an ether-derived solid electrolyte interphase. Energy Environ. Sci. 2017, 10, 370–376. [Google Scholar] [CrossRef]

- Tang, Z.; Zhou, S.; Wu, P.; Wang, H.; Huang, Y.; Zhang, Y.; Sun, D.; Tang, Y.; Wang, H. Engineering surface oxygenated functionalities on commercial hard carbon toward superior sodium storage. Chem. Eng. J. 2022, 441, 135899. [Google Scholar] [CrossRef]

- Sun, D.; Luo, B.; Wang, H.; Tang, Y.; Ji, X.; Wang, L. Engineering the trap effect of residual oxygen atoms and defects in hard carbon anode towards high initial Coulombic efficiency. Nano Energy 2019, 64, 103937. [Google Scholar] [CrossRef]

- Xiao, B.; Soto, F.A.; Gu, M.; Han, K.S.; Song, J.; Wang, H.; Engelhard, M.H.; Murugesan, V.; Mueller, K.T.; Reed, D.; et al. Lithium-Pretreated Hard Carbon as High-Performance Sodium-Ion Battery Anodes. Adv. Energy Mater. 2018, 8, 1801441. [Google Scholar] [CrossRef]

- Wang, H.; Xiao, Y.; Sun, C.; Lai, C.; Ai, X. A type of sodium-ion full-cell with a layered NaNi0.5Ti0.5O2 cathode and a pre-sodiated hard carbon anode. RSC Adv. 2015, 5, 106519–106522. [Google Scholar] [CrossRef]

- Liu, M.; Zhang, J.; Guo, S.; Wang, B.; Shen, Y.; Ai, X.; Yang, H.; Qian, J. Chemically Presodiated Hard Carbon Anodes with Enhanced Initial Coulombic Efficiencies for High-Energy Sodium Ion Batteries. ACS Appl. Mater. Interfaces 2020, 12, 17620–17627. [Google Scholar] [CrossRef]

- Bai, P.; He, Y.; Xiong, P.; Zhao, X.; Xu, K.; Xu, Y. Long cycle life and high rate sodium-ion chemistry for hard carbon anodes. Energy Storage Mater. 2018, 13, 274–282. [Google Scholar] [CrossRef]

- Zhang, B.; Dugas, R.; Rousse, G.; Rozier, P.; Abakumov, A.M.; Tarascon, J.-M. Insertion compounds and composites made by ball milling for advanced sodium-ion batteries. Nat. Commun. 2016, 7, 10308. [Google Scholar] [CrossRef] [PubMed]

- de Ilarduya, J.M.; Otaegui, L.; del Amo, J.M.L.; Armand, M.; Singh, G. NaN3 addition, a strategy to overcome the problem of sodium deficiency in P2-Na0.67[Fe0.5Mn0.5]O2 cathode for sodium-ion battery. J. Power Source 2017, 337, 197–203. [Google Scholar] [CrossRef]

- Li, Y.; Du, Y.F.; Sun, G.H.; Cheng, J.Y.; Song, G.; Song, M.X.; Su, F.Y.; Yang, F.; Xie, L.J.; Chen, C.M. Self-standing hard carbon anode derived from hyper-linked nanocellulose with high cycling stability for lithium-ion batteries. EcoMat 2021, 3, e12091. [Google Scholar] [CrossRef]

- Sun, D.; Zhu, X.; Luo, B.; Zhang, Y.; Tang, Y.; Wang, H.; Wang, L. New Binder-Free Metal Phosphide–Carbon Felt Composite Anodes for Sodium-Ion Battery. Adv. Energy Mater. 2018, 8, 1801197. [Google Scholar] [CrossRef]

- Yang, H.; Xu, R.; Yu, Y. A facile strategy toward sodium-ion batteries with ultra-long cycle life and high initial Coulombic Efficiency: Free-standing porous carbon nanofiber film derived from bacterial cellulose. Energy Storage Mater. 2019, 22, 105–112. [Google Scholar] [CrossRef]

- Hou, B.H.; Wang, Y.Y.; Ning, Q.L.; Li, W.H.; Xi, X.T.; Yang, X.; Liang, H.J.; Feng, X.; Wu, X.L. Self-Supporting, Flexible, Additive-Free, and Scalable Hard Carbon Paper Self-Interwoven by 1D Microbelts: Superb Room/Low-Temperature Sodium Storage and Working Mechanism. Adv. Mater. 2019, 31, e1903125. [Google Scholar] [CrossRef] [PubMed]

- Wang, D.; Du, G.; Han, D.; Su, Q.; Ding, S.; Zhang, M.; Zhao, W.; Xu, B. Porous flexible nitrogen-rich carbon membranes derived from chitosan as free-standing anodes for potassium-ion and sodium-ion batteries. Carbon 2021, 181, 1–8. [Google Scholar] [CrossRef]

- Wang, P.; Zhu, K.; Ye, K.; Gong, Z.; Liu, R.; Cheng, K.; Wang, G.; Yan, J.; Cao, D. Three-dimensional biomass derived hard carbon with reconstructed surface as a free-standing anode for sodium-ion batteries. J. Colloid. Interface Sci. 2020, 561, 203–210. [Google Scholar] [CrossRef]

- Dong, R.; Zheng, L.; Bai, Y.; Ni, Q.; Li, Y.; Wu, F.; Ren, H.; Wu, C. Elucidating the Mechanism of Fast Na Storage Kinetics in Ether Electrolytes for Hard Carbon Anodes. Adv. Mater. 2021, 33, e2008810. [Google Scholar] [CrossRef]

- Deng, J.; Luo, W.-B.; Chou, S.-L.; Liu, H.-K.; Dou, S.-X. Sodium-Ion Batteries: From Academic Research to Practical Commercialization. Adv. Energy Mater. 2018, 8, 1701428. [Google Scholar] [CrossRef]

- Wan, Y.; Qiu, Y.; Wang, C.; Zhang, H.; Zheng, Q.; Li, X. Enabling superior rate capability and reliable sodium ion batteries by employing galvanostatic-potentiostatic operation mode. J. Power Source 2021, 496, 229834. [Google Scholar] [CrossRef]

- Zhao, L.F.; Hu, Z.; Lai, W.H.; Tao, Y.; Peng, J.; Miao, Z.C.; Wang, Y.X.; Chou, S.L.; Liu, H.K.; Dou, S.X. Hard Carbon Anodes: Fundamental Understanding and Commercial Perspectives for Na-Ion Batteries beyond Li-Ion and K-Ion Counterparts. Adv. Energy Mater. 2020, 11, 2002704. [Google Scholar] [CrossRef]

- Hirsh, H.S.; Li, Y.; Tan, D.H.S.; Zhang, M.; Zhao, E.; Meng, Y.S. Sodium-Ion Batteries Paving the Way for Grid Energy Storage. Adv. Energy Mater. 2020, 10, 2001274. [Google Scholar] [CrossRef]

- Hu, Y.S.; Komaba, S.; Forsyth, M.; Johnson, C.; Rojo, T. A New Emerging Technology: Na-Ion Batteries. Small Methods 2019, 3, 1900184. [Google Scholar] [CrossRef]

| Anode Material | Current Rate | Electrochemical Performance * (Reversible Capacity, Cycles, Capacity Retention) | Ref. | |

|---|---|---|---|---|

| Titanium-based | NaTiOPO4 | 0.1 C | 180 mAh g−1, /, / | [15] |

| Ti2(SO4)3 | 0.1 C | 120 mAh g−1, 15, 77.5% | [16] | |

| Metal oxides | Na2Ti3O7 | 0.04 C | ~200 mAh g−1, /, / | [17] |

| α-MoO3 | 0.1 C | 100 mAh g−1, 500, 55%(0.2 C) | [18] | |

| Metallic composite | a-TiO2-x/Sb | 100 mA g−1 | 591.9 mAh g−1, 200, 96.4%(1 A g−1) | [19] |

| SiC–Sb–C | 100 mA g−1 | 595 mAh g−1, 100, 80.7% | [20] | |

| Ti3C2Tx/ SnP | 0.2 A g−1 | 587 mAh g−1, 1000, 91.2% | [21] | |

| Organic | Na2C8H4O4 | 0.1 C | 258 mAh g−1, 50, 74.4% | [22] |

| Organic sodium carboxylate salts | 40 mA g−1 | >200 mAh g−1(full-cell), 50, / | [23] | |

| Carbon−based | Carbon black | C/75 | 121 mAh g−1, /, / | [24] |

| HC | 0.1 C | 300.6 mAh g−1, 100, 98.1% | [26] | |

| Reduced graphene oxide | 0.2 C | 174.3 mAh g−1, 1000, 80.9% | [27] | |

| Soft carbon | 20 mA g−1 | 232 mAh g−1, 40, 98.1% | [28] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, L.; Tian, Y.; Abdussalam, A.; Gilani, M.R.H.S.; Zhang, W.; Xu, G. Hard Carbons as Anodes in Sodium-Ion Batteries: Sodium Storage Mechanism and Optimization Strategies. Molecules 2022, 27, 6516. https://doi.org/10.3390/molecules27196516

Liu L, Tian Y, Abdussalam A, Gilani MRHS, Zhang W, Xu G. Hard Carbons as Anodes in Sodium-Ion Batteries: Sodium Storage Mechanism and Optimization Strategies. Molecules. 2022; 27(19):6516. https://doi.org/10.3390/molecules27196516

Chicago/Turabian StyleLiu, Liyang, Ye Tian, Abubakar Abdussalam, Muhammad Rehan Hasan Shah Gilani, Wei Zhang, and Guobao Xu. 2022. "Hard Carbons as Anodes in Sodium-Ion Batteries: Sodium Storage Mechanism and Optimization Strategies" Molecules 27, no. 19: 6516. https://doi.org/10.3390/molecules27196516

APA StyleLiu, L., Tian, Y., Abdussalam, A., Gilani, M. R. H. S., Zhang, W., & Xu, G. (2022). Hard Carbons as Anodes in Sodium-Ion Batteries: Sodium Storage Mechanism and Optimization Strategies. Molecules, 27(19), 6516. https://doi.org/10.3390/molecules27196516